Essential Jewelry Making Tools And Equipment Guide For Pros

A guidebook of Basic Tools and Equipment for Jewelry Making

Bevezetés:

Jewelry-making is a complex process involving multiple procedures and various tools and equipment. A comprehensive understanding and correct use of these tools and equipment is the foundation for mastering the art of jewelry making. This chapter briefly introduces the main tools and equipment involved in jewelry production.

Tartalomjegyzék

Section ⅠCommonly Used Tools in Jewelry Making

1. Workbench

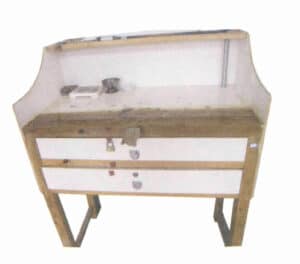

The workbench is the most basic jewelry-making equipment, usually made of wood, and can be divided into general workbenches(Figure 1-1) and micro-inlay workbenches(Figure 1-2). For general jewelry-making workbenches, although the appearance can vary, there are generally several standard requirements for their structure and function:

(1) It must be sturdy and solid, especially in the main working area of the tabletop, which is generally made of hard hardwood with a thickness of over 50mm, as the tabletop often experiences impacts during processing;

(2) There are specific height requirements for the workbench, generally 90cm high, allowing the operator’s elbows to rest or be supported;

(3) The tabletop must be flat and smooth, without significant warping or gaps, with higher barriers on the left, right, and back sides to prevent gems or workpieces from falling into gaps or bouncing off;

(4) It should have drawers for collecting metal powder and racks or hooks for placing tools;

(5) It should have convenient processing table plugs, and the tabletop generally has support for hanging Flexible Shaft Grinders. The length and width of the micro-inlay workbench should be more significant than that of the general workbench to accommodate a binocular microscope and leave enough operating space. The tabletop is generally made into a concave arc shape for ease of operation.

Figure 1-1 multi-used Workbench

Figure 1-2 Micro-inlay Workbench

2. Wax Carving Knife

Wax carving knives can be divided into two main categories: one type is general-purpose and can be purchased in the jewelry processing equipment market; the other type consists of tools made according to different needs. Based on their usage characteristics, they can be roughly divided into specialized wax carving knives(Figure 1-3), extended wax carving knives(Figure 1-4), and homemade wax carving knives(Figure 1-5)

Figure 1-3 Specialized Wax Carving Knife

Figure 1-4 Extended Wax Carving Knife

Figure 1-5 Homemade Wax Carving Knife

Wax carving knives are often used during the wax carving process of rings. They are specialized tools for enlarging the ring size, made of wood or plastic, with a blade embedded on the side. When used, the carving knife is placed into the wax of the ring and rotated evenly to enlarge the ring size(Figure 1-6).

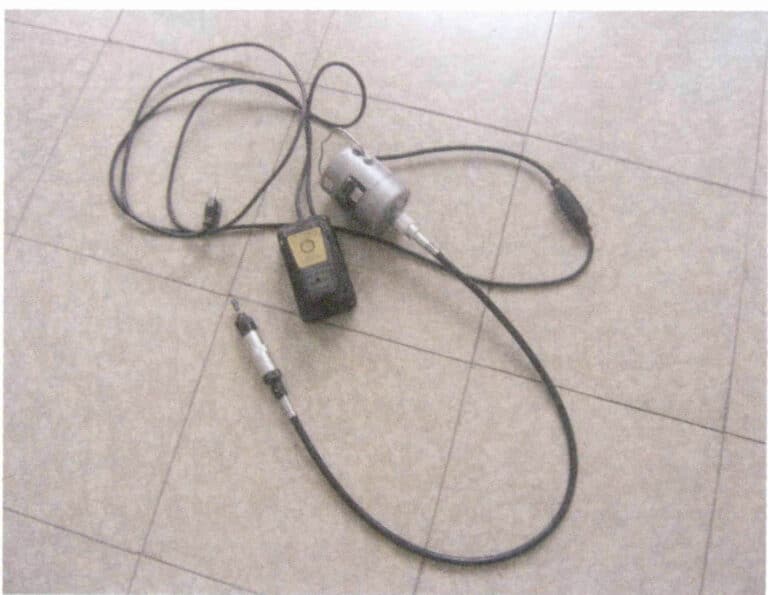

3. Electric Flexible Shaft Grinder and Steel burs

A Flexible Shaft Grinder is commonly called a suspended motor and is widely used in jewelry making. The Flexible Shaft Grinder consists of a motor, footswitch, flexible shaft, and machine head(Figure 1-7). Power is transmitted to the Flexible Shaft Grinder head through the flexible shaft, which is covered with a metal snakeskin tube, allowing for significant bending and flexible operation. The footswitch controls the speed of the Flexible Shaft Grinder, and several internal contacts are connected to the resistance wire. Pressing the pedal changes the resistance, altering the Flexible Shaft Grinder’s speed.

The complete set of steel burs (commonly known as drill bits) used with the Flexible Shaft Grinder varies in shape, and steel burs of different shapes have different uses, such as drilling, grinding, and turning. The commonly used steel burs are as follows(Figure 1-8).

(1) Drill Burs /F203

Drill burs are often used when creating jewelry molds to drill corresponding sizes of stone positions or patterns. They are also commonly used to adjust stone positions and patterns during mold holding and stone setting. The size of the drill burs is generally 0.05-0.23cm. If the drill bit is not sharp enough, it can be sharpened with an oilstone before continuing to use.

(2) Wave Burs /F1

The shape of the wave burs is close to spherical, with a size generally of 0.05-0.25cm. During the molding process of jewelry, it is often used to clean the gypsum powder or metal beads at the bottom of the flower head, reproduce the pattern lines, clean the welding areas, etc. When setting stones, the slight wave burs is often used to make a bead suction tool, while the larger one can be used for setting curved surface stones, and the most giant wave burs can be used for setting flying edges and smooth inclined positions.

(3) Wheel Burs /F3

The size of the wheel burs is generally 0.07-0.50cm. During the stone setting process, it is used to open pits and scooping bottoms, with the scooped areas relatively smooth.

(4) Peach Burs /F6

The shape of the peach burs is similar to that of a peach, with a size generally of 0.08-0.23cm. It is the primary tool for setting stones, and its positioning effect is more suitable for setting round diamonds, requiring no other tools for assistance. It can be used as an auxiliary tool during operations such as bezel setting, pave setting and channel setting.

(5) Umbrella Burs /F5

The shape of the umbrella burs is similar to that of an umbrella, with a size generally of 0.07-0.25cm. More extensive specifications of the umbrella burs are the primary tool for claw-setting stones. In comparison, smaller specifications are often used for setting heart-shaped, marquise-shaped, triangular, and other stone positions. When setting thick rocks, it can be used to position the waist of the stone.

(6) Tooth Burs /F36 & F38

The tooth burs, also known as a wolf tooth stick, can be subdivided into straight wolf tooth sticks and slanted wolf tooth sticks, with a size generally of 0.06-0.23cm. In a gemstone setting, the tooth burs is often used to smooth it out if the stone position is too narrow or the edges are uneven. It can also be used for positioning when claw setting stones. During jewelry molding, it is commonly used to scrape away seams between layers, clean up dead corners, and clarify areas with unclear lines.

(7) Flying Saucer burs F253 F25W F249

The size of the flying saucer is generally 0.08-0.25cm, with variations in thickness, which can be selected based on the thickness of the gemstone’s waist. Generally, thin flying saucers are used for setting stones with tiny particle claws, and sometimes, they can also be used for setting round diamonds. The calibration position during the initial setup will use thick flying saucers.

(8) Cup Burs /F256 F256A

The size of the suction bead is generally 0.09-0.23cm. There are ready-made suction beads available on the market, or they can be homemade. Ready-made suction beads often have tooth marks in the suction cup and are generally used for sucking thicker metal claws or rings; homemade suction beads are usually smooth and are used for sucking nail particles. When there are many rough nail particles, a large quantity of suction beads is needed, and old tools can be used to make suction beads, effectively reducing production costs.

4. Combination tools, welding tiles, and welding clamps

4.1 Combination welding tools

Combination welding tools mainly include the welding gun, air ball, and oil tank, connected into one unit by hoses(Figure 1-9). The air ball is comprised of two wooden boards shaped like table tennis paddles connected. The top and sides of the boards are covered with rubber. When stepping on the boards, the rubber of the air ball inflates, forcing air into the oil tank, which vaporizes the oil inside. The oil and air mixture is then sprayed from the welding gun, and it can be used once ignited. The welding gun is used primarily for welding, melting, and annealing.

The oil tank can be divided into the air intake pipe(the movable pipe of the oil tank connected to the air ball) and the exhaust pipe(the fixed pipe of the oil tank attached to the welding gun). Adding oil to the oil tank should only be filled to 1/3 of its capacity. If overfilled, stepping on the air ball will cause the welding gun to spray gasoline, potentially leading to an accident.

4.2 Welding tiles and welding clamps

Welding tiles are usually used to place welding materials, providing fireproof and heat-insulating functions and preventing the flame from the welding gun from directly burning the workbench. Welding clamps are divided into two types: Locking Tweezers forcep and welding tweezers. Locking Tweezers forcep can hold the workpiece in place to facilitate welding operations; welding tweezers can perform spot welding, keep the welding material in position, and stir the welding material evenly during the melting process(Figure 1-10).

Figure 1-9 Combination Welding Tools

Figure 1-10 Welding back tiles and welding tweezers.

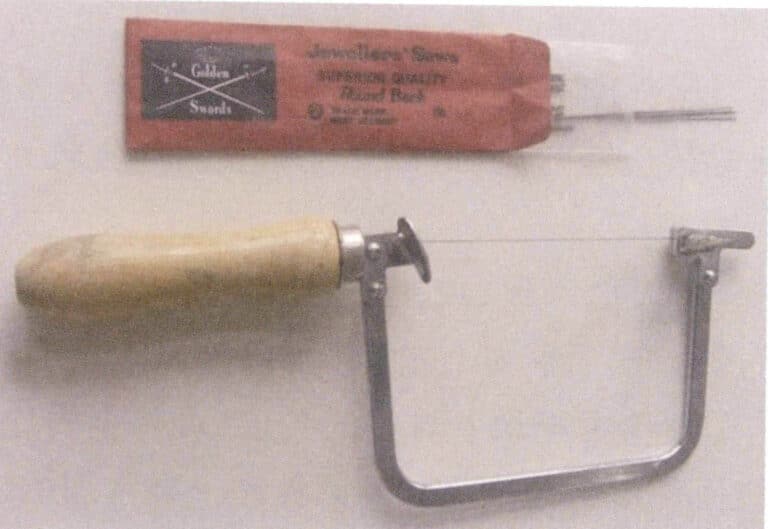

5. Bow Saw (Frame Saw)

The main purpose of the bow saw(frame saw) is to cut rods and pipes, as well as to saw out samples according to the drawn patterns, and it can even be used as a file. The saw blade(line shape) used with it have two types: fixed and adjustable(Figure 1-11).

The Bow Saw has a screw at each end to secure the saw blade. The saw blade comes in different thicknesses and widths and is used for jewelry making. Generally, the thickest is number 6, and the thinnest is 8/0, commonly referred to as “eight circles,” but the most commonly used are 4/0 or 3/0, also known as “four circles” and “three circles.” The specifications of saw blades commonly used in jewelry making are shown in Table 1-1.

Table 1-1 Specifications of saw strips for jewelry making

| Modell | Saw thickness (mm) | Saw width (mm) | Modell | Saw thickness (mm) | Saw width (mm) |

|---|---|---|---|---|---|

| 8/0 | 0.160 | 0.320 | 0 | 0.279 | 0.584 |

| 7/0 | 0.170 | 0.330 | 1 | 0.305 | 0.610 |

| 6/0 | 0.178 | 0.356 | 1.5 | 0.318 | 0.635 |

| 5/0 | 0.203 | 0.399 | 2 | 0.340 | 0.701 |

| 4/0 | 0.218 | 0.445 | 3 | 0.356 | 0.737 |

| 3/0 | 0.241 | 0.483 | 4 | 0.381 | 0.780 |

| 2/0 | 0.330 | 0.518 | 5 | 0.401 | 0.841 |

| 1/0 | 0.279 | 0.559 | 6 | 0.439 | 0.940 |

6. File

In jewelry making, the various files used mostly belong to metalworking files. However, since jewelry making is a relatively fine form of metalworking, the files used are mostly small. Nevertheless, there are many types with varying specifications, often named according to their cross-sectional shapes, such as flat files, triangular files, half-round files, and round files (Figure 1-12). The above are several commonly used files, while other more specialized files include knife files, bamboo leaf files, black tongue files, square files, flat files, etc.

The length of a file is generally standard, usually referring to the length from the tip of the file to the end of the handle, with standard lengths being 6 inches or 8 inches. The file teeth vary in spacing. The tail of the file is marked with a number starting from 00-8. Number 00 has the coarsest teeth, which file metal quickly but can make the surface of the workpiece rough; number 8 has the densest teeth, which can produce a smoother effect on the metal surface. Generally, number 3 and number 4 teeth are commonly used.

The main purpose of a file is to make the metal surface uniform or to modify the metal cut according to the desired pattern. Different shapes of files can create different shapes of metal surfaces, such as a triangular file can create triangular recesses; a round file can create round recesses and can also enlarge small round areas; the round parts of a half-round file and a square file can be used to file down the raised edges of the metal, etc. The choice of file type depends on the shape of the jewelry being made. A half-round file is a commonly used type, larger with coarser teeth, and the handle is about 8 inches long. Because its handle is painted red, it is frequently called the “red-handled file” in the industry, mainly used for shaping a product. A sliding file is another commonly used type. It is also half-round in shape, about 8 inches long, and has a sharp tail that must be inserted into a handle for use. The main purpose of a sliding file is to make final adjustments, making the metal surface smoother for sanding and polishing.

When making wax models, there is also a set of files, but the files used for filing wax differ from those used for filing metal; the former has coarser teeth(Figure 1-13).

7. Pliers, scissors

There are many shapes of pliers, and the uses of different pliers vary. Commonly used pliers include round-nose pliers, flat-nose pliers, needle-nose pliers, and wire cutters(Figures 1-14).

Round-nose and flat-nose pliers are mainly used for twisting metal wires and sheets. Flat-nose pliers are sometimes also used to hold small workpieces, making them easier to handle, and are sometimes used for setting gemstones.

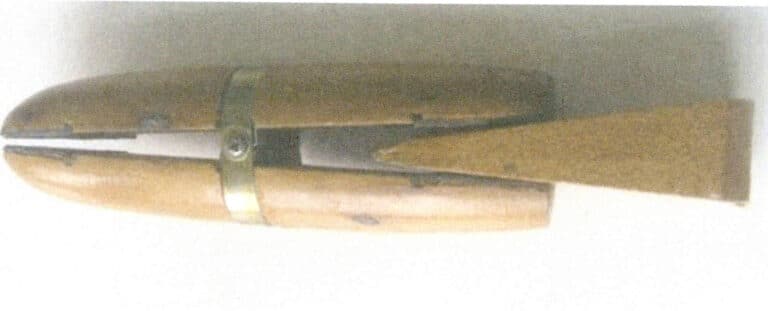

Wire cutters are actually large pliers used in hardware for pulling wires and cutting thicker metal wires in jewelry making. In addition to the pliers above, there are also vises for holding workpieces and wooden ring clamps (Figure 1-15). The bench pins used in jewelry making are usually quite small, often with a spherical joint that allows for different angles, making them convenient. A common structure of wooden ring clamps is to add a wooden wedge at the lower end to clamp the workpiece, which is mainly used to hold metal settings for stone settings. Wooden ring clamps generally do not leave any marks on the surface of finely finished jewelry.

Scissors are mainly used to cut large and thin sheet workpieces; thick and complex workpieces are unsuitable for scissors. Common types of scissors include black-handled scissors and cutting pliers, which can be further divided into Black Handled Scissors, Snips, Straight Scissors, Angled Scissors (Figure 1-16).

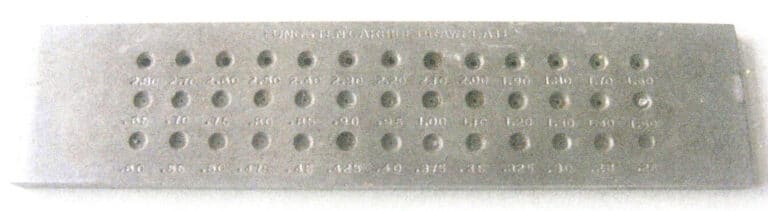

8. Wire pulling board

During jewelry-making, metal wires of varying diameters are often needed and must be made using a drawing board. The drawing board is made of steel. The drawing board typically has the following:

39 holes( 0.26-2.5mm), 36 holes(0.26-2.2mm), 24 holes( 2.3-6.4mm), and 22 holes( 2.5-6.4mm) and other specifications. The holes in the drawing board are made of special steel(Tungsten Steel), which is extremely hard and not easily deformed. The sizes of the holes in the drawing board vary, and there are many shapes, such as round, square, rectangular, triangular, and even heart-shaped, allowing for the selection of suitable wire holes based on processing needs, with the most commonly used being round(Figure 1-17).

9. Anvil, Hammer, Ring Iron and Similar Items

Anvils, hammers, and ring iron are usually used together, allowing them to shape metal into rings.

9.1 Hammer

Hammers are very useful in the jewelry-making industry; even with a rolling mill, there are still many places where a hammer is needed. In terms of material, in addition to iron hammers, commonly used ones include leather hammers, wooden hammers, and rubber hammers; in terms of shape, there are flat hammers, round hammers, and pointed hammers(Figure 1-18). Iron hammers are mainly used to strike metal or shape the ring’s circumference and can also be used with ring iron, anvils, and other tools. Small steel hammers are mainly used for setting stones. If you want to avoid leaving marks on the metal surface after striking, you can use leather, rubber, or wooden hammers.

9.2 Anvil

Anvil is an important tool used with a hammer, mainly used to support the striking of metal workpieces(Figure 1-19). The shape of the anvil varies, with square flat anvils mainly used for striking workpiece pads; there are also horn-shaped anvils that can be used to strike corners and arcs. A pit iron is also a type of anvil, which has grooves of different sizes, as well as various sizes of round and oval pits, the position is mainly used for processing semi-circular workpieces. Similar to pit iron is the bar mold, which has various semi-circular and round grooves and patterns. Additionally, there are iron or copper bowl anvils, which have some hemispherical pits of varying sizes, some of which have semi-circular grooves on the side, mainly used for processing hemispherical or semi-circular workpieces. A set of spherical punches, called bowl work, is used in conjunction with the bowl anvil.

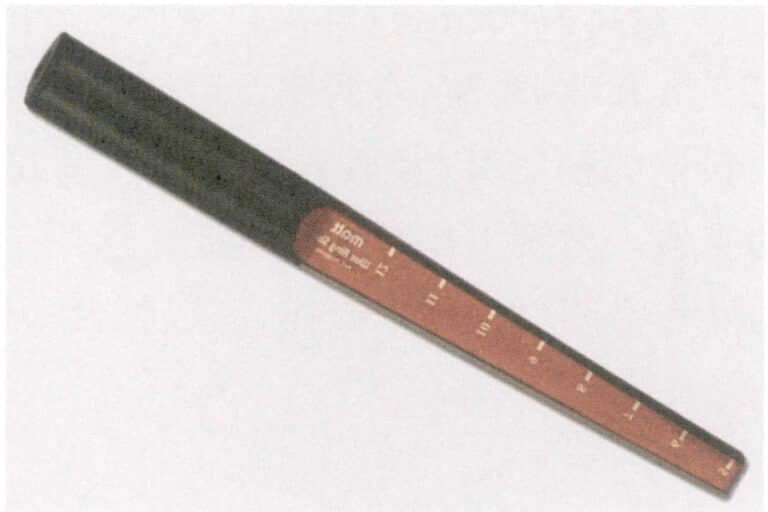

9.3 Ring Iron bar

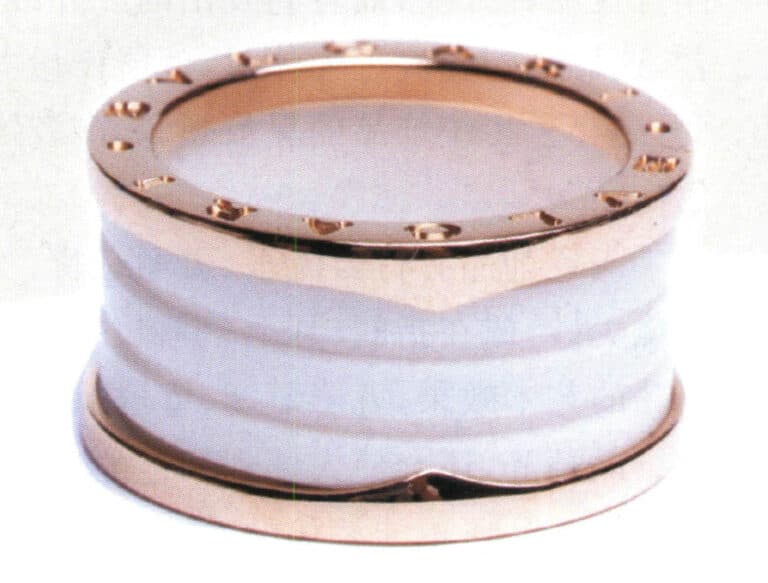

Ring iron is a conical solid iron rod(Figure 1-20). When modifying the ring’s opening or making it round, it can be placed on the ring iron for striking. Additionally, welding rings also rely on the ring iron. Similar to ring iron bar is the larger diameter iron bar used for making bracelets.

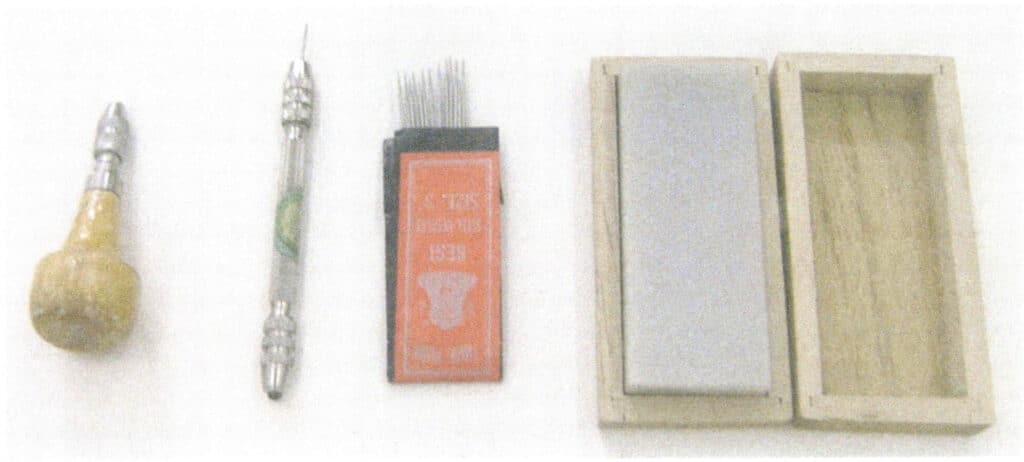

10. Chuck, Steel needle, Oil stone

10.1 Chuck

A chuck is a tool to hold a steel needle for operations such as setting stones or marking lines. The steel needle is inserted into the chuck, then the chuck head is tightened. There are several shapes of chucks; some wooden chuck handles resemble mushrooms, called mushroom chucks, while others resemble gourds, called gourd chucks. In addition to wooden handles, there are also iron handles, which have a diameter of about 1cm and are covered with anti-slip patterns(Figure 1-21).

10.2 Steel Needle

Steel needles are also commonly used in jewelry making, marking lines, drawing shapes, and engraving on metal plates. When ground into a flat shovel shape, they can be used for setting stones and edging.

10.3 Oilstone

An oilstone is an indispensable tool in stone-setting operations. When the steel needle becomes dull, it must be sharpened again or ground into a flat shovel, which requires using an oilstone. A well-performing oilstone for grinding stone setting shovels is quite expensive.

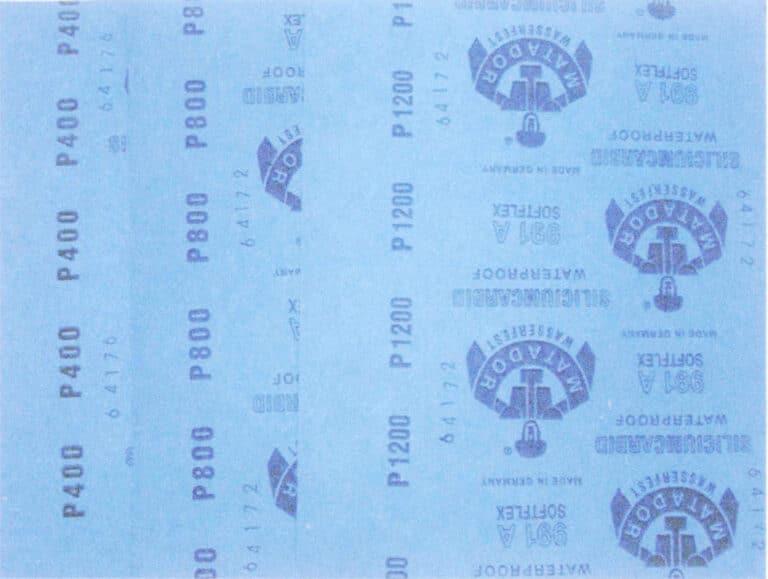

11. Sandpaper

Sandpaper comes in various degrees of coarseness, usually indicated by numbers. 200# is coarse sandpaper, 400# is relatively coarse, 800# is finer, and 1200# is the finest. These are some of the more commonly used types of sandpaper(Figure 1-22). Sandpaper can have a paper backing or a cloth backing, with paper sandpaper available in yellow, black, and dark green. The abrasive particles on sandpaper also vary, including quartz sand, corundum, and garnet sand.

Sandpaper can eliminate the rough surface marks left on workpieces after tool operation, followed by grinding and polishing. When used, the sandpaper should be shaped into different forms, such as pushers, sandpaper sticks, clamps, needles, and sandpaper points.

Copywrite @ Sobling.Jewelry - Egyedi ékszergyártó, OEM és ODM ékszergyár

12. Measuring Tools

Jewelry making is a precise craft, so the tools used for measurement must also be precise. Common measuring tools include steel rulers, electronic calipers, ring gauges, ring-size circles, and electronic balances (Figure 1-23).

12.1 Ring sizer

The ring sizer is used to measure the size of the inner circle of a ring, also known as a finger stick. This ring sizer is mostly copper, with a thin top that gradually thickens towards the bottom. The bottom of the ring sizer has a wooden handle, usually 30cm long, with scales engraved on it. Countries have different scales, commonly including American, Hong Kong, Japanese, Italian, and Swiss measurements.

12.2 Ring Gauge(also known as Finger Ring)

The ring gauge is mainly used to measure the thickness of fingers. It consists of dozens of metal rings of different sizes, each marked with a scale to indicate their size.

12.3 Vernier Caliper

The vernier caliper consists of two parts: one part is the fixed body, called the main scale, which has graduations, each graduation being 1mm; above the main scale, there is a movable part called the vernier scale, which also has graduations, each graduation being 0.02mm.

12.4 Electronic Caliper

The structure of the main scale of the electronic caliper is similar to that of the vernier caliper. Still, the vernier scale is replaced by an electronic display device, allowing the measurement value to be read directly from the display screen.

12.5 Electronic Balance

Electronic balances are widely used in jewelry making and are an indispensable weighing tool. There are many specifications for electronic balances, each with different measurement accuracies and ranges, suitable for weighing metals, diamonds, and gemstones(Figure 1-24).

Section II Common Equipment for Jewelry Making

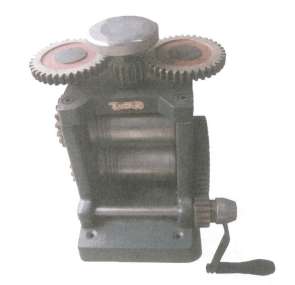

1. Press Machine

The press machine is mainly used for rolling metal sheets or wires, available in manual(Figure 1-25) and electric(Figure 1-26) types, which operate on the same principle. The working part of the press machine consists of a pair of cylindrical rollers with smooth mirror rollers, but most have grooves on both sides of the rollers. Before pressing, the rollers and metal strips must be cleaned, and the gap between the rollers should be adjusted. The gap is adjusted using screws on both sides, which are controlled by a gear plate on the press machine; turning the gear plate adjusts the gap between the rollers. The distance pressed down each time should not be too large to avoid damaging the machine.

Figure 1-25 Manual Tablet Press

Figure 1-26 Electric Tablet Press

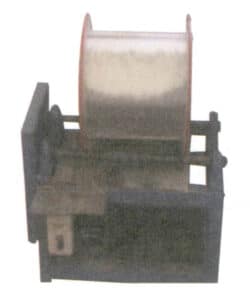

2. Rubber Molding Machine

The Rubber molding machine(also known as a vulcanizing Rubber machine, Figure 1-27) is mainly used for the vulcanization of rubber molds. The molding requires a certain pressure, which is controlled by the upper pressing plate driven by a screw pole, with a turntable on the screw for easy operation. Rubber vulcanization must be carried out at a certain temperature, and there are built-in heating wires inside the pressing plate, with a temperature controller to regulate the temperature. Various mold frames are available to match the molding machine, such as single frame, double frame, and four-frame, most of which are made of aluminum alloy.

3. Wax Injection Machine

There are many wax injection machines, with the more advanced being pneumatic injection machines(Figure 1-28) and vacuum wax injection machine(Figure 1-29). Both wax injection machines use air pressure to fill the wax liquid into the rubber mold cavity. Pneumatic wax injection machines generally use ordinary temperature controllers and are relatively inexpensive. If the product does not have high technical requirements, this equipment can be used to produce wax molds for mass production, but the quality of the wax molds is relatively difficult to guarantee. The vacuum wax injection machine vacuums the mold before waxing, optimizing the filling performance and making it easy to inject even relatively thin wax molds.

Figure 1-28 Pneumatic wax injection machine

Figure 1-29 Vacuum wax injection machine

There are also various types of vacuum wax injection machines. In the past, the automation level of vacuum wax injection machines was relatively low, requiring manual alignment of the rubber mold with the wax nozzle and foot operation of the pedal to inject wax. Now, highly automated vacuum wax injection machines have been developed, such as the digital vacuum wax injection system produced by Japan’s Yausi(Yoshida) company, which uses a secondary wax injection system that minimizes the shrinkage of the wax mold. Parameters such as primary injection pressure, secondary injection pressure, secondary injection pressure start time, mold clamping pressure, holding time, and compression pressure can be freely combined and stored to achieve the best combination of wax injection setting parameters. The rubber mold is placed in the clamping mechanical arm, the program number is input, and pressing the start button will automatically complete all actions such as clamping, advancing, automatically aligning the wax injection port, evacuating, primary wax injection, secondary wax injection, maintaining the wax mold solidification, and opening the mold. The temperature control is accurate, and the quality of the injected wax molds is good.

4. Powder Mixer and Vacuum Pump

The powder mixer is a machine that mixes casting powder and water into a uniform slurry. It replaces manual mixing, improving efficiency and ensuring a more even mix. It is divided into two types: simple and vacuum automatic.

The simple powder mixer(Figure 1-30) has an inexpensive structure. Since mixing occurs in the atmosphere, it can draw in gases. After mixing the gypsum slurry, a vacuum pump is needed to remove the gases. A common vacuum pump is a machine primarily composed of a pump and a pressure gauge, with a flat plate mounted on the top of the machine case. The corners of the plate have springs that can vibrate, and a layer of rubber mat is on the plate equipped with a hemispherical acrylic cover(Figure 1-31). During vacuuming, the cover tightly seals with the rubber mat to prevent air leakage, ensuring the quality of the vacuum. Using the simple powder mixer for powder preparation involves several steps: mixing, vacuuming, pouring, and vacuuming again, which is relatively cumbersome.

Figure 1-30 Simple Powder Mixer

Figure 1-31 Vacuum Pump

The vacuum automatic powder mixing machine is a relatively advanced powder opening device(Figure 1-32, Figure 1-33). This type of machine combines a mixer and a vacuum sealing device, allowing for the entire process, from mixing casting powder to slurry forming, while maintaining a vacuum state, effectively reducing bubbles and improving the product’s smoothness. Vacuum mixing machines are generally equipped with functions such as quantitative water addition, setting mixing time, and setting mixing speed, enhancing the powder opening automation level. Compared to simple mixing machines, it eliminates complex operations such as mixing, vacuuming, pouring, and vacuuming again, making the operation simpler and more time-efficient.

Figure 1-32 Vacuum Automatic Investment Machine 1

Figure 1-33 Vacuum Automatic Investment Machine 2

5. Burnout Furnace

The gypsum burnout furnaces used by jewelry manufacturing companies are generally resistant, with some using oil-fired furnaces, usually equipped with temperature control devices and capable of achieving segmented temperature control. Figure 1-34 shows a typical resistance burnout furnace, which can implement temperature control in four or eight-segment programs. This type of furnace generally uses three-sided heating, and some use four-sided heating; however, the temperature distribution inside the furnace is not uniform, making it difficult to adjust the atmosphere during burnout. In recent years, advanced burnout furnaces have emerged to achieve uniform temperature distribution inside the furnace, eliminate wax residues, and automate control. For example, a new furnace type developed by the Italian company Schultheiss features a heat-resistant steel cover between the heating elements and the gypsum mold, with a fan installed at the top of the furnace to force air to flow over the heating elements and return to the furnace chamber from the bottom, thus forcing air circulation inside the furnace.

Additionally, a more advanced burnout furnace developed in Germany uses a rotating bed method(Figure 1-35), allowing the gypsum mold to be heated evenly, with a smooth and fine inner wall, particularly suitable for the requirements of advanced wax-inlaid casting processes. Currently, many countries are producing this type of burnout furnace. This sturdy resistance furnace provides the best production environment for casting larger and more numerous steel bells, and the furnace box of this burnout furnace features four-sided heating, with double-layer refractory brick partitions inside, ensuring uniform and stable heat, along with good insulation. Its exhaust gas undergoes two complete combustion processes, resulting in the final discharge of non-polluting gases.

Figure 1-34 Typical burnout Furnace

Figure 1-35 Rotary burnout Furnace

6. Casting Machine

Modern jewelry manufacturing mainly uses the lost-wax casting method. Since jewelry pieces are relatively fine workpieces, they solidify quickly during pouring and lose fluidity. Therefore, conventional gravity pouring is difficult to ensure shaping, and certain external forces must be introduced to promote the rapid filling of the mold cavity with molten metal to obtain castings with complete shapes and clear outlines. The casting machine is a very important piece of equipment in the lost-wax casting process for jewelry, and it is one of the important foundations for ensuring product quality. According to the form of external force, the commonly used jewelry casting machines mainly include the following types.

6.1 Centrifugal Casting Machine

The centrifugal casting machine uses the centrifugal force generated by high-speed rotation to draw molten metal into the mold cavity. In centrifugal casting, the filling speed of the molten metal is relatively fast, which is beneficial for forming small and complex workpieces, making it suitable for casting alloys such as gold and silver. Since the time required for platinum is very short for a liquid state, centrifugal casting is also quite suitable. Therefore, centrifugal casting machines are still jewelry manufacturers’ most commonly used casting equipment.

(1) Mechanical drive centrifugal casting machine(Figure 1-36). This is a simple centrifugal casting machine, usually used in some small jewelry processing factories. It does not come with an induction heating device, oxygen-acetylene to melt the metal, or a melting furnace to smelt it and then pour it into the crucible for centrifugal casting.

(2) Manfredi brand centrifugal casting machine(Figure 1-37). This type of centrifugal casting machine is commonly used in jewelry processing factories, integrating induction heating and centrifugal pouring. It is suitable for casting gold, silver, and copper alloys.

(3) Yausi(Yoshida) brand centrifugal casting platinum machine(Figure 1-38). This type of centrifugal casting machine is commonly used for pouring platinum alloys; it completes melting and centrifugal pouring in a vacuum, which is beneficial for the quality of metal smelting.

Figure 1-36 Mechanical Drive Centrifugal Casting Machine

Figure 1-37 Manfredi Brand Centrifugal Casting Machine

Figure 1-38 Yausi(Yoshida) Brand Centrifugal Casting Platinum Machine

Compared to static casting, traditional centrifugal casting has the following disadvantages.

(1) Due to the fast filling speed, the molten metal turbulence during pouring is severe, increasing the possibility of gas entrapment and the formation of pores.

(2) The discharge of gas within the mold is relatively slow, resulting in high back pressure inside the mold, which increases the probability of pores appearing in the casting.

(3) When the pressure of the filling molten metal is too high, it exerts a significant scouring effect on the mold wall, which can easily lead to mold cracking or spalling.

(4) During pouring, slag may enter the mold cavity along with the molten metal, affecting the casting quality.

(5) Due to the high filling pressure generated by centrifugal force, the maximum amount of metal that a centrifugal casting machine can cast within a safe range is less than that of a static casting machine. Additionally, inert atmospheres are generally less commonly used because the casting chamber is larger.

In response to the above issues, modern centrifugal casting machines have significantly improved drive technology and programming, enhancing the automation level of the casting process. For example, the angle of the mold center axis and the swing arm is designed to be variable, functioning as a function of rotational speed, able to change from 90°to 0°. This comprehensively considers the roles of centrifugal force and tangential inertial force in driving the molten metal out of the crucible and into the mold, helping to improve the balance of metal flow and preventing the molten metal from preferentially flowing along the reverse rotation direction of the pouring channel walls. Additionally, an exhaust device is installed at the bottom of the mold to facilitate the smooth discharge of gas within the cavity, improving filling capacity. It is also equipped with a temperature measurement device to minimize human judgment errors as much as possible.

6.2 Static Casting Machine

The working principle of the static casting machine is to use methods such as vacuum suction casting and vacuum pressurization to promote the filling of the metal liquid into the mold cavity. Compared to centrifugal casting machines, the filling process of static casting machines is relatively gentle, and the scouring effect of the metal liquid on the mold wall is smaller. Due to the vacuum effect, the gas back pressure in the mold cavity is also lower, allowing for a larger amount of metal to be cast in one go. Therefore, static casting machines are increasingly widely used. There are many static casting machines, among which the simplest is the suction machine(Figure 1-39).

The main component of this machine is the vacuum system, which does not include a heating and melting device, so it needs to be used in conjunction with a torch or melting furnace. The suction machine is relatively easy to operate, highly efficient, and widely used in small and medium-sized jewelry processing factories. However, since the pouring is done in the atmosphere, the metal liquid has a problem of secondary oxidation and gas absorption. Additionally, because the entire pouring process is controlled by the operator, including pouring temperature, pouring speed, head height, and treatment of the slag on the liquid surface, many human factors can affect the quality of the castings.

The automatic vacuum suction casting machine is the more advanced and widely used static casting machine. There are many models of this type of machine, such as Japan’s Yausi(Yoshida, Figure 1-40), Tanabe(Figure 1-41), Italy’s Italimpianti(Figure 1-42), and America’s Neutec(Figure 1-43), all of which are well-regarded brands in the world.

Figure 1-40 Japan's Yausi(Yoshida) Vacuum Casting Machine

Figure 1-41 Tanabe Kenden (Japan) Casting Machine

Figure 1-42 Italian Italimpianti Casting Machine

Figure 1-43 American Neutec Casting Machine

The machines produced by different companies each have their own characteristics, but generally, they integrate induction heating, vacuum systems, control systems, etc., into one unit, typically adopting an upright structure, with the upper part as the induction melting chamber and the lower part as the vacuum casting chamber. They use a bottom pouring method, with a hole at the bottom of the crucible, which is sealed with a refractory plunger rod during melting. The plunger rod is lifted when pouring, allowing the molten metal to flow into the mold cavity. Generally, a thermocouple is set inside the plunger rod, which can accurately reflect the temperature of the molten metal. There are also thermocouples placed on the crucible wall to measure temperature. Still, the measured temperature cannot directly reflect the temperature of the molten metal and can only serve as a reference. Automatic vacuum casting machines typically melt and cast metals under vacuum or inert gas conditions, effectively reducing the possibility of metal oxidation and gas absorption. They widely use computer programming control, have a high degree of automation, and the quality of the cast products is relatively stable with fewer defects, making them a preferred choice for many manufacturers; they are widely used for vacuum casting of precious metals such as gold, K gold, and silver. Some models also come with granulation devices that can prepare granular intermediate alloys.

7. Polishing Machine

The highly polished surface of jewelry products relies on polishing. In the past, mass-produced jewelry typically underwent manual molding followed by polishing. To reduce labor costs and intensity during the molding process and improve production efficiency, mechanical polishing equipment is increasingly used for polishing jewelry products, and there are even grinding and polishing devices that can replace manual polishing. Common mechanical polishing equipment includes drum polishing machines(Figure 1-44), magnetic polishing machines(Figure 1-45), and vibrating polishing machines(Figure 1-46), among others.

Figure 1-44 Drum Polishing Machine

Figure 1-45 Magnetic Polishing Machine

Figure 1-46 Vibratory Polishing Machine

After the jewelry is molded and set with stones, it needs to undergo final polishing, which the polisher completes using a polishing machine. There are various styles of polishing machines, including single-station, double-station, and multi-station types, typically consisting of a motor, a sealing cover, and a dust collection system. The dust collection system can be randomly included(Figure 1-47) or can be a central dust collector. The end of the motor shaft has a reverse conical thread, and the cloth wheel is mounted on the shaft, utilizing the friction generated during polishing to tighten it further. Various materials and shapes of cloth wheels, rubber wheels, wire rods, and brushes can be installed on the shaft to meet the different surface quality requirements of the jewelry.

8. Ultrasonic Cleaning Machine

Ultrasonic waves are sound waves with a frequency higher than 20 kHz. The working principle of an ultrasonic cleaning machine is that when sound waves act on a liquid, they create many tiny bubbles within the liquid. When these bubbles burst, they generate highly energetic shock waves, thus achieving the cleaning and flushing of the surfaces of the workpiece. Ultrasonic cleaning originated in the 1960s, and in the early stages of application, due to limitations in the electronics industry, the power supply for ultrasonic cleaning equipment was relatively large, with low stability and lifespan, and was expensive. With the rapid development of the electronics industry, a new generation of electronic components has emerged. Due to the application of new electronic circuits and components, the stability and lifespan of ultrasonic power supplies have been further improved, their size reduced, and prices gradually lowered. New ultrasonic power supplies feature small sizes, high reliability, and long lifespans, further enhancing cleaning efficiency, while prices have dropped to a level acceptable to most enterprises.

Ultrasonic cleaning equipment consists of a cleaning tank, ultrasonic generator, and power supply. The ultrasonic cleaning machine commonly used in jewelry factories(Figure 1-48) has advantages such as high cleaning efficiency, good cleaning effect, wide range of use, low cleaning cost, low labor intensity, and a good working environment. Historically, cleaning the dead corners, blind holes, and hard-to-reach dirt on jewelry pieces has been a tricky problem, but ultrasonic cleaning can solve this issue. This is particularly significant for jewelry products, as they are mostly complex and delicate components, making ultrasonic cleaning machines one of the indispensable important devices in jewelry making.