3D Printing Technology Used In Jewelry Production

Contemporary data-based molding technology

Introduction:

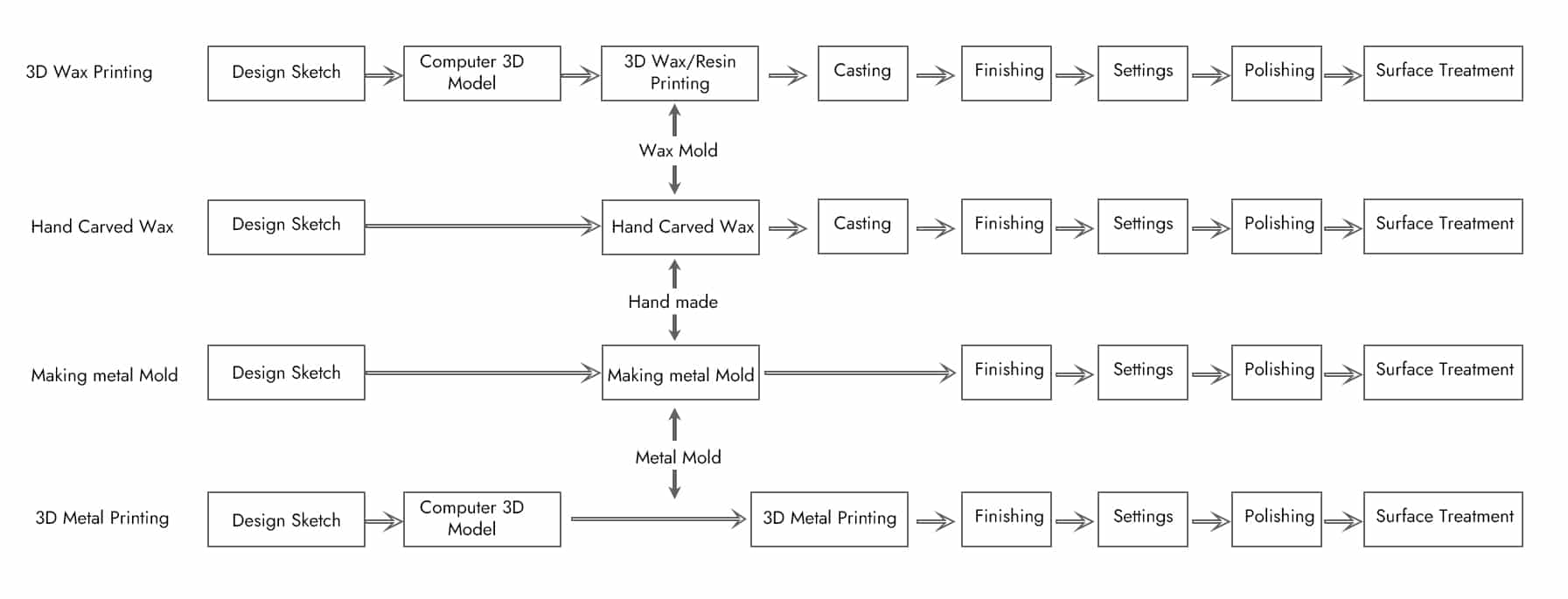

The standard operational methods of contemporary forming and processing technology can be divided into two main categories: additive and subtractive. The representative of the additive method is 3D printing technology, while the representative of the subtractive method is CNC numerical control engraving technology. These two types of data-driven forming technologies are also frequently used in the design and processing of jewelry.

SLA 3D SLA technology controls 3D printers

Table of Contents

Section Ⅰ 3D Printing Technology

3D printing originated in the United States in the late 19th century. In the mid-1980s, rapid prototyping technology (abbreviated as RP) gradually developed, and 3D printing technology is a collective term for a series of rapid prototyping technologies. This technology only requires the direct import of CAD model data of the product design to quickly manufacture molds, models, or even finished products, thus significantly shortening the product development cycle, reducing costs, and improving quality. To date, 3D printing technology has developed a wide range of applications, covering various sectors of society, such as technology, architecture, industry, medicine, food, and art design. From spacecraft to cake snacks, 3D printing technology can be seen everywhere, and the jewelry industry is no exception. After the development of jewelry software matured and integrated with 3D printing technology, it opened another door for jewelry design and production. Jewelry software makes design more accessible to operate, modify, present visually, and control costs, while combined with 3D printing technology, it can quickly convert to produce 1:1 jewelry finished products, minimizing the consumption of human and material resources in jewelry design and production, achieving twice the result with half the effort.

Georg Jensen X Zaha Hadid series jewelry

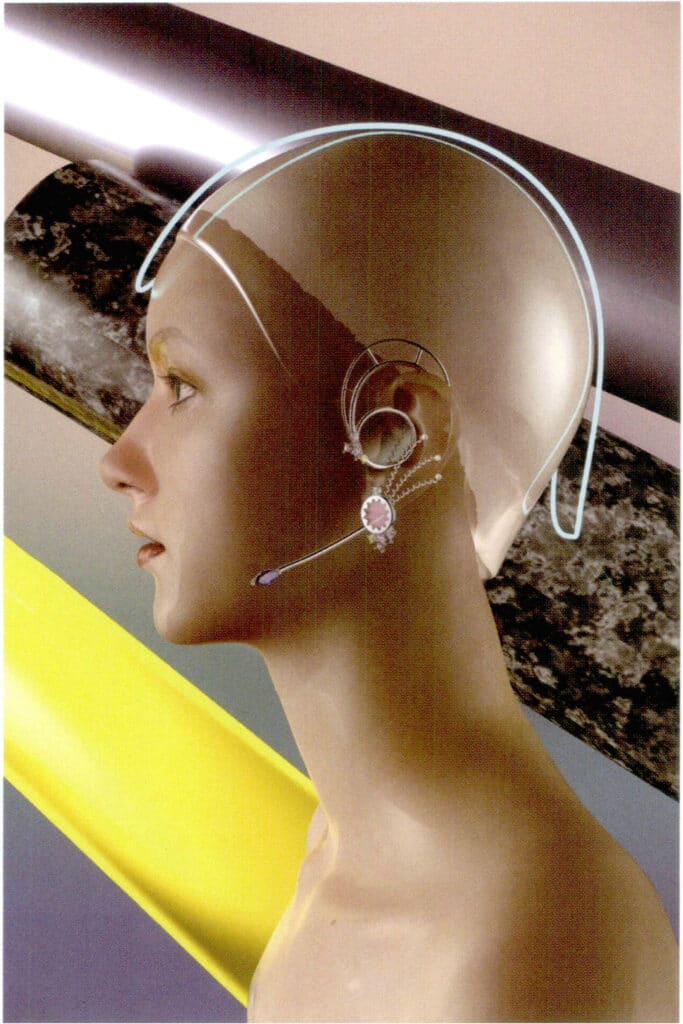

Y VMIN Especially Eye-catching, ELECTRONIC GIRL Electronic Girl Series

Y VMIN Especially Eye-catching, ELECTRONIC GIRL Electronic Girl Series

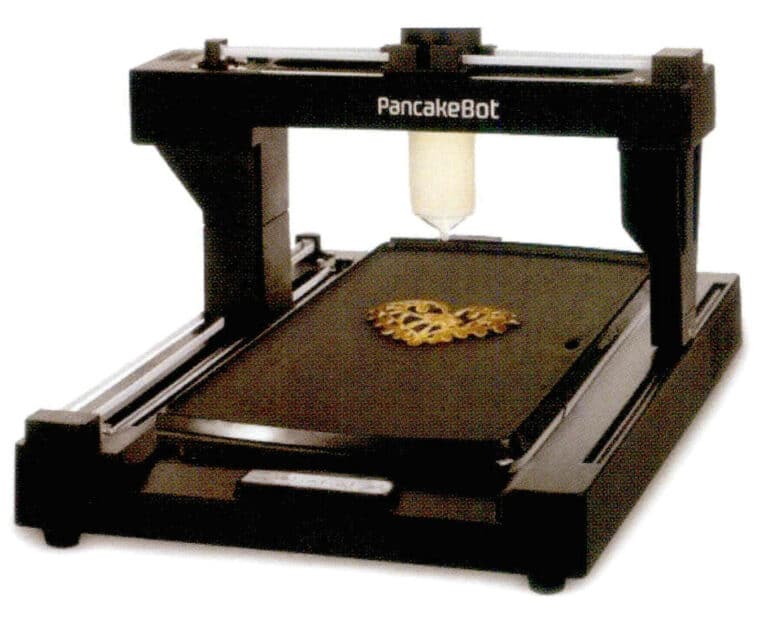

3D Printing Food Machine

3D Food made using 3D printing technology

1. The molding principle of 3D printing technology

The 3D printing technology adopts the “additive method,” known as “additive manufacturing technology. It uses 3D modeling software (such as JeweICAD, Rhinoceros, ZBrush, 3DESIGN, Autodesk Maya, 3DS Max, Grasshopper, Matrix 3D

Inputting model data designed by software such as Grasshopper and Matrix into a 3D printer and adjusting the model’s printing layer data, different types of printers can print wax models, resin models, ceramic models, food models, or metal models by layering powdered or filament materials using techniques like heating and sintering.

In the jewelry industry, 3D printing technology allows for more accurate and rapid jewelry design and model making. The industry has recognized its advantages in convenience, repeatability, and ease of adjustment. Many jewelry companies have established intelligent 3D printing production lines, enabling large-scale jewelry production and personalized customization, significantly improving design and production efficiency while reducing costs. Designers create jewelry models and input them into 3D printing equipment, choosing materials such as wax, resin, nylon, plastic, and metal for printing jewelry models, with wax molds being the most widely used. The completed wax molds can be directly used for metal casting; if one wants to create jewelry made of composite materials, one can also try printing with resin, nylon, or ceramics. With the development of 3D printing technology, machines that can directly print metals such as gold, silver, and copper are gradually being upgraded. Although the technology is not yet fully mature, resulting in high costs and waste for producing printed metal products, this technology will mature progressively and be widely used shortly.

2. Classification of 3D printing technology

The commonly used 3D printing technologies in the market include TDP powder material selective binding technology, FDM fused deposition modeling technology, SLA stereolithography technology, DLP digital light processing technology, UV ultraviolet forming technology, and SLS selective laser sintering technology.

2.1 Powder material selective binding technology

This technology uses standard inkjet printing techniques, under computer control, to spray a binder onto layers of powder material based on the information of the cross-sectional profile, causing the solid parts of the powder to bind together and form the cross-sectional profile; this process is repeated layer by layer until the model is complete.

2.2 Fused deposition modeling technology -FDM

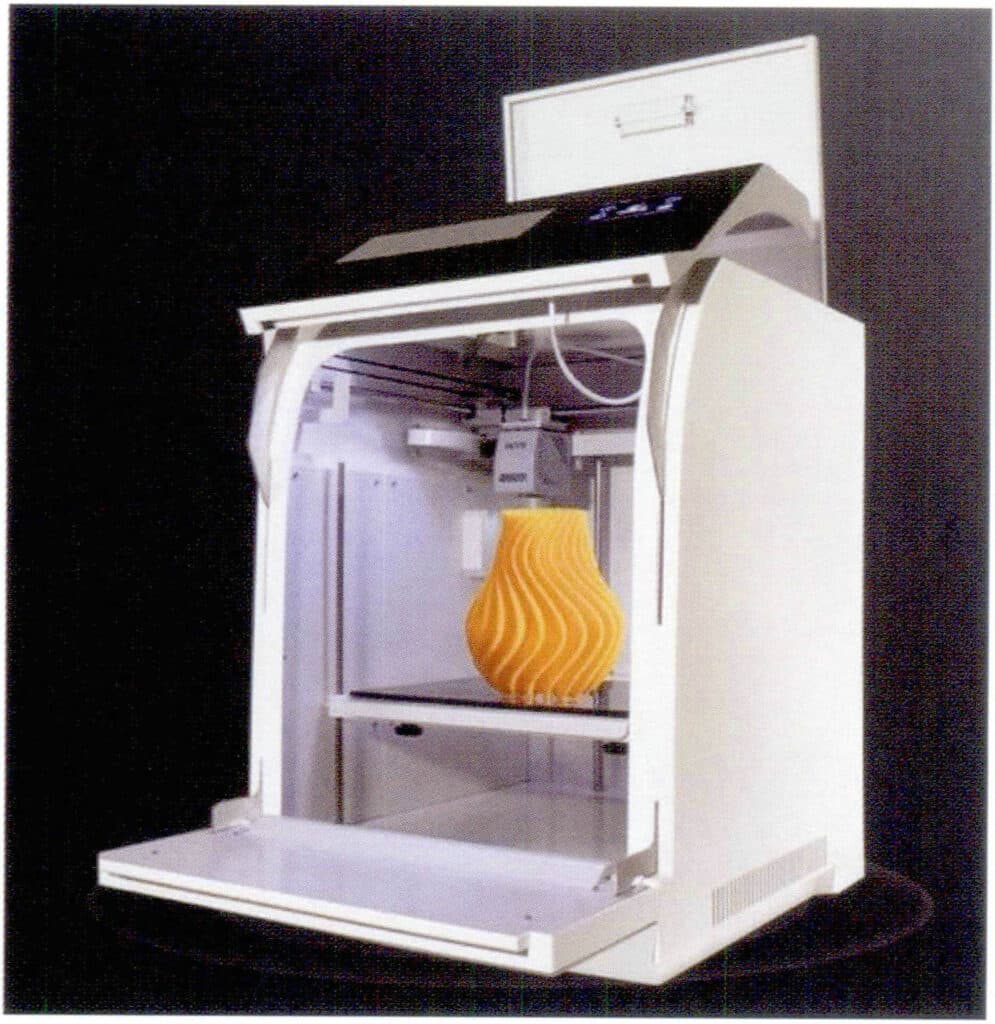

This involves heating and melting filament-like thermoplastic material while the printing nozzle, under computer control, applies the material onto the workbench according to the cross-sectional profile data, forming a layer after rapid cooling; this process is repeated for each layer until the model is fully printed.

2.3 Stereo lithography Appearance -SLA

Using photosensitive resin as the raw material, a computer controls a laser to scan point by point on the surface of the liquid photosensitive resin according to the cross-sectional information of the model. The scanned area of the resin layer undergoes a photopolymerization reaction and solidifies. After one layer is solidified, the workbench moves down by one layer’s distance, and the process is repeated until the model is fully printed.

FDM 3D FDM technology controls quasi-industrial grade 3D printers.

SLA 3D SLA technology controls 3D printers

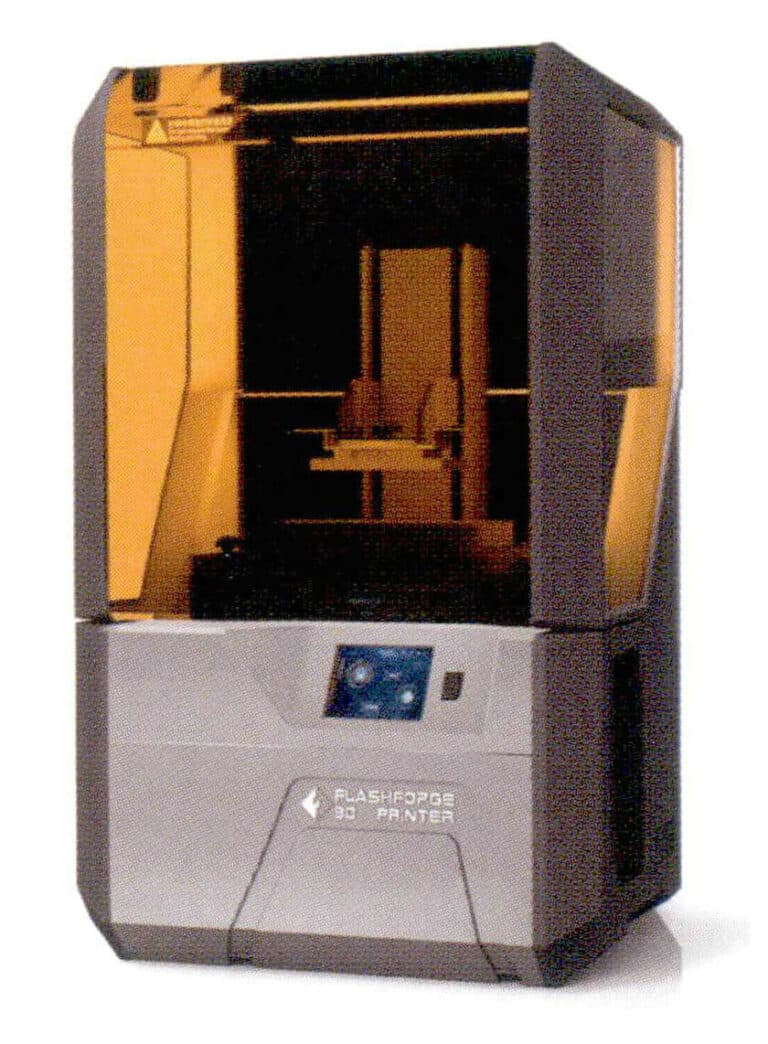

2.4 Digital Light Processing, DLP

It uses a high-resolution digital light processor (DLP) projector to cure liquid photopolymers layer by layer. Since each layer cures in a sheet-like manner, the speed is faster than that of similar SLA stereolithography technology. This technology is often used in the jewelry processing industry.

DLP 3D DLP technology controls 3D printers

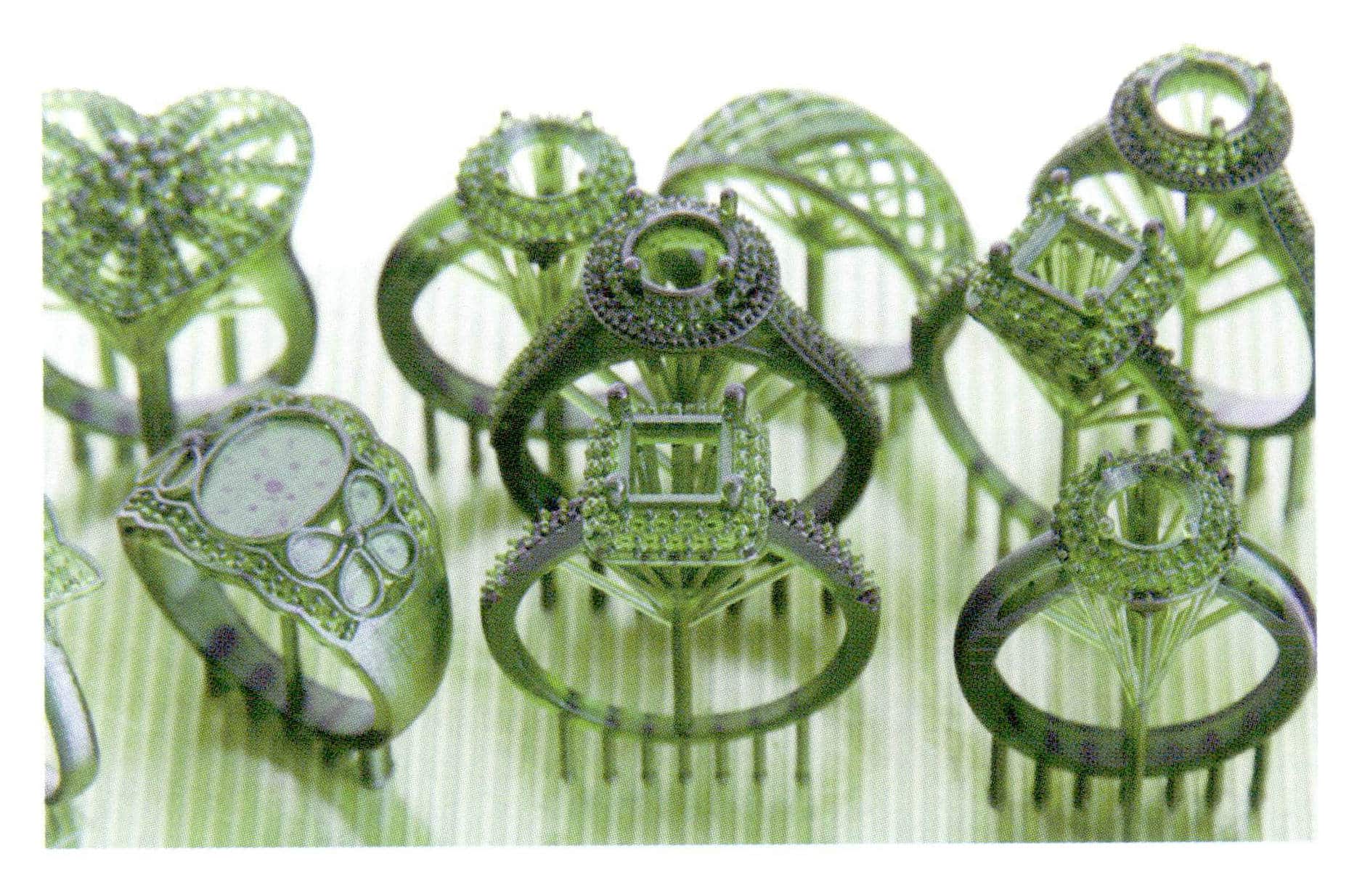

Jewelry resin models made by DLP technology-controlled 3D printers can be directly used for metal casting operations.

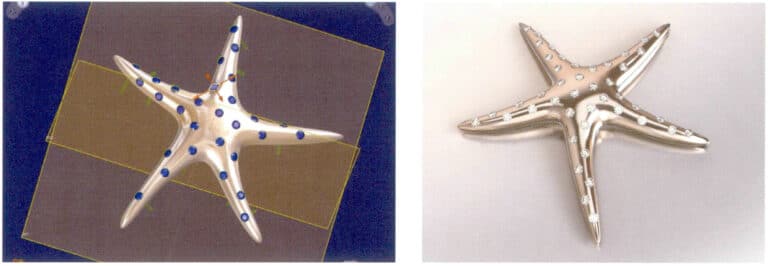

2.5 Multi-jet Modeling MJM

Materials are sprayed layer by layer and formed through chemical resin and thermoplastic light curing. It is suitable for building high-precision, high-definition models and prototypes and can be directly used for lost-wax casting. This technology allows for multiple materials to be included in a printed product, and the wax printing machine commonly used in jewelry model printing employs this technology. The jewelry models made by the wax printing machine controlled by MJM multi-jet modeling technology consist of white wax and purple wax, where the white wax serves as the supporting base for the jewelry model during printing.

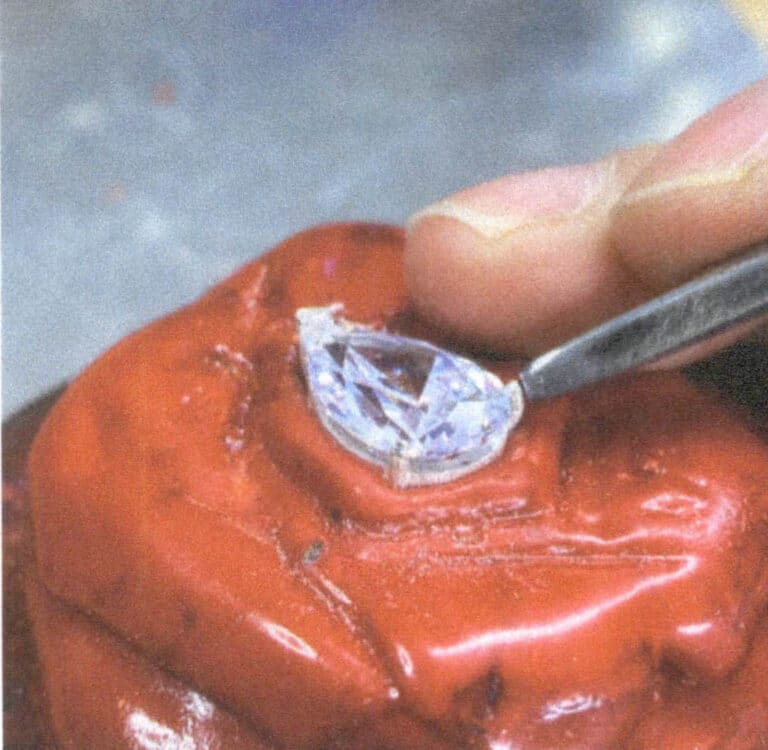

Purple wax is the jewelry model; the entire model is placed into the support white wax dissolving solution after printing. Once the white wax dissolves, it leaves the purple wax part of the jewelry model, which can be used for metal casting operations.

Support white wax, structure purple wax

MJM Jewelry models made using MJM technology wax spraying machine

2.6 UV ultraviolet forming technology

The liquid photosensitive resin is irradiated with UV ultraviolet light, layer by layer, stacking from bottom to top, with no noise during the process and high forming precision.

2.7 NanoParticle Jetting, NPJ

This process uses nano liquid metal, deposited and formed by inkjet, with a printing speed five times faster than ordinary laser printing and excellent precision and surface roughness.

2.8 Laser Metal Deposition, LMD

This technology has many names, commonly called LENS, DMD, DLF, LRF, etc. The printing powder is gathered to the work surface through a nozzle, converging with a laser at a point, and after the powder melts and cools, a deposited clad entity is obtained.

2.9 Selected Laser Sintering, SLS

Selected Laser Sintering (SLS): A layer of powder material (metal powder or non-metal powder) is pre-laid on the work surface, and the laser sinters the powder according to the contour information under computer control, continuously cycling to form a build-up.

2.10 Selective Laser Melting, SLM

Selective Laser Melting (SLM): This is currently the most common technology in metal 3D printing, using a finely focused light spot to rapidly melt preset metal powder, directly obtaining models of any shape. It can directly form metal models with nearly complete density and good mechanical properties. This technology overcomes the complexity of the SLS process for manufacturing metal parts.

2.11 Electron Beam Melting EBM

Its process is similar to SLM, but an electron beam is the energy source. The output energy of the EBM electron beam is usually an order of magnitude greater than the output power of the SLM laser, and the scanning speed is also much higher than that of the SLM. Therefore, during the operation of EBM, it is necessary to preheat the entire build platform to prevent significant residual stresses caused by excessive temperature differences during the forming process.

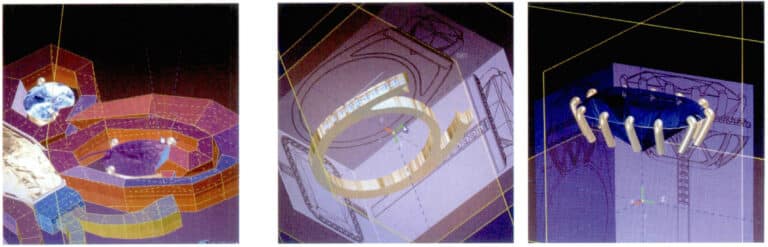

3. 3D Printing Forming Process and Digital Software Technology 3D

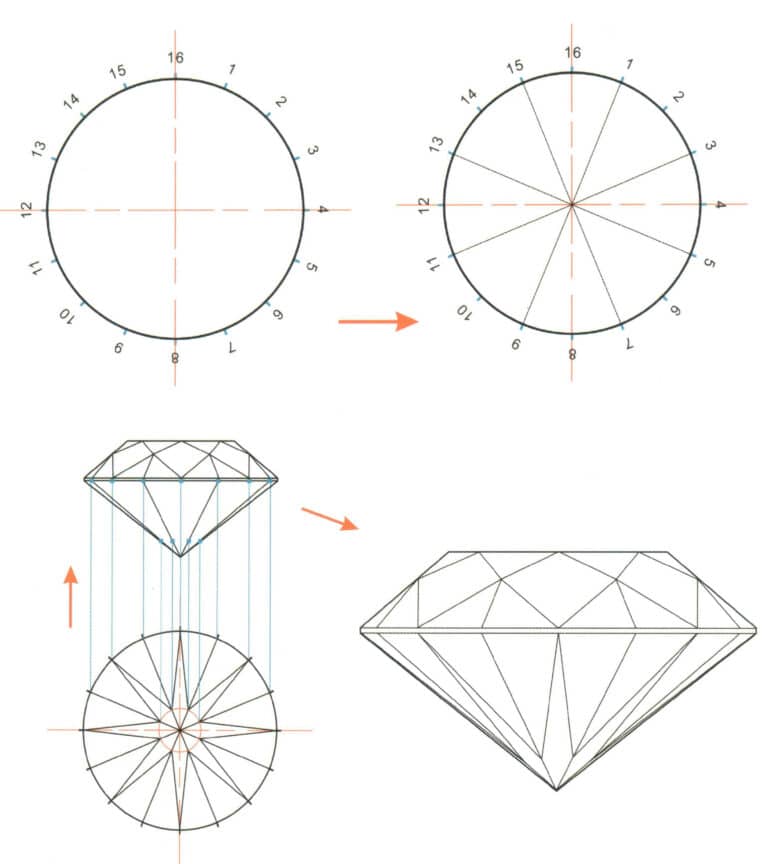

The most crucial step in the 3D printing molding process is the front-end conceptual design and digital software modeling. Software commonly used for jewelry design modeling includes JeweICAD, 3DESIGN, Rhinoceros, ZBrush, and Matrix, each with its advantages and features, capable of designing shapes that are difficult or impossible to create manually, such as repetitive structures, regular gradient structures, interspersed hollow structures, and multi-layer curved surface structures. Understanding the software’s performance and being proficient in its operation is essential to better utilizing the 3D printing molding process. Below is a brief introduction to several professional jewelry design software that can directly output for printing.

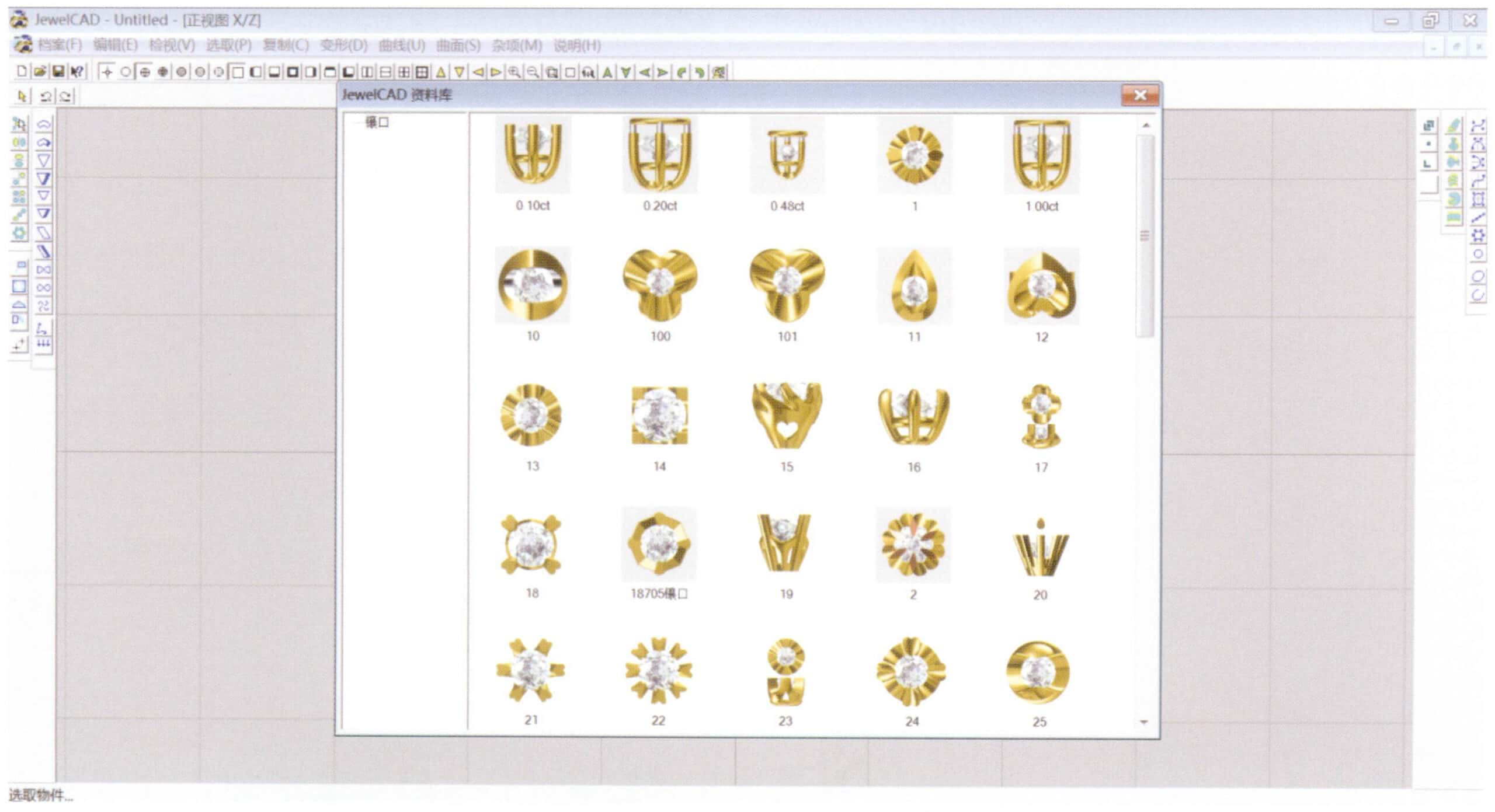

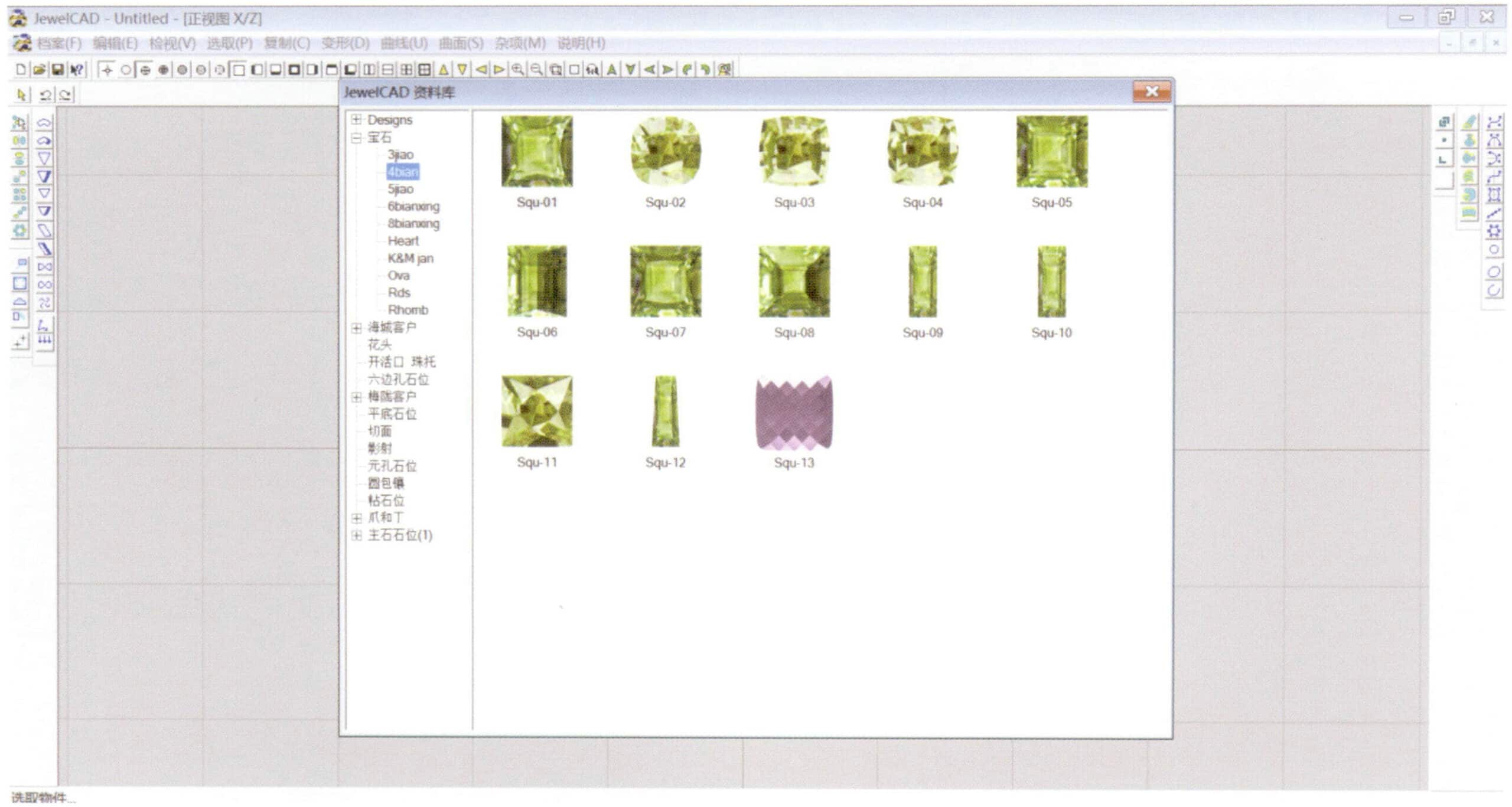

3.1 JeweICAD

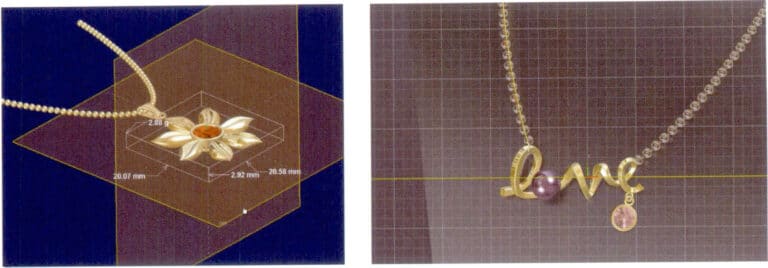

JeweICAD is a professional jewelry design software developed by Hong Kong Jewelry Computer Technology Co., Ltd. in 1990. It has evolved into powerful and stable mature software, currently used by most jewelry companies and designers for design and model printing output, and is very popular. The software has strong image processing capabilities, can produce 1:1 jewelry model output data, features complete Rail guide surface forming technology, efficient Curve modeling and drawing functions, as well as Boolean operation technology, and allows for free perspective conversion. The software has a fixed gem and jewelry parts library for direct use. After design completion, it can perform model rendering, calculate the weight of gold used, and output standard seamless STL and SLC format files, enabling quick production of jewelry models compatible with 3D printers and CNC engraving machines.

JeweICAD Operator Interface

JeweICAD Operator Interface

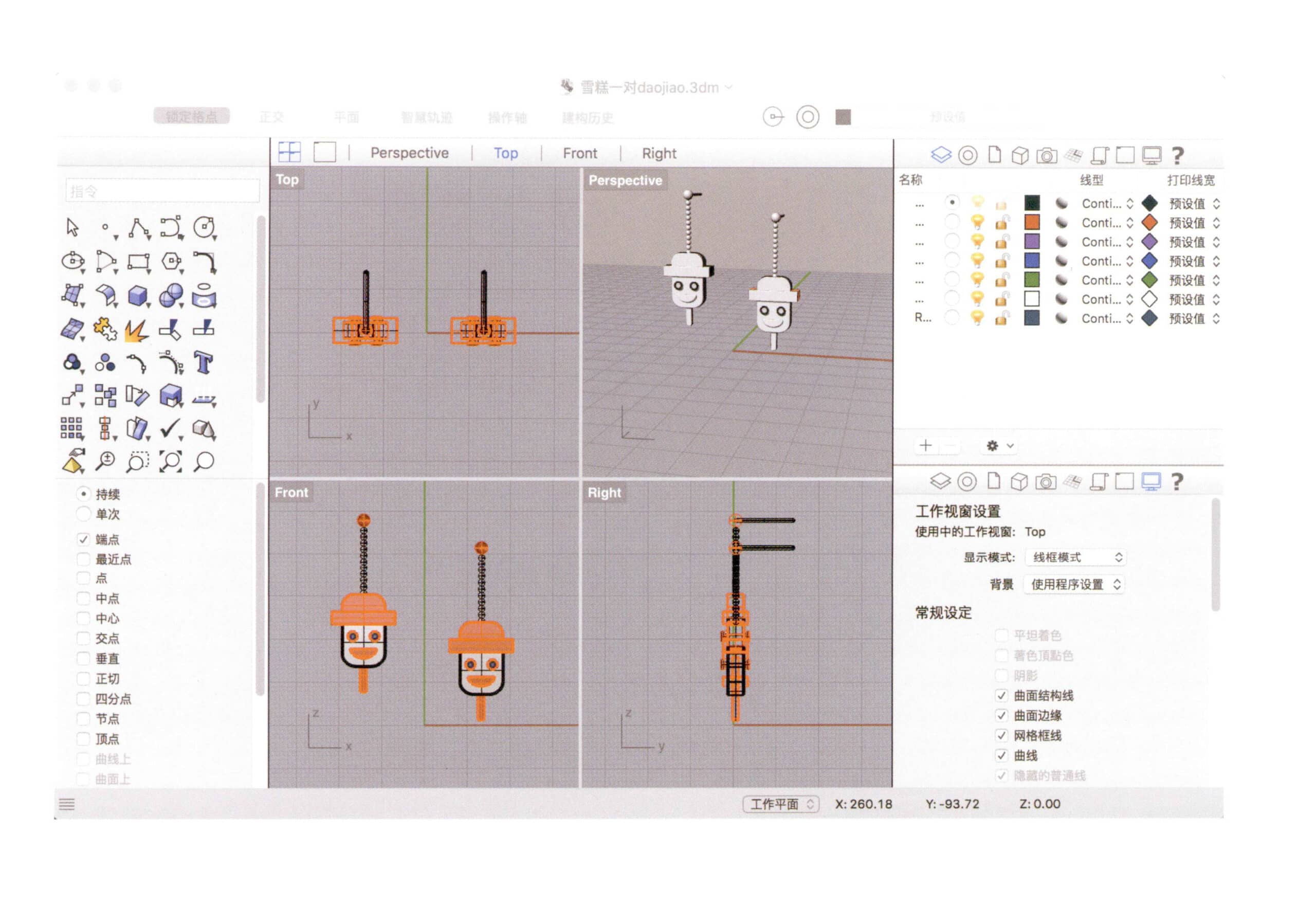

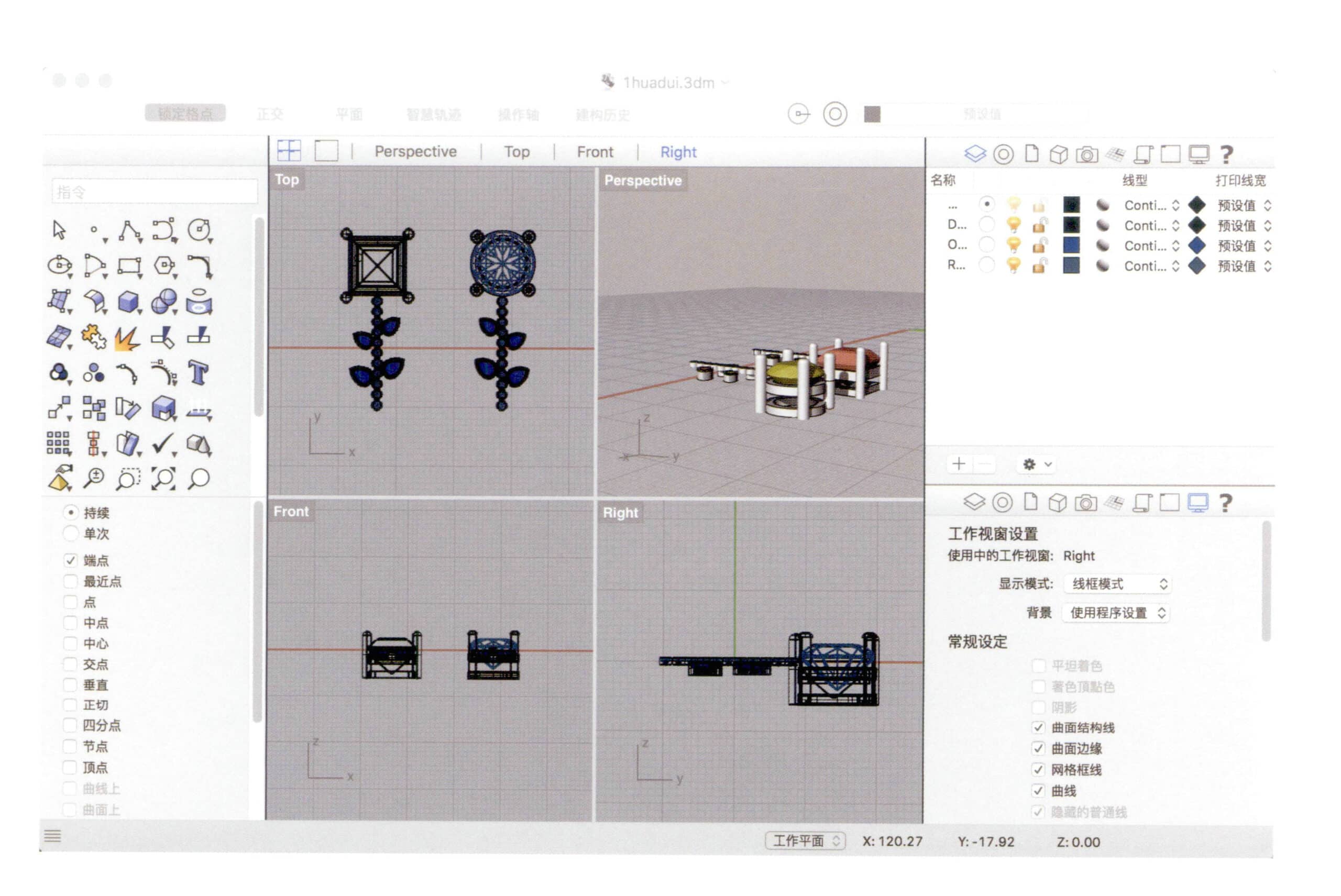

3.2 Rhinoceros

Rhinoceros, abbreviated as Rhino, was released in 1998 and is a world-class computer-aided industrial modeling software developed by Robert McNeel & Assoc in the United States. It uses an excellent NURBS (Non-Uniform Rational B- Spline) modeling method, and the development concept of the software is

With Rhino as the central system, they are continuously developing various industry-specific plugins, rendering plugins, animation plugins, model parameters, etc., constantly improving and evolving into a general-purpose series of design software. Rhino can input and output various file formats, and models can be directly manufactured through multiple CNC machines and 3D printers, serving fields such as architectural design, industrial manufacturing, mechanical design, artistic design, and 3D animation production.

3.2.1 Advantageous Technologies:

Rhino has an excellent modeling method with NURBS and a mesh modeling plugin, T-Spline, with diverse operation methods that make modeling more vivid; at the same time, it has developed various industry-specific plugins. As long as one masters the standard operation methods and techniques of the software, learning subsequent plugins becomes very easy. For example, loading jewelry design plugins into Rhino can turn them into professional jewelry design software. This is also a key factor for Rhino’s foothold in various industries.

3.2.2 Molding and Processing:

Rhino can import and export dozens of different formats, including 2D file formats, the STL format required for 3D printing, and image file formats. It can import and modify model parameters created by other software while accommodating various forms of printing output, making it very convenient to operate.

3.2.3 Easy Installation:

Although Rhino is mighty, it does not have exceptionally high requirements for the operating system and computer hardware configuration compared to other modeling software; it only occupies about 20 megabytes of space and is easy to learn and master.

3.2.4 Professional Jewelry Design Plugin:

Rhino is known for its rich plugins, with the development of professional plugins covering almost all types of design.

Gemvision Matrix: A powerful jewelry design plugin with significant advantages in parametric control modification, editing, and comprehensive capabilities.

TDM RhinoGold: A comprehensive jewelry design plugin with a full range of design tools, including modeling, stone setting, bezel setting, necklaces, rings, and reliefs, allowing for quick and precise design and modification of models. RhinoGold adds jewelry-specific tools to the essential functions of Rhino, significantly improving design efficiency and can also automate repetitive tasks.

Smart3d and Logis3d Pavetool: Both plugins can automatically set stones and automatically generate honeycomb base holes.

Pavetool: A professional virtual inlay plugin for gemstones with multiple curved surfaces.

3.2.5 Other Plugin Tools:

FlamingoPenguin V-Ray BrazilBongo RhinoAssembly RhinoDirect EasySite Alibre Design RhinoShoe Orca3D DentalShaper for Rhino

Rendering plugins Flamingo, Penguin, V-Ray, and Brazil; animation plugins Bongo, RhinoAssembly; parameter and limitation modification plugin RhinoDirect; architecture plugin EasySite; mechanical plugin Alibre Design; footwear plugin RhinoShoe; marine plugin Orca3D; dental plugin DentalShaper for Rhino; photography measurement plugin Rhinophoto; reverse engineering plugin RhinoResurf; mesh modeling plugin T-Spline, etc., and continuously updated. Rhino has such a robust library of professional plugins that the models designed with this software have precise shapes, realistic rendering effects, and attractive animated promotions. When used for jewelry design, it can also quickly model, automatically arrange stones and accurately calculate gold and gemstone net weight, just like professional jewelry design software.

3.3 3DESIGN

The professional jewelry design software 3DESIGN belongs to the French company Type3, founded in 1988 Lyon, France. As a leading artistic CAD/CAM software for industry development, it has significantly contributed to industrial engraving and 3D jewelry design.

3.3.1 Advantageous technologies:

3DESIGN focuses on jewelry design and professional watch design. The new version further enhances jewelry design and processing functions, and the commonly used computer configurations can meet the software installation requirements (compatible with Mac and Windows systems). Generally, one can master the software operation in about three months.

The software is easy to operate, allowing for model flipping and scaling at any time. It comes with rendering capabilities, enabling users to see the rendered materials of the model instantly on the interface, allowing designers to quickly observe the details of their work and control the overall jewelry design. For commercial orders, it also provides for timely revisions, online sharing, and catalog displays, obtaining effective feedback from clients before processing, thus improving the accuracy of the final product.

3DESIGN has also developed a unique “linking” technology that can quickly change existing design drafts to obtain new design models. If a design takes 4 hours to create, making four similar pieces would take about 16 hours, but “parametric” can keep track of the creative history of the design, with every step being recorded. Therefore, by modifying any of the steps and editing again, new works can be designed without limits on time or frequency, allowing for innovation at any time. Moreover, the 3DESIGN software will automatically recalculate all steps, significantly saving modeling time. The software also has a rich database of gems, settings, accessories, and powerful features such as automatic stone setting, channels, sweeping, arrays, and gold weight estimation, providing convenience for creating various jewelry styles.

3.3.2 Forming and processing:

After using software to design a good work, you can enter the processing of the model. 3DESIGN can output STL files and can be directly connected to rapid prototyping machines and 3D printers. It is an all-in-one software that integrates design and processing output.

3.3.3 Other extension plugins of the software:

3DESIGN has many related auxiliary software, such as 3Shaper and DeepImage. Using several software in combination can make jewelry creation more effortless.

3Shaper sculpting function:

This software has two of the most potent technical functions: subdivision surfaces and hybrid modeling. By running the 3Shaper plugin in 3DESIGN and opening the model to be produced, you can freely rotate and measure various angles, points, or surfaces on the model. You can also preset multiple points and lines to divide the product into countless small surfaces. By pushing, pulling, and bridging between surfaces, you can change the product’s shape and complete freeform modeling, shaping any form like molding clay. Many small sculpture designs also frequently use this software, first designing the shape of the work with the software. Using 3D printing technology to create a 1:1 model, and finally, artisans in jade carving and wood carving sculpt it according to the model. This allows for better control of the shape, saves labor time, and reduces material waste. For jewelry design, this software can be used for reworking details such as edges, so using both 3DESIGN and 3Shaper together can make jewelry works more exquisite.

DeepImage rendering function:

DeepImage is also an assistant software for 3DESIGN. As an operational feature of 3DESIGN CAD8, DeepImage allows designers to quickly create high-definition “ray tracing” images and “animations” (Quicktime, PNG, or continuous JPG images). DeepImage also has the following features: the ability to select jewelry materials and scenes from a specific database, drag-and-drop materials, presenting them with a complete environment, integrating more appropriately with product design, and automatically calculating and presenting rendering effects, all in just a few seconds.

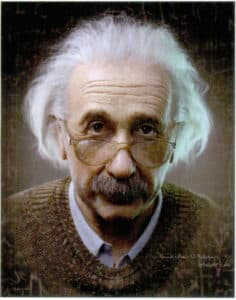

3.4 ZBrush

ZBrush is a powerful 3D digital sculpting and 2D painting software launched by Pixologic in 1999. It has become a core software in the 3D industry, mainly used in film special effects, video games, illustration design, advertising effects, 3D printing, jewelry design, human models, automotive design, concept teaching, and other industries.

3.4.1 Advantageous technologies:

The birth of ZBrush has brought revolutionary changes to the entire 3D design field. Unlike traditional 3D software that relies on a mouse and parameters for modeling, it transforms the most complex and labor-intensive tasks of character modeling and texturing in 3D production into a thinking operation akin to sculpting with clay, fully respecting the traditional working habits of designers. The software features various styles of 3D brushes and material libraries, allowing designers to control tools like 3D brushes through a graphics tablet or mouse. The concept of mouse operation is similar to various chisels and brushes, while tedious issues like topology and mesh distribution are automatically handled in the background. Designers and artists can unleash their creativity, completing their works as if they were hand-drawing or hand-sculpting. At the same time, they can continuously apply coloring, rendering, and other effects, changing the color, texture, lighting, and precision of the work, genuinely achieving the integration of 3D.

ZBrush brushes can easily shape skin details such as wrinkles, hair strands, and spots, as well as detailed bump models and textures. It can also export complex details into normal maps and low-resolution models with well-unwrapped UVs, facilitating recognition and application in sizeable 3D software like Autodesk Maya, 3DS Max, and Lightwave. Therefore, this software is also a critical modeling and material tool in professional animation production. Significant games like “Assassin’s Creed” and “Call of Duty,” as well as well-known movies like “Pirates of the Caribbean,” “The Lord of the Rings,” and “Avatar,” have all utilized ZBrush software for production.

3.4.2 Forming and Processing:

Works designed with ZBrush can be directly output in formats like STL to connect with various 3D printers for physical model output. It is also possible to import accurate model data captured by high-precision 3D scanners into the software for further modification and refinement.

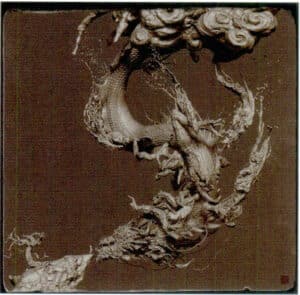

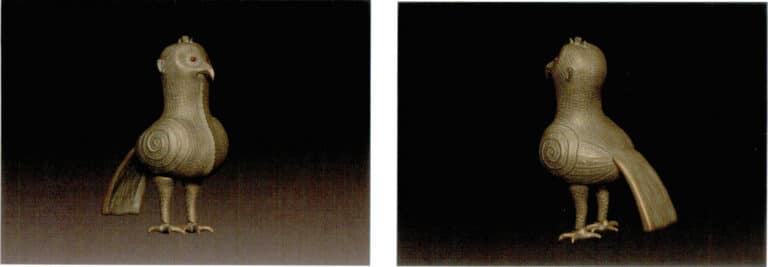

Many model artworks are created through 3D printing after being designed with ZBrush. The seamless connection between design and physical output allows the creative concepts of designers and artists to be transformed from virtual to reality quickly, significantly reducing design costs.

Alexander Beim, Einstein statue, ZBrush modeling work

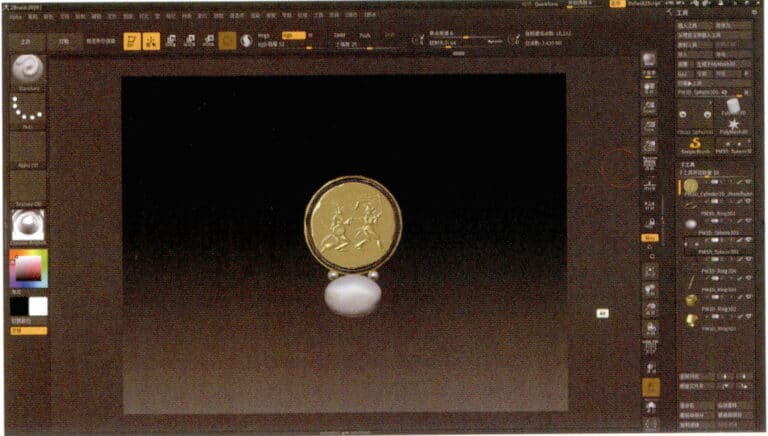

Xu Zhelong, Golden Scale Junior (unrendered image)

Xu Zhelong x Kaiten Studio,Golden Scale Junior, Physical Sculpture

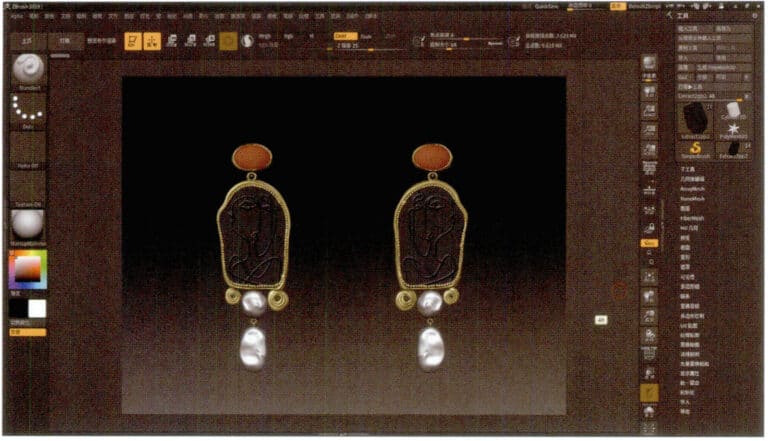

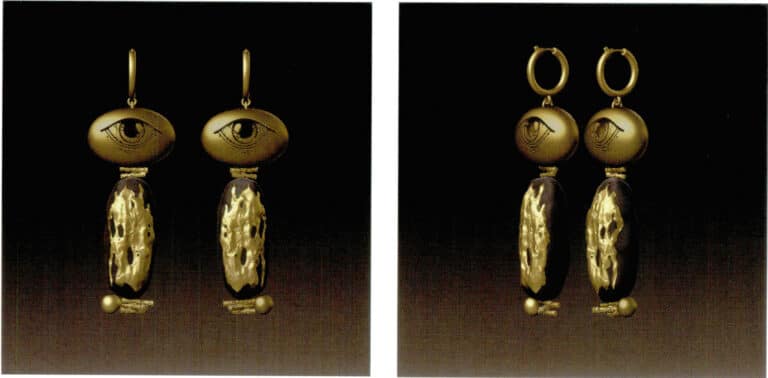

3.4.3 The application of ZBrush in jewelry design:

ZBrush’s 3D sculpting capabilities are similar to traditional hand-carved wax sculpture, with fine carving brushes and tools for pushing, pulling, and rotating that can change the modeling shape at will. This hand-operation-like functionality is very suitable for creating abstract, human, animal, floral, and various other types of jewelry while also allowing for in-depth detailing of the work, overcoming the limitations of detail design in traditional CAD or NURBS-based 3D software.

ZBrush can also be used with 3D software such as JeweICAD and Rhinoceros. For example, models of gems and jewelry accessories from JeweICAD can be exported in STL format and then imported into ZBrush for use; geometric block-type jewelry can be quickly created using Rhinoceros and refined in ZBrush. ZBrush comes with various material spheres and rendering tools, allowing each part of the jewelry to be rendered with different materials. In addition to traditional materials like gold, silver, and copper, there are various rendering materials such as glass, pearls, gemstones, sand, wood, and plastic, and users can create their material textures, enormously satisfying designers’ needs. Once the model design is complete, materials can be directly selected to render a realistic effect, which plays a good role in controlling the quality of the final product processing.

Section II CNC Numerical Control Carving Technology

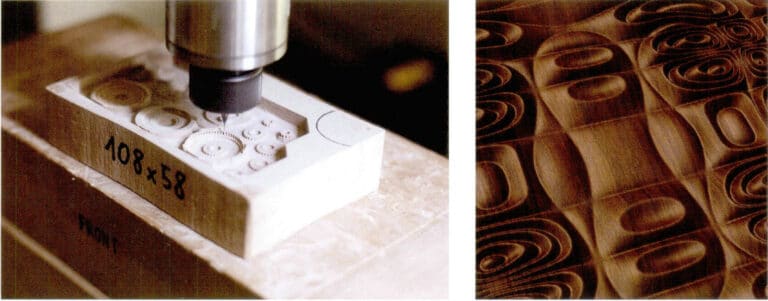

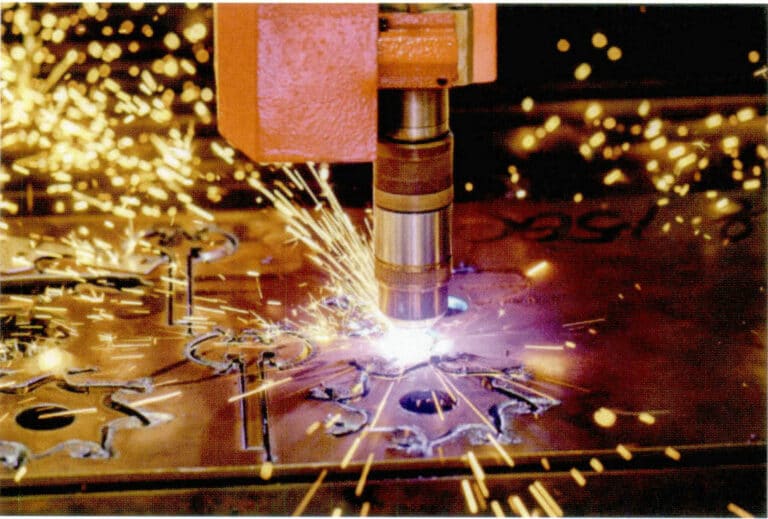

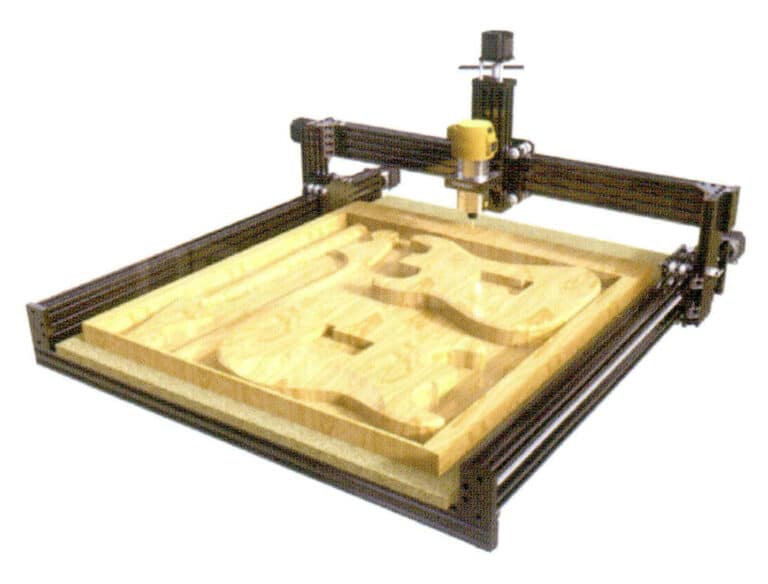

CNC is the abbreviation for Computer Numerical Control. A CNC engraving machine consists of a computer, an engraving machine controller, and the main engraving machine. The numerical control technology of the engraving machine is a trajectory control system, with the displacement of each motion axis as the control object while coordinating the movement of each motion axis. The processing idea is as follows: First, model design and layout are carried out using specialized engraving software configured in the computer, and the data information is automatically transmitted to the engraving machine controller by the computer, which then converts it into power signals for driving or servo motors. At this point, the main engraving machine generates the engraving tool path for three axes or more, and the engraving tools configured according to the processing material start to rotate at high speed, performing subtractive processes such as cutting, milling, and drilling on the material fixed on the main machine’s workbench. After the operation, various flat, three-dimensional, and relief models designed in the computer can be engraved.

Small CNC engraving machines are also widely used in the jewelry industry’s rapid prototyping process. CNC engraving machines can process a variety of materials such as wood, bamboo, leather, plastic, and wax and can also directly process metal materials; this process is suitable for various complex surface three-dimensional profiles, textures, and flat hollow carvings, and it is more challenging to process models with internal structures, semi-closed, and closed structures. CNC engraving machines used for jewelry forming can be compatible with various CAD software data formats, such as Rhino, JewelCAD, Solidworks, ArtCam, etc. They can also use professional engraving modeling software like Type3 for design, improving the quality of the models. Therefore, jewelry and small crafts carved with CNC technology are usually exquisite. Common brands of small CNC engraving machines used for jewelry processing include Beijing Jingdiao and France’s Gabar.

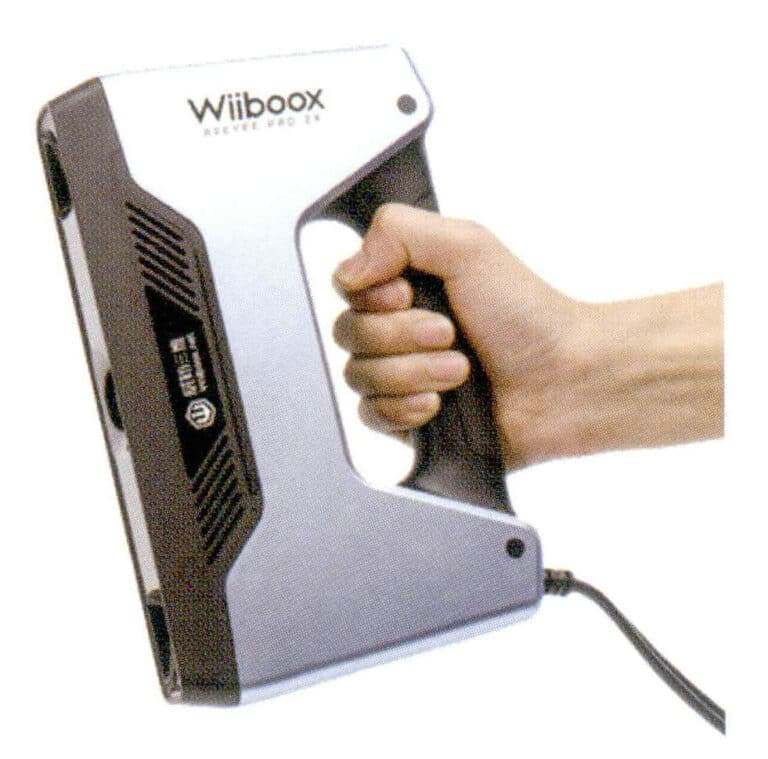

3D scanning technology is often combined with CNC engraving and 3D printing technology, importing the scanned data into a computer for adjustments and then using CNC engraving or 3D printing technology for forming processing.

CNC laser engraving machine carving metal

Metal crafts, made by CNC engraving machine

Large industrial-grade CNC engraving machine

Small CNC engraving machine

Handheld 3D Scanner

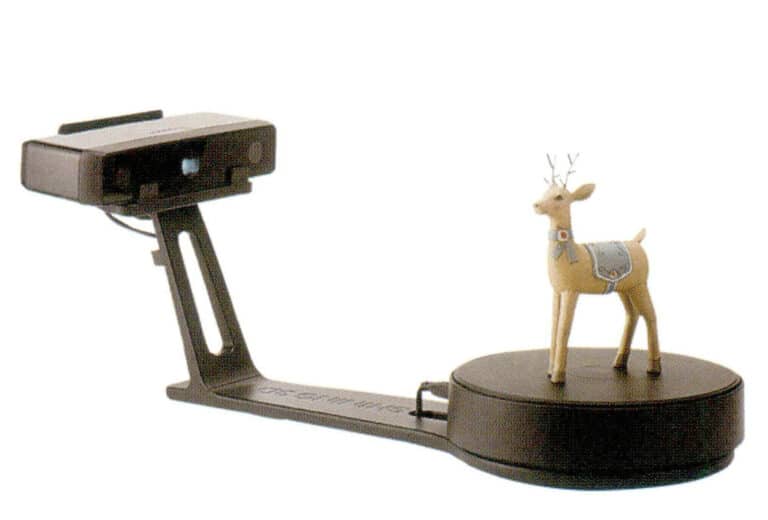

Desktop Rotary 3D Scanner

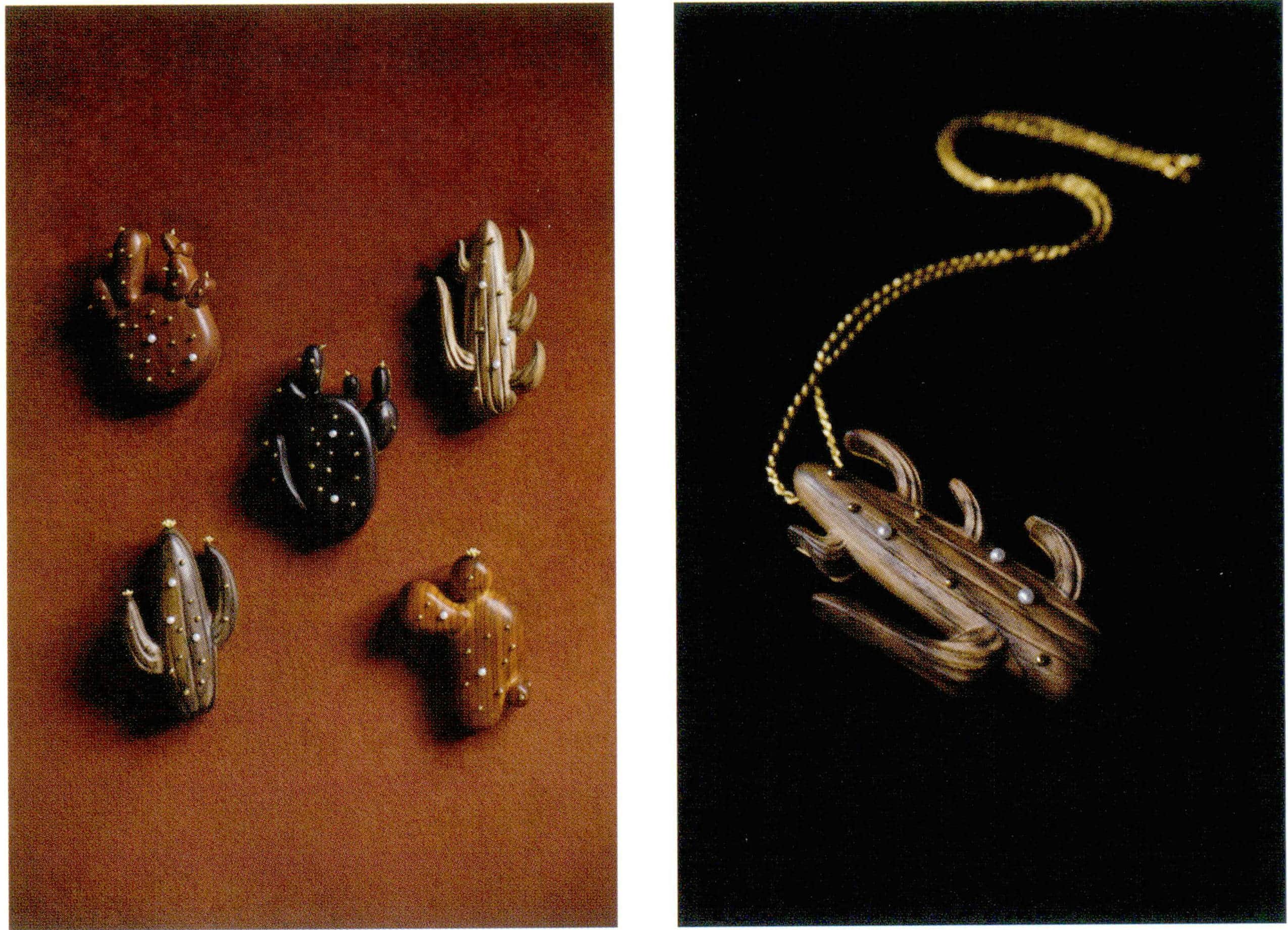

Desert Flower No.1 ~ 5 series, Purple Sandalwood, Small Leaf Red Sandalwood, Chen Gui Bao, Zebra Wood, Micro Concave Yellow Sandalwood, Pearl, 925 Silver