Jak zvládnout umění výroby forem pro investiční lití

The basic principles and operational skills for 3 typical tasks

The precision casting process is the main method for forming metal jewelry, and the quality of the Investment casting mold is an important factor that determines the quality of the castings. Jewelry casting molds are generally made using commercial casting powder mixed with water to create a investment slurry. According to the melting point and chemical properties of the casting material, jewelry casting powders are mainly divided into two categories: one type uses gypsum as a binder and is mainly used for casting materials such as gold, silver, and copper; the other type uses phosphoric acid or phosphate as a binder and is mainly used for casting materials such as platinum, palladium, and stainless steel. Casting powder typically consists of refractory aggregates, binders, and additives, and different brands of casting powder vary in the composition and proportion of additives, leading to certain differences in the performance of the investment slurry. However, in production, it is often the case that different companies use the same brand of casting powder, and even the same company uses the same type of casting powder at different production stages, resulting in fluctuations in investment slurry performance and mold quality. When mixing the investment slurry, it is necessary to establish scientific mixing process requirements and strictly implement them. The wet casting mold contains wax or resin molds and has a large amount of moisture, which must be completely burned off through high-temperature baking to remove the wax (resin) mold and the moisture in the casting mold before it can be used for pouring molten metal. The methods and processes of casting mold Roasting significantly impact casting mold quality.

This project enables students to master the basic principles and operational skills of making ordinary gypsum casting molds, wax setting gypsum casting molds, and acid-bonded ceramic casting molds through three typical tasks and after-class extension exercises.

Automatic Wax Setting Machine

Obsah

Section I Production of Ordinary Gypsum Casting Molds

1. Základní znalosti

1.1 Gypsum Casting Powder

(1) Composition of Casting Powder

Jewelry gypsum casting powder has been widely commercialized, and various types of casting powders are available on the market. The more commonly used brands of casting powder include foreign brands such as Kerr, R&R, SRS, and Golden Star, as well as domestic brands like Gaoke, Hunter, and Yihui. The casting powders produced by different manufacturers vary in chemical composition and performance. Generally speaking, gypsum casting powder typically consists of three parts. First is the refractory aggregate, the most commonly used being quartz and cristobalite, which have high refractoriness and undergo a crystal structure transformation during heating, accompanied by significant volume expansion, which can offset the shrinkage of gypsum. Second is hemihydrate gypsum, which acts as a binder and is mainly available in type α and type β. When producing casting powder, type α is preferred, as it has a smaller crystal size and requires less water when preparing the investment slurry compared to type β. Third are additives, which come in various types and serve different functions. For example, retarders can delay the dissolution and gelation process of the casting powder, allowing for a complete arrangement of internal grains in the mold, thus improving the structural strength of the mold; accelerators can adjust the viscosity of the casting powder investment slurry, speeding up the setting and enhancing the strength of both the internal and surface of the mold; dispersants can ensure the investment slurry is evenly mixed, preventing sedimentation and layering, thus improving the flowability and suspension of the investment slurry; lubricants can improve the wettability of the investment slurry; and defoamers can reduce bubbles in the investment slurry. All of these can enhance the surface finish of the casting mold.

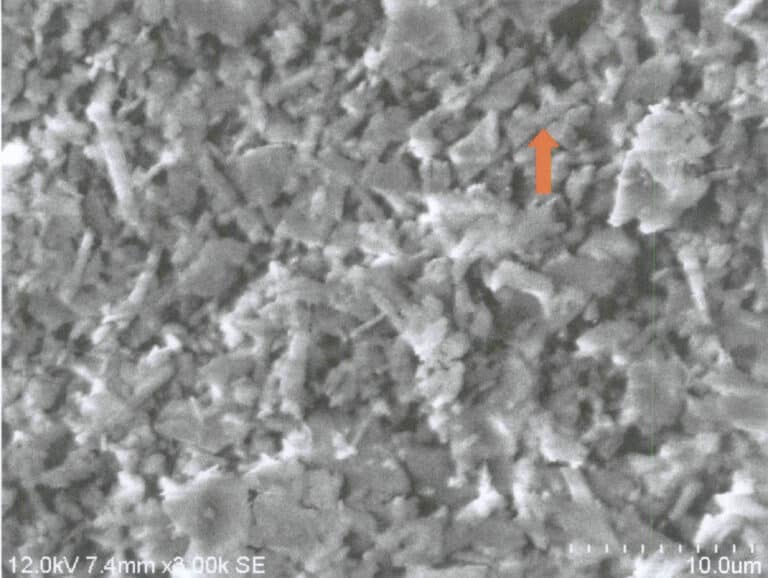

(2) Solidification Mechanism

When mixing gypsum powder with water to prepare the investment slurry, the type α semi-hydrated gypsum dissolves in water, and through stirring, a saturated solution of semi-hydrated gypsum is obtained. Hydration occurs, generating highly dispersed colloidal and particulate dihydrate gypsum. The dihydrate gypsum particles undergo recrystallization, growing into coarse crystals, allowing the investment slurry to form a hardened gypsum body with bonding and cohesion, thus achieving the desired casting mold strength. The formation of the dihydrate gypsum crystal structure can be divided into two stages: the first stage is the growth of newly formed crystals that come into contact with each other, forming the framework of the crystal structure, as shown in Figure 5-1, the second stage is the continued growth of the crystals after the framework is formed. The final strength of the hardened gypsum structure largely depends on the solubility of the gypsum binder and its dissolution rate.

1.2 Characteristics of Gypsum Casting Molds

The casting temperature for gold, silver, and copper jewelry is below 1100℃, so gypsum mold casting is commonly used. It has the following advantages: first, good reproducibility; gypsum expands while crystallizing, filling the fine details of the mold, resulting in clear patterns and strong three-dimensionality; second, good dispersibility; for delicate and complexly shaped ornaments, residual casting powder can be easily removed without damage; third, it is easy to operate and master.

However, the main component of gypsum is calcium sulfate, which has poor chemical stability at high temperatures and limited fire resistance. When the temperature exceeds 1200℃, it will decompose, releasing sulfur dioxide gas, severely affecting the castings’ quality. When the casting mold is not thoroughly roasted, and residual carbon is present, the decomposition temperature of gypsum will further decrease.

1.3 Gypsum Investment Slurry

(1) Water-to-Powder Ratio

The water-to-powder ratio is usually expressed as the water-to-investment slurry or water-to-solid ratio, indicating the amount of water added per 100 g of casting powder (in ml). The water-to-powder ratio is one of the important indicators for measuring the physical and process performance of the casting mold, and it is a crucial parameter related to the success or failure of investment slurry preparation and mold making, with multifaceted impacts. First, it affects the gel time and fluidity of the casting investment slurry. As the water-to-powder ratio increases, the fluidity of the investment slurry significantly improves while the initial and final setting times are extended. Second, it affects the thermal expansion rate of the casting mold. As the water-to-powder ratio increases, the casting mold’s thermal expansion rate and linear variable significantly increase. Third, it affects the tendency of the casting mold to crack. As the water-to-powder ratio increases, the tendency of the casting mold to crack becomes significantly greater. Fourth, it affects the strength of the casting mold. As the water-to-powder ratio increases, the casting mold’s normal temperature strength and high-temperature strength significantly decrease. Fifth, it affects the surface quality of the casting mold. Experiments and production practices have shown that each type of casting powder has a strict critical value for the water-to-powder ratio. Exceeding or falling below this value will significantly affect the surface roughness of the casting mold, thereby impacting the surface quality of the casting mold, sometimes resulting in a quality difference of two grades.

Therefore, when preparing gypsum investment slurry, it is essential to strictly control the water-to-powder ratio, carefully maintain the weighing instruments used, and ensure accurate measurements.

(2) Methods of Investment Slurry Preparation

There are two main categories of investment slurry preparation methods: manual mixing and mechanical mixing.

Manual mixing is relatively flexible and suitable for small quantities of investment slurry. When preparing the investment slurry, mix according to the required water-to-powder ratio, stir the casting powder and water, act quickly, and stir thoroughly until there are no powder clumps to ensure the investment slurry has good fluidity.

A investment mixer is a device that mixes casting powder and water into a uniform investment slurry. Using it instead of manual stirring improves efficiency and makes the mixing more uniform.

During the stirring process, a large amount of gas is mixed in, which gets trapped in the investment slurry, significantly reducing the casting mold’s strength and affecting the casting’s surface quality. Therefore, it is necessary to use a vacuum extractor to degas the investment slurry.

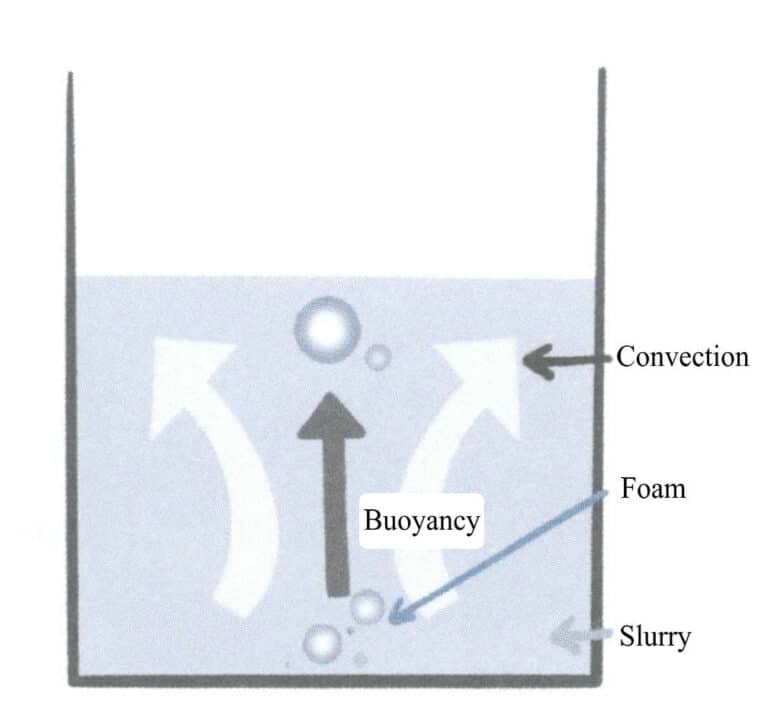

Currently, two main methods exist to eliminate bubbles generated during the investment slurry preparation process. One is to add a defoamer to the casting powder. It can diffuse in the foam, forming a double-layer film on the foam wall, reducing the surface tension of the foam locally, disrupting the self-healing effect of the foam, and causing the foam to burst. However, excessive defoamer can affect the performance of the investment slurry, and its effect in high-viscosity gypsum investment slurry is also limited. The second method is to use vacuum degassing. Gases have a certain solubility in liquids, which is influenced by factors such as pressure and temperature. Taking the solubility of air in pure water as an example, at a certain temperature, as the pressure decreases, the solubility of air in water continuously decreases. In contrast, at a certain pressure, as the temperature increases, the solubility correspondingly decreases.

Gases usually exist in liquids in the form of bubble nuclei. Still, in high-viscosity slurries, the aggregation and growth of bubble nuclei and the speed at which bubbles rise due to their buoyancy are extremely slow. Therefore, external force must be relied upon to bring the bubbles to the liquid surface, and vacuum stirring degassing is a relatively effective method. It uses a vacuum pump to draw the container’s interior to a vacuum. It stirs the investment slurry with stirring blades, forcibly causing the expanded bubbles in the investment slurry to float to the surface for degassing, as shown in Figure 5-2.

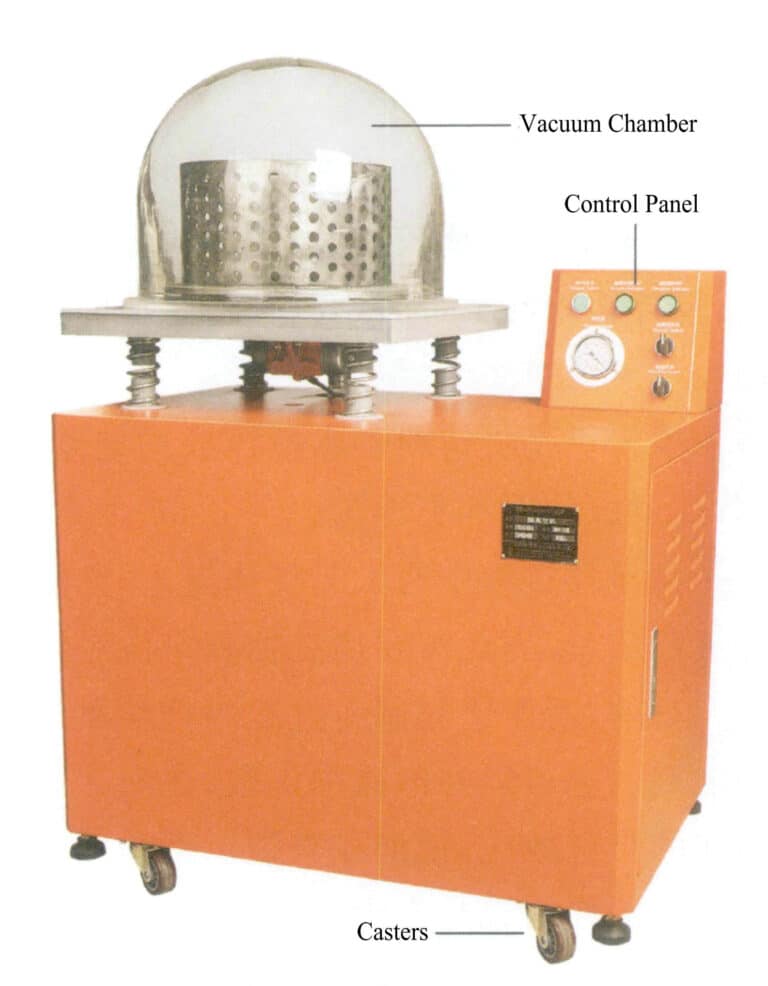

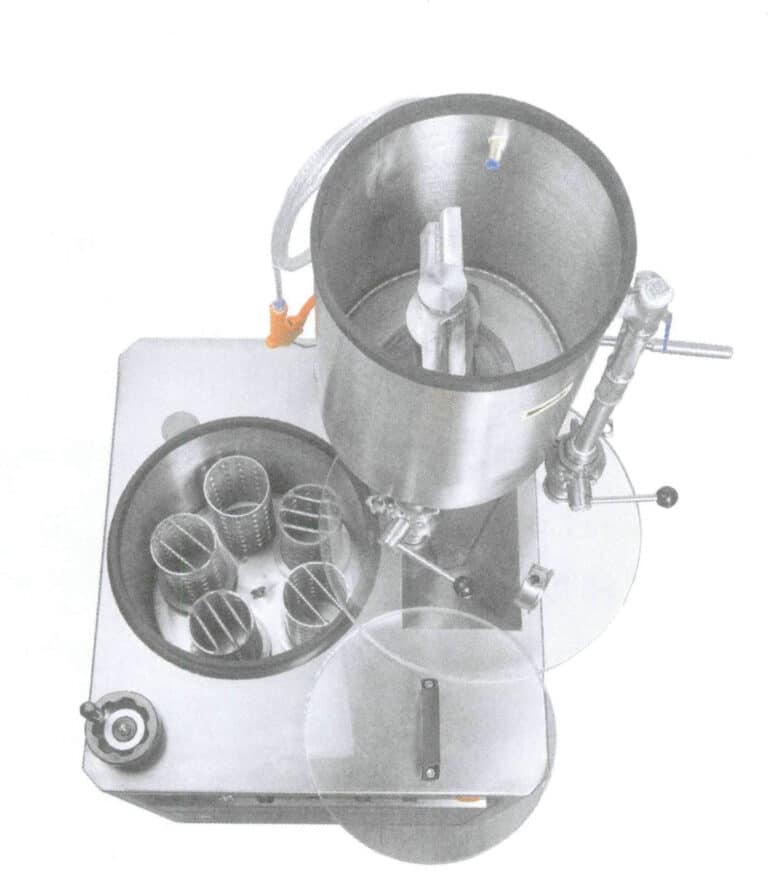

The investment mixer used in the mechanical mixing method is divided into two main categories: separate simple investment mixers and integrated vacuum investment mixers.

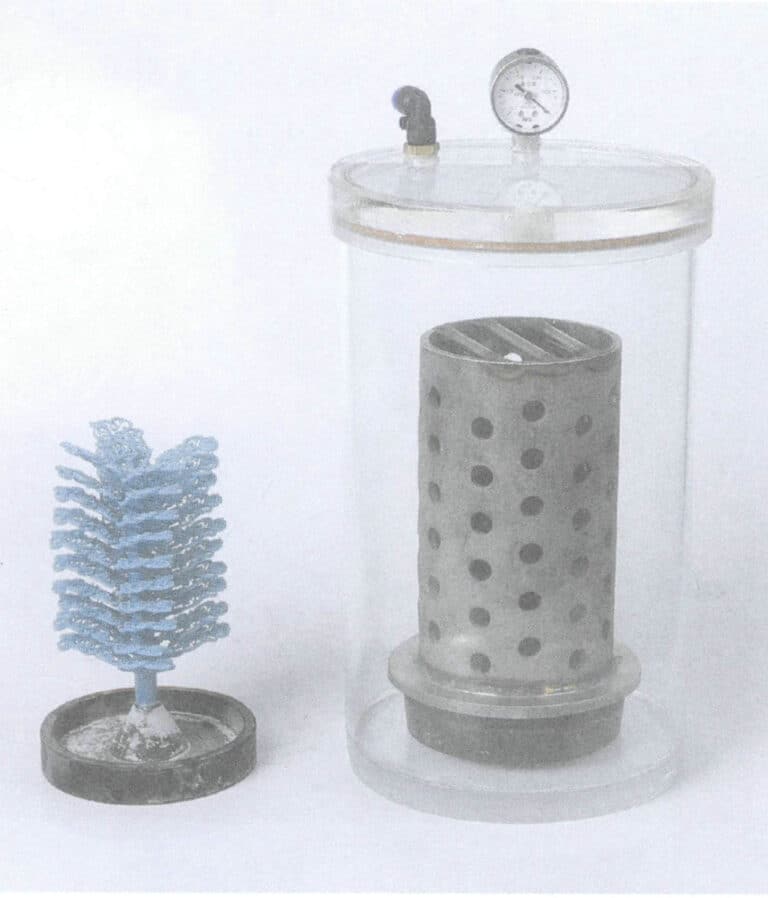

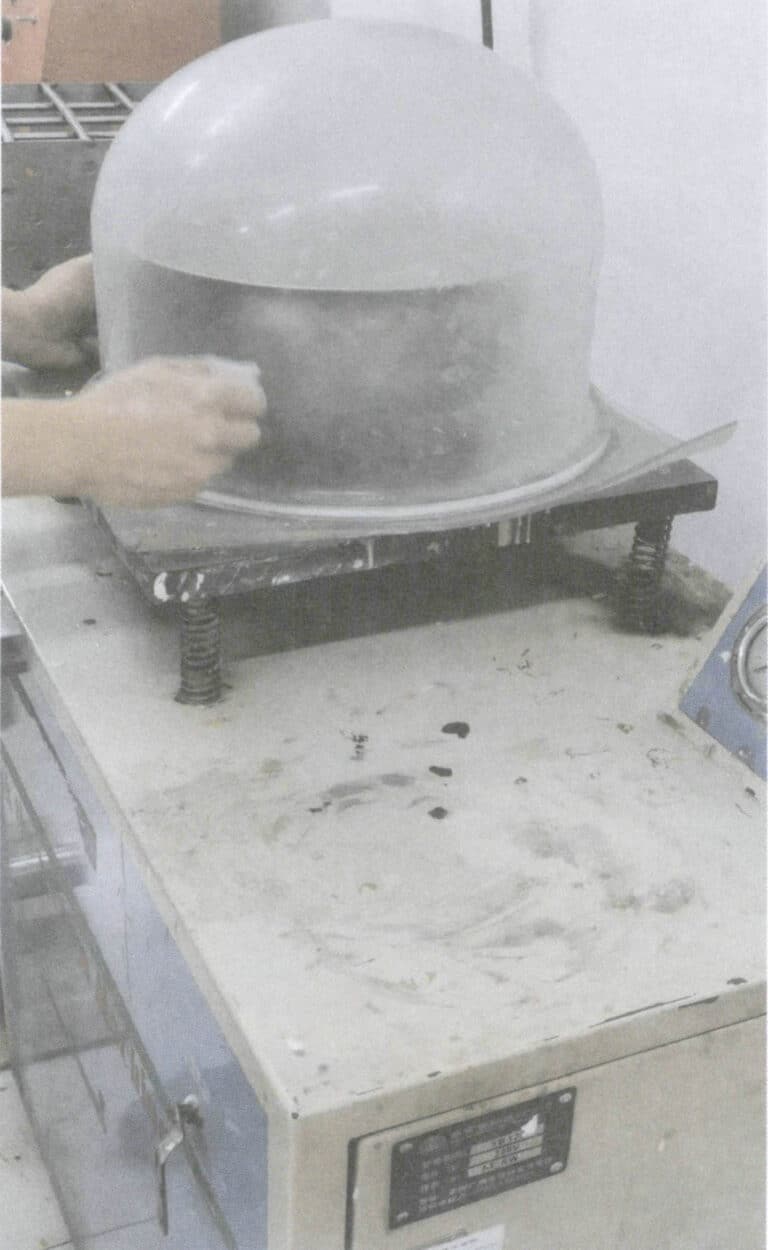

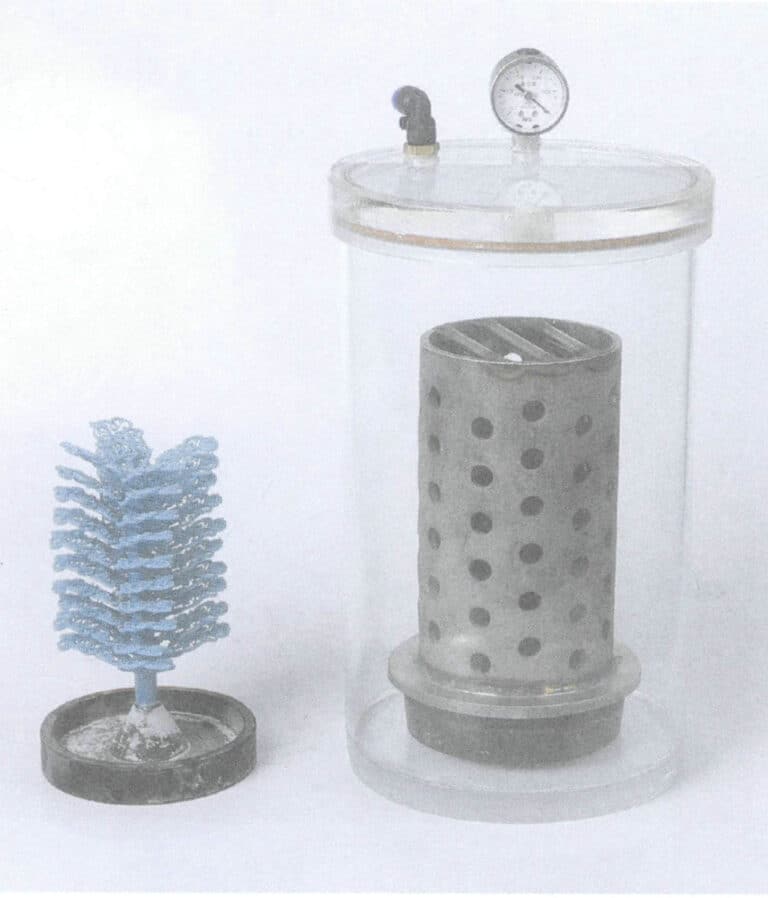

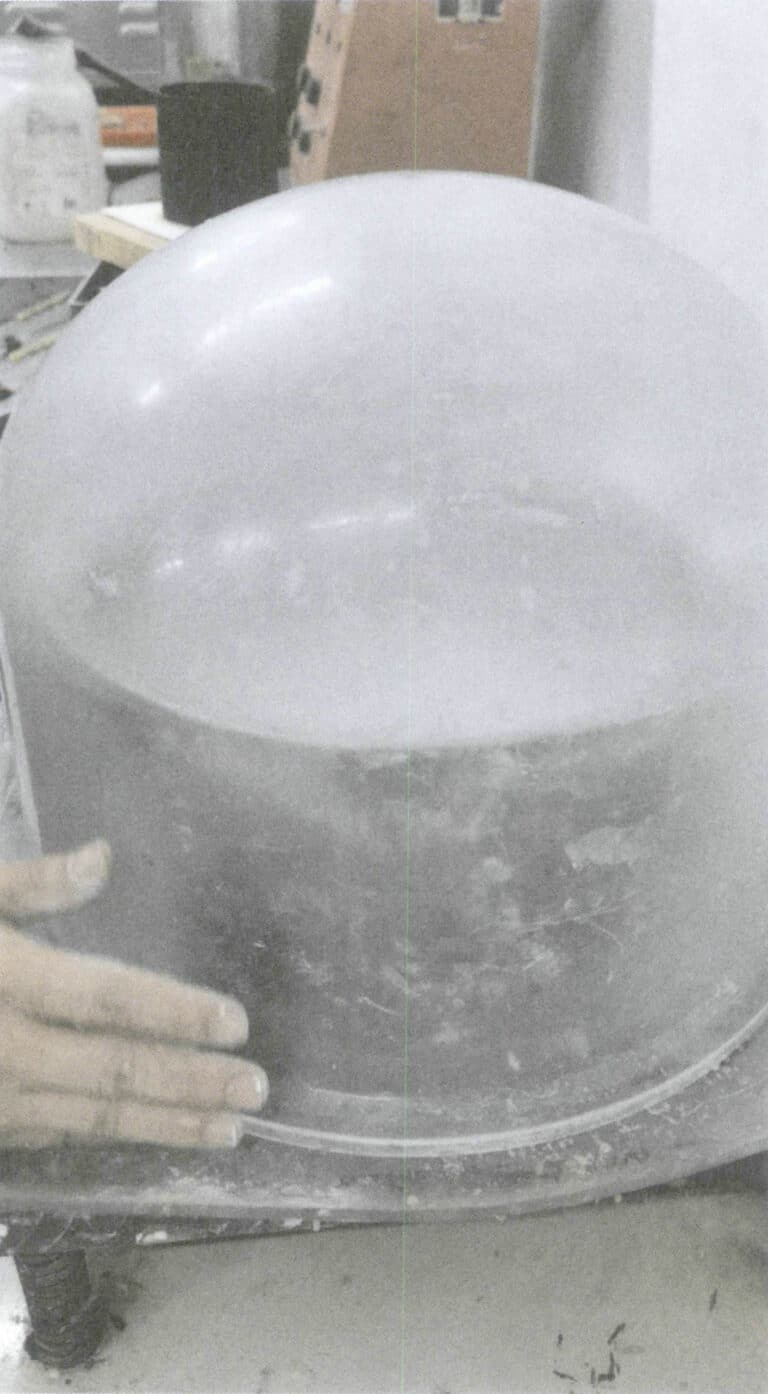

The separate simple investment mixer is shown in Figure 5-3. This machine has a simple structure and is inexpensive. Since stirring is done in the atmosphere, it is easy to incorporate gas. After stirring the gypsum investment slurry well, a vacuum extractor is necessary to remove the gas. Common vacuum extractors are machines based on vacuum springs and pressure gauges, with a flat plate mounted on the top of the machine case. The four corners of the plate have springs that can vibrate, and a layer of rubber mat is on the plate equipped with a hemispherical acrylic cover. As shown in Figure 5-4, during vacuum extraction, the cover tightly combines with the rubber mat to prevent gas leakage, ensuring the quality of the vacuum extraction. Using a separate simple investment mixer for opening powder involves several processes, including mixing, primary degassing, pouring, and secondary degassing, which is relatively cumbersome.

Figure 5-3 Split-type simple powder investment mixer

Figure 5-4 Vacuum extractor

Video 5-1 Single-flask vacuum investment mixer operation demonstration

Figure 5-6 Integrated multi-cavity vacuum automatic powder opening machine

Figure 5-7 Distribution of casting flasks in the pouring chamber

Video 5-2 Multi-flask vacuum automatic powder mixing operation demonstration

(3) Performance Indicators of the Investment Slurry

The main indicators for measuring the performance of gypsum investment slurry include fluidity, pouring time, and setting time. Fluidity refers to the ability of the casting powder investment slurry to flow and fill; pouring time is the duration from the start of mixing the casting powder investment slurry until the viscosity increases to a point where it can no longer be poured; setting time is the duration from the start of mixing until the investment slurry solidifies, at which point the surface gloss disappears, also known as the loss of gloss point time. The setting time depends on the performance of the casting powder and is also greatly related to the powder mixing operation and the water-to-powder ratio.

1.4 Wax Roasting from the Investment Casting Mold

After the investment slurry solidifies, there are two different methods to remove the wax: steam or baking.

Using steam wax removal can be more effective in removing wax, as the wax liquid permeates the casting mold’s thickness, effectively reducing it to zero, resulting in very little wax residue. During baking, a reducing atmosphere will not form inside the casting mold, which is beneficial for maintaining the stability of calcium sulfate in the gypsum, as a reducing atmosphere promotes the thermal decomposition of calcium sulfate. Additionally, steam wax removal is environmentally friendly. When using steam wax removal, it is important to ensure that the boiling of water is not too vigorous and to control the time of steam wax removal; otherwise, splashed water may enter the casting mold, damaging the surface of the casting mold and even causing the calcium sulfate crystals to crack, increasing the reactivity of the calcium sulfate crystals, lowering the thermal decomposition temperature, and promoting the formation of pores.

Wax Roasting directly utilizes a furnace to heat the casting mold, causing the wax material to melt and flow out of the casting mold. Since the boiling point of the wax material is relatively low if the wax liquid boils violently during this method, it can damage the surface of the casting mold; if the wax liquid does not drain smoothly, it may seep into the surface layer of the casting mold, deteriorating the surface quality of the casting. Therefore, it is important to control the heating temperature and speed during the wax removal phase and to set up an appropriate insulation platform. Additionally, the casting mold should not be completely dried before wax removal; otherwise, the casting mold is prone to cracking. If wax removal cannot be completed within 2~3 h after mixing the powder, a damp cloth should cover the casting mold to prevent drying.

1.5 Roasting of Investment Casting Molds

The purpose of Roasting is to eliminate moisture and residual wax in the casting mold, achieve the required high-temperature strength and air permeability, and meet the temperature requirements of the casting mold during pouring. The Roasting system and the dark Roasting equipment largely influence the final performance of the casting mold.

A suitable Roasting system must be established before Roasting gypsum casting molds. Generally, mold powder manufacturers have formulated Roasting guidelines, and the Roasting systems may differ for mold powders produced by different manufacturers. Therefore, it is necessary to understand the temperature changes of the casting mold during the heating process. The temperature changes of gypsum casting molds during heating can be divided into three stages. The first stage is the evaporation of free water. Two thirds of the moisture added to the gypsum mixture is vaporized, absorbing much heat. Since the thermal conductivity of water is much lower than air’s, the heat transfer process causes a significant temperature difference within the casting mold. The second stage is the transformation of dihydrate gypsum into hemihydrate gypsum, which undergoes an endothermic reaction, resulting in a reduced temperature gradient. The third stage is the transformation of hemihydrate gypsum into anhydrous, insoluble hard gypsum with no significant thermal effect, and the filler undergoes no phase change, resulting in a reduced temperature difference within the casting mold. The casting mold’s temperature field depends on the materials’ thermal properties and the casting mold’s bulk density.

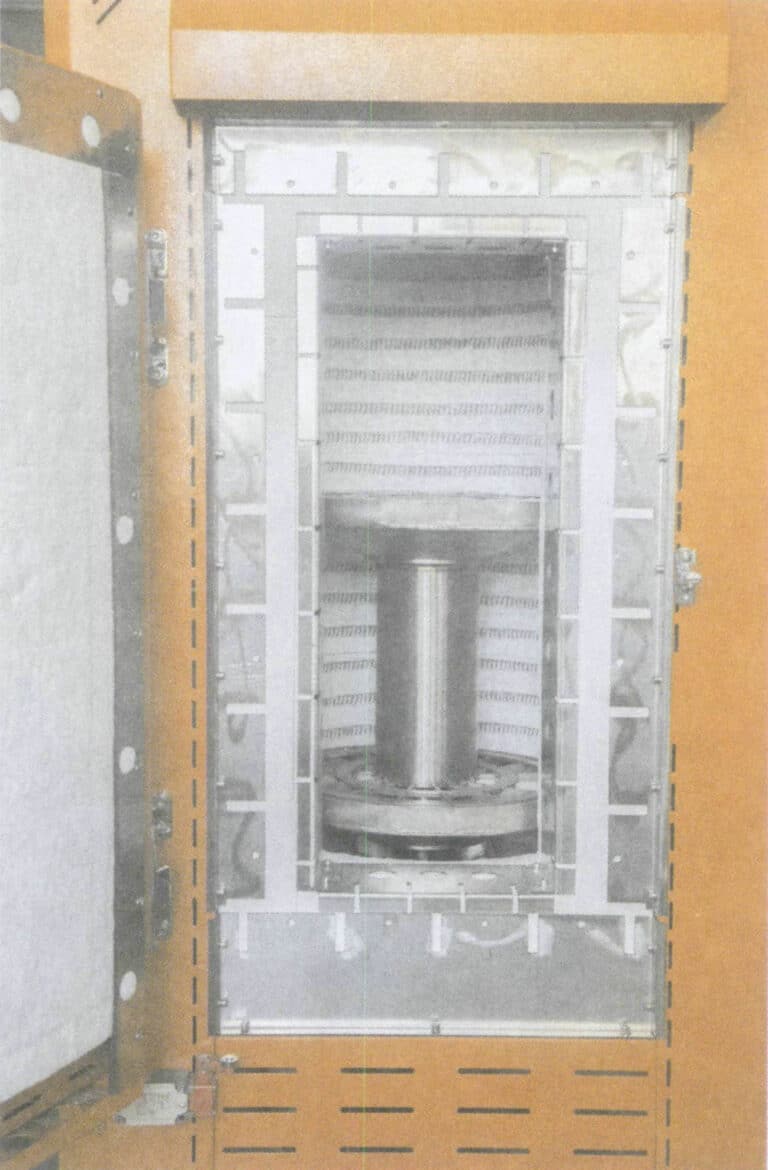

The Roasting equipment has a significant impact on the quality of casting mold Roasting. The gypsum Roasting furnaces used in the jewelry-making industry are generally electric Roasting furnaces, and some companies also use oil-fired furnaces. Regardless of the type of furnace, they usually come with temperature control devices and can achieve segmented temperature control. Figure 5-8 shows a typical electric Roasting furnace, which can implement temperature control in four or eight-segment programs. This type of furnace generally uses three-sided heating, and some use four-sided heating; however, the temperature distribution within the furnace is not uniform, making it difficult to adjust the atmosphere inside the furnace during Roasting. In recent years, some advanced Roasting furnaces have emerged to achieve uniform temperature distribution within the furnace, eliminating residual wax and automating control. For example, to address the issue of uneven temperature distribution in conventional box-type resistance furnaces, the rotary Roasting furnace uses a rotating bed method (Figure 5-9), allowing the gypsum mold to be heated evenly, with a smooth and fine inner wall, making it particularly suitable for advanced wax-set casting technology. Many manufacturers currently use this type of furnace in advanced wax-set casting technology. This sturdy resistance furnace provides the best production environment for casting larger volumes and greater quantities of steel flasks. Moreover, this furnace has heating on all four sides, with double-layer refractory brick partitions inside, ensuring uniform and stable heat and good insulation performance, and the smoke is fully burned twice before being discharged as a non-polluting gas.

Figure 5-8 Resistance Furnace

Figure 5-9 Rotary Roasting Furnace

2. Provádění úkolů

This task uses gypsum casting powder and the manual mixing method for casting gold and silver jewelry to create gypsum casting molds.

(1) Preparation Work

Use a ruler to measure the wax model tree’s maximum outer diameter and height. Based on the measurement results, choose a steel flask with an inner diameter of 100 mm and a height of 125 mm. Insert the bottom of the wax model tree core into the hole of the rubber base, keeping the wax model tree upright, and use a soldering iron to weld the contact surface to ensure it adheres firmly to the base.

Use a graver to clean the surface of the steel flask, then fit it into the rubber base so that the wax model tree is centered in the steel flask. Then, wrap tape around the outer wall of the steel flask to seal all holes, preventing leakage during pouring, as shown in Figure 5-10. The wrapped tape should be 20~30 cm higher than the steel flask to prevent the investment slurry from overflowing during defoaming.

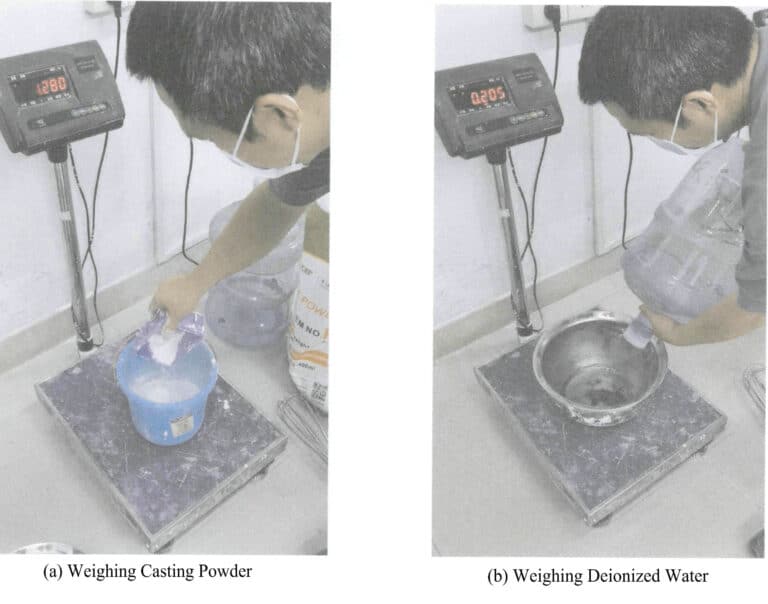

(2) Weighing Materials

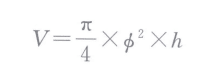

First, calculate the volume of the steel flask using the following formula:

In the formula, the volume of the steel flask is V (ml), the inner diameter and height of the steel flask are ɸ (cm) and h (cm). The calculated volume is approximately 982 ml.

According to the investment slurry density of 1.8 g/ml, the required investment slurry is about 1.768 kg. Considering losses due to adhesion on the container walls, an insurance factor of 1.15 is taken, so 2.033 kg of investment slurry must be prepared.

According to the water-to-powder ratio of 38.5 ml of water/100g of powder, the investment slurry is prepared by weighing 1.468 kg of casting powder and 565 ml of deionized water. For convenience, the deionized water can be weighed according to 1 g/ml. The casting powder and water are prepared separately, as shown in Figure 5-11.

(3) Mixing the Investment Slurry

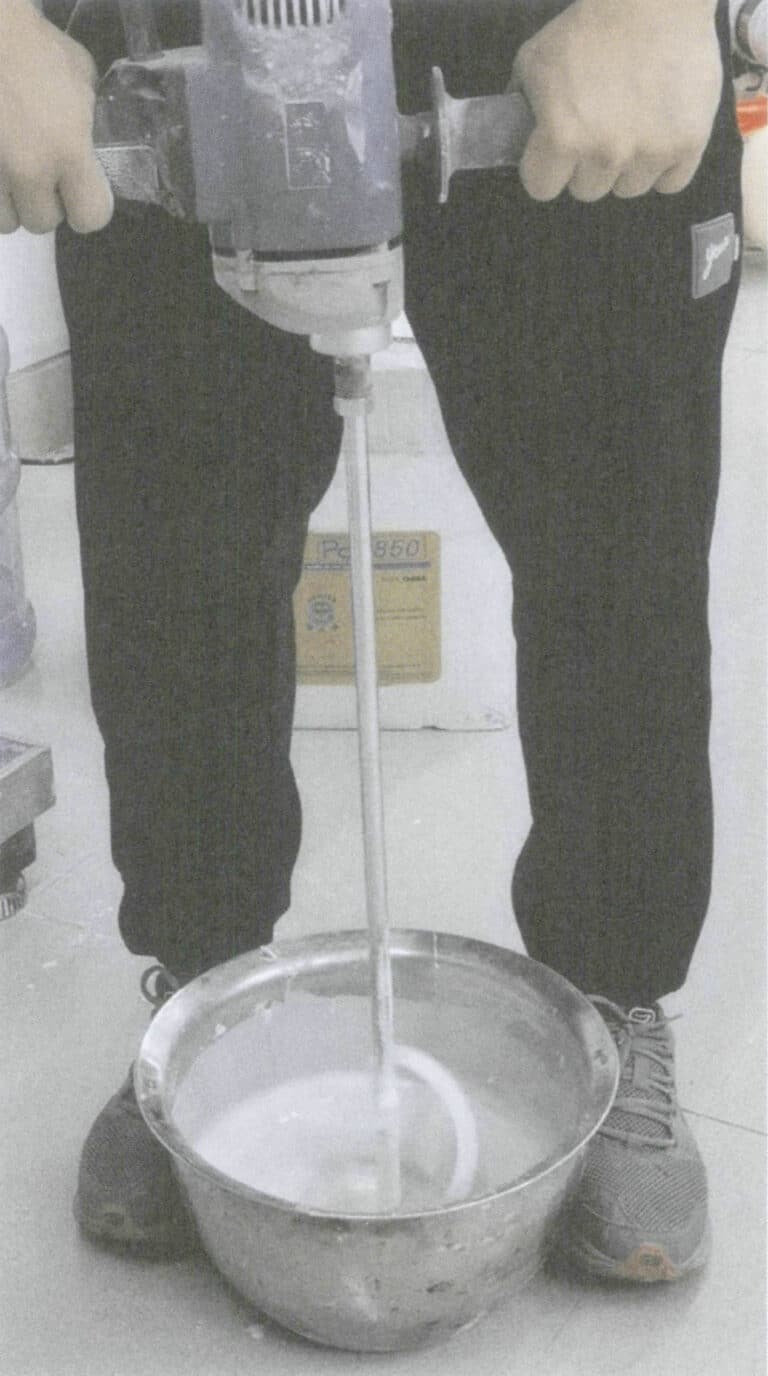

First, add deionized water to a stainless steel container, then gently pour the casting powder into the water, using a investment mixer to mix, starting slowly and then faster, with agile movements. Scrape the walls and bottom of the container to avoid the casting powder sticking to them. Stir for 2.5~3.5 minutes until a uniform investment slurry is formed, with no clumping of powder particles, as shown in Figure 5-12.

(4) First Degassing

Place the investment slurry bowl in the vacuum chamber, cover it with a transparent acrylic cover, and turn on the vacuum extractor and vibration device, allowing the bubbles in the investment slurry to dissipate under micro-vibrations and vacuum, as shown in Figure 5-13. Pay attention to the rise of the investment slurry surface; if the investment slurry is about to overflow, you can appropriately introduce a little air to lower the liquid level, then fully open the vacuum valve. The first vacuum time lasts for 1.5~2 min until no violent boiling occurs at the liquid surface. Note that the vacuum time should not be too long to avoid the investment slurry becoming viscous and losing fluidity.

(5) Grouting

Place the steel flask with the wax model tree on the vibration table and slowly pour the investment slurry along the wall of the steel flask while gently tapping the table surface to ensure the investment slurry flows smoothly, reducing the air trapped during filling. Avoid pouring the investment slurry onto the wax tree to prevent individual wax molds from dislodging, as shown in Figure 5-14. Stop adding investment slurry when the investment slurry is 20~30 mm above the wax model tree or level with the top of the steel flask.

Figure 5-13 First Degassing

Figure 5-14 Grouting

(6) Secondary Degassing

Cover with a transparent acrylic cover, turn on the vacuum extractor and vibration device, and perform secondary degassing of the investment slurry in the steel flask for 2~2.5 min, while maintaining a gentle vibration on the table to promote bubble removal, as shown in Figure 5-15.

(7) Resting

After completing the casting mold’s grouting and secondary degassing operations, it should be allowed to rest for 1.5 to 2 hours to allow the gypsum mold to fully solidify and harden, as shown in Figure 5-16.

(8) Cleaning

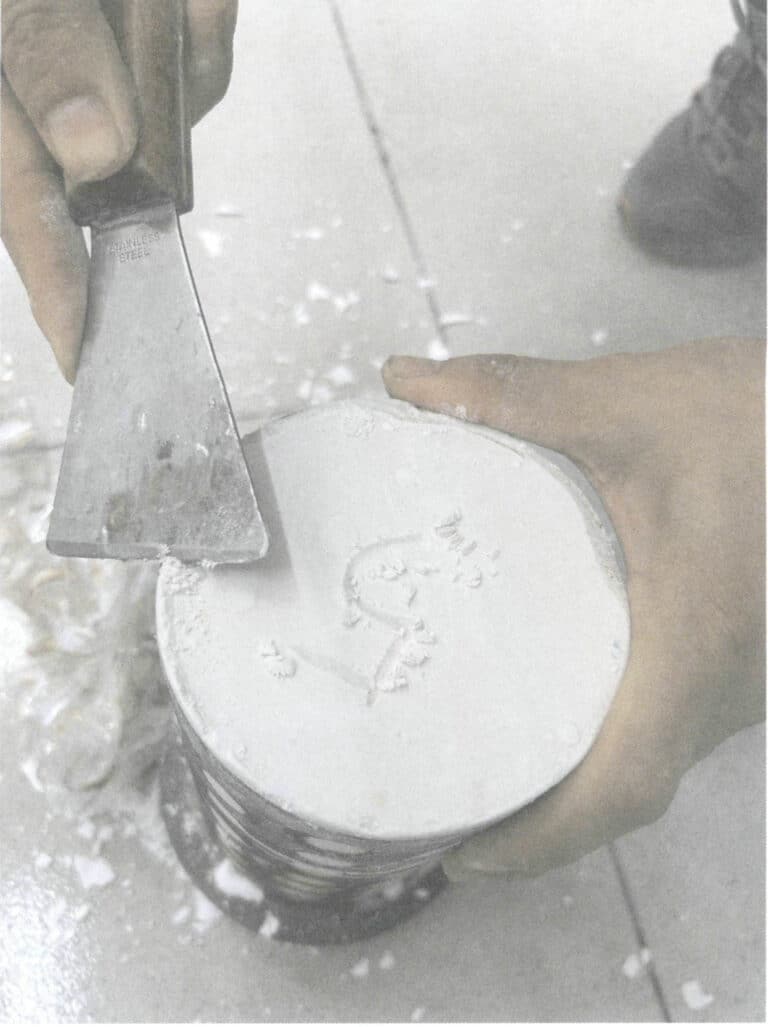

Remove the rubber base, remove the wrapping material and spilled investment slurry around the steel flask, and make marks on the top surface of the casting mold (Figure 5-17).

Figure 5-16 Static Casting Mold

Figure 5-17 Cleaning and Marking

(9) Roasting of Investment Casting Molds

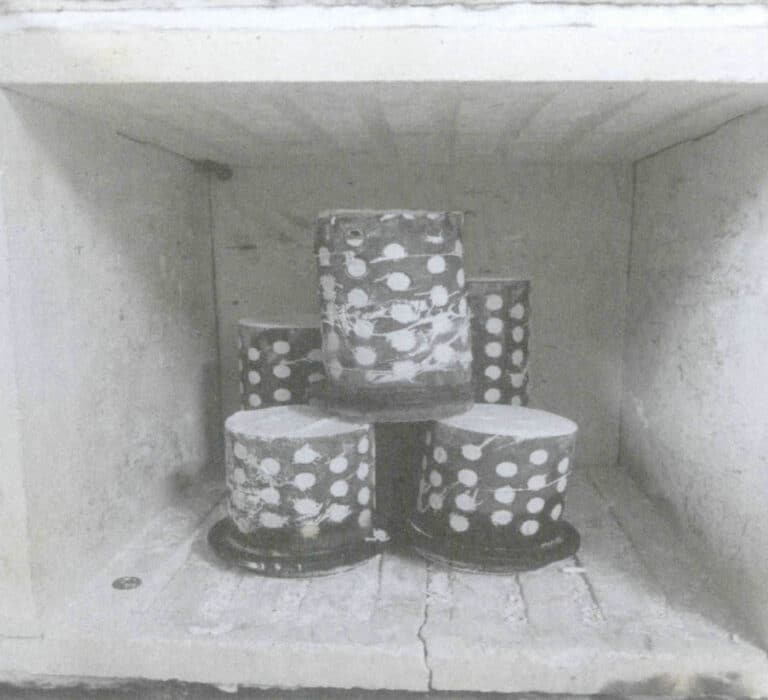

Directly place the casting mold into the Roasting furnace with the pouring port facing down, leaving a certain gap between casting molds to prevent uneven heating. If the casting molds are stacked in two layers or more, the upper layer should be staggered with the bottom layer, as shown in Figure 5-18. Set the Roasting system according to the casting powder usage guidelines, including heating time, heating rate, temperature, and holding time. To ensure precise and controllable furnace temperature and avoid large fluctuations, an intelligent temperature control system should be configured on the Roasting furnace. Different manufacturers may have certain differences in temperature control settings for their Roasting furnaces. The commonly used control system is a programmable intelligent instrument, as shown in Figure 5-19, which generally has dozens of heating program functions and PID (proportion, integral, differential coefficient) functions. Among them, the PV (process variable) window shows the measured value, the SV (set value) window shows the set value and the progress bar of 0~100% indicates the power output ratio.

Figure 5-18 Placement of two-layer casting molds in the Roasting furnace

Figure 5-19 Programmable intelligent instrument.

When performing programming operations, first turn on the power, press the ▲ key for 2s to make the SV window display “STOP,” and then follow the steps below to set it.

① Press the ▲ key, and the PV displays “C01”, indicating the starting temperature that needs to be programmed; press the ◀, ▲, ▶ key to make the SV reach the desired starting temperature.

② Then press the SET key, and the PV displays “to1” indicating the time to reach the next set temperature from the starting temperature; press the ◀, ▲, ▼ key to make the SV reach the desired time.

③ Then press the SET key again, and the PV displays “C02”, indicating the previously set starting temperature C01, which took t01 time to reach the desired temperature; press the ◀, ▲, ▼ key to make the SV reach the desired temperature.

④ Then press the SET key again, and the PV displays “t02″indicating the time to reach the next set temperature from C02; repeat the previous steps until the desired temperatures and times are set, with a maximum of 30 segments.

⑤ Set the last parameter to “-121” to enable automatic shutdown.

⑥ Wait for the SV to display “STOP,” then press the ▼ key to make the SV window show “RUN,” and the instrument will automatically start working according to the set program.

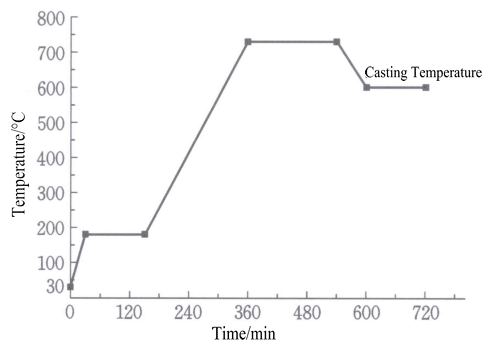

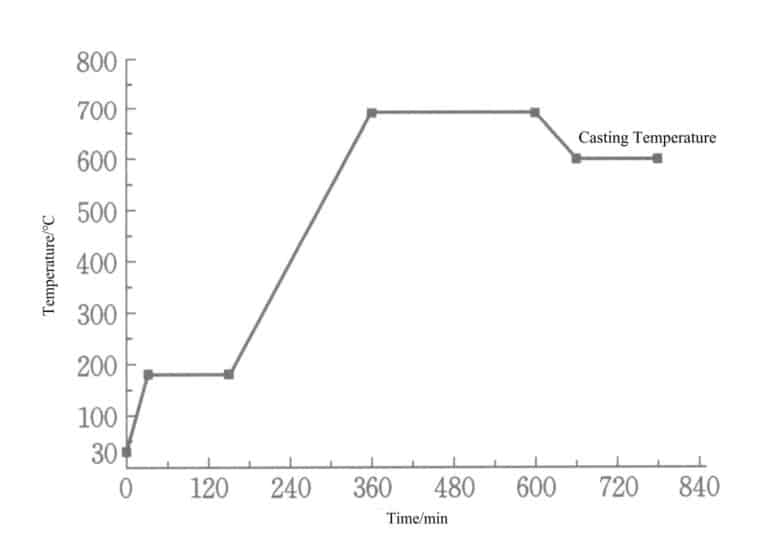

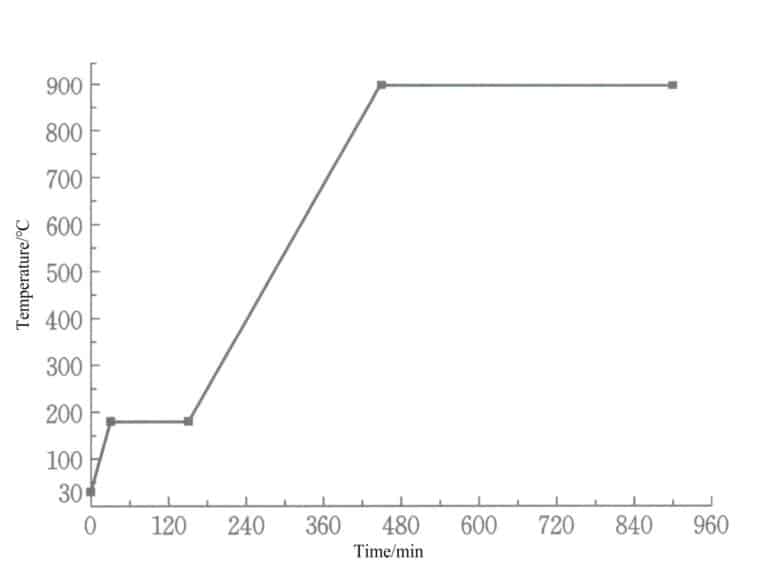

Taking the Roasting system of the gypsum model shown in Figure 5-20 as an example, the steps are set as follows.

① Press the ◀ key C01=30℃;

② Press the SET key t01=30 min;

③ Press the SET key C02=180℃;

④ Press the SET key t02=120 min;

⑤ Press the SET key C03=180℃;

⑥ Press the SET key t03=210 min;

⑦ Press the SET key C04=730℃;

⑧ Press the SET key t04=180 min;

⑨ Press the SET key C05=730 ℃;

⑩ Press the SET key t05=60 min;

⑪ Press the SET key C06=600℃;

⑫ Press the SET key t06=120 min;

⑬ Press the SET key C07=600℃;

⑭ Press the SET key t07=-121.

After the casting mold is sintered at a high temperature, the required strength is achieved, forming various cavities for models inside the casting blank and then cooling to the required casting temperature after drying the mold.

(10) End of Work

After completing the casting mold-making task, turn off the relevant power supply, clean the equipment and work area, and place the stainless steel containers, investment mixers, rubber bases, etc., in the designated location.

Kopírování @ Sobling.Jewelry - Výrobce šperků na zakázku, továrna na šperky OEM a ODM

Section II Production of Wax Gypsum Casting Molds

1. Základní znalosti

1.1 The Concept of Wax-Set Casting

1.2 Advantages of Wax-Set Casting Technology

(1) Saves time and improves production efficiency. For high-quality requirements of channel-set baguette jewelry products, the efficiency of wax setting can reach 2~4 times that of gold setting; for pave setting products with lower quality requirements, the efficiency of wax setting can even exceed that of gold setting by several dozen times.

(2) Reduces labor costs. Traditional gold setting operations require a high level of skill from the stone-setting workers, meaning that jewelry factories need to invest many skilled laborers in the stone-setting department, significantly increasing labor costs. Labor costs account for a high proportion of the total cost of producing low-value jewelry pieces. By using wax setting technology, labor costs can be greatly reduced.

(3) Reduces the loss of precious metals. When using traditional gold setting technology, it is often necessary to adjust the setting position, resulting in a relatively high loss of precious metals. In wax setting, adjustments are made to the wax mold, thus greatly reducing the loss of precious metals.

(4) Wax setting operations only require simple tools, which can greatly reduce the investment and loss costs of grinding tools such as machine burs and hanging grinder.

(5) As a new setting method, the wax-set casting process provides the technical conditions for innovation in jewelry design, and some jewelry products can only be manufactured through the wax-set casting process.

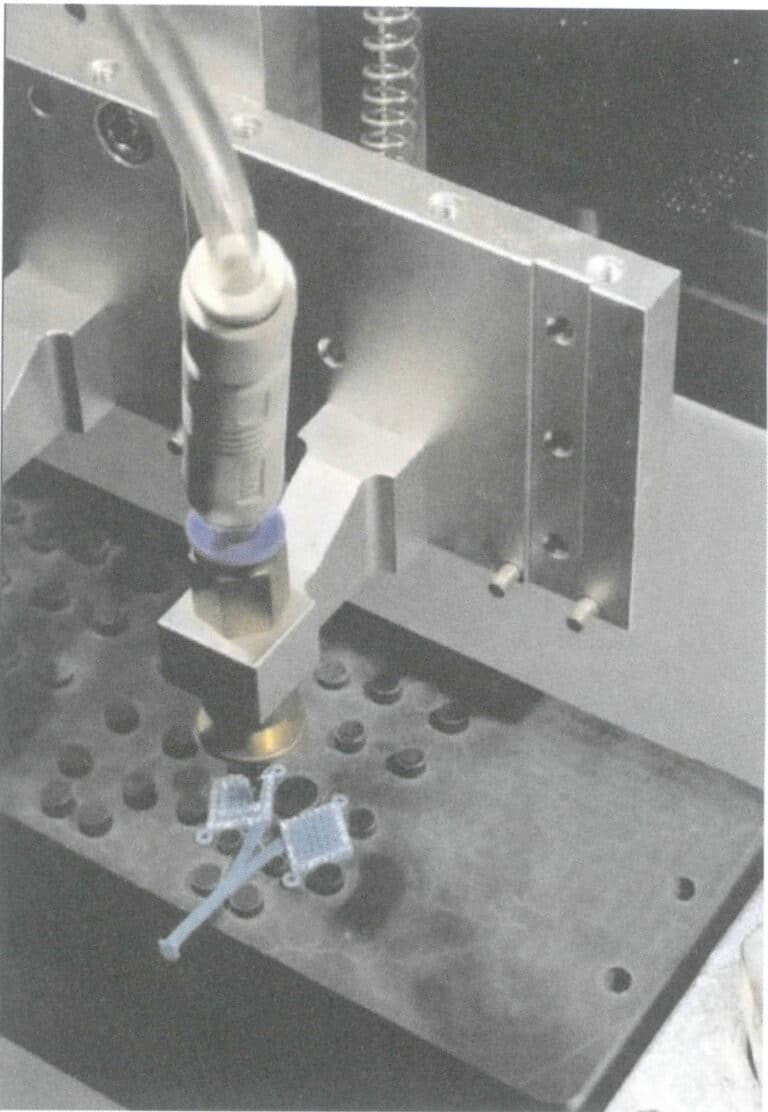

(6) Wax-set casting is an effective way to achieve automation in setting. For a long time, setting was done on defective metal blanks, relying solely on manual labor. However, when using the wax-set casting process, gemstones are embedded in wax molds, taking advantage of the low melting point and good elasticity. This allows for the automatic embedding of gemstones using robotic arms and sensing devices, significantly improving production efficiency and the stability of setting quality, as shown in Figure 5-21.

1.3 Special Requirements of Wax-Set Casting for Gypsum Casting Molds

Adding boric acid to the casting powder investment slurry helps prevent the burning and discoloration of gemstones during the Roasting and casting processes. It plays a protective role. Boric acid can be added in two ways: one is to add it directly during the production of casting powder and mix it evenly; the other is to use conventional casting powder and employ saturated boric acid water when preparing the investment slurry (at room temperature, the saturation solubility of boric acid powder in 100 ml of water is usually no more than 5 g). Due to the accelerated setting speed of gypsum after adding boric acid, the working time is 6~7 min only, so it is important to control the speed of the entire operation process to ensure that the investment slurry has enough vacuum time to remove bubbles stuck to the wax mold (any bubbles at or near the bottom of the bezel will form difficult-to-remove metal beads on the casting; a small amount of liquid detergent can be added to the investment slurry to improve its wetting properties and avoid bubbles getting trapped). In addition, care should be taken during pouring to avoid displacing the gemstones.

Now, casting powders specifically designed for wax-set casting are available on the market. When using these casting powders, follow the usage recommendations from the powder manufacturer, such as water-to-powder ratio, mixing time, vacuum time, and setting time. For the casting mold after grouting, it should be allowed to stand for 1.5~2 h before proceeding with the dewaxing and baking.

1.4 Dewaxing and roasting

Both steam dewaxing and roasting dewaxing can be used in wax-set casting. The key is to thoroughly remove all wax residues before casting, as carbon residues can cause defects in metal casting and affect the quality of the castings. Since gemstones risk burning, discoloration, or cracking when subjected to high temperatures, thermal shock, and thermal stress, a lower baking temperature than conventional casting is generally adopted in the wax-set casting process to protect the gemstones. Therefore, establishing a reasonable baking system for the casting molds is crucial in the wax-set casting process. Because wax setting techniques often reduce the baking temperature to some extent, steam dewaxing helps remove wax. Steam dewaxing should be limited to within 1 hour; if it is too long, it can easily leave watermarks or damage the mold. After steam dewaxing, the casting mold should be immediately transferred to the baking furnace for baking.

To ensure the Roasting effect, the wax-inlaid casting mold must pay attention to the following points during Roasting: First, the Roasting furnace must be able to control the temperature accurately to avoid overheating, which could cause the gemstones to burn or change color; second, the mold should be heated as uniformly as possible to reduce the risk of cracks in the gemstones due to thermal shock and thermal stress; third, there must be sufficient air circulation in the Roasting furnace to completely burn off the residual carbon from the wax.

During Roasting, setting thermal insulation platforms at certain temperature ranges helps prevent gem cracking. The Roasting temperature can vary depending on the type and quality of the gem, and the casting mold temperature during pouring should also be determined based on the material, casting structure, and other factors.

2. Provádění úkolů

This task uses a wax tree composed of wax-set diamond rings, and a one-piece single-flask vacuum powder investment mixer is used to create the gypsum mold. The production process is the same as that of ordinary gypsum casting molds, which can be referred to chapter 2 in section I and will not be elaborated on here.

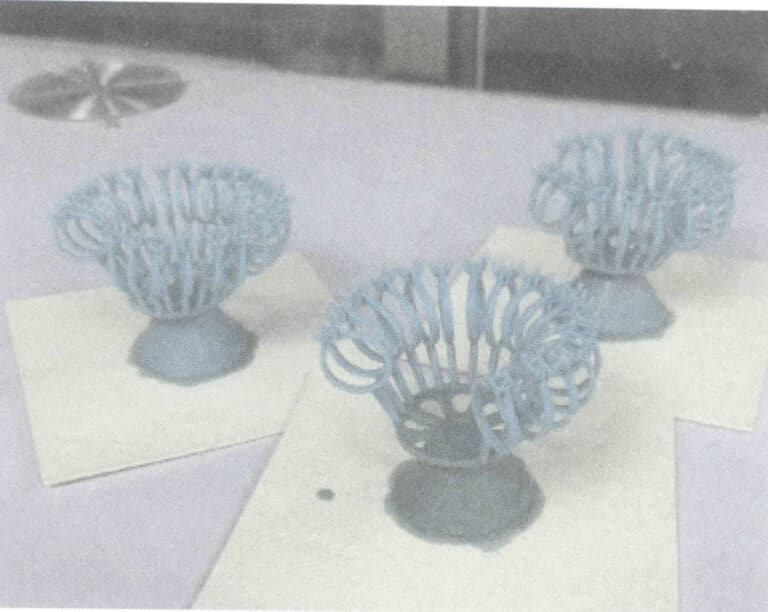

(1) Preparation Work

Measure the outer diameter and height of the wax model tree with a ruler, select an appropriate steel flask, place the rubber base of the wax model tree onto the rim of the steel flask, and ensure the wax model tree remains upright. The assembled steel flask should be able to fit smoothly into the grouting bucket, and its height should not exceed 3/4 of the height of the grouting bucket, as shown in Figure 5-22.

(2) Weighing Materials

According to the ratio of boric acid powder of 2~3 g added to 100 ml of water, weigh deionized water and boric acid powder separately, add the boric acid powder to the water, and stir to obtain a boric acid aqueous solution.

Calculate the required amount of investment slurry based on the volume of the steel flask, and prepare the investment slurry according to the water-to-powder ratio of 39 ml boric acid aqueous solution / powder of 100 g, weighing the corresponding amounts of casting powder and boric acid aqueous solution.

(3) Mixing and First Degassing

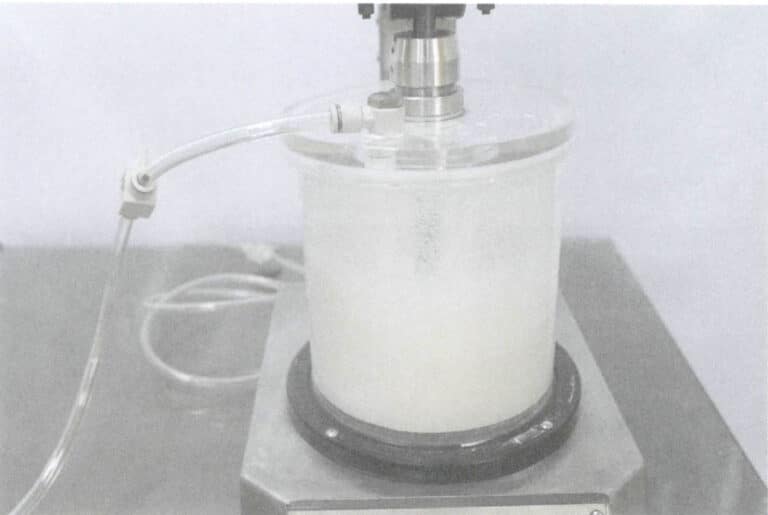

Pour the boric acid aqueous solution into the mixing bucket, slowly add the casting powder into the deionized water, cover with a lid, and connect the vacuum extractor pipe. Start the investment mixer to mix for 3~4 min, maintaining the stirring in the same direction (Figure 5-23). The investment slurry continuously removes bubbles under vacuum, as shown in Video 5-3.

Video 5-3 Mixing and First Degassing Demonstration

(4) Grouting

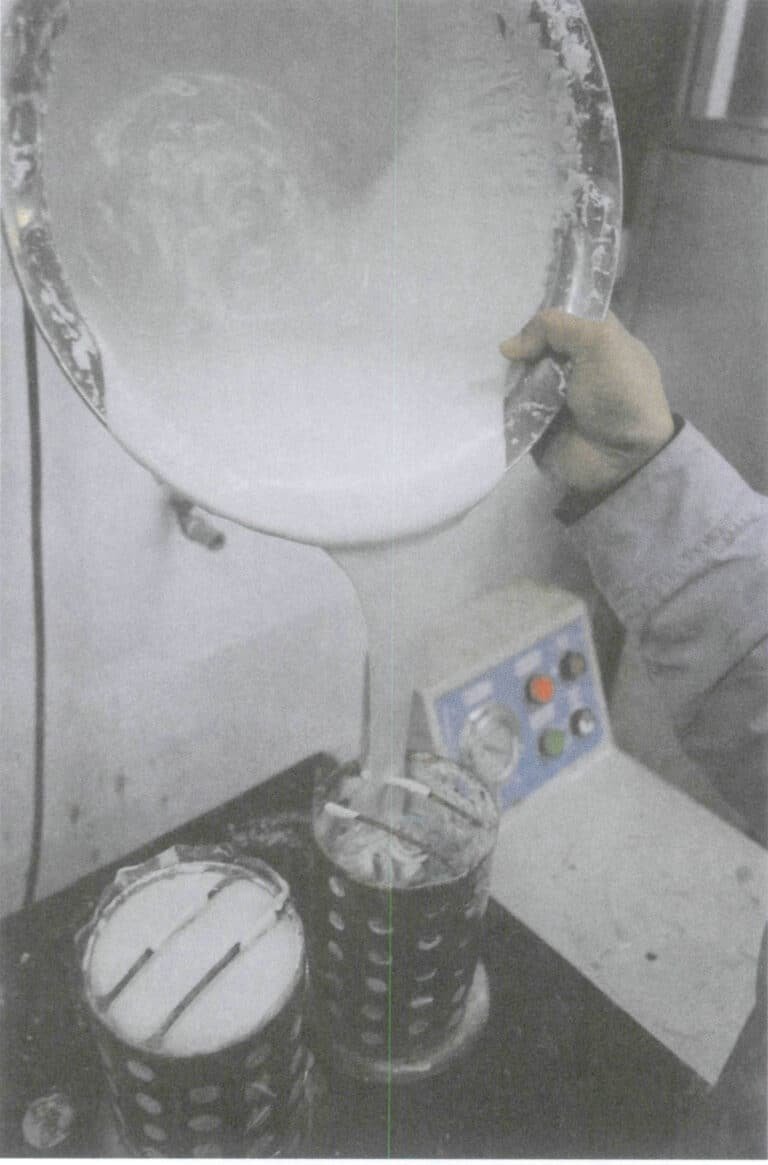

After the investment slurry is well mixed, remove the mixing bucket and replace it with a vacuum tank containing the wax model tree and steel flask, as shown in Figure 5-24. Pour the investment slurry steadily into the steel flask to reduce the amount of gas trapped during filling. Care should be taken to avoid directly pouring the investment slurry onto the wax-set workpiece to prevent gem or wax mold detachment issues.

(5) Secondary Degassing

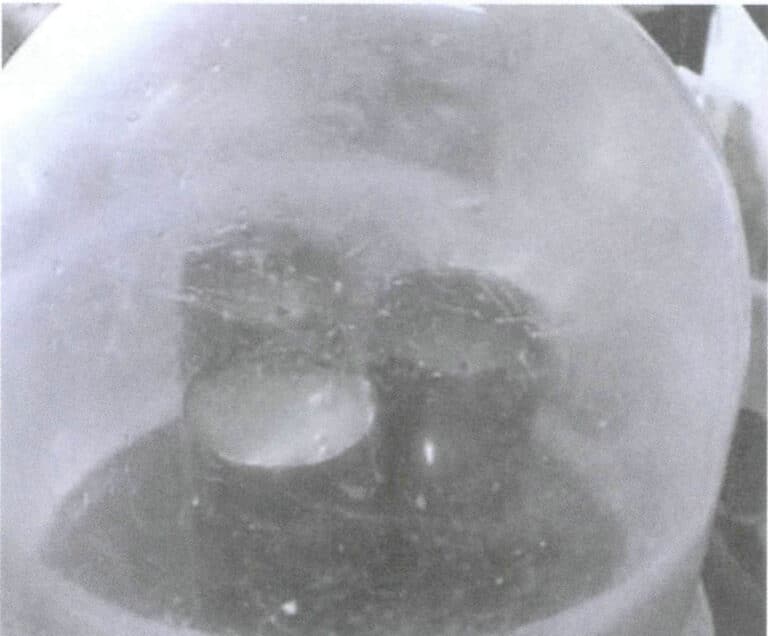

Cover the lid, start vacuuming, and perform secondary degassing of the investment slurry for 2 to 3 minutes, as shown in Figure 5-25. Be careful to avoid vacuuming when the investment slurry is too thick. The demonstration of secondary degassing can be seen in Videos 5-4.

Figure 5-24 Grouting

Figure 5-25 Secondary Degassing

Video 5-4 Secondary Degassing Demonstration

(6) Standing

Release the vacuum in the grouting barrel, remove the casting mold, place it on a flat surface, and let it sit for 1.5 to 2 hours.

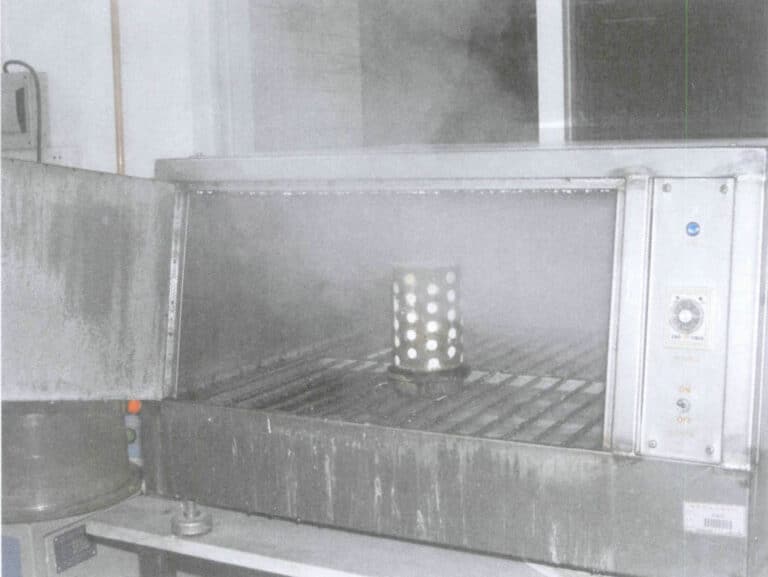

(7) Steam Dewaxing

First, fill the steam dewaxing furnace with enough water and turn on the heating device. When the water boils, invert the casting mold and place it in the dewaxing box, as shown in Figure 5-26. Use steam to melt the wax mold inside the mold, allowing it to flow out of the casting mold. The time should be controlled to around 60 minutes and should not be too long to avoid weakening the protective effect of boric acid on the gem’s surface.

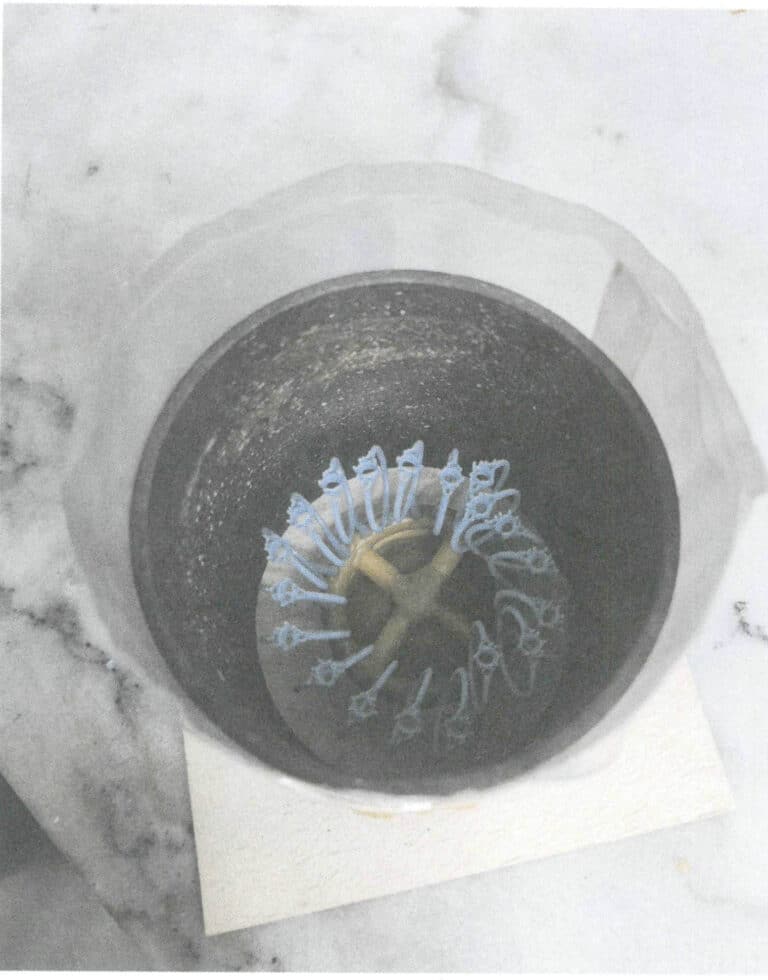

(8) Roasting of Investment Casting Molds

Prioritize using a rotary Roasting furnace, placing the casting mold on the turntable with the pouring gate facing down, as shown in Figure 5-27. Set up the wax-set casting mold Roasting system, as shown in Figure 5-28.

Figure 5-27 Placement of the casting mold in the rotary Roasting furnace

Figure 5-28 Wax-set casting Roasting system

(9) End of work

After completing the casting task, turn off the relevant power supply, clean the equipment and workplace, and place tools and materials in the designated location.

Section III Production of Acid-Bonded Ceramic Casting Molds

1. Základní znalosti

1.1 Acid-Bonded Casting Powder

(1) Basic Composition

Gypsum casting powder has poor thermal stability and is only suitable for metals with relatively low melting points. For high melting point metal materials such as platinum, palladium, and stainless steel, using gypsum molds will cause severe mold decomposition reactions, so it is necessary to use casting mold materials with better thermal stability.

Acid-bonded casting powder is currently the main casting mold material used for this type of jewelry casting, composed of binders, refractory fillers, and modifiers. The binder is made from phosphoric acid or phosphates, refractory fillers generally use quartz powder and fused quartz powder, and modifiers include wetting agents, defoamers, and suspending agents.

(2) Casting Mold Expansion Rate

The casting molds made from acid-bonded casting powder will have a certain expansion rate during the curing and sintering processes, and the size of the expansion rate is closely related to the precision of the castings. The total expansion rate consists of three parts—solidification expansion rate, moisture absorption expansion rate, and thermal expansion rate, with the total expansion rate generally between 1.3%~2.0%.

The needle-like NH4MgPO4·6H2O and columnar crystals form solidification expansion. The higher the binder content, the greater the solidification expansion rate. When the binder content is constant, the mass ratio of MgO and NH4H2PO4 affects the solidification expansion rate and solidification time. When the ratio is 6:14, it has a greater solidification expansion rate and longer solidification time compared to the ratio of 10:10. The particle size of the filler also affects the solidification expansion rate; when other conditions remain unchanged, casting powder with a mixed distribution of particle sizes of TAK2 will have a higher solidification expansion rate than casting powder with a single particle distribution.

After the initial setting of the acid-bonded casting powder investment slurry, further expansion can be obtained if it comes into contact with water again, called moisture absorption expansion. The moisture absorption expansion rate accounts for a very small proportion of the total expansion rate.

The thermal expansion of acid-bonded casting powder mainly comes from the expansion of TAK2, which is more stable than solidification expansion. The thermal expansion rate of feldspar quartz is significantly greater than that of quartz; therefore, the more filler content in the casting powder, the greater the proportion of feldspar quartz, and the higher the thermal expansion rate. A larger powder-to-liquid ratio also results in a higher thermal expansion rate.

(3) Casting Mold Strength

The casting molds made from acid-bonded casting powder have a much higher overall strength after high-temperature Roasting than gypsum casting molds, thus having a better ability to withstand the scouring of molten metal during pouring. The surface finish of the castings is high, and the probability of defects such as sand holes and flash is relatively low.

However, the residual strength of acid-bonded ceramic casting molds is relatively high, which greatly increases the difficulty of cleaning the castings from the casting molds.

1.2 Performance of Acid-Bonded Casting Investment Slurry

The investment slurry prepared for acid-bonded ceramic molds has a high viscosity, making it difficult to mix evenly. Therefore, a powerful investment mixer is generally required for mixing, and the mixing time should be appropriately extended to achieve a uniform investment slurry.

Acid-bonded ceramic casting molds are sedimentary solidification materials that must be left for more than ten hours to solidify. To adapt to the production pace of enterprises, specialized absorbent paper is often used to accelerate the solidification process. The absorbent paper has the advantages of good water absorption and high permeability, making it less likely to cause displacement during the forming process, which can reduce the surface flash of the castings.

2. Provádění úkolů

This task uses platinum-specific casting powder to create molds for vacuum centrifugal casting of Pt950 jewelry.

(1) Preparation Work

Use absorbent cardboard as the base for the casting mold, cutting a circular hole with a diameter of 25 mm in the center of the base, as shown in Figure 5-29. The wax can be discharged from the cavity through this hole during Roasting. Weld a conical pouring cup with a diameter of 25 mm and a height of 25 mm at the center of the cardboard. Fix the wax model tree or wax mold onto the wax pouring cup, as Figure 5-30 shows.

Figure 5-29 Base made of absorbent cardboard

Figure 5-30 Fixing the wax model tree

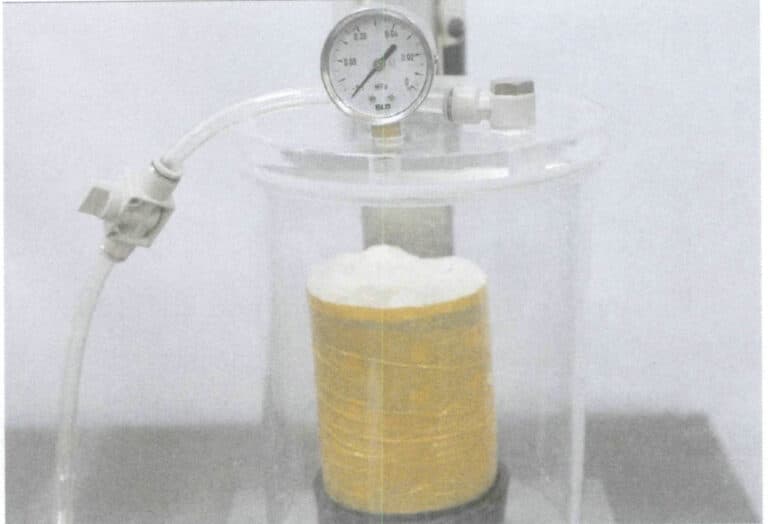

Choose an appropriate steel flask based on the wax model tree; the height of the wax model tree should be at least 25 mm lower than the steel flask. Due to the centrifugal casting method, the force of the molten metal is strong, and no holes are made in the walls of the steel flask. Attach a layer of absorbent paper to the inner wall of the steel flask to speed up the solidification process (Figure 5-31) while reserving a gap for thermal expansion compensation during the casting mold Roasting process, facilitating demolding and cleaning after casting. Use wide tape to create a cylindrical height barrier of 10~20 mm at the top of the steel flask to prevent the investment slurry from overflowing during vacuum extraction.

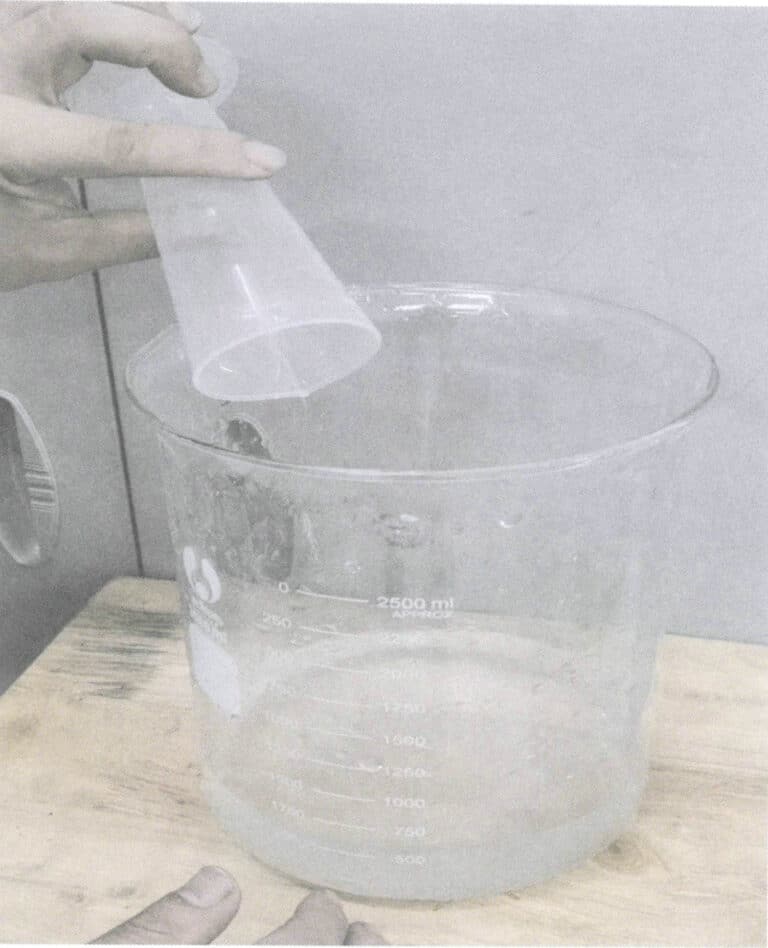

(2) Weighing Materials

According to the volume of the steel flask, calculate the volume of the required investment slurry and enlarge the calculation result by 1.15 times to prepare the material. Dilute the binder concentrate according to the volume ratio of the binder: water=1:14. Add the binder to deionized water using a clean plastic container and stir well, as shown in Figure 5-32. According to the water-to-powder ratio of 30 ml:100g, weigh the diluted binder solution and the corresponding amount of casting powder separately.

Figure 5-31 Absorbent paper in the steel flask

Figure 5-32 Diluted binder

(3) Mixing the Investment Slurry

Using a high-power investment mixer, clean the mixing bucket and the mixing liquid, add the weighed diluted binder solution, and slowly add the casting powder to the liquid while stirring slowly (Figure 5-33). When the casting powder begins to thin, switch to medium-speed stirring for 10~15 min.

(4) First Degassing

Place the casting powder investment slurry in a vacuum extractor to evacuate; when the investment slurry starts to boil vigorously, continue to evacuate for 1 minute (Figure 5-34).

Figure 5-33 Investment Slurry Mixing

Figure 5-34 Vacuuming the Casting Powder Investment Slurry

(5) Grouting

Pour the investment slurry into the steel flask, avoiding direct washing of the wax mold by the investment slurry.

(6) Secondary Degassing

Place the casting mold into the vacuum extractor, vacuum again for 1~2 min, and then add investment slurry to match the top edge of the steel flask according to the decrease in liquid level.

(7) Standing to Absorb Water

Place a layer of absorbent powder in the container, approximately 30 mm thick, and level its surface. Place the casting mold on the absorbent powder and wait for it to solidify (Figure 5-35).

(8) Casting Mold Roasting

After the casting mold has solidified, remove the absorbent cardboard from the bottom and the tape from the top of the steel flask. Use a graver to level the top surface of the mold. Place the casting mold into the Roasting furnace, setting the dark Roasting curve as shown in Figure 5-36. After Roasting, the surface of the cavity should be pure white.

Figure 5-35 Place the casting mold on the absorbent powder and let it sit.

Figure 5-36 Platinum casting mold Roasting system

(9) End of Work

After completing the casting mold-making task, please turn off the relevant power supply, clean the equipment and workspace, and put the tools and materials in their designated places.