Grow Your Brand with Trusted OEM Jewelry Manufacturer

Turn your jewelry ideas into reality in 15 days.

Low MOQ · Fast Turnaround · Fine Jewelry Quality

Stop Wasting Time, Money, and Trust on the Wrong jewelry OEM !

- “They promised 925 silver, but when tested, impurities showed up and my customers lost trust.”

- “The samples looked perfect, but when the bulk arrived, colors and plating were totally inconsistent.”

- “We’re a small brand, but they pushed me into huge orders that left my stock sitting unsold.”

- “I gave them a clear design, but the final pieces had wrong structure and poorly set stones.”

- “I received defective products, but instead of taking responsibility, the supplier blamed shipping and even my customers.”

- “I had to handle all product photos and copy myself because they provided nothing useful.”

Índice

Don’t Fall into traps Again: Take Back Control When Choosing a Jewelry OEM

What Is Jewelry OEM?

When people talk about jewelry OEM, they usually mean working with a factory that produces designs under your own brand. For many buyers, it sounds like the fastest way to expand collections without building a workshop or hiring a big team. You just send designs, place an order, and the factory handles the rest.

That’s why so many small brands, online stores, and new jewelry entrepreneurs turn to OEM. It feels practical: lower costs, faster turnaround, and the chance to compete with bigger players. For anyone trying to test a new market, launch private label jewelry, or scale without heavy investment, OEM looks like the obvious choice.

But the reality isn’t always as smooth as it looks at first.

Everything Looked Great… Until the Problems Hit Me Hard

Sourcing a new Jewelry OEM often appears straightforward. Catalogs look polished, samples seem acceptable, and communication in fluent English creates an impression of professionalism. At first glance, it can feel like a low-risk decision for buyers seeking efficiency and growth.

However, many B2B buyers discover problems after committing. Delayed deliveries, inconsistent quality, and unexpected costs are frequent issues. Packaging and logistics often fall short of requirements, while after-sales responsibility remains unclear. These problems not only damage cash flow but also impact customer trust, compliance, and long-term brand reputation.

Such challenges are not isolated cases but common traps within the jewelry OEM supply chain. A professional appearance does not always equal strong capability, and overlooked details can escalate into costly mistakes. To reduce risk, buyers need to recognize the most frequent pitfalls before placing deposits or scaling orders.

The following section outlines 10 traps jewelry buyers often regret too late — a practical guide to avoiding unnecessary losses.

10 traps of OEM That Jewelry Buyers Wish They Had Avoided

🔻 Trap 1: The Lure of Unrealistic Low Prices

🔻 Trap 2: Inconsistent Quality Standards

🔻 Trap 3: IP Leakage and Design Theft

🔻 Trap 4: Sample vs. Mass Production Double Standard

🔻 Trap 5: Nonexistent After-Sales Support

🔻 Trap 6: Sloppy Packaging and Shipping

🔻 Trap 7: Opaque Production Timeline

🔻 Trap 8: Fake or Misused Certifications

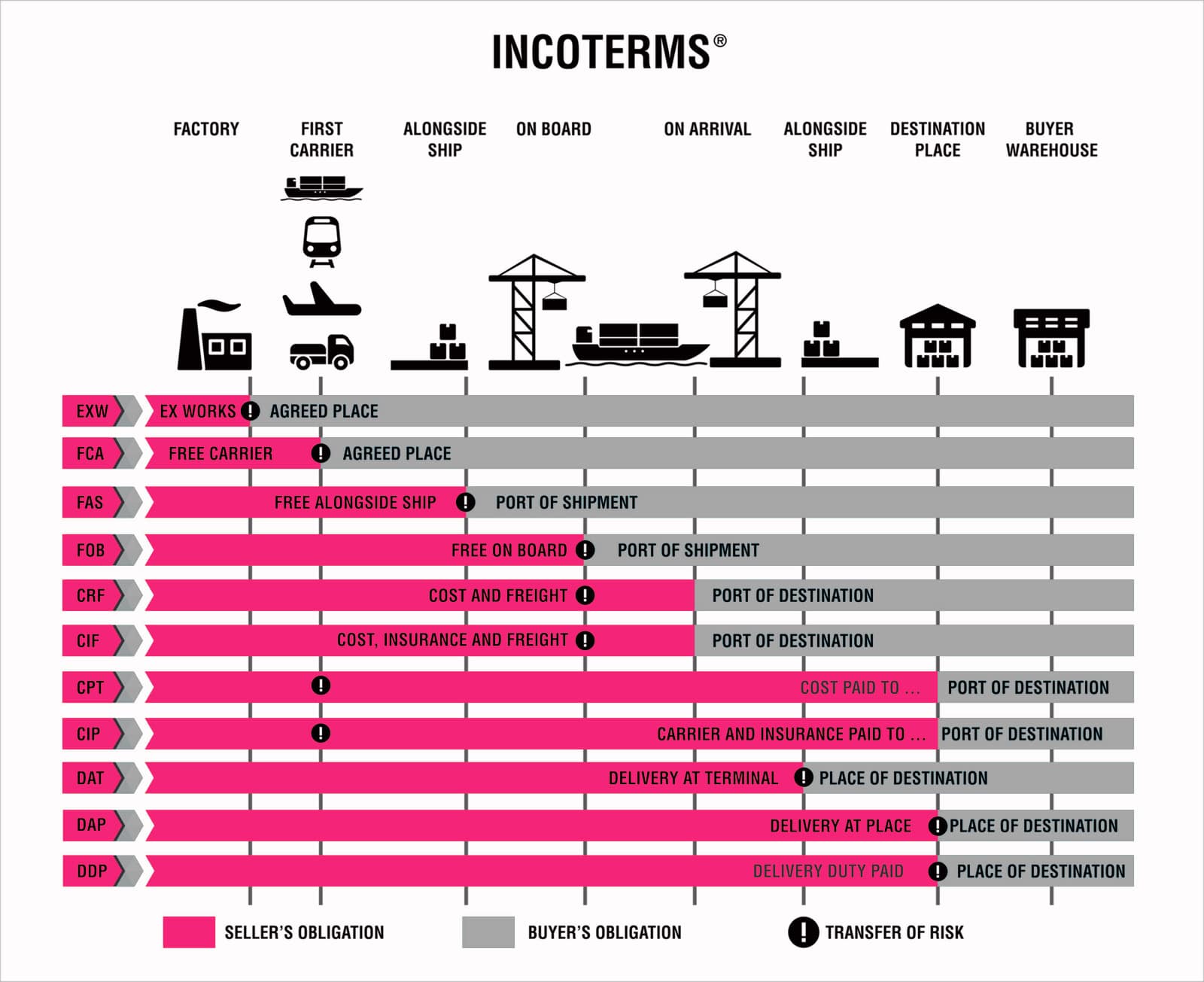

🔻 Trap 9: Allergy and Heavy-Metal Non-Compliance

🔻 Trap 10: Incoterms Misunderstandings

What You Do Next Could Save You Thousands

Erros na seleção de fornecedores não afetam apenas as margens de lucro — eles prejudicam a confiança, atrasam lançamentos e esgotam as equipes. Mas você não precisa aprender tudo da maneira mais difícil. Use estas 10 armadilhas como um guia. Compartilhe-as com sua equipe de compras. Faça as perguntas certas desde o início — e escolha parceiros cujas respostas sejam embasadas em evidências. O fornecedor ideal não é perfeito — ele é transparente, realista e está pronto para crescer com você.How to tell if a Jewelry OEM is trusted?--- 8 Essential Standards

A truly trusted jewelry manufacturer isn't just about good prices or pretty samples — it's about having the core capabilities to support your brand long term. From in-house design to QC, a solid partner should meet at least these 8 essential standards. Anything less puts your timeline, quality, and customer trust at ris

1. In House Team

Yes, Sobling has 100+ in-house engineers and QC staffs with deep production knowledge

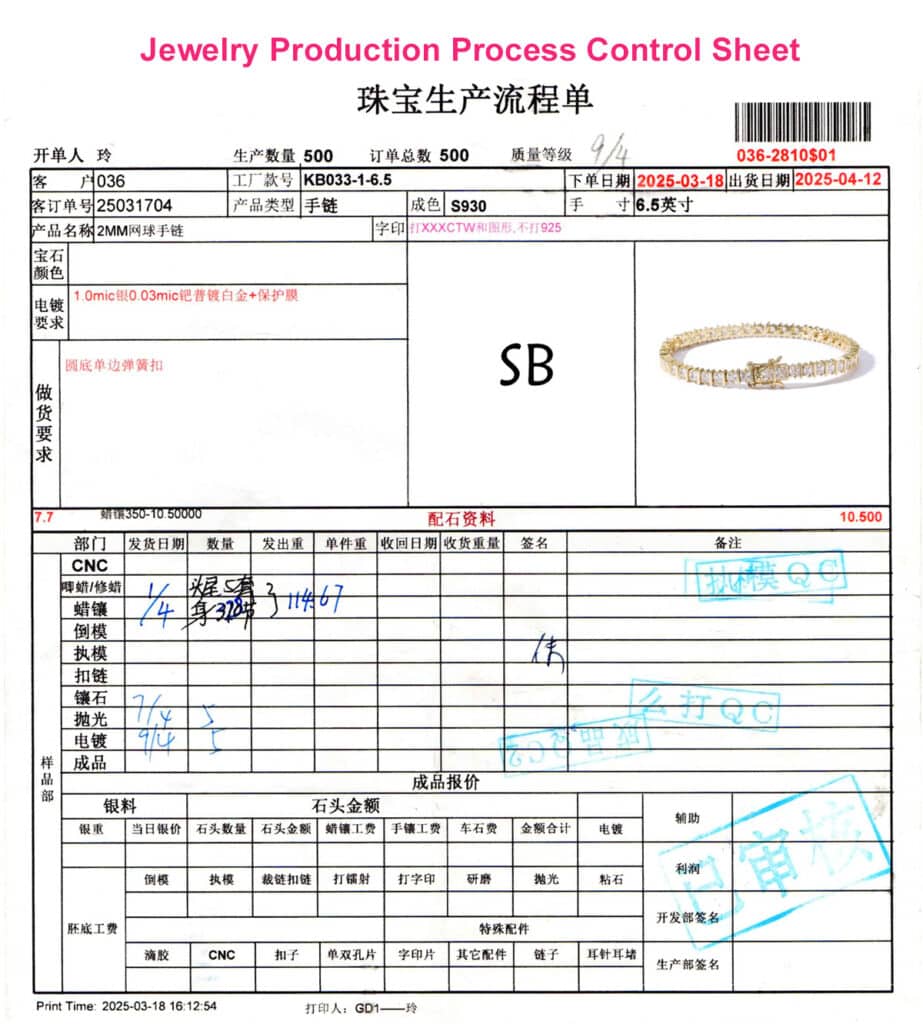

2. Transparent Process

Yes, Sobling gives clear updates at every step — no hidden costs, no surprises

3. Quality Consistent

Yes, Sobling Ensures Consistency in Every Piece Through a Proven Production Control System.

4. Clear Trade Terms

Yes, Sobling walks you through EXW, FOB, DDP, and more — no confusion

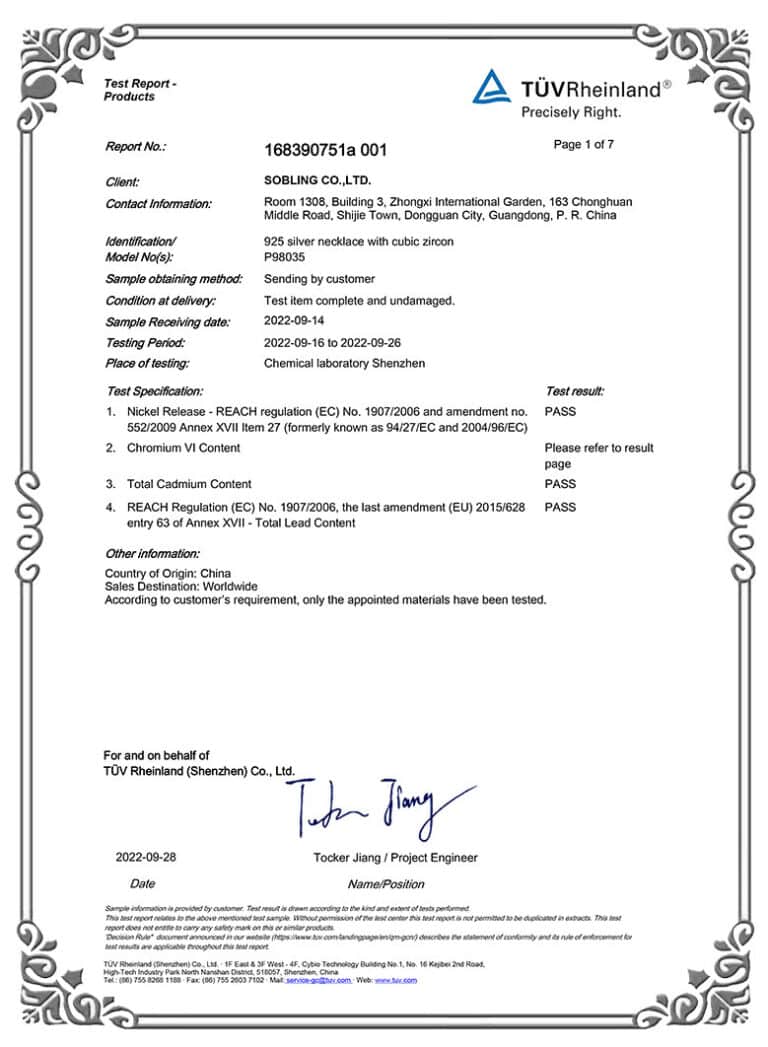

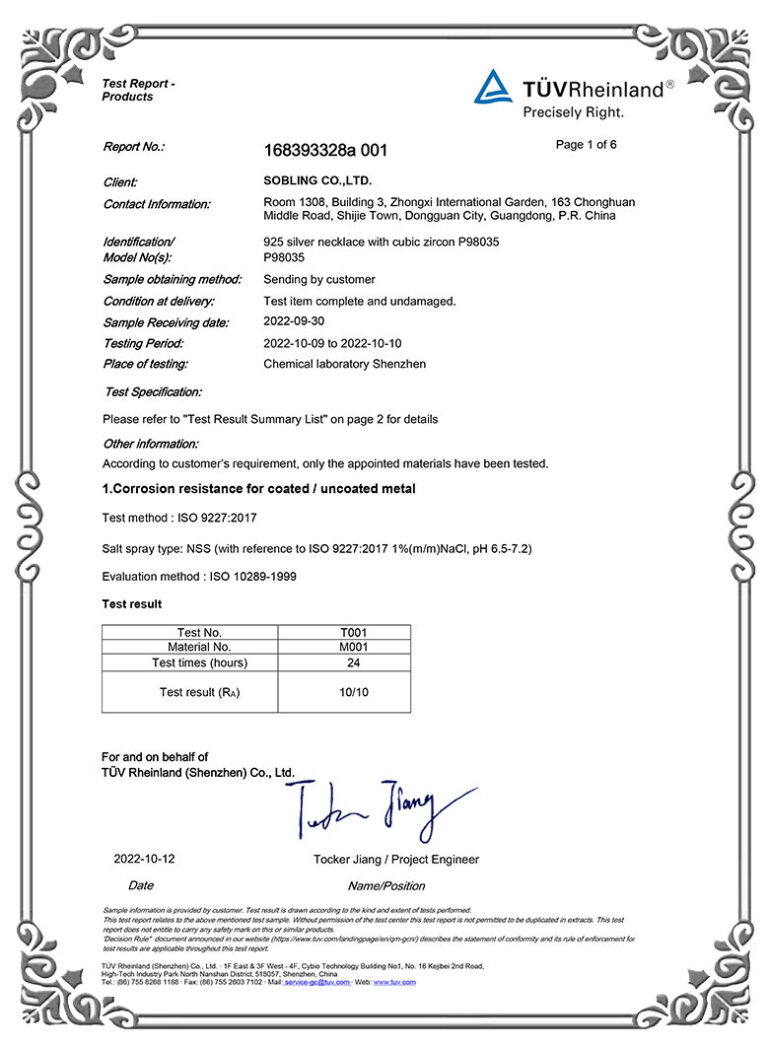

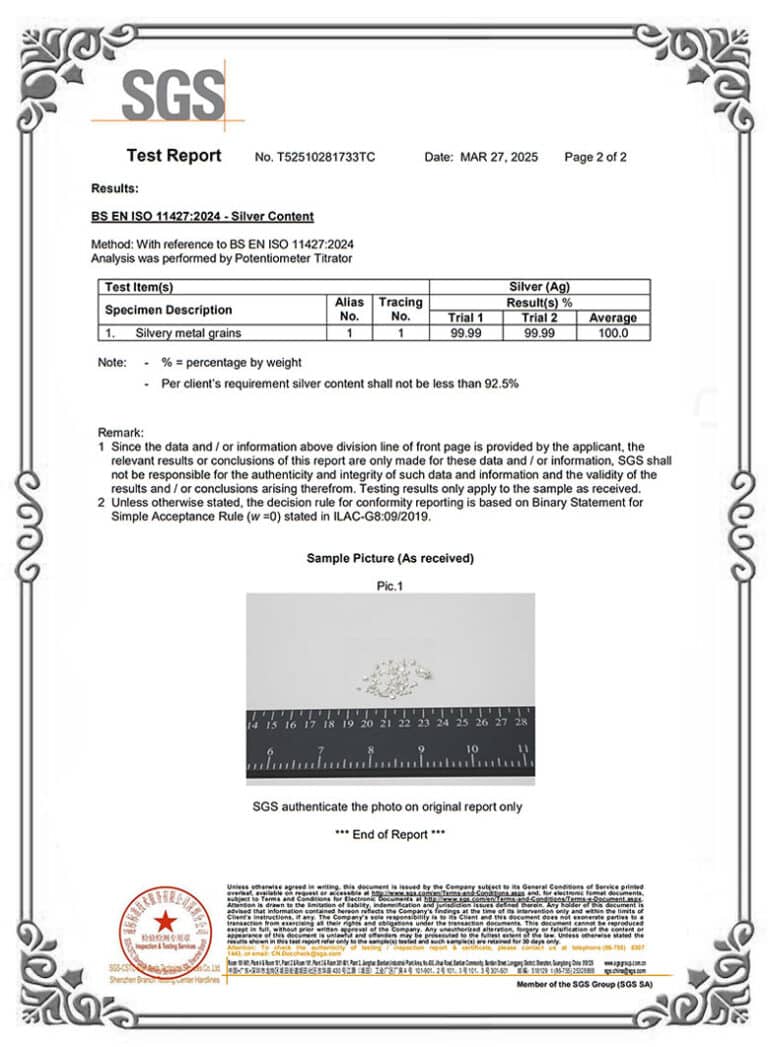

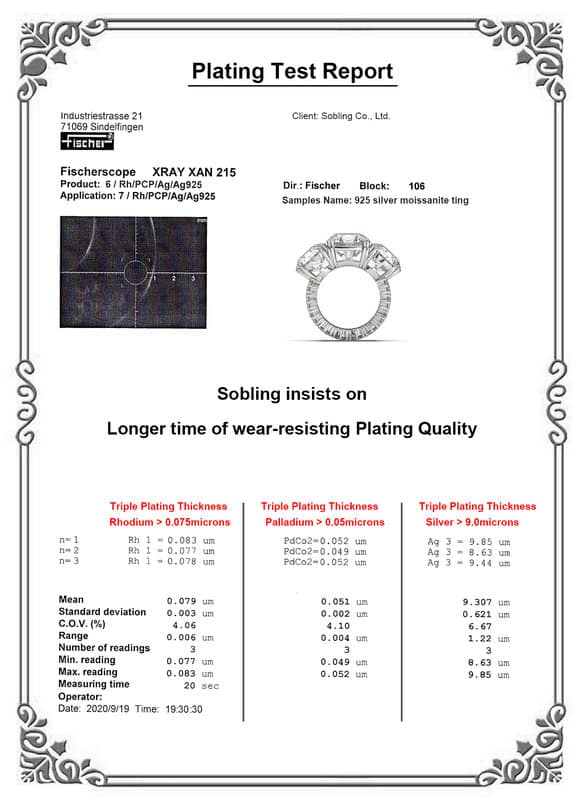

5. Real Certifications

Yes, Your Jewelry is Certified to Global Standards — No Guesswork, No Harmful Surprises

Sem substâncias químicas nocivas → Seguro para mercados globais

Forte proteção antiferrugem → As joias brilham por mais tempo

Prata genuína 999 → Pureza real garantida

Revestimento triplo durável → Beleza duradoura, menos desbotamento

6. Allergy-Free Materials

Yes, Sobling Provides Certified Allergy-Free Materials — Silver, Gold, 304 and 316 Steel — All Complying with EU REACH Standards.

7. Flexible Capacity

Sobling: Yes, You can start with 10 pieces low-volume runs and scale up only when you're confident.

8. Verified IP Safety

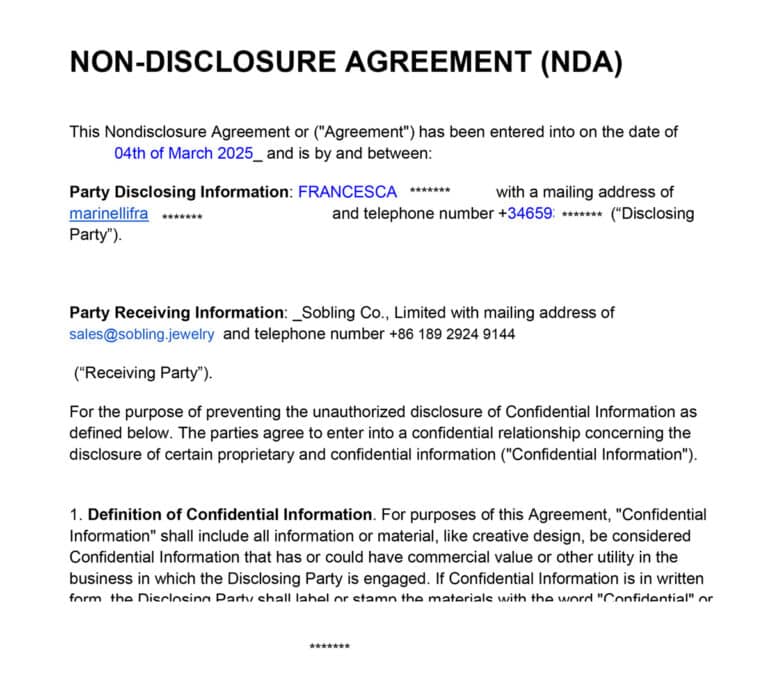

Sobling: Yes, Non-Discloure Agreement(NDA) signed before sampling, so your IP stays yours — always

7 More Key Factors to consider when choosing a trusted supplier

- 9. Focus on Jewelry OEM Over decades

- 10. Precision Equipment for Brand-Ready Quality

- 11. All-in-One Jewelry OEM Services

- 12. All-in-One OEM Jewelry Products

- 13. Real production capacities

- 14. 100% Risk Free Guarantee

- 15. 4 Steps Quality Contorl System

7 Value-Added Advantages to Choose a Trusted Jewelry OEM Supplier

- 16. Sustainable Jewelry Options

- 17. Fast Shipping and Delivery

- 18. One-stop complete jewelry Production

- 19. One-stop Jewelry material options

- 20. One-Stop Package materials

- 21. Private Label jewelry Engravings

- 22. Jewerly photoshoot for marketing ready

How to Spot a trusted Jewelry OEM? — Checklist Based on Industry Insights

Choosing the right jewelry OEM partner can make or break your brand’s success. It’s not just about low prices — it’s about finding a manufacturer who delivers consistent quality, communicates clearly, and helps you meet deadlines without hidden delays or surprises.

Below is a practical checklist to help you evaluate any OEM supplier — including what to look for, why it matters, and how Sobling meets each benchmark. Use this to compare vendors and spot early warning signs before it costs you time and money.| Fator chave | O que procurar | Como Sobling se compara |

|---|---|---|

| Transparência na Produção | Improved visibility into production progress, helping reduce delays and miscommunication. | ✅ Offers transparent factory access and visual updates |

| Material Assurance | Reliable quality control with verified and certified metals and gemstones. | ✅ RJC, SGS, EU-tested materials used |

| MOQ Flexibility | Lower entry barriers and easier scaling from small to bulk orders. | ✅ 10pcs to 10,000pcs, scalable |

| Fabricação interna | Consistent quality and better delivery control without third-party involvement. | ✅ Fully in-house from casting to finishing |

| Full-Service Workflow | Reduced coordination effort with integrated design, sampling, production, and packaging. | ✅ 9-step all-in-one production workflow |

| Fast Prototyping | Shorter product development cycles and faster go-to-market capability. | ✅ 15-day sample making, CAD + wax options |

| Quality Control | Lower defect rates and improved consistency through multi-step quality checks. | ✅ 4 steps QC system (casting, plating, finishing, Final products) |

| Global Experience | Proven capability to meet standards and expectations across different markets. | ✅ Projects across 30+ countries |

| On-Time Delivery | Reliable scheduling and reduced risk of launch delays. | ✅ 98%+ on-time delivery performance |

| English-Speaking Support | Fewer communication issues and faster response time during production. | ✅ Fluent, responsive English-speaking team |

| IP & NDA Protection | Reduced legal and commercial risks for custom or exclusive designs. | ✅ Signed NDA, strict IP protection policy |

| Certification Ready | Smoother customs clearance and compliance with international regulations. | ✅ Compliance with export standards (e.g. REACH, CA65) |

Choosing an OEM partner isn’t just about finding a supplier — it’s about finding someone who helps you move faster, avoid costly mistakes, and grow with confidence. This checklist helped me see the difference: transparent production, strong quality control, fast samples, and real communication matter more than I thought.

With Sobling, everything from IP protection to delivery feels structured and reliable. there are no longer worry about delays, vague updates, or quality gaps. If you want a partner that understands your goals and actually delivers, this checklist is the best place to start asking the right questions.

Why Jewelry Brands Like Yours Choose Sobling?

70% Poupança de tempo

Encurte sua cadeia de suprimentos.

40% custo economizado

Preço direto da fábrica, sem intermediários.

100% Sem Riscos

Garantia de devolução de 30 dias

Serviços VIP 24 horas por dia, 7 dias por semana

Resposta rápida para reduzir seu tempo de espera.

What You’ll Actually Gain from Working with Sobling?

- ✅ Melhor QualidadeCertificado pela TUV e em conformidade com o REACH. 90% Menos defeitos, 200% clientes mais satisfeitos.

- ✅ Melhor GarantiaDevolução em 30 dias, garantia de 360 dias. Tranquilidade para o seu negócio.

- ✅ Menos dores de cabeçaSolução completa, do projeto à entrega.

- ✅ Custos mais baixosDesign e modelagem 3D gratuitos. 40% Economize tempo e custos de desenvolvimento.

Sucesso comprovado: mais de 1500 projetos de joias personalizadas entregues.

Caixa com design de embalagem personalizado

Caso de renderização 3D de jóias

imagens de ensaio fotográfico

Estojo de vídeo para jóias de luxo

how to do OEM jewelry with sobling?

estudo e investigação de mercados

Explore o mercado, descubra os seus concorrentes e mantenha-se atualizado sobre as últimas modas de joalharia.

Criar os elementos da sua marca

Desenvolva uma identidade de marca distinta, incluindo um nome de marca e um logótipo convincentes, adequados para gravação nas suas peças de joalharia.

Reuniões, debates e projectos

Reunião e discussão com o Sobling para confirmar o design, incluindo a peça de joalharia e a embalagem, se necessário.

Efetuar amostras de ensaio e aprovação

Uma vez finalizado o projeto, as nossas instalações de produção iniciarão o processo de fabrico para criar o protótipo e as amostras de teste.

Encomenda e entrega a granel

Se estiver satisfeito com a amostra, sinta-se à vontade para fazer a sua encomenda oficial! Aceleraremos o processo de produção e envio para minimizar o tempo de espera e a entrega mais rápida.

What Our Clients Say About Sobling?

O que as pessoas dizem

O tempo de produção é rápido, a qualidade é sempre boa e a comunicação é incomparável. --- Vienna Domani

Get One piece Free 3D Design ( $99 Value ) — Available This Month Only

What is your competitive edge with Sobling OEM jewelry?

1. Maximize Every Dollar

2. Quality That Turns Heads

3.Launch Without Fear

4. Build a Brand That Lasts

5. Stay Ahead of the Curve

6. Your Brand, Your Way

Trabalhe com a Sobling nos seus projectos de OEM de jóias

Who Do We Serve?

- Marcas de jóias

- Vendedores de comércio eletrónico

- Vendedores de transporte direto

- Celebridades Personalizado

- Jewelry Retailers & Stores

- Jewelry Designers & Studios

Where Our OEM Services Are Used?

- Jewelry for Gift Campaigns

- Limited Collection Launches

- Wedding Jewelry Custom Orders

- Print-on-Demand Dropshipping Models

- Custom Jewelry for Celebrities & Influencers

Links externos úteis

A Sobling respeita os padrões de qualidade