What is Electroforming of Gold and How is it Applied to Special Materials?

Understanding Gold Plating: Techniques, Benefits, and Applications

Introduction:

Electroforming is an advanced electroplating-based manufacturing process that creates freestanding metal parts, primarily using gold and its alloys. Unlike conventional plating, it focuses on building thick, precise layers which are then separated from the substrate. The text explains how specific plating solutions and methods, like simultaneous or sequential deposition, are used to create complex gold alloy items such as decorative pieces and dental crowns. It also details why special surface preparations are crucial for plating challenging materials like stainless steel and titanium, addressing their passivation layers to ensure adhesion and functional performance in applications from electronics to aerospace.

what is electroforming of gold and how is it applied to special materials

Table of Contents

Section I Electroformed Gold and Gold Alloys

Electroforming is a manufacturing process based on metal electroplating, which is different from electroplating aimed at coating materials. The difference in electroforming is that various methods separate the material after electroplating, and the product is only the metal electroplated layer. Although it may seem similar to electroplating, electroforming is more advanced and requires higher electroplating technology. Especially in terms of the plating layer’s current distribution and internal stress, it is more specialized than electroplating.

Since its inception, electroforming has a history of more than 100 years. In 1840, Dr. F. V. W. Netto first published a paper on electroforming, using copper plating solution to create dense copper replicas on flat or three-dimensional objects, modeling, similar models, printing, or casting.

Currently, the materials used in electroforming are mainly copper and nickel, with small amounts of additives added to high-concentration plating solutions for electroplating. The rise of electroformed gold has been a recent development, but truly ideal electroforming gold plating solutions do not yet exist.

1. Gold Plating for Electroforming

There are many types of plating solutions for electroforming. The commonly used plating solution is cyanide plating solution, while others include sulfite, chloride, or mixed solutions of these compounds. Generally, citrate plating solutions used for electroplating cannot be used for electroforming. Up to now, electroforming has still used the gold plating solution invented by Reid & Goldie (Table 1-118). These plating technologies have historical limitations and have certain practical issues. Rogers obtained a 100~125μm/h gold plating layer from a plating solution containing 14.1g/L potassium gold cyanide, 18.3g/L potassium cyanide, 14.1g/L potassium carbonate, and 11.4g/L boric acid under the condition of temperature 65℃, 3.2A/dm2 (however, according to electrochemical equivalent calculations, even if the current efficiency reaches 100%, only about 60μm plating layer can be obtained). In 1967, Japan and the UK obtained 7 kg of electroformed gold from a neutral plating solution (pH 6.5) of potassium gold cyanide containing 28~36g/L gold, neutralized with phosphoric acid.

In sodium, potassium, or ammonium ion type sulfite electroforming gold solutions, adding gold deposition grain refiners (DOS 2249658, 1972) containing arsenic compounds for electroforming can produce 600μm gold layer.

Table 1-118 Composition and Operating Conditions of Electroforming Solution

2. Electroforming Methods

Common methods for gold alloy electroforming are: ① the simultaneous deposition method and ② the sequential deposition method.

(1) Simultaneous Deposition Method

This method involves alloy electroforming by depositing gold and 2 or 3 other metals simultaneously. The composition of the deposited alloy depends not only on the plating solution composition but also on current density and temperature. To maintain a certain alloy deposition ratio, the plating thickness must reach 100~300μm. When electroforming alloys, such as to ensure the consistency of the precipitation of electroforming 18K gold-copper-cadmium ternary gold alloy, the whole process of computerized management of electroplating is carried out in a way that the temperature of the plating solution and the concentration of metal ions are automatically controlled by sensors and the computer monitors the full current and the surface area of the product.

After electroplating the gold-copper-cadmium alloy electroformed layer must be heat-treated in an inert gas atmosphere. The investment in treatment equipment is very large (the composition of the plating solution is the same as the two types of gold alloy plating solutions in Table 1-118).

In recent years, due to environmental concerns about cadmium and the complexity of heat treatment, alloy components other than gold generally only use silver. Using the conditions in Table 1-119, gold-silver alloys from 8K to 18K are electroformed. Japanese patent Showa 58-130293 obtained gold-silver alloy electroplated layers with minimal composition variation and thickness of 150μm.

Table 1-119 Composition and Conditions of Plating Solution for Simultaneous Deposition Electroforming of 8K Gold-Silver Alloy

US PAT. 3427231 by Lechtzin records experimental results, including the PR electrification method (cathode 60 s – anode 4 s). Swiss patent CH 529843 uses a PR method with a cycle ratio of 5 to 10 to 1.

US PAT. 3427231 describes the effect of using ultrasound in electroforming, where the current density can be increased to above 100A/dm2 , and by using ultrasonic stirring and filtration, additives can be avoided.

(2) Sequential Precipitation Method

This method causes the various components in the electroformed alloy to precipitate sequentially, with cycles ranging from one to several tens or hundreds of times. The precipitates form multilayers of different metals. After heat treatment of the precipitates, the metal components diffuse into each other to form a uniform alloy. Heat treatment is performed for alloying after electroplating a certain coating thickness using the plating solution and conditions in Table 1-120.

Table 1-120 Composition and Conditions of the Plating Solution for the Sequential Precipitation Method

The gold alloy plating obtained by this method has the following advantages:

① The composition of the gold-silver-copper alloy can be adjusted arbitrarily.

② The hardness of the gold-silver-copper alloy after heat diffusion is much higher than that of ordinary electroplated layers.

③ Good corrosion resistance. The gold-silver-copper alloy electroplated layer is not an alloy but a eutectic-plated layer. After heat diffusion, it is fully alloyed, with corrosion resistance equivalent to metallurgically manufactured alloys, significantly higher than gold-silver or gold-copper electroplated layers.

④ No use of gold-copper-cadmium alloy plating solution. The plating solution for the 18K layer contains no cadmium, making it environmentally friendly and safe.

3. Applications of Electroformed Gold

(1) Uses of Pendants and other Decorative Items

US PAT. 446421 Small hollow globe made by electroforming ball-shaped injection molded objects. After electroforming, small holes are made in the globe, and the plastic inside the globe is removed by heating to obtain a hollow metal sphere. This patented method involves sequentially electroplating copper, silver, gold, and other metals, followed by heat treatment alloying to produce the product.

GB PAT. 2031024 After electroforming real flowers, place them in an electric furnace for heat treatment for 24 hours, then use high-pressure water to blow from the top of the flower stem to remove residues, obtaining electroformed flower decorations.

Other patents, such as the Japanese patent (Showa 59-80788), detail the method of manufacturing gold alloy watch exterior parts using electroforming. The manufacturing method of gold pendants is shown in Table 1-121.

Table 1-121 Manufacturing Methods of Gold Alloy Decorative Items

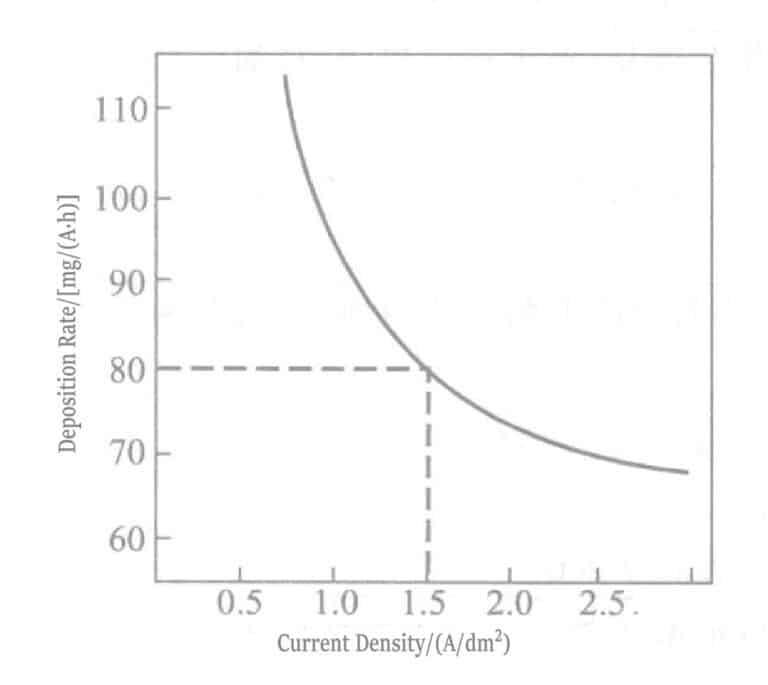

Figure 1-107 Relationship between current density and deposition rate

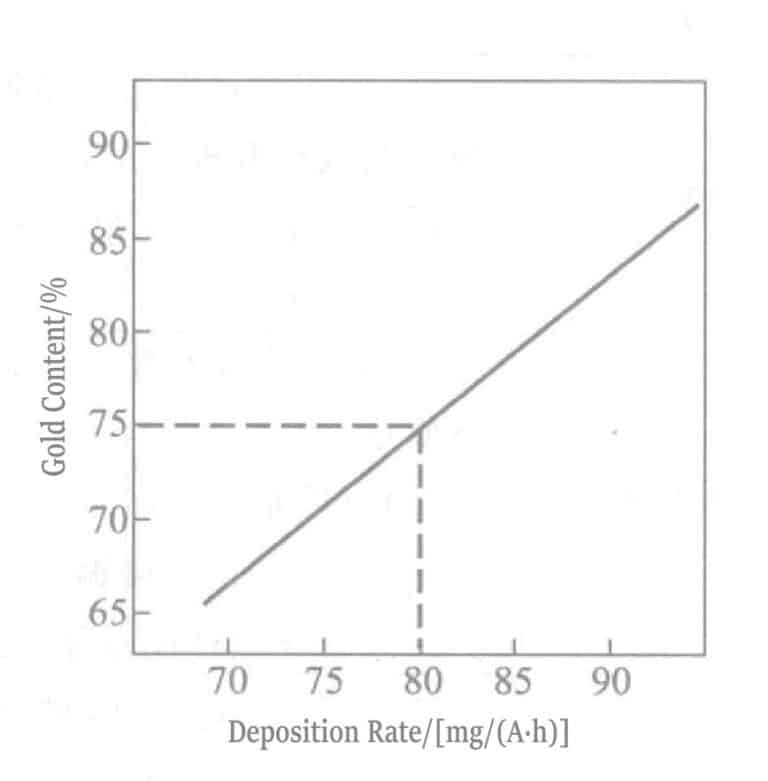

Figure 1-108 Relationship between gold content and precipitation rate

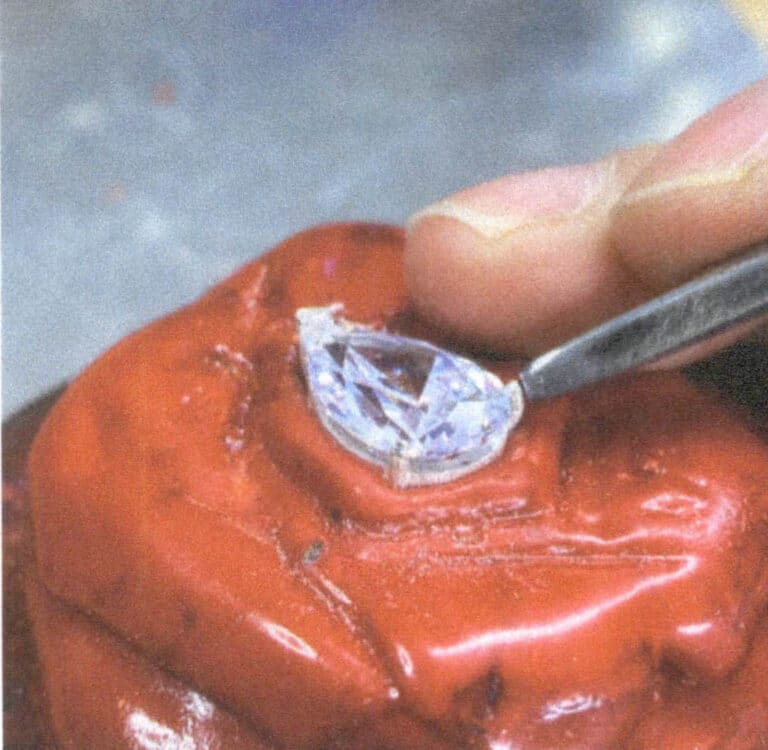

(2) Dental Use

Dental crowns and prosthetic teeth have complex shapes and thin thicknesses, requiring high strength and corrosion resistance. Besides medicine, they also involve technologies from many other disciplines. Rogers, Vr-ijhoef, and others have proposed many research reports on these specialized technologies.

(3) Functional Purpose Detection Equipment

Functional testing involves equipment related to electronics, instruments, communications, and other fields.

X-ray Photomasks Nippon Patent Showa 58-224427

Nippon Patent Showa 58-200535

Infrared Filter Gratings G. Chanin

Spiral Micrometer Young Ogbum

Protruding pad lines US PAT.4125441

Spiral micrometers manufactured by the American Standards Bureau implement alternating gold and nickel plating. Since the thickness of the plating layer can be controlled and measured by the current, it can be used for the calibration of electron microscopes.

Section II Special Materials Gold Plating

1. Stainless Steel Electroplating

Due to a passive oxide film on the surface, stainless steel has excellent corrosion resistance. However, electroplating on the passive film of stainless steel is very difficult. Currently, a method with excellent precipitation bonding strength involves precipitating an ultra-thin nickel layer in an impulse nickel plating solution while activating the stainless steel, and the gold layer plated on the impulse nickel layer can be completely and tightly bonded. However, this method has significant drawbacks, severely reducing the corrosion resistance of stainless steel. The following are key issues in electroplating a corrosion-resistant gold layer on stainless steel.

① Do not use a nickel plating intermediate layer; directly electroplate gold on stainless steel.

② Do not use hydrogen halide acids to promote pore formation (hydrochloric acid activation is prohibited).

③ Ensure good adhesion.

To meet the above requirements, in 1971, the HAu(CN)4 manufacturing method and the HAu(CN)4 adjustment method of range of Plating solutions were developed. This plating solution works very well within the pH 0.1 ~ 3.0, consisting of gold ligands, citric acid, phosphate, or weak acids such as phosphoric acid.

In 1979, a method was started to flash gold plates (strike gold plating) on stainless steel using potassium gold(III) cyanide plating solution. Conductive salt potassium nitrate, ligand ethylenediamine hydrochloride, and alloy components such as nickel, cobalt, zinc, and indium were added to the plating solution, and it was used with pH controlled below 1.5.

Chlorine-free potassium gold(III) cyanide plating solutions were developed and widely used because the plating solution contained chlorine, which is unfavorable for stainless steel. These potassium gold(III) cyanide plating solutions were especially used for brush gold plating alloyed with cobalt (see Table 1-122).

Table 1-122 Flash Gold Plating Solution for Stainless Steel

Table 1-123 Corrosion Principles of Gold Plating on Stainless Steel

There have been reports regarding the thin gold layer on stainless steel lead frames for ICs, concerning whether the weldability and wire bonding performance are good when the gold plating thickness is above 300Å(30nm), the welding performance is good around 450℃ 1min; When is it above 200Å, all gold wire bonding is good.

At this time, the thickness of the gold plating layer is 300Å, very thin. If the surface roughness of the stainless steel is coarse, it will affect the uniformity of the gold plating layer, resulting in defects such as pores. Therefore, in the activation treatment of the stainless steel surface, to smooth the surface and improve adhesion, inorganic mixed acids, and organic corrosion inhibitors can be used as treatment agents.

Besides corrosion resistance, gold and silver plating layers on IC stainless steel (SUS430) substrates are heated in an atmosphere of at 460℃, respectively 0s, 30s, 60s, 240s. Then, weldability and gold wire bonding performance are tested. Watt’s bath is used for strike nickel plating, and an intermediate plating layer is added to the nickel plating layer. When the outermost layer is gold plating, the silver plating layer and nickel-cobalt alloy plating layer as intermediate layers show better effects. When the outermost layer is silver plating, the palladium-nickel alloy plating layer (0.1μm) and electroless nickel plating layer (nickel-phosphorus, 0.1μm ) as intermediate layers show better effects. Or without intermediate layer, replacing the strike nickel layer with a strike nickel-cobalt alloy layer (0.02μm), can improve the heat resistance of the precious metal plating layer. The effect is especially significant when used as an intermediate layer for gold plating. This is because the nickel-cobalt alloy plating layer can act as a thermal diffusion layer for iron.

Copywrite @ Sobling.Jewelry — Custom jewelry manufacturer, OEM and ODM jewelry factory

2. Titanium and Titanium Alloy Plating

Titanium metal is light, with a specific strength (strength/density) twice that of steel. It has excellent corrosion and heat resistance in atmospheric and acidic environments, so it is widely used in the manufacturing of aircraft and aerospace industries. The standard electrode potential of the needle is E=-1.75V, more negative than aluminum’s, but it forms an oxide film in acidic environments and is easily passivated. The thickness of the passivation film reaches about 100Å, so it is difficult to achieve good adhesion when electroplating on titanium.

(1) Corrosion Methods

Research on electroplating sodium has reported about 33 cases from 1952. These methods all use corrosion to remove the oxide layer on the sodium surface, focusing on depositing the plating layer on the exposed activated surface. The summarized process flow from the literature is shown in Table 1-124, and various corrosion solutions are summarized by series in Table 1-125.

Table 1-124 Summary of Electroplating Methods on Titanium

Table 1-125 Composition of Various Etching Solutions

Table 1-126 Overview of Main Process Procedures and Test Results

(2) Hydrochloric acid activation

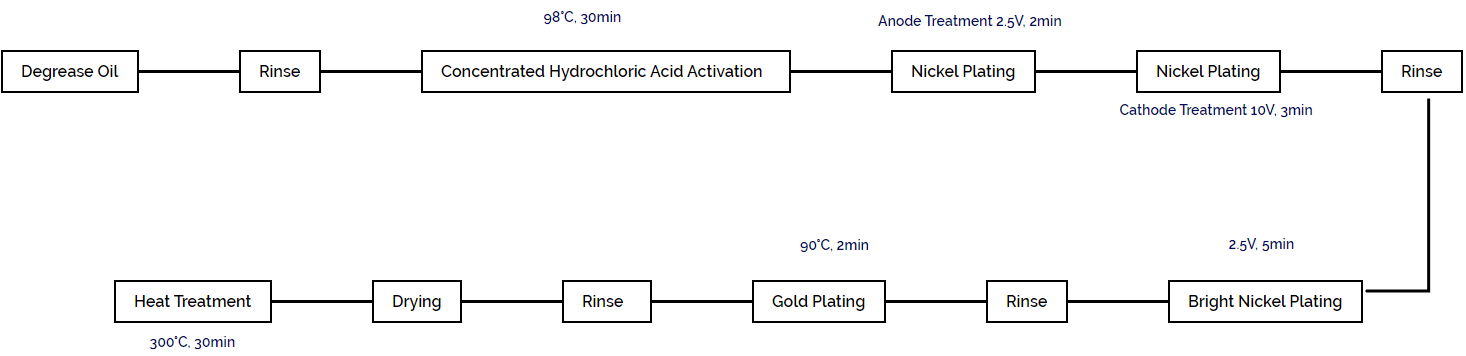

After treatment with hydrochloric acid as an etchant, the surface of titanium appears as a black mesh pattern, and direct electroplating on it can also achieve good adhesion. The comparison results of the adhesion strength of the nickel plating layer in various process steps are shown in Table 1-127. Among them, the adhesion strength test results of the plating layer after heat treatment using process No. 3 are shown in Table 1-128. In the results, the boiling samples 1 + 1 HC1 were treated for 30min, 2 + 1HC1 treated for 15min, 2 + 1HC1 treated for 5 minutes, then electroplated with nickel. Afterward, the samples were heat-treated at 300℃ for 30 minutes and subjected to a bending test. The effect of 2+1was the best among them, indicating that heat treatment at 300℃ for more than 30 minutes is necessary.

Table 1-127 Titanium Electroplating Process Steps

Table 1-128 Relationship between Heat Treatment Temperature and Time of Electroplated Layer and Bonding Strength

(3) Gold Plating

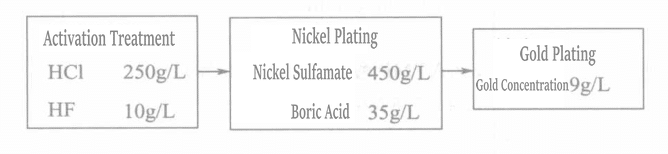

The gold plating process on the needle material is shown in Figure 1-109.

(4) Other Methods

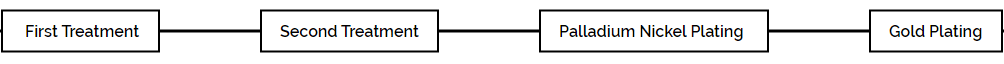

After heat treatment of titanium material in the atmosphere, a stable oxide film is generated on the surface, and the oxide film is removed with a water-soluble reducing agent and a treatment solution that dissolves titanium, and then plated immediately. The process is shown in Figure 1-110.

First step treatment: 100~600℃ heat treatment for 50~60min.

Second step treatment: Activation treatment using an aqueous solution of water-soluble reducing agents (sodium hypophosphite, hydrazine, etc.) and salts that dissolve titanium (acidic ammonium fluoride, sodium fluoride).

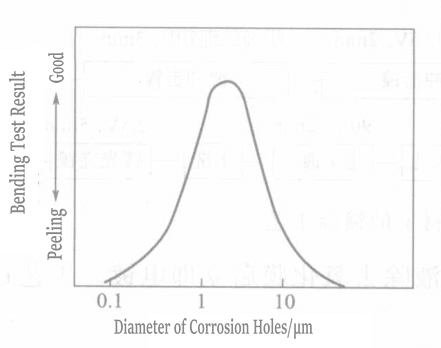

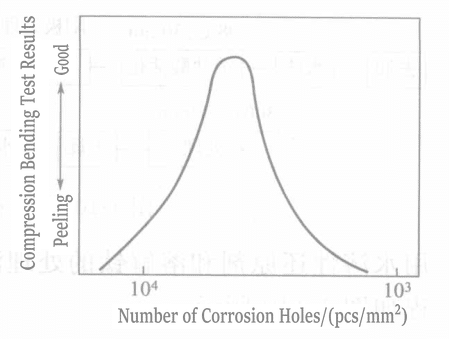

Liu and others used a method to generate micropores on the titanium surface, where controlling the micropores’ number, size, and depth is very important. The process is shown in Figure 1-111. The relationship between the size, number of micropores, and the bonding strength of the coating is shown in Figures 1-112 and 1-113.

Figure 1-112 Relationship Between Pitting Diameter and Bond Strength

Figure 1-113 Relationship Between Number of Pits and Bond Strength

(5) Summary

The key to obtaining good adhesion of the gold plating layer on titanium material is as follows:

① Quickly remove the oxide on the titanium surface and immediately electroplate before oxidation occurs.

② The fixation effect of micropores generated on the titanium surface improves the bonding strength.

③ Heat treatment methods remove sodium from the surface and gases in the coating.