What Makes Resin, Plastic and Acrylic Ornaments Jewelry So Unique:Materials, Production Process and Care

Mastering Resin, Plastic & Acrylic Jewelry: Craft, Care & Trends

Resin, plastic, and acrylic are currently popular materials for accessories. They are inexpensive, but their colors and shapes can meet people’s aesthetic requirements for jewelry and fill the demand gap that many precious metal accessories cannot fulfill.

The texture of the resin has a lightness, a soft luster, good plasticity, diverse shapes and effects, a strong three-dimensional feel, and rich colors, making it best at showcasing the vibrant colors of jewelry, leading to its widespread use in the jewelry industry.

Plastic gives the impression of being a cheap material, but using plastic as the basic material, combined with advanced manufacturing technology and surface treatment processes, and incorporating various fashion elements, makes the jewelry lightweight, highly malleable, sturdy and durable, and rich in color, thus becoming a popular product in the market.

Acrylic has high transparency, with a light transmittance of 92%, good surface hardness and gloss, and is known as “plastic crystal” and “queen of pigments.” It also has excellent weather resistance and good processability and can be made into products of various shapes. Acrylic looks like jade, with patterns, designs, and colors not limited by alloy accessories, becoming another popular fashion in jewelry.

Plastic bracelet

Indice dei contenuti

Section I Resin Ornaments and Production Technology

1. Introduction to Resin Used in Accessories

Resin (Poly) generally refers to organic polymers that soften or melt when heated, tend to flow under external force when softened, and are solid, semi-solid, or sometimes liquid at room temperature. Any polymer that can be used as a processing material for plastic products is referred to as resin.

(1) Classification of Resins

Resins can be divided into natural resins and synthetic resins. Natural resins refer to amorphous organic substances obtained from the secretions of plants and animals in nature, such as rosin, amber, and shellac. The resins used in industry are generally synthetic resin products obtained from the chemical synthesis of simple organic compounds or certain natural products through chemical reactions. There are many categories of synthetic resins, which can be classified in different ways.

- Classified by resin synthesis reactions. By this method, resins can be divided into addition polymers and condensation polymers. Addition polymers refers to polymers obtained by addition polymerization reactions, whose chain segment structure has the same chemical formula as the monomer’s molecular formula, such as polyethylene, polystyrene, polytetrafluoroethylene, etc. Condensation polymers refer to polymers obtained by condensation polymerization reactions, whose structural units have different chemical formulas from the monomer’s molecular formula, such as phenolic resin, polyester resin, polyamide resin, etc.

- Classification based on the composition of the resin molecular backbone. This method divides resins into carbon chain polymers, heterochain polymers, and elemental organic polymers. Carbon chain polymers refer to polymers whose main chain is composed of carbon atoms, such as polyethylene and polystyrene. Heterochain polymers are polymers whose main chain comprises atoms from two or more elements, including carbon, oxygen, nitrogen, sulfur, etc., such as formaldehyde, polyamide, polysulfone, and polyether. Elemental organic polymers refer to polymers whose main chain does not necessarily contain carbon atoms and mainly comprises elements from silicon, oxygen, aluminum, titanium, boron, sulfur, and phosphorus, such as organosilicon. The commonly used polymerization methods in industry include bulk polymerization, suspension polymerization, emulsion polymerization, and solution polymerization.

- Classification according to the thermal processing properties of resins. This method divides resins into two main categories: thermoplastic and thermosetting resins. Resins that can be melted by heating, cooled, and solidified, and can be repeated are called thermoplastic resins, such as polyvinyl chloride resin (PVC), polyethylene resin (PE), etc.; resins that, after being cured by heating, become irreversible, turning into solids that are neither soluble nor meltable, are called thermosetting resins, such as phenolic resins, epoxy resins, unsaturated polyester resins, etc.

For craft jewelry, the resins used are all thermosetting, mainly epoxy resin and unsaturated polyester resin. “Polyester” is a type of polymer compound that contains ester bonds, distinguished from resins such as “phenolic” and “epoxy.” This polymer compound is generated from the polycondensation reaction of dibasic acids and dibasic alcohols, and when this polymer compound contains unsaturated double bonds, it is called unsaturated polyester. When this unsaturated polyester dissolves in a monomer with polymerization capability (generally styrene) and becomes a viscous liquid, it is referred to as unsaturated polyester resin (abbreviated as UPR). It is a thermosetting resin that can cure into an insoluble and infusible polymer network under heat or the action of an initiator. However, this polymer has very low mechanical strength and cannot meet the requirements of most applications. When reinforced with fiberglass, it can become a composite material, commonly known as “fiber reinforced plastics” (abbreviated as FRP). The mechanical strength and performance of “glass steel” have greatly improved compared to resin castings.

(2) Characteristics of Resin

The texture of the resin is warm and smooth, with a soft luster, relatively light in weight, and available in transparent, semi-transparent, and opaque textures. It has the following properties.

- Lightweight and high strength.

- Good corrosion resistance.

- Excellent electrical performance.

- Unique thermal performance, it is an excellent insulating material.

- Resin differs from traditional precious metals such as gold and silver; it has excellent processing performance, can soften when heated, is easy to shape, can be molded in one go, can be formed at room temperature and pressure, or can be cured with heat and pressure. No low molecular by-products are generated during the curing process, allowing for the production of relatively uniform products.

- The material has good designability, is easy to process, and has various colors.

(3) Technical Specifications of the Resin

- Appearance. The appearance of the resin is a transparent viscous liquid, clear and colorless, changing to dark amber, with a color index generally of 25~35.

- Acid value. It indicates the degree of reaction of unsaturated polyester and is also an important indicator for controlling the quality balance of different batches of polyester, generally at 18~24mgKOH/g.

- Viscosity. Viscosity is a measure of the fluid’s resistance to flow, representing the internal friction phenomenon of the fluid. Due to viscosity, objects moving in the fluid experience frictional and pressure differential resistance, resulting in the loss of mechanical energy (see flow resistance). The magnitude of viscosity depends on the properties and temperature of the liquid; as the temperature increases, viscosity decreases rapidly. The viscosity of resin used in craft jewelry is generally 1350~1600mPa·S.

- Gel time. The time from the addition of the initiator to the appearance of gel, when the resin loses its fluidity, is called gel time.

- Curing time. When the resin changes from a gel state to a hard solid, no longer undergoing further reactions, it is also known as maturation time.

- Solid content. Dissolve the resin in solvents like acetone, causing a reaction between the solvent and the styrene cross-linking units. The remainder is the product of the original polyester, and the ratio of its weight to the original weight is the solid content. The reference value for the solid content of general resins is 50%~60%.

- Refractive index. Generally measured with a refractometer at 1.5~1.55.

- Storage. The storage period of the resin is generally 6 months, and the testing method is as follows: Place 250 g of resin in a sealed container, put it in an oven of 80℃, keep the resin away from light, and check every 4 hours. The time when the gel phenomenon is first observed is the storage life of the resin at 80℃, which is applicable for controlling the quality stability of different resins but not suitable for comparing the storage periods of different resins.

- Exothermic performance of curing. The exothermic performance of resin curing is generally at 80~85℃ that meets the processability of resin production and the applicability of products.

(4) Various Additives and Auxiliary Materials Required

- Curing agent (also known as hardener). Added to the resin, it decomposes to release free radicals under heating conditions, initiating a cross-linking polymerization reaction, causing the resin to begin the transition from liquid to solid. The storage of the curing agent is closely related to the ambient temperature; the higher the temperature, the less stable the storage safety. When selecting a curing agent, choosing a product with good stability is essential.

- Accelerator. The curing agent can only decompose and activate under certain conditions, and it decomposes very slowly at room temperature, which cannot meet the process requirements. On the one hand, the curing agent can undergo thermal decomposition by heating. On the other hand, it can be activated and accelerated through a redox reaction to initiate the cross-linking process. The reducing agent that can activate the curing agent is called an accelerator.

- Accelerator. Compounds that can activate organic peroxides decompose to generate free radicals at room temperature without heating.

- Slow agent. The resin will gradually polymerize at room temperature without adding a curing agent, losing its effectiveness. Therefore, a slow agent (also known as a retarder) needs to be added to extend the storage period of the resin. The principle is that the slow agent absorbs and eliminates free radicals that can trigger the cross-linking and curing of the resin or weaken the activity of the free radicals.

- Expanding agent (environmentally friendly resin). The water-based polyester prepared by room temperature, aqueous phase polymerization can replace the environmentally friendly unsaturated polyester expanding and cooling agent that has toxic side effects on the human body and pollutes the environment through techniques such as ultrafine emulsification, shaping, and re-protection.

2. Resin Craft Jewelry Category

As briefly introduced below, resin is widely used in the craft jewelry industry.

(1) Resin Crafts

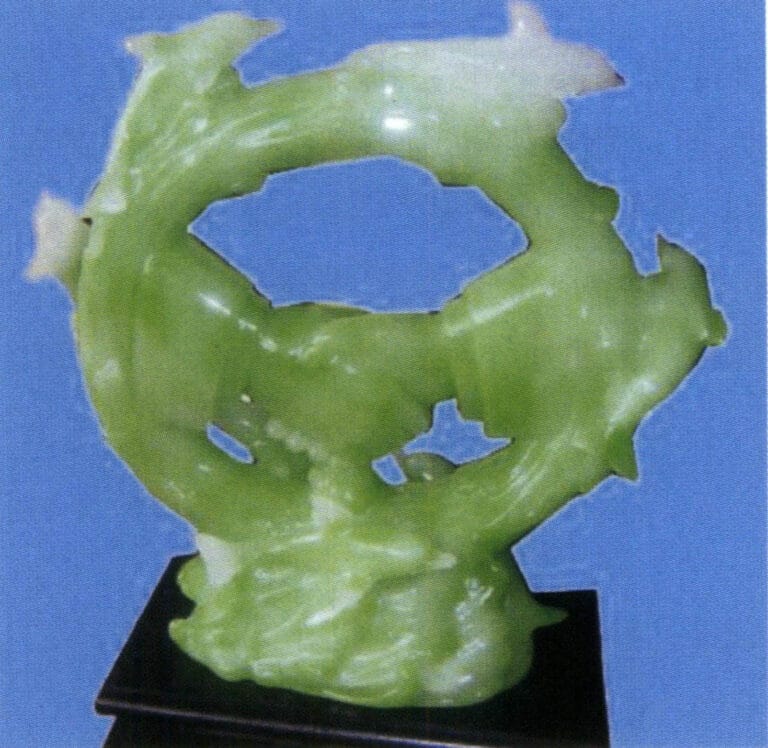

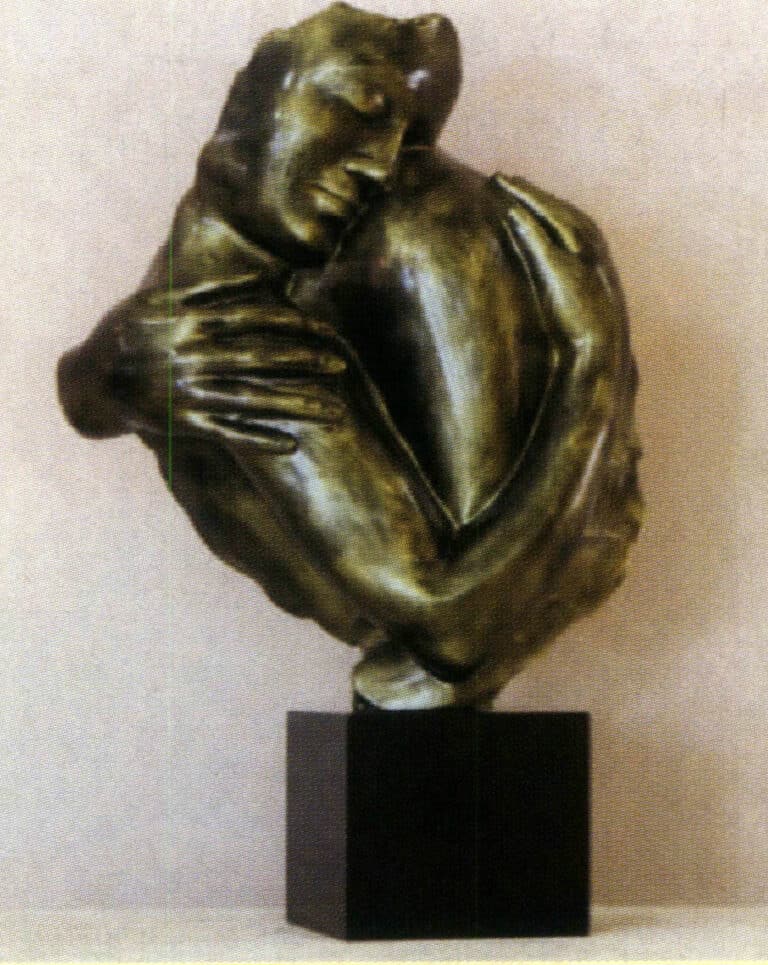

Resin crafts are made primarily from resin, combined with auxiliary materials, and molded through casting to create various aesthetically pleasing and lifelike figures, animals, birds, landscapes, etc., such as urban sculptures, home decorations, furniture, and accessories, picture frames, screens, and lighting fixtures. With the continuous improvement of living standards, the demand for resin crafts is growing increasingly strong, especially in developed countries with a special preference and astonishing demand for them. Exquisite resin crafts can serve as elegant decorations for high-end hotels and offices and fashionable furniture and gifts exchanged among friends and family. Good environmental performance and extremely low production costs determine its broad development prospects and space. Resin crafts are becoming a highlight industry for small business startups in our country.

The production cost of resin crafts is low, the production speed is fast, and the flexibility is strong. No matter how complex the shape is, it only takes a few minutes to over ten minutes to produce using molds, and it can imitate copper, gold, silver, crystal, agate, marble, white jade, redwood, and more.

- Imitation jade resin crafts.

- Imitation glass resin crafts.

- Imitation bronze resin crafts.

- Imitation ceramic resin crafts.

- Imitation of mahogany resin crafts.

- Antique-style resin crafts.

Imitation jade resin crafts

Imitation colored glass resin crafts

Imitation bronze resin crafts

Imitation ceramic resin crafts

Imitation mahogany resin crafts

Antique-style resin crafts

(2) Resin Jewelry

- Resin ring.

- Resin bangle.

- Resin bracelet.

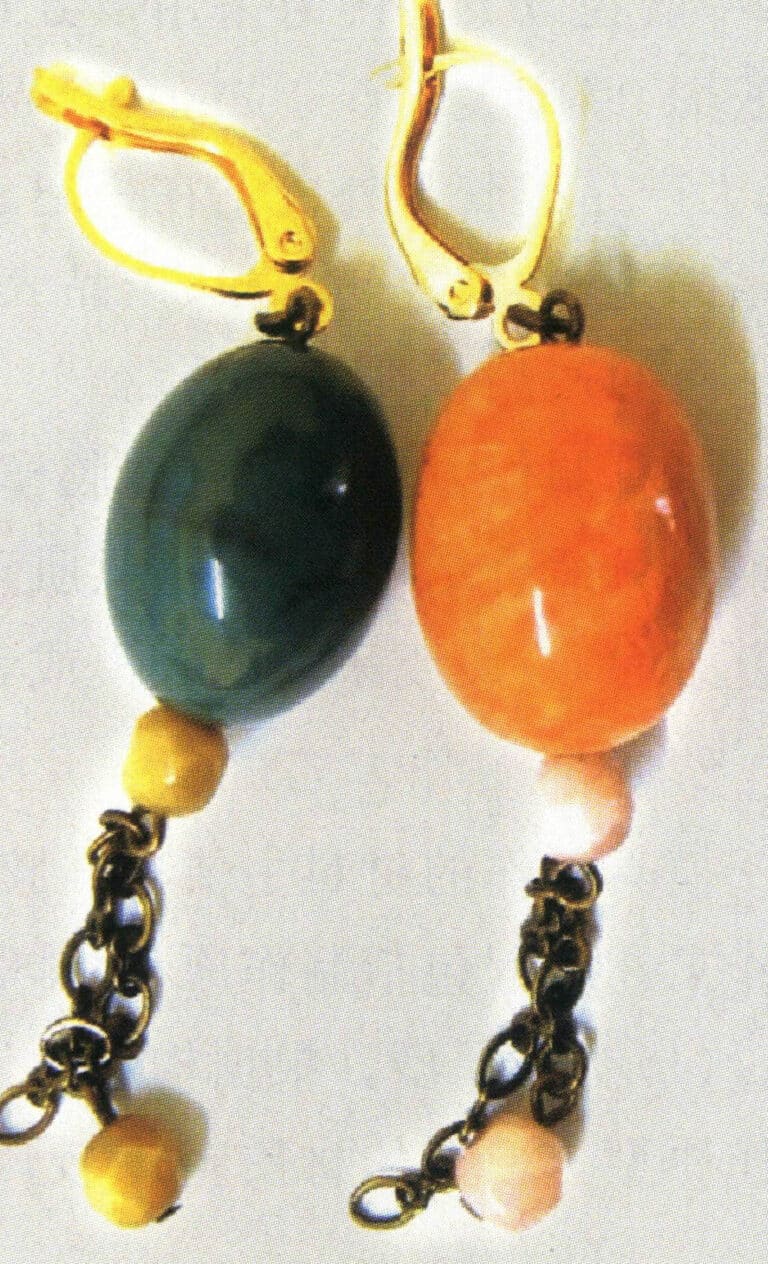

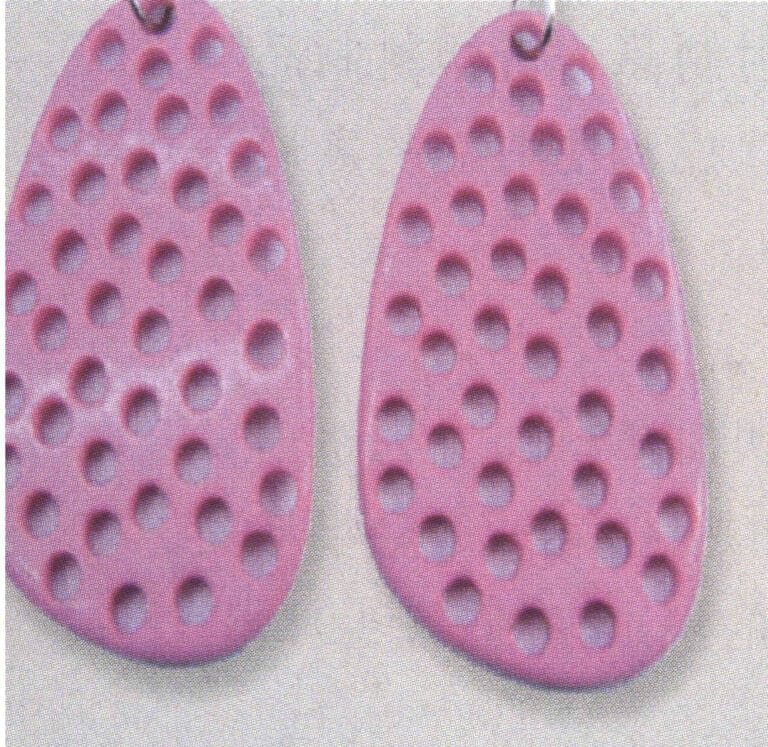

- Resin earrings.

- Resin accessories.

- Resin hairpin.

The typical examples of the above resin crafts and resin ornaments are as follows.

Resin rings

Bracciale in resina

Resin bracelt

Resin earrings

Resin accessories

Resin hairpin

3. The Production Process of Resin Craft Ornaments

3.1 Mold Making

The shape, size, surface smoothness, and ease of demolding of the mold directly affect the quality of the craft products, so mold-making is a very important production process.

(1) Mold Making Method

There are categories of mold making, such as split molds and encased molds. A split mold is a mold that divides the product into two or more pieces, generally used in the following situations: when the product structure is complex and difficult to de-mold; when the product is regular and flat, prone to deformation, and has a thickness greater than 5~6cm. A split mold typically consists of at least two pieces; for small products, the silicone and outer mold are separated, while the silicone and outer mold are bonded together for large products. An encased mold refers to a mold that consists of a single piece for the entire product. The conditions for using an encased mold are: it must be easy to de-mold; the product surface must be smooth; the handling of the mold line is difficult or even ineffective; and for products that are larger at the top and smaller at the bottom, as well as for hanging products.

The main mold-making methods include silicone molds, fiberglass silicone molds, gypsum silicone molds, and fiberglass molds. Fiberglass molds are only suitable for products with simple and regular structures, shallow textures, and easy demolding. Silicone or composite molds are generally used when the product structure is more complex.

(2) Mold Making Process Flow

The main materials for mold-making include silicone, silicone oil, hard oil, hardeners, gypsum, gauze, and fibers. The process of mold making includes steps such as creating a original model, typesetting, oil clay piling up, brushing the mold and pouring the mold, making liners, opening the mold, and finishing.

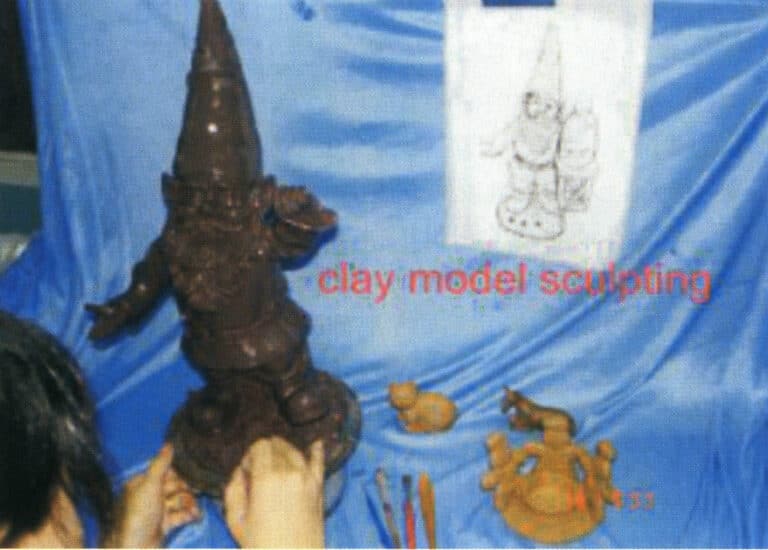

① Create a original model. Using appropriate materials and processes to create the original model based on the design plan and product structural characteristics. The range of materials for the original model is quite broad, including plastic, ceramics, wood, metal, resin, clay, etc. (Figure 9-1).

Regardless of the material used to make the original model, it must be inspected before molding to determine if there are any quality issues such as mold pulling, burning, air holes, deformation, or surface roughness. If the surface of the original model is rough or has defects, it must be repaired before making the mold; only a smooth-surfaced original model can produce a mold with clear patterns and a smooth surface, which will yield high-quality products. Damaged areas can be repaired with mold oil putty or prepared resin, and after drying, they should be polished clean with fine sandpaper of about 1000 grit and then sprayed with varnish. After drying, the mold can be made. If the original model is intact but has a rough surface, it can be carefully polished with fine sandpaper and a trimming gun.

Original models sometimes need to make accessories, and the positioning of the accessories must be appropriate, with good alignment of the interface positions. When it is impossible to mold deeply into the original model, modeling clay can be added, and areas prone to misalignment can add a protective layer of mold tape.

② Typesetting. Before typesetting, the original model structure should be analyzed, and the appropriate mold opening method should be determined before proceeding with typesetting. The size and angle of the base plate, pouring port, vent port, and parting line should be determined based on the original model dimensions. The base plate should be placed right, if not, it will affect the earthwork operation. When the position of the grouting port is inappropriate, it will affect the production of the white embryo grouting. To reduce its impact on the appearance of the process ornaments, it is generally chosen to set the grouting port in places that are not easily visible, such as the bottom or back. The size of the grouting port should be appropriate, with the premise that the slurry can reach all parts. The opening of the exhaust port should be selected based on the complexity of the product; generally, it is only opened when the slurry is not easily able to flow into place, mostly used in silicone molds for opening packages, while sheet molds generally do not require it.

No matter how many molds are opened for the original model, each mold must be made one at a time. After finishing one mold, the next one can be made, and so on. When making a mold, its reflective mold must also be created to expose the part to be made on top. To prevent the silicone from flowing everywhere, a border should be made around the exposed part of the original model using clay or wooden boards (use clay for smaller sizes and wooden boards first, followed by clay for larger sizes). The border must be larger than the original model to reserve space for fixing the position of the mold during assembly. However, if the border is too large, it will lead to silicone being wasted.

③ Oil clay piling up. It is important to choose the method and form of mold opening, considering the following aspects: first, the ease of mold removal; second, the mold line should be selected in a way that does not affect the overall effect of the product, especially in areas with patterns where the mold line should not pass; third, it should not affect product quality; fourth, minimize the workload of subsequent processes.

According to the type of the original model and production requirements, determine the mold line’s location and draw the mold line’s position on the original model with colored pens. Pile up oil clay along the mold line and cut the oil clay into rectangular or square shapes, with the thickness determining the thickness of the inner mold. Then, smooth the mold edges; otherwise, it will cause a multi-edge phenomenon.

④ Brushing and pouring the mold. Before brushing and pouring the mold, check if there are gaps between the oil clay and the original model, whether the surface of the oil clay is smooth and flat, and if positioning holes are properly made on the oil clay. After completing the above preparations, clean the original model with kerosene and apply petroleum jelly or spray a release agent. For smooth products, original models should be evenly coated with petroleum jelly using a clean cotton cloth and let it absorb the petroleum jelly for 30 minutes. Then, use a clean cotton cloth to polish the original model’s surface. For products with texture, apply the petroleum jelly evenly. After completing the first piece of the mold, clean the oil clay at the original model and mold line before making the other piece.

Determine whether to add silicone oil, apply gauze, add a top position, etc., based on the different types of the original model and production requirements, and determine the ratio of the hardener and the method of applying silicone.

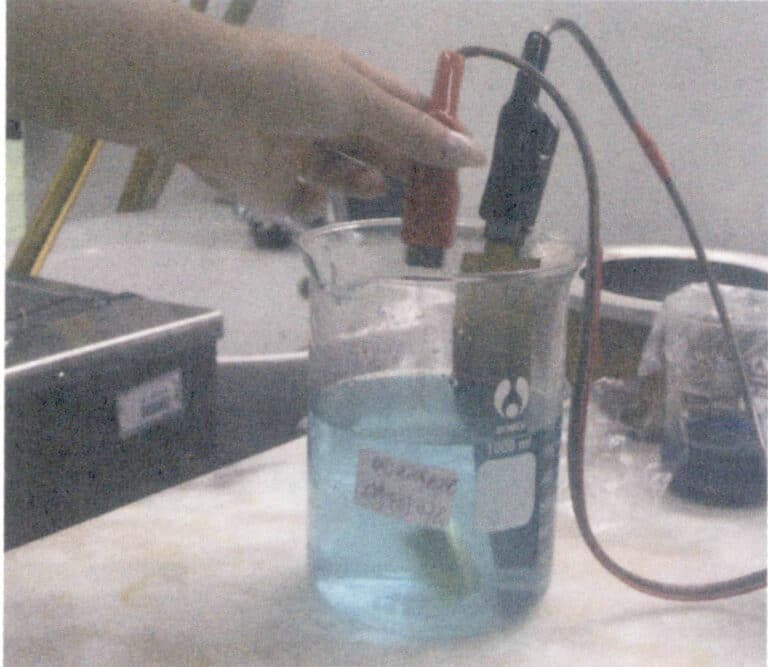

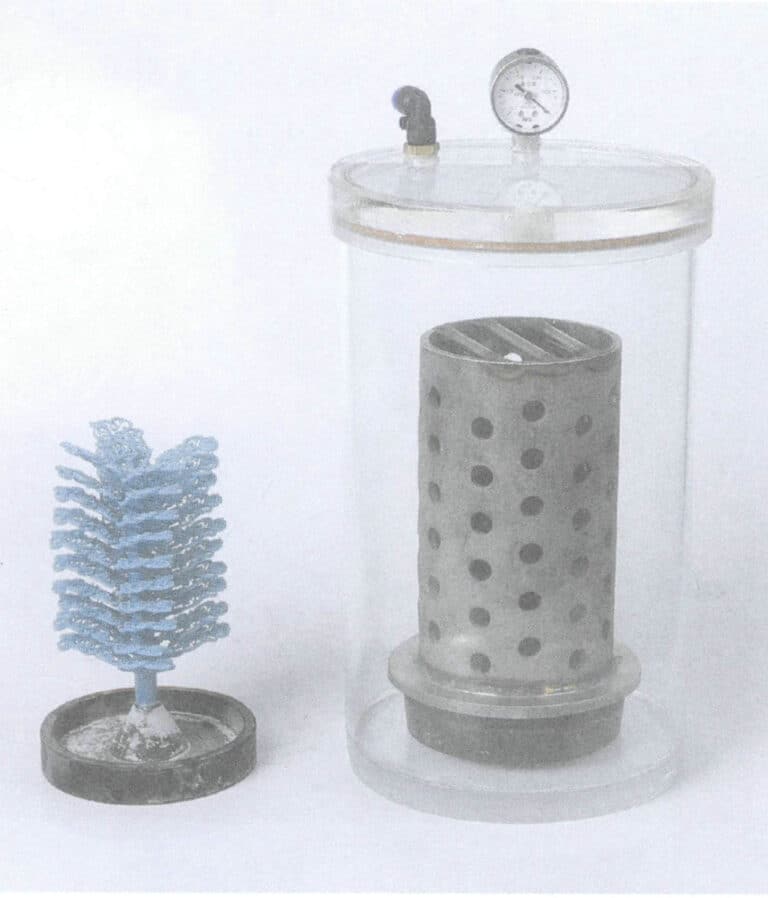

Silicone is proportionally modulated, and the temperature determines the amount of hardener; too much will reduce the mold’s shrinkage. The adjusted silicone must be vacuumed to avoid bubbles in the mold, which can affect the quality of the white product. There are generally two methods for applying silicone: one is the brushing method, where a brush is used to evenly apply silicone to the surface of the original model, ensuring that corners are adequately covered to avoid uneven thickness, mold burning, pulling issues, or easy aging of the mold; the second is the pouring method, where a border is first placed around the original model, and then silicone is poured into the border and left to harden, after which the border is removed.

⑤ Making liners. The liner can reduce the amount of silicone used and support the mold. Materials for making liners include gypsum, fiberglass, etc. When making a gypsum liner, use a border to enclose the clay board. It is important to control the thickness of the gypsum layer; if it is too thick, the gypsum will be too heavy and cause inconvenience in production, and if it is too thin, it is prone to cracking. Adjust the gypsum slurry and pour it into the border; remove the border and trim the gypsum liner after it solidifies. Each piece must be completed for crafts requiring multiple openings or molds. After finishing one part of the mold, the outer board and clay must be removed, and then the other parts can be molded by turning it over. The number of times to turn it over should be determined based on quality requirements; too many times can easily cause issues such as mold edges, large mold lines, and mold deformation.

The fiberglass liner can effectively reduce the weight of the mold, making work more convenient, and is therefore widely used. The manufacturing process is as follows: Apply a special release agent for fiberglass evenly on the original model’s surface three times, and wait for the release agent to dry before applying the next layer. For products with a smooth surface, wipe with a clean cotton cloth after the release agent has dried. Then, apply a thin layer of silicone (gel coat) on the surface, generally three layers, with each layer about 0.15~0.17mm. After the previous layer has dried, apply the next layer, with a curing time of 90 minutes for each layer at room temperature. The total thickness of the gel coat is controlled at about 0.5 mm. Layering can be done when the gel coat is completely cured and not sticky. The first layer uses surface felt, and a steel roller is used to press the layer to eliminate all bubbles; the thickening layer uses fiberglass cloth and unsaturated resin, generally based on the size of the mold and the thickness requirements is 8~15mm. The outer layer of the mold is reinforced with wooden blocks, primarily to prevent product deformation and to ensure that irregular molds can be placed steadily, facilitating production operations. When the frame structure is completely cured, the mold can be demolded. First, trim the edges of the mold neatly, then insert multiple release agents evenly into the fine seams of the mold, applying even force and tapping various parts with a rubber hammer, and finally, completely demoed. After demolding, check the mold for any defects; if there are defects, repairs are needed, and rough areas need to be polished. Then apply the release agent and secure it with screws, laying it flat on the ground or a storage rack.

⑥ Mold opening. Determine the mold opening position based on the mold’s size, structure, and production requirements, ensuring the original model can be smoothly removed. An improper mold opening position can lead to difficulties in production.

⑦ Adjustment. Due to factors such as technology and materials, bubbles and other issues may sometimes appear in the mold, directly affecting the white bad grouting operation and quality. Therefore, it is necessary to adjust the mold and fill the bubbles and use scissors to remove the excess edges.

3.2 Casting and Forming

After the silicone mold is made, the pouring and forming operation can be carried out. First, prepare the tools and materials for mixing the slurry and mix according to the ratio recommended by the resin brand. For small resin crafts, stone powder, color paste, or any other antique materials, such as imitation marble products, can be added to the resin using resin brand and marble powder; large resin crafts generally use hollow molds, which can be filled with resin waste. When mixing the slurry, weigh out the resin according to the mold size and the number of products to be made, and pour it into the mixing bucket; according to the ratio, add various auxiliary materials and fillers in a certain order to the resin. If the operating temperature is low, the resin can be heated to an appropriate viscosity range for easier operation; after fully stirring the mixture, add pigments according to the desired color. The amount of pigment can be adjusted based on the variety until the desired level is reached. When adding pigments, first dissolve the pigment in resin, stir evenly, and then pour it into the mixing bucket; after fully mixing, vacuum to remove most of the bubbles generated during stirring. When scooped up with a spoon, the prepared mixture should be thick enough to flow slowly.

After the slurry is prepared, pouring operations can be carried out. First, the mold must be properly handled, and the required inserts or cores must be installed. The inner surface of the mold should be cleaned thoroughly. When pouring, use a small spoon to slowly scoop the slurry from one side of the inner wall of the mold; do not pour it in directly. It should be poured in from the highest point to allow it to flow naturally, which can help push out air bubbles (Figure 9-2). Vacuuming can also reduce the likelihood of air holes in the finished product. Be careful not to let the slurry overflow the outer edge of the mold when pouring; if it spills over, it should be cleaned up immediately, or else it will requires further grinding and processing. After the slurry is injected into the mold, it is placed in an oven at a certain temperature or cured in a suitable environment. After a certain period, the slurry can solidify and take shape.

3.3 Surface Treatment of Craft Jewelry

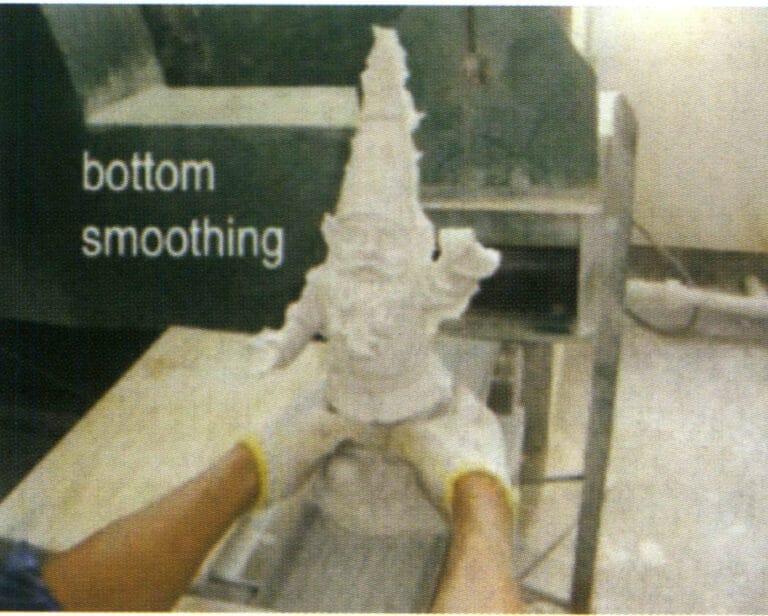

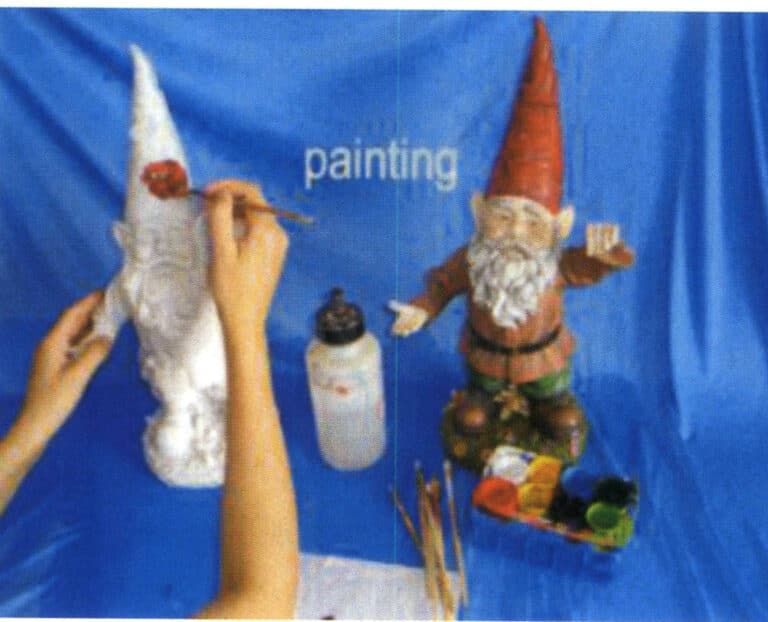

Figure 9-3 Polishing the base of resin crafts

Figure 9-4 Trimming of the raw blank

Figure 9-5 Repairing defects in the raw blank

Figure 9-6 Raw blank polishing

Figure 9-7 Raw blank cleaning

Figure 9-8 Coloring on the raw blank

4. Common Problems and Solutions in the Production of Resin Raw Blank

(1) Pore

In producing raw blank, for slender products with complex structures or smaller injection ports, air holes will likely occur when no exhaust holes are set in dead corners with greater vacuum resistance. The inner cavity of the air holes is clean; some are exposed to the product’s surface, and some appear after polishing, increasing the workload for patching. There are several methods to solve the air hole problem.

- Use a thinner resin or appropriately reduce the amount of filler added to prepare a less concentrated slurry, reducing the resistance to bubble escape and avoiding bubble retention in the product.

- Appropriately reduce the amount of red and white materials so that the initial curing time of the resin is longer, allowing enough time to evacuate the air from the mold cavity during vacuuming.

- Check the vacuum pump for any faults to ensure that the vacuum in the vacuum chamber can quickly reach -0.1MPa to achieve a good vacuum effect. Some craft production factories use a method of first vacuuming to -0.1MPa, then to -0.07MPa, and then vacuuming again to -0.1MPa, which also yields good results.

- For products with complex structures or smaller injection ports, the mold design should consider issues related to air holes and the design of the parting surface, corners, etc. Additional venting designs should be incorporated to achieve a good vacuum effect and reduce air hole problems.

(2) Oil hole, pinhole

In producing raw blank, holes appear under the product’s surface. When the hole is pierced, a liquid substance flows out, called an oil hole. If the holes are densely packed with tiny pores and a liquid substance present, it is called a pinhole.

Oil holes and pinholes are produced by the oils (to prevent the slurry from spraying when vacuuming) and thinners in the slurry. When these characteristics gather together, oil holes are formed. However, pinholes are produced when fewer oils and thinners do not gather together. This problem generally occurs in the cooler autumn and winter seasons; the slurry shows stratification after mixing. The methods to solve this problem are as follows.

- Under production conditions, use resins with higher concentrations and reduce the amount of filler added to alleviate the stratification of the slurry.

- Strictly control the added white mineral, engine, and other oils. Under conditions of no serious spraying, try to add as little oil as possible, generally below 5‰, and the less, the better.

- Pay attention to the moisture content of fillers such as stone powder, as moisture can cause the slurry to separate.

- Control the timing of adding oils, generally adding oils 15~20 minutes before the pulp production, and use after stirring evenly.

- Many layers appear, which generally easily produce oil holes and pinhole defects. This slurry should be used for products with lower requirements, and at the same time, the resin manufacturer should be contacted to adopt appropriate methods to resolve the issue.

(3) Stone Powder Appearance after Alkali Soaking

During the production of raw blank, when the product is soaked in alkali, there is a powdery substance inside its texture; this further affects product quality, and this problem is particularly likely to occur during the transition from autumn to winter and in winter. The reason is that the resin on the product’s surface has not been fully cured, and the prolonged soaking in alkali erodes the resin on the product’s surface, ultimately leaving the stone powder on the product’s surface. The methods to solve this problem are as follows.

- Strictly control the amount of curing agent. When the product has a seriously sticky surface, check whether the amount of curing agent added is sufficient. If it is not enough, increase the amount of curing agent, which is generally between 1.5%~2.5%. If the amount of curing agent is increased and the resin gels too quickly, leaving no time for operation, some slow-drying resin can be mixed in, or a slow-drying agent can be added. If the amount of curing agent is increased, the resin still dries slowly, and the surface is seriously sticky; check whether there is a problem with the curing agent or whether there is a problem with the filler and accelerator. In the cold winter, if the resin gels slowly, the ambient temperature can be increased, or the slurry can be heated in a water bath.

- Standardize the concentration of the alkaline solution and the soaking time in the alkaline solution. Good products can also experience this problem when soaked for a long time in a high-concentration alkaline solution. Generally, the pH value of the alkaline solution should be controlled between 11~12, and the soaking time should be strictly controlled as required.

- Try to avoid using low-concentration resin. Because the solid content of diluted resin is lower, its acid and alkali resistance after curing is poor, and it is easy to corrode the surface resin of the product when foaming with alkali.

(4) Deformation

In producing raw blanks, products with hanging parts are prone to bending and deformation issues. This is due to uneven internal stress generated by resin curing shrinkage within the product, ultimately leading to deformation. There are several methods to address this defect.

- Choose a resin with a lower shrinkage rate to avoid generating larger stresses that could cause the product to bend and deform.

- Appropriately reduce the amount of red and white materials to slow down the curing speed of the resin to reduce shrinkage while stacking the demolded products layer by layer to reduce bending deformation without damaging the shape and surface of the products.

- For products with large batches and high requirements, thermal insulation, and accelerated curing can be used to overcome deformation defects. The specific method is as follows: place the workpiece in an insulation box at an initial temperature of 30~40℃, stacking them layer by layer, with a suitable weight pressing down on the top, close the box door, maintain the temperature at 40℃ for 1 hour, then slowly raise the temperature to 60℃, maintain for 2 hours, then slowly raise the temperature to 80℃, maintain for 2 hours, and after allowing it to cool naturally and slowly, the product can be taken out. The above process parameters are reference values; the locations and magnitudes of internal stress will vary for different products, so the process parameter values will also differ. Small batch tests should be conducted first to determine the values.

- The filler can be increased if the product quality permits.

- Increase the reinforcement to prevent product deformation.

(5) Cracking

During the production of raw blanks, cracks may sometimes appear, generally in two situations: one is that cracks occur during the demolding process, which is mainly caused by slow post-curing of the resin or improper demolding; the other is that cracks appear after products demolding and being left for some time; this situation is rare but can easily occur in complex product structures.

During the resin curing process, there will be a phenomenon of volume shrinkage, and since resin curing is an exothermic process, there will also be thermal expansion and contraction. In both cases, this can cause significant internal stress in the cured resin products, leading to cracks in the thin parts of products with complex structures and significant dimensional changes. To solve this problem, efforts should be made in the following areas.

- Choose a resin with a higher concentration. Generally speaking, when the resin production formula is fixed, a higher resin concentration results in a higher solid content, increasing the product’s strength.

- Improve the operating process. Consider using resins with a slower curing speed to reduce internal stress in the products. Measures to prevent deformation can also be referenced: First, for hollow products, air holes should be reserved to avoid cracking due to high internal air pressure caused by temperature rise; products that require sealing at the bottom can be sealed only after the product has completely cured. Second, when opening the mold, appropriately add silicone oil to increase its elasticity and prevent damage to the product during demolding due to a hard mold. Third, reinforcements, such as iron wires, bamboo sticks, or fibers, should be placed in easily cracked areas to improve strength. Fourth, during product design, try to avoid sudden changes in dimensions and use smooth transitions at corners to avoid stress concentration.

- Try to make the grout uniform during grouting.

- Adding 10% soft resin to the formula can increase the toughness of the product.

- Increase the amount of filler appropriately while ensuring quality.

(6) Stratification

After adding the filler to the resin and stirring, let it sit for a while. A layer of transparent liquid appears on the surface of the mixing bucket, which is the diluent separating, referred to as stratification, also known as water separation. The solutions to this problem are as follows.

- The amount of substances that do not cross-link well with styrene monomer in resin production is large, causing the resin to easily delaminate.

- In pursuit of low viscosity, a large amount of diluents, such as styrene, is added, which can cause the resin slurry to easily separate into layers after the filler is mixed in. If the production cost of the raw blank allows, try to avoid using resins with excessively low viscosity.

- Adding white mineral oil, engine oil, and other oils to the slurry is one of the important reasons for resin delamination. When low-viscosity resin must be used in production, the amount of oil added should be strictly controlled, generally not exceeding 5‰ of the resin amount, and should be added within 15~20 minutes before the slurry is taken and used after thorough mixing, which will significantly reduce the stratification phenomenon.

- The moisture in the stone powder can directly cause the resin to delaminate. Damp stone powder will cause a large amount of styrene to separate from the resin after mixing while bubbles continue to rise in the mixing bucket. At this point, promptly replacing it with dry stone powder is necessary.

- The slurry should not be left for too long.

(7) Water Pattern

Water patterns can easily form during the plum rain season and in cooler temperatures. The reasons for their formation and solutions are as follows.

- The high humidity in the air causes air to enter the mold cavity during the resin curing and shrinkage process, which inhibits the resin’s curing on the product’s surface, resulting in watermarks and a sticky feeling on the product’s surface.

- Stone powder is damp. The moisture in the stone powder enters the resin, causing damage to the resin and hindering the process of resin molecular curing and cross-linking, resulting in water marks on the product’s surface. Severely damp stone powder will show layering after being mixed and left to stand for some time, leading to resin agglomeration.

- Poor quality of curing agents and accelerators. Due to the incomplete removal of low molecular weight substances, there are not enough free radicals generated in the cross-linking reaction to activate the unsaturated double bonds of the resin. At the same time, during the curing process, the exothermic reaction causes the low molecular weight substances to be expelled, resulting in watermarks.

- Insufficient curing agent dosage. The curing of the resin is completed due to the sufficient free radicals cross-linking with the unsaturated double bonds of the resin. Due to the insufficient curing agent, the generated free radicals are few, which cannot activate the unsaturated double bonds in large quantities, resulting in slow or incomplete curing, watermarks, and a sticky feeling.

- In the resin production process, materials with strong water absorption are used in large quantities, causing the resin to easily absorb moisture from the air and fillers, thereby affecting the resin curing process and creating watermarks on the surface of the products. In cases where product requirements are high, or shapes are complex, it is advisable to select high-quality resin to overcome or reduce watermark defects.

- When the temperature is low, the resin curing process is slow, resulting in the resin being relatively soft after curing, with watermarks on the product’s surface, making it difficult to de-mold and prone to damage. In the colder winter months, a hot water bath can be used to heat the resin, keeping the resin temperature at 30~40℃, which will improve the resin curing process.

- The new mold is damp, and moisture penetrates through the micropores of the silicone rubber, condensing on the surface of the blank and causing water marks. The new mold should be dried in an oven or sun-dried before use. Placing mold in the oven overnight is more effective in particularly humid weather.

Copywrite @ Sobling.Jewelry - Produttore di gioielli personalizzati, fabbrica di gioielli OEM e ODM

Section II Plastic Ornaments and Production Technology

1. Introduction to Ornaments used Plastic

1.1 The Properties of Plastic used in jewelry

Plastic used for accessories is a special application of engineering plastics, possessing general basic and certain unique properties. Plastic for accessories has the following advantages.

(1) Lightweight and high specific strength. Plastics are lightweight, with a general density of 0.9~2.3g/cm3, only about 1/8~1/4 steel and around 1/2 aluminum, while various foam plastics have even lower densities, approximately 0.01~0.5g/cm3. The strength calculated per unit mass is called specific strength, and some reinforced plastics have specific strengths close to or even exceeding that of steel. For example, the tensile strength of alloy steel is 160MPa, while glass fiber-reinforced plastics can reach 170~400Mpa.

(2) Excellent chemical stability. Plastics have better corrosion resistance to general acids, bases, salts, and fats than metals and some inorganic materials. In particular, the chemical corrosion resistance of polytetrafluoroethylene is even better than that of gold, and it can withstand the corrosion of strong corrosive electrolytes such as aqua regia, earning it the title of “king of plastics.”

(3) Good wear resistance. Most plastics have excellent wear resistance and self-lubricating properties. Many friction-resistant parts made from engineering plastics utilize these characteristics of plastics. When certain solid lubricants and fillers are added to wear-resistant plastics, their friction coefficient can be reduced, or their wear resistance can be further improved.

(4) Light transmission and protective performance. Most plastics can be used as transparent or translucent products, among which polystyrene and acrylic plastics are transparent like glass. The chemical name of organic glass is polymethyl methacrylate, which can be used as an aviation glass material. Plastic films such as polyvinyl chloride, polyethylene, and polypropylene have good light transmission properties. Plastics have various protective properties, so they are often used as protective packaging materials.

(5) Good decorative performance. Plastics can be made into transparent products and products in various bright and rich colors. They have a beautiful luster and durability. They can be made with advanced printing, embossing, electroplating, and light gold techniques to create products with various patterns, floral designs, and a three-dimensional, metallic feel. The decorative items have good self-lubricating properties, with smooth, glossy surfaces and clear patterns.

(6) Good processing performance. Various molding methods, such as molding, injection, and casting, can be used, and various machining processes, such as nailing, sawing, drilling, planing, welding, and bonding, can result in lower processing costs.

However, using plastic for accessories also has the following disadvantages.

(1) Easy aging. Plastics undergo a series of physical and chemical changes due to the effects of energy from the environment, such as air, sunlight, heat, ionizing radiation, and stress, as well as the action of chemical substances like oxygen, air, moisture, acids, bases, and salts, and biological factors like mold. These changes include molecular degradation (breaking of macromolecular chains, leading to reduced strength, elasticity, melting point, viscosity, etc.), cross-linking (causing polymers to become harder and more brittle), plasticizer migration, and stabilizer failure, resulting in phenomena such as hardening, brittleness, cracking, discoloration, and even destruction, leading to a loss of functionality, which is referred to as plastic aging. Plastic aging can be classified into several forms based on its mechanisms of action.

- Thermal aging. Thermal aging mainly occurs in plastics’ processing, production, and usage environments. It can be divided into anaerobic thermal aging and thermal oxidation. The former is also known as thermal cracking. It occurs under anaerobic high-temperature conditions, where macromolecular chains gradually or randomly depolymerize into monomers or break into smaller segments, and sometimes small molecular substances are removed, resulting in a decrease in the relative molecular mass of the plastic macromolecules and a sharp deterioration in material properties. The latter occurs under high-temperature oxygen-rich conditions, where oxygen acts on the free radicals of plastic macromolecules, triggering a chain reaction that leads to the breaking, decomposition, and performance reduction of the macromolecules.

- Photoaging. The C-H bond energy of and other bonds in the polymer chains of plastics is close to the energy corresponding to the ultraviolet spectrum, so under the action of ultraviolet light waves, the macromolecular chains can absorb energy and undergo degradation or cross-linking. In particular, under conditions of high oxygen or ozone, certain functional groups in the structure of plastic macromolecules are activated by ultraviolet light, which can undergo photochemical reactions with oxygen and ozone, causing the polymeric substances to decompose or cross-link, leading to a deterioration of material properties.

- Aging due to other reasons. Plastics can also undergo aging due to acids, bases, salts, biological factors, and strong electric fields. Generally, plastics have strong resistance to chemical corrosion, but under certain special conditions, plastics may experience damage from the surface to the interior, either quickly or slowly, known as chemical medium aging; certain organisms can secrete specific acidic substances or biological enzymes that decompose plastic polymers or turn them into food for organisms, leading to plastic degradation, referred to as biological aging; under the influence of strong electric fields, plastic polymers can experience a decrease in insulation due to thermal ion radiation and chemical decomposition, resulting in electrical breakdown damage, a phenomenon known as corona aging.

Therefore, aging is the main form of durability failure in plastics and a significant weakness of plastics. The ability of plastics to resist aging is called anti-aging properties, atmospheric stability, or weather resistance. The anti-aging properties of plastics depend on their composition, structure, nature, and characteristics of environmental degradation factors, as well as the type of resin and the properties of additives. Generally, anti-aging agents such as antioxidants, ultraviolet absorbers, and thermal stabilizers can be added to slow down the aging of plastics.

(2) Flammable. Plastics are not only combustible but also produce a large amount of smoke when burned and can even generate toxic gases. However, by improving the formulation, such as adding flame retardants and inorganic fillers, self-extinguishing, difficult-to-burn, or even non-combustible products can be made. Nevertheless, their fire resistance is still inferior to that of inorganic materials, and caution should be exercised during use.

(3) Poor heat resistance. Plastics generally have issues with deformation when heated and may even decompose, so attention should be paid to their temperature limits during use.

(4) Low stiffness. Plastic is a viscoelastic material with a low elastic modulus, only that of 1/10~1/20 steel, and it is prone to creep under long-term loading, meaning that deformation increases over time, and the higher the temperature, the faster the deformation increases. However, composite materials such as fiber-reinforced plastics and certain high-performance engineering plastics have significantly improved strength, exceeding steel’s.

1.2 Classification of Plastic used in jewelry

There is currently no exact classification for plastics, which are usually classified in the following ways.

(1) According to the physical and chemical properties of plastics, they can be divided into the following two types.

Thermoplastic: A type of plastic that can be repeatedly heated to soften and cooled to harden within a specific temperature range. Examples include polyethylene plastic and polyvinyl chloride plastic.

Thermosetting plastics: Plastics that can cure into non-melting and non-soluble materials under heat or other conditions. Such as phenolic plastics, epoxy plastics, etc.

(2) It can be divided into five types according to the plastic molding method.

Molded plastic: refers to resin mixtures used for molding, such as general thermosetting plastics.

Laminated plastic: refers to fiber fabric impregnated with resin, which can be combined through layering and hot pressing to form a cohesive material.

Injection, extrusion, and blow molding plastics: generally refer to thermosetting resin mixture that can melt and flow at the temperature of the barrel and quickly harden in the mold. Like general thermoplastic materials.

Casting plastic: is a liquid resin mixture that can harden into a certain shape when poured into a mold under no or slight pressure, such as MC nylon.

Reaction injection molding plastic: generally refers to liquid raw materials that are pressurized and injected into a mold cavity, allowing them to react and cure to produce finished products, such as polyurethane.

(3) It can be divided into three types according to plastic semi-finished and finished products.

Molding powder (plastic powder): is mainly made from thermosetting resins (such as phenolic) and fillers, fully mixed, pressed, and crushed, such as phenolic plastic powder.

Reinforced plastics: refers to a type of plastic that has added enhanced materials, resulting in significantly improved mechanical properties compared to the original resin.

Foam plastic: A type of plastic that contains countless micropores throughout.

1.3 Composition of Plastic used in jewelry

Plastics can be divided into single-component plastics and multi-component plastics based on the amount of their constituent components. Single-component plastics contain only synthetic resins, such as “acrylic glass,” made from a synthetic resin called polymethyl methacrylate. Multi-component plastics contain synthetic resins, fillers, plasticizers, curing agents, colorants, stabilizers, and other additives. Plastics used for ornaments generally belong to the category of multi-component plastics.

(1) Resin. Resin is the basic plastic component, accounting for 30%~70% in multi-component plastics, while accounting for nearly 100% in single-component plastics, the resin content is almost the same. Resin mainly serves as a binder for plastics, binding fillers, and other components. Therefore, resin is the most important factor determining the properties of plastics.

(2) Fillers. Also known as additives or fillers, they are materials added to plastic products to improve certain properties, such as increasing the strength, hardness, and heat resistance of plastic products and reducing costs. Fillers account for 40%~70% in the composition of plastics. Common fillers include wood powder, talc powder, diatomaceous earth, limestone powder, aluminum powder, carbon black, mica, molybdenum disulfide, asbestos, and glass fiber. Among them, fiber fillers can enhance the structural strength of plastics; asbestos fillers can improve the heat resistance of plastics; mica fillers can enhance the electrical insulation of plastics; graphite and disulfide fillers can improve the friction and wear resistance of plastics, etc. In addition, since fillers are generally cheaper than synthetic resins, the addition of fillers can reduce the cost of plastics.

(3) Plasticizers. To improve the plasticity of plastics during processing and the flexibility and elasticity of the products, a small amount of plasticizer must be added during the production and processing of plastic products. Plasticizers usually have low vapor pressure and are non-volatile organic compounds with low molecular weight, mainly esters and ketones. Commonly used ones include dibutyl phthalate, dioctyl phthalate, dioctyl phosphate, dimethyl phthalate, adipate, and benzophenone.

(4) Curing agent (hardener, maturation agent). Its main function is to cross-link the linear structure of certain synthetic resins into a three-dimensional structure, thereby giving the resin thermosetting properties. Different types of resins should use different types of curing agents. Hexamethylenetetramine is commonly used for phenolic resins; amines, phenolic resins, and polymers are commonly used for epoxy resins, and peroxides are commonly used for polyester resins, etc.

(5) Stabilizers. Many plastic products undergo premature degradation, oxidative chain scission, cross-linking, and other phenomena during molding, processing, and use due to heat, light, and oxygen, which deteriorate the material’s performance. To stabilize the quality of plastic products and extend their service life, various stabilizers are usually added, such as antioxidants (phenolic compounds, etc.), light shielding agents (carbon black, etc.), ultraviolet absorbers (2-hydroxybenzophenone, salicylic acid phenyl ester, etc.), and thermal stabilizers (aluminum stearate, tribasic lead phosphate, etc.).

(6) Colorants. To give plastic products specific colors and gloss, colorants can be added. Colorants are divided into dyes and pigments based on their solubility in the coloring medium. Dyes are organic compounds that can dissolve in the resin being colored; pigments are generally inorganic compounds that do not dissolve in the coloring medium. Their coloring ability comes from their highly dispersed particles in the dyed medium, which have a significantly different refractive index from the matrix, absorbing some light while reflecting another part, creating a visual color effect. Pigments provide coloring to plastics and serve as fillers and stabilizers.

(7) According to the needs of plastic use and molding processing for accessories, lubricants, antistatic agents, and antifungal agents are sometimes added.

2. Examples of Plastic jewelry

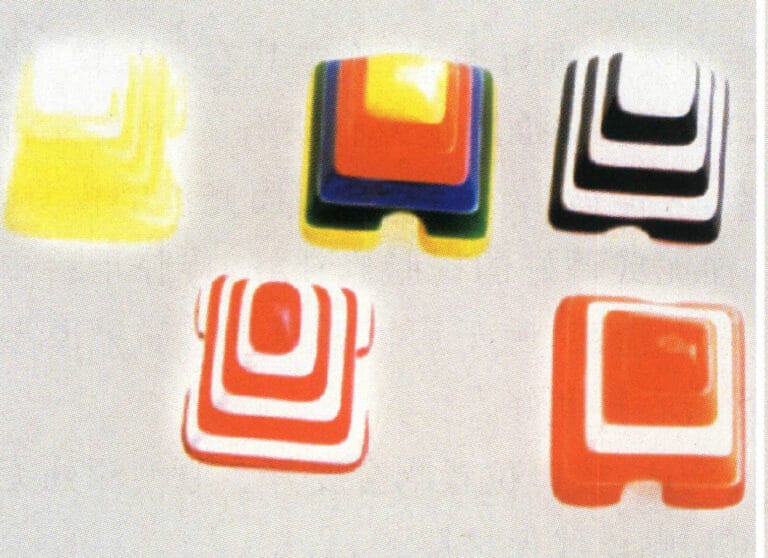

Plastic ring

Plastic bracelet

Plastic-inlaid bangle

Plastic braided rope bracelet

Vacuum coated plastic necklace

Plastic pendant

Plastic earrings

Plastic hair clips with diamonds

3. Plastic Jewelry Production Process

The plastic industry includes three production systems: producing plastic raw materials (resins or semi-finished products and additives), producing plastic products, and manufacturing plastic molding machinery (including molds). Process ornaments mainly refer to the molding processing of plastics.

Plastic molding processing is an engineering technology that involves various processes to transform plastic into plastic products. During the transformation process, one or several situations may occur, such as the rheology of polymers and changes in physical and chemical properties. There are many plastic molding methods, mainly divided into three categories: one-time molding technology, secondary molding technology, and secondary processing technology.

3.1 One-time Molding Technology for Plastic Ornaments

The one-time molding of plastic ornaments refers to the technology of making products or semi-finished products of the desired shape and size from various forms of plastic raw materials, such as powder, granules, fibers, and scraps, as well as resin solutions or pastes. There are many molding methods, and injection, extrusion, compression, and casting methods are currently widely used in production.

(1) Injection Molding

Plastic injection molding is carried out in molds divided into convex and concave molds according to the molding direction; each has its strengths. The former produces products with a strong three-dimensional effect but is more difficult to manufacture; the latter is simpler to produce and has a wider range of applications, but the three-dimensional effect is not very strong. There are four types based on material: metal molds, wooden molds, fiberglass molds, and gypsum molds. Each of these four has its advantages: metal molds are highly flexible, have a wide range of applications, have high precision, and have long service life, but they are also expensive. Wooden molds are flexible, have a wide range of applications, and are cost-effective, but their service life is short. Fiberglass molds combine the advantages of the first two types but are difficult to manufacture. Gypsum molds are low-cost, have high precision, and have a decent service life, but they have limitations on material thickness (generally not exceeding 1 mm). Therefore, it is important to choose the right mold based on the product’s manufacturing process and the materials’ performance.

Injection molding is mainly applied to thermoplastic and highly fluid thermosetting plastics, which can form geometrically complex shapes, precise dimensions, and plastic ornaments with various inserts. Currently, injection products account for about 30% of the total amount of plastic products. In recent years, the development and application of new injection technologies, such as reaction injection, two-color injection, and foam injection, have provided a broader application prospect for injection molding.

(2) Extrusion Molding

Extrusion molding, also known as extrusion forming or extrusion molding, first involves adding granular or powdered plastic into the hopper of an extruder (similar to an injection molding machine). The rotating screw of the extruder then transports the material to the heating zone, where it gradually melts into a viscous flow state. Under the action of the extrusion system, the plastic melt is shaped into a continuous profile with the desired cross-sectional shape through an extrusion die (head) with a specific shape.

The basic molding process includes drying materials, molding, shaping, and cooling products, pulling and curling (or cutting) products, and sometimes post-processing.

The internal structure of extruded plastic parts is uniform and dense, with relatively stable and accurate dimensions. Moreover, their geometric shapes are simple, and the cross-sectional shapes remain unchanged, which makes the mold structure simpler and easier to manufacture and maintain while also allowing for continuous forming, high productivity, and low costs; almost all thermoplastic plastics and a small number of thermosetting plastics can be processed by extrusion molding. Plastic extrusion products include pipes, sheets, rods, films, and various special-shaped materials. Currently, about 50% of all thermoplastic products are produced by extrusion molding. In addition, extrusion molding can also be used for coloring, pelletizing, and blending modification of plastics.

(3) Compression Molding

Compression molding refers to a forming technology that primarily relies on external pressure to achieve the shaping of the molded material in a single forming process. Compression molding is the most traditional plastic processing method widely used for thermosetting plastics. Compression molding can be divided into mold pressing and laminating depending on the material’s characteristics and the processing equipment’s features and technology.

Molding is the process of placing powdered, granular, flake, or fibrous thermosetting plastic materials into a mold, then closing the mold and applying heat and pressure to shape and harden the material in the mold, and finally removing the plastic part from the mold. The equipment used includes hydraulic presses, spinning machines, etc.

Laminated molding involves using sheet materials such as paper, cotton fabric, and glass fabric, which are impregnated in resin, then stacked one by one to the desired thickness, placed in a laminating machine, heated, and pressed. After some time, the resin cures and bonds together to form a shape. The equipment for pressing and molding is simple (the main equipment is a hydraulic press), and the process is mature, making it one of the earliest plastic molding methods. It does not require runners and gates, has minimal material loss, has a wide range of product dimensions, and can press larger products. Still, the molding cycle is long, production efficiency is low, and it isn’t easy to achieve modernized production. Products with complex shapes, dense reinforcing ribs, and many metal inserts are difficult to mold.

(4) Casting and Forming

Casting technology includes static casting, centrifugal casting, cast film casting, and rotational molding.

Static casting is a molding method in which liquid resin monomers or prepolymers are injected into a large mold cavity under normal pressure, and products are formed through polymerization and curing. Static casting can produce various profiles and products, with acrylic being a typical cast product.

Centrifugal casting adds raw materials into a high-speed rotating mold, where the centrifugal force causes the materials to fill the mold, harden, and take shape as products. Centrifugal casting can produce large-diameter pipe products and hollow products.

Cast film casting is the process of dissolving thermoplastic plastic in a solvent to prepare a solution of a certain concentration, which is then spread at a certain speed on a continuously rotating substrate (usually a seamless stainless steel strip). By heating, the solvent evaporates, causing the plastic to harden into a film, which is then peeled off from the substrate to obtain the product.

Rotational molding is adding plastic into a mold, continuously rotating along two perpendicular axes while heated. The plastic inside the mold gradually and evenly coats the cavity surface under gravity and heat, melting and adhering to it, forming the desired shape, and obtaining the product after cooling and solidifying.

3.2 Secondary Molding Technology of Plastics

Secondary molding of plastics refers to the technology of reprocessing plastic semi-finished products (such as profiles or blanks) under certain conditions to obtain the final shape of the product. Currently, several secondary molding technologies are used in production, including hollow blow molding, thermoforming, and biaxial stretching of films.

(1) Blow Molding

Blow molding is a method for manufacturing hollow plastic products, which uses gas pressure to expand a semi-molten parison closed in the mold cavity into a hollow product, a secondary molding technique. Hollow blow molding is divided into injection and extrusion blow molding.

Injection blow molding is a process where plastic is first formed into a bottomed preform using injection molding, and then the blank is transferred into a blow molding mold for blow molding. The main process involves the injection machine injecting molten plastic into the mold under high pressure, forming a tubular bottomed preform with suitable dimensions, shape, and quality on the core mold. The core mold is a tubular object with one end closed, allowing compressed air to enter from the open end and escape through multiple small holes in the wall of the tube. After the preform is formed, the injection mold is opened, and the hot preform left on the core mold is transferred into the blow molding mold. After closing the mold, compressed air of 0.2~0.7Mpa is blown into the core channel, causing the preform to immediately expand and detach from the core mold, tightly adhering to the cavity wall of the blow molding mold, and then cooling and setting under air pressure. Finally, the mold is opened to remove the finished product.

The extrusion blow molding process involves the direct extrusion of the pipe waste from the extruder, which hangs in a pre-separated cavity installed directly below the machine head; when the hanging pipe waste reaches the specified length, the mold is immediately closed, and the pipe waste is cut off at the mold’s notch; compressed air is introduced through small holes in the mold parting surface to inflate the pipe waste tightly against the mold wall to form the shape; pressure is maintained, and after the product cools and solidifies in the cavity, the mold is opened to remove the product.

Many thermoplastic materials are used for hollow blow molding, with the most commonly used raw materials being polyethylene, polypropylene, polyvinyl chloride, and thermoplastic polyester, which are often used to mold various liquid packaging containers.

(2) Thermoforming

Thermoforming is a molding method that involves heating thermoplastic sheets to soften them and then using appropriate molds or fixtures under gas, liquid, or mechanical pressure to shape them into products. Thermoforming is particularly suitable for manufacturing products with thin walls and large surface areas. There are many methods for plastic thermoforming, mainly divided into two categories: compression molding and differential pressure molding.

Compression molding is a forming method that uses a single mold (positive or negative) or a matched mold, utilizing external mechanical pressure or self-weight to shape sheets into various products. It is different from the one-time processing molding. This method is suitable for all thermoplastic materials.

Differential pressure molding is a molding method that uses a single mold (positive or negative) or a matched mold or can be done without a mold, where a heated soft plastic sheet is pressed against the mold surface under the action of gas differential pressure, and various products are formed after cooling. Differential pressure forming can be divided into vacuum and air pressure molding.

(3) Bi-directional Stretching Molding

A bi-directional stretching process is specifically performed above the glass transition temperature to reorient the molecules of thermoplastic films or sheets. The stretching orientation must be carried out between the glass transition temperature and the melting point of the polymer, and the mechanical properties of the film or monofilament in the stretching direction are greatly improved after oriented stretching and rapid cooling to room temperature.

3.3 Secondary Processing Technology of Plastics

Secondary processing of plastics is a technology that changes their shape, size, and surface state to become final products while maintaining the solid state of the one-time or secondary molded products. The secondary processing techniques used in production are diverse but can generally be divided into three categories: machining, connection processing, and finishing processing.

(1) Machining

Many mechanical processing methods can be used for plastics, such as cutting and machining.

Cutting refers to the mechanical processing method of cutting off and severing the excess parts of plastic sheets, rods, pipes, and other profiles and molded products. Common cutting methods for plastics include punching, sawing, and shearing. Electric heating wires, lasers, ultrasound, and high-pressure liquid flows are sometimes used to cut plastics.

Machining is the process of machining a workpiece using a tool. Common techniques include polishing, milling, drilling, and threading.

Laser processing is increasingly applied in the secondary processing of plastics. Lasers can be used for cutting, drilling, engraving, and welding, with drilling and cutting being the most common. Laser processing of plastics has advantages such as high efficiency and low cost. Most plastics can be easily processed with lasers; however, thermosetting plastics like phenolic and epoxy are unsuitable for laser processing.

(2) Connection Processing

The purpose of the connection is to fix the plastic parts together and to connect plastic parts with non-plastic parts to form complex components. Based on the principles of plastic connection processing, it can be divided into mechanical connection, hot melt connection, and adhesive bonding.

Mechanical connection is a method of connecting and fixing using mechanical means such as threaded connections, riveting, snap connections, and press-fit connections. It is suitable for all plastic parts, especially the connection between plastic and metal parts.

Hot melt connection, also known as the welding method, connects two parts by locally heating and melting the joint, then pressing them together, and after cooling and solidifying, they are firmly connected. Common methods include external heat contact welding, hot air welding, friction welding, induction welding, ultrasonic welding, high-frequency welding, and plasma welding. Welding is only suitable for thermoplastic plastics.

Adhesion is a method of fixing the relative position between connected parts by utilizing the cohesive force between the same type of materials or the adhesive force between different materials, also known as bonding. The bonding between plastic products and between plastic products and other material products relies on organic solvents and adhesives. Organic solvent bonding is only suitable for connecting the same amorphous plastic products with good solubility. Still, the strength of the joint area is generally relatively low, so the application of plastic connection processing is limited. The bonding between the vast majority of plastic products and between plastic products and other material products is achieved through adhesives. Bonding achieved through adhesives is called adhesive bonding. Adhesives can be natural or synthetic, with synthetic polymer adhesives, such as polyvinyl alcohol and epoxy resin, commonly used. The adhesive bonding method is suitable for both thermoplastic and thermosetting plastics.

(3) Finishing Processing

The purpose of finishing processing is to beautify the surface of plastic ornaments, usually including the following four aspects.

- Mechanical finishing. That is, using tools such as files, grinding, and polishing to remove burrs, sharp edges, correct dimensions, etc.

- Coating. This includes applying paint to surfaces, using solvents to enhance brightness, covering product surfaces with patterned films, etc.

- Applying color. This includes painting, printing, and hot stamping. Hot stamping involves transferring the colored aluminum tube layer (or other patterned film layer) from the light printing film onto the ornament under heat and pressure.

- Metal plating. Includes vacuum coating, electroplating, and chemical silver plating, etc.

Section III Acrylic Ornaments and Production Process

1. Introduction to Acrylic Materials

Acrylics refers to a general term for chemical substances of acrylic acid (esters) and methacrylic acid (esters), commonly known as “specially treated organic glass.” The polymerization of acrylic acid was discovered by scientists in 1872, and it wasn’t until 1937 that the industrial manufacturing of methacrylic acid esters was successfully developed, allowing for large-scale production.

Acrylic has many excellent properties, reflected in the following aspects.

- Acrylic has high transparency and light transmittance reaching 92%, making it the best high polymer transparent material currently available, known as “plastic crystal.” Moreover, it can maintain high transparency even at a certain thickness. In addition, this material also has good surface hardness and surface gloss.

- It is lightweight, with a density of about 1.15~1.19g/cm3, half the weight of ordinary glass, and is 43% of aluminum.

- Acrylic has outstanding weather, aging, and acid-base resistance, especially outdoors, making it the crown among other plastics. Acrylic can transmit 73% ultraviolet rays, while ordinary glass can only transmit 0.6% ultraviolet rays. Under ultraviolet light exposure, acrylic has better stability compared to polycarbonate.

- The relative molecular mass of acrylic material is about 2 million. It is a long-chain polymer compound, and the molecular chains are very flexible, so it has high mechanical strength and good toughness, is not easily damaged, and its tensile and impact resistance is 7~18 times higher than that of ordinary glass. Acrylic is not easily shattered when subjected to thermal shock, while glass it is prone to breakage during rapid cooling and heating. Especially for some acrylics that have been heated and stretched, the molecular chain segments are arranged very orderly, significantly improving the material’s toughness. When a hook is nailed into this acrylic, it does not produce cracks even if the nail penetrates.

- Acrylic materials have good processing performance, which can be formed by thermal molding (including compression molding, blow molding, and vacuum forming) as well as by mechanical processing methods such as bonding, sawing, planing, drilling, engraving, grinding, screen printing, and sandblasting. The melting point of acrylic is about 240~250℃, much lower than that of glass, making thermal molding processing relatively easy; it can be bent and pressed into various acrylic products after heating. Mechanically controlled cutting and engraving with microcomputers greatly improve processing accuracy and allow the creation of patterns and shapes that traditional methods cannot achieve. In addition, acrylic sheets can be cut and engraved with lasers to produce uniquely designed products.

- Acrylic has good printability and playability. Using appropriate printing (such as screen printing) and spraying techniques, acrylic products can achieve ideal surface decoration effects with vibrant colors and high brightness. They can meet the individual pursuit of different tastes.

- Acrylic is highly repairable, easy to maintain, and clean. Rainwater can naturally be cleaned or wiped with soap and a soft cloth; it has a soft texture and does not feel icy and biting in winter.

However, acrylic materials also have some obvious shortcomings. They have room temperature creep characteristics, leading to stress cracking as the load increases and time goes on. Acrylic is hygroscopic and must be dried before processing. In addition, acrylic has low surface hardness and is prone to scratching, which requires modification treatment.

Many low-quality and cheap “acrylics” are on the market, including ordinary organic boards or composite boards (also known as sandwich boards). Ordinary organic boards are made from ordinary acrylic cracking materials mixed with pigments, resulting in low surface hardness, easy fading, and poor polishing after being sanded with fine sand. Composite boards have only a very thin layer of acrylic on the surface, with ABS plastic in the middle, making them prone to delamination due to thermal expansion and contraction during use. The authenticity of acrylic can be identified from the subtle color differences and polishing effects on the cross-section of the board.

2. Categories of Acrylic jewelry

Acrylic bracelet

Acrylic-inlaid ring

Acrylic rings

Acrylic pendants

Acrylic bangle

Acrylic necklaces

Acrylic earrings

Acrylic jewelry display rack

3. The Production Process of Acrylic jewelry

3.1 The Craft Characteristics of Acrylic

(1) Acrylic contains polar side methyl groups, has a noticeable hygroscopicity, and the water absorption rate is generally 0.3%~0.4%. It must be dried before molding, and the drying conditions are 80~85℃ for 4~5 hours.

(2) Acrylic exhibits significant non-Newtonian fluid characteristics within the temperature range of molding processing, with the melting viscosity decreasing significantly as the shear rate increases, and the melt viscosity is also very sensitive to temperature changes. Therefore, for the molding processing of acrylic, increasing the molding pressure and temperature can significantly reduce the melt viscosity, achieving better fluidity.

(3) The temperature at which acrylic begins to flow is approximately 160℃, and the temperature at which it starts to decompose is above 270℃, with a relatively wide processing temperature range.

(4) The acrylic melt viscosity is relatively high, and the cooling rate is also fast, making it easy for the products to generate internal stress. Therefore, strict control of process conditions is required during molding, and post-processing is also needed after the products are formed.

(5) Acrylic is an amorphous polymer with a low shrinkage rate and a limited range of variation, generally about 0.5%~0.8%, which is beneficial for forming plastic parts with high dimensional accuracy.

(6) The cutting performance of acrylic is very good, and its profiles can be easily machined into various required dimensions.

3.2 Acrylic Jewelry forming Methods

Acrylic has good surface hardness and gloss, great processability, and can be made into various ornaments. Its forming methods include casting, injection forming, extrusion forming, and thermoforming, which are consistent with the production processes of plastic ornaments.

(1) Casting Forming

Casting forming is used to shape acrylic sheets, rods, and other profiles, that is, to form profiles using the bulk polymerization method. After casting forming, the products need to undergo post-processing, with the post-processing conditions being heat preservation at 60℃ for 2 hours and heat preservation at 120℃ for 2 hours.

(2) Injection Forming

Injection forming uses granules made from suspension polymerization, and forming is carried out on ordinary plunger or screw injection forming machines. Table 9-1 shows process conditions for acrylic injection forming using two machines. Injection molded products also require post-processing to eliminate internal stress, which is carried out in a hot air circulation drying oven at 70~80℃. The processing time depends on the thickness of the product, generally requiring about 4 hours.

Table 9-1 Process Parameters for Acrylic Injection Forming

| Process parameters | Screw injection forming machine | Plunger injection forming machine |

|---|---|---|

| Temperature at the rear of the material tube /℃ | 180 ~ 200 | 180 ~ 200 |

| Temperature in the middle of the material tube/℃ | 190 ~ 230 | |

| Temperature at the front of the material tube/℃ | 180 ~ 210 | 210 ~ 240 |

| Nozzle temperature/℃ | 180 ~ 210 | 210 ~ 240 |

| Mold temperature/℃ | 40 ~ 80 | 40 ~ 80 |

| Injection pressure/MPa | 80 ~ 120 | 80 ~ 130 |

| Holding pressure/MPa | 40 ~ 60 | 40 ~ 60 |

| Screw rotation speed/rpm | 20 ~ 30 |

(3) Extrusion Forming