What is Amber gemstone? Exploring the Timeless Allure of Amber from Formation to Fashion

A Journey Through amber Gemological Characteristics, Classification, Optimized processing, Identification and maintainance

Introducere:

Explore the captivating realm of amber jewelry with our easy-to-understand guide tailored for jewelry enthusiasts! Unearth the historical significance of amber, from ancient trade currencies to sacred artifacts. Learn practical care techniques to preserve your amber’s brilliance. Gain expertise in distinguishing genuine amber from imitations with our simple identification tips. This guide is a treasure trove for jewelry stores, studios, brands, retailers, designers, e-commerce sellers, and those in the custom celebrity jewelry market. Understand amber’s geological journey, its optical allure, and how to select top-quality amber for your collection. Enhance your knowledge with insights on amber’s rich history and its contemporary role in the world of jewelry design.

Tabla de conținut

Section ⅠApplication History and Culture

The English word Amber is derived from the Arabic word “Amber.” In Middle English in the 14th century, Amber referred to a solid, waxy substance derived from sperm whales and was gradually extended to Baltic Amber.

In ancient times, the inhabitants of the Baltic Sea used Amber as a currency to trade with their tribes in the south for copper weapons and other tools. Marine Amber also traveled through the Aegean Sea to the eastern shores of the Mediterranean. Archaeologists have excavated bottles and quarters from the ancient Greek Messenian civilization in Syria and found Marine Amber necklaces in the containers. During the Middle Ages, Marine Amber was also popular in religious artifacts. See Figures 5-1-1 through 5-1-4.

Figure 5-1-1 Amber artifacts from 7th century B.C. Italy(1)

Figure 5-1-2 Amber artifacts from 7th century B.C. Italy(II)

Figure 5-1-3 Amber artifacts from Italy in the 5th century B.C. (I)

Figure 5-1-4 Amber artifacts from Italy, 5th century B.C.(II)

Religious artifacts or objects made of Amber from ancient times to today are enshrined in temples in many Asian countries. Myanmar is famous for its gemstones and Buddhist temples, and Amber artifacts enshrined in the Buddhist temples in Mogok are shown in Figures 5-1-5 through 5-1-10.

Figure 5-1-5 Amber artifacts enshrined in Burmese Buddhist temples (I)

Figure 5-1-6 Amber artifacts enshrined in Burmese Buddhist temples(II)

Figure 5-1-7 Amber artifacts enshrined in Burmese Buddhist temples (III)

Figure 5-1-8 Amber artifacts enshrined in Burmese Buddhist temples (IV)

Figure 5-1-9 Amber artifacts enshrined in Burmese Buddhist temples (V)

Figure 5-1-10 Amber artifacts enshrined in Burmese Buddhist temples (VI)

Section II Formation reasons

Amber is a petrified natural plant resin. The resin of gymnosperms and the gum produced by flowering plants were buried in the ground several million years ago. After a long geological period, they lost their volatile components and polymerized and solidified to form Amber under continuous temperature and pressure. Amber is a product of sedimentation mainly produced in sandstone and coal bed sediments of the Cretaceous or Tertiary periods.

The petrification process of Amber, a fossilized resin formed by the high cross-polymerization and dehydration of terpenoids, is quite complex, with two main phases: the polymerization of the natural resin into copal resin and the evaporation of the terpene component from copal resin into Amber.

The first stage is the polymerization of resin molecules. Ancient plant secretion of half-day flower labane type material contact with air and light after polymerization, the initial polymerization occurs mainly in the labdatriene carboxylic acid molecules between the conjugated double bonds. Then by isomerization cross-linking and intermolecular and intramolecular ringing effect, the polymerization has a multi-cyclic structure of the Copal resin. This stage may take several dry years to several million years.

The second stage is the evaporation of the stilbene components. Copal resin contains many terpene volatile oils; after millions of years of evaporation, these components form Amber; the process is figuratively known as the Amberization of Copal resin. In the burial process, natural resins are affected by the geological environment, such as time, temperature, pressure, and water, and the unsaturated bonds in their organic components are gradually matured by polymerization and cross-linking. In addition to the age of petrification, there are various external factors affecting the rate of polymerization reaction of organic molecules, such as heat history, pressure, anaerobic environment, resin type, sediment type, and other geological conditions, which are important factors affecting the formation of Amber.

The age of Amber ranges from 10 million to 300 million years. Most gem-quality Amber is from 15 to 40 million years old. The oldest petrified resin dates back to the Carboniferous period, about 320 million years ago.

Section III Gemological Characteristics

1. Basic properties

The basic characteristics of Amber are shown in Table 5-3-1.

Table 5-3-1 Basic Characteristics of Amber

| Compoziție chimică | C10H16O , may contain H2S | |

|---|---|---|

| Stare cristalină | Amorphous mass | |

| Caracteristici optice | Culoare | Light yellow, yellow to dark brown, orange, red, white |

| Lustru | Resin Gloss | |

| Ultraviolet light | Weak to strong, yellow-green to orange-yellow, white, blue-white or blue | |

| Caracteristici mecanice | Duritatea Mohs | 2 ~ 2.5 , a knife or even a fingernail can carve it. |

| Densitate relativă | 1.08, can be suspended in saturated concentrated brine | |

| Break | Typical shell-like fracture | |

| Rezistență | Poor, easy to break under external impacts | |

| Special properties | Electrostatic, electrically charged by friction; melts in hot needles and has an aromatic odor; soluble in organic solutions such as sulfuric acid and alcohols | |

| Inclusions | Bubbles, flow lines, insect or animal or plant debris, other organic and inorganic inclusion | |

2. Composition

Amber is a mixture of natural organic compounds formed from the resins of plants of the Sonko family from the Cretaceous period of the Mesozoic to the Tertiary period of the Cenozoic through various geologic processes. The natural plant resins that form Amber are composed of carbon, hydrogen, and oxygen compounds.

Amber mainly comprises resin acids with conjugated double bonds and contains a small number of succinic ester alcohols, succinic oils, etc. It is a typical multi-component mixed and not easily decomposed organic compound. The chemical formula of Amber is C10H16O. It also contains a small amount of hydrogen sulfide and trace elements such as AI, Mg, Ca and Si. Amber comes from several types of plants, so the chemical composition of Amber from different sources varies.

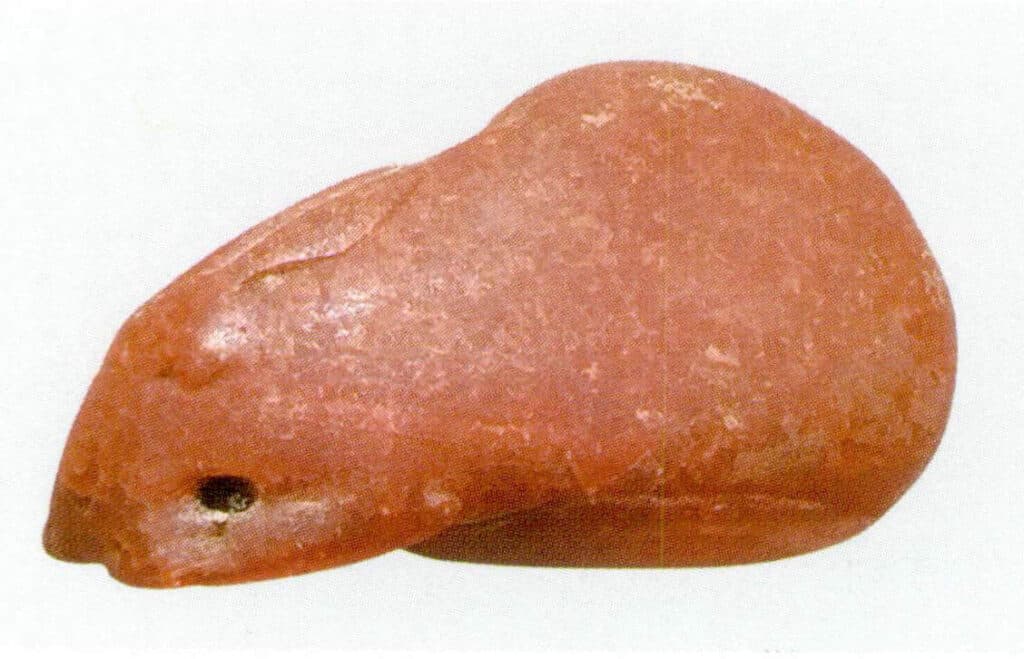

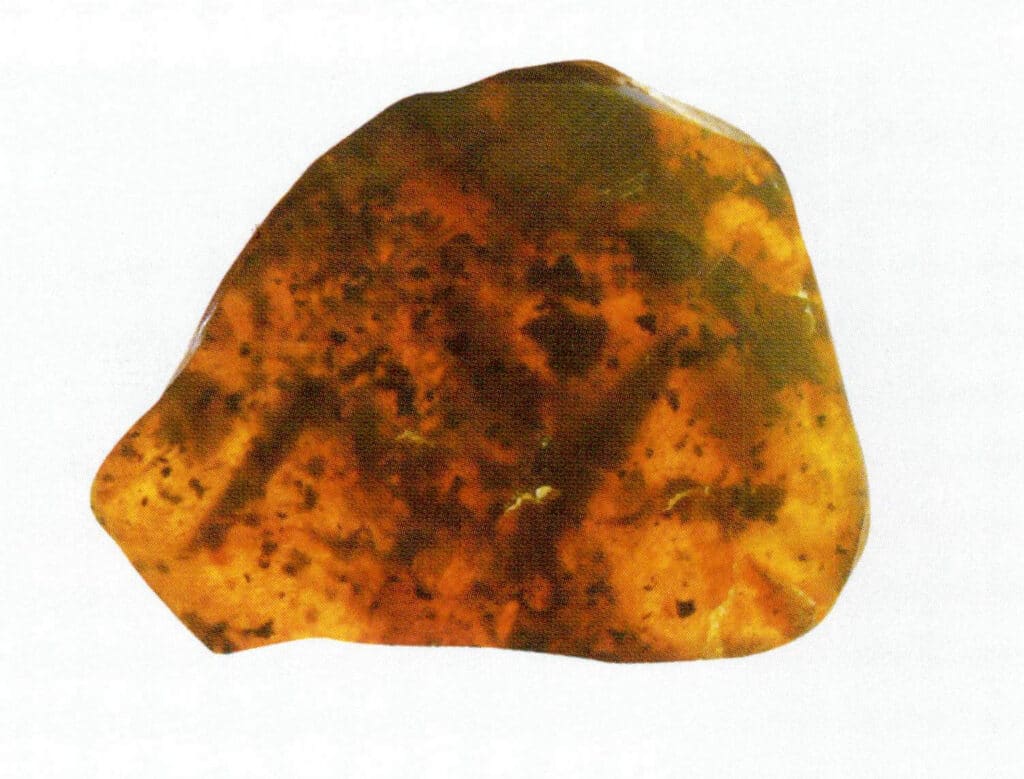

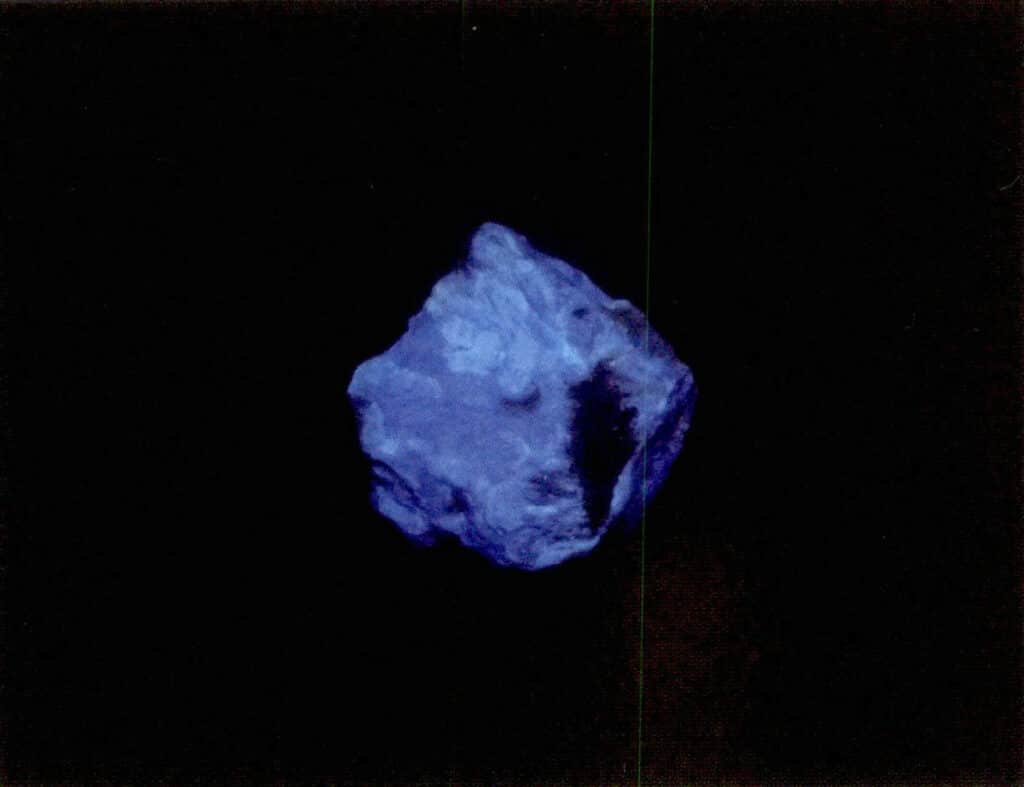

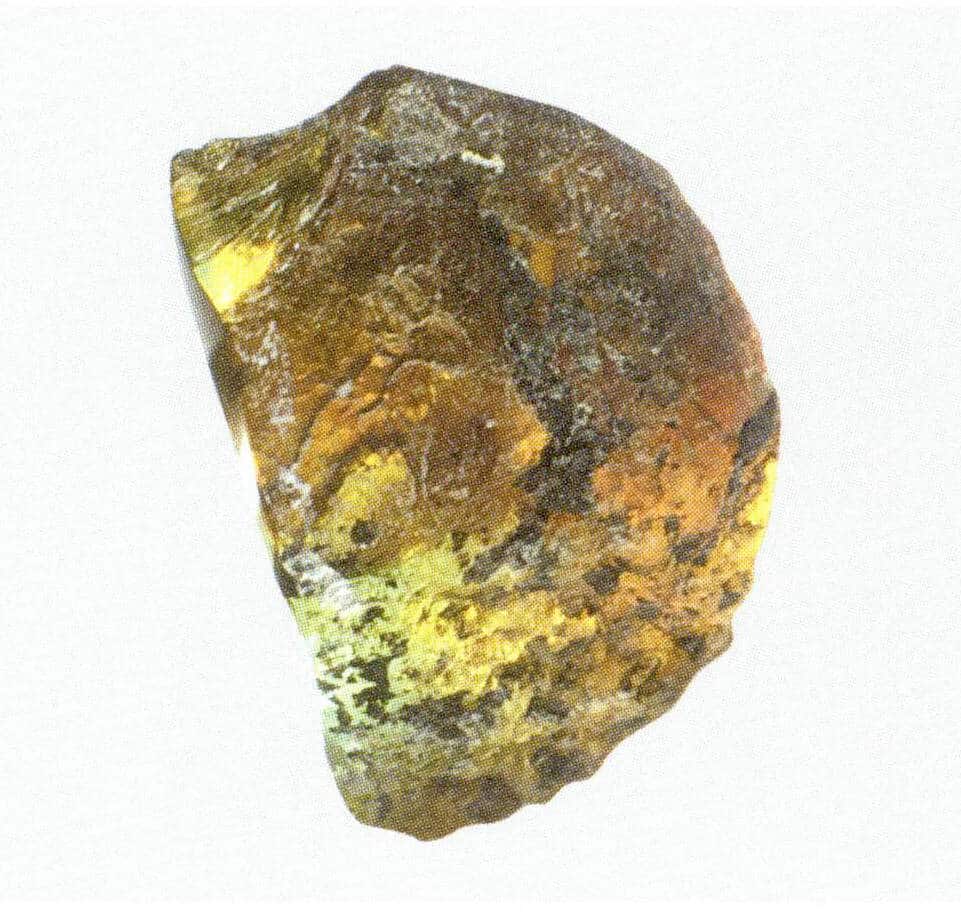

3. Raw stone characteristics

Amber is mainly produced in the sediments of conglomerate and coal beds, and the raw stone is often produced in the form of lumps, nodules, tumors, etc.. The surface is often covered with volcanic ash, commonly known as “mineral skin.”

The different densities of the various types of resins cause evaporation and volatilization during the flow process, resulting in the contraction of the skin and the formation of irregular patterns, commonly known as “veins.” During the petrification process of Amber, the surrounding environment and geological features will also impact the “grain” of beeswax Amber. Because of the different levels of shrinkage and volatilization, they create lines of different shades.

Due to the thick, dirty, impure, and cracked skin of raw Amber ore, it is generally divided into two types: those that retain the original skin are called rough, and those that have the original skin removed are called bare. Raw Amber is shown in Figures 5-3-1 through 5-3-6.

Figure 5-3-1 Raw Amber (I)

Figure 5-3-2 Raw Amber(II)

Figure 5-3-3 Raw Amber (III)

Figure 5-3-4 Raw Amber (IV)

Figure 5-3-5 Raw Amber (v)

Figure 5-3-6 Amber with and without primary mineral skin removed

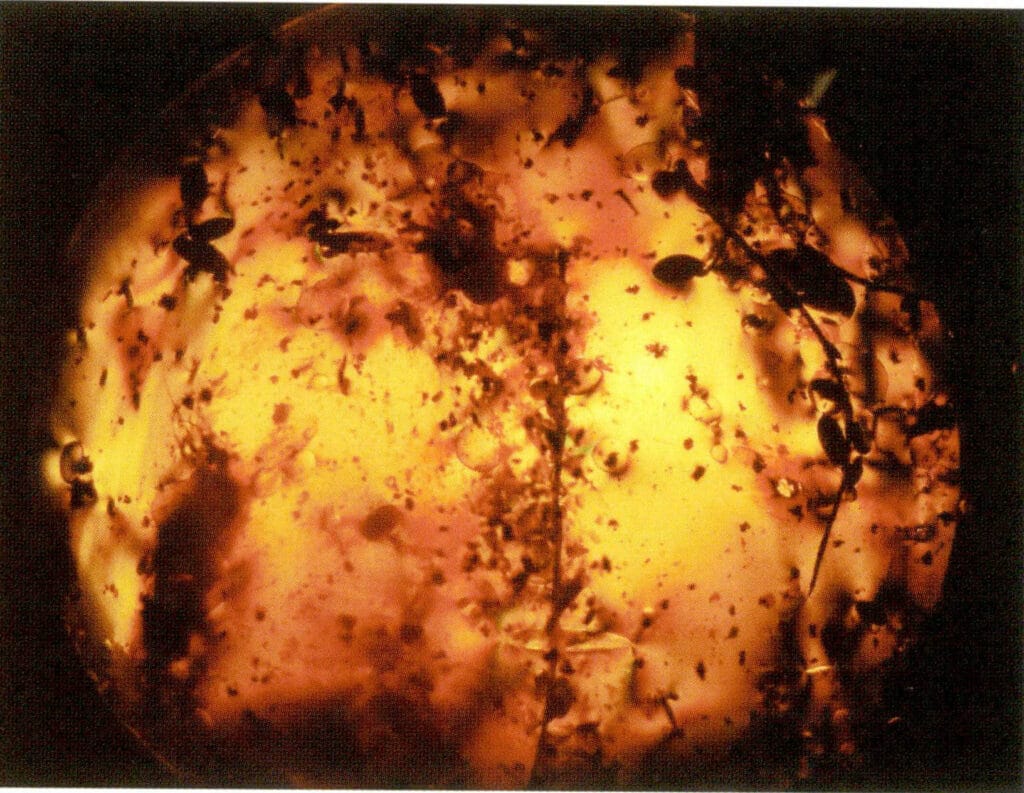

4. Inclusion

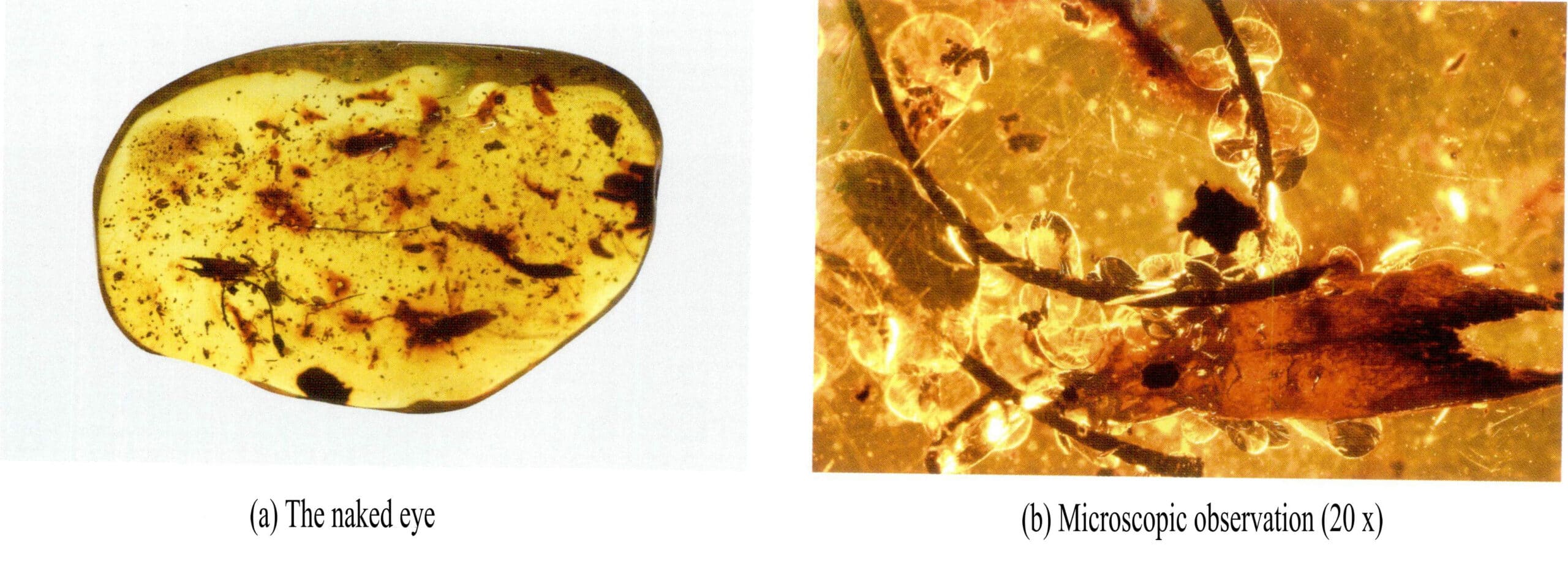

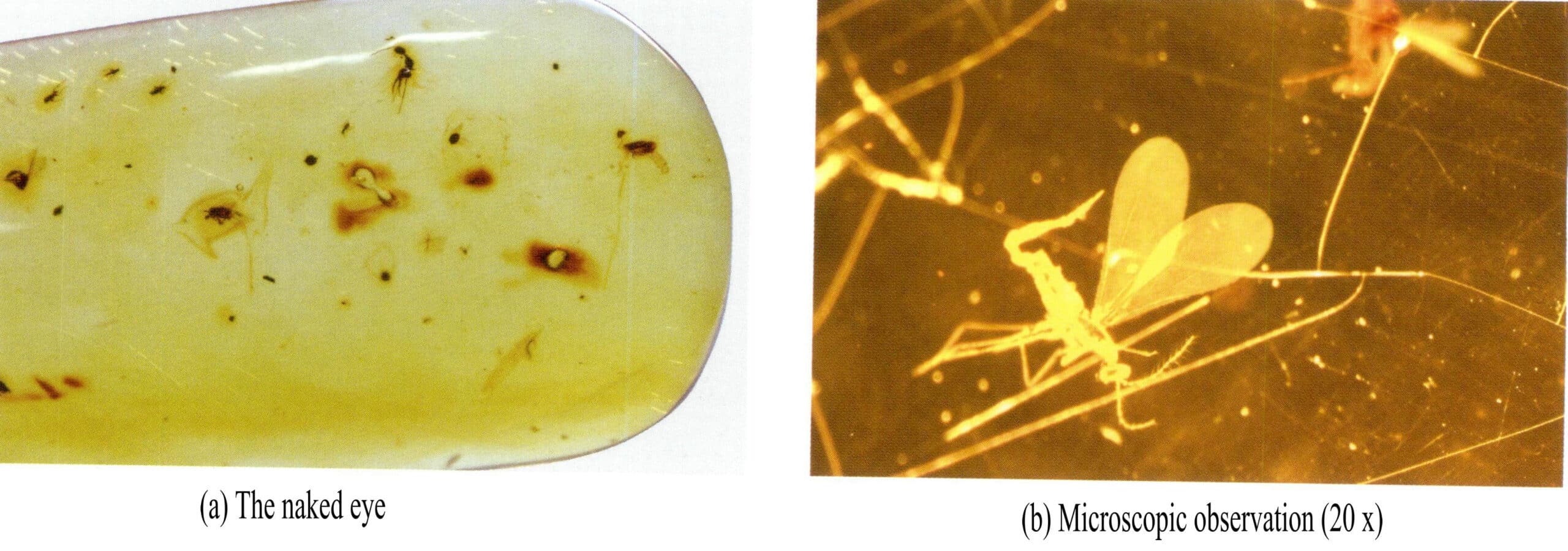

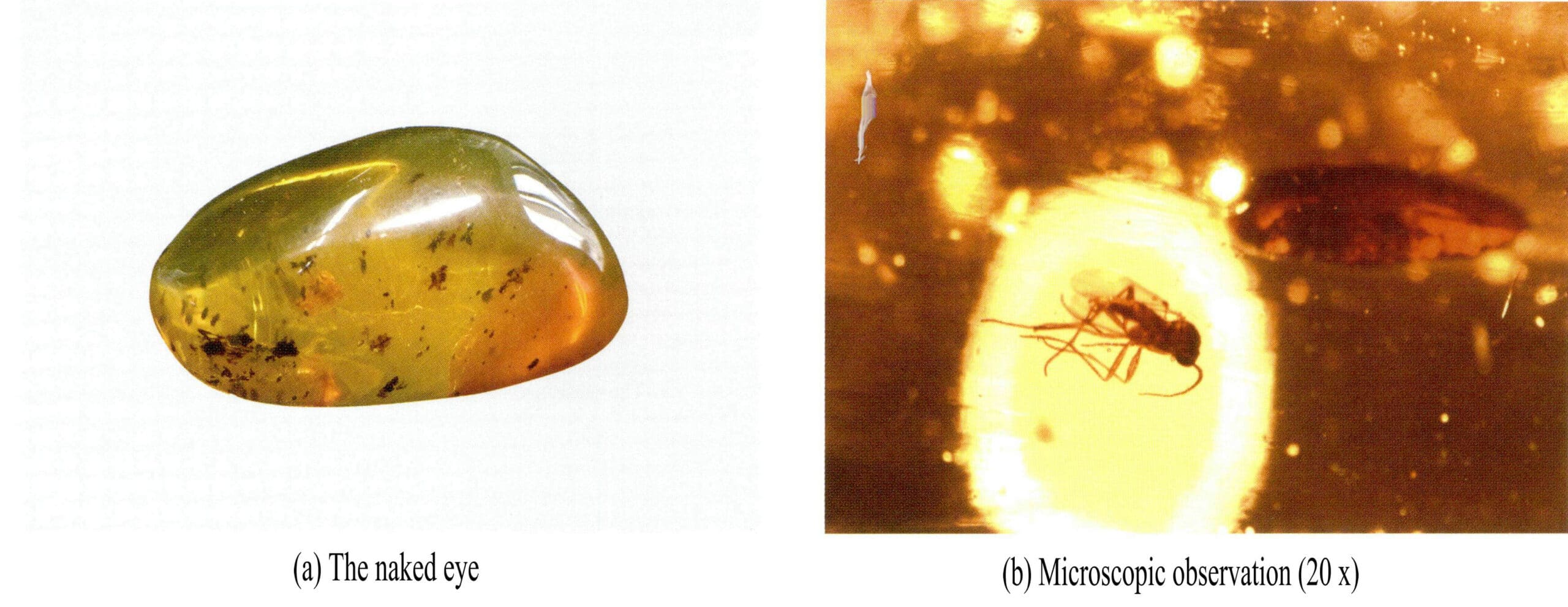

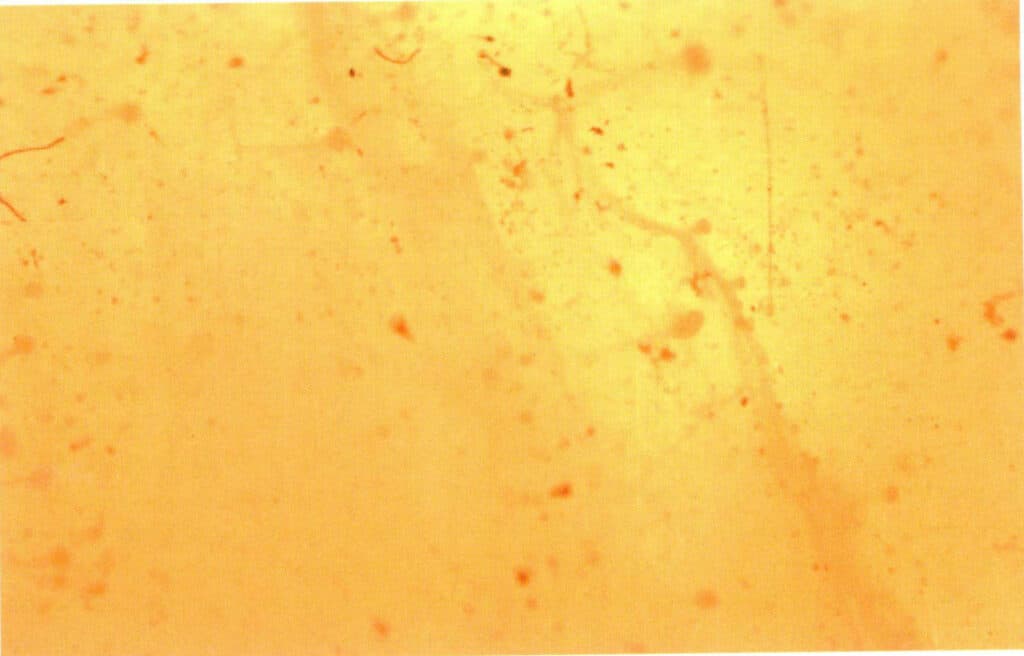

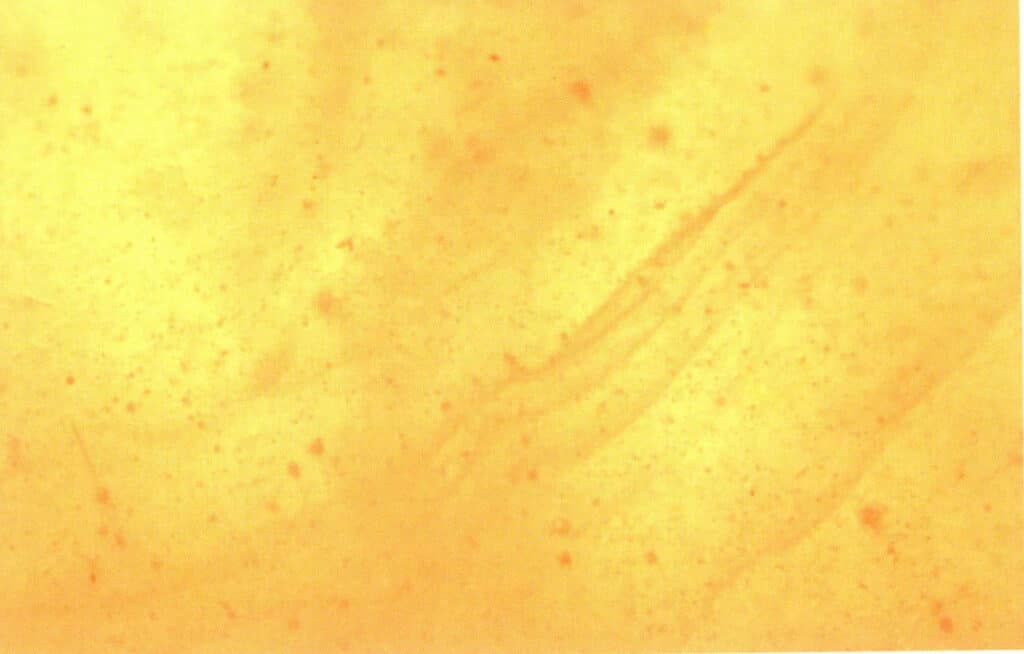

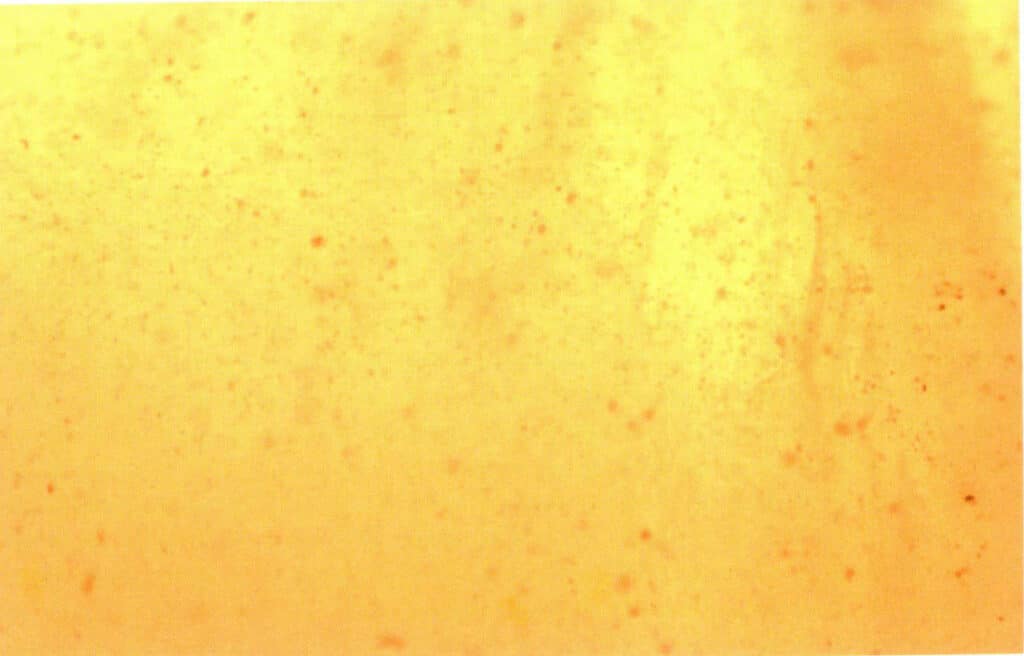

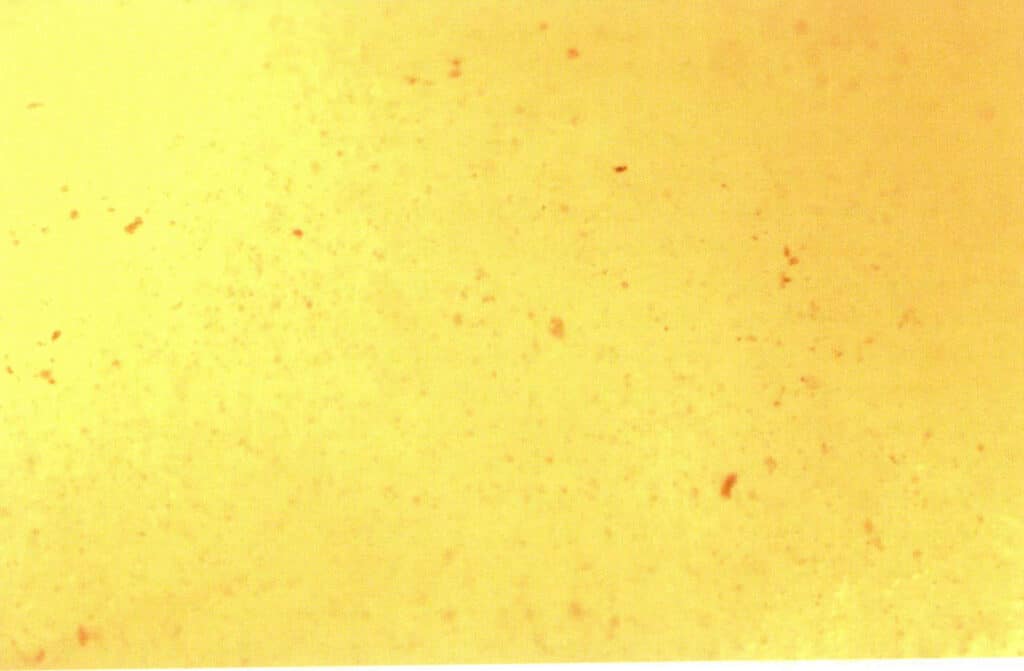

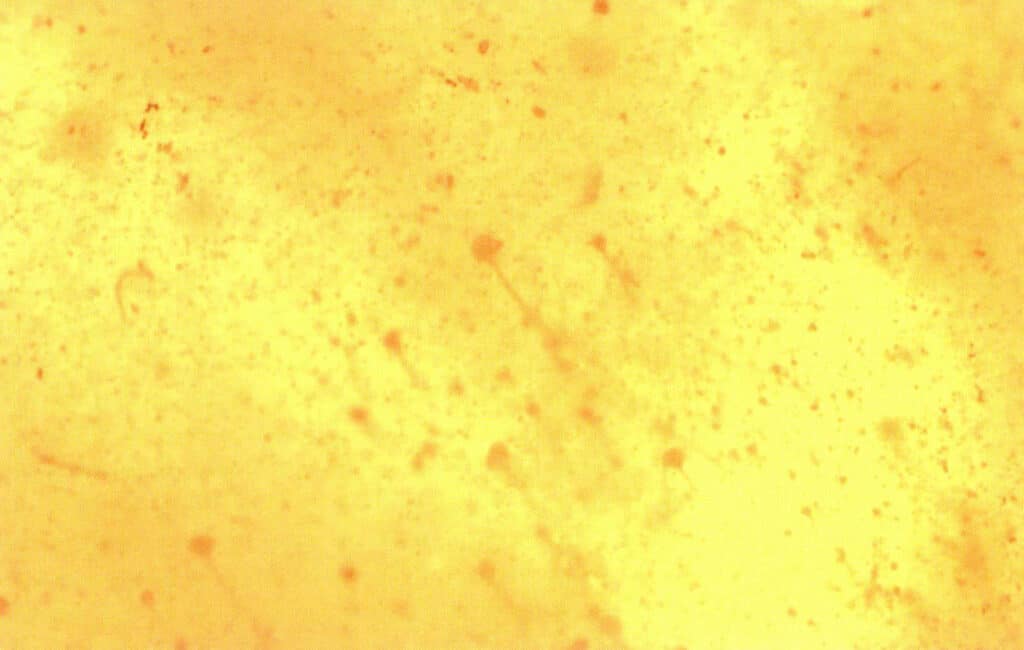

The main inclusions in Amber are bubbles, swirl patterns, flow structures; plant debris; and insects and other small animals such as beetles, spiders, mosquitoes, flies, and ants. Flow structures are shown in Figures 5-3-7 through 5-3-10.

Figure 5-3-7 Flow structures(1)

Figure 5-3-8 Flow structures(II)

Figure 5-3-9 Flow structures(III)

Figure 5-3-10 Flow structures(IV)

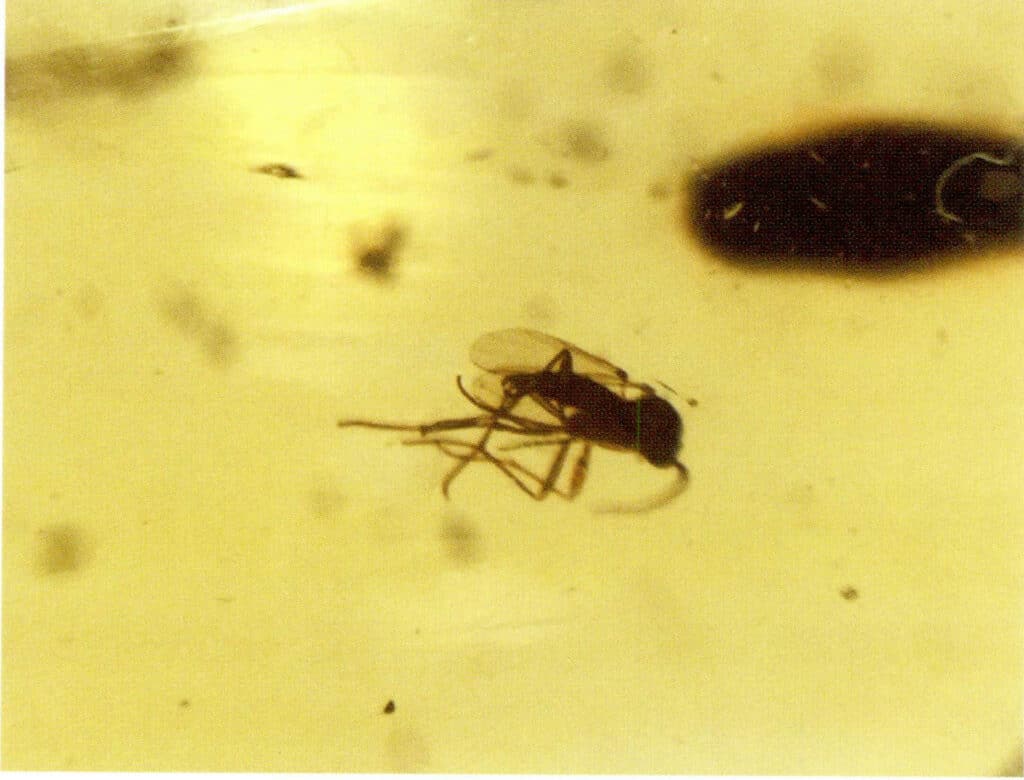

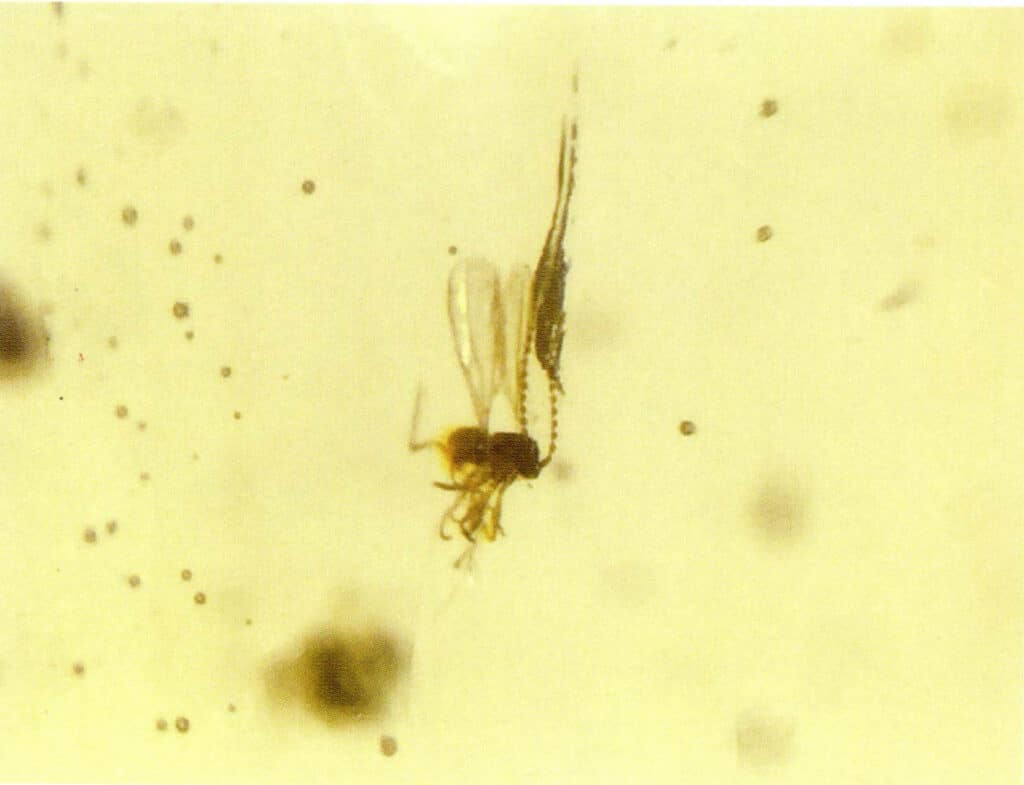

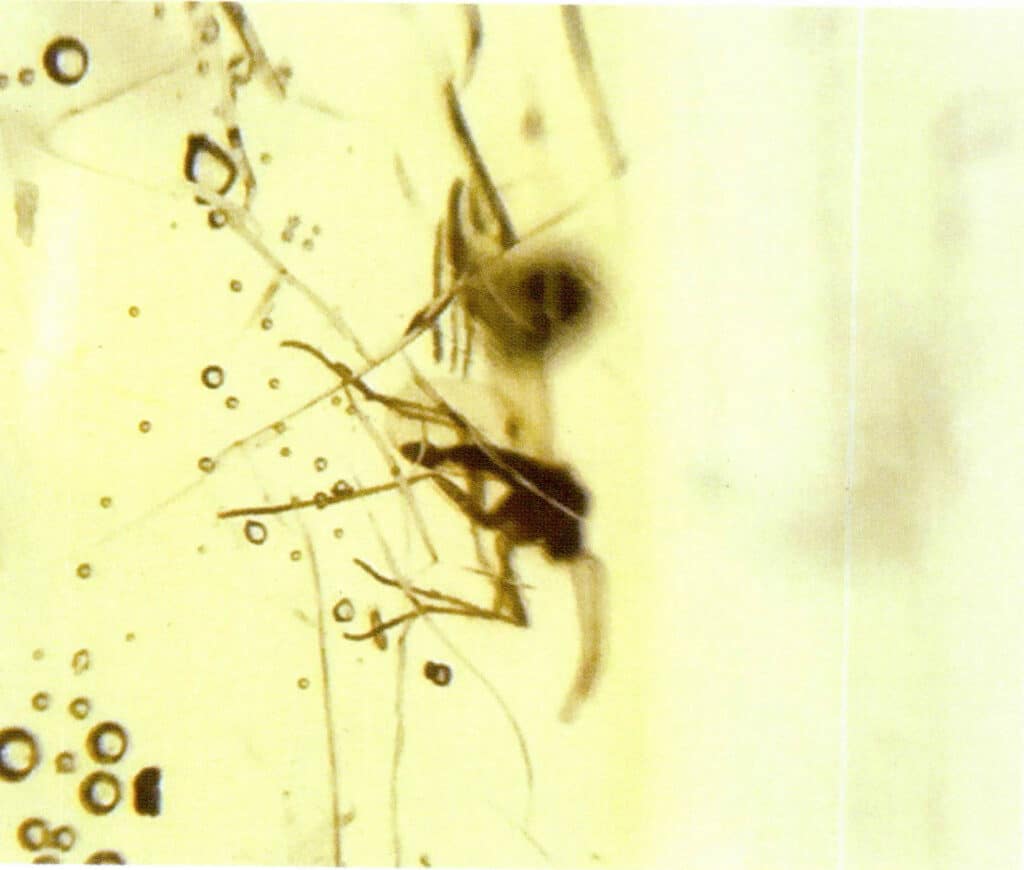

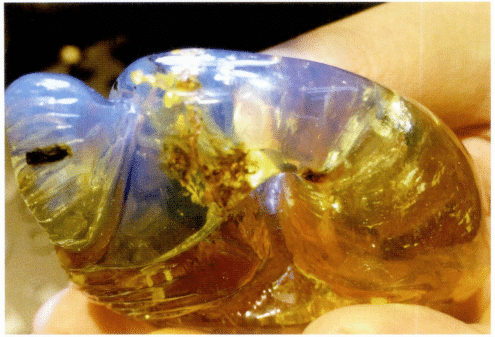

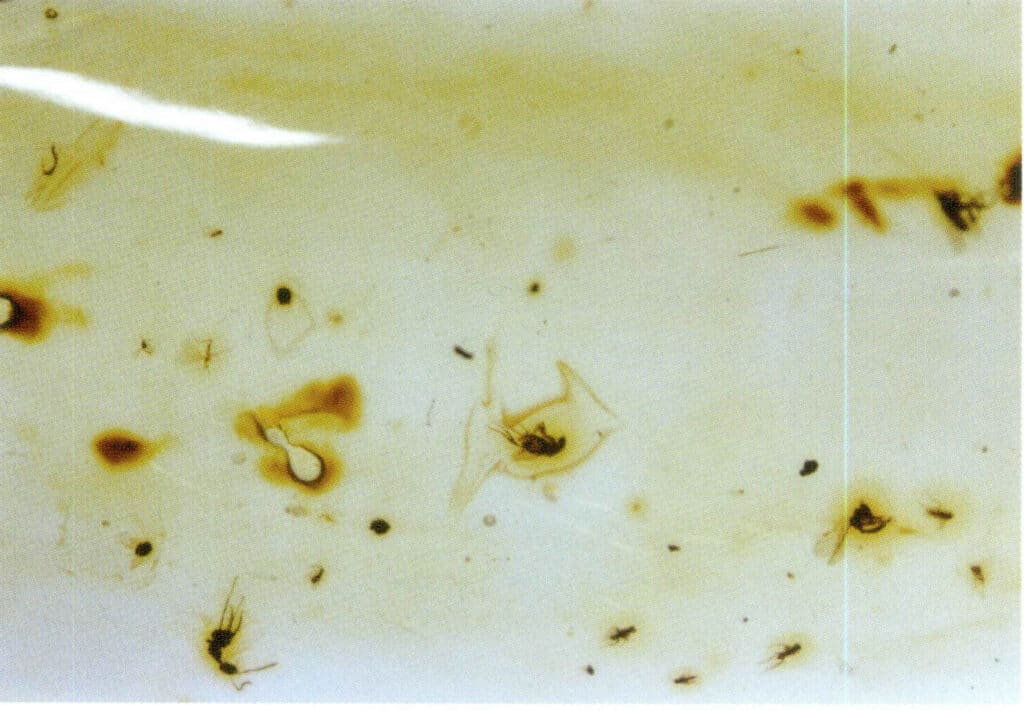

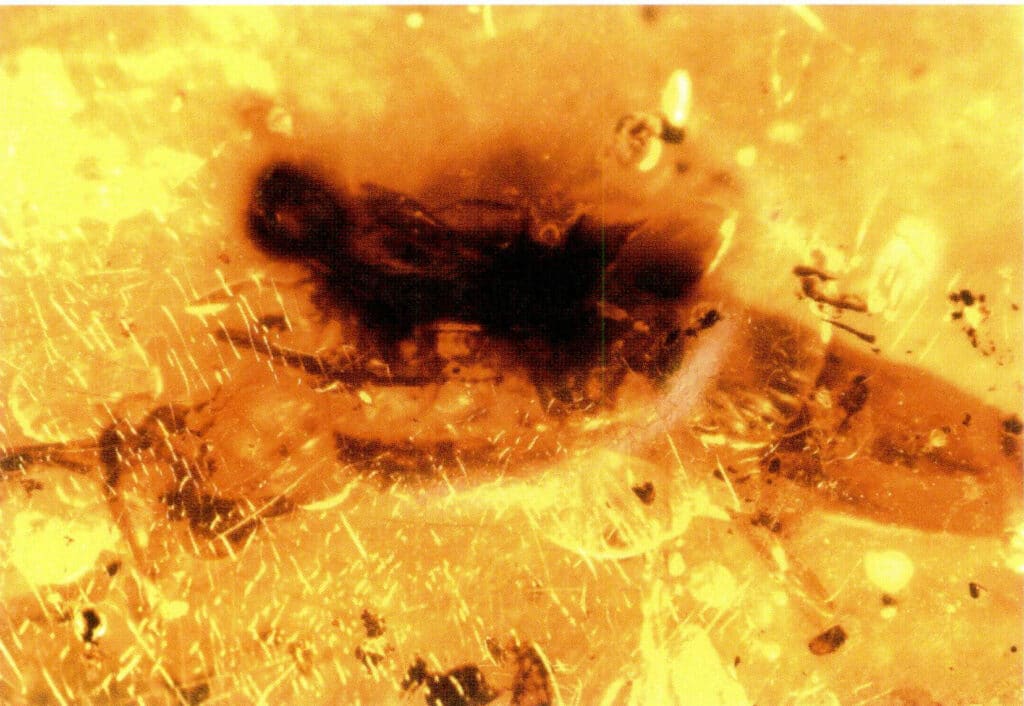

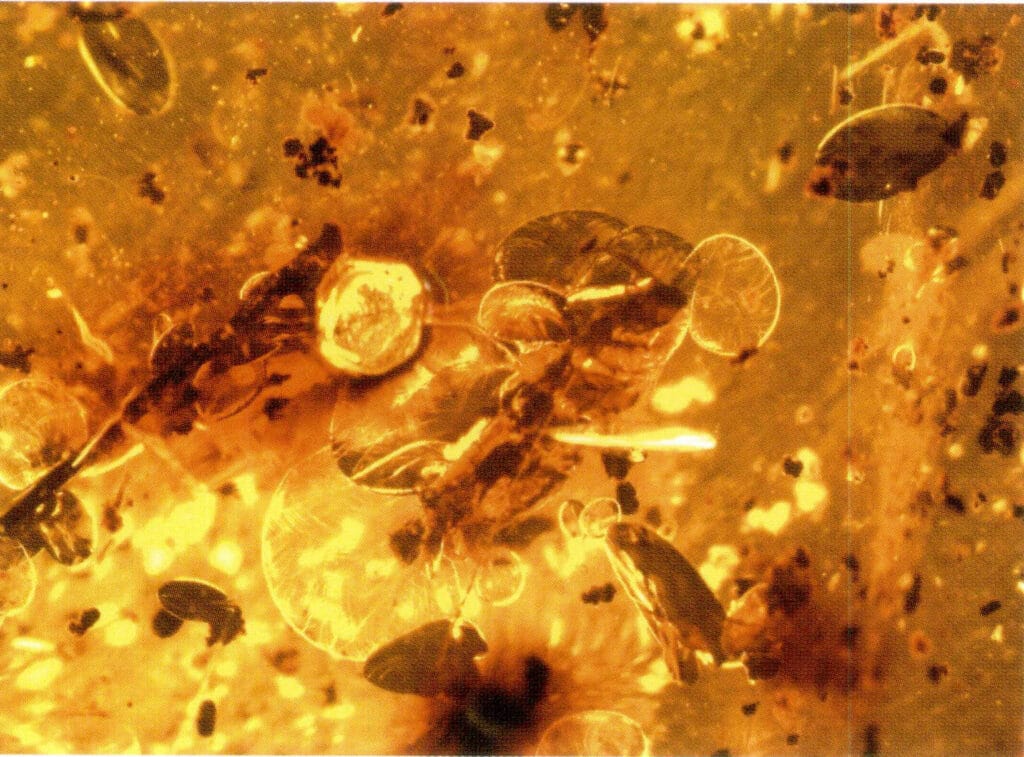

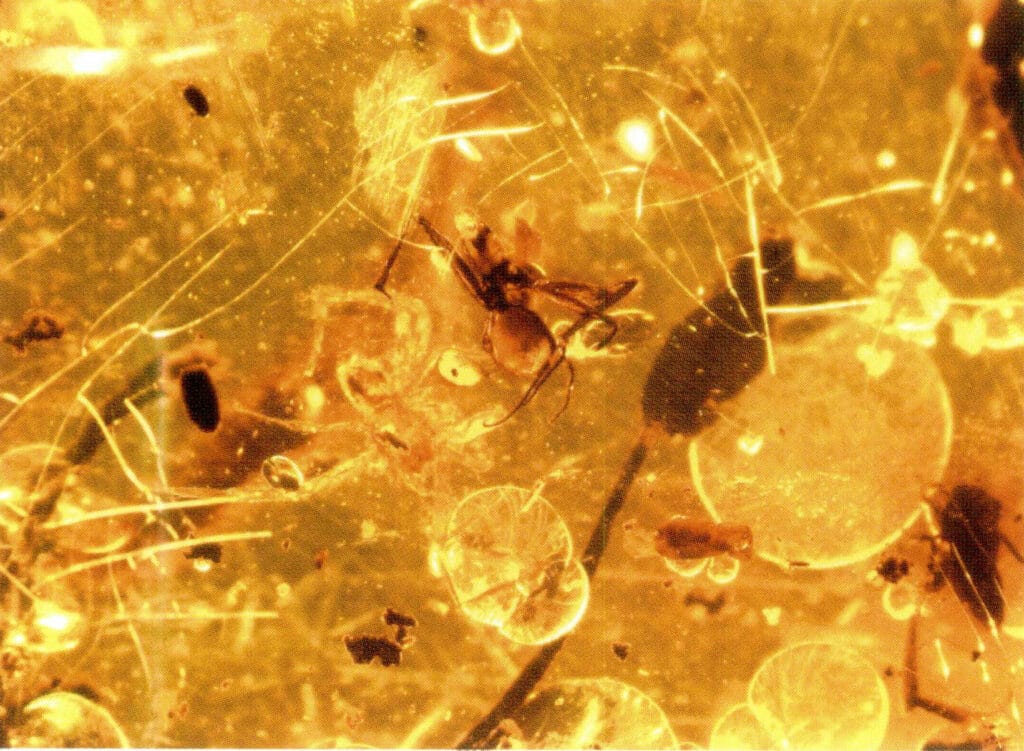

Resin is a kibble substance secreted by the tree in defense against disease and insect attack, and small insects are extremely easy to capture by it, so that insects or fragments of animals and plants, as well as other organic and inorganic inclusions, etc., are often visible inside. Insects and other inclusions can be well preserved in Amber; many belong to extinct species. Studying their modern descendants and habits can provide a great deal of information about the ecology of ancient Amber-producing forests.

Amber containing larger animals such as scorpions, snails, frogs, lizards, etc., is highly prized, especially if the inclusions are well preserved. Extinct lizards have been found in Dominican Amber, and feathered dinosaur tails in Burmese Amber.

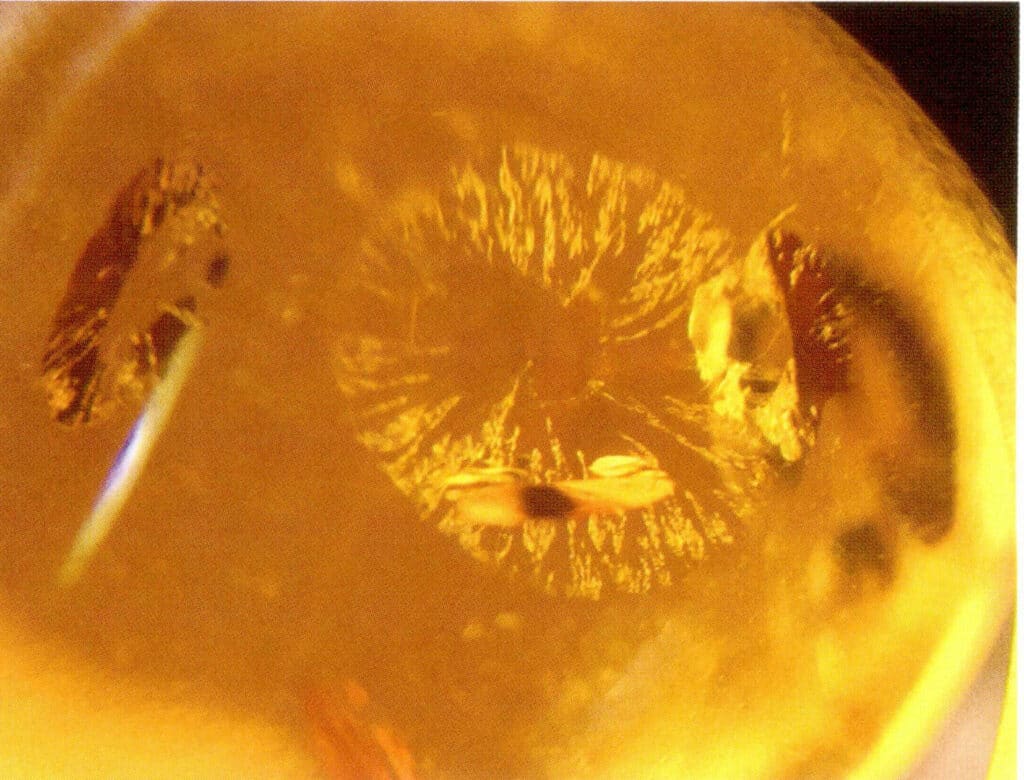

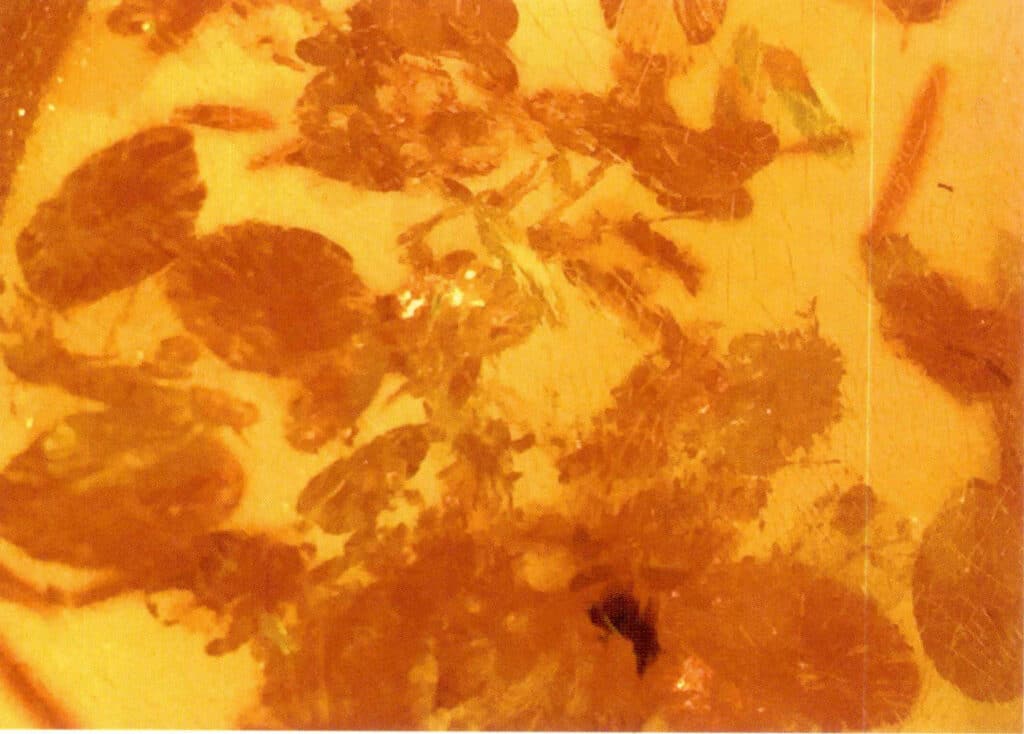

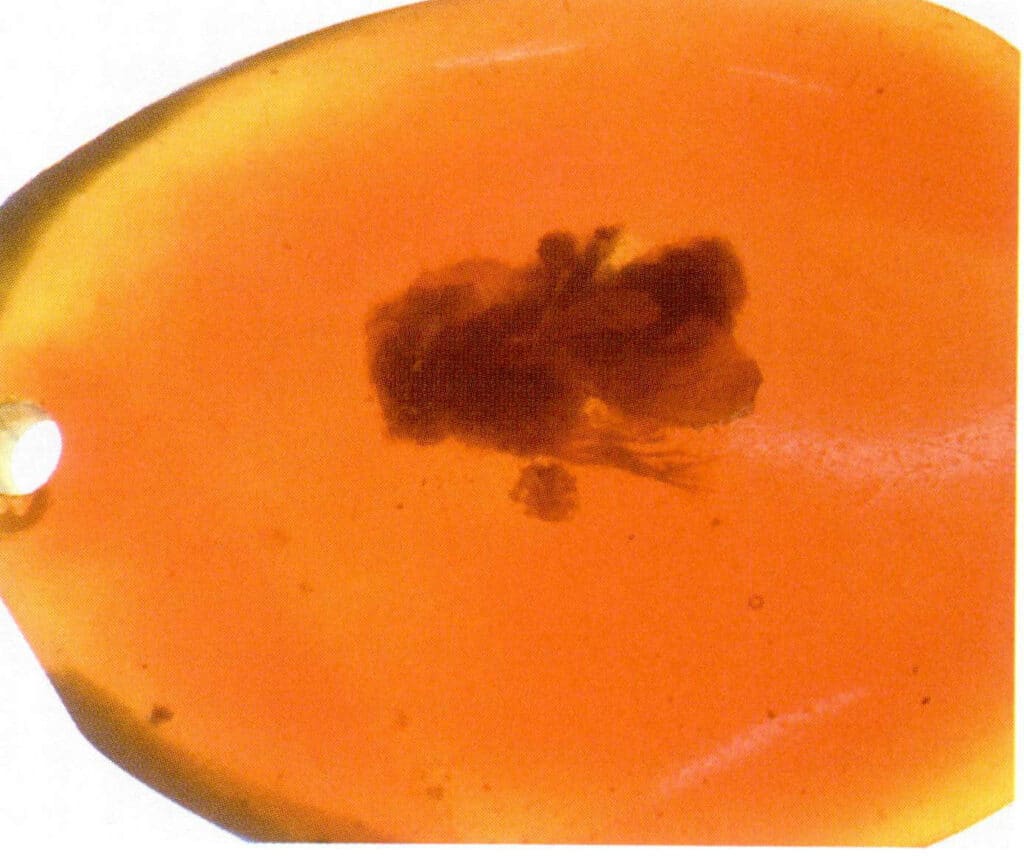

Biological Inclusion and bubbles in Amber are shown in Figures 5-3-11 through 5-3-20.

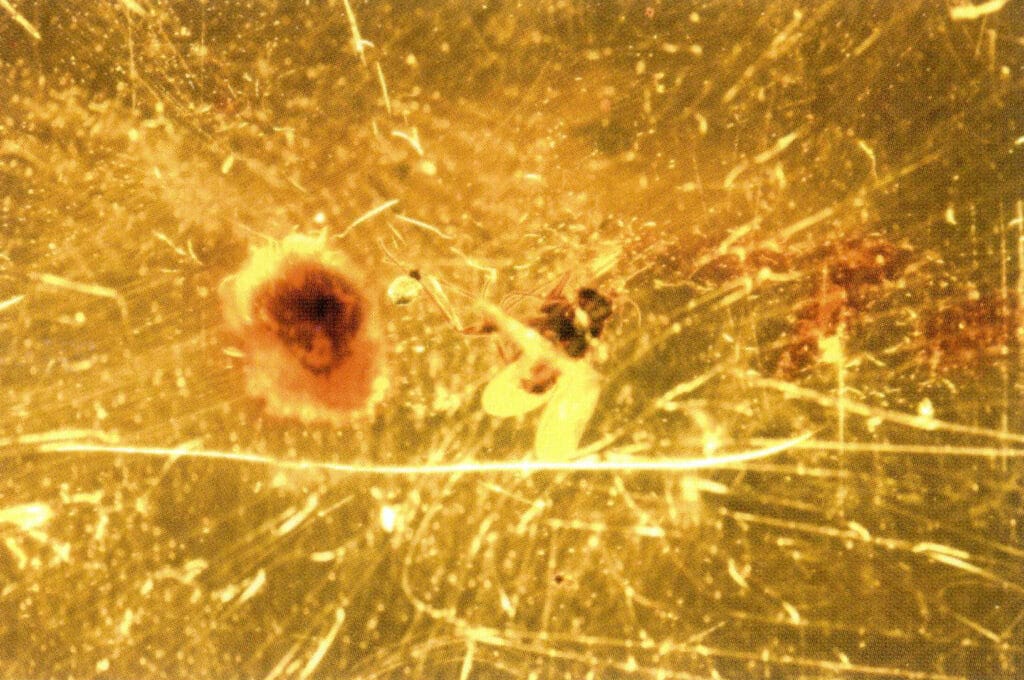

Figure 5-3-11 Insect Envelope (Microscopic View 20×)(1)

Figure 5-3-12 Insect Envelope (Microscopic View 20×)(II)

Figure 5-3-13 Insect Inclusion and Bubbles (Microscopic View 20×)(I)

Figure 5-3-14 Insect Inclusion and Bubbles (Microscopic View 20×)(II)

Figure 5-3-15 Insect Inclusion and Bubbles (Microscopic View 20×) (III)

Figure 5-3-16 Plant Debris (I)

Figure 5-3-17 Plant Debris(II)

Figure 5-3-18 Plant Debris (III)

Figure 5-3-19 Plant Debris (IV)

Figure 5-3-20 Plant Envelope (Microscopic View 20×)

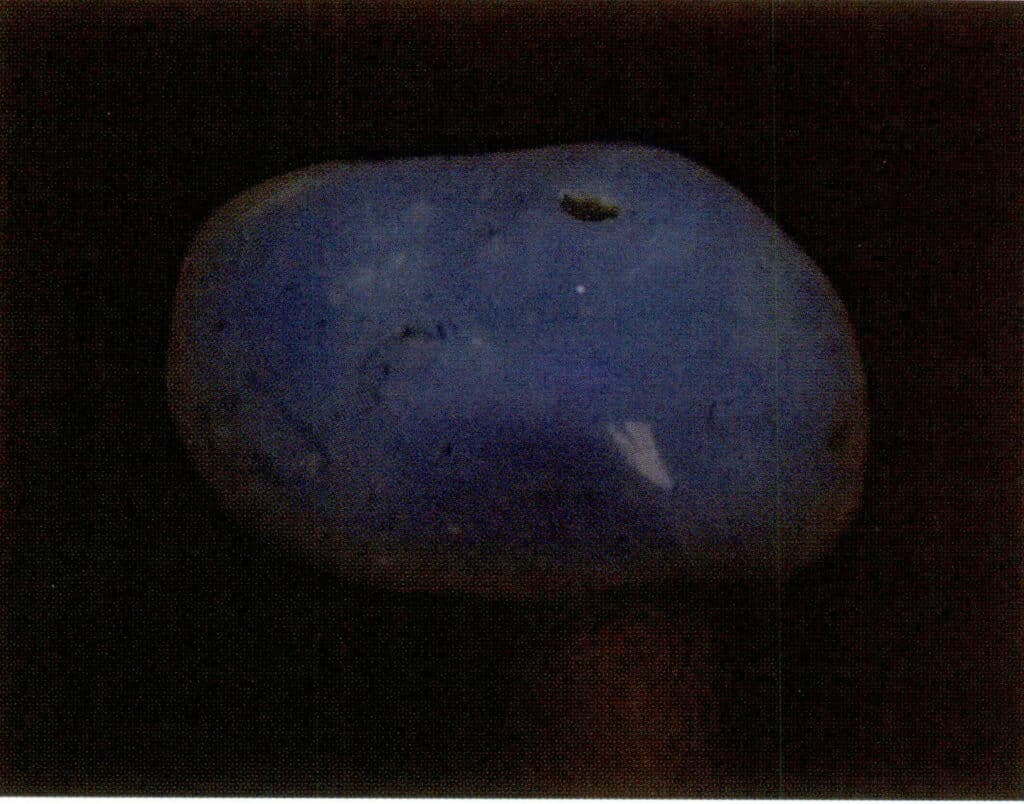

5. Ultraviolet Fluorescence Characterization

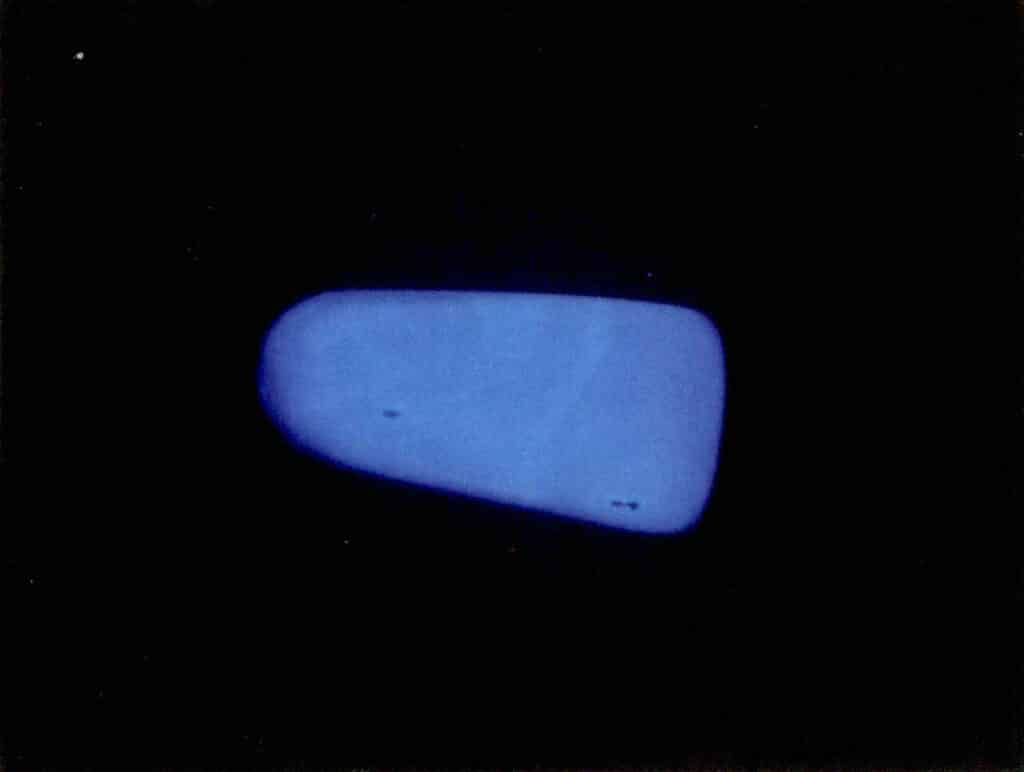

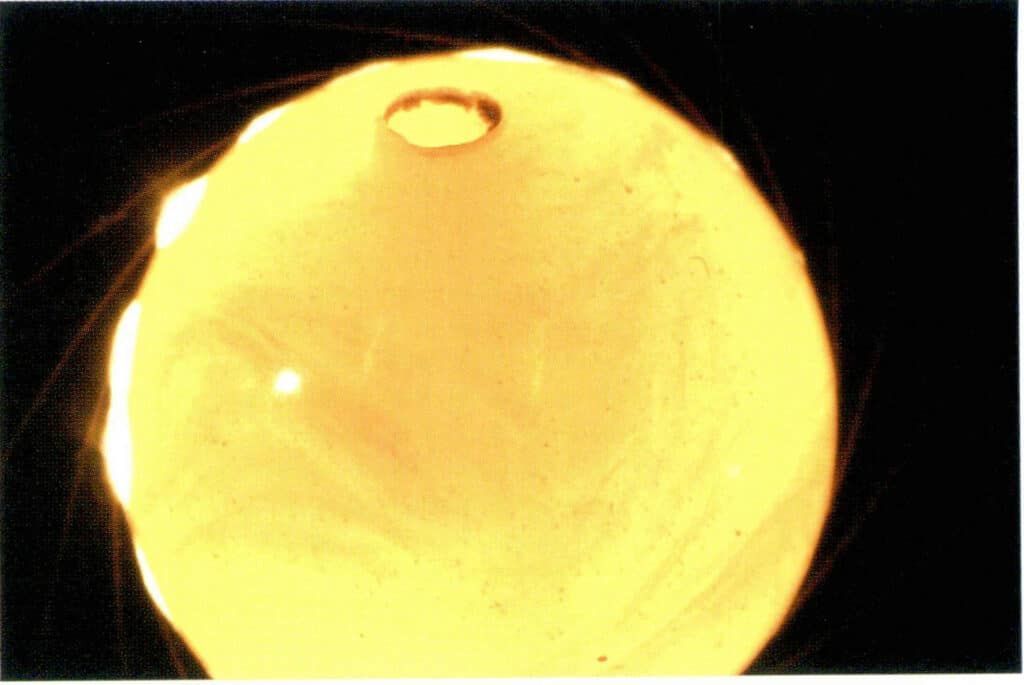

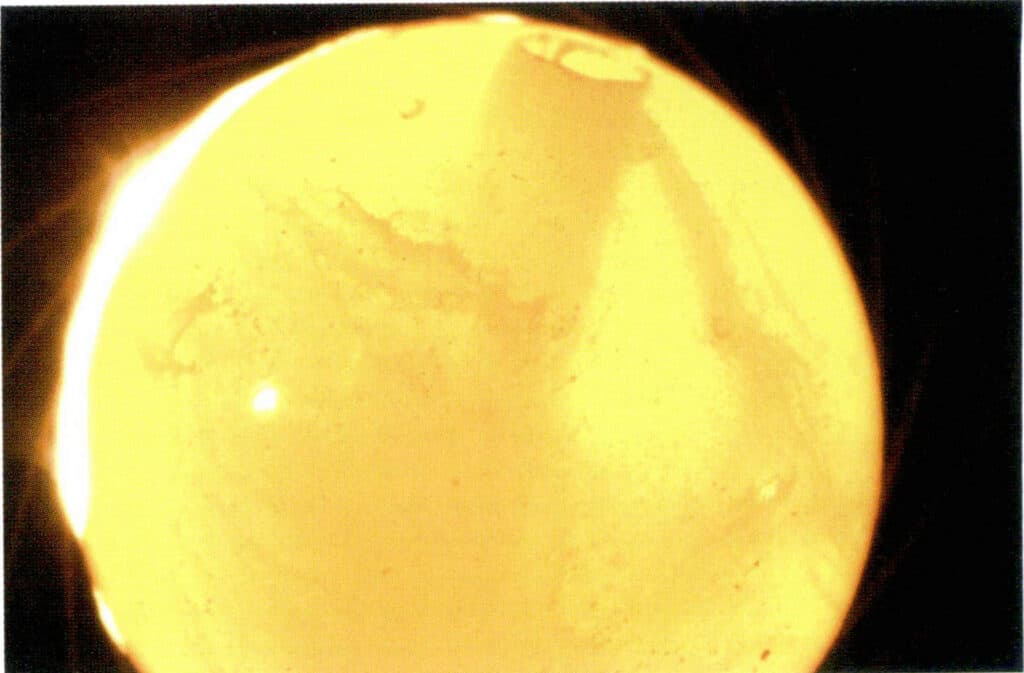

Amber usually has a light blue-white and light yellow, light green, yellow-green, to orange-yellow 苂, light of varying intensity under long-wave ultraviolet light, while under short-wave ultraviolet light 苂, light is not obvious. In particular, some Amber from Burma and the Dominican Republic often has a strong fluorescent effect. The ultraviolet fluorescent effect characteristics of Amber are shown in Figures 5-3-21 through 5-3-28.

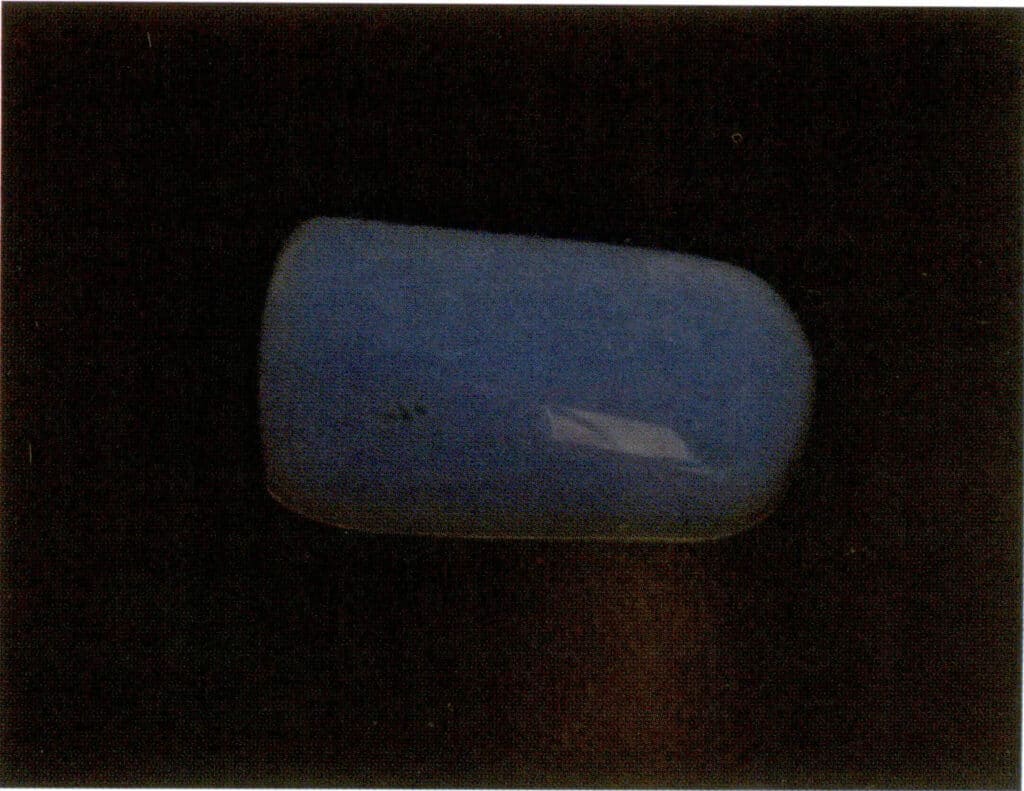

Figure 5-3-21 Characteristics of Amber pods at long wavelengths in the U.V. (I)

Figure 5-3-22 Fluorescence characteristics of amber under ultraviolet long wave(II)

Figure 5-3-23 Fluorescence characteristics of Burmese amber under ultraviolet long wave(I)

Figure 5-3-24 Fluorescence characteristics of Burmese Amber at long U.V. wavelengths(II)

Figure 5-3-25 Dominican blue amber U.V. Light (I)

Figure 5-3-26 Dominican blue amerunder U.V. light(II)

Figure 5-3-27 Dominican blue amerunder U.V. light (III)

Figure 5-3-28 Dominican blue amerunder U.V. light (IV)

6. Infrared spectral characteristics

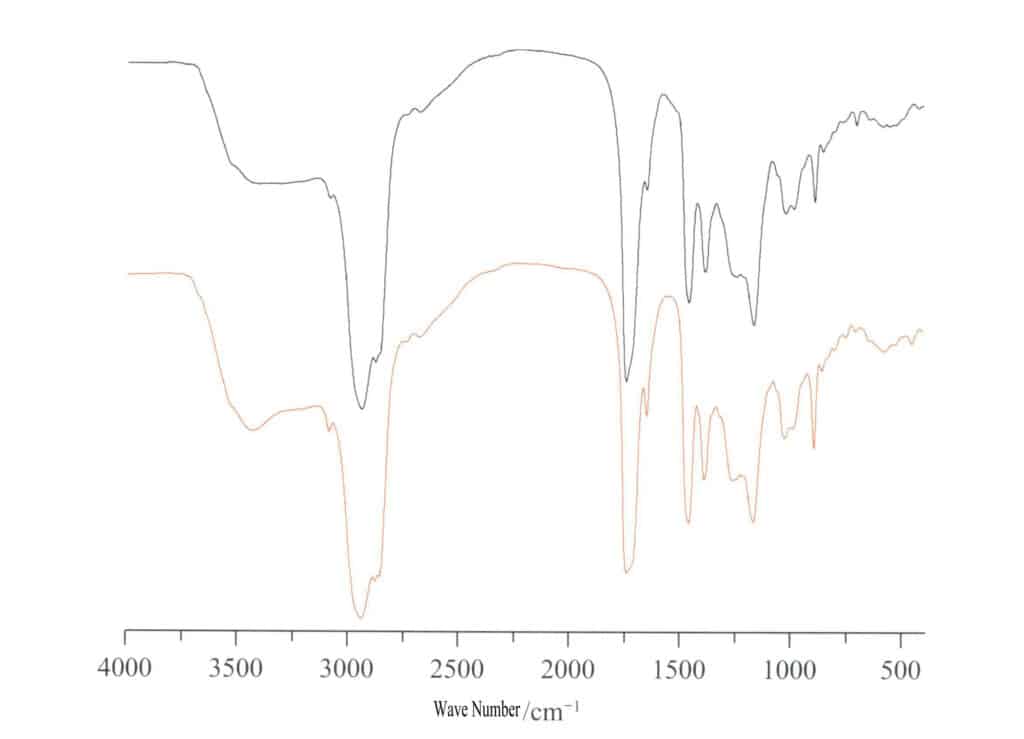

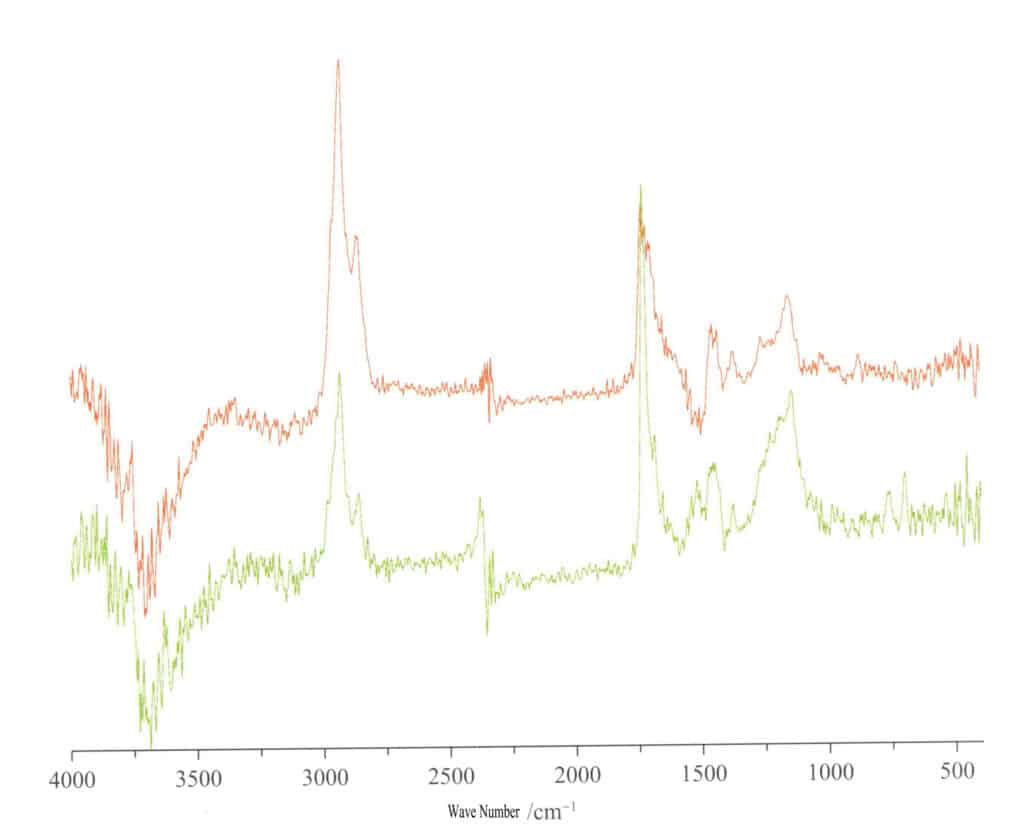

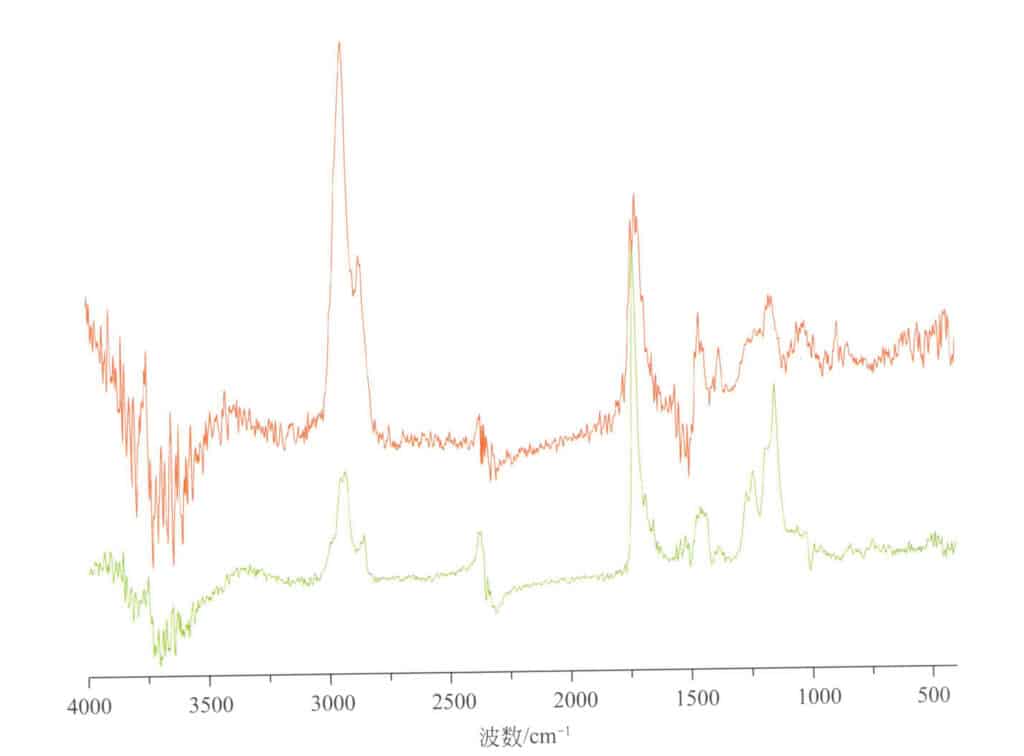

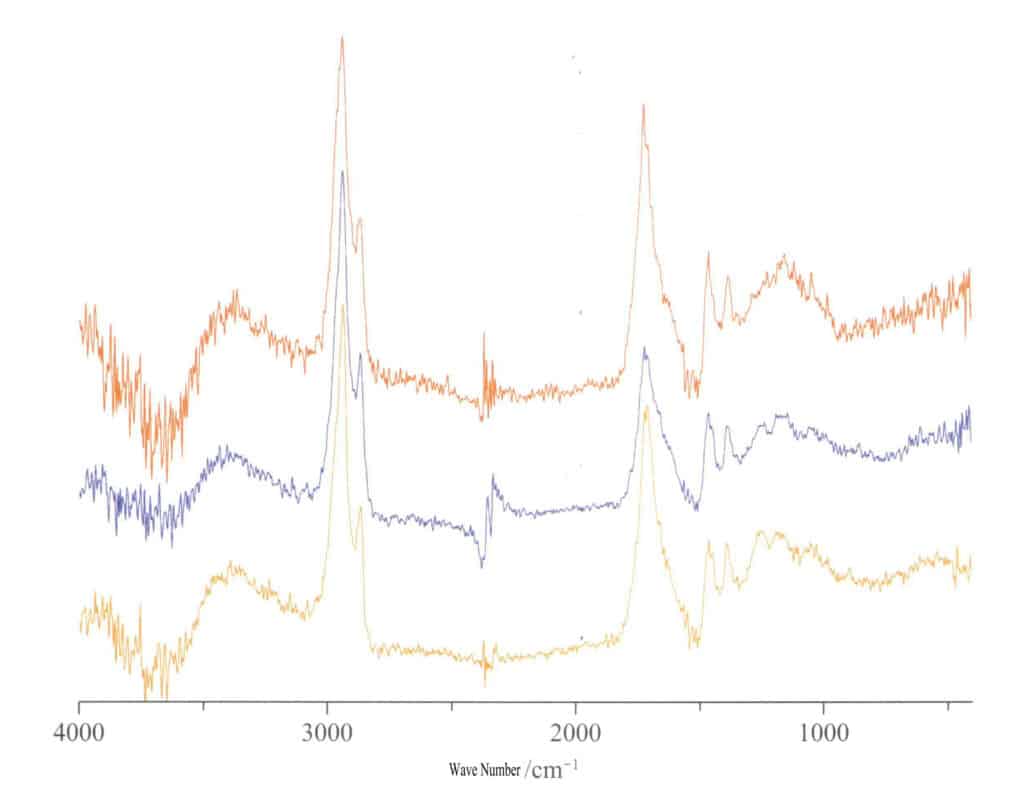

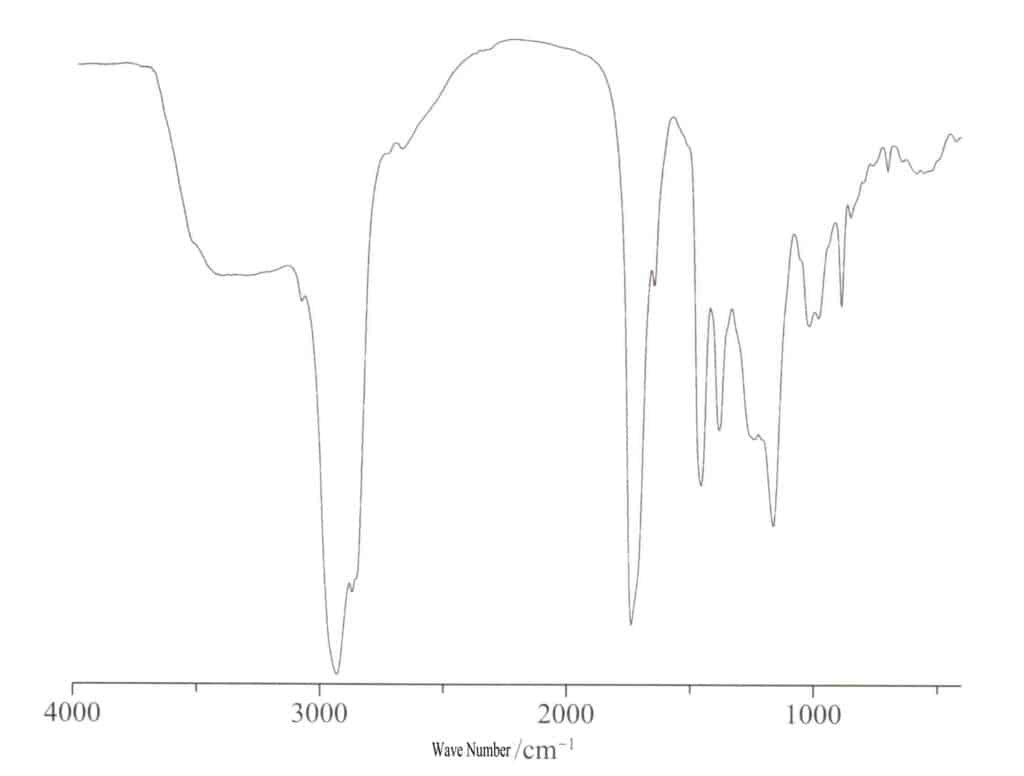

The infrared spectrum of Amber is shown in Figure 5-3-29 and Table 5-3-2.

The absorption peaks near 887cm-1 are caused by C.H. out-of-plane bending vibrations on the C = C double bond, the absorption peaks near 1161 cm-1 are caused by C-O stretching vibrations, and symmetric bending vibrations of C-H cause the infrared absorption bands near 1380 cm-1.. The asymmetric bending vibration of C causes the infrared absorption band near 1452 cm-1C—H, the infrared absorption caused by the stretching vibration of C = O functional group is located near 1733 cm-1, and the absorption peak caused by the asymmetric stretching vibration of aliphatic C-H bond is located near 2931 cm-1.

Table 5-3-2 Infrared spectral vibrations of Amber (Baltic)

| Vibration mode | Wave number/ cm -1 |

|---|---|

| -C-CH2- Out-of-plane bending | 887 |

| -CH = CH2 | 987 |

| C-O Stretch | 1161 |

| C-CH3 Bending | 1380 |

| -CH2 - Bending | 1450 |

| C = C Stretch (non-conjugate) | 1643 |

| C= O (ester non-conjugated) | 1735 |

| -CH2- | 2850, 2869, 2927 |

| = CH2 (Olefin) stretching | 3078 |

| - O-H (conjugated) | 3520 ~ 3100 |

7. Other characteristics

In addition to its electrostatic properties and solubility in acids and organic solutions, Amber has several other properties.

Amber has poor thermal conductivity and is warm to the touch. When Amber is heated to 150℃, it decomposes and softens; at 250℃, it begins to melt and emits black smoke with a burnt rosin odor; when extinguished, it emits white smoke.

Amber is not cut; and chipping or cracking will occur if you cut Amber in an inconspicuous place with a small knife.

Section IV Classification

1. Business classification

Commercially, Amber is categorized differently, and there are no certain rules. In particular, it should be noted that in commercial classification, some Amber does not have clear boundaries, and the same piece of Amber may be classified in different commercial categories by different practitioners.

According to its different colors, transparency, and types of inclusions, Amber can be classified as beeswax, golden Amber, gold amber Mixed with beeswax, blood read Amber, brown Amber, golden brown Amber, blue Amber, blue-green Amber, white beeswax, cataract amber, worm Amber, botanical Amber, water gall bladder Amber, and flower pattern Amber. The flower pattern Amber refers to the Amber obtained through the process of artificial heating “popping,” while the pressed Amber can also show a similar appearance, but the “flower” of the pressed Amber is fine and disorderly, and the background is cloudy.

Common commercial varieties of Amber are shown in Table 5-4-1 and Figures 5-4-1 through 5-4-28.

Table 5-4-1 Common Commercial Varieties of Amber

| Beeswax | Translucent to opaque amber, can be a variety of colors, yellow is the most common, mainly produced in the Baltic Sea and so on. |

|---|---|

| Golden amber | Yellow to golden yellow transparent amber, the flow pattern is generally not obvious, mainly produced in the Baltic Sea and Thailand, etc., part of the Marine Amber heat treatment products |

| Gold amber Mixed with beeswax | Transparent gold amber contains translucent beeswax, or gold amber and beeswax entangled with each other; mainly produced in the Baltic Sea, part of the product of heat treatment; based on the form of gold amber and beeswax, can be divided into "gold stranded honey" (gold amber and beeswax entangled with each other), "gold wrapped honey" (also known as "pearl honey," the outside of the gold amber, center of the beeswax) and "gold with honey" (gold amber with beeswax in it) |

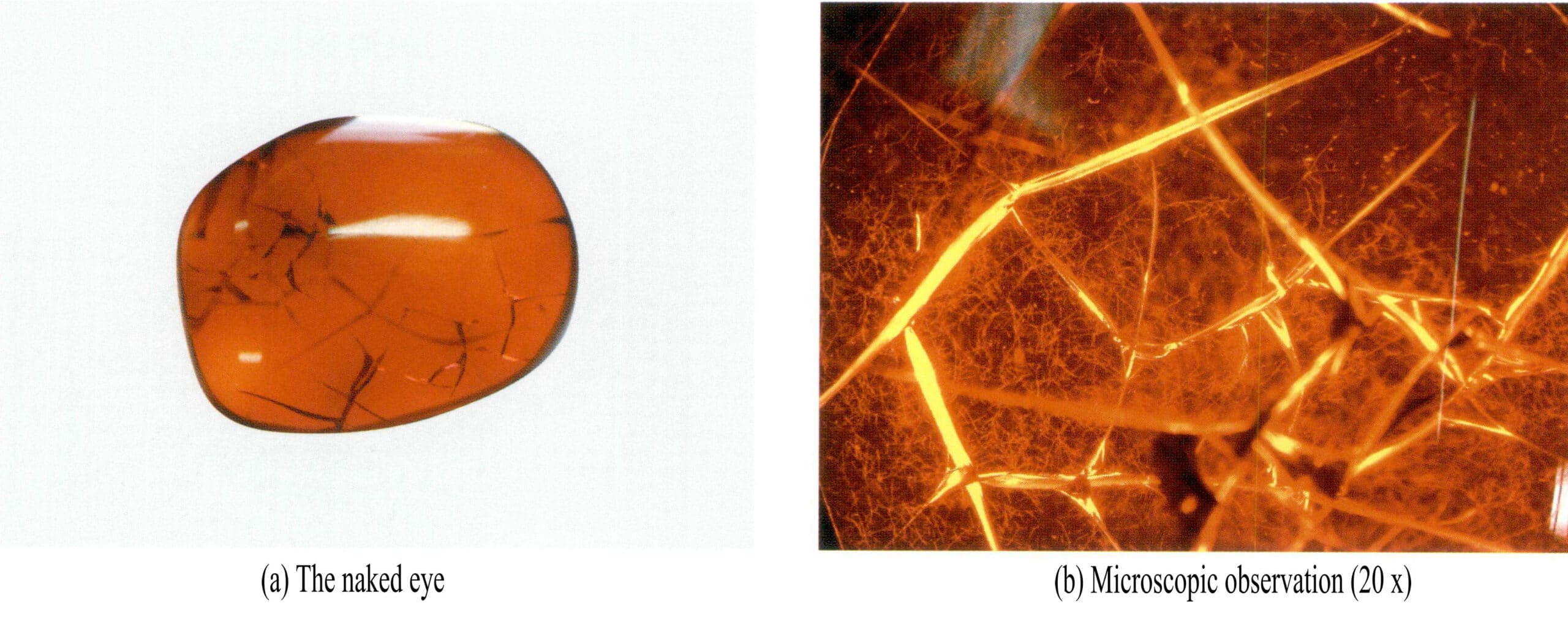

| Blood red amber | Brownish red to red transparent amber, mainly from the Baltic Sea, Myanmar, etc.; some Blood red Amber products are the product of heat treatment of amber with certain impurities, and their color is limited to the surface layer. |

| Brown amber | Brownish-red, poorly transparent, often turbid inside, with distinctive flow patterns; may have distinctive blue ultraviolet fluorescence |

| Golden brown Amber | Brownish-yellow amber, between brownish-red and golden amber, with obvious flow lines; the higher the transparency, the closer it is to golden amber, and vice versa. |

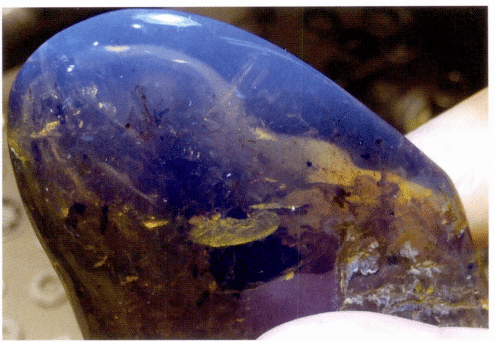

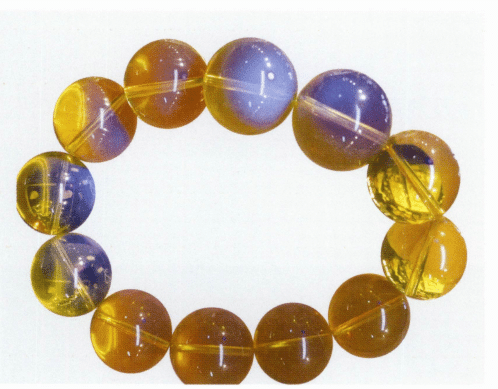

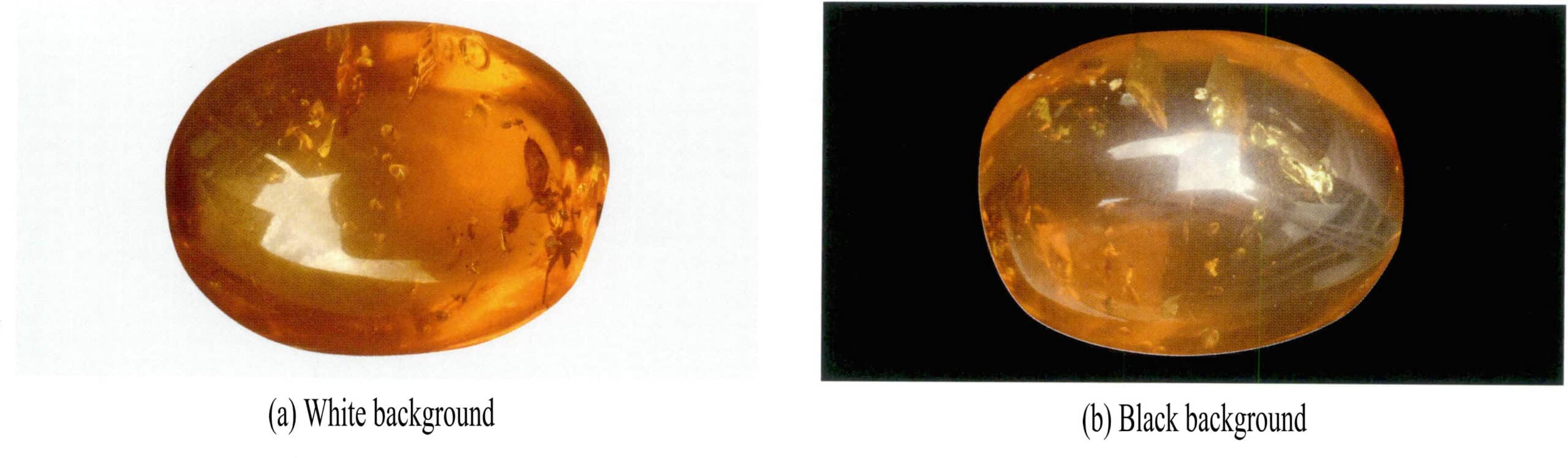

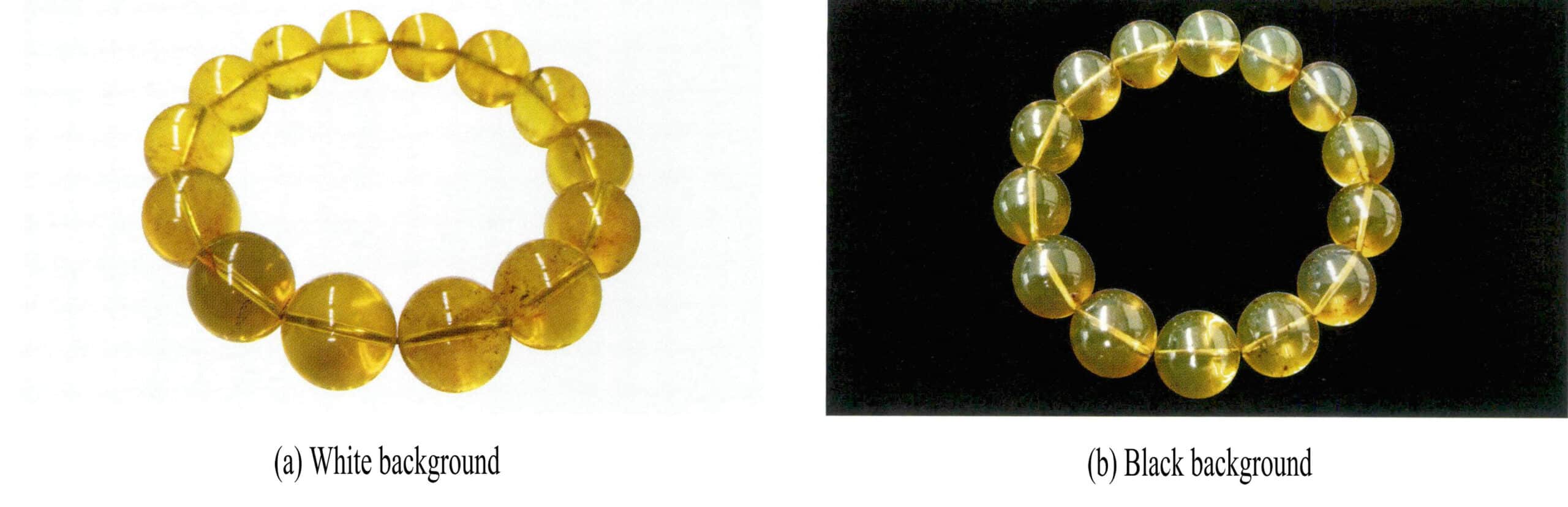

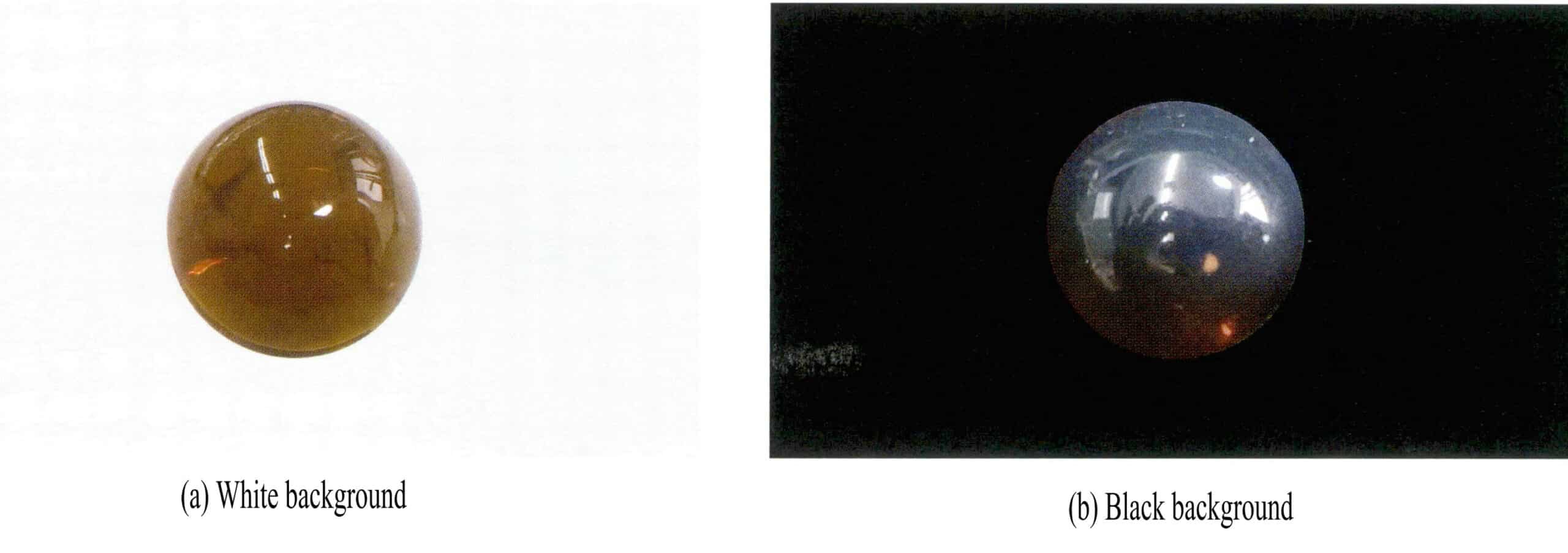

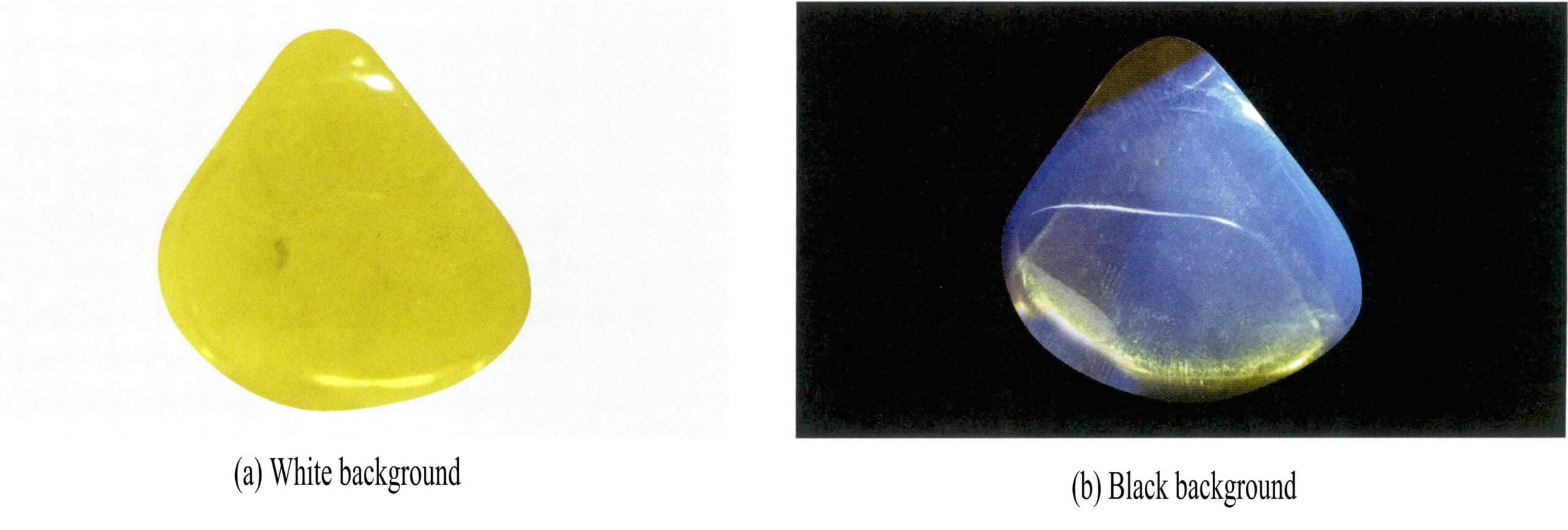

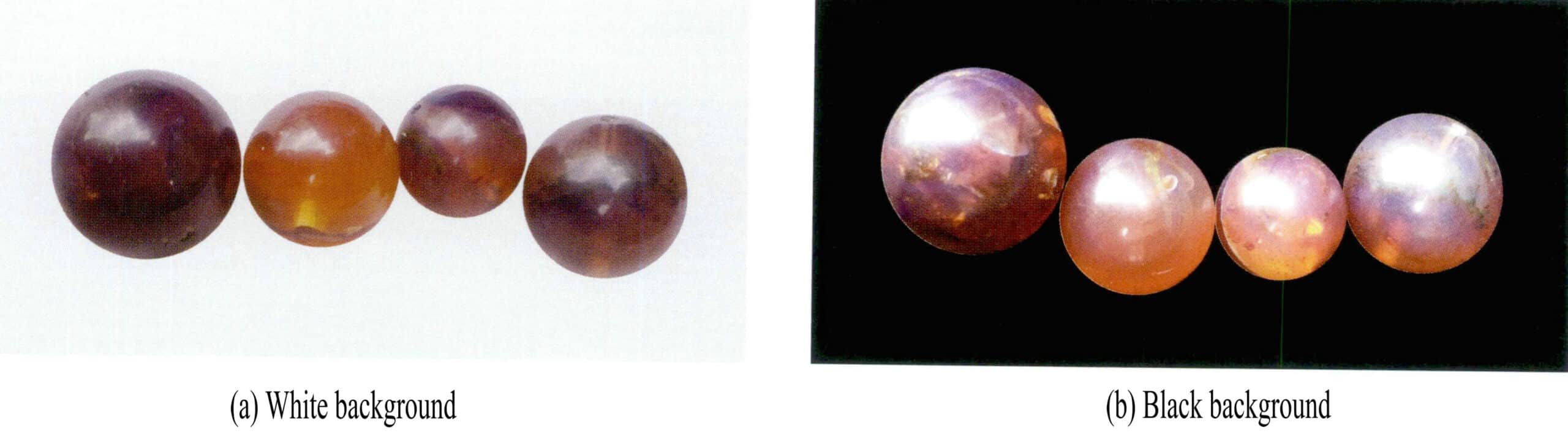

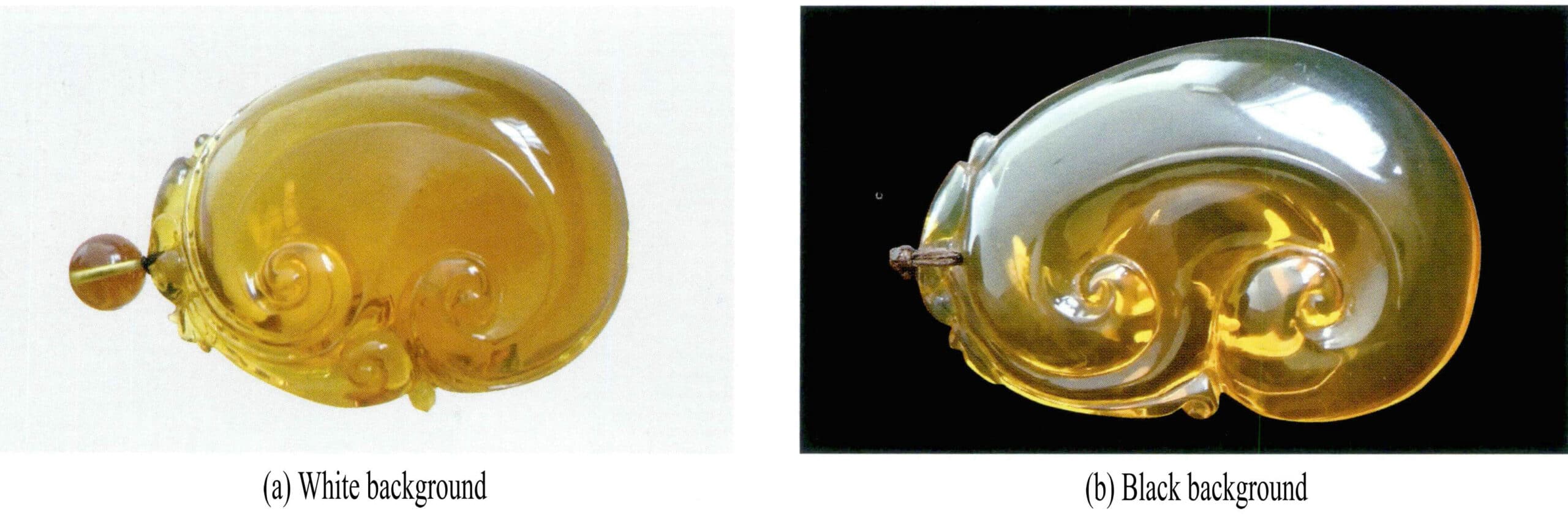

| Blue amber (geology) | Yellow, brownish yellow, yellow-green, and brownish red in perspective; distinctive shades of blue in sunlight, against dark backgrounds, or at appropriate light angles, more visible under ultraviolet light; mainly from Dominica |

| Blue-green amber | Greenish-blue color in sunlight, against a dark background or at the right angle of the light source, mainly from Mexico |

| White beeswax | White color beeswax |

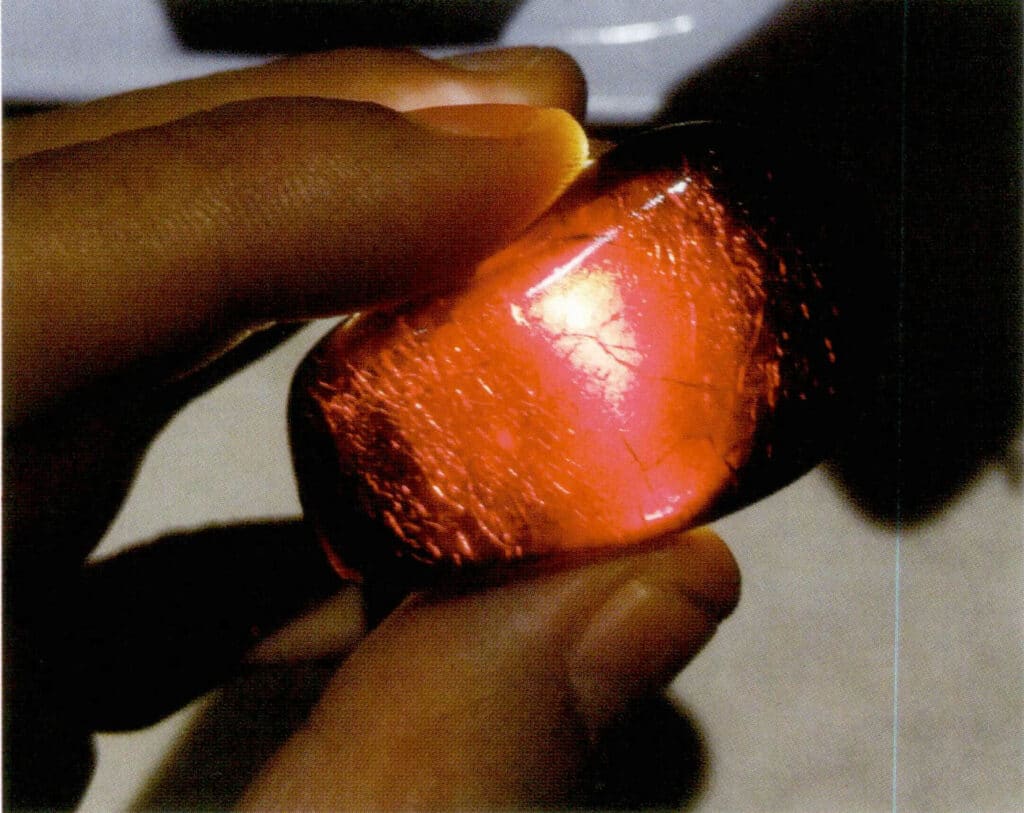

| Cataract amber | Amber that appears black in reflected light and red in transmitted light; classified as a type of Blood red Amber; mainly found in Burma, Romania, the Dominican Republic and the Baltic Sea. |

| Violet amber | Purple color when exposed to sunlight, dark background or suitable light source angle, mainly from Myanmar |

| Worm | Amber containing insects or other animals |

| Botanical amber | Amber containing plants (e.g. flowers, leaves, roots, stems, seeds, etc.) |

| Water gall bladder amber | Amber with liquid inclusions inside |

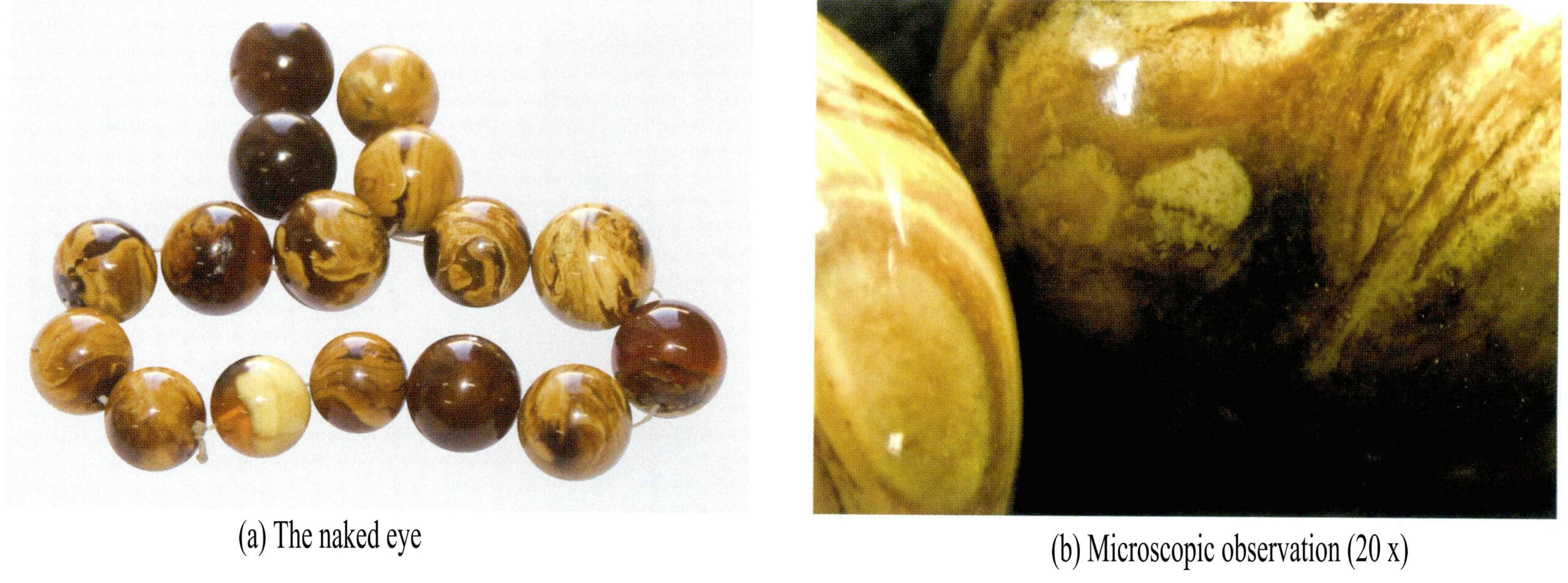

| Tree roots amber | Opaque, containing calcite veins, with dark brown and white mottled texture or yellowish white and dark brown, a material for skillful carving; mainly produced in Myanmar, with a small amount in the Baltic Sea |

| Flower pattern amber | Amber that has been artificially heated to produce "pops". |

| Old aged beeswax | It refers to the long time, opaque brownish-yellow beeswax, suitable for making beads; the old aged beeswax products on the market are mostly made of Baltic beeswax after a long time of low-temperature heating |

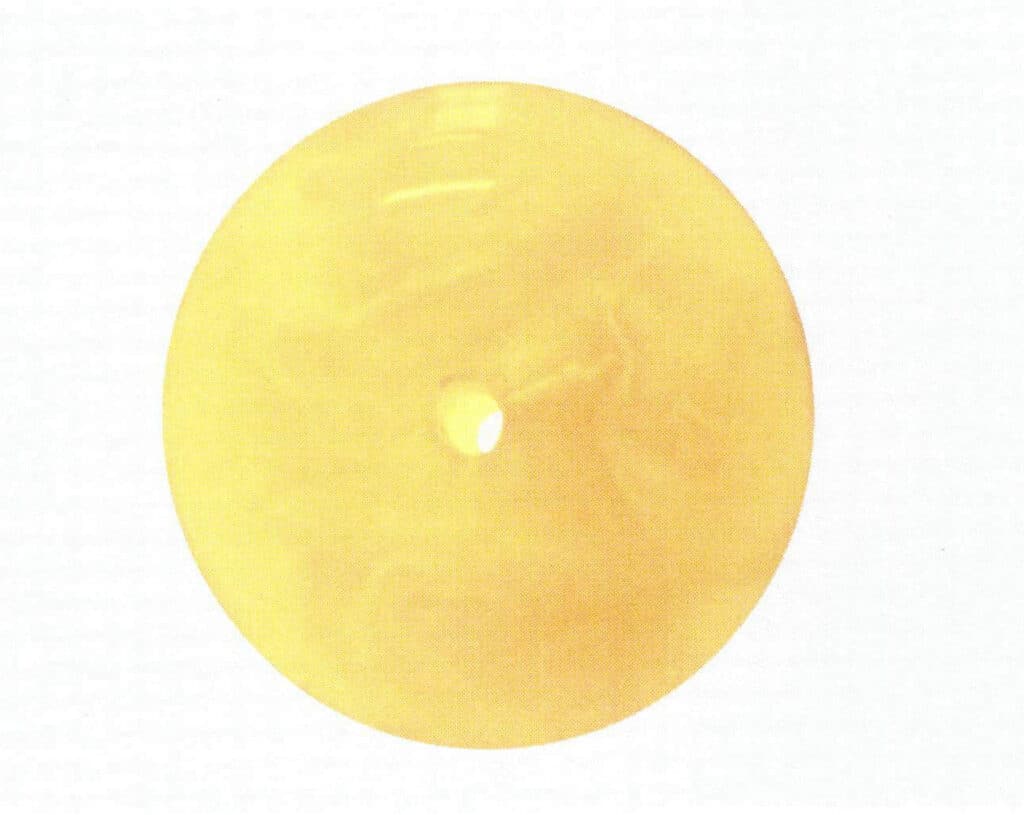

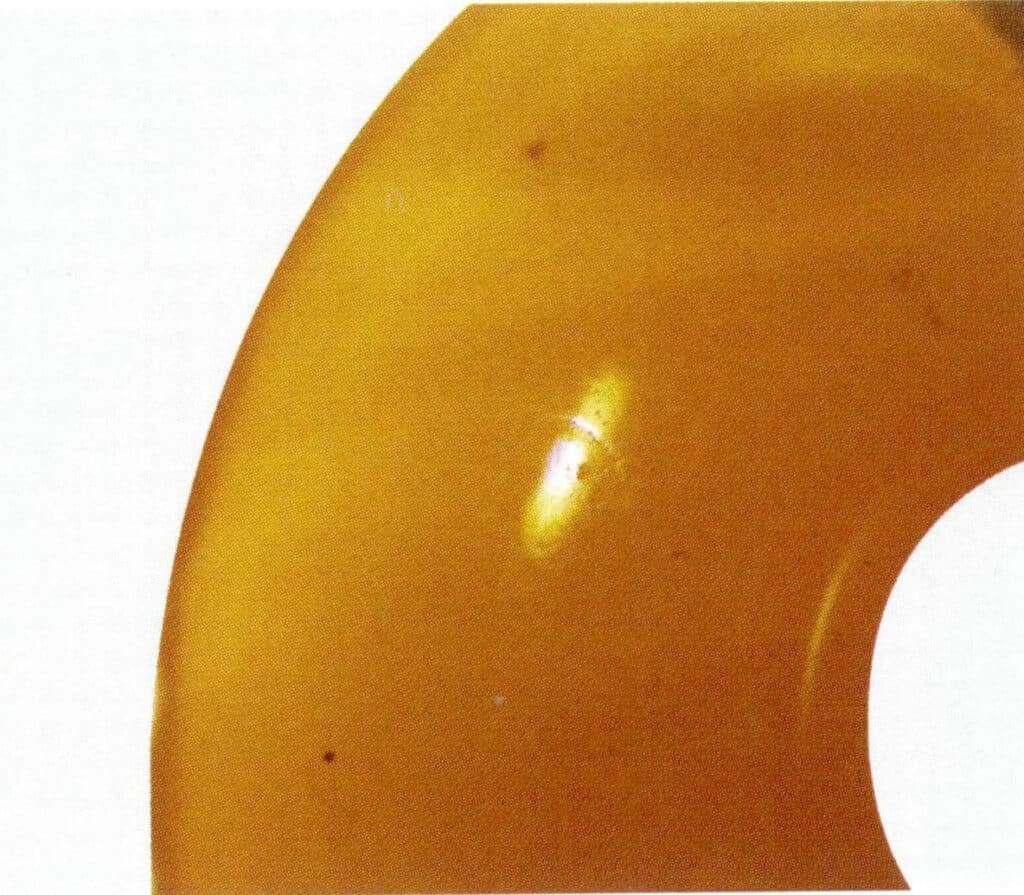

Figure 5-4-1 Beeswax (1)

Figure 5-4-2 Beeswax(2)

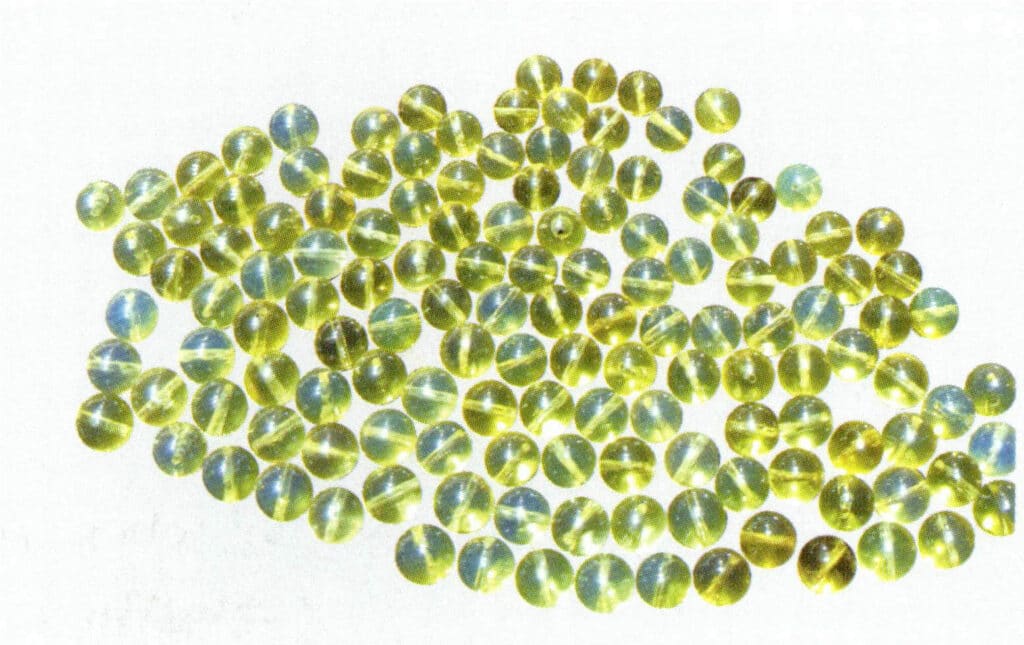

Figure 5-4-3 Gold amber (3)

Figure 5-4-4 Gold amber(4)

Figure 5-4-6 Gold amber and beeswax entangled with each other(II)

Figure 5-4-7 Gold amber and beeswax entangled with each other (III)

Figure 5-4-8 Blood red Amber (I)

Figure 5-4-9 Blood red Amber(II)

Figure 5-4-10 Brown Amber 1

Figure 5-4-11 Brown Amber(II)

Figure 5-4-12 Brown Amber(III)

Figure 5-4-13 Brown Amber (IV)

Figure 5-4-18 Blue-Green amber

Figure 5-4-19 White Beeswax

Figure 5-4-25 Worm amber (3)

Figure 5-4-26 Water bile worm amber

Figure 5-4-27 Flowering amber(1)

Figure 5-4-28 Flower pattern amber(II)

2.Origin classification

Amber can be categorized into marine and mining Amber according to its place of production. Marine Amber is best known for the Amber produced in the Baltic Sea countries. This Amber is highly transparent, crystalline, and of excellent quality. Amber is mainly mined in Myanmar and Fushun, China, where it is often produced in coal seams and accompanied by coal concentrates.

In commerce, Amber is often categorized according to its origin, with the most commercially significant being Amber from the Baltic region, Burma, Dominica, and Mexico.

(1) Baltic Amber

The Baltic Sea coast is one of the world’s most recognized Amber producers, producing Amber of the marine variety. It is one of the world’s leading Amber producers in quantity and quality. There are many countries along the Baltic Sea; the most famous Amber producers are Poland, Lithuania, and Russia. The historically famous “Amber Palace” was made in the early 18th century by the founding emperor of the Horsholen dynasty in Prussia, Wilhelm I, who hired a Danish jeweler to spend ten years processing more than 100 pieces of Amber and carving more than 150 Amber statues.

Amber from the Baltic Sea coast comes from strata dating from 40 to 65 million years ago. The Amber-bearing deposits are predominantly unformed peat layers. The Amber is distributed in layers and clusters, the largest of which are 2-3 m and the most common of which are 0.5-1.5 m, and the upper part of the ore-bearing layers is a loose silt. Local mining is generally open-pit or pit mining along the Amber-bearing strata. These Amber-rich strata extend into the sea. Amber can also be washed out of the seamounts near the sea, and many pieces of Amber are left over from workers’ processing floating on the seashore.

Marine Amber is predominantly yellow, commonly known commercially as “chicken fat yellow,” “lemon yellow,” and other color varieties; in the air or seawater exposure for too long, the surface of the Amber will be oxidized to dark orange and red; transparent Amber and opaque beeswax, large blocks, and transparent Amber are often seen within the body of a variety of plant and animal encapsulation.

Baltic Amber is shown in Figures 5-4-29 through 5-4-34.

Figure 5-4-29 Baltic Amber(chicken fat yellow)

Figure 5-4-30 Baltic Amber(Lemon Yellow)

Figure 5-4-31 Baltic Amber(gold-stranded honey)

Figure 5-4-32 Baltic Amber(beeswax) (I)

Figure 5-4-33 Baltic Amber(beeswax)(II)

Figure 5-4-34 Baltic Amber(beeswax) (III)

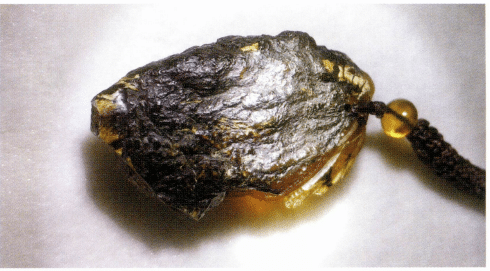

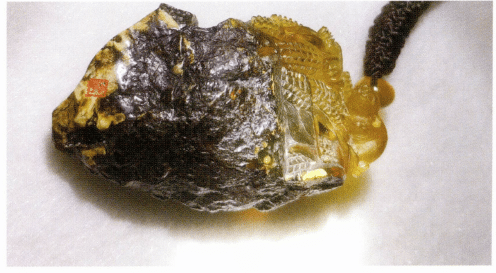

(2) Burmese Amber

Compared to other commercial sources, Burmese Amber is the earliest and oldest, producing high-quality Blood red Amber, worm Amber, golden brown Amber, and brown Amber. The age of Burmese Amber is estimated to be between 60 and 100 million years, depending on the types of organisms contained in the Amber.

The colors of Burmese Amber are mainly dark orange, red, and brown. The Amber often contains intact insect and plant bodies or debris, including the tails of feathered dinosaurs from 99 million years ago.

For Burmese Amber, see Figures 5-4-35 through 5-4-47.

Figure 5-4-35 Burmese Amber Raw and Crushed (I)

Figure 5-4-36 Burmese Amber Raw and Fragmented(II)

Figure 5-4-37 Burmese Amber Fragments

Figure 5-4-38 Burmese Amber Chips and Polished Pieces

Figure 5-4-39 Burmese Gold and Blue Sculptures

Figure 5-4-40 Burmese Gold and Blue Round Beads

Figure 5-4-41 Burmese Red-Brown (top), Root-Perch (middle), and Golden-Brown (bottom)

Figure 5-4-42 Burmese Red Brown Pendant

Figure 5-4-43 Burmese Brown Red Perch Pendant

Figure 5-4-44 Burmese Brown Amber Strings

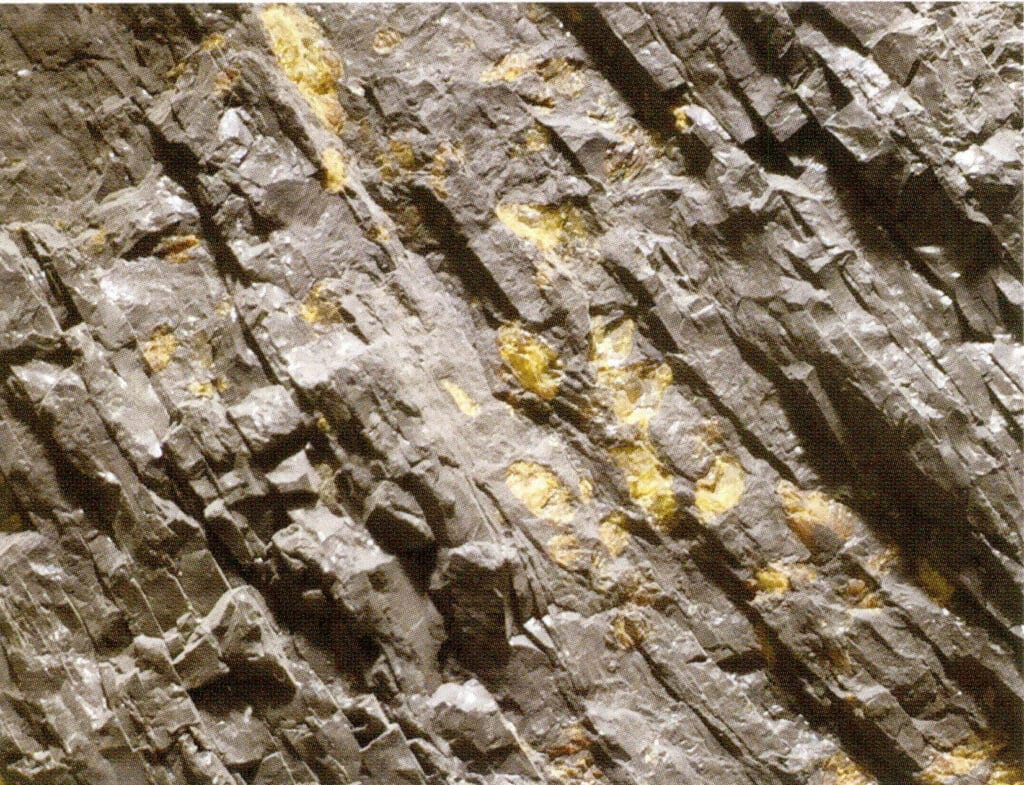

(3) Dominican Blue amber

The Dominican Republic is the most important source of blue Amber. Dominican Amber is about 15 to 30 million years old.

Dominican Amber is buried in volcanic ash, and due to crustal changes and the incorporation of other minerals into the Amber, some Dominican Amber may appear blue in ultraviolet light, against a dark background, or at the right angle of the light source. On a white background, it is often yellow or orange in color, transparent, and may contain strange and precious insects and plants.

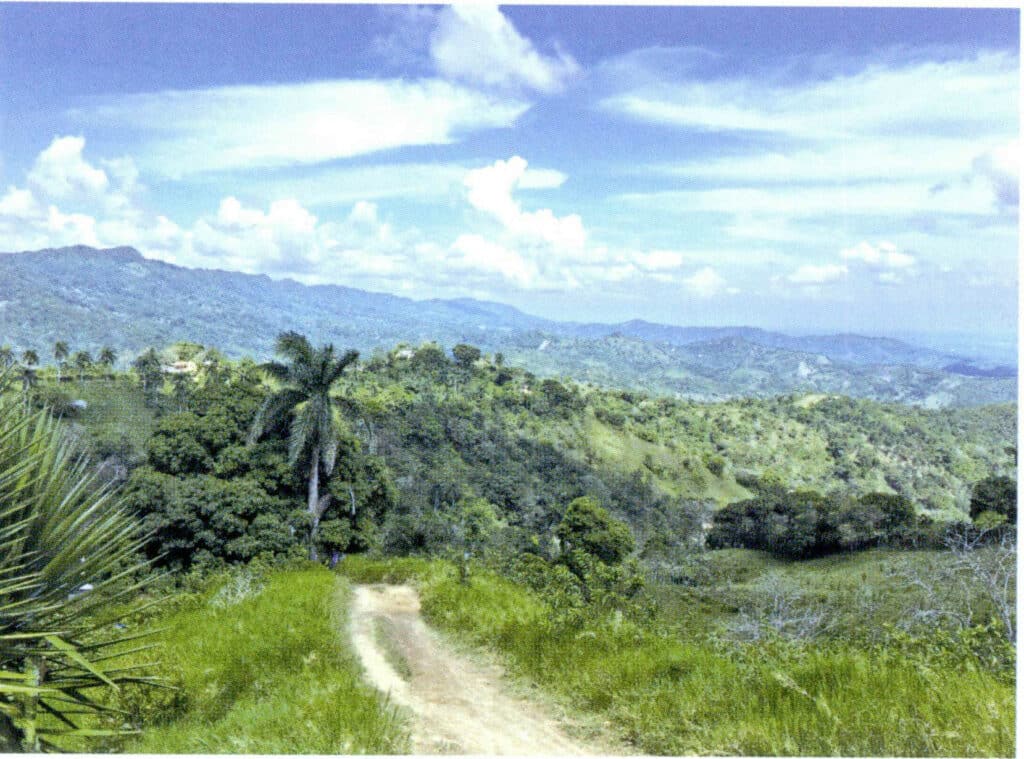

Mining, raw, and finished Dominican Amber are shown in Figures 5-4-48 through 5-4-59.

Figure 5-4-48 Mining Areas of Dominican Blue ambers ( I )

Figure 5-4-49 Mining areas of Dominican Blue amber (II)

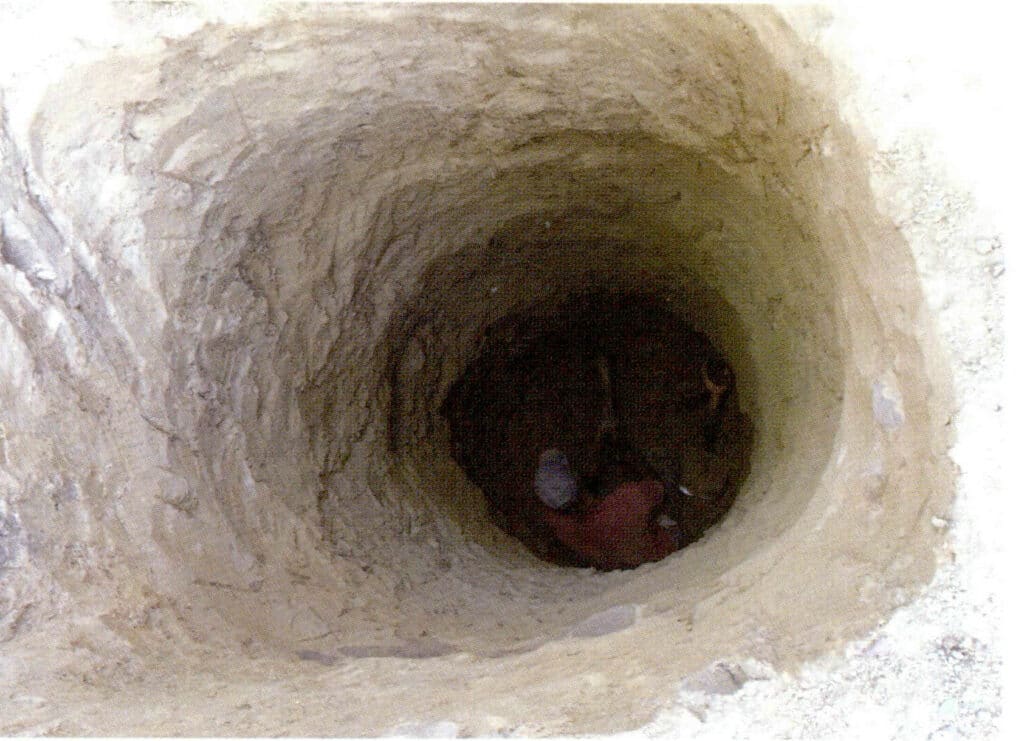

Figure 5-4-50 Pits of the Dominican Blue amber (I)

Figure 5-4-51 Pits of the Dominican Blue amber (II)

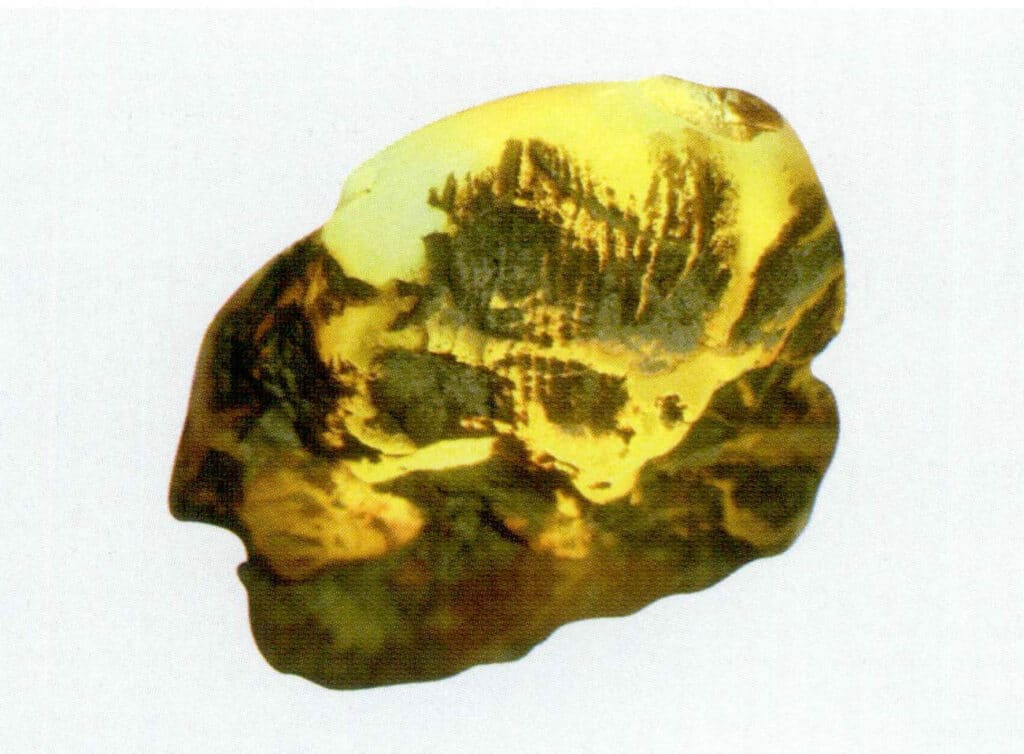

Figure 5-4-52 Feedstock mined on site (I)

Figure 5-4-53 Feedstock mined on site(II)

Figure 5-4-54 Dominican Raw Blue Amber (I)

Figure 5-4-55 Dominican Raw Blue Amber (II)

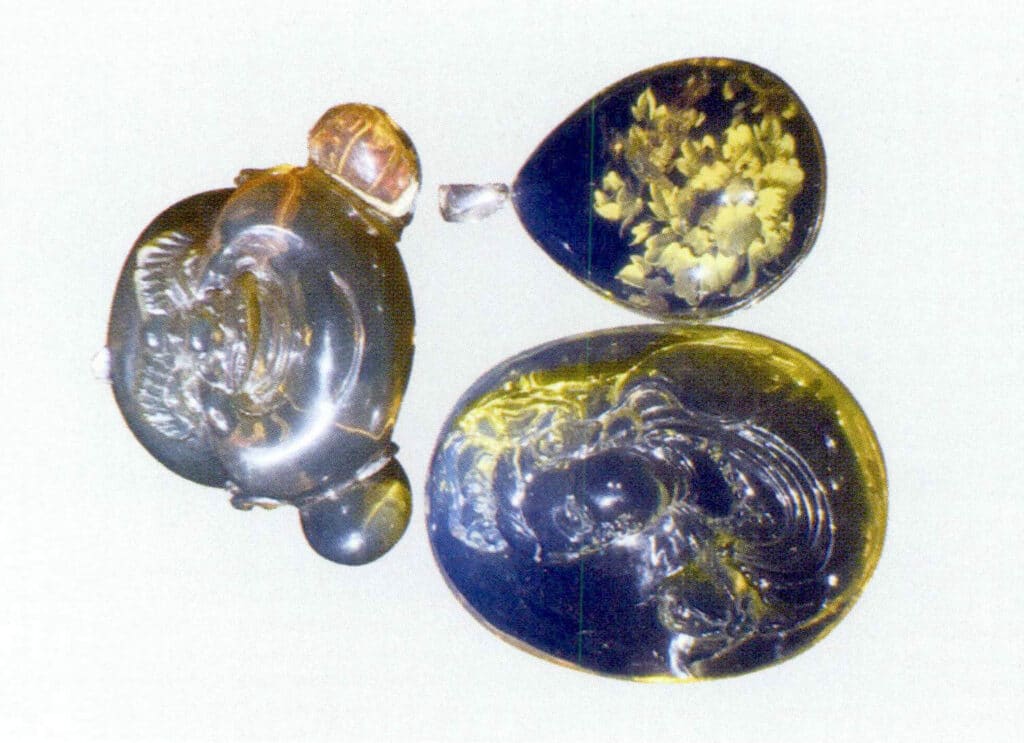

Figure 5-4-56 Dominican Blue Amber beads

Figure 5-4-57 Carved Dominican Blue amber spears

Figure 5-4-58 Dominican Blue amber Arc(I)

Figure 5-4-59 Dominican Blue amber Arc(II)

Copywrite @ Sobling.Jewelry - Producător de bijuterii personalizate, fabrică de bijuterii OEM și ODM

(4) Mexican Amber

Mexico is often considered the second-largest source of blue Amber. Mexican Amber is approximately 20 to 30 million years old. Mexican Amber tends to be yellow, light brown, or yellow or brown with a greenish tint on light backgrounds. Similar to Dominican Blue amerAmber, it can have a blue tint under ultraviolet light, against a dark background, or at the right angle to the light source; however, Mexican Amber has a more greenish tint than Dominican Blue amerAmber, with a distinctive bluish-green tint, as shown in Figures 5-4-60 and 5-4-61.

Figure 5-4-60 Mexican Blue amber (I)

Figure 5-4-61 Mexican Blue amber (II)

(5) Fushun Amber, China

China’s main Amber-producing areas are Liaoning, Henan, Yunnan, Fujian, and Tibet, with Liaoning Fushun Amber being the most famous.

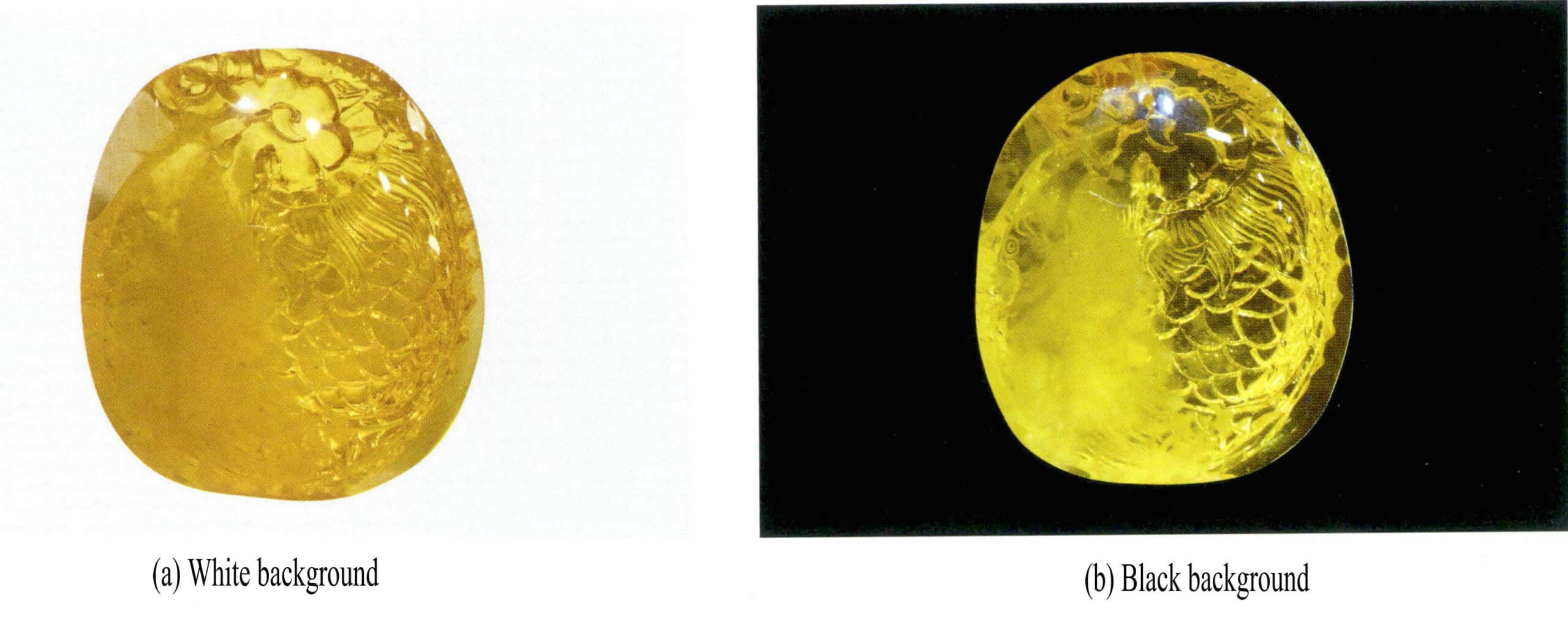

Fushun produces high-quality Amber, such as worm Amber, which is 35-60 million years old. The Amber is primarily orange or red, generally transparent, and is mainly produced in the Cenozoic Tertiary siltstone and coal-bearing strata, see Figures 5-4-62 and 5-4-63.

Figure 5-4-62 Amber in the Fushun Coal Seam

Figure 5-4-63 Fushun Amber carving (a) Reflected light

Figure 5-4-63 Fushun Amber carving (b) Reflected light

Figure 5-4-63 Fushun Amber carving (c) Transmitted light

Section V Optimized processing

The Identification of optimally treated Amber has always been a challenge in the jewelry trade and laboratory appraisals, and some of these appraisals are not completely conclusive.

1. Heat treatment

The main purpose of Amber heat treatment is to improve or change the color of Amber, to increase its transparency, or to produce inclusions with special effects.

The factors affecting the optimization of Amber are very complex and include the color, transparency, and bulkiness of the raw Amber material; the time of heating, the time of constant temperature, the time of cooling down, the initial pressure, the speed of pressure release, etc.; and the ambient atmosphere such as inert gases, oxygen, and its ratio.

The most typical inclusion in heat-treated Amber is a disc-shaped inclusion. If an inclusion, such as an insect, is wrapped in Amber, the color tends to deepen around the inclusion. The inclusions in heat-treated Amber are shown in Figure 5-5-1 and Figure 5-5-4.

Figure 5-5-1 Heat-treated Amber inclusion (10×)

Figure 5-5-2 Heat-treated Amber Cladding (30x) (I)

Figure 5-5-3 Heat-treated Amber inclusion (30×) (II)

Figure 5-5-4 Heat-treated Amber Cladding (30x) (III)

Depending on the purpose of the heat treatment, the processes are purification, baking color, popping, and baking “old aged beeswax.”

(1) Purification

Purification refers to removing air bubbles from Amber to improve its transparency by controlling the temperature and pressure of the press furnace under an inert atmosphere.

In a pressurized oven, the heat partially softens the Amber, the pressurization facilitates the expulsion of air bubbles inside the Amber, and the inert gas prevents the Amber from oxidizing and discoloring.

Process conditions for disclosure: initial air pressure of 4.5 MPa, starting room temperature of 27℃, increasing heating temperature to 200℃, heating time of 3 hours, constant temperature of about 2 hours, natural cooling of 14 hours, and removing at 35℃. For Amber materials with poor transparency and large thicknesses, it is often necessary to purify them several times or increase the pressure, temperature, and time to achieve full transparency.

The main types of purified products are gold amber and gold amber mixed with beeswax. Some Gold amber is obtained by purifying beeswax from the Baltic Sea; especially the “gold amber wrapped beeswax” variety, is also obtained by “purifying” it by heat treatment. Since the purification of Amber proceeds gradually from the outside in, the transparency of the near-surface layer is improved first so that the interior of the wax, which has not been thoroughly purified, retains the opaque “clouds” that eventually form varieties such as ” gold amber wrapped beeswax.” See Figures 5-5-5 and 5-5-6 for purified Amber.

Figure 5-5-5 Purifying Amber

Figure 5-5-6 Purifying Amber (30x )

(2) Baked color

Baking refers to the oxidation of the organic components on the surface of Amber under certain temperature and pressure conditions to produce a reddish series of oxidized thin layers, which improves the color of Amber to obtain Blood red Amber.

The color baking process is also carried out in a sealed pressure furnace; the Process is the same as the purification; the only difference is that the gas composition of the pressure furnace has been changed to facilitate the oxidation reaction; it is necessary to add a small amount of oxygen in the inert. As a rule, the longer the heating time and the higher the oxygen content, the darker the color of the Blood red Amber.

Process conditions for disclosure: Pressure 4.5 MPa, heating temperature 210℃, heating time 3 hours, inert gas and oxygen. After heat treatment, it can be transformed into dark red and black red. The longer the heating time, the darker the color of the Blood red Amber. If the first baking color does not achieve the desired effect, it can be further baking color, just under the condition that the temperature remains unchanged; the gas pressure needs to be increased by 0.5-l MPa is more than the previous time; otherwise, Amber is prone to bursting.

Blood red Amber is an important variety of Amber. Among all kinds of natural Amber, Burmese Amber is the most famous. Still, its color is gray, and impurities and quantity are rare, so most of the Amber on the market is made of Gold amber after artificial baking, especially the Baltic Amber, which is made of an artificial baking color.

Amber can be baked to obtain Blood red Amber directly. Blood red Amber can be reprocessed to obtain Amber in the form of carved Blood red Amber and Amber in two colors. Amber with a curved surface is heated to a black-red color, the curved surface is removed, the bottom surface is preserved, and various images of Buddha and flowers are carved on the bottom surface, which can be processed into shaded Amber, where the dark background can better highlight the theme of the carving. Two-color Amber is polished to remove part of the oxidized layer of the Blood red Amber, revealing the yellow color inside so that two colors are presented in the same piece of Amber, increasing the beauty of Amber. For baked-color Amber, see Figures 5-5-7 through 5-5-12.

When heat-treated into Blood red Amber, its deep red color can hide the original internal impurities of the Amber and even the “blood filament” structure of the pressed Amber.

Figure 5-5-7 Baked Amber (I)

Figure 5-5-8 Baked-color Amber(II)

Figure 5-5-9 Baked color outtakes (I)

Figure 5-5-10 The outer skin of baked-color Amber(II)

Figure 5-5-11 Baked-color Amber crust (III)

Figure 5-5-12 Baked-color Amber crust (IV)

(3) Popping flowers

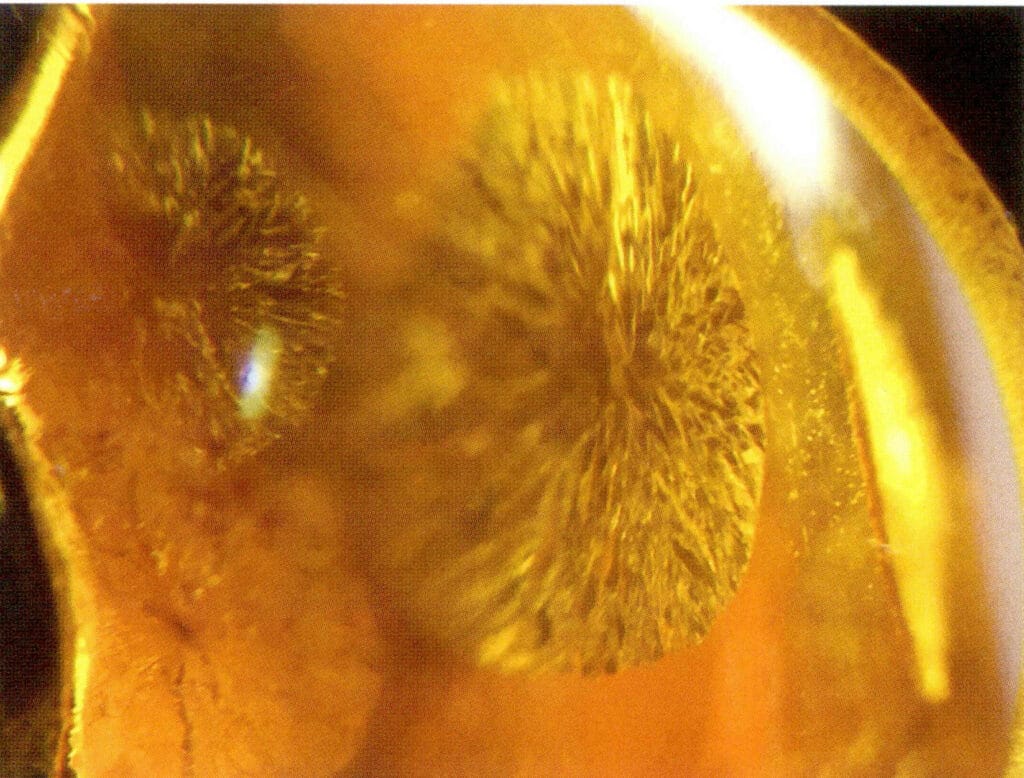

Popping flowers refers to the heating conditions resulting in the expansion of bubbles and cracking and disc-shaped fissures, that is, “sunlight” inclusions. The purpose of popping is to produce inclusions and sometimes deepen its inherent body color to obtain a different color of the flower of the Pope.

Popping flowers can produce gold flower pattern and Red flower pattern, but it is difficult to succeed once and often needs multiple processes.

Popping flowers of Amber raw materials required to contain a certain amount of gas-liquid inclusions. Traditional popping processes include submerging in hot oil (such as linseed oil), sand frying, etc. The advantage is that the popping effect can be visually controlled, but the operation is simple and time-consuming, and the number of processes is limited. Modern Process generally use the pressure furnace, heat treatment is completed, the release of the pressure furnace gas, so that the rapid depressurization, breaking the balance of the internal and external pressure of the bubble in the Amber (internal pressure is greater than the external pressure), the formation of disk-shaped cracks.

Depending on the color of the “sun rays,” it can be divided into gold flower pattern and Red flower pattern.

“Sunshine” inclusions with the same color of the body of gold, belonging to the product of heat treatment in an anoxic environment; “Sunshine” inclusions for the red gold, is the temperature and pressure treatment process under the conditions of oxygen participation, so that the open fissures oxidized and turned red, and thrown off the surface of the red skin and become golden amber; to retain a part of the red oxidized skin of the flower is two-tone Red flower pattern amber.

The process flow and the first half of the purification process are the same; the difference is that after the heating is completed in the furnace stage purification process in the stage, there is a pressure furnace-free cooling process, while the Process of popping flower is immediately turned off the power, the direct release of gas in the furnace.

The Process disclosed: Initial pressure 2.0 MPa, maximum temperature 200℃, heating time 2 hours, constant temperature for one hour, followed by rapid depressurization. The pressure and temperature can be increased or repeated if the effect is not achieved. See Fig. 5-5-13 to Fig. 5-5-16.

Figure5-5-13 "Sunshine" in Gold Flower Amber (10x)

Figure5-5-14 "Sunshine" in Gold Flower Amber (20x) (I)

Figure5-5-15 "Sunshine" in Gold Flower Amber (20x) (II)

Figure5-5-16 "Sunshine" in Gold Flower Amber (20x) (III)

Red flower pattern amber process is similar to the gold flower pattern amber, only its internal disc-shaped fissures need to be extended to the surface, are at a certain temperature and pressure, and oxidation conditions under the fissures are oxidized red. Popping flower often has two ways: the first is in the Process of baking color in the blood red when the furnace stops heating directly deflated, instantaneous pressure release and temperature and pressure conditions of the combined effect will lead to popping out of the blood red amber of flower pattern; the second is to pop out of the flower and then back to the furnace baking color, baking color process, as in the Process of the blood red amber of the production process. See Figure 5-5-17 to Figure 5-5-20 for Red flower pattern amber.

Figure 5-5-17 " Sunshine" in Red flower pattern amber(I)

Figure 5-5-18 " Sunshine " in Red flower pattern amber(II)

Figure 5-5-19 " Sunshine " in Gold flower pattern amber (10×) (I)

Figure 5-5-20 " Sunshine " in Gold flower pattern amber (10×)(II)

(4) Roasted “old aged beeswax”

Baking “old aged beeswax” is the Process of changing the appearance of Amber using heat treatment to imitate the old.

The production process of “old aged beeswax” is relatively simple but time-consuming and energy-consuming, and it is slowly oxidized over a long period of time under atmospheric pressure and low-temperature heating conditions.

First, the Amber semi-finished products are placed in an iron plate covered with fine sand and put into the oven; the heating system is located outside of the independent device, but it can also be connected to the oven of the numerical control device. The “old aged beeswax” process must have a relatively constant temperature; the temperature is 50 -60℃, and the time is 60 to 100h. “Old aged beeswax” See Figure 5-5-21 and Figure 5-5-22.

Figure 5-5-21 old aged beeswax

Figure 5-5-22 old aged beeswax

(5) Color change

Amber can be changed to a green color by heat treatment through two or more times of heating and pressurizing, constant temperature and pressure, and cooling.

2. Dyeing Color

The most common treatment for Amber is a dye treatment. To mimic dark red Amber treated with dye, it may also have a green or other color-stained finish, with dye visible along the notches.

3. Irradiation

A significant portion of the “scarlet beeswax” on the market claiming to be from Ukraine may have been irradiated.

Method of disclosure: A 10 MeV electron linear gas pedal with a power of 20 kW was used at ambient temperature and pressure. The samples were irradiated on a conveyor belt under the titanium window of the gas pedal. Dendritic stress cracks were produced in both Amber and cobalt resins.

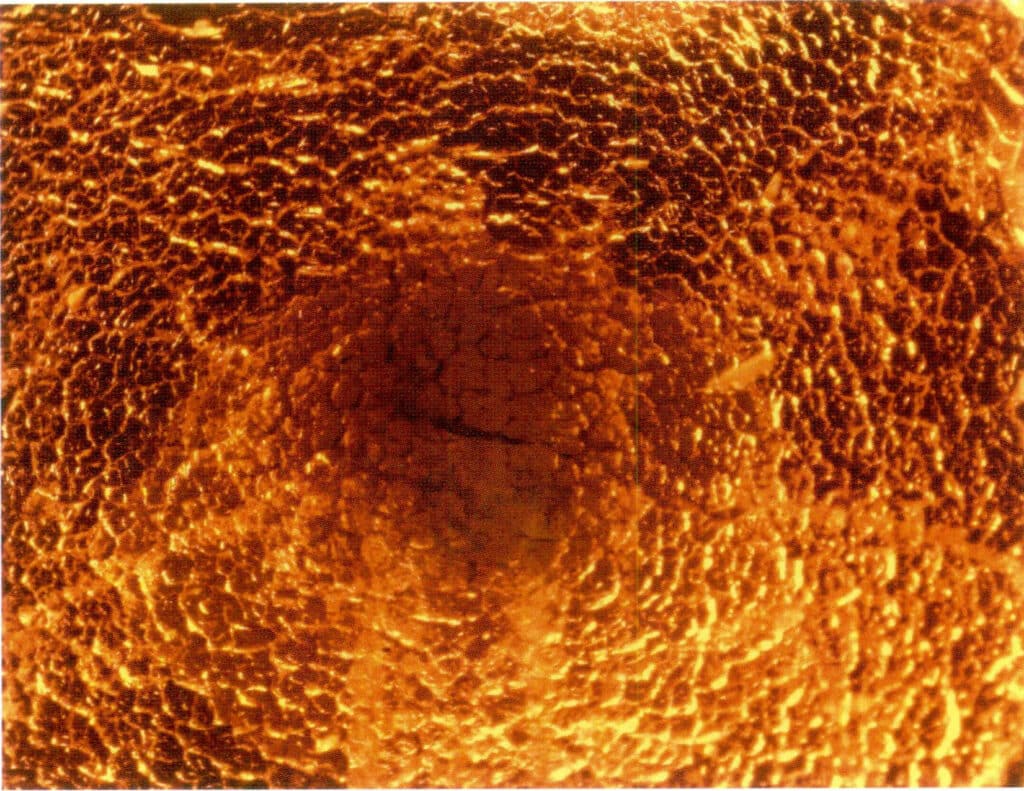

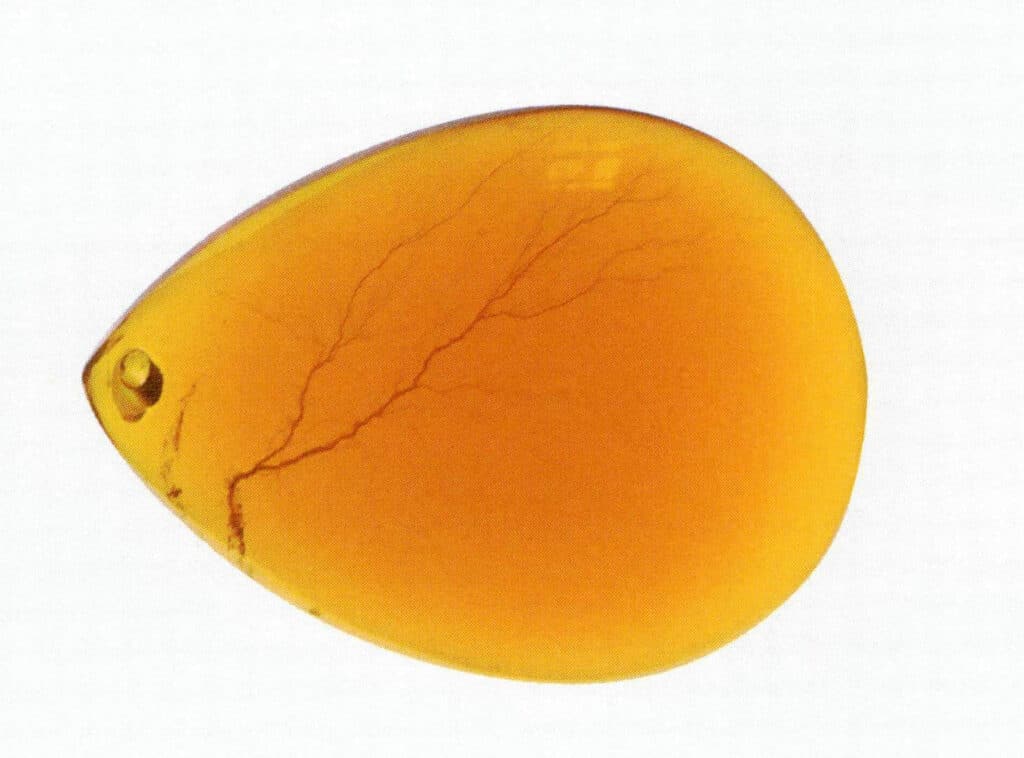

The most important feature of this type of irradiated Amber is the formation of root-whisker stress cracks, also known as Lichtenberg patterns, in insulators such as Amber when electron beam discharges penetrate them. Irradiated Amber is shown in Figure 5-5-23 and Figure 5-5-24, and the characteristics of the Amber envelope before and after Irradiation are shown in Table 5-5-1.

Figure 5-5-23 Irradiated amber 1

Figure 5-5-24 Irradiated amber 2

Table 5-5-1 Characteristics of Amber Inclusions before and after Irradiation

| Inclusion bodies of amber before irradiation | Characterization of irradiated amber root-whisker-like inclusions |

|---|---|

| Inclusions with depressions, fissures, etc. | In depressions and clefts, easily forming root-whisker-like inclusions; from the original location of clefts you fractal, coarse to fine root whiskers or dendrites |

| High number of depressions and fissures | Produces more numerous and finer root-whisker-like envelopes |

| Low number of depressions and fissures | Thick and thin branches producing root-whisker-like inclusions are evident |

4. Coating

(1) Processes for Coating Amber

Two main types of Coating films are available on the market: Coating with colorless films and Coating with colored films.

The colorless coating is used more often and can be designated as “optimized” in laboratory appraisals without the need for a declaration, so merchants mostly use this method to increase the luster of Amber, omitting the polishing process while still maintaining credibility in the Process of selling it. At present, colorless film plating is mainly used on complex carvings. To avoid the inefficiency of manual polishing, machines are directly used instead of manual labor, and the Amber will have a strong resin luster after the coating, which greatly increases its beauty.

The other is the Coating with colored film, which changes the appearance of the Amber considerably and is defined as a “treatment” in laboratory identification.

The coating process currently used in factories is mainly based on the use of a spray gun, where the Amber to be coated is first dried, then a so-called “oil” is sprayed evenly onto the surface of the Amber using a spray gun, and left to solidify, i.e., the coating process is completed. The Process occurs in the air, so the sprayed “oil” contains substances that react with the air and solidify.

There are different ways of drying during this Process: some factories dry Amber by placing it in an oven and micro-heating it, some dry it directly in the shade or by using incandescent light, and some dry it directly by placing it in the sun.

Another coating process is the direct immersion method. In this method, the Amber is directly immersed in a solution of oil, which is then taken out and left to cure to complete the coating process. However, the Amber produced by this method may have a lot of air bubbles in the depressions, and the oil does not cover the Amber uniformly during the immersion process, resulting in an uneven thickness of the Amber. This method is easier to recognize.

(2) Identification of coated Amber

There are some differences in the infrared spectra of the overlay Amber and the internal Amber, and it is possible to distinguish the two, but identifying the Amber as overlay Amber requires conventional gemological Characterization. The Identification of overlay Amber is shown in Table 5-5-2 and Figures 5-5-25 to 5-5-28.

Table 5-5-2 Identifying Characteristics of Covered Amber

| Content of the appraisal | Characterization |

|---|---|

| Glossy | Strong resinous luster, stronger than normal amber. |

| Pit | There are a lot of air bubbles |

| Observație microscopică | The colorless film amber is light in color; the tinted film is dark in color and the transition is not natural. |

| Needle picking or acetone soaking | The film will come off in flakes |

| Spectrul infraroșu | Infrared absorption bands that are not present in natural amber: absorption peaks at 1518 cm-1 due to aromatic C-C stretching vibrations, and combined peaks at 760 cm-1 and 702 cm-1 ; 2930 cm-1 and 2862 cm-1 infrared absorption bands are weaker than in amber; C = O stretching vibrations The 1726 cm-1 absorption peaks due to telescopic vibrations are unusually sharp and have a narrow half-wave width. |

Figure 5-5-25 Coating the Outside of Amber

Figure 5-5-26 Coating Amber Profile

Figure 5-5-27 Infrared spectra of Baltic ferry dark film Amber (top: Baltic Amber; bottom: coated)

Figure 5-5-28 Infrared spectra of Marine Amber with light-colored coating (top: Baltic Amber; bottom: coating)

5. Pressing

Since some pieces of Amber are too small to be used directly for jewelry making, these Amber chips are sintered under appropriate temperature and pressure to form larger pieces of Amber, known as pressed Amber, also known as reclaimed Amber, fused Amber, or molded Amber.

(1) Traditional methods

Pressed Amber originated in Austria at the end of the 19th century as a technique of synthesizing large pieces of Amber by melting fragments of Amber at high temperatures. Subsequently, Germany, Russia, and other countries began to produce pressed Amber in large quantities. During the Process, it can be colored with pigments or linseed oil.

- Process The traditional development method is pressing by hot pressing in a press. The basic production method for pressed Amber is as follows.

- Prepare a metal container containing a special filtration system to facilitate filtering of impurities during the heating process;

- When the heating temperature reaches 170-190℃, the Amber pieces gradually soften, and the impurity precipitates are filtered out of the filter system;

- When the temperature is raised to 200 -250℃, the air bubbles in the Amber are pressed out;

- Finally, by applying pressure to the Amber, the pieces are pressed together to form a larger piece of Amber, which can also be processed into various shapes, such as rounds, squares, carvings, etc., with the help of various molds.

Pressed Amber is unbreakable and malleable, so it is also often used to make various kinds of carvings and rosaries or pressed into insects to make worm amber

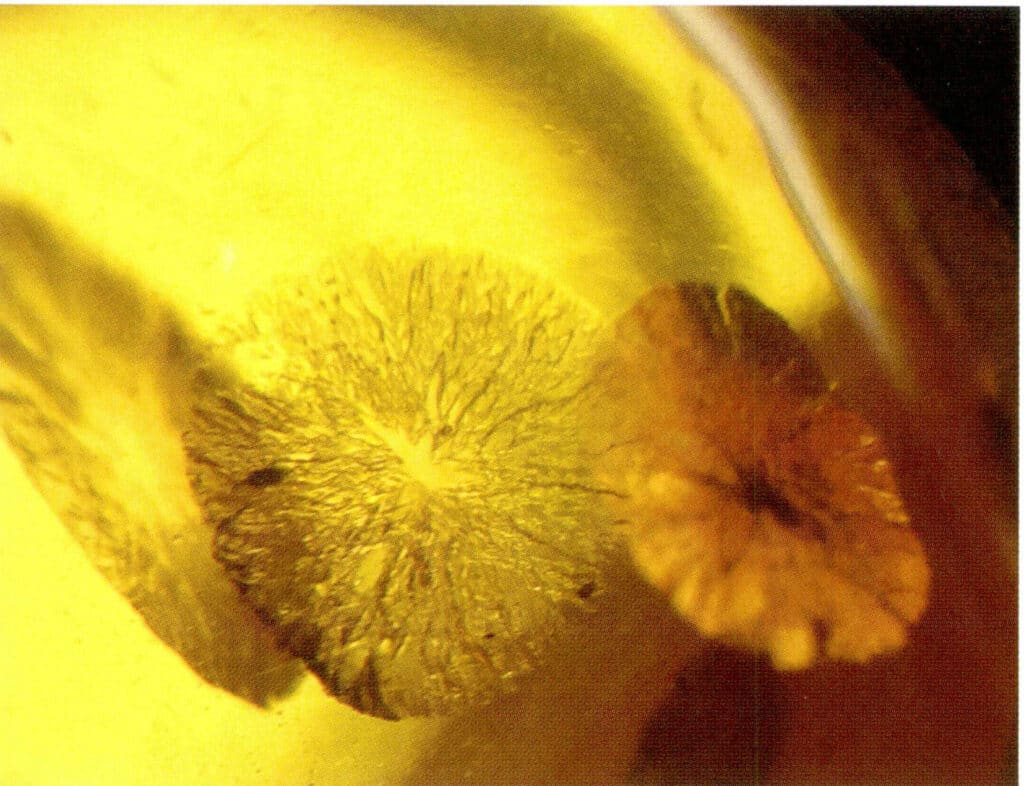

- Characteristics This amber is characterized by a syrupy churning structure, which can be seen under magnification as “blood filaments”, see Table 5-5-3. In addition, the color distribution of pressed amber under UV fluorescence is roughly the same as that of its own color distribution, which is intermittent and twisted, with an obvious granular structure.

Table 5-5-3 Microscopic Characteristics of Pressed Amber

| Observations | Impunity |

|---|---|

| "Blood filaments." | The "blood filaments" surrounding the particles are indicative; the shape is like capillaries, filamentous, cloudy, flocculent, etc., which can be observed more clearly under UV fluorescence; the uneven boundaries between neighboring fragments can be seen on the polished surface due to the difference in hardness. |

| Mobile structure | Ancillary features; debris churned state and swirled state irregular ripples |

| Elongated and interfacial distributed bubbles | Abundant bubbles: new bubbles are formed between the particles as well as during casual movements and are thus more abundant than in natural amber. Due to the high pressure, the bubbles become elongated; dense, fine bubbles are irregularly distributed throughout the amber, and some of the particles have small bubbles inside them, distributed along the contact surfaces. When heat-treated again, they appear as tiny, directionally arranged, layer upon layer of densely arranged disc-shaped "sun rays" |

(2) New approaches

The demand for Amber is constantly increasing, and consequently, the Process of pressing Amber is constantly being improved. The main varieties of Amber pressed by new methods include pressed gold, pressed Blood red Amber, pressed blue Amber, and other composite treatments. These pressed Amber beads are often ground into rounds to make jewelry such as bracelets and Buddha beads or intermixed with finished natural Amber products for sale.

Today’s methods include pressing in an anaerobic environment, low-temperature and high-pressure treatments, and secondary composite treatments. The newly pressed Amber has improved the “blood filament” structure surrounding the particles in the traditional pressed Amber, resulting in a perfect fusion of the particles, see Figures 5-5¬29 to 5-5-38.

Figure 5-5-29 Pressed Amber (I)

Figure 5-5-30 Pressed Amber(II)

Figure 5-5-31 Flow pattern of pressed Amber (10×)(I)

Figure 5-5-32 Streamer pattern of pressed Amber (10×)(II)

Figure 5-5-33 Microstructure of pressed Amber (30x)(I)

Figure 5-5-34 Microstructure of pressed Amber (30 x )(II)

Figure 5-5-35 Microstructure of pressed Amber (30 x ) (III)

Figure 5-5-36 Microstructure of pressed Amber (30 x ) (IV)

Figure 5-5-37 Microstructure of pressed Amber (30 x ) (v)

Figure 5-5-38 Microstructure of pressed Amber (30 x ) (VI)

Pressed gold amber

- Process Firstly, the pressed material is “peeled,” i.e., the oxidized and dirty skin on the surface of the raw material is stripped off; then it is sorted in detail according to the size of the grains, the color and the transparency of the material; finally, the sorted crushed material is fed into the press equipped with a vacuum pump and a heating system to heat and soften the Amber, and at the same time, directional pressure can be applied to obtain a larger volume of pressed Gold amber.

- Identification An important characteristic of pressed Gold amber is a perfect fusion between particles and a more hidden granularity, which is distinctly different from traditional pressed Gold amber characteristics. Most of the fragments of pressed Gold amber are smaller than 0.5 cm, mostly angular to sub-angular in shape, with a three-dimensional granular “mosaic” structure, and the polished surface can sometimes be seen on the adjacent grains due to the difference in hardness of the unevenness of the performance.

The infrared spectra of pressed gold amber are essentially identical to those of natural Baltic amber, except that the ratio of the intensities of the infrared absorption bands at I = 2933cm-1 / I = 1735cm-1 is close to 4:3 whereas the normal ratio for natural Baltic amber is mostly (2.5-3):1.

Pressed Blood red Amber.

- Technique: First, the Amber powder is ground to a fine powder, which is put into a cylindrical mold of a certain shape. The mold is heated so that the powder reaches a softening temperature, and at the same time, directional pressure is applied. After condensation, a relatively transparent and homogeneous pressed Blood red Amber can be formed. The uneven oxidation of the Amber powder may cause the red spots in the pressed Blood red Amber.

- Identification. The appearance of Blood red Amber. is a uniform red color, both inside and out, unlike “baked” treated hematopoiesis, where the color is limited to the surface and which is often processed into large carvings or cut and ground into round beads.

The refractive index of pressed Blood red Amber is 1.55-1.56, higher than that of natural Amber 1.54; under long-wave ultraviolet light, it emits a weak earthy-yellow fluorescence or no fluorescence; under reflected light, the pressed Blood red Amber has a clear crushed grain to crushed powder structure, and in the transmitted light, it shows a uniformly distributed red spot-like structure.

The ratio of the intensities of the infrared absorption bands at I = 2933 cm-1 / I = 1735 cm-1 in the infrared spectrum of the pressed blood perforation is less than 1, and the C-O stretching vibration bands at 1262 cm-1,1165cm-1have become stronger, reflecting an increase in the concentration of the C-O functional group, which suggests that the pressing process was carried out in an open system in an ambient atmosphere with the participation of oxygen.

Pressed blue amber

- Process Raw material with large pieces and large fissures is placed in a hot press Amber press to soften the fissure surfaces and fuse the fissures, thus improving the usability of the blue, Amber material.

- Appraisal. blue perch is always on the surface of the vaguely maroon tint, and the color is dull, boring, less than the color of natural blue perch dynamic.

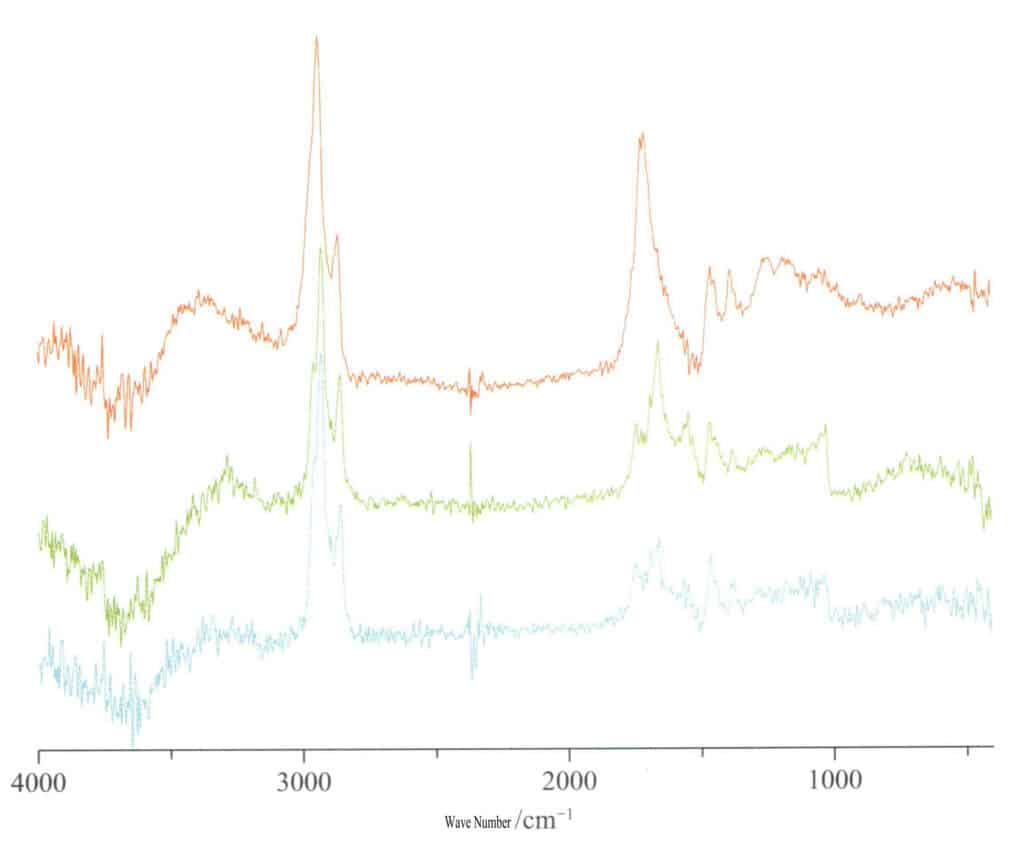

In the infrared spectrum of natural blue amber, the intensity ratio of the infrared absorption bands at I = 2933 cm-1 /I = 1735 cm-1 is mostly (3-5): 1, and the carbonyl peaks at 1723 cm -1, 1698 cm-1 are split; in the infrared spectrum of pressed blue amber, the intensity ratio of the absorption bands at I = 2933 cm -1 /I = 1735 cm-1 decreases to 4 : 3, or the carbonyl peaks at 1: 1,1723 cm-1, 1698 cm -1merge, and the shape of the peaks is steepened. The peak shapes of the carbonyl peaks at 1242 cm -1, 1175 cm-1, 1146 cm-1,, 1107 cm-1, which correspond to the C-O stretching vibration bands, are steepened and broadened.

Pressed cemented blue amber

- Process: The raw material of small pieces of blue Amber without molding, partially with or without skin, mixed with a certain proportion of Copal resin powder or natural resin powder of the same origin with a low degree of maturity, under the conditions of heat treatment Amber Process, firstly, make the melting point lower than the blue Amber of the powder of Copal resin melted into a liquid state to cement the fragmentation of the role.

Blue amber trimmings can also be fused and pressed into larger volume blocks.

2. Identification There may be white opaque streaks or other forms of incompletely melted powdered cobalt resin remaining among the pieces of the blueprint.

To prevent the melting of Copal three fingers into the press furnace, commonly used tinfoil to wrap the treatment of Amber so the surface of the processed carvings or near the surface can be attached to the silver-white tinfoil fragments with a metallic luster or residues such as crumbs.

If the compaction cementation treatment is still not perfect, often also need to use other inorganic or organic materials mixed with quartz sand for repair to imitate the natural blueprint of the surface of the bonded dark gray carbonaceous marl, Limestone surrounding rock “crust,” the main identification characteristics of the “crust” is strictly controlled by the form of the hollows and show the flow of the structure.

Infrared spectroscopy of the white residue on the surface, except for the carbonyl stretching vibration to 1695 cm-1, increases the intensity of the infrared absorption band for the Copal resin. The infrared spectral characteristics of the white residue exposed on the surface are the same as those of the Copal resin. The differences only lie in the following: the intensity of the infrared absorption band at 1695 cm-1 is stronger due to the carbonyl stretching vibration and the intensity of the infrared absorption peaks at 3081 cm-1, 1646 cm-1, 888 cm-1 is weakened due to the heat treatment. The double bond is weakened by heat treatment.

Pressed beeswax:

The color of pressed beeswax is similar to that of natural beeswax and baked old aged beeswax.

The refractive index and relative density of pressed beeswax are essentially the same as those of natural beeswax. At long ultraviolet wavelengths, pressed beeswax emits a medium to weak earthy yellow color, which is far different from natural beeswax’s strong yellow-white fluorescence.

The infrared spectra of pressed beeswax around 1260 cm-1 and 1158 cm-1 mostly show the “Baltic Shoulder,” a peak shape characteristic of Baltic Amber, caused by C-O stretching vibrations; sometimes, the weak absorption peaks at 888 cm-1, which disappears when heated to 200℃, are still present, caused by bending vibrations outside the CH plane on the extra cyclic methylene double bond. Sometimes, the weak absorption peaks at 888 cm-1 that disappear when heated to 200℃ due to the CH out-of-plane bending vibrations on the exocyclic methylene double bond are still present.

Only a few dark-colored pressed beeswax samples have infrared absorption band ratios at I = 2933 cm-1 /I = 1735 cm-1, which is close to 4 : 3, indicating heating. The infrared spectra of some completely opaque powdered pressed beeswaxes are similar to those of Baltic Amber, showing broad, steep absorption at 1154 cm-1 and 874 cm-1.

Natural beeswax has a relatively regular, well-defined, agate-like flow pattern of numerous tiny bubble groups. The flow pattern of pressed beeswax is significantly different; see Table 5-5-4.

Table 5-5-4 Microscopic Characteristics of Pressed Beeswaxes

| Observations | Phenomenon |

|---|---|

| Veinlet in the pattern of veins on a leaf | Diagnostic basis for pressed beeswax; the flow pattern is like the stem veins of a leaf spreading symmetrically outward from the root, and the flow pattern is clearly shown by the difference in transparency |

| Loofah-associated rhythms | Similar to the Luffa pouch, the grain is irregularly tugged and pulled, which is caused by the interweaving of the pressed and unpressed parts of the powder. |

| Irregularly striped flow pattern | Striped or irregular, streamer border is rough, poor smoothness |

| Granular structure | Fragmentation of a fragmented base, a fragmented base and a fragmented powder structure, with translucent particles sporadically distributed in an opaque fragmented base |

In addition, pressed beeswax is sometimes carved into flower carvings or processed into frosted beads, and its pressed structure can be disguised or covered. Identification should be used fiber-optic lamps to illuminate the strong light, and detailed observation of the structure of the samples and the flow pattern to make an accurate determination of the

Pressed “Green amber”

Pressed “Green amber” (as it is known in the marketplace) is hot-pressed Colombian Copal resin, which is not made from Amber powder.

Section VI Identification

1. Imitations

Amber is a kind of natural resin fossil formed by various geological processes of pine and coniferae plant resins from Mesozoic Cretaceous period to Cenozoic Tertiary period. Currently, the two main types of Amber imitations commonly found on the market are natural and synthetic resins, also known as cobalt resins and plastics.

(1) Plastics (synthetic resins)

Plastics are macromolecular compounds polymerized through polymerization or polycondensation using monomers as raw materials. The main component of plastics is resin; fillers, plasticizers, stabilizers, lubricants, colors, and other additives exist. Resin is a polymer compound that has not yet been mixed with various additives and is named for the lipids originally secreted by plants and animals, such as rosin. Resin accounts for about 40%-100% of the total weight of the plastic and determines the main properties of the plastic; of course, additives also play an important role.

Plastic imitation Amber is often added to insects to achieve realism; often put into dead insects, insects are curled up after death, rather than Amber is captured by the resin when they struggle; in addition, the plastic is often added to the metal catalyst, and thus visible metal flakes of the flash.

Malisan is a polyimide gelatin material that is mainly used in industry. A significant portion of the plastic that imitates Amber on the market is American. Other plastics are also available. Plastics that imitate Amber are shown in Table 5-6-1 and Figures 5-6-1 through 5-6-10.

Table 5-6-1 Identification of Amber with Plastic

| Characterization | Chihlimbar | Plastics |

|---|---|---|

| Surface characteristics | Smoother | Mold mark |

| Internal Insects | Struggle | Curling, small metal pieces |

| In saturated brine | Suprafață | Submerge |

| Odor (Hot Needle Test ) | Float up | Curly, small metal pieces |

| A knife cuts in an inconspicuous place. | Special odors | Sink down |

Figure 5-6-1 Malisan Imitation Amber Raw Stone(I)

Figure 5-6-2 Malisan Imitation Amber Raw Stone(II)

Figure 5-6-3 Malisan Imitation Amber Raw Stone (III)

Figure 5-6-4 Malisan Imitation Amber Raw Stone (IV)

Figure 5-6-5 Plastic Products Imitating Worm amber (I)

Figure 5-6-6 Plastic Products Imitating Worm amber (II)

Figure 5-6-7 Plastic Products Imitating Worm amber (III)

Figure 5-6-8 Plastic Products Imitating Worm amber (IV)

Figure 5-6-9 Plastic Imitation Beeswax (I)

Figure 5-6-10 Plastic Imitation Beeswax (II)

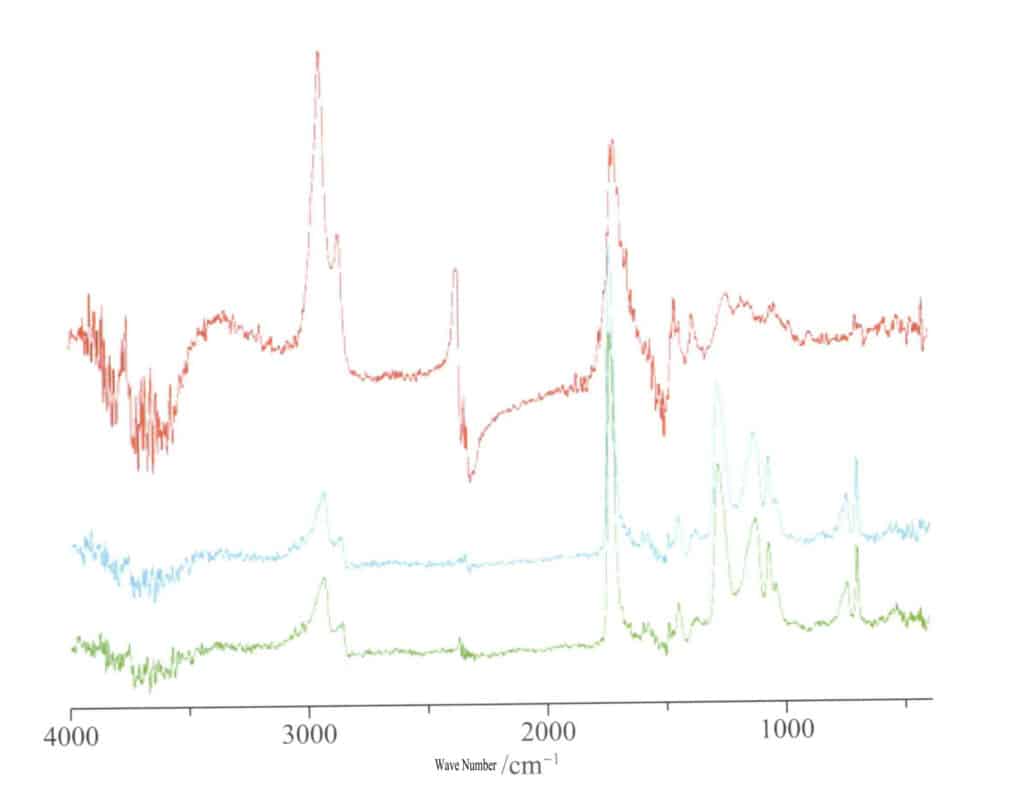

The infrared spectra of Amber and plastic are shown in Figure 5-6-11.

The infrared spectra of plastic and natural Amber are quite different, both in terms of vibrational position and intensity: in the 2800-3000 cm-1 range, the intensity of the infrared vibrational bands of Amber is significantly stronger than that of synthetic resins; in the 400-1500 cm-1 range, synthetic resins show infrared vibrational bands at 753 cm -1, 704 cm-1 that are not present in natural Amber.

Infrared spectroscopic testing can easily and quickly distinguish Amber from common plastics (synthetic resins) on the market,, such as amino resins, alkyd resins, polymethylmethacrylate, and epoxy resins.

(2) Copal resin (natural resin)

Two types of natural resins are similar in appearance to Amber: rosin and copal resin.

Rosin is a kind of resin without geological action; its chemical composition is mainly resin acid, a small amount of fatty acids and turpentine acid, etc., belongs to the unsaturated fatty acids, and when burned, it has an aromatic flavor. Because the fragrance of rosin is not completely volatile, its surface is easy to crack, often with cracks, so it is easier to distinguish from Amber.

Copal resin is the most important imitation of Amber. Both Amber and copal are products of natural resins that have evolved under different geological conditions and at different times. Copal resin is a hard resin that has not been petrified for less than 2 million years and contains mainly volatile terpene components and resinoids, most of which are less than 1 million years old. Amber is petrified by various geological processes and is transformed into organic compounds by the evaporation of the volatile terpene components of copal resin, mainly containing succinic acid, succinic rosin acid, succinic acetic acid, etc..

Their chemical compositions are transitional and similar. The difference between Amber and Copal resin is shown in Table 5-6-2, 5-6-3, and Figures 5-6-12 to 5-6-18.

Table 5-6-2 Identification of Amber and Copal Resin

| Characterization | Chihlimbar | Copal Resin |

|---|---|---|

| Cut a shape | Various facets | Raw or polished shapes and simple facets predominate; no facets such as beads or intricate carvings are present. |

| Surface characteristics | Smoother | Crackles |

| Internal Insects | Struggle | Struggle |

| In saturated brine | Float up | Float up |

| Odor (hot-needle test) | Special odors | Rosin scent |

| A knife cuts in an inconspicuous place. | Chipped or ruptured | Chipped or ruptured |

| Drops of alcohol/ether/glacial acetic acid solvent | Unresponsive | The surface becomes sticky or opaque after 30s. |

| Expose to sunlight | Generally unresponsive | Very small, deep hair-like cracks |

Table 5-6-3 Characteristic Vibration Peaks of Copal Resin

| Vibration mode | Characteristic bands |

|---|---|

| C = CH3 Two-button antisymmetric telescopic vibration | 3083cm -1 Weak absorption bands in the vicinity |

| CH = CH Two-button telescopic vibration | 1637cm -1 Weak absorption bands in the vicinity |

| [CH(CH3)2] Skeleton Vibration | 889cm -1 Spectral bands nearby |

| C-C Key stretching vibration | 700cm -1 , 637cm -1 Weak spectral bands in the neighborhood |

Figure 5-6-12 Copal resin (I)

Figure 5-6-13 Copal resin (II)

Figure 5-6-14 Copal resin (III)

Figure 5-6-15 Copal resin (IV)

Figure 5-6-16 Copal resin (V)

Figure 5-6-17 Copal resin (VI)

884 cm-1, 1645 cm-1, 3078 cm-1 The combined absorption peaks at 884 cm-1, 1645 cm-1, 3078 cm-1 are indicative of Amber and cobalt, and while cobalt shows all three of these peaks, Amber tends to be missing some of them. Therefore, it can be said that these three combined absorption peaks can show the maturity of Amber to some extent, and the degree of petrification of Amber can be judged accordingly. Still, it is impossible to completely distinguish Amber from cobalt resin based on these combined peaks alone.

2. Amber of four origins

Amber from Burma, Dominica, the Baltics, and Fushun, Liaoning can be differentiated by tests such as infrared spectroscopy, as shown in Figures 5-6-19 and 5-6-20 and Table 5-6-4.

Table 5-6-4 Comparison of characteristic peaks in the infrared spectra of amber of four origins

| Characteristic peaks/cm-1 | Baltic amber | Burmese amber | Dominican amber | Liaoning Fushun Amber |

|---|---|---|---|---|

| 888 | Da | Nu | Da | Da |

| 1033 | Nu | M-shaped peaks | Nu | M-shaped peaks |

| 1134 | Nu | With V shaped peaks | Nu | With V shaped peaks |

| 1250 ~ 1150 | Baltic shoulder | Partially W-shaped vibrational peak trend | - | - |

| 1645 | Da | Nu | Da | Da |

| C-O functional group | 1733 cm-1 a strong vibrational peak | 1720 ~ 1728 cm-1 | 1700 ~ 1726 cm-1 Characterization of the split double vibrational peaks | 1696 ~ 1725 cm-1 Two vibrational peaks of different strengths. |

| 3082 | Da | Nu | Da | Nu |

The relationship between the degree of petrification of Amber from the four origins is Burmese Amber > Liaoning Fushun Amber > Baltic Amber> Dominican Amber. Burmese Amber is the earliest Amber known to have been formed and, therefore, has the highest degree of petrification, as seen from the data in Table 5-6-4.

Section VII Quality assessment

Internationally, the quality of Amber is evaluated based on color, transparency, block size, inclusions, and complex cracks, see Table 5-7-1, Figure 5-7-1, Figure 5-7-10.

Table 5-7-1 Quality Evaluation of Amber

| Factori de evaluare | Conținutul evaluării calității |

|---|---|

| Culoare | Generally speaking, the golden yellow color of gold, blood and blue amber is more valuable, brown amber, white beeswax, etc. are slightly less valuable. Gold: The closer the color is to golden yellow, the higher the quality. Blood: the color is positive and strong, the top quality. Blue: the more golden yellow the color of the body, the better; in the ultraviolet lamp, dark background or the appropriate angle of the light source, the more obvious and vivid blue, the higher the quality! |

| Incluziune | The type and rarity of inclusions, as well as their beauty and completeness, are key factors in determining quality; those with many and complete animal and plant remains are the best, while those with incomplete individuals are poorer. |

| Clarity | The less fissures, cracks and impurities in amber, the better; amber often has gas or liquid inclusions, which in large quantities affect the transparency. |

| Transparență | Generally the more transparent the better, to crystal clear for the best; some countries and regions favorite opaque varieties of beeswax |

| Degree of lumpiness | Requires a certain degree of lumpiness; generally speaking, the larger the lumpiness, the better |

| Carve and sculpt | Whether vivid, full, fine, etc.; Blood red Amber often have a variety of internal fissures, difficult to carve, and difficult to make round beads, once the carving pieces, round beads or even egg surface, the value will be higher than with the shape of the beads |

Figure 5-7-1 Well-carved, high-clarity Dominican Blue Amber

Figure 5-7-2 Well-Carved Dominican Blue amber with Slightly Poor Clarity

Figure 5-7-3 Dominican Blue ambers of Increasing Quality from Right to Left

Figure 5-7-4 Domenica Blue ambers of Different Qualities

Figure 5-7-5 High-quality Dominican Blue amber jewelry

Figure 5-7-6 Fissured, impurity-laden Mexican blue amber

Figure 5-7-7 Burmese gold and blue Amber with slightly poorer color and clarity

Figure 5-7-8 High-quality Burmese gold and blue Amber

Figure 5-7-9 Well-carved Burmese Brown Gold Purple

Figure 5-7-10 Larger Diameter Beads of the Same Quality Have Higher Unit Prices

Section VIII Maintenance

Amber has a low hardness and is afraid of being dropped or bumped, so it should be stored separately, not with diamonds or other sharp or hard jewelry. Blood red Amber jewelry is afraid of high temperatures and should not be placed in the sun or next to a heater for a long time; if the air is too dry, it can easily produce cracks. Try to avoid strong fluctuations in temperature.

Avoid contacting organic solutions such as alcohol, gasoline, kerosene, and nail polish containing alcohol, perfume, hairspray, insecticides, etc. Remove your blood purity jewelry when spraying perfume or hairspray.

Rubbing Amber against hard objects can cause the surface to become rough and produce fine marks, so do not use hard objects such as brushes or toothbrushes to clean Blood red Amber.

In addition, due to the blood of more fissures, when the Blood red Amber stained with dust and sweat, it can be put into the addition of neutral detergent soaked in warm water, rubbed dry by hand rinse, and then wiped clean with a soft cloth, and finally a small amount of drops of olive oil or tea oil to wipe the surface of the Blood red Amber gently, and later with a cloth will be excess oil stains off, can make it restore the luster. Many Blood red Amber are soaked in oil before sale; see Figures 5-8-1 and 5-8-2.

Figure 5-8-1 Blood red Amber Multiple Fissures

Figura 5-8-2 Chihlimbar roșu sânge impregnat cu ulei