What Is Wax Setting Casting And How Does It Transform Jewelry Making?

The Process, Requirements, Common Issues, and Solutions of Wax Setting Casting

Wax setting for princess cut gemstones

Tartalomjegyzék

Section I Advantages of the Wax Setting Casting Process

(1) Save time and improve production efficiency. For example, when setting square gemstones, a skilled setter can only set 100 pieces a day, while using wax setting technology, an employee with short-term training can set 200 to 300 pieces.

(2) Reduce labor costs. Traditional metal setting operations require a considerable level of skill from the setting worker, meaning that jewelry factories must invest heavily in skilled labor for the setting department, significantly increasing labor costs. This is especially true for low-value jewelry items, where labor costs account for a high proportion of the total cost. Using wax setting technology can greatly reduce labor costs.

(3) Reduced metal loss. In traditional metal setting techniques, it is often necessary to adjust the setting position, resulting in relatively high metal loss. In wax setting, adjustments are made to the wax model, thus greatly reducing metal loss.

(4) Wax setting operations only require simple tools, which can significantly reduce the investment and loss costs of grinding tools such as needles and flex shaft grinders.

(5) as a new setting method, the wax setting casting process provides the technical conditions for innovation in jewelry design. Some jewelry design products can only be manufactured through wax setting casting.

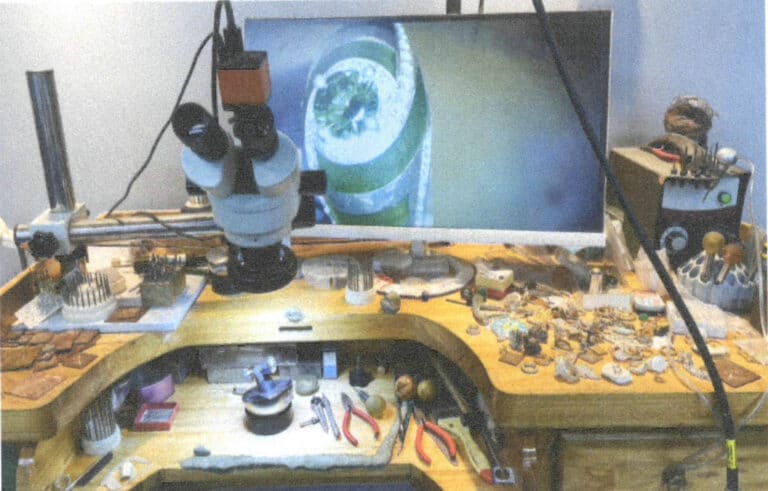

Section II The main tools used in the wax setting casting process and their functions

Table 5-2 Main tools used in the lost wax casting process and their functions

| Tool name | Function |

|---|---|

| Chuck | Fasten steel needle & chisel |

| Electric soldering iron | (1) Round the prong tip, fill sunken pits; () Repair the wax model's damaged area |

| Brush | Clean the wax powder |

| Surgical knife | (1) Trim the wax surface; (2) Remove the wax powder |

| Tweezers | Stone clamp, place the stone |

| Flat chisel | (1) Used for chisel pits and edges; (2) Trimming the wax surface; (3) Cleaning the wax powder; (4) place the stone |

| Flying Disc | Hold the prongs during claw and inverted pin settings |

| Ball Bur | (1) Create base for claw setting; (2) Create cavities for bezel setting |

| Ring gauge | After the wax setting completed, put the ring on the gauge to check the roundness of the ring. |

| Oil stone | Used for smoothing the shovel |

| Sewing needle | Remove the tip and grind it into a flat shovel. |

| Steel needle | Clean the wax setting base |

Section III Wax-setting casting process flow

1. Master mold production

Since the gemstones need to be left in the plaster mold during wax setting, they must be fixed to prevent displacement or loosening during investment, burnout, and casting. Therefore, the mold must support the gemstones in at least two positions. Generally, a hole is grinded at the bottom of the setting, and the hole should be as large as possible, ideally more than half the diameter of the gemstone, to avoid metal covering the surface at the bottom of the gemstone or the gemstone being unstable after casting.

Due to the shrinkage that occurs during the rubber molding, wax mold making, and metal casting processes, which can significantly affect the embedded gemstones, it is essential to consider all shrinkage factors when designing and making the original version, namely rubber mold shrinkage, wax mold shrinkage, and metal shrinkage. Special attention should be paid to closely arranged gemstones, ensuring an appropriate gap between them to accommodate wax setting casting. If the gap is too small, the gemstones may be pressed against each other and break during casting shrinkage; if the gap is too large, metal may get trapped between the gemstones or affect aesthetics. The size of the reserved gap can be calculated based on the casting shrinkage rate. The specific size should be adjusted according to the number and size of the gemstones, and various thickness gauges can be used to assist the operator in judgment.

To reduce the risk of gemstones fracturing or discoloring due to thermal shock from the molten metal, the thickness of the setting area of the master mold has special requirements. Suppose there is too much or too thick metal in this area. In that case, the thermal capacity during pouring will be large, and the thermal effect on the gemstones will be stronger, increasing the risk of fracturing and discoloration. Therefore, from the perspective of gemstone safety, the direct contact area between the setting area and the gemstones should be minimized, and the thickness of the metal in the setting area should be reduced as much as possible. However, this brings another issue regarding the safety of the setting; if the metal in the setting area is too weak, it will reduce the strength of the setting structure, increasing the chances of the gemstones loosening or falling out.

2. Make sprue line

In a wax setting, to protect the gemstones, casting is generally done at a lower temperature than the conventional casting temperature, and during the casting process, the gemstones will have a chilling effect on the molten metal. Therefore, when designing the pouring system, it is essential to fully consider the speed of the molten metal filling the cavity and the compensation for shrinkage. Typically, larger sprue cup or risers than conventional methods are used, which helps fill and compensate the molten metal, avoiding underfilling or shrinkage defects in the gemstone setting area.

When making the sprue line, consider placing it on the wax model edge near the gemstone area. For some pieces with multiple gemstones, multiple sprue lines may be needed to ensure that the molten metal supplies heat to the gemstone area. Be careful not to let the molten metal directly hit over the gemstones to avoid displacing them.

3. Making the Rubber Mold

Different rubbers have varying shrinkage rates, elasticity, and replication capabilities. Before making the master mold, it is important to understand the shrinkage rate of the rubber mold being used, and it is advisable to use high-quality organic rubber. When cutting the rubber mold to remove the master mold, try to hide the parting line as much as possible to avoid direct passage or contact with the gemstone surface. The parting line can turn into a flash, and direct contact with the gemstone may cause it to crack after casting. Generally, the inner parting line can be placed at the tip of the setting, avoiding the gemstone. In contrast, the outer parting line can be set at the edges of the master mold, reducing the cleaning workload and enhancing aesthetics. Additionally, when cutting the rubber mold, ensure the wax model is easily removed without deformation. While making the rubber mold, ensure the wax model has appropriate venting to reduce defects during wax injection and add some venting grooves if necessary. Regularly check for any deformation or damage during the rubber mold use.

4. Wax Mold Making

5. Gemstone Preparing

6. Setting Preparation

Before setting the gemstone, careful and thorough Preparation must be done, including observing the gemstone, arranging it, digging the setting base, and Test setting base it.

(1) Observing the gemstone and the wax mold. First, based on the order’s technical requirements, observe the shape and specifications of the gemstone. Next, check whether the wax mold matches the order and the gemstone to be set and whether the quality and quantity of the gemstones are appropriate.

(2) Arranging the gemstone. Place the gemstone at the setting position, checking whether the gemstone fits the specifications of the setting position, whether the length of the prongs is appropriate, and whether the depth of the setting base matches.

(3) Carve the setting base. Install the flat chisel and steel needle on the double-headed clamp, hold the wax model steady with the left hand, and use the steel needle with the right hand to carve the setting base from left to right according to the shape of the setting (the thickness of the setting base to the wax surface is 0.5 mm)

(4) Test setting base. Test setting base uses the gemstone to measure the setting position after digging the setting base. Without defects, it can enter the gemstone setting.

7. Setting Gemstones

Setting gemstones has various forms of expression and methods of operation. Based on production practice experience, several methods are introduced.

(1) Prong setting. Hold the wax mold steady with the left hand, and with the right hand, use a tweezers to pick up the gemstone, placing the gemstone at the setting position (Figure 5-32).

Place the gemstone in the setting base, and check the height of the gemstone in the setting. If the gemstone surface is too high, use a ball bur to lower the setting base slightly or use a flat chisel to grind it down; if the gemstone surface is too low, use an electric soldering iron with wax to build up the setting. Clean the wax powder off the mold with a flat chisel and a brush. If the prongs are too long, trim them with scissors so they are slightly higher than the gemstone surface; if the prongs are too short, use an electric soldering iron to add wax to raise the tips (Figure 5-33).

Figure 5-32 Wax Setting Position

Figure 5-33 Pointing Prongs

In a prong setting, whether the prongs are long or short, use an electric soldering iron to round the tips and ensure they attach the gemstone. The prongs should be straight, not crooked, and of uniform size. The bottom of the setting must be pierced; otherwise, the finished product may make the gemstone opaque (dark) . When setting the gemstone, try to separate the gemstones by thickness and use a ball bur or electric soldering iron to adjust the height of the setting, ensuring that after setting, the gemstone surface is flat and at the appropriate height.

(2) Bezel Setting and Cup Setting. Hold the wax mold steady with your left hand, and with your right hand, use a flat chisel to pick up the gemstone, placing the gemstone onto the setting position. If the gemstone is larger than the setting, use an appropriate ball bur to adjust the setting base to match the size of the gemstone; the thickness of the gemstone should determine the depth of the setting. Generally, after setting, the gemstone surface should be 0.4 mm lower than the wax surface. After adjusting the setting, clean the wax powder from the setting with a brush, then use a flat chisel put the gemstone into the setting, ensuring the gemstone is stable, and use an electric soldering iron to seal the edges with wax, making sure the wax attach to the gemstone and rounding the inner edge smoothly.

(3) Channel setting (round gemstones, square gemstones, princess cut) . According to the shape and size of the gemstones, a flat chisel is used to create setting bases at the setting position on the wax model, with the setting base height from the wax surface being about 0.5 mm. Note that the width of the pave edges on both sides must be consistent; one side cannot be wide and the other narrow; otherwise, one side may not cover the edge of the gemstone while the other side obscures the gemstone’s face. It is important to ensure that the heights of the setting bases on both sides are consistent to avoid slanting after the gemstone is set. When setting multiple gemstones in the same row, additional cross bar supports should be added to reinforce the setting, and care must be taken not to break the support of the wax model while grinding; otherwise, the fixed size of the setting will be lost. If the setting bases are grinded too large at once, use a soldering iron to apply wax to seal it back to its original state, then regrind the setting bases.

After the setting bases are grinded, use tweezers to pick up the gemstone, place one side of the gemstone into the setting base, and then press down the other side with the flat chisel to stabilize the gemstone. When setting multiple gemstones, special attention must be paid to controlling the gaps between the gemstones, with specific dimensions determined by the size of the gemstones, alloy type, casting process conditions, etc. If the gaps are too large, the gemstones on the jewelry will also leave larger gaps; if the gaps are too small, it may cause the gemstones to crack after casting (pouring) . (Figure 5-34) .

Wax Setting Video

8. Wax model repairing and trimming

9. Planting wax trees

When planting wax trees, the size of the casting tree should be determined based on the size of the steel casting flask and the type of casting equipment. When connecting the wax mold to the central main pouring channel, ensure a sufficient angle; generally, the wax mold should be angled outward at 45 degrees, which helps the molten metal flow smoothly into the mold cavity. When using hot wax repair tools, be careful not to touch the wax models or let the wax liquid drip onto the gemstone, which will cause the gemstone on the casting to be covered with metal.

Note that in centrifugal casting, when the height of the wax tree exceeds 150 mm, the pressure of the molten metal in the top area may sometimes cause some metal flash around the gemstone. Therefore, it is necessary to control the height of the wax tree appropriately or plant no wax-settings models in the top two layers and only start planting wax-settings models since the third row. Conversely, do not plant the wax model too close to the bottom of the tree or near the pouring cup, as the filling pressure of the molten metal is low in this area, which may lead to incomplete filling.

After planting the wax tree, it can be soaked in a wetting agent or anti-static liquid and dried before pouring the slurry. This can prevent bubbles from adhering to the wax and reduce the surface tension on the wax tree.

10. Investment

To prevent gemstones from discoloring during burnout and casting, special treatment of the casting powder is required, usually by adding boric acid to the casting powder, which helps prevent the burning and discoloration of gemstones during burnout and casting. Generally, for 100 g of casting powder, add 2.5-4 g grams of boric acid powder and 40-42 mL of water. Since the setting speed of plaster increases after adding boric acid, it usually only takes 6-7 minutes; it is important to control the speed of the entire operation process to ensure that the slurry has enough vacuum time to remove bubbles stuck to the wax model. Any bubbles in the setting bottom or nearby areas will form difficult-to-remove metal beads on the casting. A small amount of liquid detergent can be added to the slurry to improve its wetting properties and avoid bubble entrapment. Additionally, care should be taken not to displace the gemstone during pouring.

There are now casting powders specifically for wax casting available on the market. When using these casting powders, follow the usage recommendations from the powder manufacturer, such as the water-to-powder ratio, mixing time, vacuum time, and setting time. After pouring, let the mold sit for 1-2 hours before proceeding with the dewaxing and firing.

Copywrite @ Sobling.Jewelry - Egyedi ékszergyártó, OEM és ODM ékszergyár

11. Dewaxing and burnout

Both steam dewaxing and dry dewaxing can be used in wax casting. Still, the key is to thoroughly remove all wax residues before casting, as carbon residues can cause defects in metal casting and affect the quality of the castings. The time for steam dewaxing should be limited to 1 hour; if it takes too long, it can easily cause water stain or damage to the mold on the castings. After steam dewaxing, immediately transfer to the burnout furnace for burnout.

Due to the risk of burning, discoloration, or cracking when gemstones are subjected to high temperatures, thermal shock, and thermal stress, a lower burnout temperature is generally used in wax casting compared to conventional casting to protect the gemstones. Therefore, establishing a reasonable burnout system for the molds is key to wax-setting casting. Some factories use steam dewaxing, which is helpful for wax removal. To ensure burnout effectiveness, the following points should be noted for burnout wax-casting molds.

(1) The burnout furnace must control the temperature accurately to avoid overheating, which can cause burning or discoloration of the gemstones.

(2) The molds should be heated uniformly to reduce the risk of gemstone cracking due to thermal shock and thermal stress.

(3) There should be sufficient air circulation in the burnout furnace to ensure that the residual carbon from the wax is completely burned off.

During burnout, setting a heat preservation platform at certain temperature ranges helps prevent gemstones from cracking. The burnout temperature can vary based on the type and quality of the gemstone, and the mold temperature during pouring should also be determined according to the material, casting structure, and other factors.

12. Pouring

Wax-setting jewelry casting can use either vacuum casting or centrifugal casting methods. However, vacuum casting is generally more common in wax-setting casting because it reduces the risk of gemstone displacement due to turbulence during the casting process. Nevertheless, good results can also be achieved with centrifugal casting, especially for smaller jewelry, with the key being the control method. When using centrifugal casting, attention should be paid to the tree’s height and the selection of rotation speed, as excessive pressure from the molten metal may cause the metal to flash around the gemstone, leading to cracking or increased difficulty in cleaning.

Since the molten metal comes into direct contact with the gemstone, the gemstone experiences a significant thermal shock instantaneously; the higher the pouring temperature, the greater the thermal shock. Therefore, it is important to control the number of jewelry on the tree while ensuring proper forming to lower the temperature of the molten metal as much as possible. Alloys used for wax-setting casting should have a lower melting point, better fluidity, and oxidation resistance. The casting equipment used for wax-setting casting should ideally allow for precise temperature control, ensuring consistent and stable quality of the castings.

13. Cooling and removing the mold

14. Polishing

Section IV Requirements for Wax-setting Casting

1. Requirements for Gemstones in Wax-setting Casting

An important indicator for measuring the effectiveness of the wax-setting casting process is the stability of the gemstones. After wax-setting casting, the gemstones should not exhibit discoloration, cracking, or breaking issues. During the wax¬-setting casting process, gemstones must withstand high-temperature burnout and the thermal shock from the high-temperature molten metal during pouring. Therefore, gemstones must endure relatively high temperatures and have a certain capacity to withstand uneven heating and cooling. This imposes specific requirements on the type and quality of gemstones used. Using gemstones with cracks or those sensitive to temperature and thermal shock may lead to cracking after wax-setting casting; similarly, gemstones that have undergone heat treatment to change color may negatively affect their appearance and color after wax-setting casting. Additionally, in this complex process, there are many influencing factors, and the impact of any single factor may cause the gemstones to crack or alter their appearance. Thus, the wax-setting casting process always carries some risks.

By categorizing the applicability of various commonly used gemstones to the wax-setting process, gemstones can generally be divided into two main categories: those suitable for wax-setting and those not suitable for wax-setting.

(1) Gemstones suitable for wax-setting casting.

If the quality of the gemstone is good and the casting process parameters are correctly controlled, these gemstones can achieve good results after wax-setting. Such gemstones include gemstones, rubies, sapphires, garnets, peridots, cubic zirconia, etc.

(2) Gemstones not suitable for wax-setting casting.

This mainly includes the following three types:

① Gemstones with internal cracks, cleavage, or a large number of inclusions are likely to crack or break after enduring high temperatures and thermal shock or may change color during the casting process due to inclusions (milky or frosted appearance) . Therefore, gemstones of this quality are unsuitable for wax-setting casting, such as opals, which have many internal cracks, and other low-quality gemstones often have these issues.

② Gemstones that cannot withstand high temperatures or change color at high temperatures, including amethyst, bicolor tourmaline, citrine, etc. Some gemstones that have been artificially treated to improve color may change or fade after heating. Emeralds have poor heat resistance, especially to uneven heating, which is also unsuitable for the wax-setting casting process.

③ Gemstones that will burn at high temperatures, such as pearls, amber, coral, and turquoise, will burn at high temperatures, causing the surface of the gemstone to become rough and the interior to show slight cloudiness. Thus, they cannot be used in the wax-setting casting process.

2. Requirements for jewelry alloys in wax casting

Compared to conventional lost wax casting processes, wax setting casting generally reduces the burnout temperature, and to minimize the thermal shock of the molten metal to the gemstones, a lower pouring temperature should be used whenever possible. Therefore, the alloys used for wax setting casting should have a lower melting point, better fluidity, and oxidation resistance. The jewelry alloys commonly used for wax setting casting are as follows.

(1) K yellow metal alloy.

Generally speaking, K yellow metal alloys have a lower melting point and better casting performance, usually achieving a good wax setting effect, such as the widely used 8KY, 9KY, 10KY and 14KY,18KY alloys (Figure 5¬-35). The higher purity, the higher the alloy’s melting point, which has corresponding requirements for the wax setting process, equipment, etc. The centrifugal casting method is more suitable for high-purity metal alloys than vacuum casting. This is because the mold temperature used in vacuum casting is higher, and the temperature system formed with the molten metal is too high for gemstones. Centrifugal casting can lower the mold temperature and reduce the risk of damaging the gemstones. Experiments have shown that 20KY and 22 KY metal alloys can also be used for wax setting.

(2) K white metal alloy.

The market demand for K platinum is very high, such as 10KW、 14KW、 18KW. Much of K white metal is used in set jewelry, making the wax casting process suitable for producing this type of alloy of significant practical importance. However, the bleaching elements currently used for K white metal alloys are mainly Ni and Pd. Due to their high melting points, the casting temperature of K white metal alloys is higher, and the solidification speed is faster. Therefore, when performing wax casting with K white metal alloys, gemstones are more susceptible to thermal shock, leading to potential issues, and the casting metal can also encounter problems. The wax casting process reduces the maximum firing temperature, which may leave wax residues in the mold. The reaction between the alloy and these residues can cause gas holes in the casting.

Additionally, in the wax-setting gemstone area, the rapid cooling effect of the gemstones can easily block the feeding channels, leading to shrinkage cavities in the casting. Furthermore, after wax casting, the mold requires a longer time for natural cooling, which extends the stay time between 260-430℃, causing aging hardening effects on Ni-containing alloys, resulting in higher hardness. Many types of feeding are used for K white metal alloys, each with its advantages and disadvantages.

The melting point of metal is relatively low, it has good fluidity, and its casting performance and recyclability are quite good, making it advantageous for wax casting. Experiments show that excellent wax casting results can be achieved by selecting suitable casting alloys and strictly adhering to process requirements during operation (Figure 5-36).

(3) K Red Metal Alloy.

Generally, it is advisable to avoid using pink or red K metal alloys for wax casting, especially 18K pink or 18K red. This is because after pouring, the cooling time of the mold is long, which can cause an ordered phase transformation in the cast piece, leading to cracks and brittleness on the surface of the cast piece.

(4) Silver Alloy.

Silver alloys have a lower melting point and better casting performance, making the results of wax casting easier to guarantee. Cubic zirconia (CZ) and various inexpensive synthetic gemstones are typically used (Figure 5-37) . To achieve good results in wax-casting silver alloy jewelry, it is advisable to select a filler with good oxidation resistance, which can significantly reduce the porosity of the cast piece and minimize the formation of oxide patterns.

Figure 5-36 Wax-cast diamond 18KW metal alloy ring

Figure 5-37 Wax-cast CZ 925 silver alloy ring

Section V Common Issues and Solutions in Wax Casting

Table 5-3 Analysis of Common Problems, Causes, and Countermeasures in Wax Casting

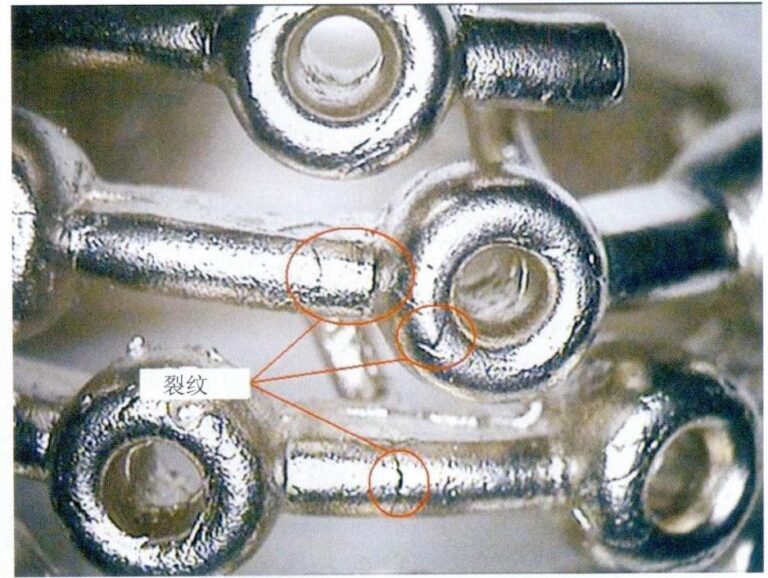

| Common problems | Sample Images | Okok | Improved methods |

|---|---|---|---|

| The gem cracks |

|

(1) The quality of the gem is problematic or not suitable for wax inlay casting; (2) The shrinkage rate of the master model is incorrect; (3) The gaps between the gems are too small or in contact with each other during inlaying; (4) The heating rate during roasting is too fast; (5) The pouring temperature is too high; (6) The shrinkage rate of the alloy is too large | (1) Use higher quality gems suitable for wax inlay casting; (2) Consider the total shrinkage of rubber molds, wax molds, and metal; (3) Distribute the gems reasonably to ensure uniform and sufficient gaps; (4) Control the heating rate during roasting; (5) Appropriately lower the metal temperature; (6) Choose suitable alloys |

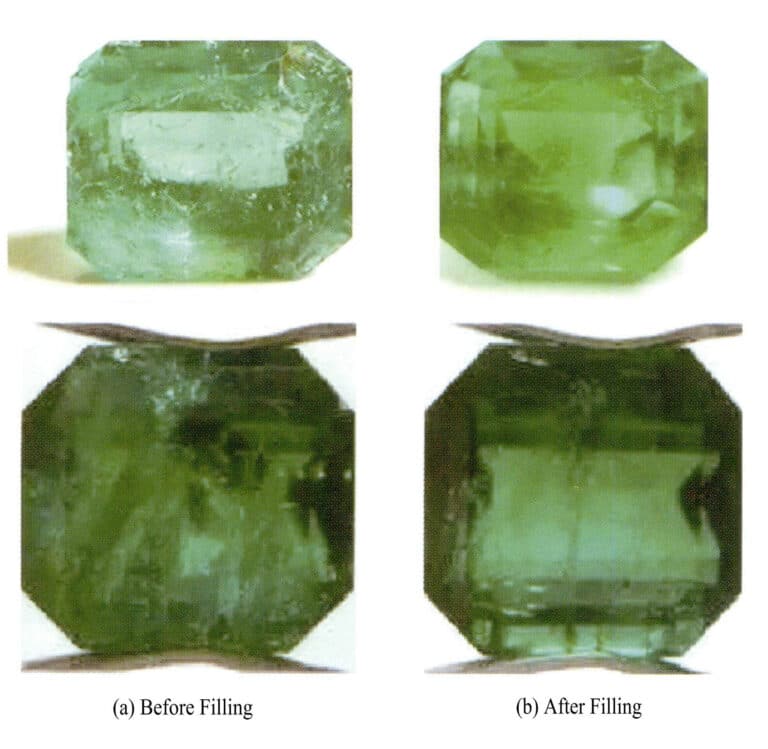

| The gem changes color |

|

(1) The gem is not suitable for wax inlay casting; (2) The gem has been artificially treated; (3) The casting temperature is too high; (4) The metal casting temperature is too high | (1) Do not use gemstones such as amethyst, citrine, or blue topaz; (2) use unoptimized, untreated gemstones; (3) lower the roasting temperature and the pouring temperature of the mold, add protective agents to the casting powder; (4) lower the metal casting temperature |

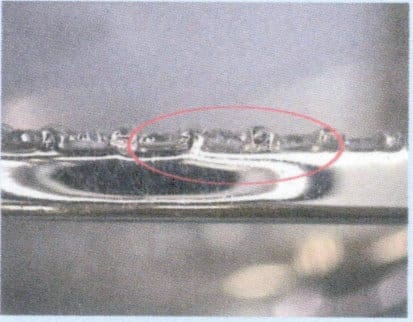

| Metal between the gemstones |

|

(1) The shrinkage left by the master mold is too large, resulting in excessive gaps between the gemstones; (2) the dimensions of the gemstones are not suitable; (3) the distribution of the gemstones is uneven; (4) the metal temperature is too high | (1) Correctly select the shrinkage amount of the master mold; (2) choose gemstones of appropriate size; (3) evenly distribute the gemstones to ensure suitable gaps; (4) lower the pouring temperature |

| Gemstones fallen off |

|

(1) The pre-setting holes at the bottom of the master model are not suitable; (2) The gate is not large enough or positioned incorrectly; (3) The wax mold was not checked before setting the stone; (4) The gemstone is not securely set in the wax mold; (5) The size of the gemstone is not suitable; (6) The metal casting temperature is too low. | (1) Correct the pre-setting holes of the master model; (2) Increase the size of the gate or open another gate to improve metal filling capability; (3) Carefully check the wax mold, especially the pre-setting hole area; (4) Securely set the gemstone in the wax mold, paying attention to the firmness of the gemstone; (5) Use gemstones of appropriate size; (6) If necessary, appropriately raise the temperature of the molten metal to obtain a complete casting. |

| The gemstone is uneven. |

|

(1) The quality of the master model is poor, and the setting position is uneven; (2) The gemstone was not placed evenly when set into the wax mold; (3) The wax mold is deformed; (4) The size of the gemstone is irregular; (5) The wax mold was subjected to external vibrations during transportation and operation. | (1) Ensure the setting position is even when making the master model; (2) The gemstone should be placed evenly when set into the wax mold; (3) Pay attention to check the wax mold, and correct any deformations; (4) The size of the gemstone should be regular; (5) Be careful not to vibrate the wax mold during operation |