How to Master Cabochon and Bead Gemstone Processing and How to do the Quality Analysis of Gemstone Processing

Bevezetés:

Unlock the secrets of cabochon and bead gemstone processing with our concise guide. It’s packed with practical tips for jewelers and designers to shape and polish these gems for maximum luster. Plus, learn quality analysis to spot defects, ensuring your creations meet the highest standards. Essential for anyone in the jewelry business, from stores to custom makers.

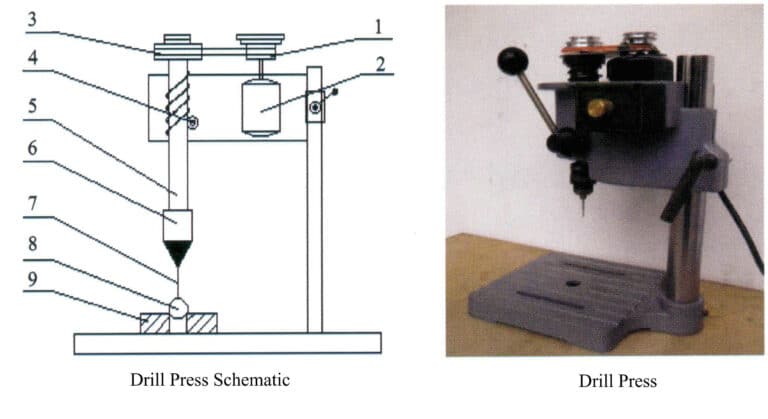

Drill press schematic and drill press

Tartalomjegyzék

Section I Processing of Cabochon and Bead-shaped Gemstones

1. Varieties of Cabochon Gemstones

Curved and bead-shaped gemstones are products primarily composed of curved surfaces, also known as convex or smooth surface gemstones. Smooth surface gemstones are made from semi-transparent to opaque gemstone materials, and the characteristics of smooth surface gemstone processing can fully showcase the luster and special optical effects of the gemstone surface.

1.1 Varieties and classifications of cabochon (convex) gemstones

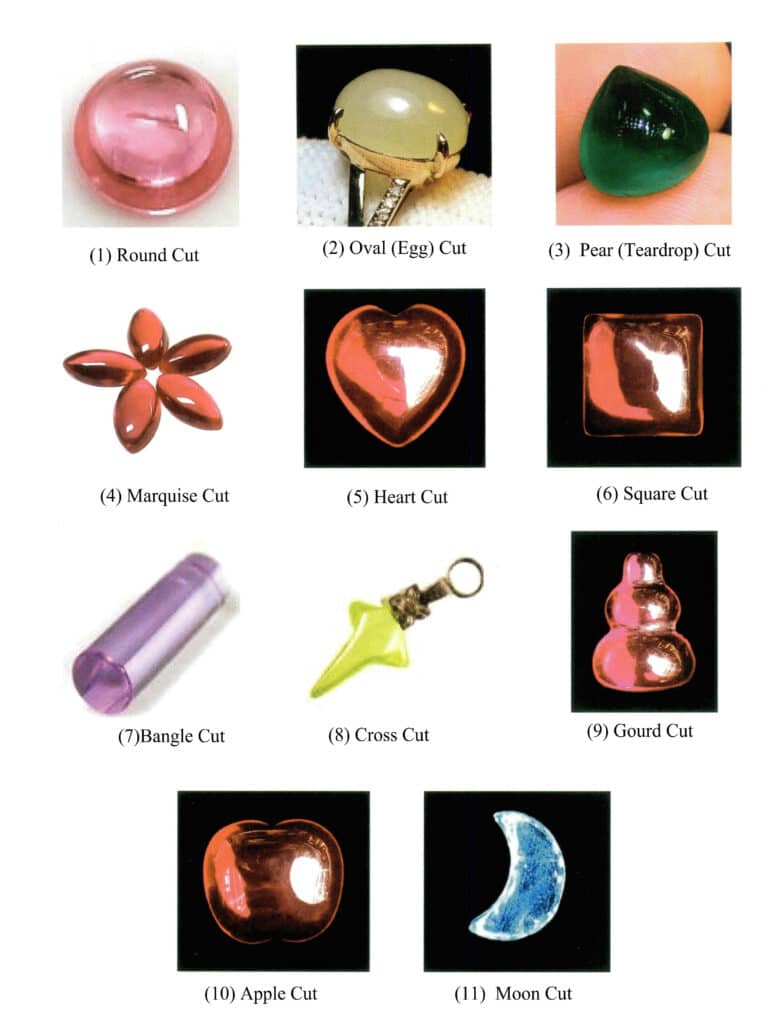

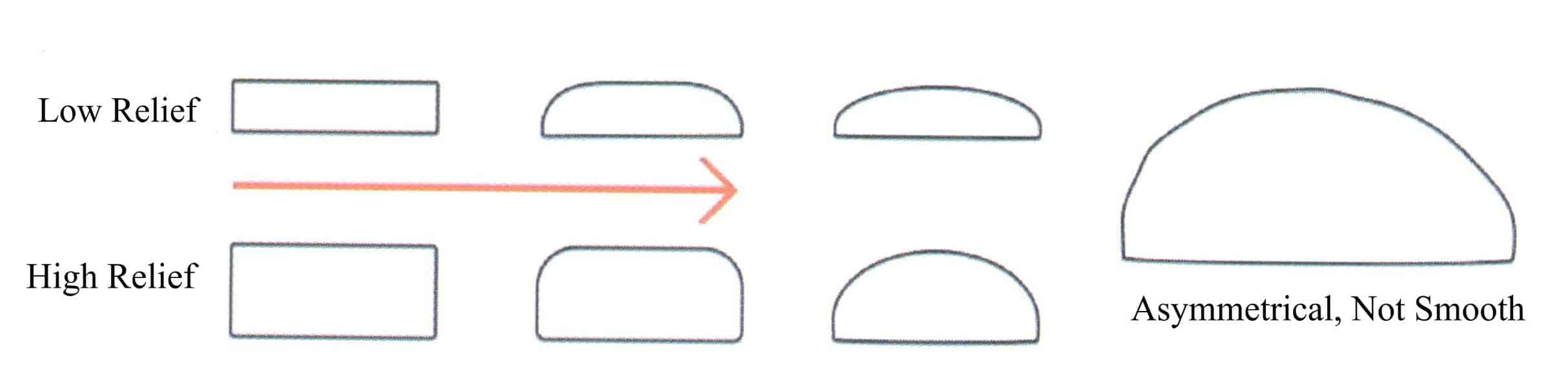

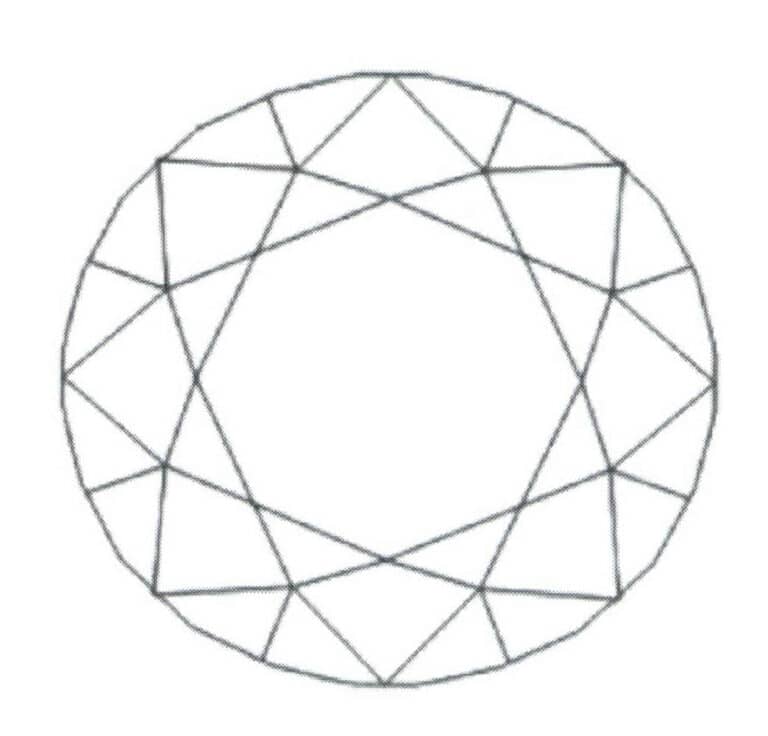

(1) Classification based on the shape of the waist edge and cross-section (Figure 8-1)

(2) Classification based on the side shape

- Single convex surfaces can be divided into high, medium, and low convex.

- Double convex surfaces can be divided into high, medium, and low convex.

High convex types are often used for product preservation, while medium convex types are commonly used for mid-range and low-end gemstone materials. Low convex and hollow types reflect material transparency and color, as Figure 8-2 shows.

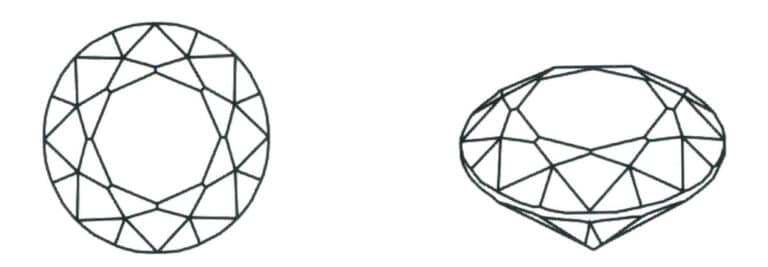

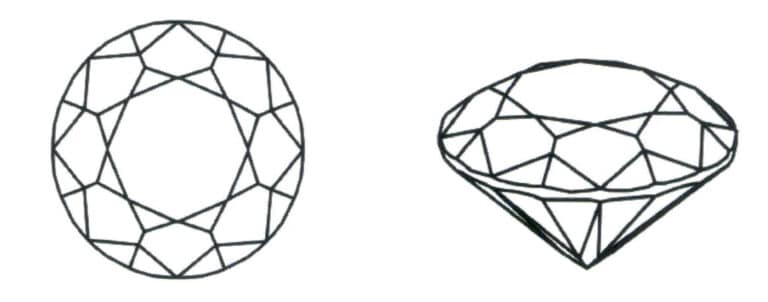

1.2 Common Gemstone Styles

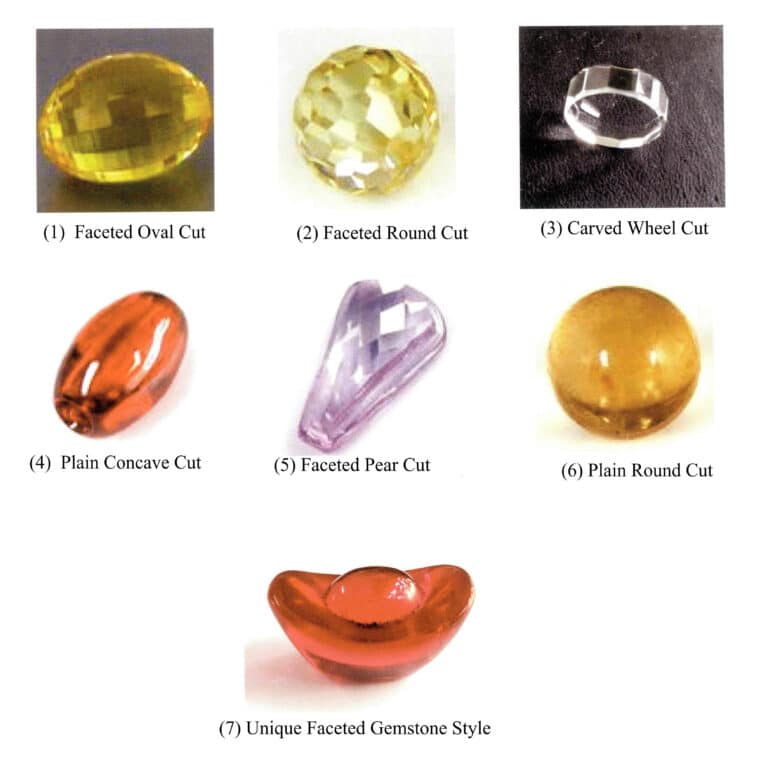

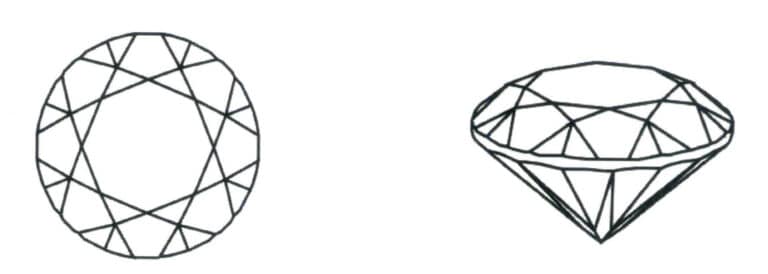

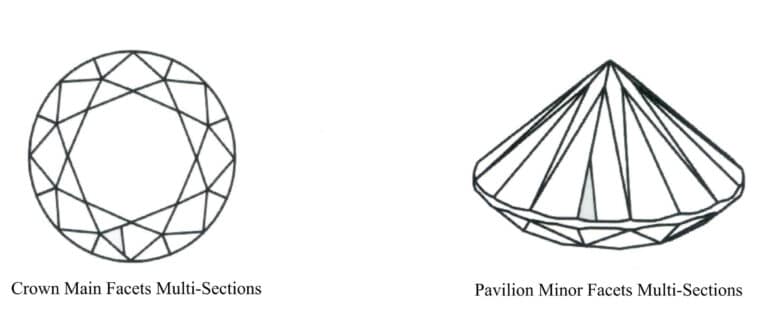

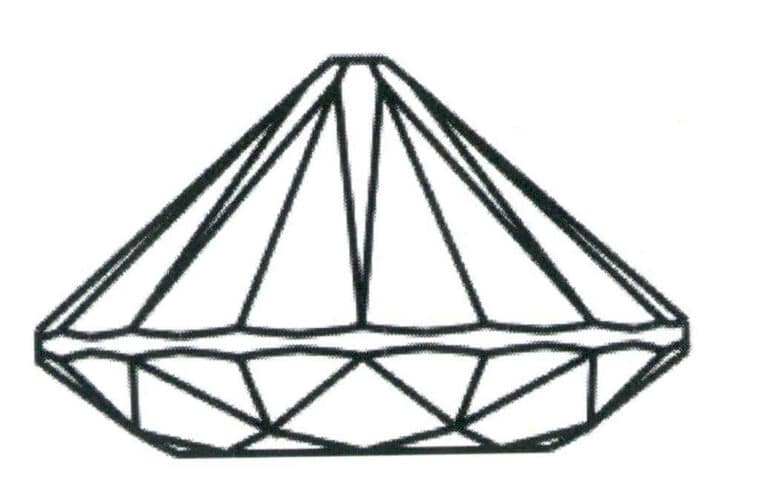

Gemstone shapes are also divided into faceted and smooth types, as shown in Figure 8-3.

2. Processing of Cabochon Gemstones

2.1 Techniques for Processing Cabochon Gemstones

(1) Processing Workflow for Single-Curved Gemstones

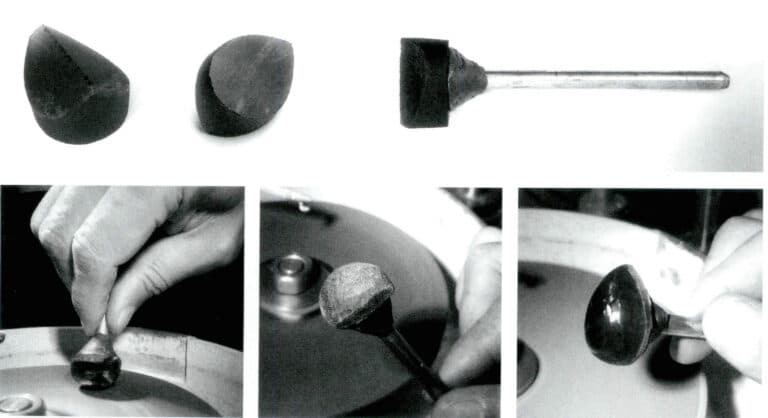

The main workflow for processing single curved gemstones is cutting the stone, breaking it, grinding the base, gluing the stone, shaping the outline, fine grinding, polishing, removing the stone, and cleaning (Figure 8-4).

Single-Cut Cabochon Gemstone Processing Video

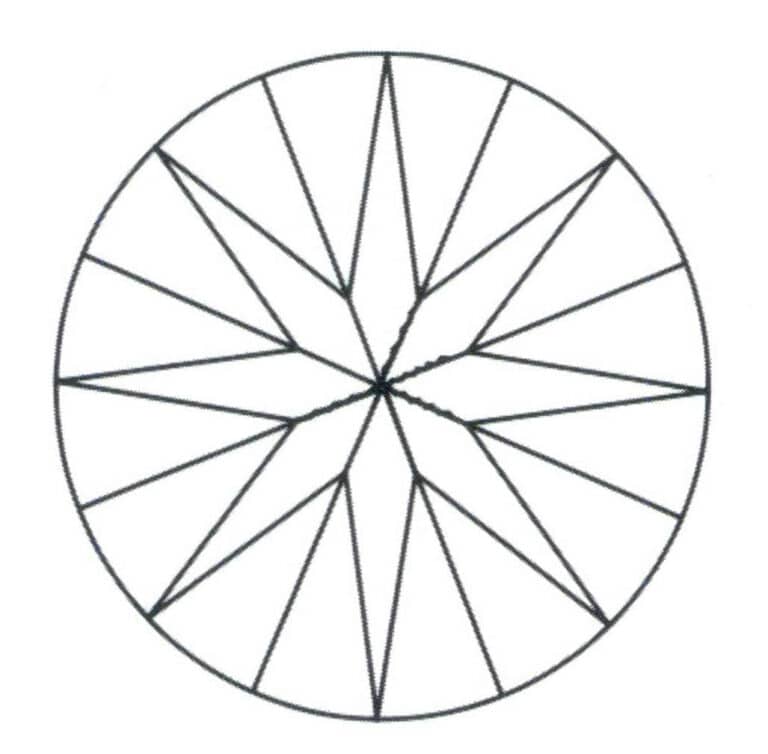

(2) Principles of Curved Gemstone Processing (Figure 8-5)

2.2 Mass Production Process of Cabochon Gemstones

The main processes for the mass production of curved gemstones are cutting—shaping—point grinding—vibratory polishing—and cleaning.

2.3 Factory Gemstone Processing Techniques

Bead-Cut Gemstone Processing Video

2.4 Equipment for processing holes in spherical gemstones

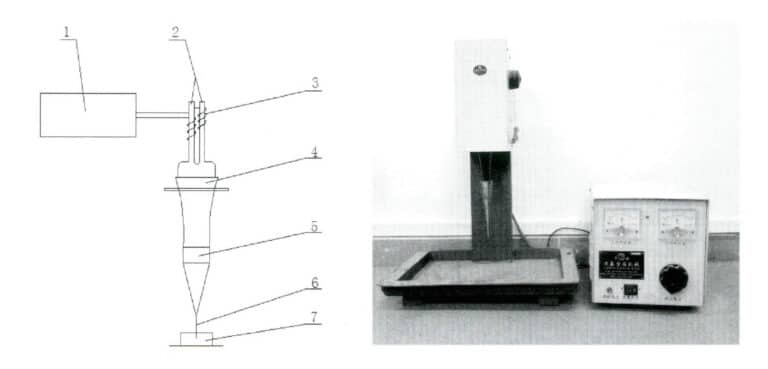

(1) Ultrasonic drilling machine

The ultrasonic drilling machine comes in two models: single-needle and multi-needle. Their structures are the same, but the difference is that the power of the single-needle ultrasonic drilling machine is smaller than that of the multi-needle ultrasonic drilling machine. The amplitude rod can weld multiple steel needles, allowing multiple gemstone holes to be drilled simultaneously. The working principle of the ultrasonic drilling machine: the ultrasonic generator produces ultrasonic waves, which drive the magnet to vibrate through the coil. Under the action of the transducer, ultrasonic frequency electrical vibration waves are generated, and the amplitude is amplified to 0.01~0.15mm through the amplitude insert, which is then transmitted to the needle to create ultrasonic vibrations, striking the processing material more than 16,000 times per second. Under the cooperation of diamond and water-liquid processing suspension, the material in the processing area is crushed into very fine particles by impact, and the suspension washes away the particles crushed by impact and replenishes new diamonds until the drilling work is completed.The schematic diagram of the single-needle ultrasonic drilling principle and the single-needle ultrasonic drilling machine is shown in Figure 8-6.

1.Ultrasonic generator; 2. Magnet; 3. Coil; 4. Transducer; 5. Amplitude transformer; 6. Steel needle; 7. Gem material

Ultrasonic drilling Video

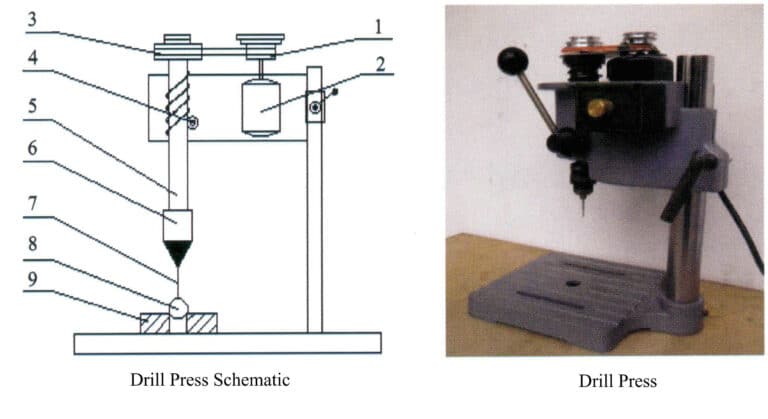

(2) High-speed drilling machine

The structure of the drilling machine consists of a motor, belt, pulley drilling device, spindle, drill chuck frame, etc. Its working principle: The motor mounted on the frame has a speed-adjustable pulley on the motor shaft, which drives the rotation of the spindle’s pulley through the belt. A diamond drill bit is installed on the drill chuck, and the drilling device’s vertical movement and the spindle chuck’s rotation with the diamond drill bit complete the drilling of hard material gems.

The schematic diagram of the high-speed drilling machine and the drilling machine is shown in Figure 8-7.

1.Electric motor; 2. Belt; 3. Pulley; 4. Drilling device; 5. Spindle; 6. Drill chuck; 7. Drill bit; 8. Gemstone; 9. Fixture

3. Polishing technology for gem inner holes

3.1 Mechanism of inner hole polishing

After the gemstones are drilled, especially transparent and translucent bead-shaped gemstones, the rough texture of the holes is very clear, affecting the aesthetic quality of bracelets or necklaces, so the inner holes must be polished. The purpose of polishing the inner holes is to remove the uneven and cracked layers produced during drilling, achieving the required surface smoothness. The first stage removes the uneven layers inside the gemstone holes. The second stage removes the crack layers. During the polishing of the inner holes, diamond powder and polishing liquid are pushed by the corrugated copper wire, with some abrasive particles being pressed into the depressions of the corrugated copper wire. In contrast, a large number of free abrasive particles on the surface of the hole are pushed, pulled, vibrated, and rolled as the corrugated copper wire moves relative to the inner hole of the gemstone, colliding with the peaks of the uneven layers on the surface of the hole. However, since the corrugated copper wire is soft, it is in a state of elastic floating during work, resulting in a relatively weak cutting effect, leaving only shallow scratches on the processed surface, thus requiring a longer polishing time. With the vibration and pulling action, the abrasive particles increase on the corrugated copper wire, giving it a certain micro-cutting effect, allowing the polishing to proceed relatively quickly, and the surface smoothness of the hole improves rapidly.

3.2 Equipment, tools, and polishing process for inner hole polishing

- Vibratory polishing machine.

- Corrugated copper wire.

- Polishing process.

String the beads with corrugated copper wire, 5~10 beads per string, securing both ends of the copper wire to prevent the beads from falling off. Place polishing powder in the vibrating machine’s hopper, and you can start polishing.

Section II Quality Analysis of Gemstone Processing

1. Common product defects and causes in faceted gemstone processing

Faceted gemstones will more or less encounter product quality issues during processing. Analyzing the quality of the products and the reasons for their quality and avoiding quality problems during production is a method for enterprises to control costs.

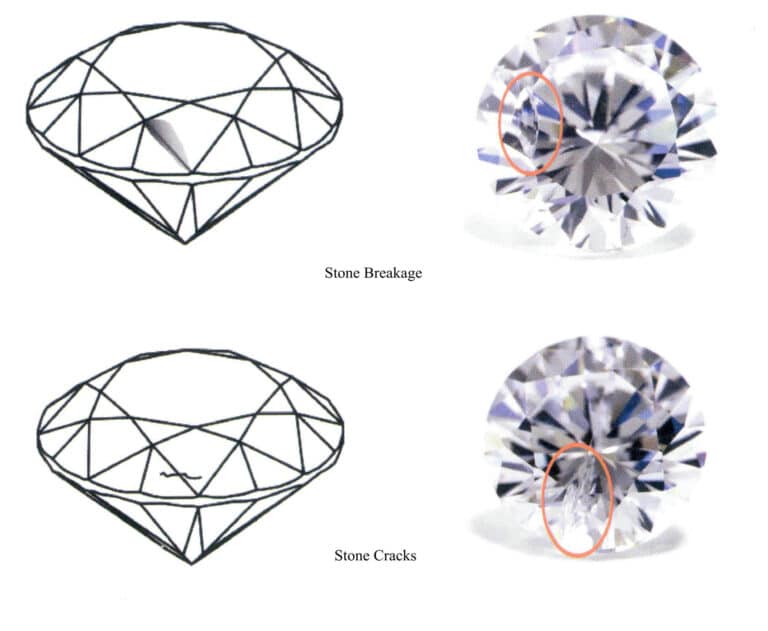

(1) Breakage and Cracking

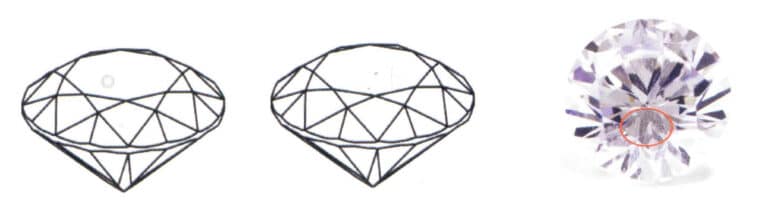

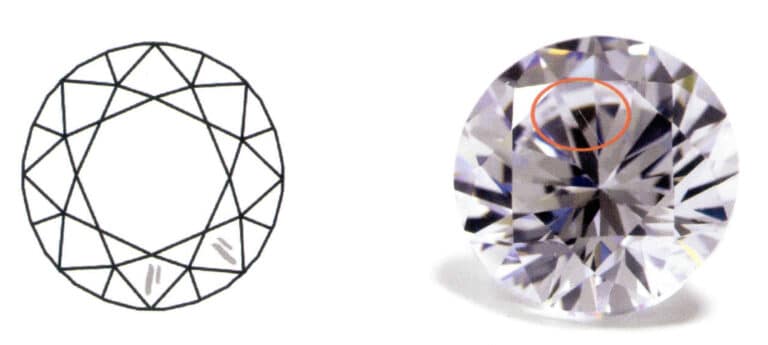

Chipping refers to the product having notches. Cracking refers to internal or external cracks (Figure 9-1).

The main reason for breakage is colliding with hard objects during engraving, polishing, and cleaning. The cause of cracks is the failure to remove existing cracks in the raw material during cutting or improper cutting operations. The heat generated during engraving and polishing can also cause cracks.

(2) Bubbles and Impurities

Bubbles and impurities are inclusions within the gemstone raw material that were not completely removed during cutting, as shown in Figure 9-2.

(3) Heavy cloudiness

Heavy cloudiness refers to the product having a non-glossy finish, with a surface that appears foggy white, caused by poor polishing, as shown in Figure 9-3.

(4) Cloudiness

Cloudiness refers to the product having insufficient brightness on the polished surface, with visible dark grayish-white areas caused by poor polishing, as shown in Figure 9-4.

(5) Slightly Cloudy

Slightly cloudy refers to products with relatively bright facets, with no grayish-white visible to the naked eye, but grayish-white defects can be seen under magnification caused by poor polishing.

(6) Chipping

Chipping refers to defects where part or all of the waistline of the product has been worn away, resulting in a knife-edge appearance, as shown in Figure 9-5.

(7) Thick Edge

Thick edge (waist thickness) refers to the product’s waistline exceeding the 2% of total height, as shown in Figure 9-6.

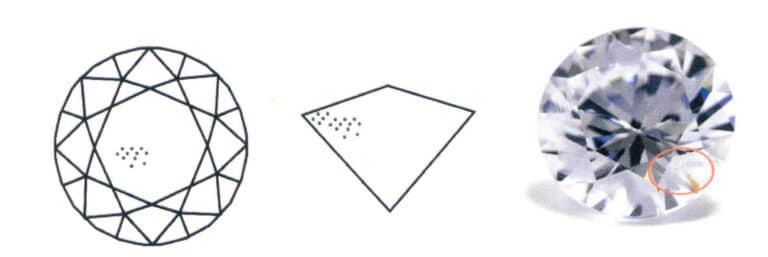

(8) Sand Pores

Sand pores are marks left by the polishing process that did not completely remove the scratches from the gemstone, as shown in Figure 9-7.

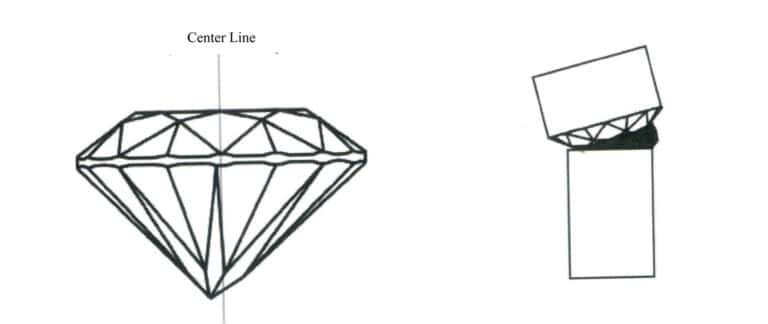

(9) Off-center culet

The phenomenon where the bottom tip of the product deviates from the centerline is called a off-center culet. The tabletop is not perpendicular to the iron rod when counter-stoning, as shown in Figure 9-8.

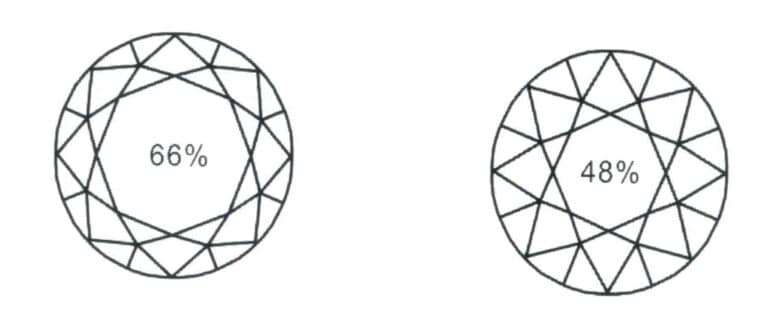

(10) Tabletop size is unqualified

The tabletop of faceted gemstone products should account for 58%~60% of the diameter. If the tabletop of faceted gemstone products is greater than 60% of the diameter or less than 58% of the diameter, it is considered unqualified, as shown in Figure 9-9.

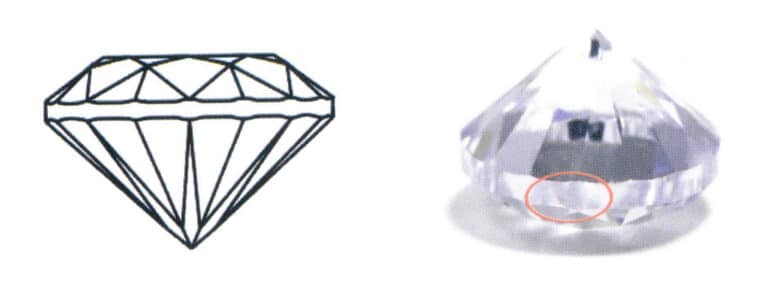

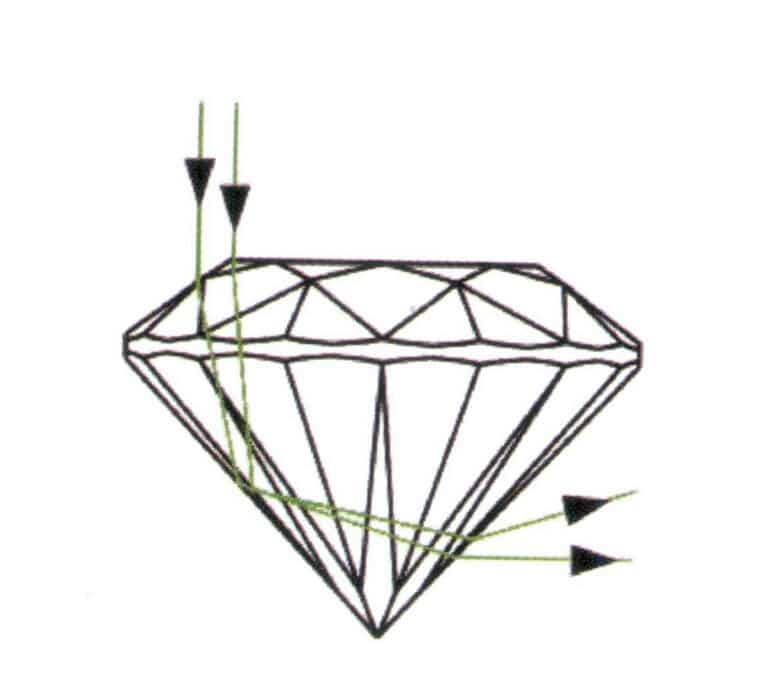

(11) Light leakage

The defect of the pavilion angle is that it needs to be bigger, and the total height of the pavilion needing to be qualified is called light leakage. The main reason is that the pavilion angle is less than the design angle, as shown in Figure 9-10.

(12) Dark bottom

The defect of the pavilion angle being too large and the pavilion being too high in faceted gemstone products is called a black base. The main reason is that the pavilion angle is greater than the design angle, as shown in Figure 9-11.

Copywrite @ Sobling.Jewelry - Egyedi ékszergyártó, OEM és ODM ékszergyár

(13) Star Separation

The phenomenon where the angles between adjacent star facets in faceted gemstone products do not meet at a point is called star separation, as shown in Figure 9-12.

(14) Star Collision

The phenomenon where the angles between adjacent star facets in faceted gemstone products excessively connect is called star collision, as shown in Figure 9-13.

(15) Star Waist Collision

The phenomenon where the angles between the star’s small face and the upper waist small face in faceted gemstone products connect at the corners is called star waist collision, as shown in Figure 9-14.

(16) Star Waist Separation

The phenomenon where the angles between the star’s small face and the upper waist small face in faceted gemstone products do not connect is called star waist separation, as shown in Figure 9-15.

(17) Waist Separation

The phenomenon where the angles between the two upper waist facets of a faceted gemstone product do not connect is called waist separation, as shown in Figure 9-16.

(18) Waist Collision

The angle and angle transition connecting two upper waist facets in faceted gemstone products is called waist collision, as shown in Figure 9-17.

(19) Multi-faceted

The defect of having two or more facets appearing on an ideal facet in faceted gemstone products is called multi-faceted, as shown in Figure 9-18.

(20) Drag board

The defect at the junction of adjacent facets of faceted gemstone products that does not form sharp edges but presents a rounded arc shape is called a drag board, as shown in Figure 9-19.

(21) Not Pointed

The defect of faceted gemstone products where the bottom point is not collected is called “not pointed.” This is generally caused by the insufficient height of the rough stone, as shown in Figure 9-20.

(22) Poorly pointed

The defect in faceted gemstone products where the main facet of the pavilion does not converge at a point with the bottom point is called “poorly pointed,” as shown in Figure 9-21.

(23) Size is unqualified

In faceted gemstone products, size errors exceeding the design requirements are referred to as unqualified sizes, as shown in Figure 9-22.

(24) Loss of roundness

In round gemstone finished products, the waist circumference diameters are not equal, and irregularly shaped products are called losing roundness. This issue is caused by non-compliance in the shape during the production of rough stones or improper manual edging operations, as shown in Figure 9-23.

(25) Scratch tip

The phenomenon of small dot-like scratches on the bottom tip or bruises on the edges near the bottom tip in faceted gemstone products is called flower tip, as shown in Figure 9-24.

(26) Damaged stone

The phenomenon of striped scratches on faceted gemstones is called “damaged stone,” as shown in Figure 9-25.

2. Gem Quality Inspection

2.1 Gem Quality Inspection Tools

(1) Gemstone inspection special towel

Choose towels made of cotton with good water absorption, as shown in Figure 9-26.

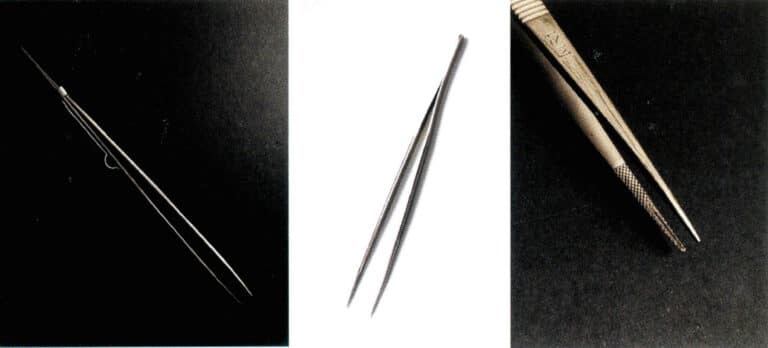

(2) Gemstone tweezers

Gemstone tweezers should be made of stainless steel, with or without a locking mechanism; the tweezers’ tips may have teeth with or without grooves. Tweezers without grooves are commonly used for counting gemstones, while tweezers with grooves are commonly used for holding gemstones, as shown in Figure 9-27.

(3) Gem Magnifier

The commonly used folding gem magnifier for gem processing and inspection typically has a magnification of 5~10 times. The focal length of the folding magnifier is fixed, making it simple, convenient, and intuitive to operate, as shown in Figure 9-28.

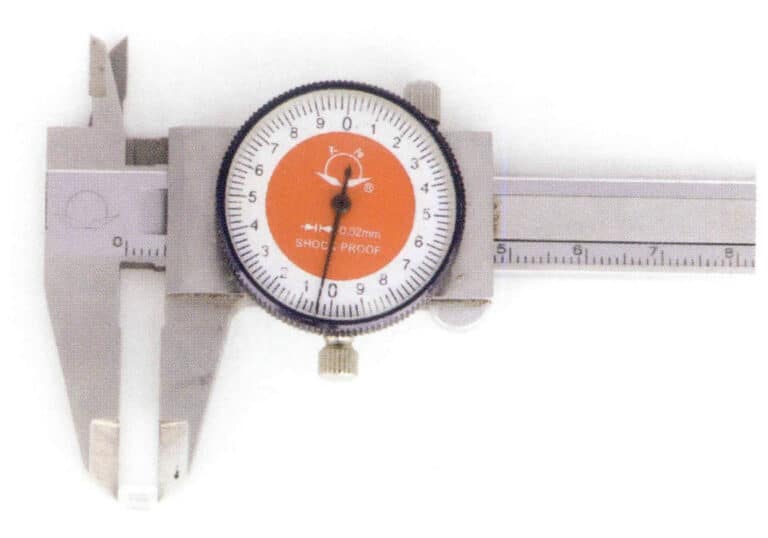

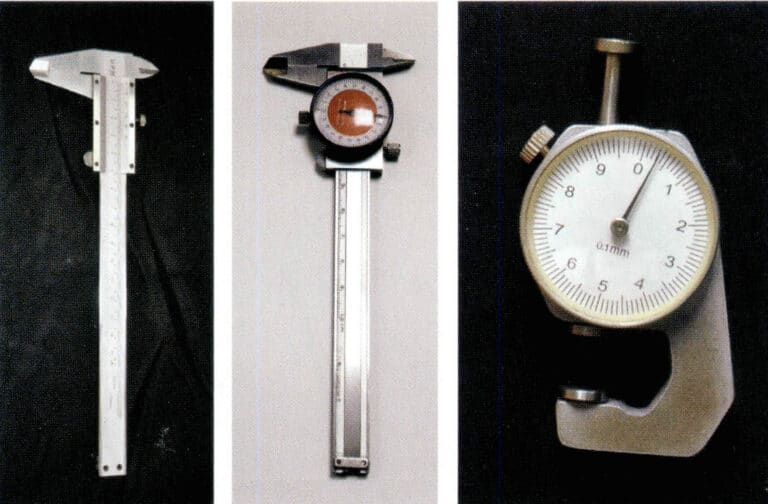

(4) Caliper

The caliper is used to measure the dimensions of gem products, as shown in Figure 9-29.

2.2 Market Grading Standards for Artificial Gem Quality Inspection

(1) Technical Standards

① Specifications and Dimensions

The diameter of the circle measures the specifications of round diamond products. Irregular products are measured by the short and long axes, with specifications size being 1~110mm.

② Allowable size deviation (Table 9-1)

Table 9-1 Allowable size deviation

| Specification size (mm) | AAA | AA | A | B | C | D |

|---|---|---|---|---|---|---|

| 1 ~ 2 | ±0.01 | ±0.02 | ±0.03 | ±0.04 | ±0.05 | ±0.12 |

| > 2 ~ 5 | ±0.02 | ±0.03 | ±0.04 | ±0.05 | ±0.08 | ±0.15 |

| > 5 ~ 25 | ±0.03 | ±0.04 | ±0.05 | ±0.06 | ±0.10 | ±0.18 |

| > 25 | ±0.05 | ±0.08 | ±0.10 | ±0.15 | ±0.20 | ±0.20 |

(2) Gem inspection standards at all levels

① Market AAA grade gem inspection standards

- Size is accurate, and light is transparent. When checked with a 10x magnifying glass, the surface of the facets should have no grayish-white foggy polishing marks, good roundness, cutting proportions: 59%≤total depth ratio≤64%, 53% ≤table width ratio≤58%, 2%≤waist thickness ratio≤5%, and the surface is uniform.

- No chipping, crooked points, cloudiness, sand holes, light leakage, black base, thick edges, loss of roundness, not pointed, multiple plates, dragging plates, and other defects.

- Symmetry: no star collisions, star separations, star waist collisions, star waist separations, waist collisions, waist separations, and other defects. The main facet of the crown presents a kite shape; the point is well-defined.

② Market AA grade gemstone inspection standards

- Size is accurate, and light is transparent. When checked with a 10x magnifying glass, the surface of the facets should have no grayish-white foggy polishing marks, good roundness, cutting proportions: 59%≤total depth ratio≤64%, 53%≤table width ratio≤58%, 2%≤waist thickness ratio≤5%, and the surface is uniform.

- No chipping, crooked points, cloudiness, sand holes, light leakage, black base, thick edges, loss of roundness, not pointed, multiple boards, dragging boards, and other defects.

- Slight star waist collisions, waist collisions, waist separation are allowed, but star waist separation is not allowed; or no star waist collisions, star waist separation, waist collisions, waist separation, slight star collisions are allowed, but star separation is not allowed, the main facet of the crown presents a kite shape; pointedness is preferred.

③ A-level gemstone inspection standards

- Accurate dimensions, good light transmission, checked with a 10x magnifying glass, the surface of the facets should be free of gray-white foggy polishing marks, good roundness, cutting proportions: 59%≤full depth ratio≤64%, 53%≤table width ratio≤58%, 2%≤waist thickness ratio≤5%, uniform board surface.

- No chipping, crooked points, cloudiness, sand holes, light leakage, black base, thick edges, loss of roundness, not pointed, multiple boards, dragging boards, and other defects.

- Allow slight star waist collisions, waist collisions, waist separations; do not allow star waist separations; or no star waist collisions, star waist separations, waist collisions, waist separations, allow slight star collisions, do not allow star separations, the crown main facet presents a kite shape; sharp tip preferred.

④ B-grade gemstone inspection standards

- Relatively bright, slight haze, extremely small sand holes, extremely slight crooked tips, and relatively round are allowed.

- No obvious defects such as chipping, not pointed, multiple facets, or dragging facets are allowed.

- Allow non-obvious star collisions, star separations, star waist collisions, star waist separations, waist collisions, and waist separations.

⑤ C Grade Gem Inspection Standards

- Serious defects such as inclusions and sand holes.

- Defects such as chipping, not pointed, loss of roundness, multiple boards, and dragging boards are more obvious.

⑥ D Grade Gem Inspection Standards

- Serious defects such as inclusions and sand holes.

- Defects such as edge chipping, off-center culet, loss of roundness, and multiple boards are quite serious, with phenomena of not pointed or multiple boards.

➆ E-grade gemstone inspection standards

Refers to those with breakage, cracks, decay, impurities, bubbles, heavy cloudiness, and the most severe D-grade, also known as waste stones.

(3) Market grading methods

The gemstone grading in the Wuzhou market of Guangxi generally adopts the following methods (with exceptions for special requirements).

AAA goods: AAA grade.

A goods: A grade, AA grade, AAA grade.

AB goods: A and B grades are each accounted for 50%.

Total upper goods: A and B grades account for 80%, and C grades account for 20%.

Total lower goods: A grade accounts for 10%, B and C grades account for 90%.

BC goods: Grade B and C.

Secondary stone: Grade D.

Waste stone: Grade E.

3. Gem Cleaning

After the gem processing, the oil stains and residual gem glue must be cleaned on the gem’s surface. There are many cleaning methods, and when designing the cleaning solution formula, the solution should be able to remove the adhesive and other dirt adhering to the surface of the workpiece.

The commonly used cleaning methods are described below.

(1) Alkaline cleaning method

Mix soda ash and water in a ratio of 1:10, and heat to 100℃. Place the processed gemstone products in a stainless steel basket, immerse them in the soda ash water, and boil them for 10 minutes to clean them thoroughly.

(2) Alcohol cleaning method

Place the gemstone products in ceramic, plastic, or glass containers, then pour in alcohol to soak the surface of the gemstones until the adhesive comes off.

(3) Tiana cleaning method

Place the gemstones to be cleaned in a ceramic bowl, pour in tiana to submerge the gemstones, then rinse thoroughly with clean water after 10~15 min.