How does Sobling inspect quality of Finished Jewelry?

Electroplating Production Quality Inspection and Defect Analysis of Finished Jewelry

Bevezetés:

Different jewelry production enterprises have different organizational structures, with most of them integrating the jewelry polishing, electroplating, or other surface treatment processes after casting and setting into the electroplating department. Electroplating belongs to the semi-finished product process and is the final process for products to become finished goods. Thus, the inspection of goods covers both semi-finished and finished product inspections, with higher inspection requirements. In jewelry production, although each batch of goods has been inspected and approved by inspectors from various departments before reaching the electroplating department, inspections are often carried out only partially at a particular process, leading to incomplete inspections and omissions. Therefore, jewelry production enterprises are expected to face disruptions and accumulate reworked products in the electroplating department.

Tartalomjegyzék

Section Ⅰ Electroplating Quality Inspection Contents and Methods

According to the surface decoration requirements of goods, the production process of the electroplating department can be divided into several types:

1st type is the polished surface goods that only require Polishing, with the process flow as follows: grinding– cleaning – finished product.

2nd type is goods that require single-color electroplating, with the process flow as follows: grinding – cleaning-electroplating —finished product.

3rd type is goods that require electroplating, surface sandblasting, etc., with the general process flow as follows: grinding – cleaning – applying protective paper – sandblasting – degreasing – etching-electroplating – finished product.

After wax removal and cleaning, a polishing QC is set up, usually to a semi-finished product QC, and a finished product QC is set up after electroplating. As the final process, the electroplating quality inspector must possess comprehensive inspection capabilities, be familiar with the production processes of various goods and departmental work procedures, take inspection work thoughtfully and responsibly, promptly inspect products transferred from the previous process, and quickly provide feedback on any issues found to relevant personnel; strictly inspect finished product quality according to company product standards or customer requirements, strictly control product quality, and prevent non-conforming products from leaving the factory.

The content and methods of quality inspection for electroplating are as follows:

1. Understand the requirements of the production work order.

After the QC staff checks the number of goods received, they should then read the order to understand the general situation of the batch of goods, such as the quality of the goods, the required engraved inscriptions, the size of the goods (hand size), the stone data, whether it needs edge grinding, sanding, whether it involves color separation and the desired effect of the goods. The QC staff should know the products’ general quality standards and consider each customer’s requirements.

2. Check the quality of the stones and the stone setting.

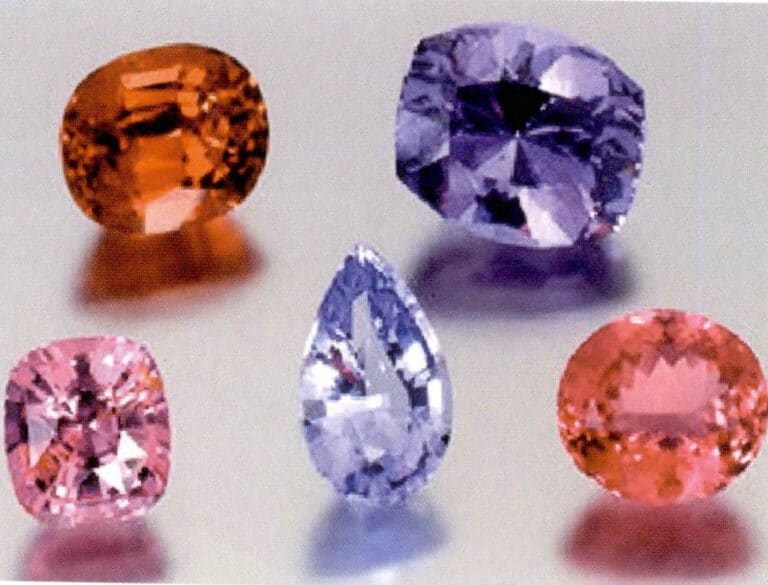

The quality inspector should master the basic identification methods of common gemstones, compare the stone data and setting requirements on order, and carefully inspect each Stone to see if the quality, size, cutting, color, etc., are to the order requirements. According to the characteristics and requirements of different setting methods, carefully check the setting quality to see if there are problems such as scratch stones, broken stones, loose stones, slanted stones, uneven stones, twisted stones, and tilted stones, and whether the prongs, mounts, and prongs are polished to a bright shine.

3. Check the size and characters of the goods.

If the order specifies the size of the goods, the actual size must be measured during inspection to see if it matches the order requirements. Check for missing or incorrect inscription, whether the position is correct, and if the inscription is clear.

4. Check the functionality of the goods.

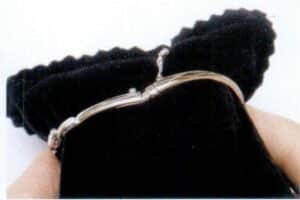

For example, when inspecting earrings, please pay attention to whether the ear pins are straight, the flexibility, elasticity, and tightness of the ear clips; the function of the bracelet clasp and hinge, whether it moves smoothly when worn; whether the gaps between the two sides are too long; whether the chain buckle is flexible; in addition to paying attention to the elasticity and flexibility of the brooch clasp pin, also note the direction of the pin (fasten from right to left); the bail of the pendant should be flexible, and the loops should be round.

5. Check the metal quality.

Carefully inspect the goods for any metal-related issues.Common metal quality problems include metal withering, sand holes, metal cracks, lack of smoothness, metal inclusion residue, and other defects. When these problems exist, rework is required. For milgrain and sandblasting goods, thorough grinding and Polishing must be done after migraine and sandblasting so that incomplete polishing defects can be ignored before milgrain and sandblasting. Still, it must be ensured that the goods have no issues with the setting, size, movement function, metal quality, etc., before milgrain or sandblasting. After milgrain, pay attention to whether the milgrain edges are uniform, whether there are broken stones or collapsed edges; after sand pushing, the sand should be neat and in place without crossing the boundaries or forming wrinkles. Before electroplating, check again for loose stones, wax crumbs, and metal crumbs at the bottom of the stones, and before and after electroplating, ensure that the goods are kept clean and tidy.

6. Inspect the overall quality of the goods.

According to the order requirements or reference samples, inspect the overall quality of the goods. Check whether there are any problems with the metal edge lines, angles, and levels, ensuring smooth lines, precise angles, distinct levels, roundness where it should be round, and squareness where it should be square. The gemstone settings should be secure and positioned correctly, and the stone holes should be transparent. The metal content should meet the requirements, and the metal surface and edges should be smooth, without deformation, obvious sand holes, withering cracks, or clean interlayers. No positive and negative surfaces in electroplating should exist, and no gray-black, yellow spots, or haze should be present in rhodium plating.

Pay attention to the specific requirements of different types of goods. For example, for ring-type goods, the ring size and ring shank should be consistent, and the ring size should be correct round; for earring-type goods, the earring length should match the order, the ear pins should be straight, soldered through, the loops should be asymmetrical, and the ear clips should be flexible; for pendant-type goods, the bail should be adaptable, soldered through, and the loops should be round; for necklace and bracelet-type goods, the links should be smooth, and the angles should be consistent. Since the chain’s metal is relatively thin, special attention should be paid to whether there are any signs of breakage in the movable joints. The soldering of the connected position should be complete and clean, without noticeable marks of soldering for bracelet-type goods. The higher function should be flexible, and when closed, the clasp should touch closely, without gaps.

7. Methods for dealing with issues.

After the inspector identifies the defects in the goods, different techniques are adopted based on the severity of the problems. Generally, a repair team is set up in the electroplating department. In addition to metal base trays with metal withering, cracks, lack of smoothness, and sand holes, there are also issues such as ring size being not round due to improper processing, ring shank not being smooth, hinges being too loose or too tight, clasps not being soft or flexible, missing engravings, broken chains, over-polishing, inconsistent prong sizes, etc., which can all be handed over to the repair team for rework. All issues must be addressed before electroplating to avoid repairing or grinding the goods after electroplating, as this can cause significant damage to the items.

Section Ⅱ Common Electroplating Defects

Different jewelry categories have both standard quality requirements and unique requirements. In terms of electroplating defects, there is a distinction between common issues and category-specific issues.

Part 1. Common Electroplating Defects in Various Types of Jewelry

These defects can be encountered in various types of jewelry, mainly covering aspects such as metal quality, setting quality, electroplating quality, or other surface treatment effects.

1. Jewelry Metal quality

The content and methods of quality inspection for electroplating are as follows:

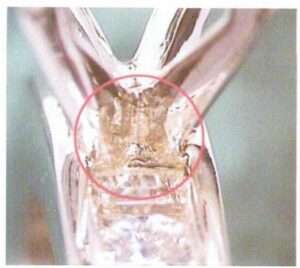

【Case 9-1】The content does not meet the standard requirements

A probléma leírása:

The goods’ material must be 18K white metal. A fluorescence spectrometer was used to test the content of the goods, and the metal content was only 74.6%, which does not meet the minimum requirement of 75%.

Analysis: The content of precious metal jewelry must strictly comply with the standard requirements. Goods that do not meet the content requirements will not be shipped. The casting process determines the content. When formulating alloys, the internal control standards should be specified based on the loss situation of our factory. For example, 18K metal is not formulated according to 75%, but with a slight excess, formulated according to 75.3% or 75.5%. In addition to the casting process, welding in the jewelry finishing process may also affect content detection. When the welding material used is lower in content than the body of the goods, it will affect the overall content of the alloy, as shown in Figure 9-1. Therefore, welding should use materials with the same content as the body.

【Case 9-2】Rose metal is prone to discoloration, as Figure 9-2 shows.

Elemzés:

Among the metal alloy series used in jewelry, rose metal has become a trend in today’s international jewelry and watch industry due to its gorgeous and elegant color. As a decorative rose metal, it should have a good rose color and brightness, good resistance to dullness, and not easily discolored during storage and use. However, rose metal jewelry often has poor color and discoloration, causing many troubles for production companies and users. No rose metal will discolor, but different alloys significantly differ in anti-dullness and discoloration performance regarding discoloration tendency and severity. Production companies should make reasonable choices and conduct necessary tests. They can also use artificial sweat immersion and electrochemical tests to infer the alloy’s anti-discoloration ability.

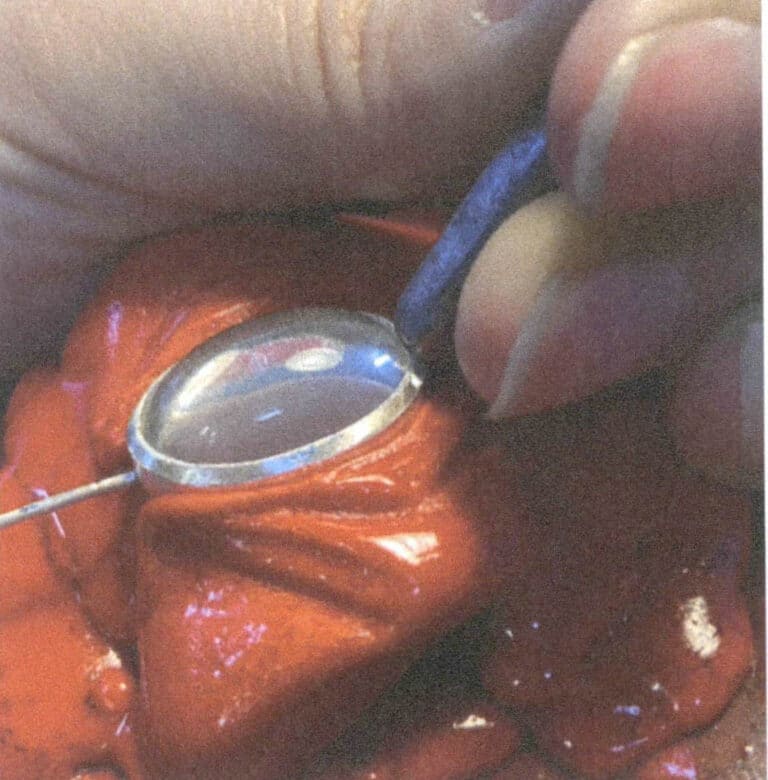

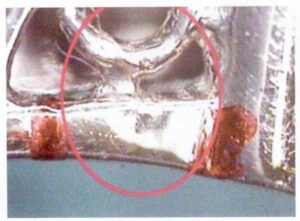

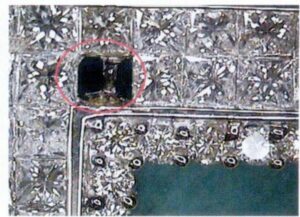

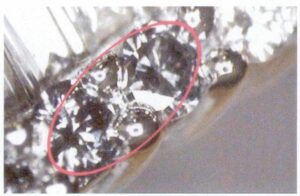

【Case 9-3】Sand holes are exposed after the goods are polished, as shown in Figure 9-3.

Elemzés:

Sand holes are formed during casting but hidden below the surface. The sand holes are exposed to the surface when the goods are polished. At this time, the sand holes should be cleaned thoroughly to reveal the metal quality, and then the defect should be welded. Since the goods already have gemstones set, the laser should be used as a priority instead of flame soldering to avoid heat damage to the gemstones.

Repair must be carried out when the sand holes are exposed on the surface after the workpiece is polished. For small sand holes, mount the sand stick on the grinder during repair, grind off the sand holes on the workpiece with the sand stick, polish the workpiece smooth with sandpaper, and then polish it. For larger sand holes, mount the jewelry bur on the motor grinder during repair to grind the sand holes. Soak in boric acid water, preheat the workpiece with a blowtorch, and melt the metal grains used for repair. Dip the tweezers in metal beads, then dip in borax, place the metal beads at the repair site of the workpiece, and fill the depression. Place the repaired workpiece in a pot filled with alum water, and heat the alum water to boiling with a blowtorch to remove borax and other impurities from the workpiece. Rinse with clean water and blow dry. Grind the repair area flat with the sand stick, then smooth with sandpaper.

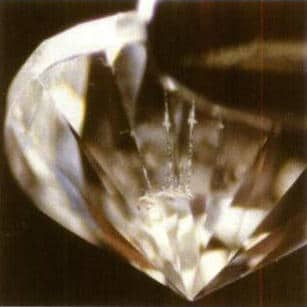

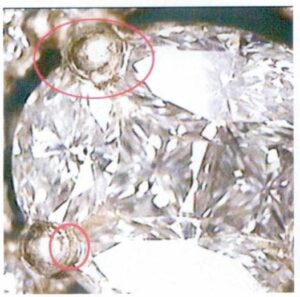

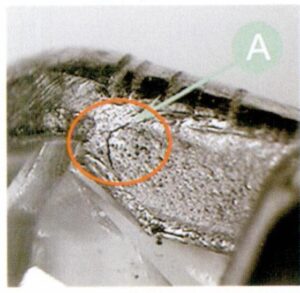

[Case 9-4] The product shows severe shrinkage after Polishing, as shown in Figure 9-4.

Elemzés:

Shrinkage is a standard metal quality defect, a hole defect formed in the casting process, significantly affecting the quality of the jewelry surface. Shrinkage often extends from the surface to the interior. Only the surface is usually polished when casting and the shrinkage cannot be eliminated. Even when using a sand stick, it isn’t easy to compact. Therefore, shrinkage is easily exposed to the surface after Polishing. It is necessary to strengthen the casting process’s control and improve the casting quality for such defects.

【Case 9-5】After polishing, Metal slag appears on the metal surface, as shown in Figure 9-5.

Hiba leírása:

Hard spots were found on the surface of the jewelry during Polishing, visually appearing as yellow-brown hard particles, either in large single particles or mount-like small particle clusters, commonly known as Metal slag. It is challenging to polish the metal surface to a shine, resulting in many comet-tail-like polishing marks.

Elemzés:

The source of complex spot defects may come from the following aspects:

(1) Nickel segregation. It often manifests as relatively concentrated bulging protrusions on the surface of the jewelry. These complex objects are mainly caused by incomplete smelting and uneven stirring, resulting in nickel segregation. Due to the high melting point and lower density of nickel than metal, if the smelting time is too short or stirring is not done correctly, nickel segregation may occur, forming hard spots.

(2) Formation of nickel silicide. These hard spots are common in alloys containing silicon. In the casting of nickel-bleached white metal, a small amount of silicon is often added to improve the casting performance of the alloy. It helps to enhance the alloy’s fluidity and filling performance, reduce the alloy’s oxidation absorption, make the casting surface brighter, reduce the tendency of the alloy to shrink, and improve the overall casting performance of the alloy. However, if the process is incorrect or not handled correctly during smelting, nickel silicide complex spot defects are more likely to occur for alloys containing nickel and silicon.

(3) Oxidation of silicon. When nickel-platinum alloy containing silicon is smelted in an oxidizing atmosphere and at a high melting temperature due to the intense activity of silicon, it oxidizes preferentially, quickly forming silicon dioxide, especially when a small amount of metal liquid remains in the crucible. The subsequent smelting is carried out directly, and the oxidation of silicon is more severe. In addition, silicon dioxide will have an accumulative effect on the metal, so if too much recycled material is used, it will quickly lead to the batch hardening problem after some time.

A batch hardening problem occurs. Silicon dioxide has a small density and tends to float to the surface of the workpiece, so it often appears on one side of the casting.

(4) Segregation of grain refiners. Refined and dense grains are beneficial for obtaining excellent polished surfaces in jewelry metal alloys, especially silicon alloys. Since silicon has a significant coarsening effect, measures must be taken to refine the grains. Iridium, cobalt, rare earth elements, etc., are commonly used grain refiners in nickel platinum alloys. These can form high-melting-point heterogeneous crystal nuclei, increase the number of nuclei, and thus refine the grains. However, the alloying of these elements is relatively tricky. Appropriate smelting temperature and time are required to dissolve them in the metal liquid uniformly; otherwise, segregation may occur, leading to hard spots.

(5) External inclusion of complex foreign substances. This situation is wide-ranging, involving multiple aspects such as recycled materials, smelting operations, etc. The most common is contamination of recycled materials, such as residual gypsum investment powder in recycled materials. The main refractory components of investment powder are quartz and cristobalite, with calcium sulfate as the binder. Due to the poor thermal stability of calcium sulfate, it quickly decomposes in high-temperature metal liquid, forming sulfur dioxide gas, leading to the gradual appearance of blowholes, and sulfur dioxide exacerbates the reaction of nickel and silicon to form nickel silicide. In addition, inherent silicon dioxide in the investment powder enters the metal liquid, forming silicon dioxide hard spots.

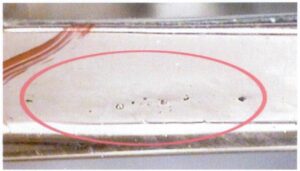

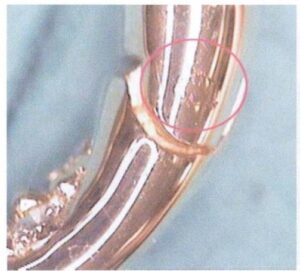

【Case 9-6】Cracks appeared in 18K red metal, as Figure 9-6 shows.

Elemzés:

18K red metal is a red metal alloy mainly composed of copper, which undergoes an ordering transformation at 410℃, significantly improving the strength and hardness of the alloy but greatly reducing the material’s malleability. The alloy will exhibit obvious brittleness, and slight external force or impact may cause the jewelry to fracture. This transformation occurs during the casting cooling stage and may happen to a certain extent during annealing or welding processes if the cooling is slow. To solve this problem, in addition to selecting appropriate mixed alloys, when hot working jewelry, it is necessary to reduce the total thermal stress and structural stress to the lowest level rather than just adopting a slow cooling method to reduce thermal stress.

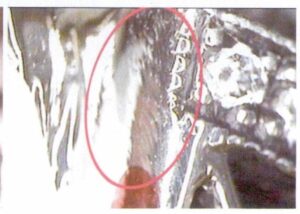

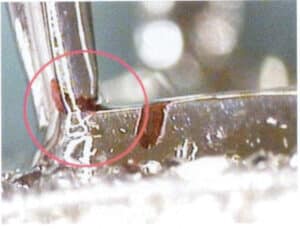

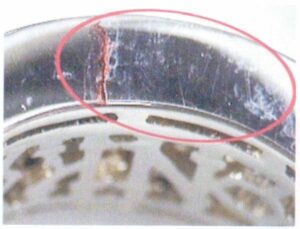

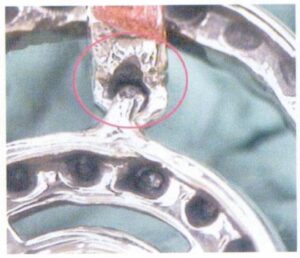

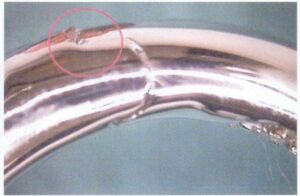

[Case 9-7] Cracks appeared on the 18K white mesh bottom, as shown in Figure 9-7.

Elemzés:

The mesh bottom is a component assembled in the inner ring of the jewelry, generally slender. When fixing it during assembly, it is sometimes inevitable that residual stress is generated inside the mesh bottom. When the stress exceeds its strength, it will lead to cracks. Some cracks have already appeared during the wax setting stage and are exposed to the surface after grinding and Polishing. In contrast, others are caused by exacerbating internal stress during grinding and Polishing, leading to crack initiation.

2. Jewelry Shape issues

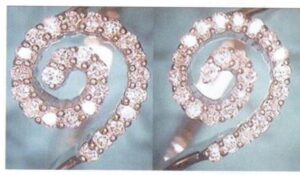

[Case 9-8] Final products not follow original sample, as shown in Figure9-8, the left image is the sample, and the right image is the

Analysis: For products produced in batches, a sample is generally made first, confirmed by the customer for inspection, and serves as one of the inspection bases for batch production. If there is a problem with goods needing to be up to standard during batch production, the customer has the right to reject them. The reasons for goods not meeting standards are diverse, such as wrong production orders, wrong mold materials, wrong assembly of parts, product deformation, etc.

【Case 9-9】Product deformation, as shown in Figure 9-9.

Elemzés:

In this case, the edge of the gypsy setting is not round, resulting in obvious deformation. For such problems, attention should be paid to correction in jewelry sanding and Polishing, as well as strengthened inspection; in addition, due to the thin edge of the setting, attention should be paid to the polishing direction and intensity during grinding and Polishing.

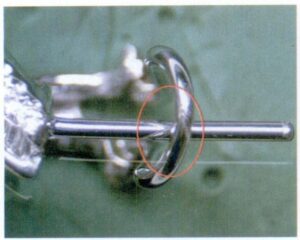

【Case 9-10 bottom support pole not removed, as Figure 9-10 shows.

Elemzés:

For products similar to this case, the structure presents multiple circular rings with specific gaps between them, requiring good concentricity of each ring. To reduce the problem of eccentric circular rings due to deformation during production, several bottom supports are added between the circular rings to increase strength and prevent deformation. These bottom supports are only process measures to ensure smooth production, not requirements of the product itself. Therefore, the bottom supports should be removed when the product is close to completion.

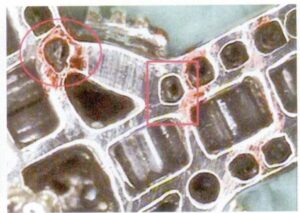

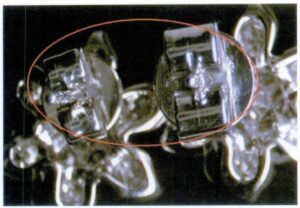

【Cases 9-11】Abnormal bottom hole of the product, as shown in Figures 9-11.

Elemzés:

The bottom hole of the setting is a necessary measure to improve the optical properties of the gemstone setting, reduce the amount of metal used in the product, and increase the decorative effect of the product. The bottom setting hole must be regular and transparent. In this case, some of the bottom holes have severe deformities, which must be modified at the jewelry grinding stage rather than passed on to the electroplating department.

[Case 9-12] The edge is not smooth, as shown in Figure 9-12.

Elemzés:

In this case, the metal edge of the baguette diamond in the channel setting stage could be smoother after Polishing, mainly due to the uneven edge trimming in the setting stage.

[Case 9-13] The edge size is unsmooth, as shown in Figure 9-13.

Elemzés:

In this case, the widths of the metal edges on both sides should be consistent, but the width of one side of the metal edge is significantly narrowed, and there is a phenomenon of wave fluctuations. The possible reasons include the master mold, wax mold, grinding, Polishing, and other processes that may cause it.

[Case 9-14] Metal edge collapse, as shown in Figure 9-14.

Elemzés:

This type of problem is more common in the jewelry-making process. The reasons may include the edge of the jewelry master mold collapsing, damage or loss during the making of wax or casting, the goods being damaged during the holding mold, the metal edge broken during stone setting, and the metal edge eroded during Polishing.

3. Jewelry Polishing issues

[Case 9-15] The polishing work is insufficient, as Figure 9-15 shows.

Elemzés:

The polishing work is insufficient because some parts of the product have not been thoroughly polished, and the previous process’s original surface state or processing traces still need to be retained. Its problem is most likely to occur in end corners, concave areas, crevices, and other product areas because these places often need suitable tools, or the operator is prone to overlook them.

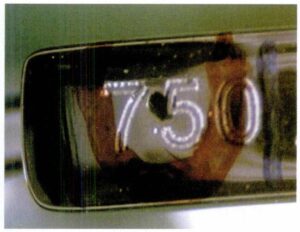

【Case 9-16】The product inscription is unclear, as shown in Figure 9-16.

Elemzés:

Correct and precise inscription is essential for jewelry products, and national standards have made clear regulations. Due to the delicate nature of jewelry products, the inscription is relatively small and complex to cast soundly during casting. The inscription should be clear when making the mold, reducing the polishing difficulty. If a high-quality inscription is required, it is best to avoid casting and use laser engraving after polishing the product so that the inscription is both delicate and clearly defined.

【Case 9-17】Metal surface perforation, as shown in Figure 9-17.

Elemzés:

After jewelry polishing, perforation occurred on the surface in certain areas. The reasons for this problem include the wall thickness of the master mold, wax model, or cast blank being too thin in certain areas, some areas being too thin when waxing, and some areas being too thin when grinding. When the blank has defects such as sand holes and slag inclusions, to obtain a good surface

The polishing quality often vigorously polishes these areas during operation, resulting in a perforation.

[Case 9-18] Figure 9-18 shows an uneven metal surface.

Elemzés:

Jewelry must be ground and polished to achieve a smooth, highly glossy metal surface. However, suppose the operation is improper, and the metal surface is not smooth during Polishing, resulting in the appearance of positive and negative surfaces. In that case, it will affect the surface appearance and brightness.

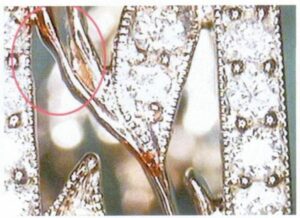

[Case 9-19] Excessive Polishing, as Figure 9-19 shows.

Elemzés:

In this case, when polishing the root of the prong with a bristle brush, improper selection of bristle brush type, excessive force, or prolonged time of Polishing may cause excessive metal to be removed from the root, significantly reducing the strength of the prong setting, posing a risk of prong breakage and stone loss. Bristle brushes come in different materials, structures, and sizes. Bristle brushes with high hardness have strong cutting force, but care must be taken to prevent over-polishing. When polishing the setting, bending, or concave positions, constantly change the angle for Polishing, do not polish the same spot for a long time, and do not polish at a single angle to avoid excessive Polishing, which may cause edge collapse, flattening of prongs, or sharpening of prongs.

[Case 9-20] Scratches on the Polished Surface, Figure 9-20 shows.

Elemzés:

The purpose of jewelry polishing is to achieve a smooth, bright mirror effect on the metal surface. Due to the low hardness of many jewelry metal materials, scratches can quickly occur due to friction after Polishing. Therefore, it is necessary to handle the jewelry gently after Polishing and avoid collisions between products or contact with items such as sandpaper and pins, which can easily cause scratches.

【Case 9-21】Poor Electrolytic Polishing Effect

Problem Description:

Often encountered in jewelry production When encountering problems such as stones yellowing, blackening, and poor gloss of the setting, relying on manual mechanical Polishing is not only time-consuming and laborious but also ineffective. Therefore, chemical polishing methods are widely adopted. The chemical polishing process used in the past was potassium cyanide + hydrogen peroxide, which features a good polishing effect and high efficiency but has significant drawbacks. Potassium cyanide is a highly toxic chemical substance, posing significant safety hazards to the environment and operators. The use of cyanide-free electrolytic Polishing is an inevitable trend. However, when using cyanide-free electrolytic Polishing to process K metal products, the problem of poor processing effect is often encountered.

Elemzés:

The basic principle of electrolytic Polishing is that the workpiece is connected to the anode. After electrification, a thick and viscous film with high resistivity is formed on the surface with uneven thickness. The surface micro-protrusions are thin, with high current density and fast metal dissolution, while the micro-depressions are thick, with low current density and slow metal dissolution. Due to the uneven distribution of the dense and viscous film and current density, the micro-protrusions decrease rapidly, and the micro-depressions decrease slowly, achieving a smooth surface. The anodic dissolution process of metal electrolytic polishing is quite complex, influenced by many factors such as the surface properties of the metal, uniformity of metallographic structure, the composition of the electrolyte, temperature of the electrolyte solution, operating current density, solution flow, polishing time, anode-cathode area ratio, electrode distance, etc. The variation of these factors directly affects the polishing effect and quality. If the anodic dissolution is uneven, sometimes the processed surface may be worse than the original condition, or it may lack luster or show pitting, local corrosion, and other conditions. Therefore, to achieve an excellent electrolytic polishing effect, attention should be paid to several aspects:

(1) Selection of electrolytic polishing solution. When selecting an electrolytic polishing solution, the following factors need to be considered: there must be a certain amount of oxide to dissolve the active protrusions on the surface; there must be enough complex ions to chelate and precipitate the dissolution products on the surface; and maintain the freshness of the electrolyte; there must be a sufficient quantity of large radius, small charge anions to promote ion migration, improve surface dissolution efficiency, increase polishing speed and quality; there must be enough viscosity to form a viscous film layer on the anode surface, thinner on the protrusions and thicker on the recesses, to ensure the polishing quality of the surface; there must be a wide operating temperature range, stable solution performance, long service life; and it should not cause pollution to the environment.

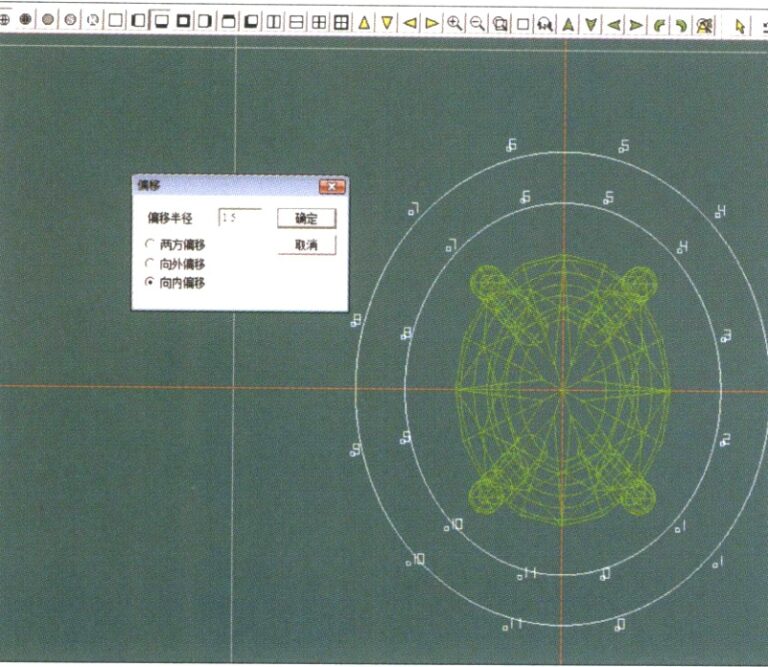

(2) Electrolytic hanging method. Before electrolytic hanging, consider the distance between the electrodes and the position of the workpieces; use shielding as needed to ensure uniform distribution of power lines; ensure good contact between the wire and the workpiece for electrical conduction; consider the timely discharge of gases precipitated during the electrolytic polishing process. Figure 9-21 shows the hanging methods of several typical workpieces.

(3) Electrolytic process parameters. Reasonably select voltage, time, temperature, stirring, and other process parameters according to the structure of the workpiece.

(4) Maintenance and recovery of electrolytes and precious metals. In production, avoid dust and debris from entering the electrolyte; recover metal every two weeks, clean the electrode plate and metal-absorbing bag, and remove crystals from the electrode bag; supplement the consumed reagents promptly during use; when the amount of electrolysis reaches a certain level, the electrolyte should be renewed.

4. Jewelry Settings issues

[Case 9-22] Glue not removed, as shown in Figure 9-22.

Elemzés:

In the setting operation, some organic gemstones, such as pearls, amber, etc., are generally fixed with glue. Some gemstones are sometimes added with glue in the setting pits to prevent the gemstones from shifting during the tightening process when using methods such as forcing setting and bezel setting. If too much glue is added, it will squeeze out to the setting base and flow to the gemstone surface when the gemstone is tightened. It must be wiped clean immediately after setting; otherwise, removing the glue after the glue is cured will be difficult, affecting the gemstone’s appearance.

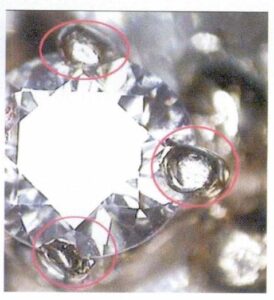

【Case 9-23】Stones falling off during Polishing, as Figure 9-23 shows.

Elemzés:

In this case, the bezel-set pendant experienced diamond loss during Polishing. During Polishing, pressure is applied to the wheel to achieve the desired effect. This poses a particular risk for gemstone settings (especially some sensitive setting methods). When polishing, attention should be paid to controlling the force and angle. If there are signs of gemstone loosening, Polishing should be stopped immediately, the gemstone should be re-secured, and then the operation can continue.

【Case 9-24】Pearl surface scratched, as shown in Figure 9-24.

Elemzés:

Pearls are generally set using prong settings, where a hole is drilled into the pearl, glue is applied to the prong, inserted into the pearl hole, and fixed after the glue hardens. This process is usually arranged as the final step because pearls are soft and cannot come into contact with corrosive chemical solutions. In this case, the scratching on the pearl surface is mainly due to using unclean cloth during wiping. Since pearls have a lower hardness than dust particles in the air, friction with unclean cloth can easily cause abrasion or scratches.

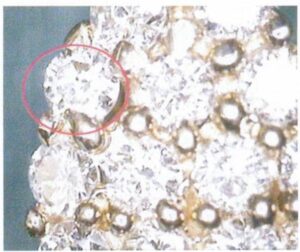

4-1. táblázat ASTM B562 szabvány szerint a tiszta arany rögök megengedett legnagyobb szennyeződéstartalma

Elemzés:

In this case, after polishing the pave setting jewelry, the outermost diamond shifted, resulting in a noticeable gap. This occurred because the diamond waist was not wholly secured during setting, and the diamond loosened and shifted during Polishing.

[Case 9 - 26] Jewelry pieces are thrown away with great force in Polishing, causing diamond fractures, as shown in Figure 9-26.

Elemzés:

When polishing workpieces, it is essential to concentrate fully and avoid thinking about other things while working, especially when polishing gaps and prong heads. A moment of inattention can lead to “flying” (referring to the phenomenon of the workpiece slipping from the hand and flying away), resulting in gemstone damage, workpiece scrapping, and other consequences.

[Case 9-27] Stone drop off during ultrasonic cleaning, as shown in Figure 9-27.

Elemzés:

Ultrasonic cleaning uses the impact of cavitation to generate shock waves, applying force to the surface of the workpiece to remove polishing compounds, waxes, and other oil contaminants to achieve cleaning purposes. This cleaning process also impacts the set gemstones. Detachment issues may occur under continuous shock wave action if the gemstones are not securely set.

It also impacts the gemstone setting. Stone drop-off issues may occur if the gemstones are not securely set under continuous shock wave action.

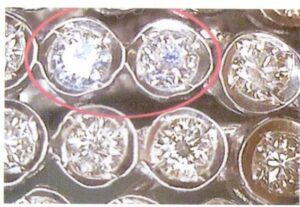

【Case 9-28】Uneven height of gemstones, as shown in Figure 9-28.

Elemzés:

When channel setting multiple gemstones, the arrangement of gemstones should follow the metal edge, be flat and smooth, and not have uneven heights. When such issues are transferred to the electroplating process, repair personnel should first reset and polish the uneven gemstones after meeting the requirements.

【Case 9-29】Gemstones turning dark, as shown in Figure 9-29.

Elemzés:

In this case, the melee diamonds on the side are set with wax casting. After polishing and cleaning the product, two diamonds appear to be dark. When the diamonds are removed, it is found that the diamonds themselves have not turned dark, indicating that the visual effect mainly causes this. The main reasons for the visual impact are:

(1) The hole at the bottom of the setting is too small. The gemstone must typically absorb and reflect light to show a good luster and natural color. Gemstones set on metal bases rely on absorbing light from the bottom hole of the setting. When the bottom hole is too small, more of the pavilion is covered by metal, affecting the gemstone’s light absorption. Therefore, when designing the master molds, ensure that the bottom hole of the setting is of sufficient size. In wax casting, the diameter of the bottom hole of the setting is generally more than half of the gemstone diameter, which is beneficial for fixing the gemstone during casting.

(2) Even if the bottom hole size of the master mold is large enough, a poor match between the setting position and the gemstone diameter can also cause a visual effect. Therefore, before setting the Stone, it is necessary to match and measure the Stone. If it is not suitable, adjust the setting position first and place the gemstone on the setting to calculate the position. If the gemstone diameter is larger than the setting size, it is necessary to use a suitable grinding bur to match the setting position with the gemstone size; after setting the Stone, carefully clean the bottom of the setting.

(3) When preparing the investment mold with gypsum slurry, if air bubbles adhere to the bottom of the setting, the bubbles will be replaced by metal after casting, forming metal beads. At this time, the gemstone often appears to be dark near the setting pit. Metal beans can be seen if the jewelry is upside down at the bottom of the setting. When the strength of the gypsum is insufficient, or the wetting property between the gemstone and the gypsum slurry is poor, the gemstone being covered by metal will occur, severely affecting the color and luster of the gemstone. To solve this problem, attention should be paid to the water-to-gypsum ratio, vacuuming time, vacuum degree, wetting property, etc., when mixing the gypsum slurry.

【Case 9-30】High prong scratching hand, as shown in Figure 9-30.

Elemzés:

When the prong is too high, it not only affects the optical effect of the gemstone but also causes trouble in wearing and using, easily scratching hands, hooking clothes, and even causing the gemstone to fall off. Therefore, the height of the prong should be reasonably controlled, and the prong height should generally be slightly lower than the stone surface. Thus, when the prong height is too high during setting, use pliers to cut the prong first, then file the prong to the height suitable for polishing the prong, and keep the prong height consistent. After cutting the prong, use a triangular file to file the prong to the height ideal for polishing the prong and keeping the prong height consistent. Then, use a bamboo leaf file to trim the inside of the prong to fit the Stone, and then round the outside for easy polishing and cup burs.

【Case 9-31】The Prong is not round, as Figure 9-31 shows.

Elemzés:

This is a problem left in the stone-setting process, which is not carefully checked before Polishing, resulting in the finished product still having the issue of prongs not being round. It is required to inspect the goods before polishing, and if there is a problem with the prongs not being round, they should be trimmed to be round before polishing.

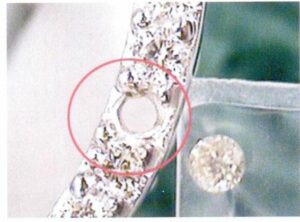

【Case 9-32】The prong head is not smooth, as shown in Figure9-32

Elemzés:

In this case, the prong head of the stone setting is not smooth after Polishing, showing an apparent “capping” phenomenon. This is mainly caused by the unreasonable use of the cup bur and improper operation of polishing prongs in the stone-setting process. The inner hole of the cup bur must be centered, not skewed, and the inner wall should be smooth and round. The hole should be drilled only a little deep or shallow, and the depth should be determined according to the length of the prong for the reverse setting. The size of the prong head determines the size of the cup bur. If it is too large or too deep, the prong head will not adhere to the Stone, leading to stone damage. If it is too tiny, pressing steps on the prong head is easy, causing the “capping” problem.

【Case 9-33】The prong of the gypsy setting is broken, as shown in Figure9-33

Elemzés:

The gypsy setting surrounds the gem with a metal edge and sets prongs on the metal edge to fix the gem. The prongs are generally shovel-shaped and relatively thin to achieve sound optical effects for the gem. Particular attention should be paid to the intensity and direction during grinding and Polishing. Otherwise, it is easy to grind or break it.

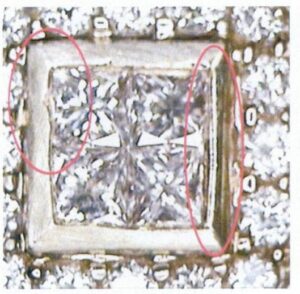

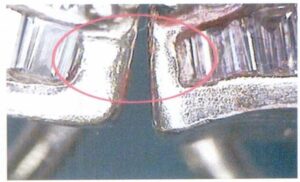

Figure 9-34 The metal edges of the channel setting is uneven is uneven

Elemzés:

In the princess-cut diamond of channel setting, the diamonds need to be arranged neatly and evenly distributed, and the metal edges must also be consistent. In this case, the problem of inconsistent sizes of the metal edges is mainly caused by inconsistent stone setting base or shovel edges. Repair should be done before Polishing, and attention should also be paid to ensure that each setting edge’s polishing degree is consistent.

4-1. táblázat ASTM B562 szabvány szerint a tiszta arany rögök megengedett legnagyobb szennyeződéstartalma

Elemzés:

Sometimes, the stone setting edge requires the separation of the Prongs and milgrain, which should be separated and not mixed.

5. Jewelry Plating Issues

【Case 9-36】The polishing wax removal is not clean, as shown in Figure 9-36.

Elemzés:

After the workpiece is polished, the surface and crevices will be covered with polishing wax and various mixtures, which must be removed to clean the workpiece.

When the wax removal is not clean, problems such as the inability to put the plating color and contamination of the plating solution will occur. To achieve satisfactory wax removal results, several aspects should be ensured: First, the workpiece should be taken for wax removal as soon as possible after polishing; otherwise, if it stays for a long time, the residual wax layer will clump, increasing the difficulty of cleaning; second, the ratio of the wax removal solution should be reasonable, neither too concentrated to reduce the shock force, nor too dilute or used for too long to become ineffective; third, the ultrasonic shock should be strong enough, and the cleaning time should be sufficient.

When performing wax removal operations, hang the polished goods on hangers. For goods that are prone to stone loss, the stone setting should face upwards, and immerse them in a spoon containing wax removal water for wax removal; heat the wax removal water to the operating temperature (60-80℃), and turn on the ultrasonic waves to remove wax dirt from the surface of the workpiece. For crystal stones and large diamonds, adjust the temperature of the wax removal water to around 40℃ to avoid damage due to significant temperature differences.

Before wax removal, the goods should be preheated with pure water and then immersed in the wax removal water. After wax removal, do not rinse immediately with room temperature pure water; rinse with preheated pure water first, then proceed with cleaning. Clean the surface of the goods with pure water using a three-stage countercurrent rinsing method for 3-5 minutes; carefully inspect the cleanliness of the surface, pay attention to whether there is residual wax dirt on the stone bottom (pattern) and stone setting, and repeat the wax removal process if necessary until the wax dirt is completely removed.

For some goods that are difficult to clean, the following cleaning methods should be applied: use steam to squeeze out some wax and buff residue left over from the polishing process; for those that cannot be handled, use manual pin picking (when using manual pins, care should be taken not to scratch the goods). After removing the wax, rinse immediately because after the goods are de-waxed by ultrasonic waves, a layer of oil dirt will come out. Suppose it stays in the air for a certain period. In that case, it will dry and solidify, making cleaning difficult, failing to achieve the de-waxing effect, and contaminating the metal solution.

[Case 9-37] The oil removal needs to be more thorough, as shown in Figure 9-37.

Elemzés:

The cleanliness of the metal surface determines the electroplating effect. Once the oil is not completely removed and there are surface residues of oil dirt and dust, it will hinder the average deposition of metal, resulting in slow deposition of the plating layer, leading to problems such as white spots, haze, yellowing, water stains, too thin plating layer, or even no plating. The method commonly used to inspect the quality of oil removal is the water-wetting method, which is based on the principle that as long as there is grease on the surface of the workpiece, it cannot be wetted by water. It mainly includes two types: the water droplet test method, where water is dropped onto the surface of the workpiece. If the water spreads evenly and forms a continuous water film, it indicates that the oil removal is clean; if a discontinuous and intermittent water film is formed on the surface of the workpiece, it suggests that the oil is not thoroughly removed.

An electrolytic degreasing process is required in jewelry production to remove oil from the surface of metal parts thoroughly. It places the workpiece in a solution with a specific formula. It electrifies it, carries out electrolysis treatment according to the cathode first and then anode, removes surface oil stains, and promotes the muscular tearing of the oil film on the workpiece surface into discontinuous oil droplets with the action of the H2 and O2 deposited on the electrode, and strengthens the degreasing process by stirring the solution.

In the process of electrolytic degreasing, it is necessary to select the process parameters reasonably. The voltage determines the current density. A high current density can correspondingly increase the degreasing speed and improve the quality of deep hole degreasing. Generally, the voltage is selected at 9 -11 V. The degreasing time is determined by the size of the goods and the number of degreasing tanks for a single degreasing. It is around 100s for large goods, and for general goods, it is around 60s. Increasing the temperature can reduce the solution resistance, thereby increasing the conductivity and decreasing efficiency. When the temperature is too high, the degreasing agent will decompose and volatilize, polluting the environment, and a layer of oil stains will appear on the electrolyte’s surface. It is recommended to choose 65 ~70℃.

The dirt on the surface of the electrolytic degreasing solution will affect the degreasing quality. In the reaction process of electrochemical degreasing, while decomposing oil stains, substances such as glycerol and stearic acid esters will be produced. These substances and the free oil stains that have not yet reacted with the alkali solution are suspended on the solution’s surface. When the workpiece enters and exits the solution, it will adhere to the workpiece’s surface, seriously affecting its degreasing quality. It is necessary to clean and maintain the electrolytic degreasing solution’s surface regularly.

Improper hanging method of the workpiece during electrolytic degreasing will affect the degreasing effect. When the workpiece is undergoing electrochemical degreasing, gas trapping in certain parts will involve the removal of oil stains in these parts, leading to incomplete degreasing. The cathode can be moved during degreasing, and the workpiece can be continuously shaken to prevent gas adsorption. When hanging the workpiece in the degreasing tank, shake it in the alkali solution first to remove the dirt adhered to the surface of the workpiece when it comes into contact with the surface of the alkali solution during the hanging process. When the workpiece is removed from the tank, shake it in the alkali solution first and quickly lift it out while the dirt on the liquid surface spreads around.

【Case 9-38】The inspection of the coating color is not standardized, and the client has objections to the inspection results.

Elemzés:

The coating color is an essential indicator of electroplating quality. Many jewelry factories are relatively casual when inspecting the coating color.

Subjectively, the inspection results are not accepted by customers. To address this, standardized inspection conditions, methods, and procedures should be established as much as possible and agreed upon by both parties. Currently, the most commonly used method is to produce electroplating color samples and configure standard color temperature lightboxes.

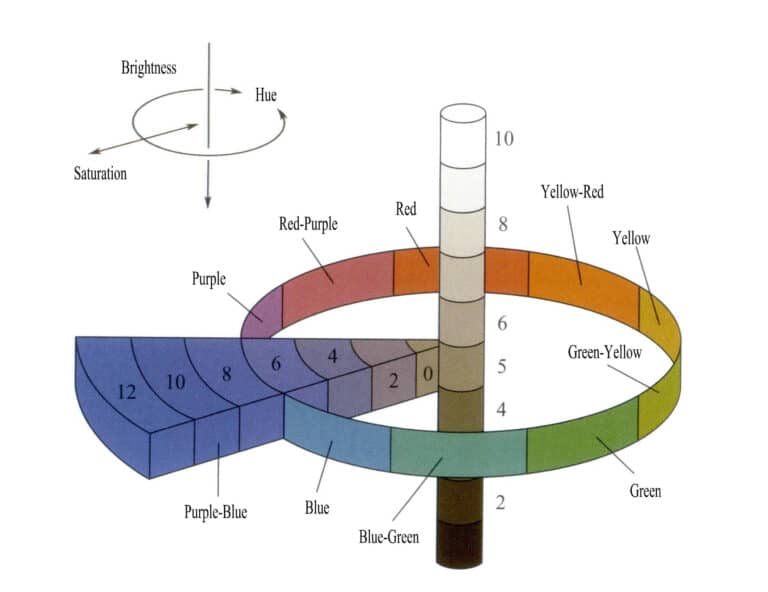

During the inspection process, QC personnel should wear thin white cotton gloves for testing and check for any dirt or complex objects on the gloves to prevent scratching the product surface when the gloves come into contact with it. Turn on the lightbox switch and adjust the intensity of the light source to stabilize the color temperature at the standard 6500K. Place the electroplating color samples and the goods to be inspected in the standard light box for color comparison and initial inspection. Change the product’s position and examine the surface from different angles for fogging, yellowing, scratches, etc.; compare the color and whiteness of the electroplating color samples and the goods to be inspected, as shown in Figure 9-38.

[Case 9-39] The Rhodium plating color is not bright enough, as shown in Figure 9-39.

When electroplating white rhodium for jewelry, good brightness is required, but in actual production, the problem of insufficient brightness in color is often encountered. The main reasons for this problem are as follows:

(1) The rhodium content in the plating solution needs to be increased. Under certain temperatures and current density conditions, the rhodium concentration in the rhodium plating solution significantly impacts the color of the coating. When the rhodium content is less than 1.0 g/L, the coating appears red, lacks luster, allows for low current density, and has very low current efficiency, resulting in high brittleness of the plated parts; some coatings may crack. Therefore, it is often necessary to add high-concentration rhodium sulfate solution during production. With the increase of rhodium content, the whiteness of the coating gradually increases, and the current efficiency also increases. The whiteness does not change significantly when the rhodium content exceeds 1.5 g/L. When the rhodium content exceeds 3.0 g/L, the plated parts appear white, the electroplating speed is too fast, the coating is uneven, and the adhesion to the base metal is poor. The rhodium content during electroplating is generally controlled within 1.0-2.5 g/L.

(2) The plating solution temperature is insufficient. When the temperature is below 20℃, the current efficiency is very low, the coating stress is high, and the coating is not bright. With the increase in temperature, the allowable current density value increases, the current efficiency improves, and the coating stress decreases. However, if the temperature is too high, the solution evaporates rapidly, and a large amount of sulfuric acid mist is entrained, deteriorating the operating conditions. Electroplating is generally carried out at around 40℃.

(3) Excessive sulfuric acid content in the plating solution. Sulfate ions are the primary complex ions of rhodium ions. Increasing the sulfuric acid concentration strengthens the complexation of trivalent rhodium with sulfate ions, reducing the tendency for displacement reactions of ligands. However, strong corrosion may occur when the sulfuric acid concentration is too high and the workpiece is not properly grounded. The addition of sulfuric acid can increase the conductivity and acidity of the plating solution, stabilizing the solution. Generally, as the free sulfuric acid content in the plating solution increases, the current efficiency decreases, and the coating stress rises. However, when the content is too high and the workpiece is not grounded correctly, strong corrosion may occur, and it can also increase the internal stress of the coating, leading to cracks in the coating. When the sulfuric acid content is less than 15ml/L, the color of the coating darkens, so a certain sulfuric acid content should be maintained.

(4) Insufficient additives in the plating solution lead to solution deterioration. With the increase of rhodium plating time, the color of the plating solution changes from bright yellow to dark brown, making the solution unstable. This is mainly due to the oxygen evolution reaction at the anode, where oxygen has a strong oxidation ability, causing the plating solution to deteriorate. Therefore, the plating solution needs to be frequently adaptively filtered with activated carbon, and some additives need to be added to improve the performance of the plating solution. Additives such as leveling agents, wetting agents, and brighteners have a significant impact on the plating solution, changing the kinetic properties of electrodepositing metals, the properties of the deposit layer and electrolyte, such as reducing the internal stress of the coating, preventing crack formation, improving the corrosion resistance of the coating, significantly affecting the whiteness of the plated parts, making the coating fine, smooth, bright, and the electrolyte stable.

[Case 9-40] The white color of the Stone turns yellow after plating

Elemzés:

In this case, some diamonds in the 18K white gold jewelry set with prong setting appear yellowish after rhodium plating. When one diamond is removed and inspected, it is found that it has not turned yellow. Therefore, this issue should be attributed to the illusion caused by the metal surrounding the bottom of the diamond, which results from poor plating and yellowing of the plating layer. Factors affecting the yellowing of the plating layer include low cathode current density, too-low rhodium content, too thin a plating layer, and inadequate cleaning of the plating layer.

[Case 9-41] The jewelry surface turns cloudy after plating, as shown in Figure 9-41.

Elemzés:

After rhodium plating on the surface of the jewelry, white cloudy patches appear locally. Possible reasons for this problem include: (1) Inadequate degreasing of defective metal parts hinders average metal deposition; (2) The metal quality is not dense, there are shrinkage defects, the potential is low in this area, the plating speed is slow or difficult to plate, it should be repaired before electroplating again; (3) Prolonged plating time leads to darkening and graying of the plating layer; (4) Excessive current density will cause dark and gray phenomena on the surface of the plating layer, which should be controlled within the specified range; (5) Prolonged plating time.

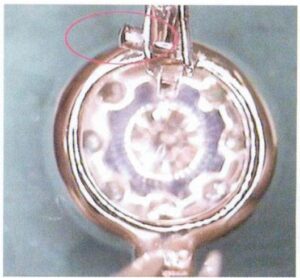

[Case 9-42] The bottom of the Earring is not plated, and the diamond appears black, as shown in Figure 9-42.

Elemzés:

The bottom hole of the round diamond is too small, and the hole mouth has a burr. Removing the wax crumbs during the waxing process is complex, failing electroplating. To solve this problem, after setting the Stone, the burr must be removed entirely, combined with the electrolytic polishing process to carefully polish the bottom of the Stone, and clean these parts thoroughly before electroplating.

[Case 9-43] The bottom of the caged back is dull, as shown in Figure 9-43.

Elemzés:

The so-called dull color refers to the lack of brightness. In this case, although the hollow walls of the mesh bottom have been electroplated, they lack brightness compared to the surface of the mesh bottom, mainly because the hollow walls cannot be polished or are not polished through during Polishing.

[Case 9-44] Color change during electrolytic oil removal, as shown in Figure 9-44.

Elemzés:

During electrolytic oil removal, when the workpiece is connected to the cathode, the surface undergoes a reduction process with hydrogen gas evolving. When the workpiece is connected to the anode, the surface undergoes an oxidation process with oxygen gas evolving. The advantage of cathodic oil removal is fast oil removal speed, generally does not corrode the workpiece but is prone to hydrogen embrittlement, affecting the mechanical properties of the coating and quickly causing pinholes; anodic oil removal does not cause hydrogen embrittlement in the matrix, can remove etching residues on the workpiece surface, but the oil removal speed is.

Relatively slow will cause the workpiece to undergo a certain degree of corrosion. Since the corrosion of the metal surface will seriously affect the brightness and coating deposition, cathodic degreasing is generally used in production, and cathodic degreasing is also used in this example. However, when the current density is too high, and the workpiece is too close to the anode, the jewelry metal surface may come into contact with the oxygen released by the anode, causing oxidation and discoloration.

[Case 9-45] Coating pinholes and pitting, as Figure 9-45 shows.

Elemzés:

Pinholes refer to the appearance of delicate pores on the surface of the electroplated layer, like being pricked by a pin; they are generally tiny and invisible to the naked eye but can be detected by magnifying glass or test methods. Pitting refers to non-penetrating depressions on the electroplated layer, with an electroplated layer in the depressed part thinner than the casting layer in other parts, forming a depression. The naked eye can see large pits, while small pits can only be detected after magnification. Pinholes and pitting not only affect the decorative effect of the coating but also reduce the protective performance of the coating.

The primary reason for the formation of pinholes and pitting is that hydrogen gas evolved at the cathode during electroplating and was adsorbed on the surface of the plated part, hindering the deposition of the metal of the coating. If hydrogen bubbles stay on the surface of the plated part for a long time, pinholes are formed; if they wait for a short time, pitting is formed. Many factors affect the formation of pinholes and pitting, such as the cleanliness of the pretreatment of the plated part, the accumulation of various impurities in the plating solution, the content of the wetting agent, the pH value, the cathodic current density, the movement of the workpiece, etc., all of which will directly affect the adsorption of hydrogen bubbles. The specific analysis is as follows:

(1) Poor pretreatment. Inadequate degreasing or improper storage during processing can lead to dust falling on the surface, mixing with grease, and becoming difficult to remove. During Polishing, abrasive materials and polishing pastes embed into micro-pits on the surface, making them hard to clean. Pinholes will form if these areas cannot be coated continuously to form a plating layer. Speckles will form when the plating layer only grows outward to cover the metal but is thinner than in clean areas.

(3) Influence of substrate defects. Despite appearing intact to the naked eye, the substrate surface contains many defects, such as sand holes, cracks, and impurity-rich areas upon microscopic examination. Compared to the metal atoms of the plating layer, these defects are relatively significant in volume. Pinholes will form when the plating layer cannot completely cover and seal these defects. As a substantial amount of metal atoms from the plating layer are consumed to fill these defects, the plating layer becomes much thinner at the micro-pores, resulting in fine speckles. Hydrogen has a lower overpotential on rough surfaces, leading to more severe hydrogen evolution during electroplating, which can generate more pinholes and speckles.

(4) Insufficient wetting agent content. Hydrogen gas precipitates on the surface of the plating layer, hindering metal deposition and causing pinholes or speckles. Wetting agents help reduce the surface tension of the electroplating solution, enhance the hydrophilicity of the electroplated surface, reduce the adhesion of hydrogen bubbles, and facilitate their rapid departure from the surface of the electroplated part without retention.

Improper control of operating conditions. Excessive cathode current density intensifies hydrogen evolution at the cathode. The resistance to escaping hydrogen bubbles increases when the plating solution temperature is too low. A low pH value exacerbates the cathodic hydrogen evolution side reaction. Inadequate speed of workpiece movement results in more muscular relative motion between the electroplating solution and the workpiece surface and insufficient flushing action. It hinders the escape of bubbles adhering to the plating layer surface.

In actual production, the shape, dispersion degree, and location of pinholes and speckles on the plating layer can be used to determine the influencing factors. Then, targeted measures can be taken to address them.

Part 2. Defects of various types of jewelry in electroplating

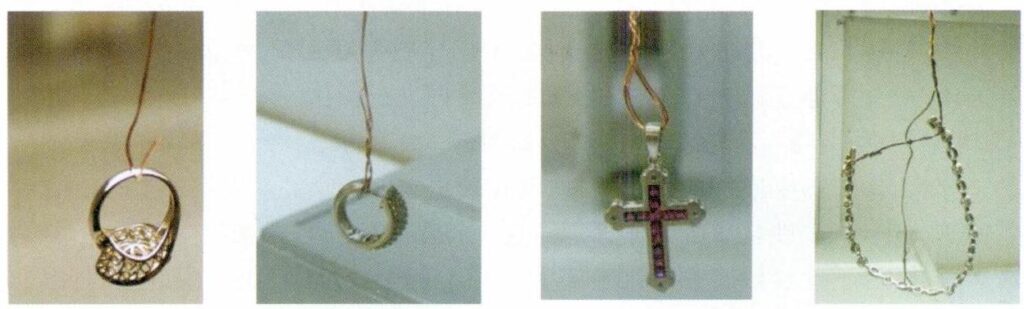

1. Defects of pendant electroplating

[Case 9-46] The bail and the jump ring cannot be fastened, as shown in Figure 9-46.

Elemzés:

The pendant’s bail must be fastened with the jump ring to ensure the appearance and regular use of the pendant. If it cannot be attached, it is easy to tilt and be inflexible when worn.

【Case 9-47】The bail is too small, and the chain is complex.

Elemzés:

The bail is used in conjunction with the necklace, requiring the necklace to pass smoothly through the bail and move freely. If the bail is too small, even if the necklace can pass through, it is prone to stiffness during wearing, affecting the wearing experience.

Case 9-48】Defect in the welding position of the bail

Elemzés:

When assembling the bail with the ring, the bail is usually first opened, and the jump ring is put into it and then welded at the tip of the opening. Welding quality is an important aspect affecting the quality of the pendant, and welding defects are not allowed. However, in actual production, welding defects such as pores, slag inclusions, weld beads, cracks, etc., often occur at the welding position. These defects cannot be eliminated during grinding and Polishing, requiring sanding rework.

【Case 9-49】The jump ring is not round, and the pendant is not aligned, as shown in Figure 9-47.

Elemzés:

Vertical suspension is an essential requirement for pendants. The jump ring and bezel side window are connected in this example. Still, due to the non-circular shape of the jump ring, the two cannot be adequately suspended after assembly, causing the pendant to tilt to one side and affecting the appearance and comfort of wearing. When inspecting the pendant, pay attention to the side view center of gravity and the front view center of gravity of the pendant. When hanging the pendant, there should be no tendency to lean forward or backward when viewed from above, and the overall center of gravity must be vertical when viewed from the front, without tilting.

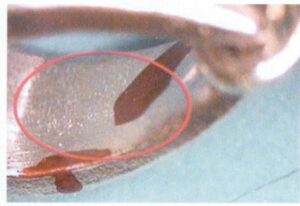

[Case 9-50] Loose shrinkage on the inner wall of the bail, as shown in Figure 9-48.

Elemzés:

The bail has a relatively small surface area, making it prone to internal wall shrinkage during casting. However, due to the small size of the chain through position, the operation is limited during grinding, or shrinkage defects may be left due to negligence. Therefore, it is necessary to choose the appropriate tools for processing, rework the shrinkage area, and then proceed with grinding and sanding.

【Case 9-51】Bail and Jump ring welded together, unable to move

Elemzés:

When welding, the welding position should be isolated from the Jump ring to avoid the welding material flowing to the contact area of the Bail and Jump ring during heating, causing them to be welded together.

2. Defects of finger ring electroplating

【Case 9-52】Improper position of the inscription

Elemzés:

Customers generally specify where to engrave. If not specified, the engraving is usually done in a place that does not affect the appearance of the jewelry. For rings, the inscription is usually engraved on the ring’s inner circle, but it should not be engraved in the exact center of the ring shank bottom; it should be slightly off-center.

【Case 9-53】The ring shank is asymmetric, as Figure 9-49 shows.

Elemzés:

For rings with single large stone prong settings, symmetry along the central vertical line on both sides is required, and the asymmetric issue, in this case, should not occur.

【Case 9-54】The decorative pattern is deformed, as shown in Figure 9-50.

Elemzés:

The delicate hollowed-out floral decoration on the side of the ring shank is prone to deformation or over-polished due to force during Polishing. Pay attention to techniques and strength when timing.

[Case 9-55] Inlaid parts skew, as Figure 9-51 shows.

Elemzés:

In this case, the crown of the ring head is an inlaid part. When welded together with the ring, apparent skew occurs. The reason is that the two parallel positioning holes of the crown are too close, and one of the positioning holes has too large a gap with the positioning pin, resulting in positioning deviation. To solve this problem, the two parallel positioning holes can be changed to upper and lower positioning holes. Try to pull the distance apart, and the fit between the hole and the pin should be tight.

[Case 9-56] Stress Corrosion Cracking of 14 KW Ring's Prong, as Figure 9-52 shows.

Elemzés:

In this case, the material of the ring is a nickel-containing 14 K white metal alloy. Residual stress is generated on the prong during the manufacturing process. After wearing the ring for some time, residual stress and the corrosive environment may cause stress corrosion, leading to prong cracking.

Residual stress refers to the stress system inside an object without applying external force, maintaining self-equilibrium. It is inherent stress or internal stress. There are many reasons for the appearance of residual stress on the prong of the ring, as shown in Table 9-1.

Table 9-1 Reasons for residual stress in prong-set rings

| Operation process | Causes of residual stress | Possible consequences related to stress |

|---|---|---|

| Weldin g claws onto ring band | Excessive heating speed and temperature of claw during welding | Thermal stress may cause fracture |

| Ring welding or quenching after heating | Premature hardening of workpieces after welding | Fast cooling of the outside and slow cooling of the center leads to inconsistent heat shrinkage, causing stress and cracks in the claws. |

| Make setting position on claws | Improper operation can cause overheating | Causes brittleness and cracks in claws |

| Press the claw pliers onto the gemstone surface | Clamp claws when the force is too large, too much bending, caused by the claw grain organization change | Generation of residual stresses, microcracks and eventual fracture |

Residual stress, on the one hand, reduces the electrode potential of the alloy, decreasing the material’s corrosion resistance. At the same time, the prongs themselves are relatively thin and may even cause stress corrosion cracking. On the other hand, residual stress can lead to exposed or potential microcracks. These microcracks are challenging to detect, often serving as sites for corrosive media accumulation. As jewelry is frequently exposed to various corrosive media during use, such as sweat, tap water, chlorine in swimming pools, multiple salts, etc., sebum and dander tend to adhere to the inside of the prongs.

Under the action of these corrosive media, high-stress areas become anodic regions, undergoing electrochemical corrosion, weakening the material and even causing fractures. The higher the concentration of the corrosive medium, the longer the contact time, the higher the temperature, and the thinner the prongs, the faster the weakening of the prongs, exacerbating stress corrosion cracking and leading to failure. To effectively prevent stress corrosion cracking of nickel K white metal, efforts should be made to eliminate residual stress and microcracks in the material during production, and attention should be paid to cleaning jewelry and reducing the accumulation of corrosive media in sensitive areas during use.

【Case 9-57】Ring shank too thin

Elemzés:

The thickness of the ring shank should generally be at least 0.8 mm. When it is too thin, it is easy to deform and uncomfortable to wear.

[Case 9-58] The ring size does not meet the requirements.

Elemzés:

All finished ring products must be inspected for ring size. When the actual ring size exceeds the standard ring size tolerance of ±1/4, it must be trimmed to the required range.

3. Defects in bracelet and necklace electroplating.

[Case 9-59] Excessive gap and chain breakage, as shown in Figure 9-53.

Elemzés:

For bracelets and necklaces, the chain body must be vertical; the chain links must be uniform, flexible, and knot-free. If there is a problem of excessive clearance, the chain body is elementary to fold.

[Case 9-60] non-uniform connected gaps, as Figure 9-54 shows.

Elemzés:

When there are non-uniform connected gaps, it affects the appearance and makes the chain not smooth to wear.

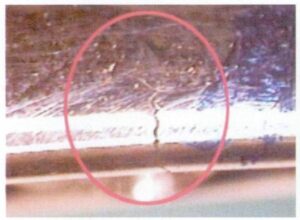

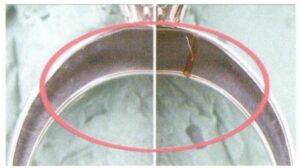

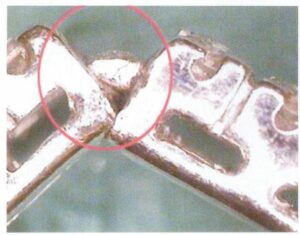

【Case 9-61】welding incomplete, as shown in Figure 9-55.

Elemzés:

The welded part of this workpiece is welded together, but it has yet to reach the degree of firm fusion. The strength of the joint surface is meager, and separation occurs in the subsequent processing operation, which is typical false welding. The essence is that the temperature of the joint surface during welding is too low, the size of the fusion zone is too small, and it may not even reach the melting point. The welding material accumulates on the weld, and the metals on both sides barely bond together, so it looks like a good weld but has yet to fuse fully. Whether it is laser welding or flame welding, a false wedding is possible.

To solve the problem, the following points should be noted during operation: The workpiece to be welded should be thoroughly cleaned, keep the weld and welding material clean, remove oxidation, grease, residual acid immersion liquid, residual polishing adhesives, etc. Carefully align the workpiece welds, which helps to obtain a strong and clean welding area, reducing the amount of cleaning work. Fix the workpiece with chain clamps, welding clamps, etc., to prevent displacement during welding. Before welding, immerse the entire workpiece in boric acid alcohol, then slightly heat the workpiece to form a protective layer of boric acid on the surface to prevent oxidation. The weld should be well protected with boric acid, which acts as a flux; it can quickly burn off, providing good protection for the welding material and weld. Heat should be transferred from the workpiece to the welding material during welding. Do not heat the welding material intensely with a flame and force it into the weld, which usually results in poor weld quality.

【Case 9-62】Chain breakage, as shown in Figure 9-56.

Elemzés:

The chain is a flexible component connected by chain links. The strength of the connection between the chain links is crucial for the safe use of the chain. If the external force on the chain exceeds the connection strength, it may cause the chain to break. The chain’s processing involves casting, linking, welding, grinding, Polishing, electroplating, etc. Various factors influence the strength of the connection between the chain links.

Impact of chain breakage, for example, the metallurgical quality of the chain links, linking operation methods, welding quality, grinding and Polishing methods, etc. If the metallurgical quality of the chain links is poor, with defects such as inclusions sand holes, it will reduce the effective cross-sectional area of the chain links, lowering the mechanical strength of the chain; if the chain links are repeatedly bent back and forth during linking, it will reduce the ductility of the chain links; if there are defects such as incomplete welding, slag inclusion during welding, it will reduce the strength of the welding area; if excessive force is applied to the chain links during grinding and Polishing, even causing entanglement, it can easily lead to chain breakage.

[Case 9-63] Chain specifications do not match.

Elemzés:

The requirement was to use a 1.5 mm diameter cross-chain, but a 1.3 mm diameter bone chain was used.

[Case 9-64] Pendant is not centered.

Elemzés:

The lengths of the chains on both sides should be the same for necklaces with pendants, with the pendant and lobster clasp at the center of the necklace. However, in this case, the necklace was produced with uneven chain lengths on both sides, causing the lobster clasp to shift to one side during wear.

[Case 9-65] The chain length does not meet the requirements, as shown in Figure 9-57.

Elemzés:

The required length for the bracelet is 7 inches, with an allowable size tolerance of ±0.5 inches. However, the actual length is only 6.25 inches, exceeding the permissible range.

[Case 9 - 66] The leather cord is not securely fastened and comes loose from the leather cord clasp.

Elemzés:

Bracelets and necklaces are sometimes made of leather cords, and the usual way to secure the leather cord is to insert the end of the cord into the cord buckle and fix it by using a combination of glue and pliers. Detachment issues may occur when not clamped tightly or when the adhesive strength is insufficient.

4. Defects in earrings electroplating.

[Case 9-67] The position of the earring pin welding is incorrect, as shown in Figure 9-58.

Elemzés:

It is an essential quality requirement for earrings to be symmetrical on the left and right sides. When welding the earring pins, the pins on both sides should be symmetrically distributed. In this case, the earring pin on the left is welded to the edge of the Earring, while the earring pin on the right is welded to the inner mesh bottom, resulting in asymmetry.

[Case 9-68] Earring edge is not symmetrical, as shown in Figure 9-59.

Elemzés:

In this case, the width of the stone edge of the earring body needs to be consistent, which does not meet the requirement for prettiness.

[Case 9-69] Earring face is not symmetrical, as Figure 9-60 shows.

Elemzés:

In this case, the height and angle of the decorative convex platform on the front of the Earring could be more consistent, which does not meet the requirement for symmetry.

[Case 9-70] The jump ring is deformed & incomplete, as shown in Figure 9-61.

Elemzés:

Dangling earrings require the dangle part to hang vertically and freely. In this case, the jump ring of the dangling part is incomplete and deformed, causing it to be skewed.

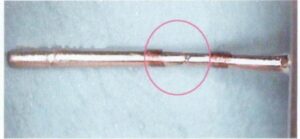

[Case 9-71] The support pole of the Earring clap is too thin, as shown in Figure 9-62.

Elemzés:

In this case, the support pole of the Earring clap is too thin, which affects its mechanical strength and makes it prone to deformation.

[Case 9-72] Earring post with sanding marks, as shown in Figure 9-63.

Elemzés:

The diameter of the ear post is generally 0.8 ~ 0.9 mm, with a length of about 11 mm. The pin tip is usually blunt, with a groove 5 mm from the tip and a groove on each side of the clip to prevent slipping. The rest of the ear pin should be smooth and comfortable to wear, but in this case, deep sanding marks appear in the area that requires a smooth surface.

[Case 9-73] The ear back pressure is too loose, as Figure 9-64 shows.

Elemzés:

Ear back is a specialized term for jewelry, referring to a small accessory used to fix the ear studs on earrings behind the ear. When wearing ear studs, after putting on the ear studs, the ear back is clipped behind the ear to secure the ear studs. The ear back material needs to have a certain elasticity in structure to facilitate wearing and removal. Common ear back structures include butterfly ear backs, disc ear backs, screw spring ear backs, and movable spring ear backs. The ear back used in this case is a movable spring ear back, but the spring is too loose to ensure firmness when worn.

【Case 9-74】The ear pin is crooked and deformed, as Figure 9-65 shows.

Elemzés:

The ear pin must be perpendicular to the earring surface without crooked deformation. The issue in this case is that the ear pin was subjected to external force during Polishing, and due to the thinness of the ear pin, deformation quickly occurred. It should be straightened after Polishing.

【Case 9-75】The ear pin is broken, as shown in Figure 9-66.

Elemzés:

The ear pin is fixed on the earring body by welding. Due to the thinness of the ear pin, attention should be paid to prevent problems such as melting loss and false welding during welding. When polishing, attention should be paid to not polishing the root of the ear pin too much. Otherwise, it may cause the ear pin to break.

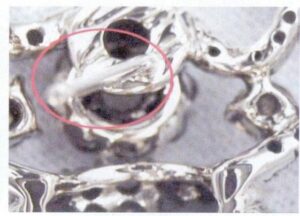

【Case 9-76】The earring hinge pivot falls off, as Figure 9-67 shows.

Elemzés:

The clip-on earrings achieve the rotating function through the hinge mechanism. The hinge mechanism is composed of a pivot and a rotating cylinder. The pivot is mounted in the rotating cylinder and is welded flat at both ends. If the welding is not firm and there is false welding, the hinge pivot may become loose during Polishing.

[Case 9-77] There is a crack at the welding position of the earring hinge pivot, as shown in Figure 9-68.

Elemzés:

false welding occurred during the welding of the earring hinge pivot. Only some parts are connected after polishing the welding position, while the rest show cracks and separation.

[Case 9-78] Skin Scratches on the earring hinge pivot, as shown in Figure 9-69.

Elemzés:

Hoop earrings that open and close on both sides require smooth closure without reverse edges, protrusions, etc. Otherwise, it will affect the safety and comfort of wearing.

[Case 9-79] The earring clap does not sit in the center of the earpin, as shown in Figure 9-70.

Elemzés:

It is required that the ear pin be in the center of the earlobe without any left or right deviation. The cause of this problem is misalignment during the earring clap forming process or deformation of the earring clap during grinding and Polishing.

[Case 9-80] Ear back sizes are inconsistent, as Figure 9-71 shows.

Elemzés:

Earrings require consistency, and ear canals, as accessories, are generally purchased from the market. Due to the various specifications available, attention should be paid to matching when ordering production.

Bracelet electroplating defects

[Case 9-81] The bracelet is not smooth, as shown in Figure 9-72.

Elemzés:

The bracelet’s body must be flat and smooth, and when viewed from above, the curvature of the entire bracelet should be natural. To address this issue, the bracelet needs to be reshaped before polishing.

【Case 9-82】The bracelet is uneven and deformed

Elemzés:

The face of the bracelet should be flat and smooth; put the bracelet flat on the glass plate and finger any point of the bracelet; there should be no wobbling feeling. In this case, the bracelet’s surface has undergone uneven deformation and needs to be reshaped.

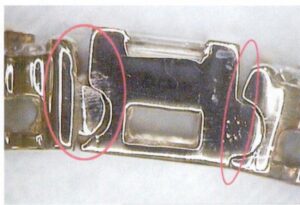

【Case 9-83】The bracelet opening clasp is not flexible, as Figure 9-73 shows.

Elemzés:

Generally, a Security Latch is set on both sides of the box clasp to prevent slipping when the tongue spring is lost. The Security Latch is the most common safety device, requiring appropriate tightness. It may break due to long-term friction; if it is too loose, it cannot play the “clasp.” Therefore, using a little force when close to fit together is best.

【Case 9-84】The Security Latch is not tight, as Figure 9-74 shows.

Elemzés:

Generally, a Security Latch is set on both sides of the box clasp to prevent slipping when the tongue spring is lost. The Security Latch is the most common safety device, requiring appropriate tightness. It may break due to long-term friction; if it is too loose, it cannot play the “clasp.” Therefore, using a little force when close to fit together is best.

[Case 9-85] The size of the open bangle does not meet the requirements, as shown in Figure 9-75.

Elemzés:

The open bangle has specific requirements for the bangle diameter and opening size. In this case, the required opening size of the open bangle is 3.51 cm, while the actual size is 3.84 cm. Due to the open bangle, deformation may occur during production, resulting in dimensions failing to meet the requirements, especially when the material strength is low. To solve this problem, on the one hand, choose materials with sufficient elasticity, and on the other hand, pay attention to size correction of the bangle during Polishing.