How to make jewelry rubber mold?

Methods and process of making jewelry rubber mold

Introduction:

In the jewelry’s shaping and casting process, mold-making is essential. To replicate a piece, one must master making a mold. We generally use rubber or silicone materials in the mold-making process for jewelry or small items.

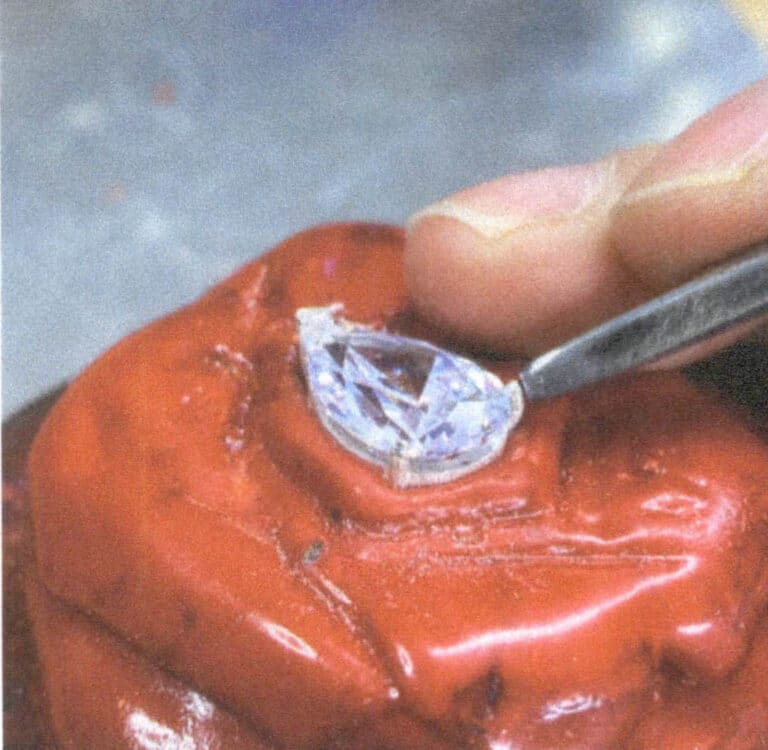

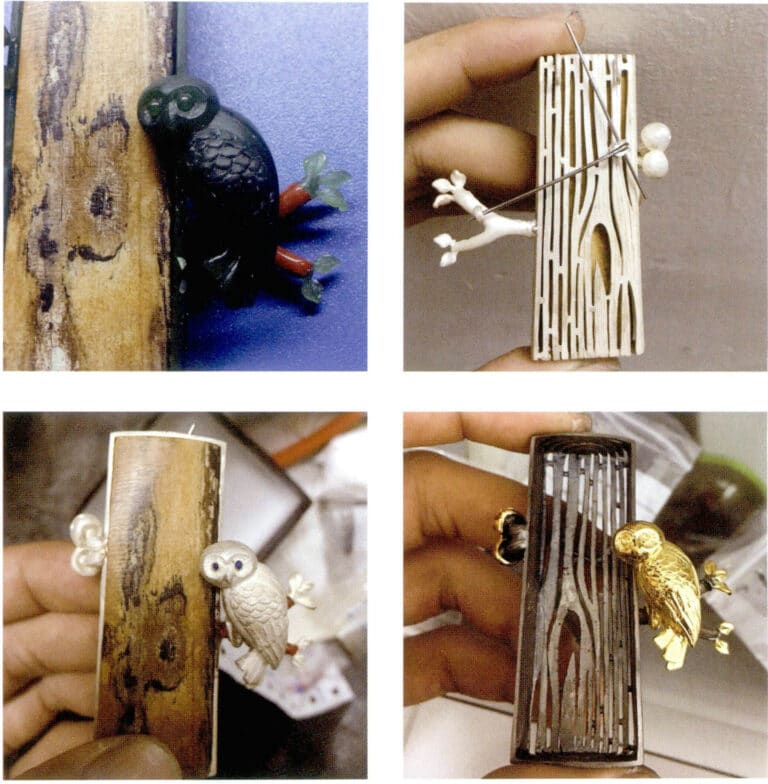

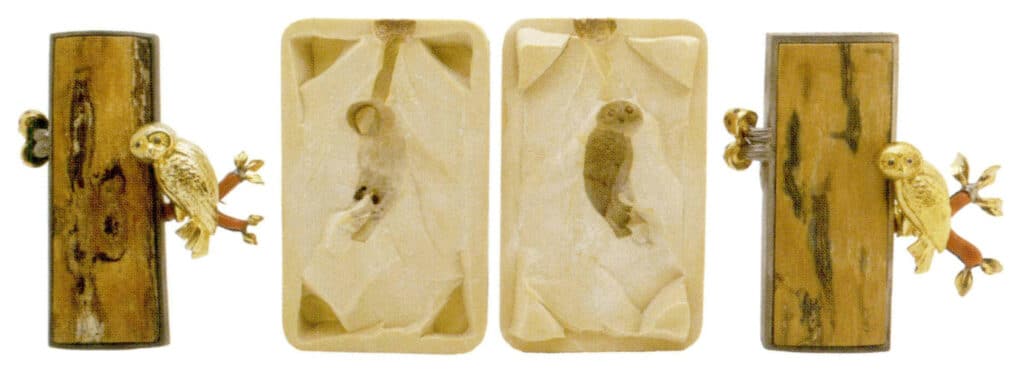

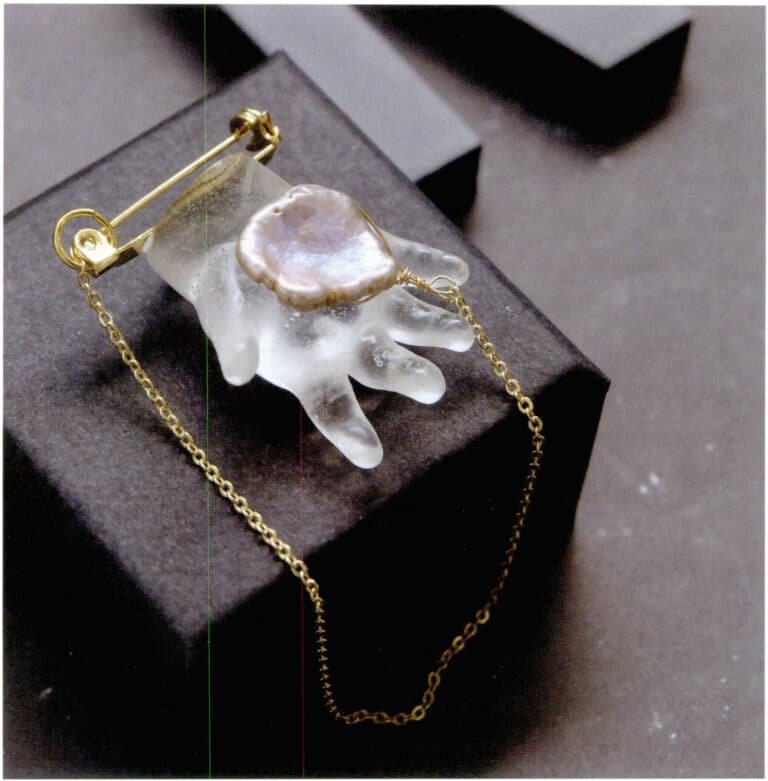

"Night Guardian" uses traditional hand-carved wax modeling techniques and is cast into a metal piece using the lost-wax casting method.

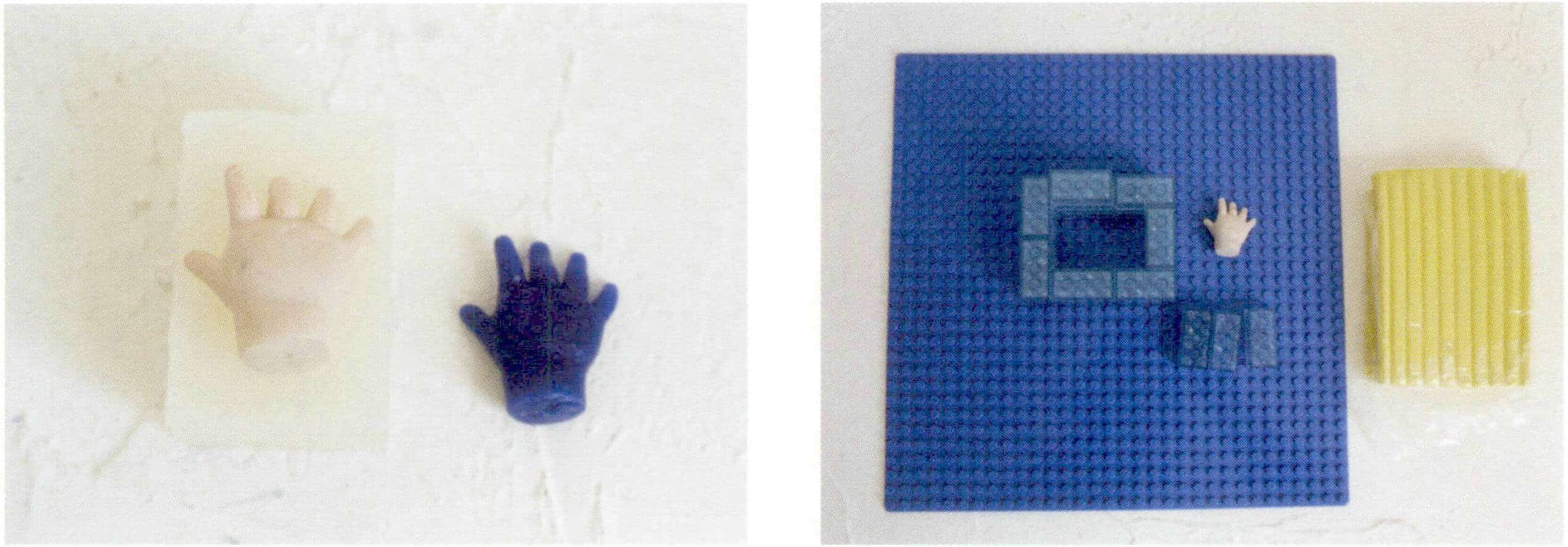

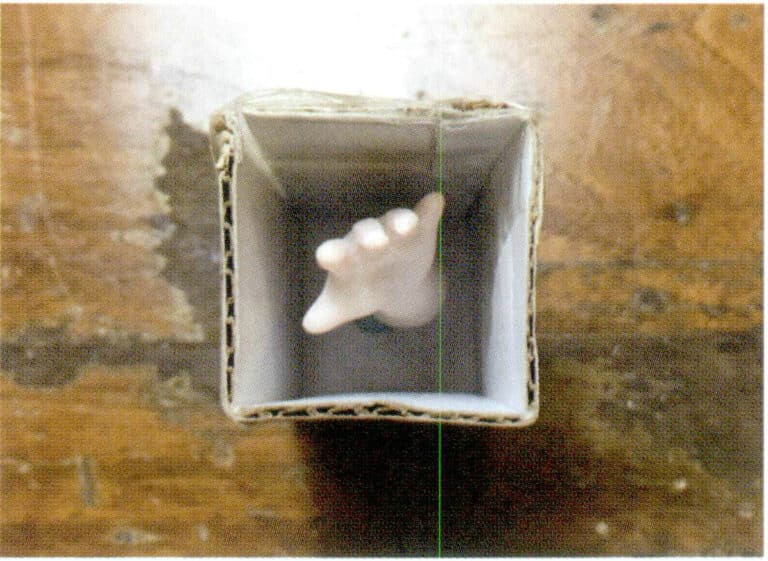

Rubber mold of the owl part

After the metal piece is finished, a rubber mold is made. The owl on the left side of the image is hand-carved from wax, while the one on the right is made using a rubber mold for wax injection modeling.

Table of Contents

Section Ⅰ Jewelry Rubber Molds and Wax Model Production

The production of rubber molds is an essential part of jewelry processing, as it can replicate jewelry prototypes in large quantities, making it widely used in the mass production of commercial jewelry. The process of making rubber molds is commonly referred to in the industry as rubber molding, and many intricately designed pieces of jewelry can be produced using this technique. Under proper operation, a rubber mold can last for over 10 years, and typically, rubber molds are made by specialized factories.

1. Tools and Materials for Rubber Mold Production

Aluminum Alloy Mold Frame:

Usually made of aluminum alloy or aluminum, available in various sizes.

Raw Rubber:

The rubber used for making molds is uncured raw rubber, mostly in sheet form, as raw rubber has good plasticity. After heating vulcanization, the shape of the mold will be fixed, and it has good elasticity and flexibility.

Scalpel:

The primary tool for cutting rubber molds.

Mold repair pen:

Similar to a particular electric soldering iron, it can be used to repair defects in rubber molds.

Sprue base:

Usually, a sprue base is fitted onto the edge of the rubber mold to form a flared opening, facilitating the subsequent operation of injecting wax models.

Jewelry Rubber Mold Vulcanizer:

Also known as a molding machine, it is a device for curing raw rubber molds, with adjustable temperature electric heating wires in the upper and lower pressure plates. The upper-pressure plate is connected to a screw to adjust the distance and pressure between the two pressure plates.

Aluminum alloy mold frame

Jewelry Rubber Mold Vulcanizer

2. The basic process of rubber mold making

Clamp the jewelry prototype with the casting sprue into the rubber, place it in an aluminum frame, then shape it after pressing and heating vulcanization in the Jewelry Rubber Mold Vulcanizer. The rubber used for making should have characteristics such as corrosion resistance, aging resistance, and good flexibility.

2.1 Welding water

Weld the casting sprue onto the jewelry prototype, or it can also be bonded with a strong adhesive.

2.2 Clean the surface

The surface of the jewelry prototype must be kept clean before molding.

2.3 Cut the rubber and place it in the box

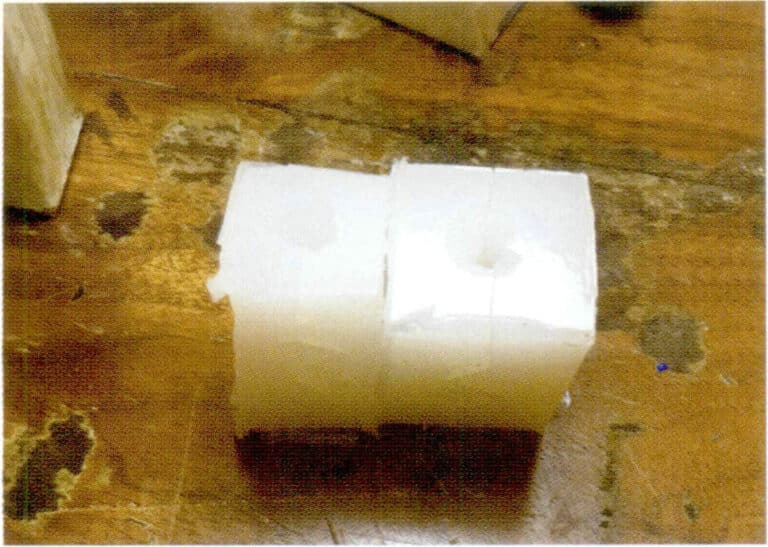

Choose an aluminum alloy frame of the appropriate size, and cut two pieces of raw rubber that are the same size as the aluminum alloy box.

Clamp the jewelry prototype with the welded casting sprue between the raw rubber sheets and place it in the aluminum alloy frame. If there are gaps, cut appropriately sized raw rubber sheets to fill them, ensuring no gaps between the jewelry prototype and the raw rubber sheets, and place metal nails for fixing around the inside edges of the box, finally closing the aluminum alloy box tightly.

Cutting rubber and placing it into the frame

2.4 Heating and Pressurizing

Cutting rubber and placing it into the frame

Place the aluminum alloy frame in the preheated automatic press machine, heating and pressurizing from both top and bottom simultaneously, with the temperature generally controlled at around 150 ℃, for about 45 minutes (adjust the time based on the size of the jewelry prototype and the number of layers of raw rubber sheets). After heating and pressurizing, the raw rubber sheets in the aluminum alloy frame will vulcanize and harden. Once the mold cools down, the rubber mold can be removed.

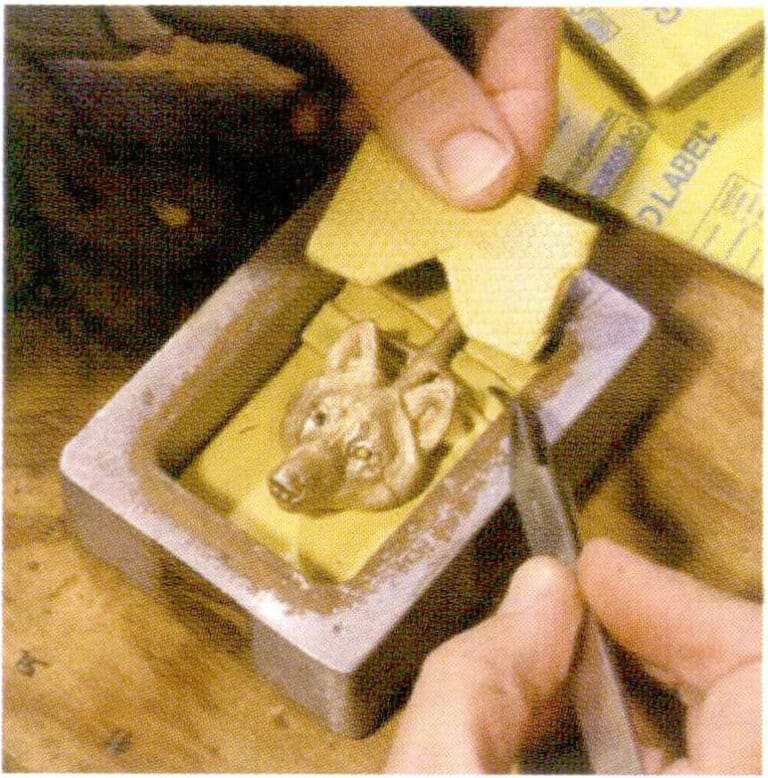

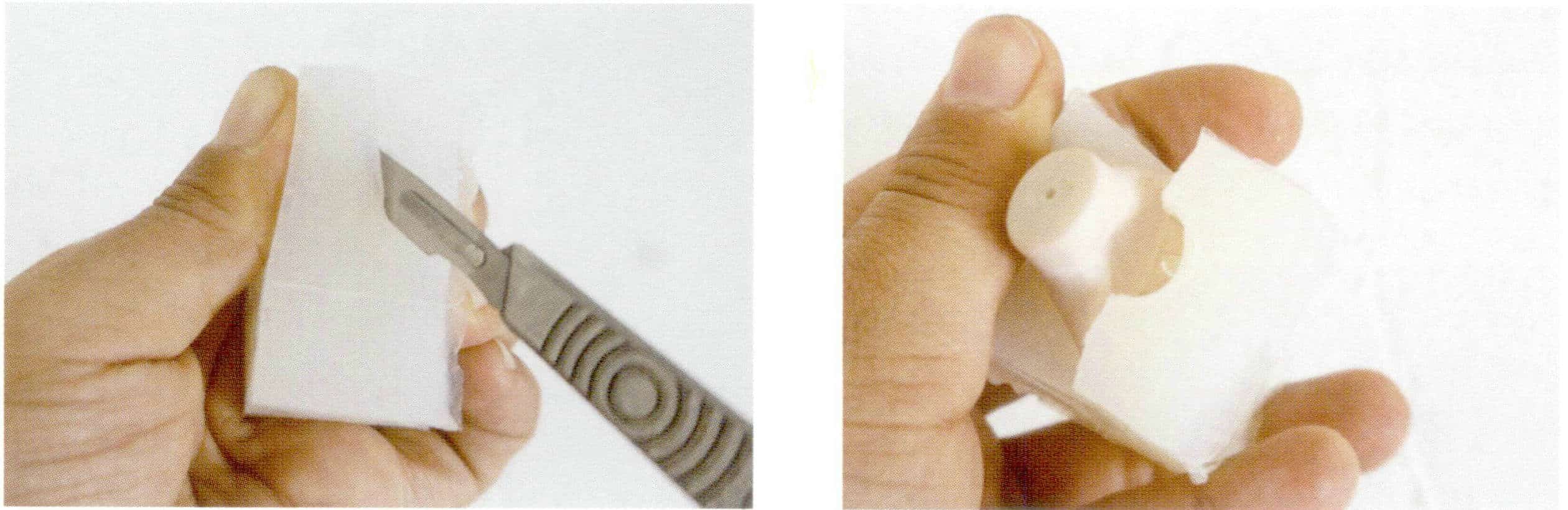

2.5 Cutting the Rubber Mold

Remove the metal nails used for fixing the rubber mold, draw the cutting line from the pouring gate, and use a scalpel to cut the rubber mold into two pieces, allowing the jewelry prototype to be removed. The cutting surface is usually shaped into teeth or curves, which helps to make the fit between the two rubber molds tighter and more precise when injecting the wax model. Care must be taken when cutting the rubber mold; water can be dabbed on the scalpel blade to ensure smooth cutting, and care should be taken not to scratch the internal jewelry prototype, ensuring that the rubber mold remains undamaged and unwrapped.

Cutting the rubber film

3. Basic Process of Making Wax Models

Jewelry wax molds are made using rubber molds, commonly referred to in the industry as wax injection or filling. The wax material can be selected from precision-casting granule wax.

3.1 Wax Injection

We usually use a vacuum pressure wax injection machine to make paraffin models. First, adjust the temperature of the paraffin melting pot and the nozzle, generally controlling the temperatures at 73℃ and 75℃. The lower the temperature, the more minor the wax shrinkage. If the wax injection temperature is too high, the wax will flow into the gaps of the rubber mold, absorb air, and form tiny bubbles in the wax during cooling, affecting the integrity of the wax mold. Secondly, the injection pressure, injection time, and suction time are set according to the shape of the mold.

When injecting wax, the following points need to be noted: First, to ensure that the wax can smoothly fill all parts of the mold and facilitate the subsequent demolding of the wax mold, talcum powder or silicone oil should be applied inside the rubber mold before injection to provide a certain degree of lubrication; second, the operating temperature of the rubber mold is also very critical. The more times the same mold is used for wax injection, the hotter the mold becomes and the slower the hardening speed of the paraffin model. At this time, one should wait a little before removing the paraffin model.

Manual wax injection operation

3.2 Remove the wax mold and detail trimming

The timing for removing the wax mold must be well controlled; if done too early, the wax may not have fully solidified and can easily deform; if done too late, it may become too hard and brittle, making it prone to breakage when removed. It should be handled gently to avoid damaging the paraffin model. Due to issues during the wax injection process, minor defects may sometimes appear on the surface of the wax mold. After removal, the wax mold should be carefully inspected. If there are air bubbles, spots, or gaps, they can be appropriately repaired using a soldering iron to add wax and tools for scraping. After that, the entire production of the paraffin model is complete.

Semi-automatic digital display wax injection machine

Fully automatic wax injection machine

Section II Basic Process of Silicone Mold Making

In small studios or home workshops that do not have professional molding conditions, if you want to replicate some simple-shaped jewelry or small items, you can use non-toxic and healthy silicone to make molds.

1. Chemical and Physical Properties of Silicone

Silicone, also known as silica gel, has the English name Silica gel; its main component is silicon dioxide. It has stable chemical properties and is fire-resistant and low-temperature resistant. Usually, the silicone we come into contact with is a type of highly active adsorption materials are insoluble in water and any solvents, are non-toxic and odorless, and have good elasticity and flexibility. Silicone is used with curing agents, making it convenient and easy to shape.

Based on the molding process, silicone products can be divided into the following categories.

(1) Molding and compression silicone products

This is the most widely used type in the silicone industry, mainly used for industrial parts, ice cube trays, cake molds, etc. There are also many design molds and artworks made of silicone in art design.

(2) Extruded silicone products

It is mostly in long tubular form can be cut freely, and is commonly used in medical devices and food machinery.

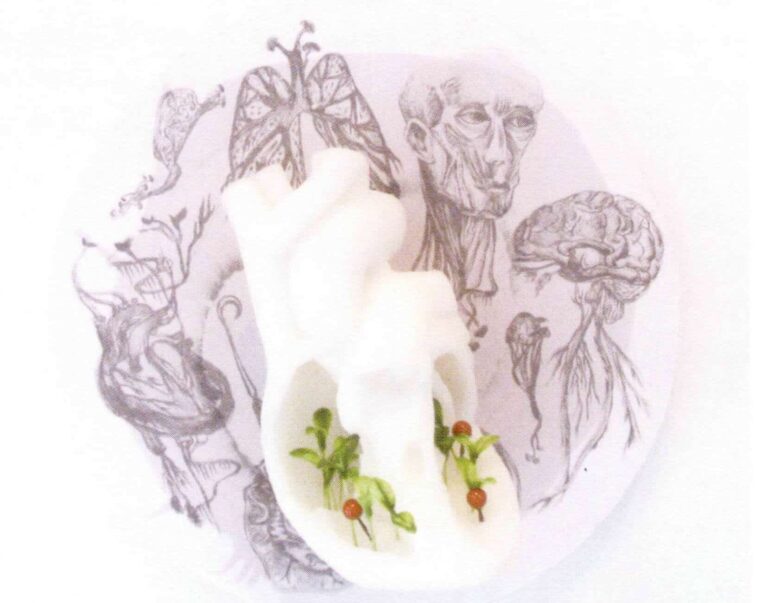

(3) Liquid silicone products

Formed by silicone injection molding, due to its soft characteristics, it is often used to make lifelike human organs, etc.

Xie Bai、Xie Zhouqiang, Touch my body- house, silicone、synthesized material, 30cmx30cm, 2011

Xie Bai、Xie Zhouqiang, Touch my body- organics, silicone、synthesized material, 30cmx30cm, 2011

2. Standard processing methods for silicone

Silicone is in a flowing viscous liquid state when no curing agent is added. If the curing and molding of silicone is required, it needs to be mixed in a ratio of 100:2 or 100:2.5 with the curing agent (or according to the brand’s instructions). For example, take 100 grams of silicone, add about 2 grams of curing agent, and stir clockwise to cure. Note that the curing agent and silicone must be stirred evenly in the same direction; some silicone may not cure if not stirred evenly. Under normal circumstances, silicone will start solidifying after half an hour and solidifying after 2~3 hours. To speed up the curing process, you can add a little more curing agent or use a hair dryer to heat it. If silicone is used for mold-making, it is recommended to demold after 12 hours for a higher success rate. If bubbles are produced while stirring the silicone, they can be eliminated using a vacuum pump. Since silicone is relatively thick, if you need to enhance its fluidity, you can add silicone oil in a ratio of 100:10 and stir evenly.

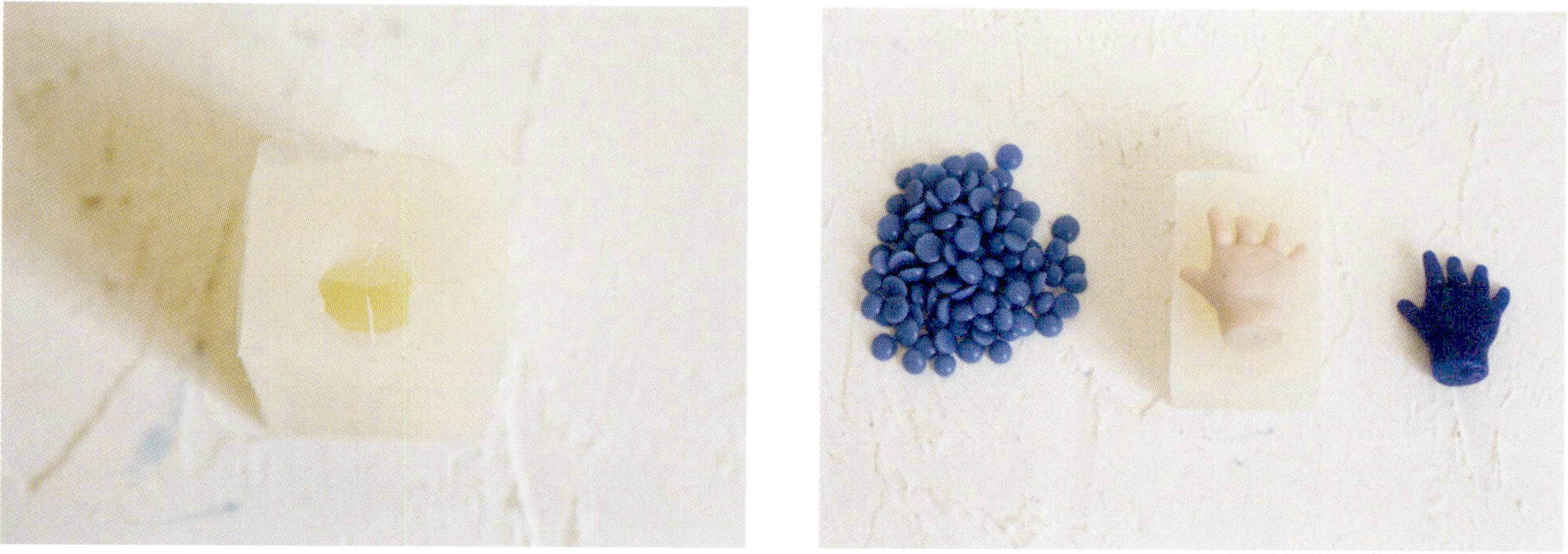

The commonly used silicone is translucent and white. If you want to change the color of the silicone, you can add special silicone color paste or oil paint and stir evenly in a clockwise direction.

Translucent silicone (with strong flexibility)

Milky white silicone

3. Basic materials and tools for silicone mold making

Food-grade silicone; silicone curing agent; disposable plastic cups or small plastic bowls for weighing and mixing silicone; disposable chopsticks for stirring silicone and making water outlets; plastic blocks or rigid cardboard boxes for making pouring channels; oil clay for fixing models and sealing leaks; transparent tape applied to the inside of the cardboard box to facilitate smooth demolding after the silicone solidifies; scissors; scalpel; utility knife.

4. Silicone Mold-Making Process

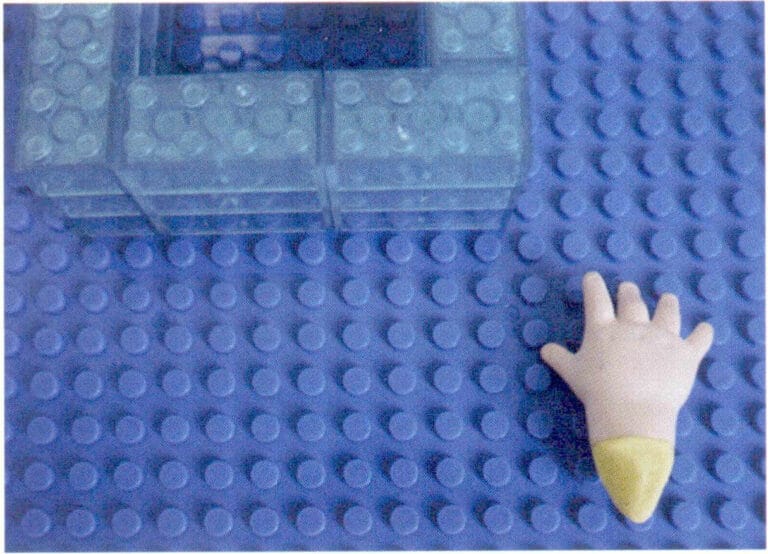

4.1 Fat Baby Hand Block Version Silicone Mold-Making Process

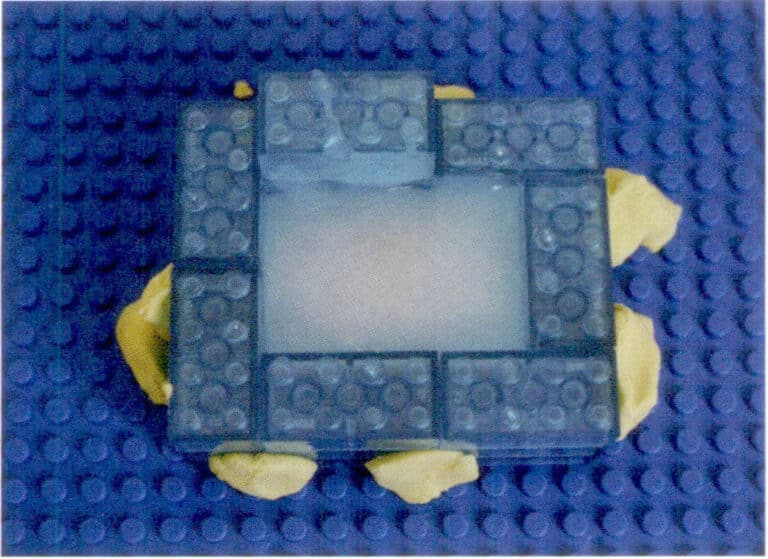

1. Prepare the model blocks for injecting silicone, oil clay, silicone, and other materials and tools, and surround the blocks to form a suitably sized pouring channel.

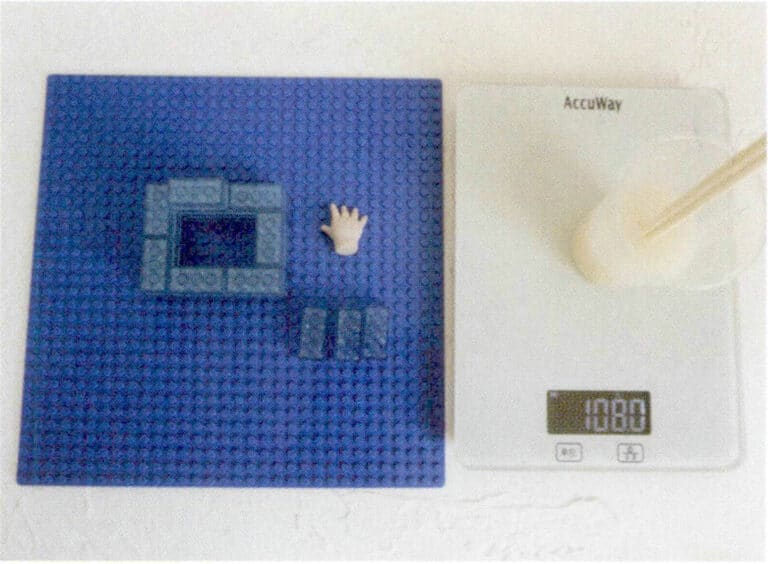

2. According to the requirements in the silicone brand's instruction manual, weigh an appropriate amount of silicone and silicone curing agent in proportion.

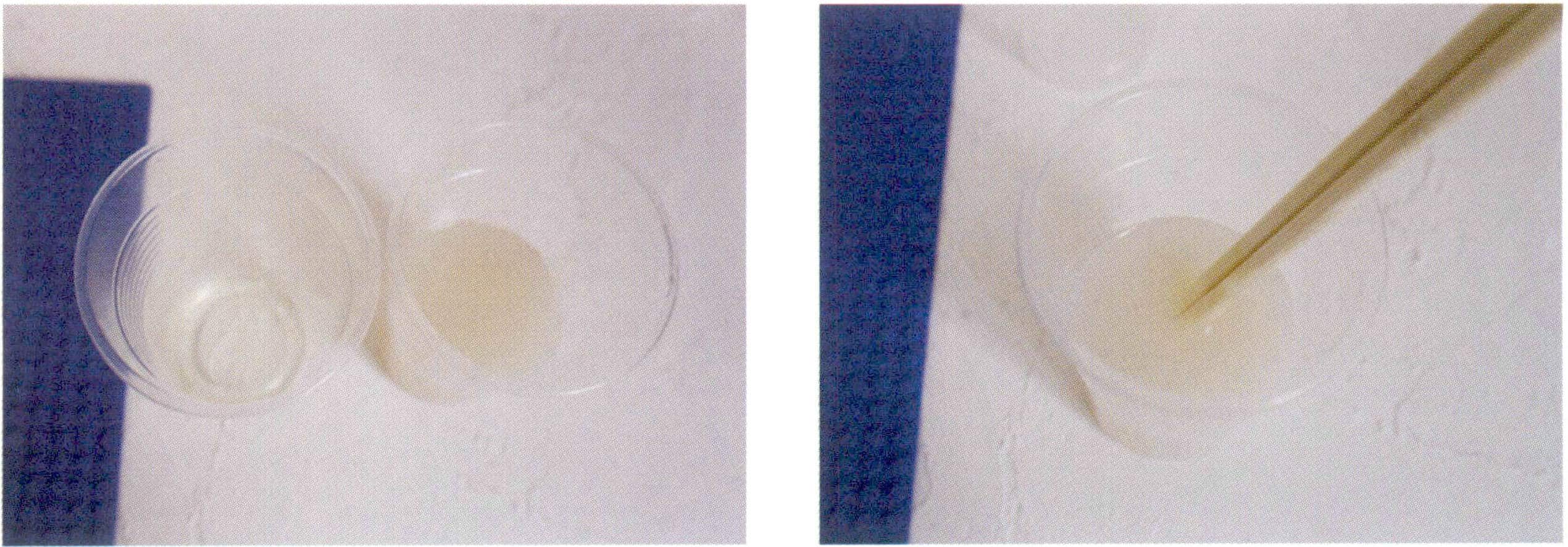

3. Pour the curing agent into the silicone and stir clockwise to ensure the curing agent and silicone are evenly mixed; uneven mixing may cause some silicone not to cure.

4. Take an appropriate amount of oil clay and stick it to one end of the model.

5. Pour the evenly mixed silicone into the wooden mold; at this time, only pour in half the amount of silicone, and then stick the prepared model to one side of the mold; part of the model needs to touch the silicone and be careful not to touch the bottom and sides of the mold; the model must be at least 6 mm away from the bottom to avoid perforation of the silicone mold after it solidifies.

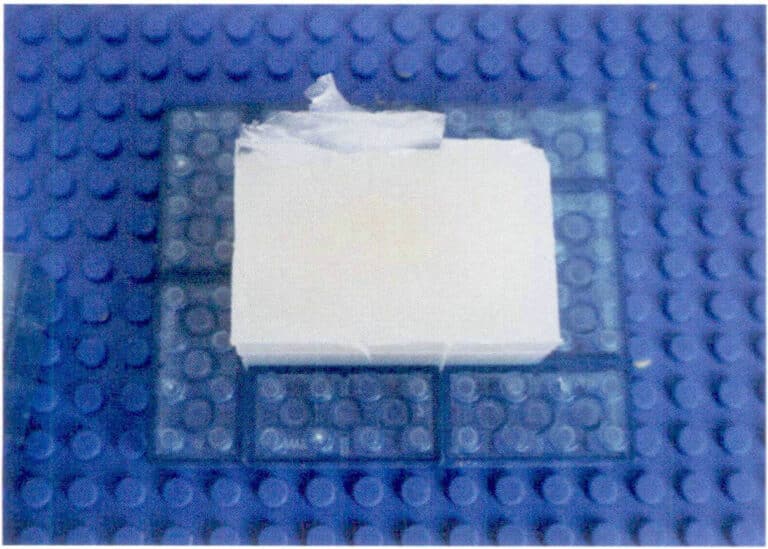

6. After securing the model, pour the remaining silicone into the mold to cover the entire model.

7. Wait for the silicone to solidify; the solidification time varies for different brands of silicone. If not in a hurry, taking it out after 12 hours is recommended to ensure that the silicone inside is wholly solidified and has good flexibility.

8. Use a scalpel to cut the silicone, noting that the cutting line should be in an S shape or Z shape, which can improve the fit of the mold. For simple, small items, there is no need to cut the entire silicone mold; just cutting the opening is enough to remove the model

9. After removing the model, the silicone mold is completed, and the position where the oil clay is applied naturally forms the casting sprue; then, after melting the casting wax and injecting it into the silicone mold, a small wax hand can be obtained, which can then be cast into metal using the lost-wax method; the silicone mold can also be directly injected with resin, cement, gypsum, and other molding materials to obtain models with different textures.

4.2 Multi-item paper box version silicone mold wax injection production process

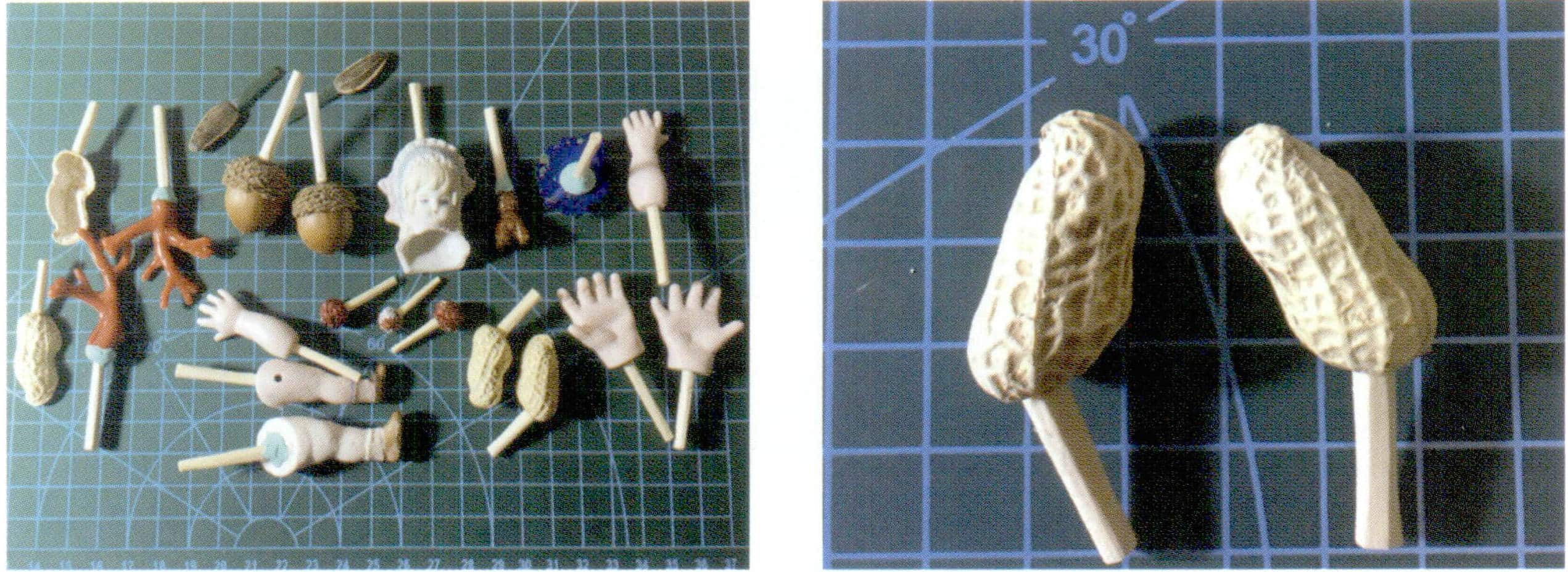

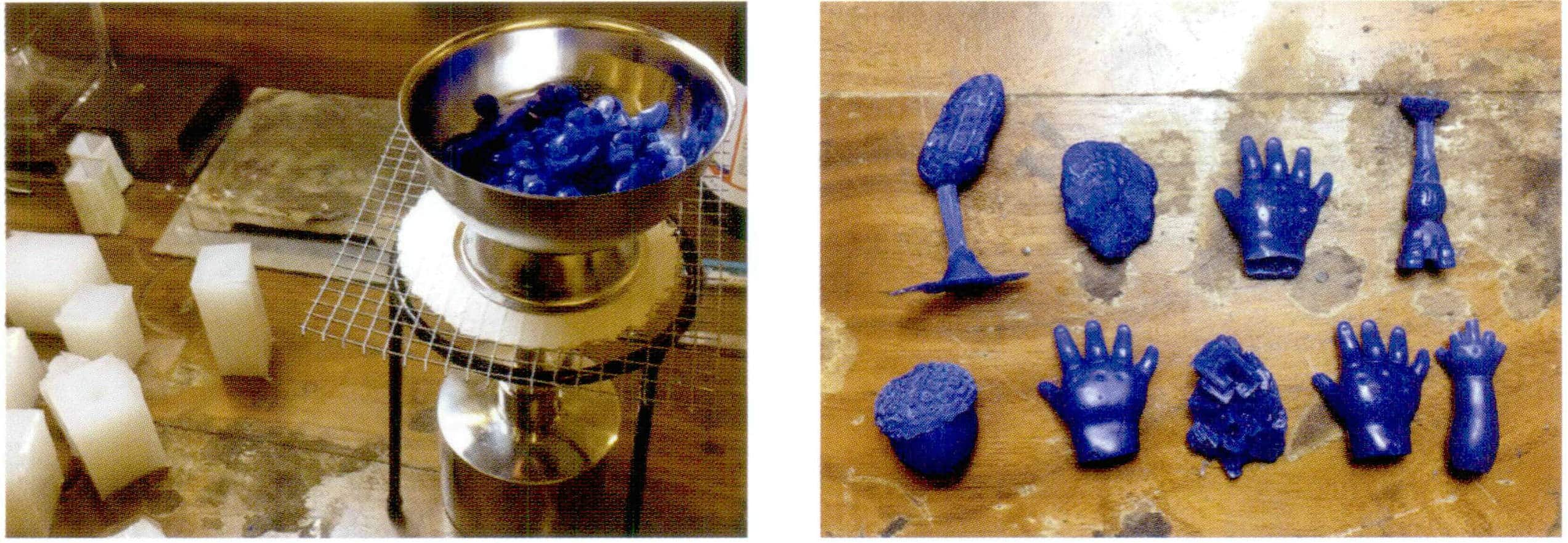

1. Prepare silicone, curing agent, electronic scale, paper box, disposable cups, chopsticks, surgical knife, and other materials and tools.

2. Select interesting small items for mold making, and be careful that the structure and shape of the objects are not too complex

3. Cut disposable chopsticks into appropriately sized short sticks to serve as the sprue inlet channel, and use oil clay to stick them to the object.

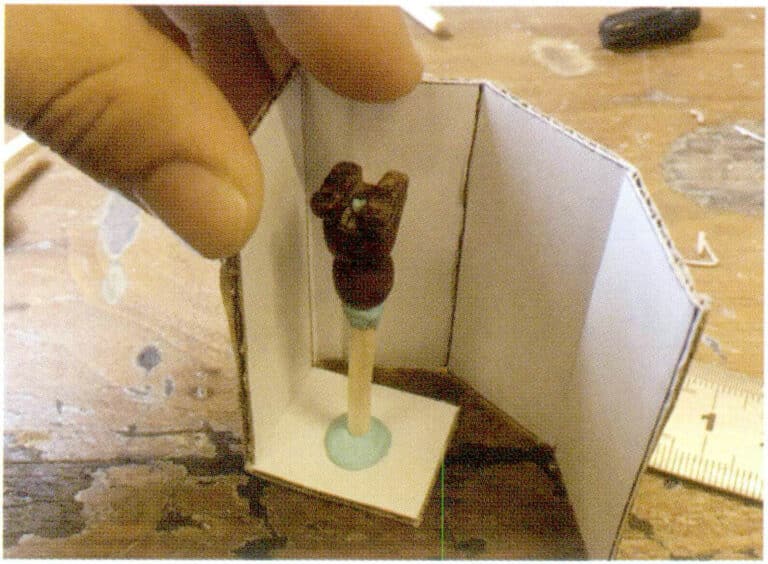

4. Make a casting box of suitable size from stiff cardboard. If the cardboard box is too small, first stick the prepared object's sprue down to the bottom, ensuring it is securely fixed, as liquid silicone has a certain buoyancy. If not securely attached, the item may float up during the pouring process, leading to a failed mold.

5. After securing the item, stick the entire cardboard box into shape. If the inside of the box is not covered with plastic film and is not very smooth, you can line the inside with transparent tape. This way, after the silicone solidifies, it can be easily demolded. At the same time, all gaps on the outside of the box must be covered with transparent tape to prevent silicone from leaking out during pouring.

6. Wait for the silicone to solidify

7. Take out the solidified silicone mold and use a scalpel to open the mold, noting that the cutting line should be in an S shape or Z shape.

8. After removing the item, the silicone mold is complete

9. After heating the casting wax with an alcohol lamp, inject it into the silicone mold, and you can obtain a wax model after cooling. It is important to note that if the structure of the item is relatively elongated or has small details, manual wax injection may result in an incomplete wax model due to pressure issues. In this case, we must use a vacuum-pressure wax injection machine to pour the wax mold.