What is a Professional Jewelry Workbench and the Main Tools for Jewelry Making?

Essential Metalworking Tools for Jewelry Craftsmanship

“If a craftsman wants to do his job well, he must first sharpen his tools.” The general meaning is that for a craftsman to do his work well, he must first ensure that his tools are sharp. This statement illustrates that preparation is very important for accomplishing a task. Especially in metalworking and other crafts that involve using tools and materials, it is essential to first understand and learn the basic tools and materials.

Measuring Tools

Obsah

Section I Workbench

1. Professional Jewelry Workbench, Goldsmith's Forge

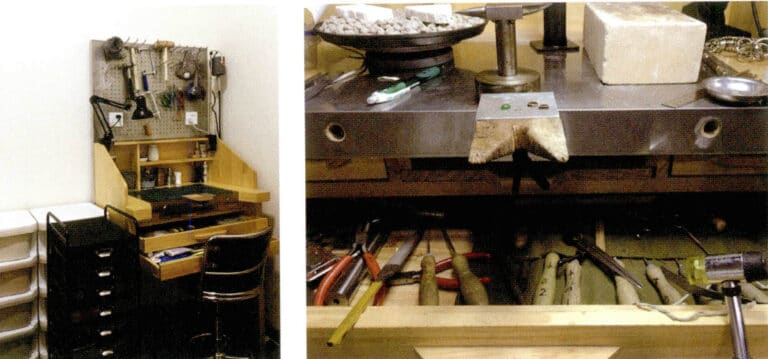

Every jewelry worker needs a workbench suitable for their operations. In early jewelry processing factories, several craftsmen often worked together at a long workbench, each having an independent work area cut into a semicircle. Nowadays, most jewelry craftsmen have replaced this with independent workbenches to reduce mutual influence, facilitate personal operations, and allow for custom design according to their needs or to purchase finished products.

Central Academy of Fine Arts Jewelry Major Studio

Jewelry Workbench

2. Transforming a Regular Table into a Jewelry Workbench

If you want to set up a jewelry processing area on an existing work table, you can fix a portable vise to the table and then purchase a wooden block for jewelry use. This way, you can also create a simple jewelry working area. However, since a regular desk is lower than a jewelry workbench, it is advisable to pair it with an adjustable chair, adjusting the chair to a suitable height for more comfortable operation and to reduce strain on the shoulders, neck, and lumbar spine.

Designers and craftsmen can arrange the tools on the workbench according to their preferences. The first consideration should be whether frequently used tools are easily accessible. You can sit in front of the workbench and imagine where each item is most suitable and convenient to place. With continuous use, everyone can arrange the tools and materials to best suit their operational workflow.

Section II Main Tools for Jewelry Making

For most jewelry makers, collecting various tools is a great pleasure. Some basic tools can be purchased in the market, but interesting special or limited edition tools must be collected over time. Professional jewelry makers may also develop and customize special tools according to their needs, often taking years to collect a relatively complete set. Since high-quality tools are expensive, many second-hand tools are also in high demand in the jewelry tool market. At the same time, some tools become easier to use after years of use; for example, a good second-hand hammer is more sought after than a new one. However, when purchasing second-hand tools, it is important to check carefully. If some serious scratches or tools are no longer standard, there is no need to buy them. When purchasing brand new tools, avoid being tempted by low prices; overly cheap tools usually have a short lifespan, seem inexpensive but perform poorly, and are prone to damage, resulting in low cost-effectiveness.

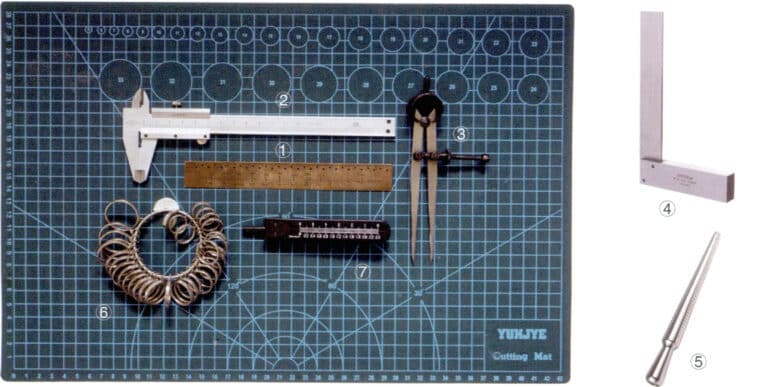

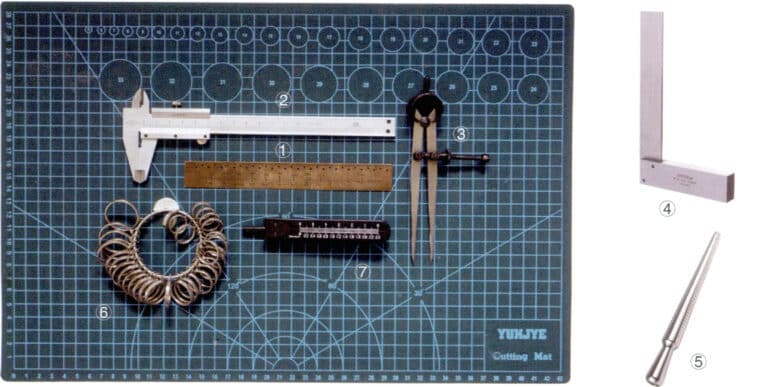

1. Measuring Tools

(1) Steel Ruler:

The scale needs metric and imperial units, and the length can be chosen as 20~50 cm, which is more convenient for making slightly larger pieces.

(2) Caliper:

One of the most commonly used measuring tools in jewelry making, it can measure the length, width, thickness, outer diameter, inner diameter, depth, etc., of objects, and has high precision, suitable for measuring small volume sizes of jewelry.

(3) Compass:

A compass with two legs made of stainless steel metal pins is widely used in jewelry making. It can measure the corresponding dimensions from a steel ruler or other objects and then draw them onto metal materials. It can also be used for segment cutting, marking, drawing parallel lines, arcs, circles, etc.

(4) Square Ruler:

This ruler is used to measure the degree of 90° angle, and it can also be used to check whether an object is straight and smooth.

(5) Ring gauge:

A tool used to measure the size number of an existing ring sizer, usually made of aluminum and shaped like a cone, marked with the corresponding size numbers of the ring sizer.

(6) Ring sizer:

Generally made of stainless steel, it can be used to measure the finger ring size when customizing a ring. In Asia, the size of Hong Kong is usually used for conversion.

(7) Divider:

Both legs are extremely fine steel needles, functioning the same as a regular metal compass but with more precise operation and positioning, suitable for use on smaller components.

2. Cutting tools

(1) Plate shears:

Jewelry studios often use shears in various models, which are divided into manual and electric. Manual shears are generally fixed to a table and resemble a guillotine. Thinner metal sheets and wires can be cut using the cutting table. Still, this tool is unsuitable for thicker metal sheets, such as those over 2 mm thick, as cutting can easily lead to deformation or difficulties.

(2) Tin snips scissors:

There are many sizes, mainly used for cutting thinner metal sheets, but the drawback is that the metal sheets are prone to deformation during cutting.

(3) Wire cutter:

Generally used for cutting very thin metal pieces like welding rods.

(4) Cable scissors:

Generally used for cutting metal wires.

(5) Saw frame:

Cutting metal materials with a saw is a basic and common technique in jewelry making, so choosing a good saw bow is important. Saw frames are available in adjustable arm length types and fixed length types, allowing you to choose the appropriate style based on your needs.

(6) Saw blades:

Used with a saw frame made of carbon steel materials, they can be used to cut common metals such as gold, silver, and copper. Saw blades are classified by thickness, with sizes generally ranging from the finest 8/0 to the coarsest 14. Finer saw blades make fine jewelry, while thicker metals can be cut with coarser saw blades. Commonly used saw blade sizes are from size 4/0 to size 4. When making precious metal jewelry, a 4/0 saw blade is generally chosen for cutting materials to minimize the loss of precious metals.

3. Bending tools

(1) Flat nose pliers:

The jaws are flat on both sides and can be used to clamp, fold metal sheets, tighten, and straighten metal wires, and this tool is often used for closing metal rings.

(2) Needlenose pliers:

The jaws are conical, bend metal wires, and reach areas difficult for general tools to access.

(3) Parallel pliers:

The inner side of the jaws has no serrations or is made of hard plastic material, commonly used for clamping, folding, bending, or untangling knots made with metal wire.The advantage is that it only easily leaves marks on metal materials.

(4) Roundnose pliers:

Used for bending metal wire, making metal rings, and creating curved shapes.

(5) Tool holder:

Allows the tool handles to be inserted into holes for upright storage and placement.

4. File Repair Tools

(1) Flat file:

Available in various models with different coarseness, commonly used for smoothing metal and cleaning weld joints.

(2) Half-round file:

Various models with different thicknesses are commonly used for shaping rings or the internal metal of circular objects.

(3) Triangle file:

Various models with different thicknesses, commonly used for filing grooves and polishing difficult-to-reach metal areas.

(4) Dead smooth file:

Various models with relatively fine teeth can process metal surfaces to a relatively fine finish.

(5) Round file:

Various models with different thicknesses are commonly used for shaping holes and narrow areas.

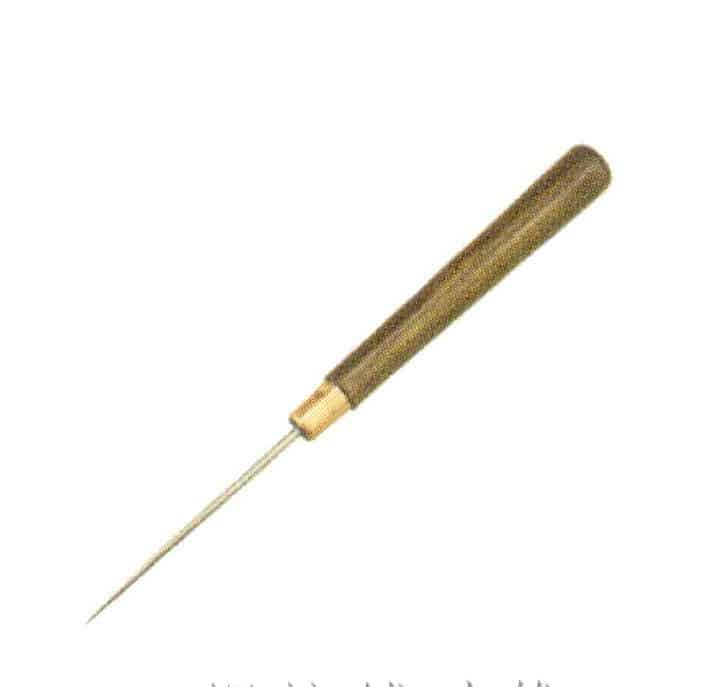

(6) Needle:

Handling fine seams and wrapping sandpaper to polish fine parts.

5. Molding Tools

(1) Double Horn Anvil:

Used for shaping forms, can be placed directly on the workbench.

(2) Flat Iron:

Used with a hammer to flatten metal sheets, it must be kept clean and smooth; if any marks appear, maintenance is required immediately. Otherwise, it will affect the usage effect.

(3) Nesting Anvil and Nesting Chisel:

Used together to create spherical and curved metal shapes.

(4) Dapping block and dapping punch:

They can create metal grooves and pipes when used together. The metal to be processed can be placed in the groove of the dapping block, and the dapping punch can be placed on the metal. An arched metal shape can be formed by striking the dapping punch with a hammer.

6. Striking tools

(1) Chasing hammer:

It has two hammerheads; one is round and protruding, and the other hammer’s face is relatively flat, which is used for flattening metal and creating textures.

(2) Staking and setting hammer:

Also known as the flat-convex hammer, the flat hammer head is used for striking, and the convex hammer head is used for texture creation.

(3) Riveting hammer:

Very lightweight, with a small hammerhead, mostly used for fine texture creation.

(4) Sledge hammer:

Various models are commonly used for fine jewelry making, usually from 4 ounces to 8 ounces.

(5) Texture hammer:

The surface of the hammer head is covered with uneven texture patterns, allowing for quick striking to create corresponding textures. Many of these hammers are custom-made by artisans.

(6) Wooden mallet:

Used for shaping metal.

(7) Rubber mallet:

Used for shaping and forming, it is less likely to leave marks on the metal surface during operation.

7. Drill Tools

(1) Foredom Electric Hanging Grinder:

A motor installed on the workbench that provides power, the tightening chuck can rotate at high speed. It can be used with different types of drill bits, grinding wheels, and polishing tools and is very commonly used in jewelry making.

(2) Bench Drill:

An electric drill installed on a workbench or tabletop to drill holes in objects.

Foredom electric hanging grinder

Bench drill

(3) Hand Drill:

This can be fitted with different drill bits and used for drilling holes in objects.

(4) Twist Drill Bit:

Usually made of steel and available in various thicknesses, it can be used with electric hoists, benches, and manual drills.

Hand drill

Twist drill burs

Kopírování @ Sobling.Jewelry - Výrobce šperků na zakázku, továrna na šperky OEM a ODM

(5) Steel Drill burs:

There are various shapes and specifications, such as cylindrical, conical, flame-shaped, round-headed, diamond-shaped, etc. Installed on cranes, they can cut, grind, shape objects, or be used for texture creation.

(6) Diamond Grinding burs:

Available in various shapes and sizes and made from aluminum oxide powder or hard minerals, they can be installed on cranes for cutting and grinding metal.

Steel Drill burs

Diamond grinding burs

8. Welding tools

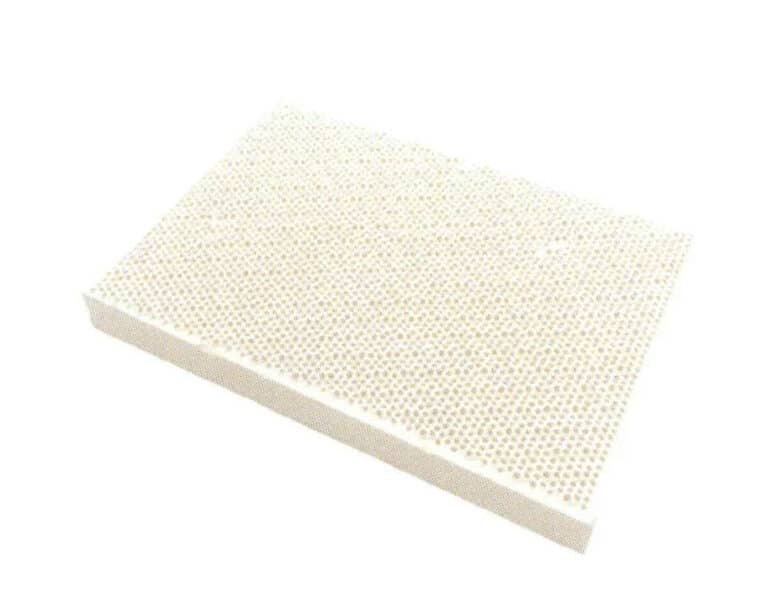

(1) Rotatable welding table:

The tabletop is covered with refractory bricks, and it can rotate during the welding process, making it easy for the flame to heat the metal from different angles.

(2) Refractory tiles and bricks:

Blocks the heat from flames to the workbench; sometimes, it is necessary to place more than one piece; it can also be cracked and placed next to it to support metal objects in welding.

Rotatable welding table

Refractory tiles and bricks

(3) Gas welding torch:

Used for heating operations, the torch head produces a flame connected to a rubber hose, which can be linked to a gas cylinder, gas pipeline, or No. 0 gasoline, etc.

(4) Handheld torch:

Compact and portable, fueled with butane gas, heating and welding small objects.

Gas welding torch

Handheld torch

(5) Metal solder:

Includes exclusive metal solders such as gold, silver, and copper, available in sheets, granules, powder, strips, and paste. Different solders are composed of various metal compounds, with melting points lower than the base metal being welded, allowing them to connect metals when melted with fire.

Sheet welding flux

Powdered solder

(6) Borax powder:

A type of flux, in dry powder form, can be mixed with water to create a paste, applied with a small brush to the required areas on unglazed borax-specific ceramic bowls during metal welding, assisting in welding and keeping the weld seam uniform and clean.

(7) Steel tweezers:

Used for grasping metal objects.

Borax powder

Steel tweezers

(8) Anti-magnetic tweezers:

This type comes in pointed and curved tips, with heat-insulating rubber on the tail. When the tweezers are squeezed, the tips open and have a certain gripping force. Generally used to hold metal parts that need to be welded.

(9) Binding wire:

Usually made of fine steel or iron wire, it is used to bind and secure multiple metal components during welding, making the welding process easier to operate.

Anti-magnetic curved tips tweezers

Binding wire

(10) Welding auxiliary needle:

When the welding flux melts, a metal auxiliary cone can guide the molten flux, allowing it to flow around the joint.

(11) Quenching bowl:

A thickened tempered glass container can be used, filled with clean water, for rapidly cooling metal objects after quenching.

Welding aid needle

Quenching bowl

9. Polishing Tools

(1) Sanding Spiral Cone:

Sandpaper comes in different grits and can be rolled into a spiral cone for use with a hoist. Metal can achieve a finer surface through sanding, and the sanding process should follow the order from coarse to fine.

(2) Copper Wire Brush:

Used for rough cleaning of metal surfaces; when used, the ornament and brush should be placed under running water.

(3) Brush:

A multipurpose brush that can be replaced with a shoe or toothbrush used with a cleaner to clean items.

(4) Rubber Abrasive Polishing Wheel:

Installed on a hoist for polishing, available in various models and shapes.

(5) Copper Brush:

Installed on the hoist for polishing, available in various models and shapes, and can create a suede texture effect.

(6) Nylon Brush:

Installed on the hoist for polishing, available in various models and shapes.

(7) Polishing Wheel:

Used on the hoist, made of materials such as wool, cotton, and felt.

(8) Silver Polishing Cloth:

The cloth surface is generally coated with a brightening agent, used to remove oxides and dirt from the surface of silver jewelry. However, using a silver polishing cloth on gold-plated products may cause some wear to the plating.

(9) Copper Burnishing Bar:

Used for Burnishing the surface of metals.

(10) Agate Burnisher:

Generally, natural agate is used as the burnisher head to Burnish the metal surface, making it shine brightly.

(11) Polishing materials:

Mostly grinding rods or grinding blocks, with many models available, can be used in sequence from coarse to fine when polishing metal.

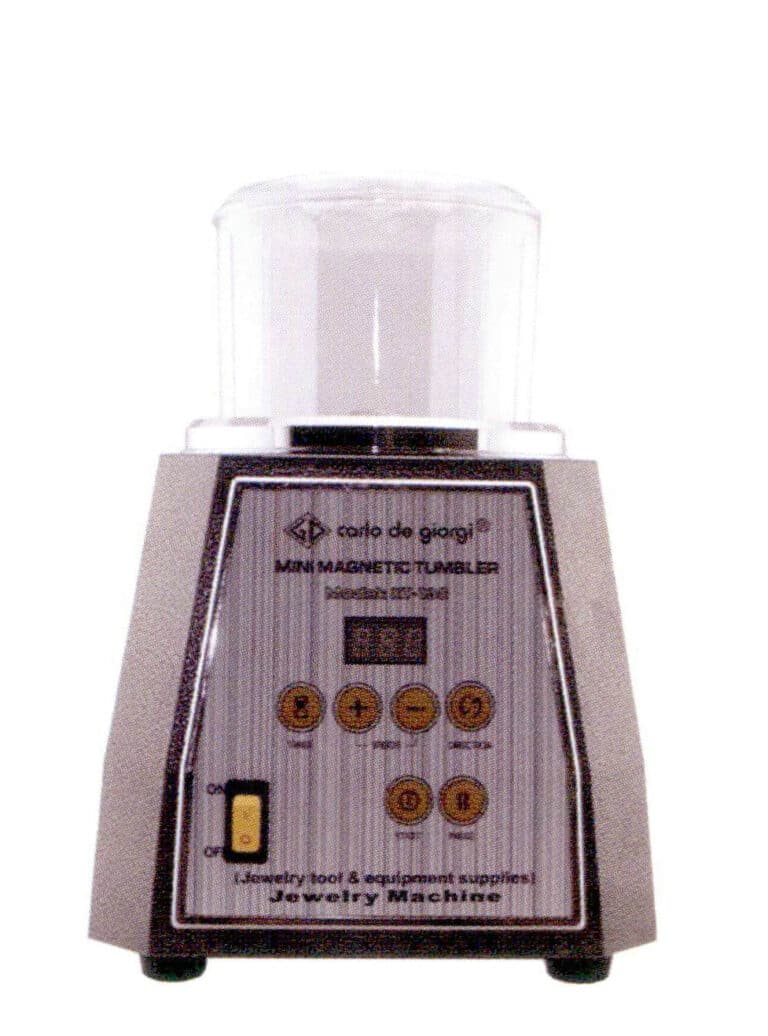

(12) Magnetic tumbler:

Place steel needles, lubricants, and clean water into the machine, then put the metal items to be polished inside, adjusting the polishing time and force according to the manual and design requirements.

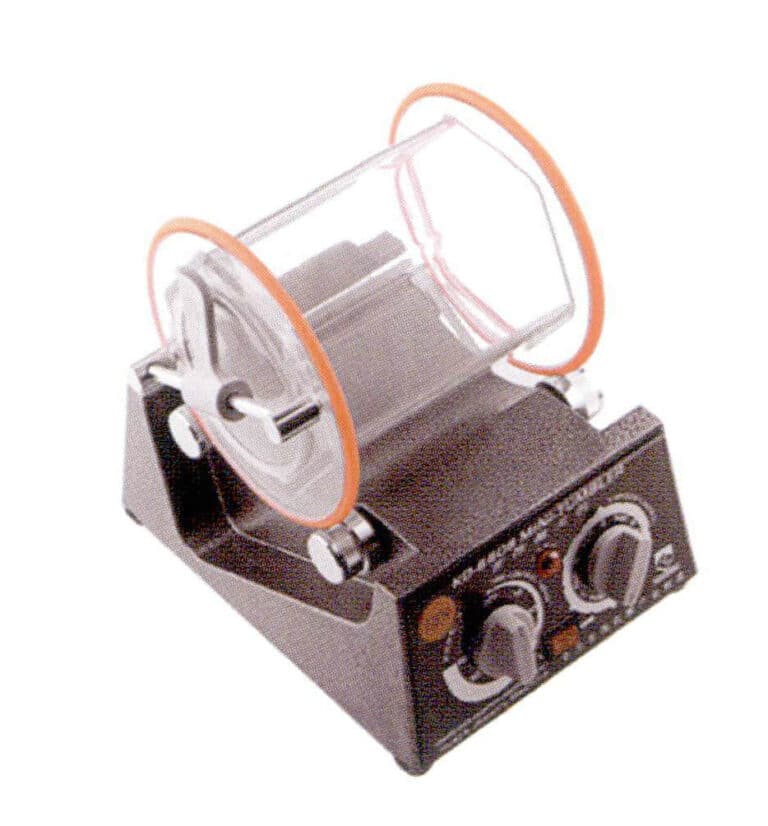

(13) Rotary tumbler:

Place steel balls, polishing paste, and clean water into the machine, then put the metal items to be polished inside, adjusting the polishing time and force according to the manual and design requirements.

(14) Ultrasonic cleaner:

Used with special cleaning agents, it can remove dirt, polishing residues, grease, and other stains attached to the metal.

Magnetic tumbler

Rotary tumbler

Ultrasonic cleaner

10. Chemical reagents

(1) Degreaser:

Turpentine, which can dissolve and remove marks left by paint, sticky glue, and markers.

(2) Ultrasonic cleaning agent:

Used with an ultrasonic cleaning machine, it can remove dirt from the surface of metal objects.

(3) Rotary polishing agent:

Used with a drum polishing machine, it can be used for burr cleaning.

(4) Metal maintenance oil:

Used to lubricate metal tools and equipment to prevent rust.

(5) Beeswax:

This can be used to maintain saw blades, preventing them from becoming dull, and can also be used with polishing cloth wheels to assist in polishing.

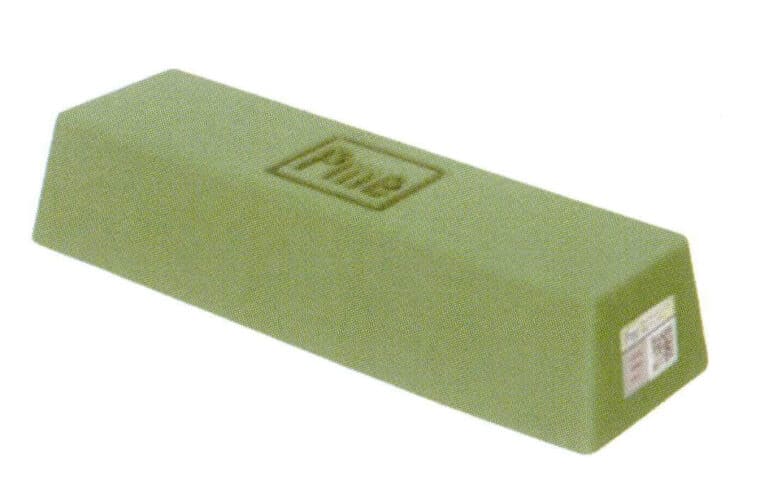

(6) White and green polishing compound:

They are used with polishing cloth wheels to assist in polishing.

Beeswax

White polishing compound

Green polishing compound