Takı Dökümleri Nasıl Temizlenir ve İncelenir: Farklı Kalıp Türleri için Teknikler

The basic principles and operational skills for 4 typical tasks

After the metal liquid solidifies in the mold, the cleaning process for the casting needs to be determined based on factors such as whether wax setting is used, the alloy’s properties, the product’s structure, and the mold’s nature. Using the residual heat of the mold for water explosion cleaning is an effective method for demolding castings. Still, it is only suitable for gold, silver, and platinum jewelry castings that are not very sensitive to thermal shock. For wax-set jewelry castings, to avoid the risk of gemstones shattering due to thermal shock, mechanical demolding can only be performed after the mold has cooled to a certain temperature. After demolding, the casting metal tree remains somewhat wrapped in the residual mold, requiring high-pressure water jets to wash it off, effectively cleaning the residual mold. The jewelry castings, after washing, still inevitably retain a small amount of mold in certain areas, and the surface often forms oxides, increasing the difficulty of subsequent polishing and causing contamination for the reuse of charging materials. Therefore, solutions such as hydrofluoric acid need to be used for soaking until a clean casting tree is obtained. Tools such as bolt cutters and saws are used to remove the castings one by one from the metal tree and are classified according to orders and materials. A diamond grinding wheel is used to grind off the residual sprues, and a magnetic tumbler is used to clean the jewelry casting blanks.

This project enables students to master the corresponding cleaning methods and operational skills for jewelry castings of different materials and product types through four typical tasks and post-class extension exercises.

Automatic Gypsum Investment Cleaner

İçindekiler

Section I Cleaning of Jewelry Castings Using Ordinary Gypsum Molds

1. Arka Plan Bilgisi

1.1 Casting Stress

Casting stress is the elastic stress generated after the casting completely enters the elastic state due to restricted shrinkage or asynchronous shrinkage. Casting stress can weaken the structural strength of the casting, leading to deformation or even cracking. Casting stress includes three types: phase change, thermal, and mechanical stress.

During the cooling process of the casting, solid-state phase changes occur, resulting in changes in volume. Due to the casting’s uneven composition and temperature distribution, different casting parts undergo phase changes at different times, leading to uneven volume changes. This mutual constraint between parts generates residual stress, known as phase change stress. For example, 18K rose gold castings are prone to ordering transitions during cooling, forming ordered phases such as Au3Cu, AuCu and AuCu3, which have inconsistent volumes with the matrix, and the timing of phase changes in different areas also varies, resulting in phase change stress within the casting.

Thermal stress occurs during the final solidification stage of the casting (close to the solidus line, at which point the solidified structure has formed a dendritic network framework) and during the subsequent cooling process. Due to temperature differences, casting stress arises in different areas of the cross-section of the casting, both inside and outside, and in areas of varying thickness. The cooling rates differ in various casting parts, leading to inconsistent solid-state shrinkage rates. However, the different parts of the casting are interconnected as a whole, mutually constraining each other, thus generating thermal stress. The magnitude of thermal stress is proportional to the temperature difference between thick and thin wall sections when the thick-walled part transitions from a plastic state to an elastic state; the greater the wall thickness difference in the casting, the greater the thermal stress.

Mechanical stress is caused by the casting being hindered by the casting mold or other obstacles during cooling shrinkage. This stress can be tensile or shear stress. The mechanical stress disappears once the casting is de-molded and the obstacles to its shrinkage are removed.

1.2 Demolding Time

During the cooling process after the casting solidifies, the cooling rates at different locations vary. The cooling rate at thin-walled areas is fast and slow at thick-walled areas. The difference in wall thickness is a major factor affecting casting stress. Since gypsum molds are poor thermal conductors, the cooling rate of the casting inside the gypsum mold is very slow, which helps reduce the difference in cooling rates between various parts. When the casting is de-molded at high temperatures, its cooling rate significantly increases. If the demolding time is too short, the high-temperature casting is directly exposed to air or comes into contact with water, which may lead to deformation, cracking, and high internal stress in the casting. Therefore, appropriately extending the demolding time to allow the casting to be demolded at a lower temperature is beneficial for reducing thermal stress in the casting. However, if the demolding time is too long, it will increase the difficulty of demolding, affect production efficiency, and raise production costs.

The demolding time of the casting has a significant impact on production efficiency and product quality. It is necessary to comprehensively consider factors such as the material properties of the casting, solidification time, and the changes in microstructure during the solidification and cooling process, as well as the structure of the casting, to determine a reasonable demolding time. For high-purity precious metal jewelry such as pure gold and pure silver, due to the materials having very good plasticity and undergoing structural changes during cooling, there is almost no risk of cracking when demolded at high temperatures. However, for materials like 18K gold, 14K gold, and 925 silver, their plasticity at high temperatures is significantly inferior to that of pure gold and pure silver, and solid-state phase changes may occur during cooling. If demolding and cleaning are done too early, the probability of deformation and cracking in the casting will significantly increase.

1.3 Demolding Cleaning Methods

In jewelry casting production, the demolding methods for castings mainly include mechanical cleaning, water explosion cleaning, and hydraulic cleaning.

(1) Mechanical Cleaning

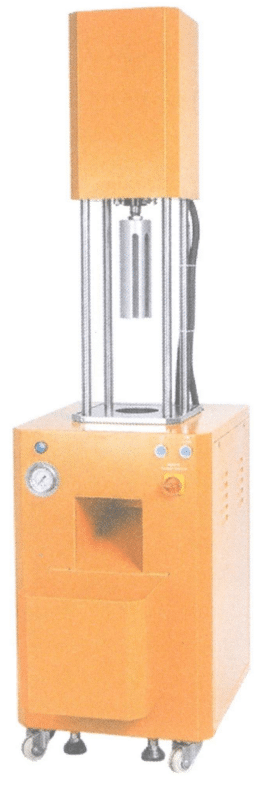

For castings such as wax-set jewelry and glass jewelry that are very sensitive to thermal shock, mechanical cleaning is generally performed at low temperatures to avoid high-temperature demolding that can cause cracks in the castings. The traditional mechanical cleaning method involves manual operation, using tools like hammers and iron rods to clean the molds, which have high labor intensity, low work efficiency, and poor working conditions and are rarely used in production.

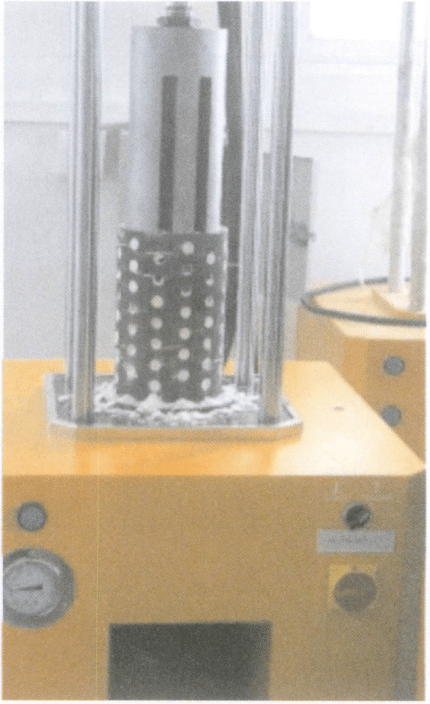

The mechanical extrusion demolding method is mainly used for such products, with the equipment shown in Figure 8-1. It uses a hydraulic mechanism, and the pressure rod head can press down along the inner wall of the steel flask, extruding the metal tree along with the encased gypsum mold, making demolding simple and quick, especially suitable for the demolding treatment of wax-set casting products at low temperatures. Since dust is generated during the extrusion demolding cleaning process, specialized ventilation facilities are generally required in the work area to improve working conditions.

(2) Water Explosion Cleaning

Water explosion cleaning involves placing the castings, which have been poured and cooled to a certain temperature, along with the molds into a water pool, allowing water to rapidly enter the molds, causing rapid vaporization and pressure increase, resulting in an explosion that blasts the molds off the castings. It consists of three stages: water entry, vaporization, and pressure explosion.

① Water Entry. Water enters the mold material under the dynamic pressure head and static pressure head, and the “capillary” action of the gaps between the mold materials also penetrates the inner layers through the gaps between the casting powder particles and vaporizes due to heat. Therefore, taking all measures to quickly promote a large amount of water entry is the first basic condition for forming a water explosion.

② Vaporization. After water enters the hot mold, it vaporizes due to heat, and steam continuously expands. When the steam pressure is less than the water infiltration pressure, water still penetrates deep into the mold, and the amount of steam continues to increase, raising the steam pressure. When the steam pressure equals or exceeds the water infiltration pressure, there will be a phenomenon where the steam pressure hinders the water from continuing to infiltrate or reduces the water inflow rate, affecting the effectiveness of water explosion cleaning. During the water explosion operation, swinging the mold in water can induce cracks in the mold, increase the dynamic pressure head of the water, and accelerate the inflow and vaporization speed. Therefore, sufficient water inflow and accelerated vaporization are the second basic conditions for forming water explosion.

③ Pressurized Explosion. The pressurized explosion is the final stage of the water-explosion cleaning process. Its pressure mainly comes from two aspects: on the one hand, the continuous vaporization of water increases the pressure; on the other hand, the already vaporized steam expands and increases the pressure under continued heating conditions. In addition, the steam must be surrounded in a certain sealed area; otherwise, if the steam leaks out and the pressure does not meet the requirements, it will weaken the effect of water explosion. Therefore, creating certain closed conditions and promoting a rapid increase in steam pressure are the third basic conditions for forming water explosion.

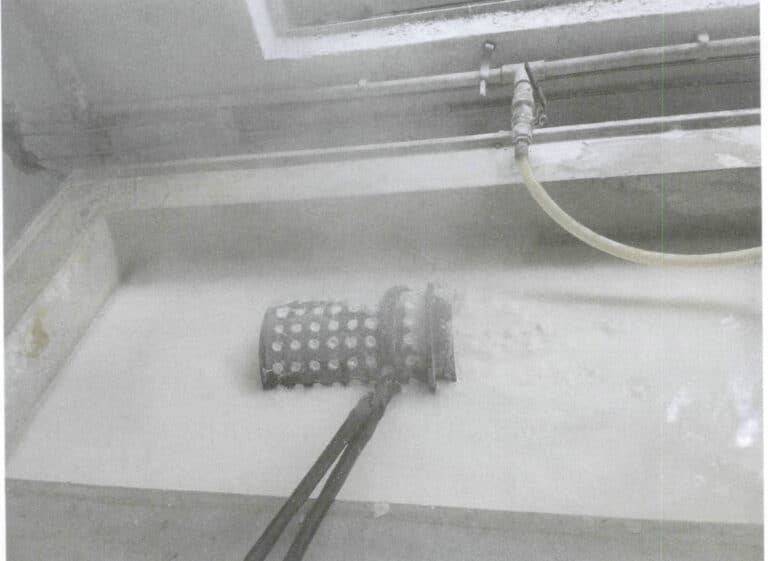

Since jewelry casting molds are generally small, the water-explosion cleaning devices are usually small. Some enterprises even use water barrels to complete water explosion cleaning with a long water flow. When producing larger batches or casting larger craft ornaments and other castings, it is necessary to set up water-explosion cleaning pools, commonly made of all stainless steel or stainless steel frames lined with PVC. These water-explosion cleaning pools have good pressure-bearing and corrosion-resistant properties, as shown in Figure 8-2.

(3) Hydraulic Cleaning

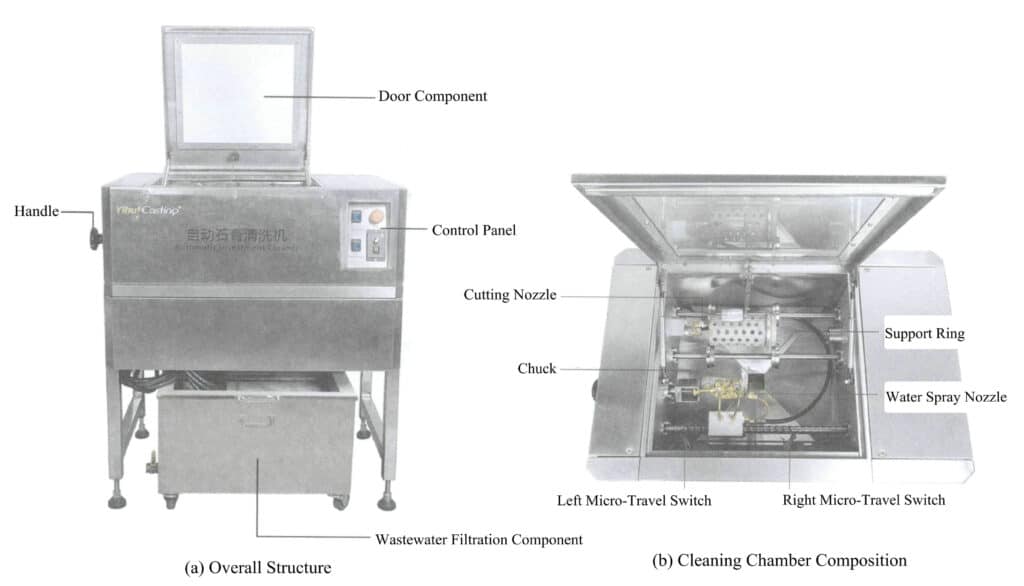

Hydraulic cleaning is the process of using the impact force of water to clean the mold materials wrapped on the surface or inside castings. Compared to dry mechanical cleaning, this method avoids the generation of large amounts of dust during the cleaning process and is widely used. Hydraulic cleaning-related equipment can be divided into two categories based on the degree of automation: high-pressure casting plaster mold cleaners and automatic gypsum investment cleaners.

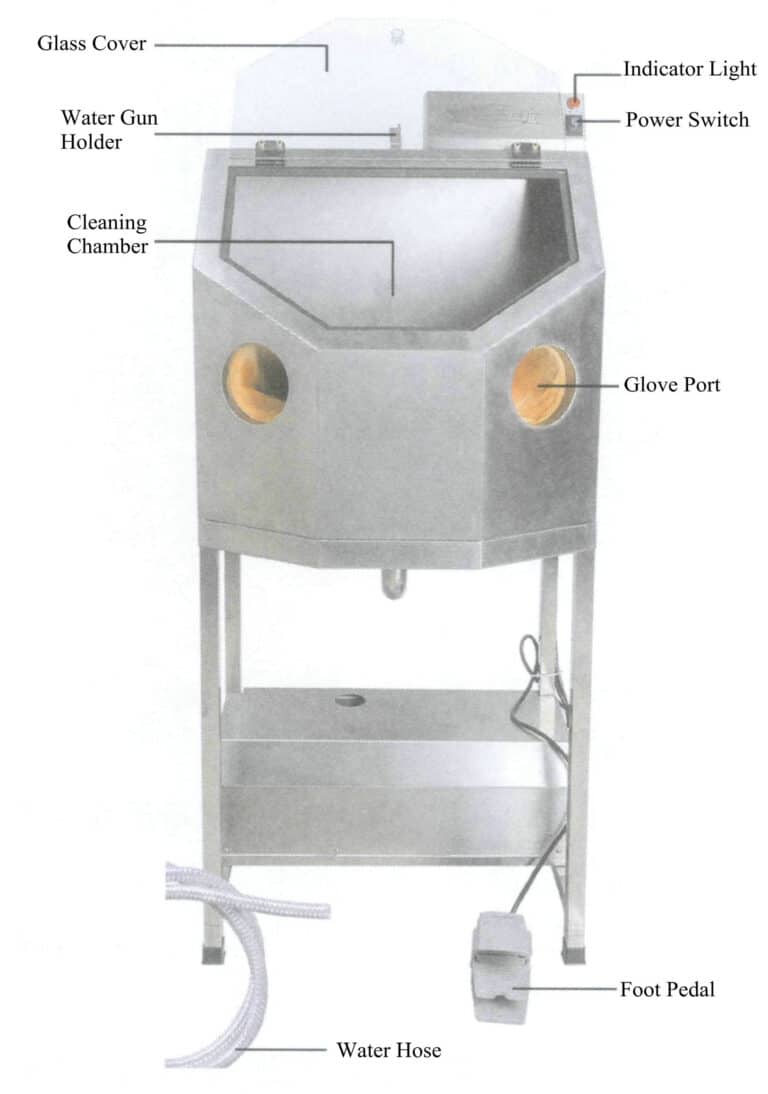

The high-pressure casting plaster mold cleaner is a widely used cleaning device for jewelry molds, as shown in Figure 8-3. Its principle is to convert tap water into high-pressure water through a high-pressure pump and to direct it through pipes to the nozzle of the high-pressure water gun. The high-pressure, low-speed water is then transformed into low-pressure, high-speed water jets, which continuously act on the surface of the metal tree with high-impact kinetic energy, causing the casting powder to fall off and achieving the cleaning purpose. Gloves are set on both sides at the front of the cleaner to prevent water from spraying out; a glass cover is placed on top for easy observation of the internal conditions of the washing chamber.

1.4 Treatment of Gypsum Waste Liquid

Whether using water explosion cleaning or hydraulic cleaning methods, a milky white waste liquid containing a large amount of waste gypsum casting material will be produced. If this waste liquid is discharged directly, it will harm the environment. Therefore, measures need to be taken to treat the waste liquid.

Currently, the main treatment method for gypsum waste liquid is sedimentation, which is based on the principle of allowing suspended solid particles in the water flow to settle down in a time shorter than the time it takes for the water to flow out of the sedimentation tank, thus separating the suspended solids from the water flow and achieving water purification. To this end, waste liquid collection tanks are set up at the sites of water explosion cleaning and hydraulic cleaning, which include components such as an inlet, sedimentation tank, and outlet, as shown in Figure 8-5. Multiple baffles are arranged along the flow direction of the waste liquid in the sedimentation tank to slow down the flow rate of the waste liquid, allowing sufficient time for the solids in the waste liquid to settle down. To further purify the tail liquid, some jewelry companies have also specially set up large outdoor sedimentation tanks to further purify the waste liquid that has undergone primary sedimentation, as shown in Figure 8-6.

1.5 Acid Immersion of Castings

After rinsing, the jewelry metal tree inevitably retains casting materials in some gaps, recesses, and blind holes. Additionally, the metal surface often retains a brown film or black metal oxide. Before proceeding with the next operation on the metal tree, cleaning the metal surface using a chemical soaking method is necessary.

Gypsum casting materials are mainly composed of refractory aggregates and gypsum binders. Refractory aggregates are generally made from silica materials. After high-temperature roasting and casting cooling, silica undergoes multiple crystalline transformations, and the gypsum part turns into anhydrous calcium sulfate reducing the bonding strength. Soaking in a chemical solution aims to react with most components in the residual mold to form soluble substances, allowing for further cleaning of the casting surface. Various inorganic acids can dissolve the oxide film on the metal surface. Still, only hydrofluoric acid significantly affects silicon dioxide, with the reaction formula as follows: SiO2+4HF==SiF4↑+2H2O. The product tetrafluorosilane (SiF4) is a colorless, toxic gas with a pungent odor at room temperature.

Therefore, hydrofluoric acid is widely used to soak jewelry metal trees in actual production. The concentration of hydrofluoric acid solution and soaking time should be selected based on the corrosion resistance of the metal material. The soaking time for K gold, pure gold, and silver jewelry castings is 20 minutes, with a hydrofluoric acid concentration of 20%~30%; The soaking time for purple copper and brass jewelry castings is 20 minutes, with a hydrofluoric acid concentration of 5%~10%; The soaking time for platinum jewelry castings is 60 min, and the concentration of hydrofluoric acid is 50%~60%. Due to the strong corrosiveness of hydrofluoric acid, it should be stored in specialized plastic containers and not in glass containers; safety precautions should be taken during operation, including wearing plastic gloves and goggles.

1.6 Residual Sprue Polishing

1.7 Magnetic Polishing Cleaning

The surface of castings after acid immersion may still have issues such as dirt, oxide film, burrs, and residual casting powder, increasing the workload of finishing. Therefore, most manufacturers will perform magnetic polishing cleaning on castings.

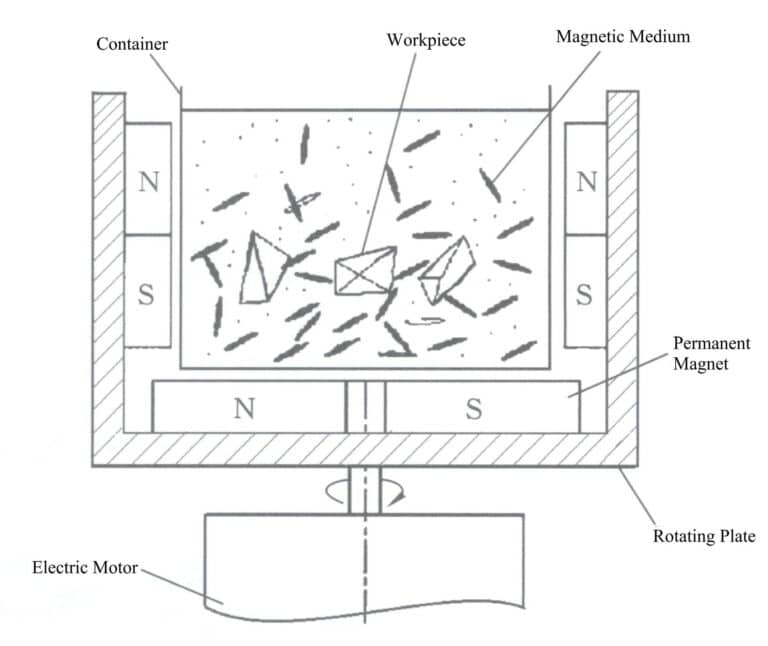

The principle of magnetic polishing cleaning is shown in Figure 8-8. It utilizes a high-frequency magnetic drive to generate strong and stable magnetic effects, causing stainless steel grinding burs to perform high-speed jumping, flowing, and turning actions, creating comprehensive and multi-angle friction in the gaps, recesses, dead corners, and surfaces of the castings, achieving rapid removal of dirt, burrs, and oxide films, while it does not damage the workpiece surface or affect the workpiece precision and can also increase its surface hardness.

2. Görev Uygulaması

This task is the cleaning method for 18K platinum jewelry castings made from gypsum molds.

(1) Determining the Water Explosion Cleaning Time

Commercial 18K platinum mostly uses nickel as a bleaching element and is an alloy material primarily composed of gold, nickel, copper, etc. This type of material is a continuous solid solution with good plasticity at high temperatures. Still, it undergoes phase separation at lower temperatures, increasing strength and hardness while reducing toughness and plasticity. When determining the water explosion cleaning time, it is necessary to comprehensively consider factors such as the size of the steel flask and product structure, striving to achieve an optimal balance between reducing casting stress and the effectiveness of water explosion cleaning. If water explosion cleaning is done too early, excessive casting stress may cause deformation or cracking; if done too late, the cleaning effect will be poor. For steel flasks with an outer diameter of less than 4 inches, the standing time of the mold in the air after pouring is generally around 10~15 min; for steel flasks with an outer diameter of 4~6 inches, the standing time is generally around 15~20 min; for larger steel flasks, the standing time should be appropriately extended and adjusted according to the product structure.

(2) Water Explosion Cleaning

Use pliers to secure the mold and immerse it in the water explosion cleaning tank, as shown in Figure 8-9. When the high-temperature mold comes into contact with cold water, a water explosion effect occurs instantly, and a low rumbling explosion sound can be heard. Gently move the held mold to ensure sufficient contact with the water to achieve a good water explosion effect. During production, it is necessary to promptly clean the sedimented waste mold material at the bottom of the water explosion tank to maintain sufficient water depth in the cleaning tank.

(3) High-Pressure Washing

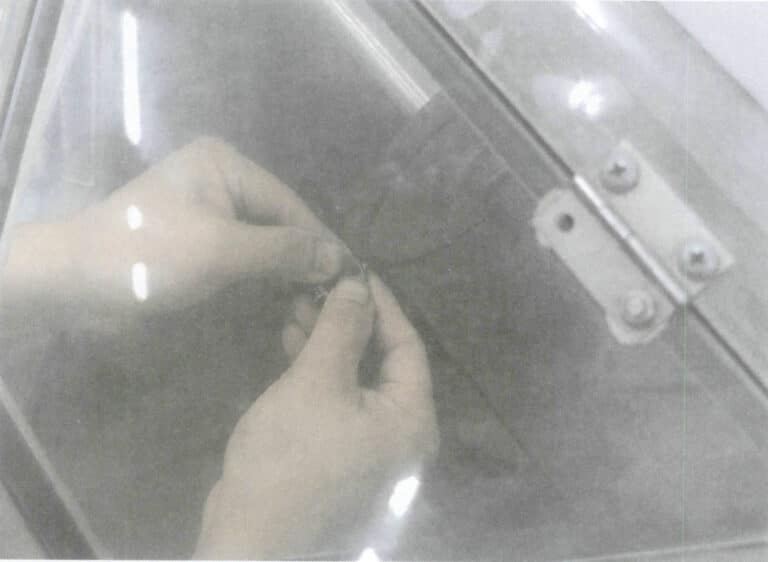

Remove the metal tree from the steel flask, place it in the high-pressure casting plaster mold cleaner, and close the observation window. Insert your hands into the washing chamber through the rubber gloves, steady the metal tree, and aim it at the nozzle. Step on the footswitch to turn on the cleaner and wash the metal tree with a high-pressure water jet. Move and flip the metal tree with both hands to thoroughly wash all parts, as shown in Figure 8-10.

(4) Acid Immersion

Use hydrofluoric acid with a concentration of 25%, wear protective gear, secure the metal tree with pliers, and carefully place it into the acid solution, as shown in Figure 8-11. Cover it and let it sit. After soaking for 20 minutes, remove the metal tree, rinse it in a dedicated recovery bucket, and thoroughly wash it under running water. Check for any residual casting powder in the metal tree; if present, it must be soaked again. After a period of use, the effectiveness of the hydrofluoric acid solution decreases, requiring an extension of the soaking time or the addition of new acid.

(5) Cleaning and Drying

Clean the metal tree thoroughly, dry it with a hairdryer or hot air furnace, as shown in Figure 8-12, weigh it, and calculate the melting and casting loss for this batch.

Figure 8-11 Metal tree soaking in acid

Figure 8-12 Drying

(6) Cutting Blanks

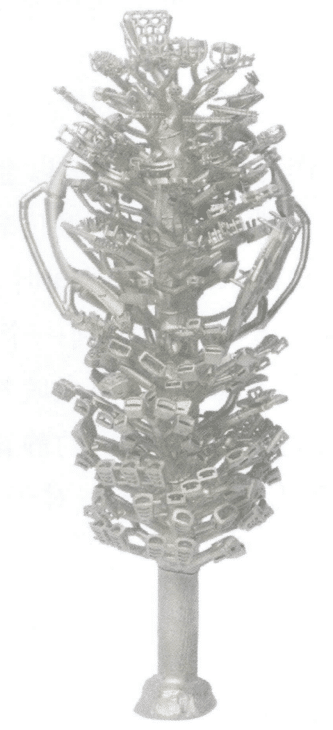

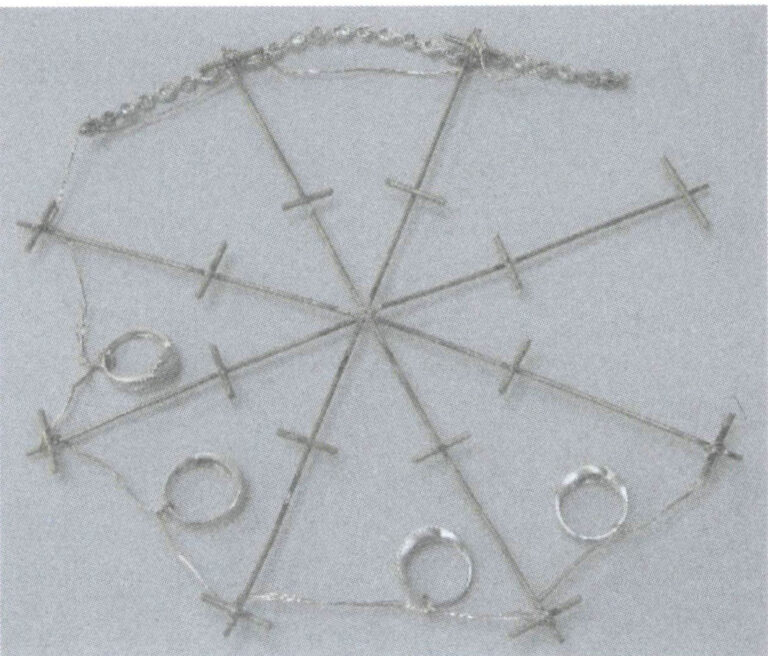

The cleaned jewelry castings are still tree-shaped and must be cut off at the sprue, sorted by category and type, to prepare for the next production process.

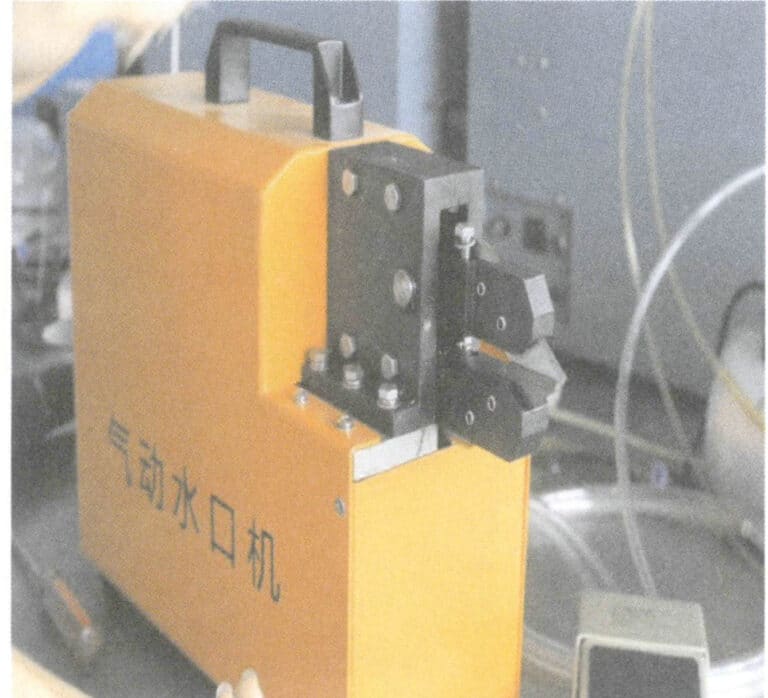

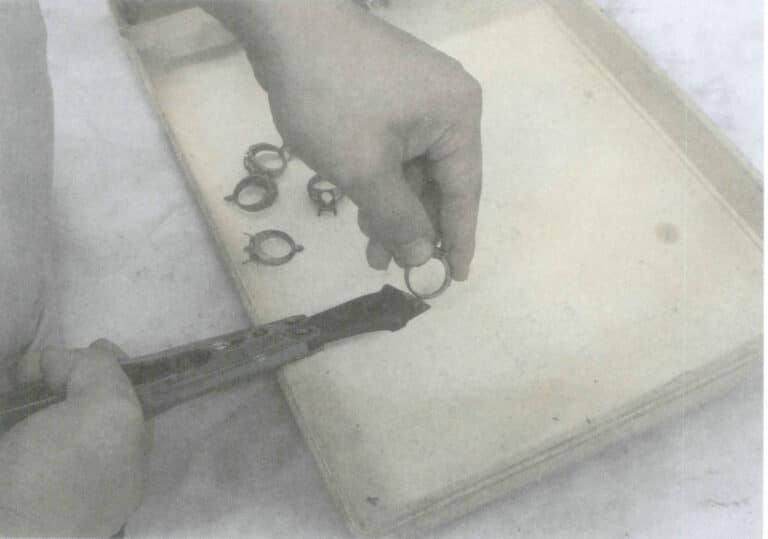

Since the sprues of the castings are all connected to the tree core and are relatively close to each other, and the sprues are at a certain angle to the tree core, it is not easy to cut the sprues downward. Therefore, the castings should be cut off from the tree core in the order from the adjacent pouring cup to the top of the tree. To avoid damaging the castings, a two-step cutting method is generally used: cut the sprue at a certain distance from the casting and then cut off the excess sprue. To improve production efficiency and reduce labor intensity, a pneumatic crimping machine can be used for cutting at once, as shown in Figure 8-13. Handheld cutters are used for operation when cutting each casting separately, as shown in Figure 8-14, which facilitates control of the cutting direction and residual sprue. Generally best at a distance of 1.5 mm from the blank. When the residual sprue is too short, it can easily deform or damage the blank; when it is too long, it increases the workload for subsequent processing.

Figure 8-13 Cutting the sprue with a pneumatic crimping machine

Figure 8-14 Uses cutters to trim the residual sprue

(7) Polishing the Residual Sprue

To improve work efficiency, priority is given to using sprue polishing machines to turn the residual waterline during production. After starting, adjust the cooling sprue, with a general droplet speed of 2~3 drops per second being optimal. Observe the position of the workpiece’s waterline to determine the grinding angle of the workpiece. After starting, use a discontinuous method close to the steel wheel, as shown in Figure 8-15, while observing and trying to keep the sprue smooth, being careful not to damage the workpiece, especially paying attention to the prong, claw, and groove positions. When turning the workpiece, classify the metal powder into containers according to the material. After each workpiece is polished, promptly clean the metal powder and wash your hands in the designated recycling bin to minimize precious metal loss.

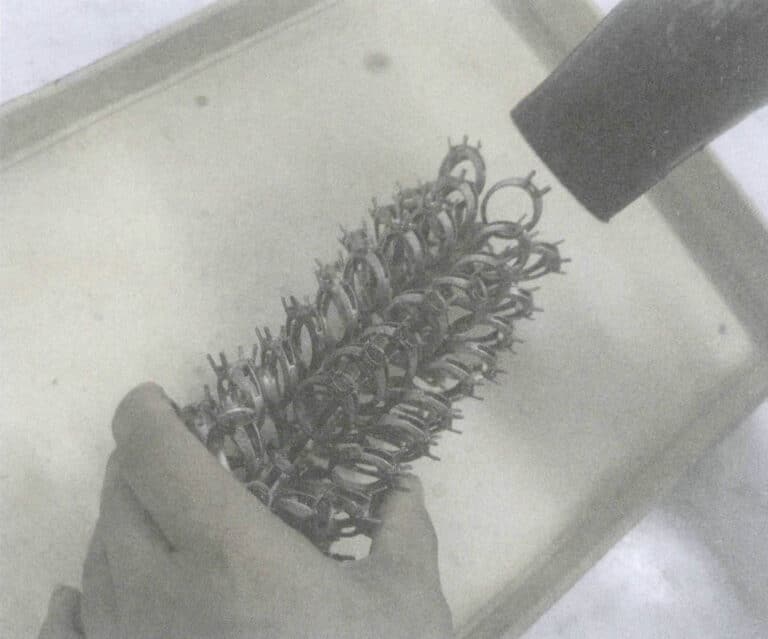

(8) Magnetic Polishing Cleaning

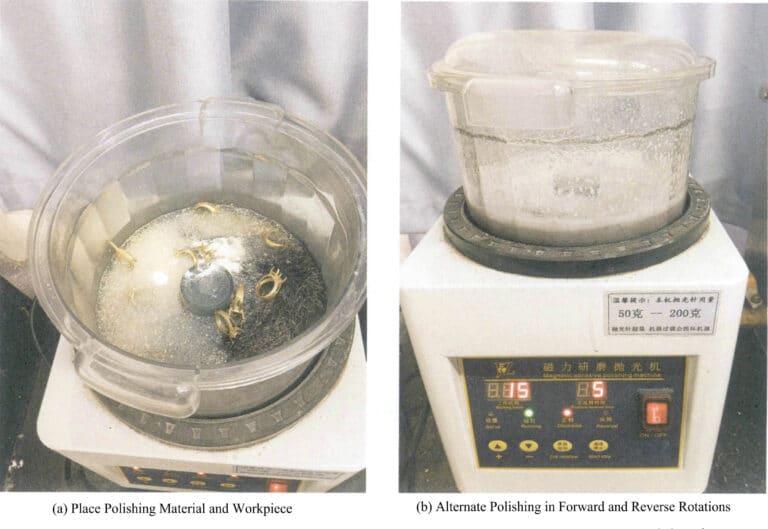

First, prepare the polishing liquid by mixing the polishing powder with water in a mass ratio of 3.5%. Then, place the steel burs (diameter 0.5 mm and 0.3 mm, in a ratio of 4:1 ) into the container, as shown in Figure 8-16. The mass of the workpiece is determined by the tumbler model, which generally does not exceed 500 g. The rotation speed should be selected based on the jewelry material; for K platinum can generally choose 1800~2000 r/min. Set the clockwise and counterclockwise rotation time, typically changing direction every 5 minutes, with a total time of 15~30 min. Note: If the workpiece in the container is too large, too many are placed, or the set direction changes too frequently, it may cause the machine to stop working urgently. After daily work is completed, the equipment should be wiped clean to keep it dry and tidy. When the color of the steel burs darkens, they should be cleaned with a neutral detergent. New and old steel burs should not be mixed, and the polishing liquid should be replaced when it turns brown.

Copywrite @ Sobling.Jewelry - Özel takı üreticisi, OEM ve ODM takı fabrikası

Section II Cleaning of Jewelry Castings Using Wax-Set Gypsum Molds

1. Arka Plan Bilgisi

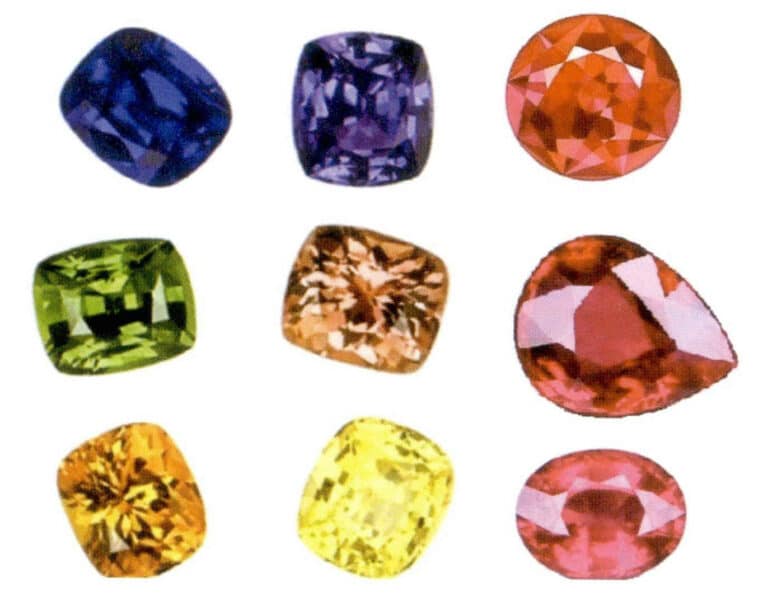

(1) The Loosening and Breaking of Wax-Set Gemstones

Compared with traditional gold setting techniques, the wax setting casting process can significantly improve production efficiency and reduce production costs, thus making it widely used in jewelry manufacturing. An important indicator of the quality of wax setting is the stability of the gemstones; after wax setting casting, the gemstones should not experience loosening, discoloration, or breaking. However, wax setting casting is a complex process, as gemstones must endure a series of temperature changes, thermal stresses caused by thermal shocks, and casting shrinkage. The mechanical stress generated during the shrinkage process poses risks such as loosening, cracking, and discoloration, especially when setting multiple gemstones, which can easily lead to breakage issues, causing significant economic losses for enterprises. Moreover, once a gemstone breaks, it is difficult to handle; the broken gemstone needs to be removed and then repaired in place using gold setting methods, which greatly affects production costs and efficiency.

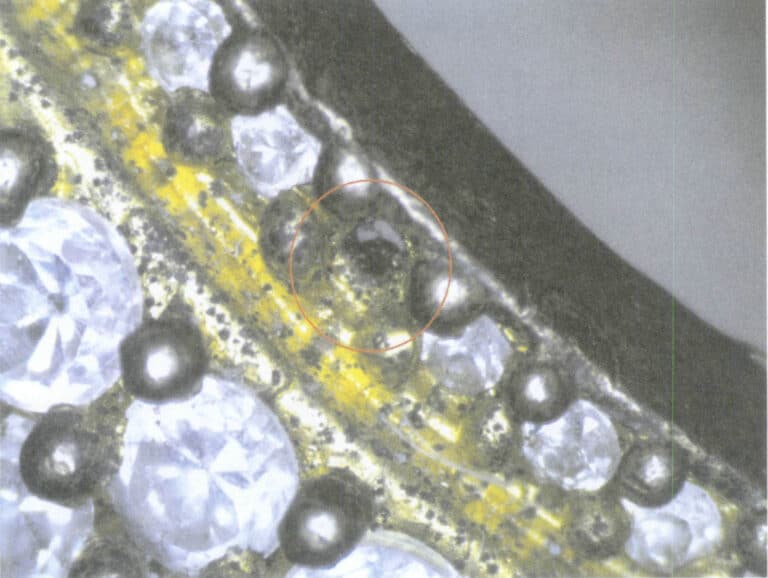

Gemstones have poor resistance to thermal shock. Suppose the wax-set casting is de-molded at high temperatures. In that case, the gemstones can generate significant thermal stress during rapid cooling, leading to a high risk of breakage, especially when using gemstones with internal cracks for wax setting casting, as shown in Figure 8-17. Therefore, jewelry castings made with wax setting are unsuitable for water-explosion cleaning; the mold must be slowly cooled to a low temperature before demolding. A more suitable demolding cleaning method is mechanical extrusion demolding.

To achieve a good appearance for gemstones, it is generally not advisable to use large prongs (claws) or wide, thick edges to secure them during setting. Instead, finer wax prongs (claws) or thin-walled, narrow wax edges should be used for setting, which is replaced by metal after casting to secure the gemstones in place. This structure provides relatively weak support for the gemstones; when subjected to external forces, if the force exceeds the strength of the metal, it may cause deformation at the metal setting site, leading to gemstone displacement or loosening, as shown in Figure 8-18.

During the cleaning process of castings, when using mechanical extrusion demolding, if the extrusion force directly acts on the metal tree, certain parts of the casting on the metal tree may deform under the hindrance of the mold, causing the gemstones to loosen. This is especially true when the extrusion rod is a solid cylinder, as it easily transmits the extrusion force to the casting, causing deformation and breakage, leading to a gemstone drop. Therefore, the extrusion rod needs to be designed as a dispersive plate, as shown in Figure 8-19, so that most of the extrusion force only acts on the contact area, causing the mold in that area to collapse without affecting the casting farther away. If the extrusion head is set as a thin-walled cylindrical shape, with an outer diameter slightly smaller than the inner diameter of the steel flask, then during the extrusion process, only the wall of the cylinder wedges into the mold, causing the thin layer of mold adjacent to the cylinder wall to collapse, while having almost no effect on the surrounding mold, significantly reducing the extrusion impact on the casting.

Figure 8-18 Gemstones falling from wax-set casting jewelry

Figure 8-19 Structure of the head used in mechanical extrusion demolding

(2) Acid Immersion Treatment of Wax-Set Castings

After washing, the jewelry casting tree generally needs to be soaked in hydrofluoric acid to remove residual casting powder, oxide film, inclusions, etc., from the surface of the casting. However, for wax-set castings, gemstones are also inlaid on the casting in addition to the metal body. Therefore, it is necessary to determine whether acid immersion is suitable based on the properties of the gemstones. Among common gemstones, quartz, obsidian, and other silica-based gemstones, as well as aquamarine, emerald, and topaz, which are silicate-based, can be corroded by hydrofluoric acid, so they are not suitable for hydrofluoric acid soaking.

2. Görev Uygulaması

This task uses a casting extruder and an automatic gypsum casting cleaner to clean the metal casting tree of wax-set gemstone jewelry.

(1) Static Casting

After casting, the mold is suspended on a rack, as shown in Figure 8-20, to allow the entire mold to cool evenly until the mold temperature drops to around 100℃.

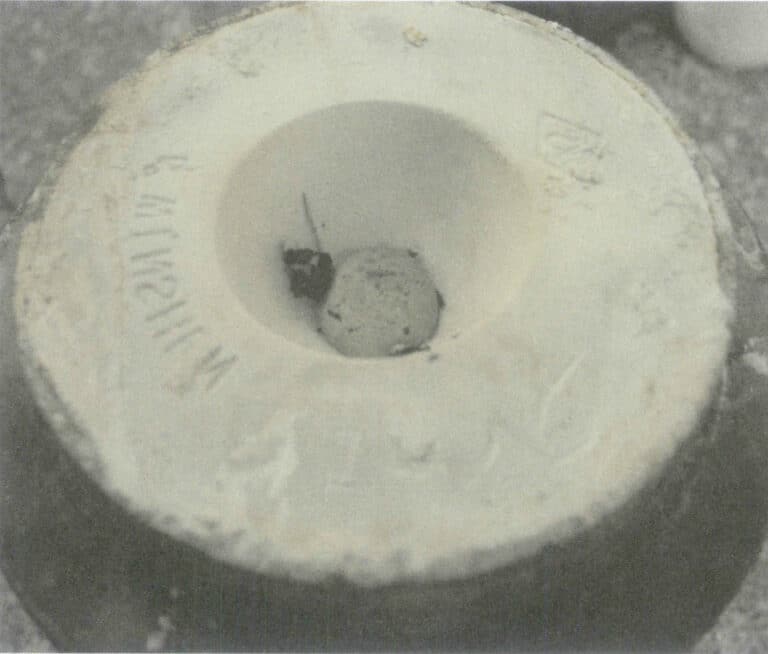

(2) Mechanical Extrusion Demolding

Invert the mold with the flange edge of the steel bowl clamped at the mouth of the extrusion chamber, keeping the mold upright. Start the extruder, allowing the extrusion rod to descend slowly, extruding the metal tree, as shown in Figure 8-21.

Figure 8-20 Mold cooling in place

Figure 8-21 Extrusion demolding of the steel flask

(3) High-Pressure Cleaning

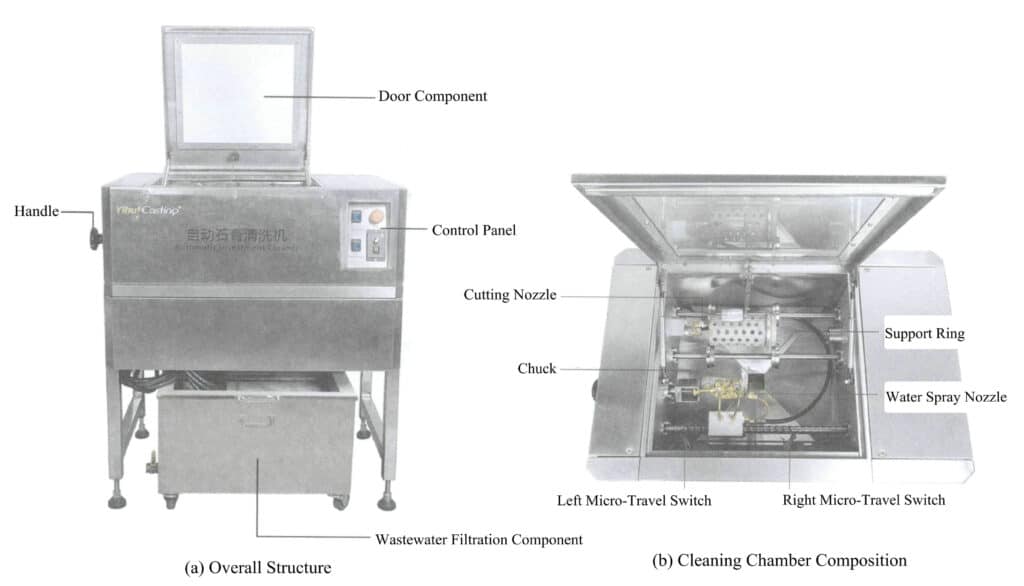

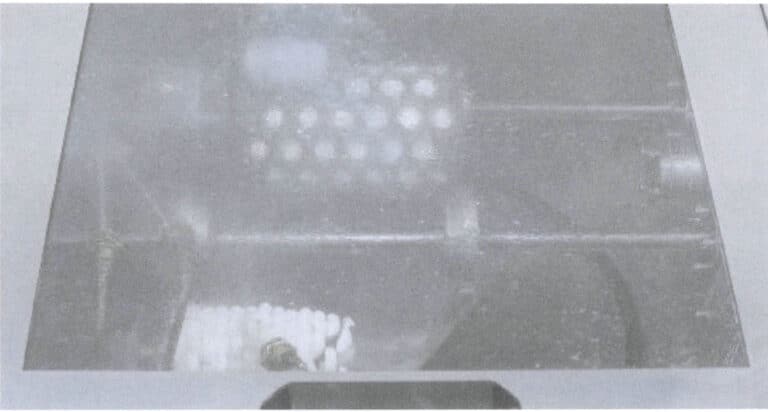

When the casting mold temperature, along with the wrapped metal tree, drops below 50℃, please place it in the automatic gypsum casting cleaner and put the steel flask inside. Set the rated water pressure to 11MPa, start the cleaner, and wash the metal tree and steel flask. The steel flask and metal tree should continuously rotate during the washing process to ensure all parts are adequately cleaned, as shown in Figure 8-22. Additionally, a filter screen should be set at the return port of the cleaner to prevent gems from being washed away and flowing into the sedimentation tank, increasing the retrieval difficulty.

(4) Cutting the Sprue

After the metal tree is cleaned, dry it, weigh it, and calculate the melting and casting loss. Then, the cutting and polishing of the residual sprue operations are performed. The operation method is the same as chapter 2 in section I reference case.

(5) Magnetic Polishing Cleaning

Magnetic polishing and cleaning on the cut metal tree cores and wax-set castings are performed separately. The former facilitates metal reuse, while the latter allows for further cleaning of areas not sufficiently washed under high pressure, such as the setting base and around the bezel. To prevent wax-set castings from colliding and cracking during the magnetic cleaning process, a special fixture can be made, as shown in Figure, to tie the castings to the fixture separately, preventing mutual collisions. However, each casting can flexibly rotate and change direction, which does not significantly affect the cleaning effect.

Section III Cleaning of Jewelry Castings Using Acid-Bonded Ceramic Molds

1. Arka Plan Bilgisi

(1) Cleaning of Acid-Bonded Ceramic Molds with Water Explosion Cleaning

For casting jewelry made from high melting point materials such as platinum, palladium, stainless steel, and cobalt alloys, acid-bonded ceramic molds are currently the main forming method. After high-temperature roasting of the acid-bonded casting powder slurry, the original models are burned off and vaporized, moisture is completely removed, and the refractory materials of the mold are consolidated and ceramicized under the action of the binder. Compared to gypsum molds, acid-bonded ceramic molds have very high high-temperature strength and maintain relatively high residual strength after pouring the metal liquid. Still, the mold’s yield is poor, hindering the solidification shrinkage and cooling shrinkage of the casting, leading to increased internal casting stress and resulting in risks of thermal cracking, deformation, and cold cracking in the casting.

The residual strength of ceramic molds is high, and their collapsibility is much worse than that of gypsum molds. Therefore, the difficulty of demolding and cleaning metal castings is greatly increased. It is necessary to fully understand the physical, chemical, and mechanical properties of metal materials and develop corresponding cleaning plans for the castings. Suppose only mechanical squeezing or vibration methods are used for demolding due to the high hardness of ceramic molds. In that case, they are not easy to break, making cleaning more difficult, which can easily lead to deformation and surface scratches of the castings, as well as deformation of the steel flask. Under the premise that the metal castings can withstand thermal shock, priority should be given to combining the water explosion cleaning process, using the explosive force of steam at high temperatures to burst the mold and facilitate high-pressure water cleaning. The higher the water temperature during water explosion cleaning, the stronger the explosive effect, but the thermal shock effect on the castings will also be greater. Therefore, it is necessary to closely combine the properties of jewelry metal materials and the structural characteristics of the products to determine the water explosion cleaning process plan.

Platinum jewelry materials with high ductility and plasticity, such as Pt950Ir50 and Pt950Pd50, are not sensitive to thermal shock. A high-temperature water explosion cleaning method can be adopted for molds made from such materials. Even if the mold is quenched in water within seconds after pouring, the castings will generally not experience cracking issues. However, for lower-fineness Pt900 and Pt850 platinum alloys and some Pt950 alloys that are sensitive to thermal shock, it is necessary to appropriately lower the temperature of the mold-quenching water.

Non-precious jewelry materials such as stainless steel and cobalt alloys usually have worse thermal conductivity than precious metals. During the cooling process of the castings, phase changes occur, and ductility and plasticity decrease. Therefore, it is necessary to comprehensively consider thermal, phase change, and mechanical resistance stress to determine the appropriate temperature for mold quenching.

(2) Cutting the Sprue

Due to the high viscosity of the molten metal during the casting process of platinum jewelry, which maintains a liquid state for a short time and has poor fluidity, the sprue for platinum jewelry is generally set thicker than that for gold and silver jewelry to improve the filling and shrinkage performance of the molten metal. Therefore, the difficulty of cutting the sprue for platinum jewelry castings increases, making it easier to cause deformation of the castings. When shearing the sprue, it is necessary to choose the appropriate shearing method based on the diameter of the sprue to prevent deformation of the castings. Cutting should be combined with a saw or small slices if necessary.

(3) Magnetic Polishing Cleaning

Magnetic polishing is an effective means of cleaning castings, but different types of metal materials have different strengths and hardness, which leads to varying requirements for the magnetic polishing process. Common high-grade platinum such as Pt990 and Pt950 has low hardness; if cleaned at excessively high speeds, it can easily cause surface scratches and increased roughness. When platinum jewelry is mixed with K gold jewelry for magnetic polishing cleaning, the surface is prone to marks and scratches.

2. Task Implementation

This task involves cleaning acid-bonded ceramic molds and vacuum centrifugal casting of Pt950 jewelry castings.

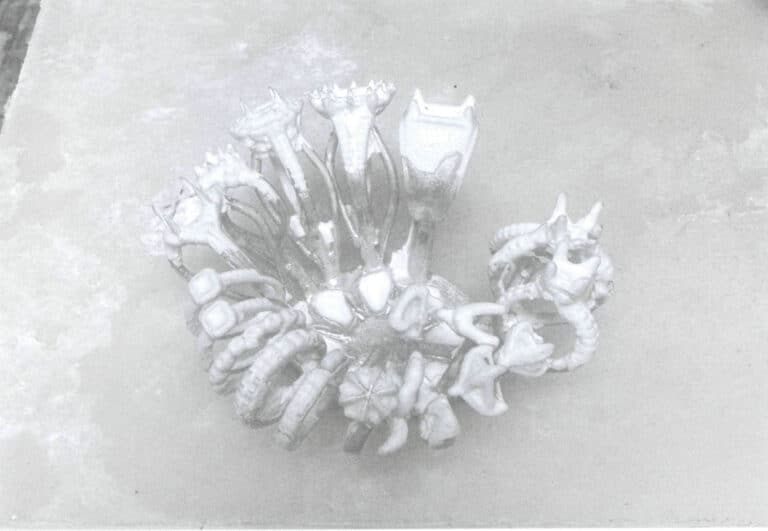

(1) Water Explosion Cleaning

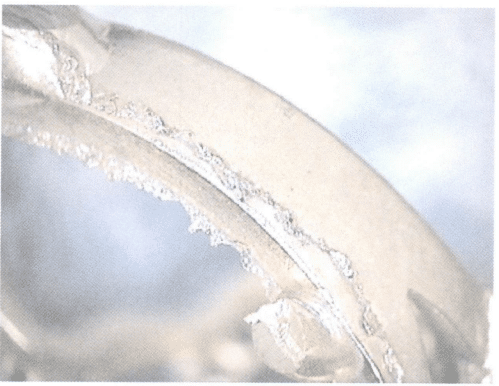

Using vacuum centrifugal casting for Pt950 jewelry, the steel flask is cylindrical with no holes in the wall. The casting temperature of the mold is 900℃, and the temperature of the molten metal is 1880℃. After pouring, wait for the equipment to stop operating, use pliers to remove the mold, and quench in water for water explosion cleaning pool, resulting in a metal tree wrapped in mold material, with residual mold material forming interconnected crack networks, as shown in Figure 8-24.

(2) High-Pressure Cleaning

Use a high-pressure plaster mold cleaner to clean the mold wrapped around the metal tree and the molds embedded in the casting’s recesses, seams, and other areas. Since the residual ceramic mold is not easily dispersed, relying solely on jet washing cannot clean some hidden molds thoroughly. Therefore, it is sometimes necessary to use small tools such as steel rods and machine burs for auxiliary cleaning, as shown in Figure 8-25, and continue washing.

(3) Acid Immersion

Due to the high residual strength of the acid-bonded ceramic mold and its dense structure, and because Pt950 alloy has excellent corrosion resistance, high-concentration hydrofluoric acid can be used, typically adjusting its concentration to 55% with an immersion time of about 1 hour, which can achieve good immersion cleaning results.

(4) Cutting the Waterline

Cutting pliers can generally be used for castings with a sprue diameter of less than 3.5 mm. However, when the sprue diameter reaches 4 mm or larger, there is a deformation risk when cutting pliers. It is advisable to first use pneumatic crimping pliers to cut near the tree core and then use a saw to cut near the surface of the casting, as shown in Figure 8-26.

(5) Polishing the Residual Sprue

As previously mentioned, a sprue polishing machine will be used to remove the residual sprue.

(6) Magnetic Polishing Cleaning

Place the casting into the magnetic tumbler, set the speed to, and set the direction to 800~900 r/min, change every 5 minutes, with a total polishing time of 20~30 min.

Section IV Jewelry Casting Quality Inspection

1. Arka Plan Bilgisi

Jewelry casting is a complex process involving multiple procedures, with many factors affecting casting quality, making it prone to various problems.

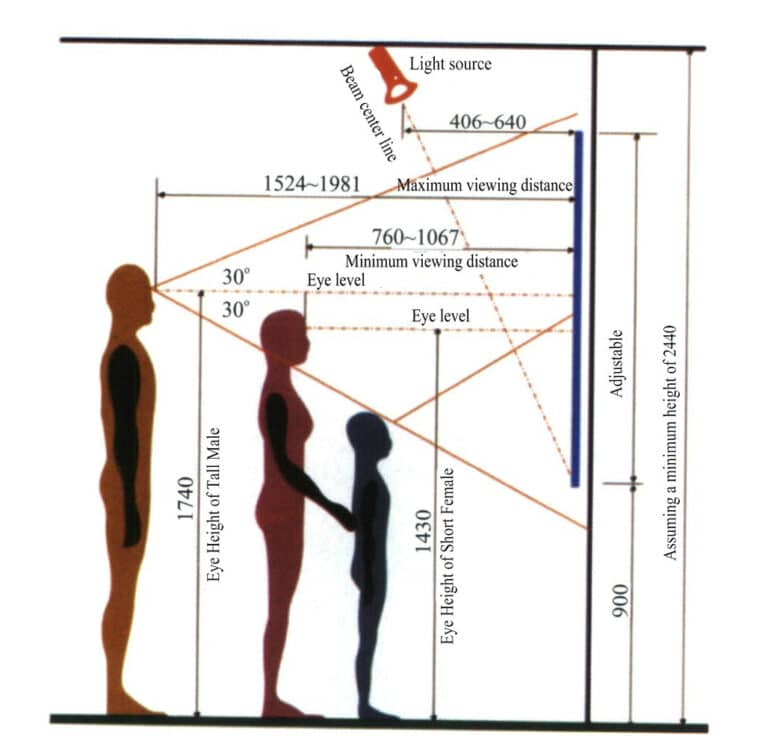

(1) Appearance Inspection Tools and Equipment

During the quality inspection of jewelry appearance, it is necessary to inspect the quality of detailed parts, and the human eye has a limited ability to distinguish details of objective objects, generally being able to discern the smallest length between 0.15~0.30mm. Therefore, magnifying glasses, microscopes, and other observation tools must be used.

A magnifying glass is a simple visual optical device used to observe the details of objects, consisting of a converging lens with a focal length much smaller than the eye’s near point. The principle of magnification is that the size of the image formed on the human eye’s retina is proportional to the angle subtended by the object at the eye (visual angle). The larger the visual angle, the larger the image, and the more details of the object can be distinguished. When using a magnifying glass, one hand holds the magnifying glass close to the eye. In contrast, the other hand uses the index finger and thumb to hold the jewelry and bring it close to the magnifying glass until the desired part of the jewelry can be observed. Bringing the object closer can increase the visual angle, but the eye’s focusing ability limits it. The most commonly used magnifying glass in the jewelry industry has a magnification of 10 times, as shown in Figure 8-27, and consists of 3 lenses. A qualified magnifying glass should have high clarity and eliminate spherical and chromatic aberration that affects the observation of gemstones.

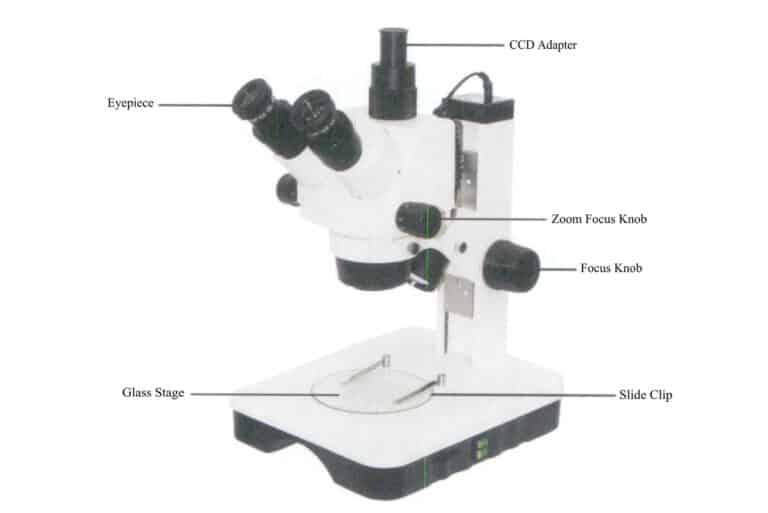

The stereomicroscope has the following characteristics: ① large field diameter and large depth of focus, which facilitates the observation of all layers of the object being inspected; ② although the magnification is not as high as that of conventional microscopes, its working distance is very long; ③ due to the prism below the eyepiece inverting the image, the image appears upright, making it easier to operate.

The typical technical parameters of the stereomicroscope for jewelry inspection are as follows: the eyepiece magnification is 10 times, the field diameter is 20 mm; the objective lens uses a rotating drum for continuous zoom, with a range of 0.7~4.5 times; the total magnification is 7~45 times; the zoom ratio is 6.5:1.

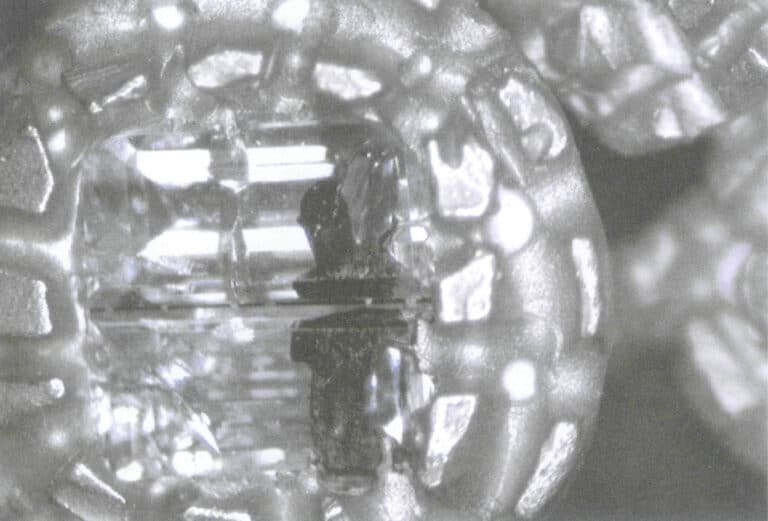

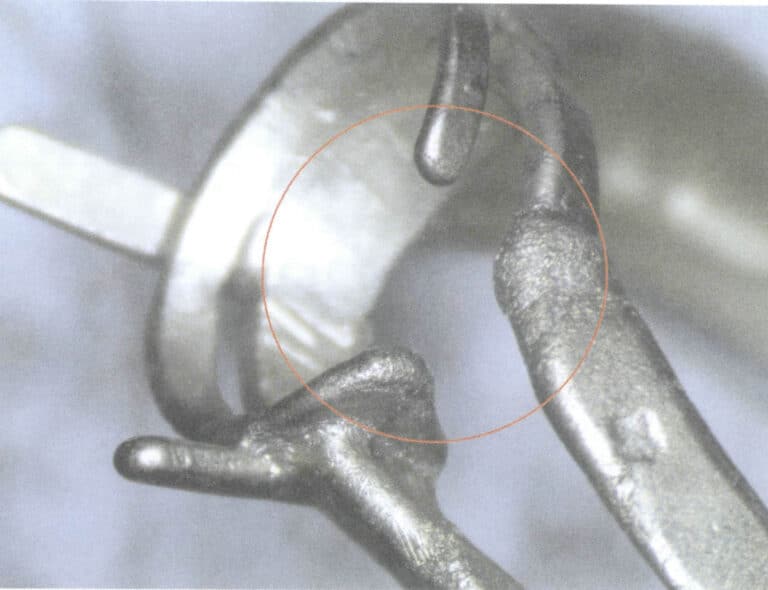

(2) Porosity Defects

Porosity defects are holes formed by foreign gases or gases precipitated from molten metal being trapped within the metal. Their characteristics include round or irregular holes with generally smooth inner walls, as shown in Figure 8-29. The color is metallic or oxidized, and it is difficult to distinguish them when they coexist with slag holes or shrinkage holes. Porosity can affect the surface quality of castings, making jewelry difficult to obtain a smooth and shiny polished surface. The presence of pores reduces the effective cross-section of the workpiece, which can have a certain impact on the mechanical properties of the workpiece; the extent of the impact depends on the size and shape of the pores. According to the different formation mechanisms, pores can be classified into reactive, precipitative, and entrapped pores.

Reactive pores are formed by the chemical reaction between the molten metal and internal or external factors, generating gas. They can be divided into endogenous and exogenous types. Endogenous reactive pores are formed when the molten metal solidifies, where the chemical elements of the metal itself react with compounds dissolved in the molten metal or between compounds, generating gas. Exogenous reactive pores are formed by the chemical reaction between the molten metal and external factors such as molds, slag, and oxide films, resulting in gas generation. Based on their characteristics, exogenous reactive pores can be classified into subcutaneous, surface, and internal pores.

Precipitative pores refer to the pores formed by the precipitation of gas dissolved in the molten metal. The solubility of gas is high when in a high-temperature liquid state, and as the temperature decreases, the solubility also decreases. When the metal transitions from a liquid to a solid state, gas solubility sharply decreases, and the gas that cannot be dissolved will precipitate. If the precipitated gas cannot escape in time and is trapped by the solidifying dendrites, it will form precipitative pores.

Entrapped pores are formed by gas being entrapped during the pouring process, where the gas cannot escape in time during the solidification process and remains within the casting. Their characteristic is that they are irregularly distributed, often appearing in isolated distributions, and some pores may be relatively large.

(3) Shrinkage Defects

The phenomenon of volume reduction due to temperature decrease during the cooling process of casting alloys in liquid, solidification, and solid states is called the shrinkage of casting alloys. Shrinkage is a fundamental cause of many defects in castings, such as shrinkage cavities, shrinkage porosity, stress, deformation, and cracks. It is one of the important casting properties of casting alloys. It significantly impacts castings (such as achieving the required geometric shape and dimensions and producing dense, high-quality castings).

The change in volume when the casting alloy transitions from liquid to room temperature is called volume shrinkage. The shrinkage of the alloy in the solid state can be expressed not only in terms of volume change but also in terms of length change, known as linear shrinkage. The alloy undergoes three stages during shrinkage: liquid shrinkage stage, solidification shrinkage stage, and solid-state shrinkage stage.

Liquid Shrinkage: Refers to the shrinkage that occurs when the liquid alloy cools from the pouring temperature to the liquidus temperature at which solidification begins, manifested as a decrease in the liquid level within the mold cavity.

Solidification Shrinkage: For alloys with a certain temperature range, the shrinkage that occurs when transitioning from liquid to solid state is called solidification shrinkage due to the alloy’s solidifying state. The solidification shrinkage of such alloys mainly includes temperature reduction (related to the crystallization temperature range of the alloy) and state change (volume change during the state change).

Solid-state shrinkage: Refers to the shrinkage that occurs when casting alloys cool from the solidus temperature to room temperature. In actual production, solidification shrinkage often manifests as a reduction in the dimensions of the casting, so a linear shrinkage rate is generally used to represent it. The linear shrinkage of casting alloys not only directly affects the dimensional accuracy of the castings but is also a fundamental cause of stress, cracks, and deformation in the castings.

The casting shrinkage rate is not only related to the factors of the alloy used but also to the casting process’s characteristics, the casting’s structural shape, and the amount of dissolved gas during the melting process of the alloy. Liquid and solidification shrinkage are the fundamental causes of shrinkage cavities and porosity in castings.

During the cooling and solidification process of the casting, due to the alloy’s liquid shrinkage and solidification shrinkage, holes often appear in the areas where the casting solidifies last. Large and concentrated holes are called shrinkage cavities, while small and dispersed holes are referred to as shrinkage porosity, as shown in Figure 8-30. The shrinkage cavities and porosity shapes are irregular, with rough surfaces, and developed dendritic tips can be seen. Thus, they can be clearly distinguished from gas holes. Suppose shrinkage cavities or porosity exist in the casting. In that case, it will reduce the effective bearing area of the casting, cause stress concentration, significantly lower the mechanical properties of the casting, and also reduce the physical and chemical properties of the casting, damaging the surface density and polishing performance.

(4) Fluidity Defects

When the filling performance of molten metal is poor, defects such as incomplete filling and cold shuts are likely to occur. Incomplete filling is when the molten metal fails to fill the mold cavity completely, resulting in an incomplete casting, as shown in Figure 8-31. Its characteristic is smooth, round-edged holes on the casting walls, or one or more ends of the casting are not filled with molten metal. Cold shut refers to a significant discontinuity defect in the casting due to the failure of two areas of metal to completely fuse. Its appearance often manifests as streaks similar to cracks, but compared to cracks, their edges are smoother, and the surface around the streaks is slightly wrinkled.

(5) Surface Roughness Defects

Surface roughness refers to the uneven and non-smooth surface of casting blanks, which may have defects such as burrs and sand holes, as shown in Figure 8-32. A burr refers to an irregular thin layer of material adhering to the edge of the casting, also known as “flash.” The surface roughness defects that appear on jewelry castings are closely related to the quality of the original model, the quality of the wax mold, the quality of the casting mold, and the casting process. When the mold strength is low and the casting powder particles flake off, a rough surface will form; when the mold cracks, it will lead to burrs on the casting; when the flaked casting powder particles or foreign inclusions are not promptly removed from the cavity, they will become trapped in certain areas of the cavity, leading to sand hole defects. Since these substances are lighter than molten metal if time and conditions permit, they will float to the surface of the casting, so sand holes often appear on or near the surface of the casting.

2. Görev Uygulaması

Table 8-8 Defects and Possible Causes of Jewelry Casting Samples

| Casting defect | Defect legend | Olası nedenler |

|---|---|---|

| Appearance of flash, burr |

|

① improper proportion of casting powder and water, water is too much ② open powder casting in the static mold was mixed ③The burnout furnace is too fast to raise the temperature ④ casting into the furnace before placing too long, the cavity inside the dry cracks |

| Raised gold beads on the surface |

|

① improper water-powder ratio, the water is too little ② mixing powder operation working time is too long ③Vacuum extractor operation is not normal |

| Surface roughness |

|

① rough surface of castings ②Poor quality or failure of casting powder ③The temperature of burnout is too fast |

| Defective casting |

|

①Irrational sprue setting or wax model tree planting ② low temperature of casting metal ③Low casting temperature during pouring ④Insufficient amount of casting metal |

| Appearance of Porosity |

|

① casting metal temperature is high ② casting mold is not completely burned through ③The proportion of reused material in casting is too high ④Severe gas absorption during melting |

| Appearance of shrinkage cavity |

|

① liquid metal pouring temperature is too high ② casting mold temperature is too high ③ improper location or size of the sprue ④Insufficient pouring pressure |