Değerli Taş Renk Sırları: Mücevherleri Bilimle Geliştirin

Çağdaş veri tabanlı kalıplama teknolojisi

İçindekiler

Section I Colour Grading

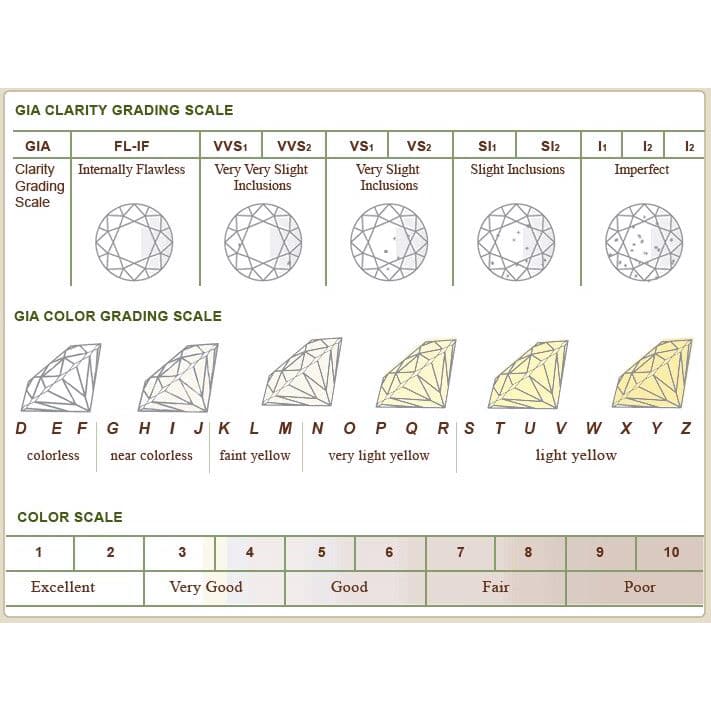

1. Characteristics of Diamond Colour Grades

Table 4-1 Classification Standards of Colour Grades by the World’s Major Diamond Grading Institutions

| GIA | China Standard (GB/T16554—2017) | CIBJO (1991) | HRD | IDC (1979) | |

|---|---|---|---|---|---|

| D | D | 100 | Exceptional White (+) | Exceptional White (+) | |

| E | E | 99 | Exceptional White | Exceptional White | |

| F | F | 98 | Rare White (+) | Rare White (+) | |

| G | G | 97 | Rare White | Rare White | |

| H | H | 96 | Beyaz | Beyaz | |

| I | I | 95 | Slightly Tinted White | Slightly Tinted White | |

| J | J | 94 | |||

| K | K | 93 | Tinted White | Tinted White | |

| L | L | 92 | |||

| M | M | 91 | Slightly Yellowish (Grade 1) | Slightly Yellowish (Grade 1) | |

| N | N | 90 | |||

| O | <N | <90 | Slightly Yellowish (Grade 2) | Slightly Yellowish (Grade 2) | |

| P | |||||

| Q | Slightly Yellowish (Grade 3) | Slightly Yellowish (Grade 3) | |||

| R | |||||

| S--Z | Slightly Yellowish (Grade 4) | Slightly Yellowish (Grade 4) | |||

2. Methods for Grading Diamond Colour

The method used for grading diamond colour is the traditional visual comparison method. Its principle is to first establish a complete set of standard colour comparison diamonds, then compare the sample to be judged with the standard stones to determine the diamond’s colour grade.

The following conditions should be met for diamond colour grading.

(1) Standard light source. The standard light source is a daylight lamp with a colour temperature of 5500~7200K. Under different light sources, the same diamond will exhibit slight colour differences (subtle colour changes). To ensure uniformity in colour grading, this condition is imposed so that laboratories and technicians around the world can grade diamond colour under the same conditions, ensuring consistency and comparability of results.

(2) Standard diamond comparison stones. Standard diamond comparison stones are a set of 7~10 diamonds whose colour grades have been calibrated, usually consisting of a set of stones. Each comparison stone represents the lower limit of that colour grade. Diamond colours range from white to yellow in the following sequence: D, E, F, G, H, I, J, K, L, M, with each diamond representing one colour grade (Figure 4–2). Comparison stones must meet strict requirements: each should weigh at least 0.25 ct, and the weights within a set should be approximately the same; clarity should be above Sl1; the cut should be the standard round brilliant; they should typically show no fluorescence or only very faint fluorescence under ultraviolet light; and aside from yellow, gray, or brown tones, comparison stones should have no other tints.

(3) Ideal laboratory environment. The ideal laboratory environment should be colour-neutral, meaning the surroundings are predominantly white or grey, with no direct sunlight or other colored light interference. The surface or V-shaped paper tray used to place the standard comparison stones and diamond samples should be pure white, non-fluorescent, non-reflective whiteboard or white paper, and there should be no colored objects nearby.

(4) Reference stones for comparing fluorescence intensity. This is a set of standard round brilliant-cut diamond samples calibrated at long-wave ultraviolet light intensity levels, consisting of 3 diamonds that respectively represent the lower limits of the strong, medium, and weak levels. Each diamond weighs not less than 0.20 ct. During grading, according to the intensity of the luminescence, they are classified in sequence into four levels: strong, medium, weak, and none.

(5) Trained graders. Diamond colour graders should receive specialised training, possess a certain ability to recognise colour, be familiar with the colour differences of each standard comparison stone, and be able to correctly master the colour grading procedures. They must be able to discern subtle colour differences and grade accurately. Usually, the operation should be performed independently by 2~3 persons, and can only determine the colour grade of the diamond after reaching consistent results.

(6) Operating steps. ① Clean the sample; ② Weigh; ③ Turn on the comparison lamp and place the comparison paper; ④ Arrange the comparison stones; ⑤ Compare the sample from left to right, with the line of sight parallel to the girdle or perpendicular to the pavilion of the diamond, until the final color approaches that of the comparison stone; ⑥ Pay attention to the area of concentrated color; ⑦ Change the distance and angle of the light source for observation; ⑧ Compare fluorescence intensity; ⑨ The duration of the color comparison operation should not be too long. The principle of the lower limit determines diamond colour comparison grading.

Section II Clarity Grading

1. Diamond Clarity Grading

Table 4-2 Diamond Clarity Grade Classification

| China (GB/T 16554—2017) | Gemological Institute of America (GIA) | International Jewellery Confederation (CIBJO) | International Diamond Council (IDC) | ||||

|---|---|---|---|---|---|---|---|

| Loupe Clean | FL | Kusursuz | FL | Loupe Clean | LC | Loupe Clean | LC |

| IF | Internally Flawless | IF | |||||

| Very Very Small Included | VVS1 | Very Very Slightly Included | VVS1 | Very Very Small Included | VVS1 | Very Very Small Included | VVS1 |

| VVS2 | VVS2 | VVS2 | VVS2 | ||||

| Very Small Included | VS1 | Very Slightly Included | VS1 | Very Small Included | VS1 | Very Small Included | VS1 |

| VS2 | VS2 | VS2 | VS2 | ||||

| Slightly Included | SI1 | Slightly Included | SI1 | Slightly Included | SI1 | Slightly Included | SI1 |

| SI2 | SI2 | SI2 | SI2 | ||||

| Piqué | P1 | Included | I1 | Piqué | P1 | Piqué | P1 |

| P2 | I2 | P2 | P2 | ||||

| P3 | I3 | P3 | P3 | ||||

2. Clarity Grading Rules of the "Diamond Grading" National Standard

Table 4-3 “Diamond Grading” National Standard (GB/T 16554-2017) Clarity Grading Rules

| Berraklık Derecesi | Definition | Relevant Rules & Explanations | |

|---|---|---|---|

| Loupe Clean (LC) | Under 10x magnification, no internal or external characteristics of the diamond are observed. Subdivided into FL and IF. | Types of Internal Characteristics: Pinpoint, Cloud, Light-colored crystal, Dark-colored crystal, Needle, Internal graining, Indented natural, Feather, Bearded girdle, Chip, Cavity, Etch channel, Grain boundary, Twinning wisp, Laser drill hole Types of External Characteristics: Natural, Surface graining, Polish lines, Scratch, Extra facet, Nick, Bruise, Abraded facet junction, Burn mark, Burn mark from dop, "Lizard skin" effect, Artificial inscription | |

| FL | Grade is FL if no internal or external characteristics are observed under 10x magnification. The following external characteristics are still acceptable for FL: ① An extra facet on the pavilion, not visible from the crown; ② A natural on the girdle, not affecting the symmetry of the girdle and not visible from the crown. | ||

| IF | Grade is IF if no internal characteristics are observed under 10x magnification. The following characteristics are still acceptable for IF: ① Internal graining that is non-reflective, colorless, and does not affect transparency; ② Extremely minor external characteristics that can be removed with minor repolishing. | ||

| Very, Very Slightly Included (VVS) | Under 10x magnification, the diamond has very, very small internal and/or external characteristics. Subdivided into VVS₁ and VVS₂. | ||

| VVS₁ | Grade is VVS₁ if the diamond has minute inclusions that are extremely difficult to see under 10x magnification. | ||

| VVS₂ | Grade is VVS₂ if the diamond has minute inclusions that are very difficult to see under 10x magnification. | ||

| Very Slightly Included (VS) | Under 10x magnification, the diamond has very small internal and/or external characteristics. Subdivided into VS₁ and VS₂. | ||

| VS₁ | Grade is VS₁ if the diamond has minor inclusions that are difficult to see under 10x magnification. | ||

| VS₂ | Grade is VS₂ if the diamond has minor inclusions that are relatively easy to see under 10x magnification. | ||

| Slightly Included (SI) | Under 10x magnification, the diamond has noticeable internal and/or external characteristics. Subdivided into SI₁ and SI₂. | ||

| SI₁ | Grade is SI₁ if the diamond has noticeable inclusions that are easy to see under 10x magnification. | ||

| SI₂ | Grade is SI₂ if the diamond has noticeable inclusions that are very easy to see under 10x magnification, but not visible to the naked eye. | ||

| Piqué (P) | Inclusions are visible to the naked eye when viewed face-up. Subdivided into P₁, P₂, and P₃. | ||

| P₁ | Grade is P₁ if the diamond has noticeable inclusions that are visible to the naked eye. | ||

| P₂ | Grade is P₂ if the diamond has obvious inclusions that are easily visible to the naked eye. | ||

| P₃ | Grade is P₃ if the diamond has extremely obvious inclusions that are very easily visible to the naked eye and may affect the durability of the diamond. | ||

3. Factors Affecting the Determination of Diamond Clarity Grading

The visibility of clarity characteristics is the main basis for determining the clarity grade. Visibility is determined by the size, number, position, nature, colour and contrast of clarity characteristics. Therefore, the clarity grade must be determined by comprehensively considering these characteristic factors. In some cases, potential threats that clarity characteristics pose to the durability of the diamond must also be taken into account.

(1) The nature of clarity characteristics. External characteristics have a relatively large impact on high-clarity diamonds, especially for LC-grade diamonds, where external characteristics usually determine the clarity grade. For diamonds below VVS grade, internal characteristics generally determine the clarity grade, with external characteristics used as a reference factor for grading.

(2) Size of clarity characteristics. The size of clarity characteristics is an important factor determining the clarity grade. The premise for clarity grading is observation under 10× magnification. Whether internal or external, the larger the clarity characteristic, the easier it is to see, and the lower the clarity grade. For example, even if a diamond has no internal characteristics, the presence of a large original crystal face prevents it from being assigned a high clarity grade; large internal characteristics are the decisive factor in determining clarity grade. In terms of clarity grading, HRD proposed a quantitative analysis method: measure the size of inclusions with a microscope and determine the diamond’s clarity grade accordingly. The IDC 5μm standard’s rule is an embodiment of quantitative evaluation. However, the quantitative method for evaluating diamond clarity has not been widely accepted or supported.

The so-called 5μm rule refers to, under 10× magnification, 5μm being the limit of resolution for most people’s naked eyes; that is, inclusions smaller than 5μm cannot be seen with the naked eye under 10× magnification. Therefore, it is taken as the dividing line for clarity grades.

(3) Number of clarity characteristics. The greater the number of clarity characteristics, the greater their visibility, and the lower the clarity grade. Even inclusions of the same size will result in a lower clarity grade when they are numerous rather than single or few, whether they are dispersed or clustered in the diamond. For example, clouds in a diamond are composed of numerous tiny fluid inclusions smaller than 1μm; under 10× magnification, individual inclusions cannot be resolved, but a large aggregation of small inclusions increases light scattering and forms a hazy cloud, reducing the diamond’s transparency. Clouds can lower a diamond’s clarity grade to P. In addition, if inclusions in the diamond create multiple reflections, that is another reason for a reduced clarity grade.

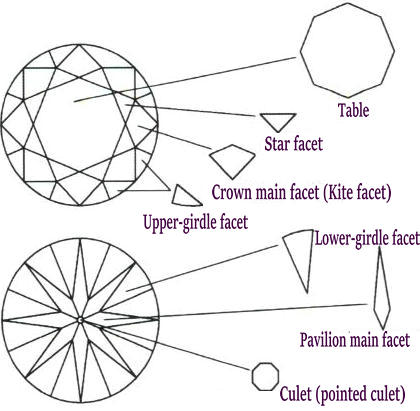

(4) Location of clarity characteristics. The same clarity characteristic can have different visibility depending on its location within the diamond. For example, a clarity characteristic of the same size is very easy to see when located in the centre of the table, whereas it is harder to detect near the girdle. Thus, identical clarity characteristics may lead to different clarity grades depending on their position. However, this effect is not as great as that of inclusion size and number, and it usually leads to a reduction of one small-level grade. For example, VVS1 does not permit needle-like inclusions located in the centre of the table; if present, they should be graded as VVS2. Inclusions near the crown facet junctions and in the pavilion main facet (culet) area can produce reflections. A single inclusion can produce multiple images through facet reflections, increasing its visibility and thus having a greater effect on clarity. Generally, clarity characteristics located directly beneath the table have the greatest impact on the clarity grade, followed by the crown, girdle, and pavilion.

(5) Colour and contrast of inclusions. Whether an inclusion is easy to detect in a diamond depends not only on its size and location but also on the contrast between the inclusion’s colour and the diamond’s body colour. Two inclusions of the same size and in the same position may differ in visibility if their colours or surface lustres differ. Black or colored inclusions are more conspicuous than colourless, transparent, or pale inclusions. Inclusions with strong surface lustre and high brightness are also easier to see. Therefore, under the same conditions, dark inclusions or highly bright inclusions will be judged as giving a lower clarity grade.

(6) Effect on durability. Fractures are inclusions that have a direct effect on durability. If a fracture causes the diamond to be at risk of breaking or creates a danger of a portion chipping out, it should be graded at the lowest clarity P3 level, even if the fracture has not yet seriously affected the diamond’s brilliance.

Section III Cut Grading

Cut refers to the entire technical process of cutting and polishing a diamond according to design requirements to produce an ideal diamond product. Among the “4 C” evaluation standards, cut is the only factor for assessing diamond quality that is controlled and determined by human craftsmanship and technique. The quality of the cut greatly affects a diamond’s colour, clarity, weight, and other attributes. A good cut can bring a diamond’s shape, size, proportions of its parts, polishing angles, symmetry, colour, optical effects, weight, and other aspects to ideal standards.

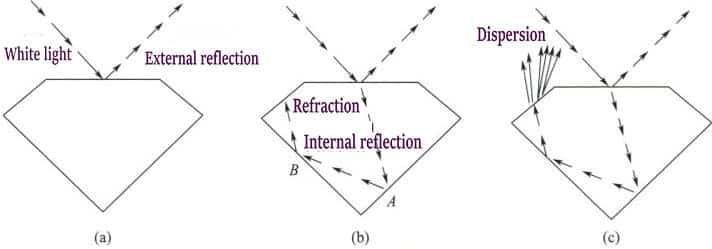

Diamond cutting can take different styles; in other words, the shapes, sizes and arrangements of a diamond’s individual facets can vary. But in any case, the cutting of a diamond must follow one principle: the polished diamond should have the most beautiful appearance, the best optical performance, and retain the maximum weight that the diamond should have. Most people are familiar with the attractiveness of a polished diamond and the effort to preserve maximum weight. Still, they may be less knowledgeable about the best optical performance, which is mainly determined by the diamond’s own physical properties. Diamonds are colourless and transparent, homogeneous isotropic bodies with a very high refractive index (2.417) and a strong dispersion value (0.044). A well-cut diamond radiates brilliance from its surface after cutting, manifested as the brilliance (the intensity of white light reflected from the diamond’s surface), the fire (the diamond’s ability to disperse white light into the various colours of the spectrum), and scintillation (the flashes of light seen on the diamond’s surface when it is moved), see Figure 4-4.

Figure 4-4 Diagram of diamond fire formation

(a) When a beam of light strikes the surface of a diamond, part of the light is reflected, called external reflection; (b) the remaining light passes through and is refracted into the diamond; the light reaches A point and B point on the diamond's surface inside the diamond, called internal reflection; (c) the light reflected to the diamond's surface is further broken down there into spectral colors, i.e., dispersion

1. Types of Diamond Cuts

In today’s global jewellery industry, many diamond cutting shapes are studied and designed, but the most common are the standard round brilliant, oval, heart, emerald, pear, marquise, and square cuts. Among these, the standard round brilliant cut is the most widespread, and the latter varieties are referred to as “fancy cuts.” For any rough diamond, when planning its cutting and polishing, the first preference is to cut it into the standard round brilliant, and only then consider cutting it into other shapes. The main reason is that the standard round brilliant cut best showcases the diamond’s characteristic beauty.

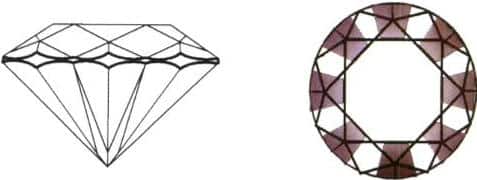

(1) Standard round brilliant cut. In 1919, Marcel Tolkowsky, based on the optical principles of diamonds, designed the optimal proportions and angles for cutting a round brilliant; this shape is called the “standard round brilliant” (Figures 4–5 to 4–7). This cut has a total of 58 facets (Figure 4–8, Table 4–4).

Figure 4-6 Standard round brilliant diamond side view

Figure 4-7 Standard round brilliant diamond top view

Table 4-4 Names of the Facets of a Standard Round Brilliant Diamond

| Part | İsim | Şekil | Miktar |

|---|---|---|---|

| Crown | Table | Regular Octagon | 1 |

| Bezel Facet | Quadrilateral | 8 | |

| Star Facet | Triangle | 8 | |

| Upper Girdle Facet | Triangle | 16 | |

| Girdle | |||

| Pavilian | Lower Girdle Facet | Triangle | 16 |

| Pavilion Main Facet | Quadrilateral | 8 | |

| Culet | 1 | ||

| Toplam | 58 |

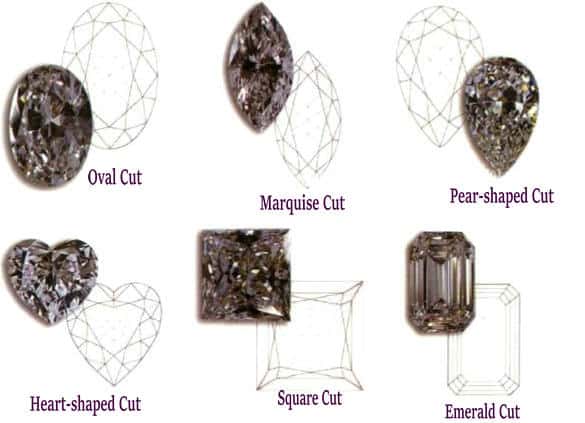

(2) Fancy cuts. Refers to modern diamond faceting styles other than the standard round brilliant cut. The common main types include oval, marquise, pear, emerald, heart, and square cuts (Figure 4–9).

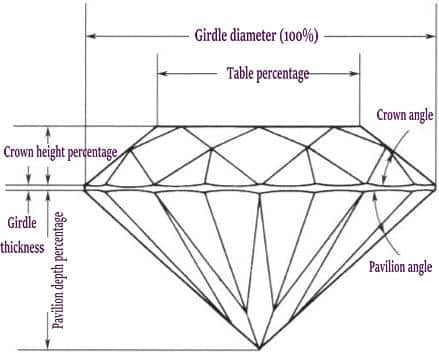

2. Proportions of the Standard Round Brilliant Cut

Cut proportions are the most important factor determining the quality of a diamond’s cut; when the cutting proportions are appropriate, the brilliance is good; otherwise, the brilliance is poor. The main proportions are as follows.

(1) Table width ratio. The proportion of the table’s width relative to the average diameter at the girdle.

(2) Crown height ratio. The proportion of the crown’s height relative to the average diameter at the girdle.

(3) Girdle thickness ratio. The proportion of the girdle’s thickness relative to the average diameter of the girdle.

(4) Pavilion depth ratio. The proportion of the pavilion’s depth relative to the average diameter at the girdle.

(5) Pavilion apex ratio. The ratio of the pavilion apex diameter to the average girdle diameter.

(6) Total depth ratio. The ratio of the vertical distance from the pavilion apex to the table to the average girdle diameter.

(7) Star facet length ratio. The ratio of the horizontal projection of the distance from the star facet vertex to the table edge (ds) to the horizontal projection of the distance from the table edge to the girdle edge (ds) (Fig. 4-11).

(8) Lower girdle length ratio. The ratio of the horizontal projection of the distance between the junction point of two adjacent pavilion main facets and the nearest point on the girdle edge (dl) to the horizontal projection of the distance from the pavilion apex centre to the girdle edge (dp) (Fig. 4-11).

Figure 4–11 Illustration of star facet length ratio and lower girdle facet length ratio

[According to "Diamond Grading" (GB/T 16554–2017)]

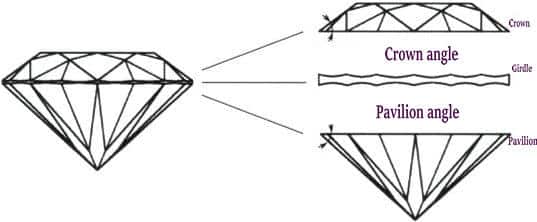

In addition to the ratios of the line segments mentioned above, two angles are also very important in the diamond cutting process. Although these angles are directly related to the ratios of the line segments mentioned earlier, in diamond cut grading, they are customarily listed separately to emphasize their importance.

(1) Crown angle. The angle between the main crown facet and the girdle plane.

(2) Pavilion angle. The angle between the main pavilion facet and the girdle plane.

Once the proportions of each part of the standard round brilliant cut are determined, the relative sizes of each part and the angles of the major facets are also established. For example, the crown angle is determined by the crown height ratio and table width ratio; the pavilion angle can be determined by the pavilion depth ratio, thereby defining the geometric shape of the standard round brilliant profile and achieving the purpose of evaluating the proportions of the standard round brilliant cut.

Copywrite @ Sobling.Jewelry - Özel takı üreticisi, OEM ve ODM takı fabrikası

3. Basic Methods for Evaluating Diamond Cut

There are two main basic methods for evaluating diamond cut: visual inspection and instrument measurement.

(1) Visual inspection. Using a 10× loupe, the proportions of the parts of a round brilliant are estimated directly by eye. This method is convenient, intuitive, and fast.

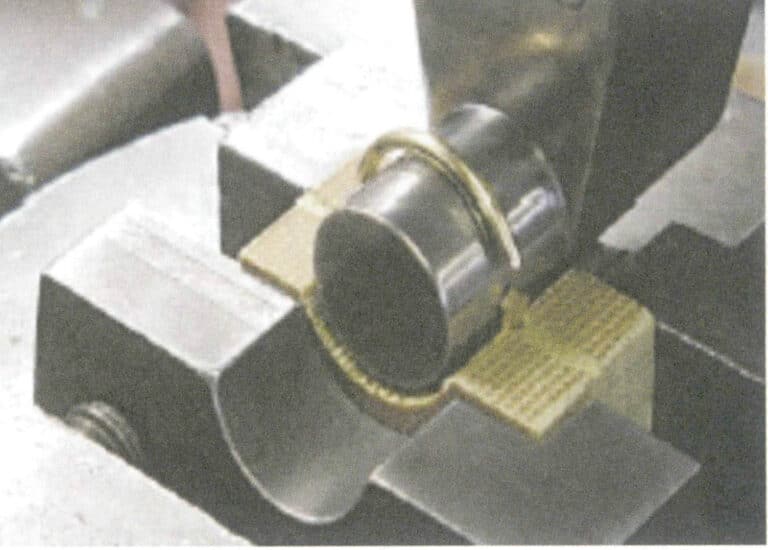

(2) Instrument measurement. Using a diamond proportion analyzer, the proportions of the diamond’s parts are measured precisely. This method is accurate and fast, but the instrument is not easy to carry.

As the diamond market places increasing importance on cut grading, the evaluation of diamond cut has become more refined. The national standard “Diamond Grading” (GB/T 16554–2017) divides diamond cut proportions into five grades: Excellent (abbreviated EX), Very Good (VG), Good (G), Fair (F), and Poor (P).

Using a fully automatic diamond cut proportion instrument under different table-to-diameter ratio conditions, measure values for items of the standard round brilliant cut such as crown angle (α), pavilion angle (β), crown height ratio, pavilion depth ratio, girdle thickness ratio, culet ratio, total depth ratio, α+β, star facet length ratio, lower girdle facet length ratio, etc., and determine the grade corresponding to each measured item; the overall ratio grade is represented by the lowest grade among all measured items. The national standard “Diamond Grading” (GB/T 16554–2017) lists the cut proportion grading tables for different table-to-diameter ratios for reference.

4. Finish Grading

Finish refers to the quality of the diamond cutting and polishing process and is another important factor in evaluating a diamond’s cut, divided into symmetry and polish. In terms of diamond cutting, although finish is less important than cut proportions, it can still affect the overall cutting outcome of the diamond.

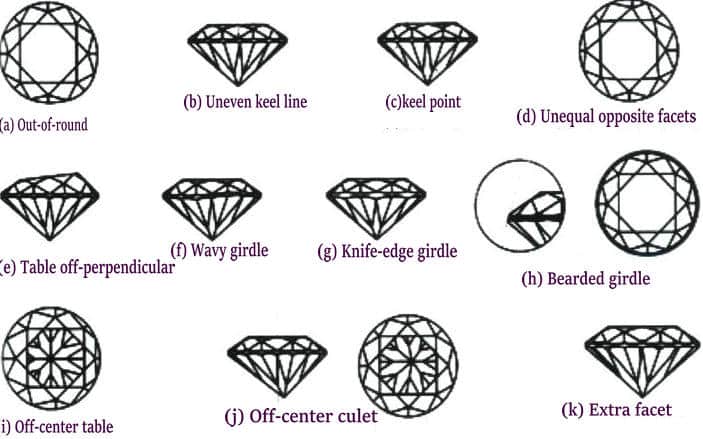

(1) Symmetry. Refers to the characteristics of shape, position, arrangement, and symmetry of the diamond’s various facets. The quality of symmetry has a certain effect on the brilliance of the standard round brilliant cut; symmetry deviations, however, will disrupt the uniformity and aesthetics of the geometric pattern of the standard round brilliant cut. Symmetry characteristics are mainly manifested in the following aspects (Fig. 4-12).

① Girdle not round. The diameters of the girdle measured at different positions are unequal. Generally speaking, if the difference between the maximum and minimum diameters of the girdle is less than 2%, it can be very good.

② Misalignment of crown and pavilion culets/points (crown and pavilion displacement). Observed from the girdle, the intersection point of the crown facets and the corresponding intersection point of the pavilion facets are not in the same vertical direction. This deviation is caused by differing rotation angles when polishing several main upper and lower facets, causing the corresponding upper and lower main facets to become misaligned, which in turn leads to the displacement of other facets and their intersection points.

③ Facet points are not sharp enough (facet junction angles are inaccurate). The facet edges do not meet at the points where they should; most commonly, the girdle area shows the crown and pavilion main facet edges either open or prematurely closed.

④ Facets of the same name are unequal in size (table octagon inconsistent, facets asymmetric). On the same diamond, facets bearing the same name vary in size. This is especially severe with unequal crown facets.

⑤ Table and girdle planes not parallel. Normally, the plane of the table should be parallel to the plane of the girdle, but cutting errors can cause these two planes to form an angle. This deviation is a fairly serious finishing fault and can affect the diamond’s brightness and fire.

⑥ Wavy girdle (girdle undulates up and down). A wavy girdle means the plane of the girdle is no longer parallel to the table but shows an up-and-down wave. A wavy girdle can produce the “bow-tie effect”: because the pavilion angles change, two corresponding directions in the pavilion suffer light leakage and appear dark, resembling a bow tie, hence the name “bow-tie effect” (Fig. 4-13).

⑧ Conical girdle. A conical girdle means the diamond’s girdle is not cylindrical but conical. A conical girdle results from improper crown or pavilion proportions—chiefly an overly high crown or an excessively deep pavilion—and is created when the diamond is re-cut to preserve as much of its original weight as possible, cutting the girdle into a conical form. Under 10× magnification, a conical girdle will show a “white ring” at the girdle; this “white ring” is more easily seen when the crown height is reduced.

⑨ Off-centre culet (culet not centred). Viewed from the side, the culet is not on the central symmetry point, or the table is off-centre; viewed from the table, the culet is displaced from the table’s centre point.

⑩ Extra facets (redundant small facet). Any surplus facets beyond the specified facets are called extra facets. Extra facets are caused by improper cutting and typically appear near the girdle, less often in the pavilion and crown. When extra facets are not visible from the table of the diamond, they usually have little effect on the cut; extra facets that can be seen from the crown more or less affect the diamond’s cut.

The national standard “Diamond Grading” (GB/T 16554–2017) divides symmetry into five grades.

① Excellent (EX). Under 10× magnification, no or very difficult-to-see features that affect symmetry.

② Very Good (VG). With the table facing up under 10× magnification, there are a few features that affect symmetry.

③ Good (G). Viewed table-up under 10× magnification, there are noticeable features that affect symmetry. To the naked eye, the overall appearance of the diamond may be affected.

④ Fair (F). Viewed table-up under 10× magnification, there are readily visible, large features that affect symmetry. To the naked eye, the overall appearance of the diamond is affected.

⑤ Poor (P). Viewed table-up under 10× magnification, there are significant, large features that affect symmetry. To the naked eye, the overall appearance of the diamond is noticeably affected.

(2) Polish. This refers to external features produced during the cutting and polishing process and is an assessment of the perfection of the polished surfaces. The quality of the polish directly affects the optical performance of the diamond. When the polish is very poor, it reduces the intensity of surface reflections and diminishes the diamond’s brilliance. Even if the diamond’s cut proportions are excellent, inadequate polishing can prevent it from shining brilliantly. Features that influence the polish grade include polishing lines, scratches, burn marks, chips, girdle abrasion, nicks, rough girdles, the “lizard skin” effect, burn marks from dop sticks, etc.

The national standard “Diamond Grading” (GB/T 16554–2017) divides polish into five grades:

① Excellent (EX). Under 10× magnification, no to very difficult-to-see features affecting the polish.

② Very Good (VG). Under 10× magnification with the table facing up, there are a few features affecting the polish.

③ Good (G). Under 10× magnification with the table facing up, noticeable features affecting the polish. To the naked eye, the diamond’s lustre may be affected.

④ Fair (F). When viewed table-up under 10× magnification, there are noticeable polishing-related features. To the naked eye, the diamond’s lustre is affected.

⑤ Poor (P). When viewed table-up under 10× magnification, there are pronounced polishing-related features. To the naked eye, the diamond’s lustre is noticeably affected.

5. Cut Grade

The national standard “Diamond Grading” (GB/T 16554–2017) divides cut grades into five levels: Excellent (EX), Very Good (VG), Good (G), Fair (F), Poor (P).

The cut grade is determined by a comprehensive evaluation based on proportion grade and finish (symmetry grade, polish grade); see Table 4-5.

Table 4-5 Rules for Dividing Cut Grades (according to national standard GB/T 16554-2017)

| Cut Grade | Polish \ Symmetry Grade | |||||

|---|---|---|---|---|---|---|

| Excellent (EX) | Very Good (VG) | Good (G) | Fair (F) | Poor (P) | ||

| Proportion grade | Excellent (EX) | Mükemmel | Mükemmel | Çok iyi | İyi | Zayıf |

| Very Good (VG) | Çok iyi | Çok iyi | Çok iyi | İyi | Zayıf | |

| Good (G) | İyi | İyi | İyi | Fair | Zayıf | |

| Fair (F) | Fair | Fair | Fair | Fair | Zayıf | |

| Poor (P) | Zayıf | Zayıf | Zayıf | Zayıf | Zayıf | |

Section IV Weight Grading

Carat weight is the most objective criterion among the diamond “4 C” evaluations and is directly related to a diamond’s price. The larger a diamond’s weight, the rarer it is, and the higher its value. When appraising and pricing diamonds in the trade, the first factor considered is their weight, followed by colour, clarity, and cut. It is generally believed that there is the following relationship between diamond weight and its price:

Diamond Price = (Carat Weight)2 × Base Price per Carat

This principle has been the basic rule for diamond pricing for over 200 years and still provides guidance today. Because of the immense importance of weight to a diamond’s price, diamonds are usually divided into many weight grades. For example, the famous De Beers company divides diamonds into more than 2,000 weight grades, then refers to colour, clarity, and cut to determine the price for each grade. Because diamonds are so precious and expensive that the “carat” was considered too coarse, the “point” was introduced as a unit of diamond weight, where one ct equals 100 points. When selling diamonds on the international market, the required precision for weight measurement reaches points, i.e., . However, whether indicated by GIA or HRD, diamond weights are reported to two decimal places, such as 1.08 ct, 0.32 ct, etc.

1. Weight Measurement of Rough Diamonds

The weight of a rough diamond can be measured directly with an electronic balance or an electronic carat scale; this yields the most accurate result.

Additionally, the weight of the diamond can also be obtained by determining the volume of the diamond particle and then multiplying it by the density of diamond.

2. Estimating the Weight of Set Diamonds

Set diamonds are generally not likely or permitted to be removed and weighed directly on an electronic balance (or electronic carat scale), so other methods must be used for measurement and estimation.

Usually, the dimensions of the various parts of the diamond are measured first, and then its weight is calculated using specific empirical formulas. The weight obtained in this way is called the “estimated diamond weight.” Although it has some errors compared with the diamond weight obtained by directly weighing with an electronic balance (or electronic carat scale), it is still a good method for determining the weight of set diamonds.

The Gemological Institute of America (GIA) has proposed several empirical formulas for estimating the weights of major diamond cutting styles:

(1) Round brilliant. Estimated diamond weight (ct) = Average girdle diameter2×Depth×0.0061.

(2) Oval. Estimated diamond weight (ct)=Average diameter2 ×Depth ×0.0062 (average diameter is the average of the oval’s long and short diameters).

(3) Heart. Estimated diamond weight (ct)= Length×Width×Depth×0.0061.

(4) Emerald (rectangular), marquise, pear. Estimated diamond weight (ct)=Length×Width ×Depth×Adjustment factor.

The adjustment factor in the above formulas is related to the length-to-width ratio of the diamond cut. First, calculate the length-to-width ratio, then choose the corresponding adjustment factor and substitute it into the above calculation formula to calculate the estimated diamond weight. The adjustment factors for the three cuts above are shown in Table 4–6.

Table 4-6 Weight Estimation Adjustment Coefficients

| Emerald Cut (Rectangle) | Marquise Cut | Pear Cut | |||

|---|---|---|---|---|---|

| Length-to-Width Ratio | Adjustment Factor | Length-to-Width Ratio | Adjustment Factor | Length-to-Width Ratio | Adjustment Factor |

| 1.00 : 1.00 | 0.0080 | 1.50 : 1.00 | 0.00565 | 1.25 : 1.00 | 0.00615 |

| 1.50 : 1.00 | 0.0092 | 2.00 : 1.00 | 0.00580 | 1.50 : 1.00 | 0.00600 |

| 2.00 : 1.00 | 0.0100 | 2.50 : 1.00 | 0.00585 | 1.66 : 1.00 | 0.00590 |

| 2.50 : 1.00 | 0.0106 | 3.00 : 1.00 | 0.00595 | 2.00 : 1.00 | 0.00575 |

Table 4–7 Corresponding Relationship between the Average Girdle Diameter and Weight for Standard Round Brilliant Cut Diamonds

| Average Diameter / mm | Approximate Weight/Ct | Average Diameter / mm | Approximate Weight/Ct |

|---|---|---|---|

| 2.9 | 0.09 | 6.2 | 0.86 |

| 3.0 | 0.10 | 6.3 | 0.90 |

| 3.1 | 0.11 | 7.2 | 1.39 |

| 3.2 | 0.12 | 7.3 | 1.45 |

| 3.3 | 0.13 | 7.4 | 1.51 |

| 3.4 | 0.14 | 7.5 | 1.57 |

| 3.5 | 0.15 | 7.6 | 1.63 |

| 3.6 | 0.17 | 7.7 | 1.70 |

| 3.7 | 0.18 | 7.8 | 1.77 |

| 3.8 | 0.20 | 7.9 | 1.83 |

| 3.9 | 0.21 | 8.0 | 1.91 |

| 4.0 | 0.23 | 8.1 | 1.98 |

| 4.1 | 0.25 | 8.2 | 2.05 |

| 4.2 | 0.27 | 8.3 | 2.13 |

| 4.3 | 0.29 | 8.4 | 2.21 |

| 4.4 | 0.31 | 8.5 | 2.29 |

| 4.5 | 0.33 | 8.6 | 2.37 |

| 4.6 | 0.35 | 8.7 | 2.45 |

| 4.7 | 0.37 | 8.8 | 2.54 |

| 4.8 | 0.40 | 8.9 | 2.62 |

| 4.9 | 0.42 | 9.0 | 2.71 |

| 5.0 | 0.45 | 9.1 | 2.80 |

| 5.1 | 0.48 | 9.2 | 2.90 |

| 5.2 | 0.50 | 9.3 | 2.99 |

| 5.3 | 0.53 | 9.4 | 3.09 |

| 5.4 | 0.57 | 9.5 | 3.19 |

| 5.5 | 0.60 | 9.6 | 3.29 |

| 5.6 | 0.63 | 9.7 | 3.40 |

| 5.7 | 0.66 | 9.8 | 3.50 |

| 5.8 | 0.70 | 9.9 | 3.61 |

| 5.9 | 0.74 | 10.0 | 3.72 |

| 6.0 | 0.78 | 10.1 | 3.83 |

| 6.1 | 0.81 | 10.2 | 3.95 |

| 6.4 | 0.94 | 10.3 | 4.07 |

| 6.5 | 1.00 | 10.4 | 4.19 |

| 6.6 | 1.03 | 10.5 | 4.31 |

| 6.7 | 1.08 | 10.6 | 4.43 |

| 6.8 | 1.13 | 10.7 | 4.56 |

| 6.9 | 1.18 | 10.8 | 4.69 |

| 7.0 | 1.23 | 10.9 | 4.82 |

| 7.1 | 1.33 | 11.0 | 4.95 |

By measuring the average diameter at the girdle, the approximate weight of a standard round brilliant diamond can be estimated. However, it should be noted that if the diamond’s cutting proportions are not standard—for example, if the girdle is very thick—this method will yield inaccurate results.

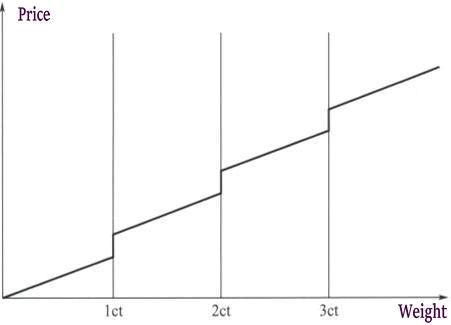

One noteworthy phenomenon regarding diamond weight is the carat step phenomenon. Because most people prefer whole-carat diamonds, diamond prices show a step-like increase at whole-carat points, called Carat Premiums or Carat Steps (Figure 4-15). This is caused by market demand and is a basic rule of how weight affects diamond price. The per-carat price of a full one-carat or slightly heavier diamond is higher than that of a 0.9-carat stone; similarly for full two-carat and three-carat stones. In short, the per-carat price of diamonds at each whole carat increases in a stepwise fashion—at least up to 10 ct, beyond which the premium effect diminishes. Carat premiums also appear at common, simple fractional carat marks, such as 1/4, 1/3, 1/2, and 3/4 in the market.

The carat premium phenomenon is also closely related to the quality of the diamond. Generally speaking, for high-quality diamonds, the carat steps are very distinct and the premium is large; for relatively lower-quality diamonds, the carat steps are less obvious and the premium is smaller.