Mücevher Dökümü Hakkında Bilmeniz Gerekenler: Malzeme Hazırlamadan İleri Tekniklere

The basic principles and operational skills for 5 typical tasks

Jewelry is widely made using casting, which is the process of melting metal raw materials and pouring them into a mold to obtain castings after cooling. There are two methods for jewelry casting: manual operation and automatic operation. The former involves melting the metal using a torch or induction furnace and then manually pouring it into the casting mold; the latter is done in an automatic casting machine that integrates melting and pouring. To achieve excellent casting results, melting metals often employ a method of first vacuuming and then filling with inert gas for protection to improve melting quality, and precise melting temperature control is achieved through program settings. Due to the relatively delicate structure of jewelry pieces, relying solely on gravity pouring cannot ensure that the castings fill the mold and solidify properly, necessitating the introduction of external forces to promote metal filling and increase compensation pressure. Depending on the method of introducing external force, jewelry pouring can be done through vacuum suction casting, vacuum pressure casting, vacuum centrifugal casting, etc. In production, choosing suitable melting and pouring processes is necessary based on the material properties and product structural characteristics. Additionally, in jewelry production, profiles (materials with fixed shapes such as wire and pipe) are often processed, and profiles are mainly prepared through vacuum continuous casting of molten metal. The melting and pouring of raw metal materials involve knowledge from various disciplines, such as materials, machinery, metallurgy, and casting, with many factors affecting casting quality. A scientific production process must be established and strictly followed to ensure high-quality and stable casting quality.

This project enables you to master the basic principles and operational skills of vacuum suction casting, vacuum pressure casting, vacuum centrifugal casting, and vacuum continuous casting through 5 typical and post-class extension tasks.

Vacuum suction casting machine

İçindekiler

Section I Material Preparation

1. Arka Plan Bilgisi

(1) Composition of Charging Materials

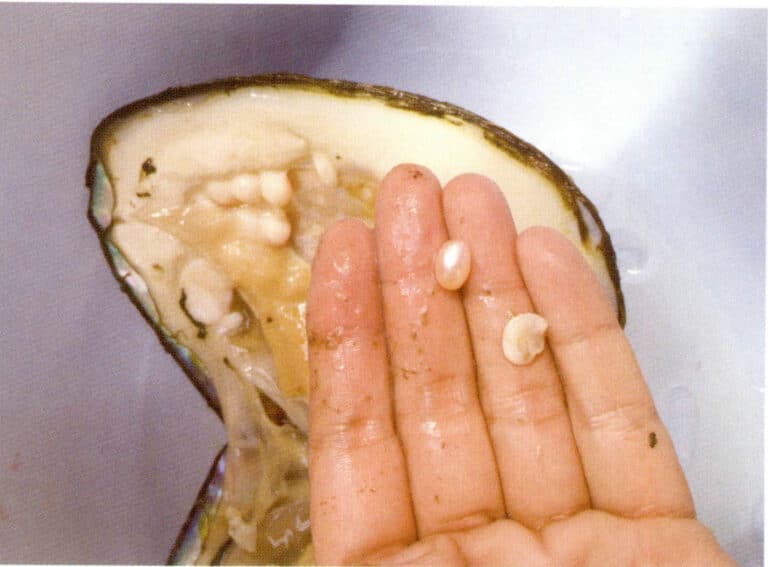

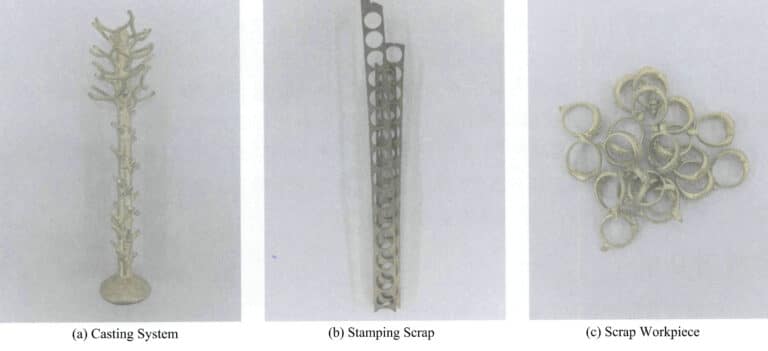

In jewelry production, the materials are not all converted into products, and various waste materials are generated, including the casting system during pouring, edge scraps during stamping, and defective workpieces during the production process, as shown in Figure 7-1. These waste materials are usually recycled to reduce the amount of new materials.

Waste materials often have dirt on their surfaces; for example, the casting system may have residual gypsum casting powder and oxidized impurities, edge scraps from stamping may have oil stains, and defective workpieces may contain impurities, etc. If these are recycled directly without treatment, it will affect the color and metallurgical quality of the materials. Therefore, for waste materials during the production process, it is necessary to determine their material categories before reuse to avoid mixing; cleaning waste materials should avoid oxidized impurities, dirt, etc.

To ensure the stability of product quality, it is necessary to correctly handle the ratio of new materials to recycled materials during batching. Many filler material suppliers suggest that the proportion of recycled materials in each batch should be 30%; However, in actual production, except for some simple parts with a higher casting yield, many products have a yield of only around 50% or even lower. If the required recycling ratio is followed, a large amount of recycled material generated daily cannot be reused in time and quickly accumulates, leading to significant material management and production cost issues for jewelry manufacturing companies. Therefore, many companies use a recycled material proportion exceeding 50% during batching, sometimes even reaching as high as 70%. It is important to note that alloys inevitably become contaminated during melting and casting. If the proportion of recycled materials is too high, it can cause fluctuations in filling performance and other properties of the alloy. The easily volatile elements in the alloy will decrease, increasing the probability of oxidation inclusions and insufficient pouring defects.

(2) Density

Density is the mass per unit volume of a substance, represented by the symbol ρ. In the International System of Units and China’s legal measurement units, the unit of density often uses kg/cm3, while in production, the unit g/cm3 is often used. In metallic materials, metals with a density less than 5.0×103 kg/cm3 are referred to as light metals, while those with a higher density are called heavy metals. According to this classification method, all precious metal jewelry materials fall under the category of heavy metals.

The selection range of filler material alloy elements is quite broad in precious metal jewelry alloys. Each alloy element has its atomic mass and corresponding density, and different filler material compositions will have varying densities. The density of materials within the same category is not constant but is influenced by the material’s chemical composition and internal structure. Materials with a dense internal structure will have a higher density than those with internal void defects. For a certain material’s jewelry product, if its density is detected to be lower than the theoretical density, it can indirectly reflect the internal void situation of the product. Changes in external environmental factors such as temperature and pressure can also affect material density to a certain extent, but the degree of influence is related to their range. When heated to a certain temperature at room temperature, the density of materials generally decreases slightly with increasing temperature. When the temperature reaches the melting point of the metal, and the metal melts into a liquid state, the density of the material significantly decreases.

Density is an important characteristic of materials. It can be used to identify the type of material, detect the content of precious metals such as gold and silver, and determine whether the material is dense, hollow, or loose based on its density. In jewelry casting production, the relative density of precious metal materials and wax is often used to calculate the required materials for batching.

2. Görev Uygulaması

This task uses 18K rose gold pre-melt and recycled materials to achieve a fineness of 18K and a rose red color.

(1) Cleaning of Recycled Materials

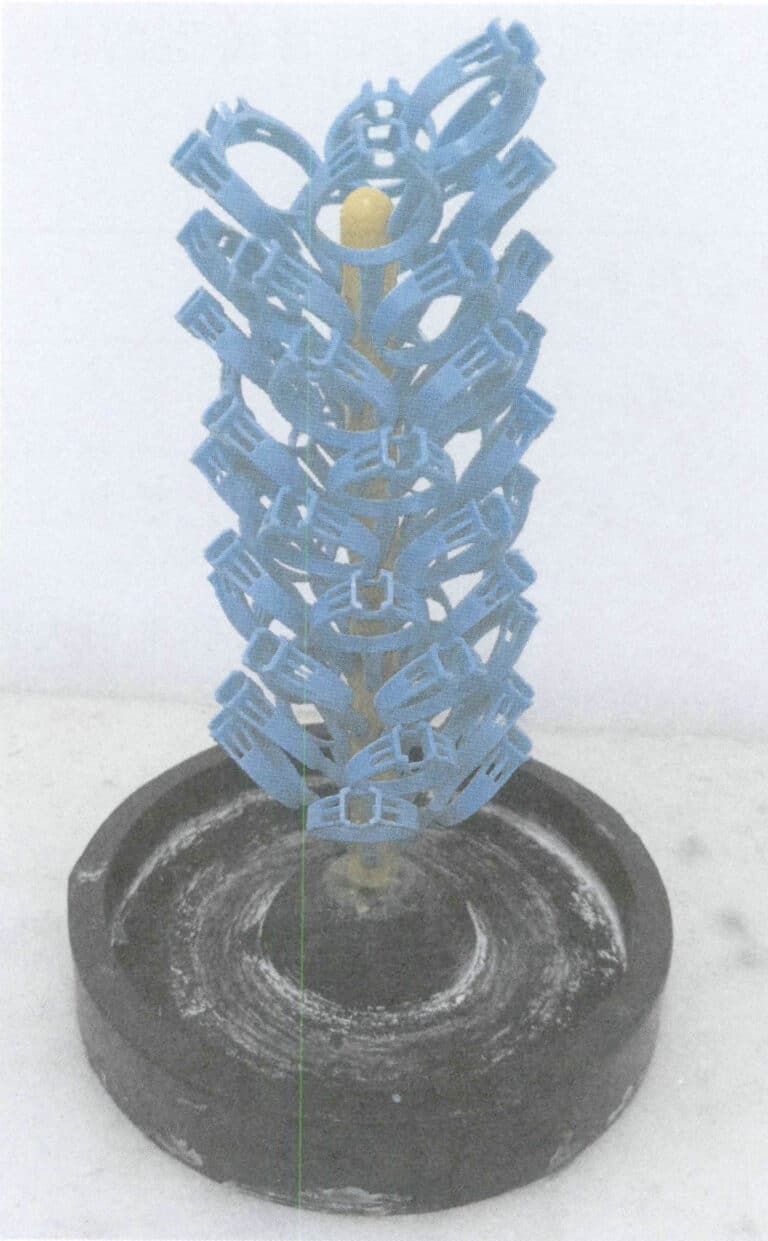

Check the types of recycled materials and select the parts with clear components, such as metal tree cores, pouring tree heads, residual sprues, scrap castings, etc.; then check the surface condition of the recycled materials. If there are residual casting powders, surface oxidation, slag, oil stains, and other dirt, use a magnetic tumbler or sandblasting machine to clean the surface, as shown in Figure 7-2.

(2) Pre-alloying of New Materials

Prepare the materials according to the internal control requirements for 18K gold; refer to Project 6 for specific operations.

(3) Charging Material Decomposition

Oversized or overly long charging materials must be decomposed into smaller pieces for accurate mixing and melting in the furnace. Large bolt cutters or electric punching machines can be used for processing, and the operation method can be found in Project 6.

(4) Mixing

Check the weight of the wax model tree measured during the production of each gypsum casting mold and calculate the required metal charging material for this steel flask casting mold based on the density comparison between the wax material and the metal charging material. In this case, the weight of the wax model tree is 30 g, the density of the wax is 0.95 g/cm3, and the density of rose gold is 16 g/cm3, so 505 g of material is needed. To ensure that the metal model tree head has a certain height after pouring, it is generally increased by about 20 g on top of the calculated value during production, resulting in a total material amount of 525 g.

To ensure metallurgical quality and avoid waste accumulation, configure the recycled material to match the ratio of the new material : the old material= 6 : 4. The amount of new material added is 315 g, and the amount of recycled material added is 210 g.

(5) Labeling

Place the prepared furnace charge in the material basin, label it with material type, quality, and steel flask number, and have it picked up by the pouring personnel.

(6) End of Work

After completing the batching, submit the precious metal materials, turn off the electronic balance, and clean the work area.

Section II Vacuum Casting

1. Arka Plan Bilgisi

1.1 Metal Liquid Pouring Methods

Pouring is the process of injecting molten metal into the cavity of a casting mold. Since jewelry pieces are relatively fine products, the molten metal solidifies quickly during the pouring process and loses its fluidity. Therefore, conventional gravity pouring is difficult to ensure proper shaping, and some external force must be introduced to promote the rapid filling of the cavity with molten metal, resulting in castings with complete shapes and clear outlines.

According to the method of using external force during the pouring process, metal liquid pouring methods can be divided into two main categories: centrifugal casting and vacuum suction casting; based on the degree of automation in pouring, it can be divided into manual pouring and automatic pouring by casting machines.

(1) Centrifugal Casting and Vacuum Suction Casting

Centrifugal casting involves pouring molten metal into a rotating casting mold, where the molten metal fills the casting mold and solidifies under centrifugal force. Centrifugal casting has high production efficiency, significant metal pressure, and fast filling speed, which is beneficial for the shaping of castings, especially suitable for pouring small accessories like chain links and ear studs, as well as high-melting-point platinum jewelry. Compared to vacuum suction casting, traditional centrifugal casting has some weaknesses: due to the fast filling speed, the molten metal experiences severe turbulence during pouring, increasing the likelihood of gas entrapment; the gas discharge speed within the cavity is relatively slow, resulting in high back pressure inside the casting mold, which increases the probability of gas holes; when the filling pressure is too high, the molten metal can severely scour the mold walls, easily leading to casting mold cracking or peeling; additionally, during pouring, slag may enter the cavity along with the molten metal. Due to the high filling pressure brought by centrifugal force, the maximum amount of metal that can be safely cast using centrifugal casting is less than that of vacuum suction casting.

Vacuum suction casting is a process in which an external vacuum is used to reduce the internal pressure of the casting mold to below atmospheric pressure, allowing the molten metal to fill the cavity not only by its weight but also by an additional pressure difference. Compared to centrifugal casting, the filling process of vacuum suction casting is relatively gentle, with less scouring effect of the molten metal on the mold wall; due to the vacuum effect, the gas back pressure in the cavity is smaller, and the maximum amount of metal cast in one go is larger. Therefore, this casting method has been widely used in jewelry casting, especially suitable for casting large and medium-sized ornaments, such as men’s rings, pendants, bracelets, etc.

(2) Manual Pouring and Automatic Pouring by Casting Machines

Manual pouring is generally done with torch melting or induction melting furnaces. After the molten metal is refined and slag is removed, the temperature is adjusted to the pouring temperature range, and then the mold is taken out from the burnout furnace in preparation for pouring. Depending on the type of equipment used, manual pouring mainly includes centrifugal pouring and vacuum suction casting. Manual centrifugal pouring uses a simple mechanical transmission centrifugal machine used in some small jewelry processing factories. It does not come with an induction heating device, oxygen, or liquefied petroleum gas to melt the metal or an induction furnace to melt the metal and pour the molten metal into the crucible for centrifugal pouring. Manual negative pressure pouring is the simplest form of vacuum suction casting, using equipment known as vacuum suction casting machines, as shown in Figure 7-3. The main component of this machine is the vacuum system, which is without a heating melting device, so it needs to be used in conjunction with a torch or melting furnace. After melting, the molten metal is manually poured into the mold. The operation is relatively simple, with higher production efficiency, and it has been widely used in small and medium-sized jewelry processing factories. Since pouring is done under atmospheric conditions, there is a problem of secondary oxidation and gas absorption of the molten metal. The entire pouring process, including pouring temperature, pouring speed, head height, and handling of the slag on the liquid surface, is controlled by the operator, so many factors can affect quality.

1.2 Filling Performance of Molten Metal

The ability of molten metal to fill the mold cavity, resulting in castings with complete shapes and clear outlines, is called the filling performance of molten metal. The main factors affecting the filling performance of molten metal are the fluidity of the molten metal itself, as well as the properties of the mold, pouring conditions, and the structure of the casting.

(1) The Impact of the Fluidity of Molten Metal on Filling

A good casting can be obtained only when the molten metal fills the cavity. This filling ability of molten metal is called fluidity. The fluidity of liquid metal is one of the important casting properties of metals. Good fluidity of molten metal can help remove gases and non-metallic inclusions before pouring or float them out during the pouring and solidification process, improving the internal quality of the casting, which is beneficial for obtaining castings with precise dimensions and clear outlines, which is advantageous for the casting to receive timely replenishment of molten metal during solidification, preventing the formation of shrinkage cavities and porosity defects.

The internal factors affecting molten metal’s fluidity are mainly the alloy’s chemical composition, and there is a certain regularity between the fluidity of the alloy and its composition. For example, under the same degree of superheating, pure gold’s fluidity is better than pure platinum’s. If the jewelry material contains easily oxidizable alloy elements, they may oxidize into insoluble oxide inclusions during melting, worsening the molten metal’s fluidity. In summary, any factor that increases the friction resistance between the molten metal and the mold or causes a decrease in the metal temperature will reduce the fluidity of the molten metal.

(2) The Influence of Casting Mold Properties on Filling

If the casting mold material (such as metal molds) has good thermal conductivity, the molten metal will cool quickly after pouring, resulting in a short insulation time, and the fluidity will sharply decrease, leading to a decline in filling capacity, conversely, if the casting mold (such as gypsum casting molds) has poor thermal conductivity, the molten metal will cool slowly, improving the filling capacity. Preheating the casting mold can reduce the temperature difference between the molten metal and the casting mold, slowing down the cooling rate of the molten metal and extending the liquid time, thereby improving the filling capacity. When gas is not discharged smoothly from the casting mold cavity, it will hinder the flow of the molten metal.

(3) The Influence of Pouring Conditions on Filling

Increasing the pouring temperature is beneficial for improving filling capacity. The greater the pressure exerted on the molten metal in the direction of flow, the better the filling capacity.

(4) The Impact of Casting Structure on Filling

When the volume of the casting and the pouring conditions are the same, castings with a larger equivalent thickness (the ratio of casting volume to surface area) have a relatively smaller contact surface area with the mold, resulting in slower heat loss and higher filling capacity. The thinner the wall of the casting, the harder it is to fill. The more complex the casting, the more complex the mold cavity structure, with more bends, leading to greater flow resistance, making mold filling more difficult.

1.3 Ways to Form a Vacuum

2. Görev Uygulaması

(1) Verifying Material and Product Structure

Before melting and pouring, determine the product’s material to be poured, check the prepared charge, and inspect the cleanliness of the charge to avoid contamination of the furnace. At the same time, verify the type and structure of the product in the casting mold and set the pouring temperature to 1010℃.

(2) Preparation for Melting and Pouring

The melting crucible should be a dedicated crucible for brass, and the cleanliness of the crucible’s interior should be carefully checked, removing any residual metal beads, slag, etc., to avoid contaminating the molten metal. Place the crucible into the induction coil, ensuring the bottom is supported with a heat-resistant pad. Please turn on the cooling water, switch on the induction power supply, check the equipment status, and only use it after confirming it is normal.

Check the condition of the vacuum casting machine, place a graphite packing in the socket seat, and put a dedicated unburned gypsum casting mold into it. Turn on the vacuum pump and check whether the equipment is vacuuming normally; the pointer should quickly move to -0.1MPa when normal. If the vacuum level does not drop for a long time, check for air leaks at the graphite packing, adjust the position of the graphite packing, clean the flask flange, and then conduct a vacuum test again. The vacuum oil should be replaced if the vacuum level does not meet the requirements.

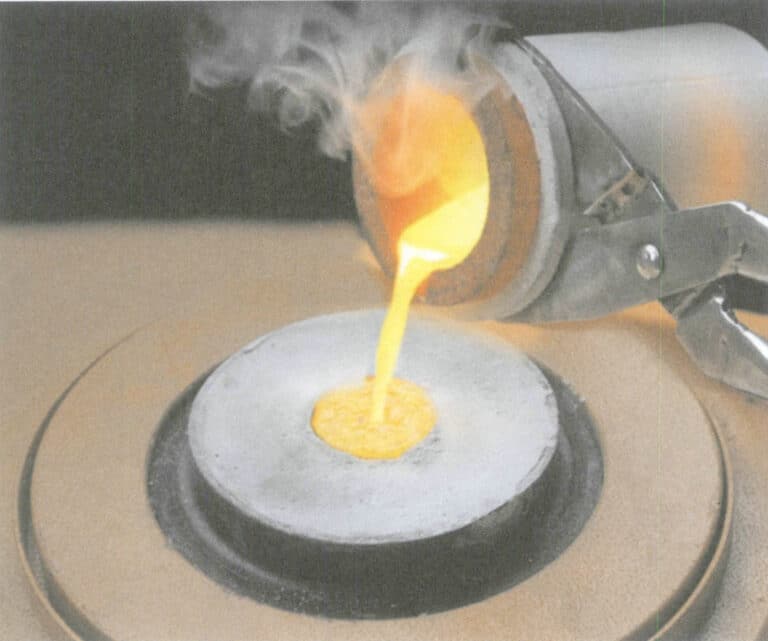

(3) Melting Furnace Charging Materials

Add brass materials to the crucible, ensuring they are not packed too tightly to avoid the “material jamming” problem (where materials press against each other, preventing them from descending evenly). Press the “Heating” button to start heating; adjustments to the current during heating should not be too rapid, especially after the materials melt, to avoid overheating the molten metal (Figure 7-8). During the melting process, pay attention to the downward movement of the materials; if “material jamming” occurs, promptly clear the materials. To reduce oxidation of the molten metal due to air exposure, cover the surface of the molten metal with crushed charcoal for protection. Add the returned materials to continue melting once the pre-melted materials have melted completely. After melting, stir the molten metal with a glass rod to ensure uniform composition and temperature. Adjust the power of the induction furnace to keep the molten metal in a heat-preserving state.

(4) Placing the Gypsum Casting Mold

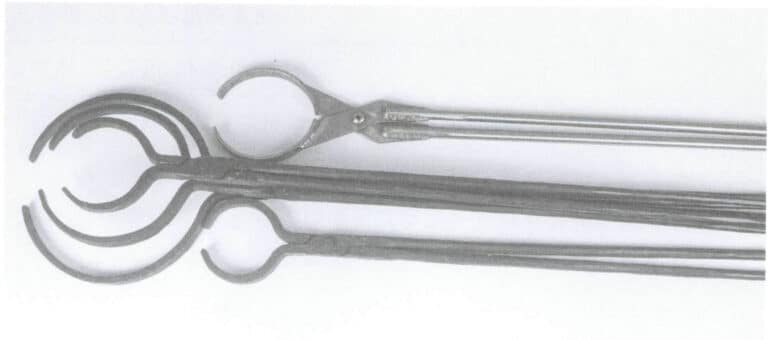

A steel flask clamp takes the gypsum casting mold out of the burnout furnace and places it into the vacuum casting machine’s socket, as shown in Figure 7-9. Attempt to create a vacuum and check the sealing performance. Rotate the casting mold to ensure a good fit between the flange and the graphite packing, achieving the required vacuum level.

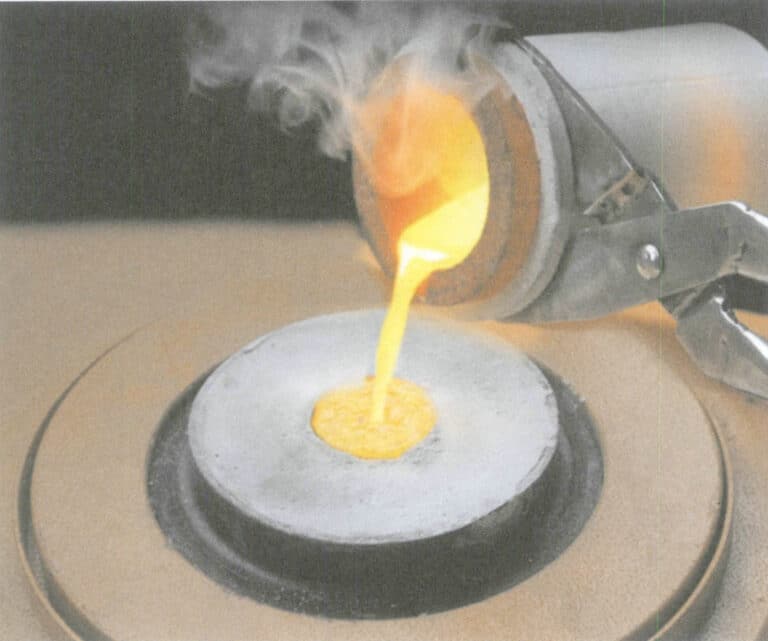

(5) Pouring

Use a glass rod to remove the slag from the surface of the molten metal, stop heating, and use crucible pliers to hold the crucible, aligning the crucible spout with the mold pouring cup, and steadily pour molten metal into the mold. During the pouring process, the flow must not be interrupted; control the speed by starting slow, then fast, and finally slow again. Be careful not to let the molten metal overflow from the pouring cup, as shown in Figure 7-10.

(6) Removing the Casting Mold

After pouring, vacuum for 2~3 min until the molten metal in the pouring cup solidifies. Then turn off the vacuum extractor and open the gas valve waiting for the air pressure in the pouring chamber to return to normal pressure, then use a steel flask tong to grip the edge of the steel flask and vertically pull the casting mold out, placing it in the designated position to cool.

(7) End of Work

After pouring all casting molds, place the crucible in the designated position and cover it with refractory cotton. The induction melting furnace should continue circulating cooling water for 30 minutes before it can be shut down. Clean the equipment and work area using a broom, vacuum cleaner, cloth, etc.

Section III Vacuum Pressure Casting

1. Arka Plan Bilgisi

In the jewelry casting process, attention must be paid to the casting performance of the metal. The casting performance of an alloy is mainly measured by indicators such as filling ability, shrinkage, segregation, and gas absorption. A strong filling ability makes it easier to obtain castings with clear outlines and exquisite patterns, reducing defects such as unclear outlines, insufficient pouring, and cold shuts; it is beneficial for the gas and non-metallic inclusions in the molten metal to rise and be discharged, reducing defects like porosity and slag inclusion. Shrinkage refers to the phenomenon of volume reduction that occurs in castings during solidification and cooling. The smaller the shrinkage produced by the liquid metal poured into the mold during solidification, the easier it is to obtain flawless casting. If solidification and shrinkage are not properly controlled, defects like shrinkage cavities, shrinkage porosity, deformation, and cracks will appear inside the casting. Segregation refers to the phenomenon of uneven chemical composition in the casting. Segregation is a casting defect that should be avoided or minimized for precious metal jewelry, as it directly affects the quality of the product. Gas absorption refers to the property of the alloy to absorb gas during melting and pouring. Excessive gas absorption will lead to the formation of pores in the casting. Pores can damage the continuity of the alloy, reduce the effective load-bearing area, and cause stress concentration near the pores, leading to a decrease in the mechanical properties of the casting and deterioration of surface quality.

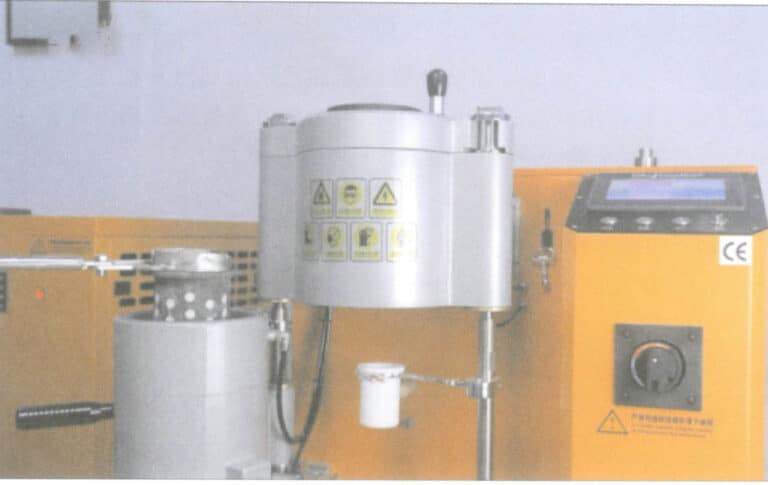

The jewelry casting process involves many technological elements, all of which can directly or indirectly impact the metal casting performance and the quality of the blank. Casting defects are often the result of the accumulation of various factors throughout the entire process. Manual melting and pouring methods are traditional experiential production methods where the subjective factors of the operator are significant, leading to large fluctuations in product quality. With the increasing quality requirements for jewelry products and the technological advancements in the jewelry industry, automatic casting machines have become very important equipment in the lost-wax casting of jewelry, serving as an important foundation for ensuring product quality. The induction melting vacuum pressure casting machine is the most widely used automatic casting equipment. There are many models of such machines, and the casting machines produced by different companies have their own characteristics. Still, they generally consist of an induction heating system, a vacuum system, a control system, etc. Structurally, they are generally upright, with the upper part as the melting chamber, the middle part as the casting chamber, and the lower part as the lifting cylinder, as shown in Figure 7-11.

The casting chamber is cylindrical, with a sealing rubber ring set at the center of the top opening, and a flange socket is set inside, which is matched with the flask flange plate through graphite packing, similar to the setup of a vacuum suction casting machine. A lifting cylinder is set at the bottom of the inner cavity of the casting chamber. When the casting chamber rotates outward clockwise, the lifting cylinder automatically rises to place the mold; when the casting chamber rotates inward counterclockwise, the cylinder automatically descends, allowing the mold flange to hover on the flange socket. A lifting cylinder is also set directly below the casting chamber, which, when raised, ensures that the sealing ring at the top of the casting chamber is in close contact with the bottom of the melting chamber. The melting chamber is also cylindrical, with a furnace cover on top and an observation window. A sealing rubber ring is set at the center of the top opening of the melting chamber, and after locking the furnace cover, raising the casting chamber containing the mold can create independently sealed chambers for the melting chamber and the casting chamber, thus allowing the metal liquid to be poured and solidified under different air pressures.

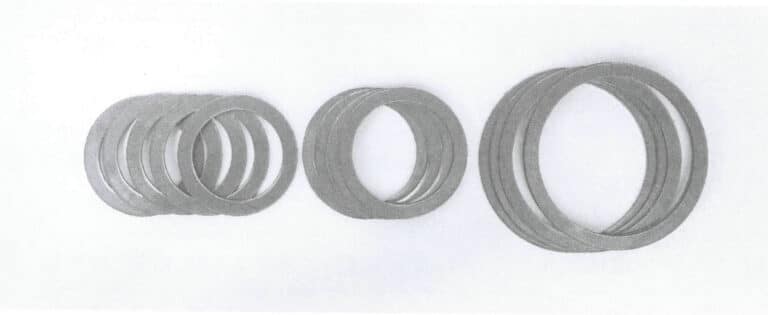

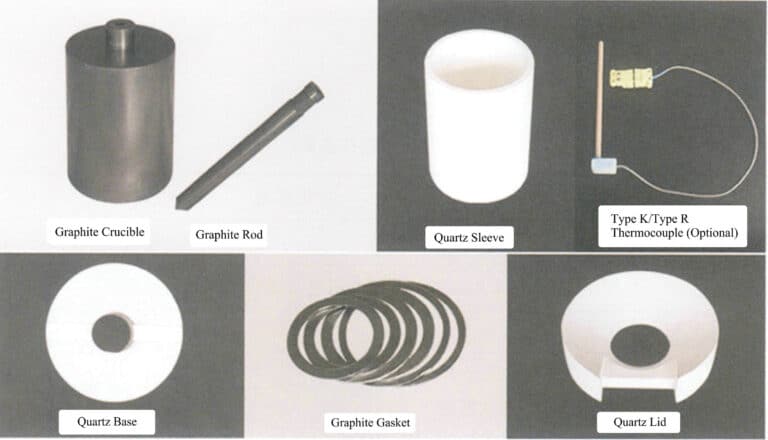

Common consumable parts for vacuum pressure casting machines include graphite crucibles, graphite rods, quartz outer shells, thermocouples, quartz bases, and gaskets, as shown in Figure 7-12. When melting conventional jewelry materials such as gold, silver, and copper, graphite crucibles are used, with quartz outer shells fitted outside the graphite crucibles to reduce the burning loss of the graphite crucibles. When using a bottom-pour casting method, a pouring hole is opened at the bottom of the crucible, and the opening and closing are controlled by a graphite rod—during melting, the graphite rod completely blocks the pouring hole under air pressure to prevent the metal liquid from leaking; during pouring, the graphite rod is lifted, allowing the metal liquid to flow into the mold cavity. A thermocouple for temperature measurement is installed inside the graphite rod, which can accurately reflect the temperature of the metal liquid. Vacuum pressure casting machines generally melt and cast metals in a vacuum state or inert gas, thus effectively reducing the possibility of metal oxidation and gas absorption; they widely use computer programming control, achieving a high degree of automation; the quality of the cast products is relatively stable, with fewer hole defects, making this equipment highly regarded by many manufacturers and widely used for vacuum casting of metals such as gold, silver, and copper. Some models even come with granulation devices that can prepare granular intermediate alloys.

Video 7-1 Manual operation of vacuum pressure casting

Video 7-2 Automatic program of vacuum pressure casting

Copywrite @ Sobling.Jewelry - Özel takı üreticisi, OEM ve ODM takı fabrikası

2. Görev Uygulaması

This task uses a vacuum pressure casting machine to melt and cast 925 silver jewelry.

(1) Verifying Material and Product Structure

Before melting and pouring, determine the material of the product to be poured, check the prepared 925 silver charge, and inspect the cleanliness of the charge to avoid bringing dirt into the furnace. At the same time, verify the type and structure of the product inside the casting mold and set the pouring temperature to 980℃.

(2) Preparation for Melting and Pouring

Check for any residual metal beads in the crucible; if present, they must be cleaned out to avoid contaminating the molten metal. Please turn on the chiller and air compressor, align the graphite rod with the pouring hole at the bottom of the crucible, and press it tightly using a cylinder, checking the tightness of the connection. Turn on the power of the vacuum pressure casting machine and check if the thermocouple displays normally. Wipe the observation window of the melting chamber with a soft cloth and anhydrous alcohol. Check the sealing condition of the casting chamber, place graphite packing in the socket, and put a dedicated unsintered gypsum casting mold inside, then turn on the vacuum pump to test if the vacuum function of the equipment is normal.

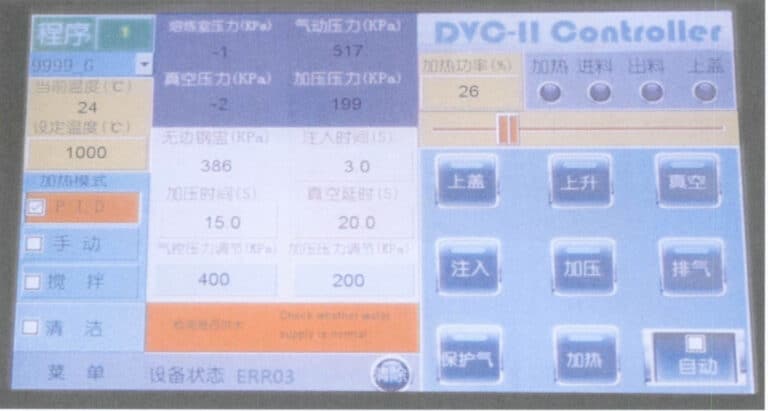

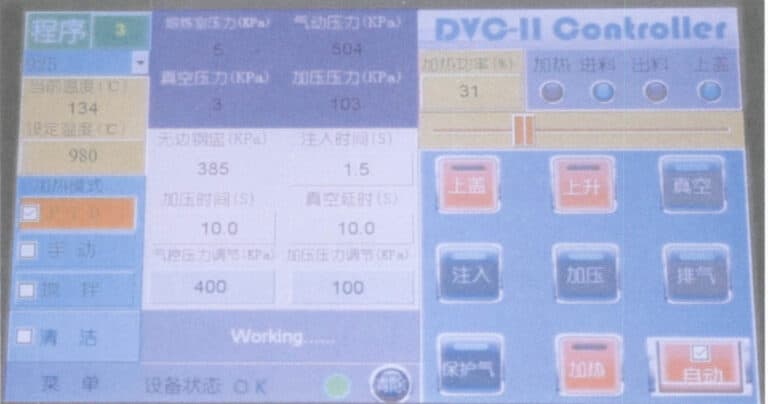

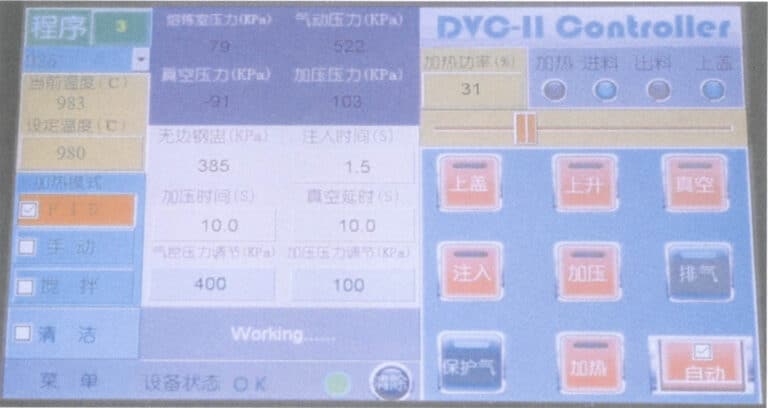

Enter the operating interface, select the preset 925 silver casting program, choose PID mode, and check each preset process parameter for suitability.

(3) Melting Charging Materials

Add 925 silver pre-melt and recycled materials into the crucible, as Figure 7-14 shows. Be careful not to pack the materials too tightly to avoid the “material jamming” issue. Close and lock the furnace cover, raise the casting chamber, and press the “automatic” button; the equipment will first vacuum to the preset value, then fill with protective gas to reach the preset pressure, and automatically enter PID mode to heat the charging materials. The equipment will automatically couple and adjust the heating power until it approaches the preset melting temperature (Figure 7-15).

(4) Placing the Casting Mold

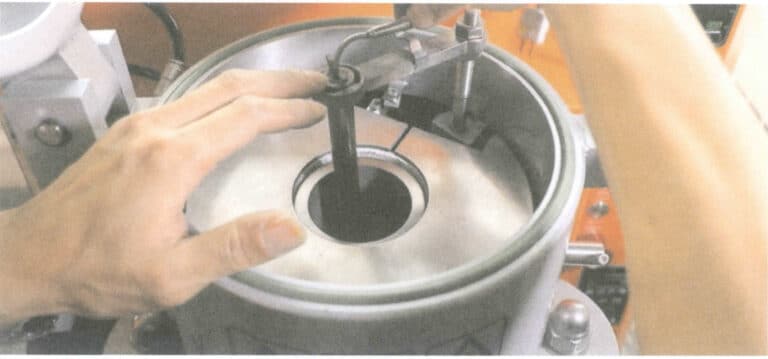

The casting chamber automatically descends when the reminder “Please place the steel flask” pops up on the operation interface. Use your hand to turn the casting chamber clockwise to the end, and when it touches the limit block, the bottom cylinder of the casting chamber rises. Use the steel flask clamp to hold the flask, placing the pouring port facing up on the bearing plate of the cylinder, as shown in Figure 7-16. Rotate the casting chamber counterclockwise; the cylinder drives the mold to automatically descend, allowing the casting chamber to smoothly turn into position and automatically rise, forming a seal with the bottom of the melting chamber. The bottom cylinder of the casting chamber rises, pressing the top surface of the mold against the bottom surface of the melting chamber.

(5) Pouring

Under program control, the casting chamber is vacuumed to the set value, the graphite rod is lifted, molten metal is injected into the mold, and then the pressure in the melting chamber is rapidly increased to the set value, allowing the molten metal in the mold to solidify under pressure, which helps improve the density of the casting, as shown in Figure 7-17.

(6) Removing the Casting Mold

After reaching the predetermined pressurization time, the system automatically shuts down the vacuum pump, while switching the “inject,” “rise,” and “pressurize” buttons also to the off-state. The equipment then enters the exhaust phase. When the air pressure in the melting chamber and casting chamber returns to normal pressure, the casting chamber automatically descends and rotates clockwise to the end. The cylinder at the bottom of the casting chamber rises to lift the steel flask. The steel flask is clamped by the steel cup clamps, removed vertically upward, and placed in the designated position to cool.

(7) End of Work

After all casting molds have been poured, the induction melting furnace should continue circulating cooling water until the crucible temperature is below 100℃ before shutting down. Use tools such as brushes and tweezers to collect spilled metal debris, clean the melting room and casting room with a vacuum cleaner, wipe the observation window with a cloth soaked in anhydrous alcohol, and clean the surface of the casting machine and the workplace.

Section IV Vacuum Centrifugal Casting

1. Arka Plan Bilgisi

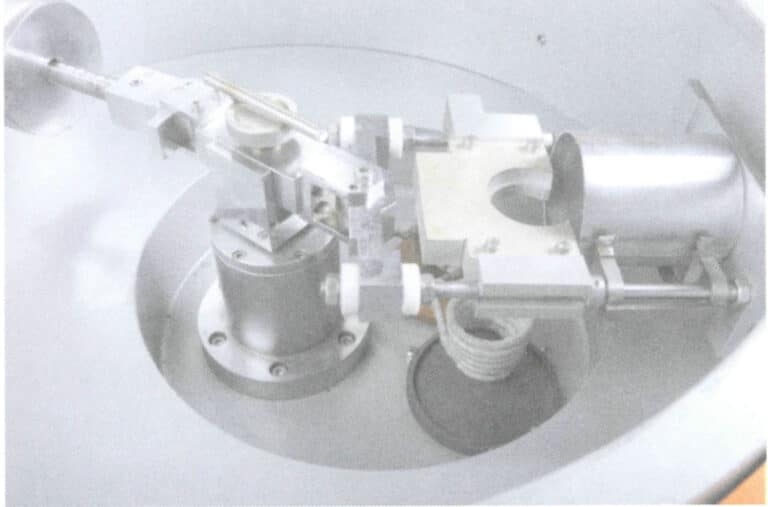

(1) Vacuum Centrifugal Casting Machine

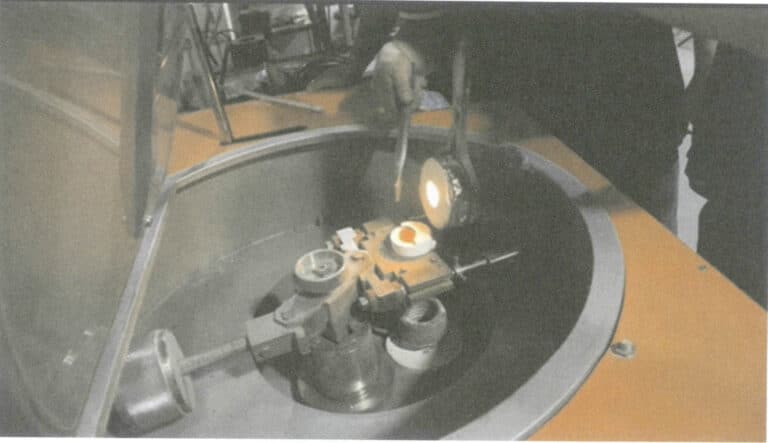

Centrifugal casting has a fast filling speed, which is beneficial for materials with fine structures or high melting points, as it helps the molten metal overcome flow resistance and improve filling rates. However, if the mold cavity is filled with air or inert gas, the molten metal can create back pressure when filling it at high speed, making it difficult for the gas to escape and hindering complete filling. Additionally, traditional simple centrifugal casting machines have melting and pouring processes that are manually controlled, and the structure of the casting machine does not match the fluid dynamics of the molten metal, resulting in poor uniformity in filling distribution. Some centrifugal machines only have pouring functions, leading to low production efficiency and unstable casting quality. Therefore, modern centrifugal casting machines have undergone significant improvements in functional integration, automatic control, and vacuum protection, and various models have been developed. From the perspective of crucible placement, there are vertical and horizontal crucibles; from the perspective of mold placement, there are also vertical and horizontal molds; and from the pouring methods, there are synchronous centrifugal pouring with the crucible and mold rotating together and crucible tilting with mold rotating centrifugal pouring. Among them, vacuum casting machines that use vertical crucibles, horizontal molds, and synchronous centrifugal pouring are widely used in the casting of platinum jewelry, with a typical structural appearance shown in Figure 7-18. It combines the melting and pouring chambers with induction heating and centrifugal pouring functions. It forms a completely sealed chamber that facilitates vacuum extraction, allowing melting and pouring to occur under vacuum. The angle of the mold’s central axis and the rotating arm is designed to be variable, capable of changing from 90°to 0°, as shown in Figure 7-19. This comprehensively considers the roles of centrifugal force and tangential inertial force in driving the molten metal out of the crucible and into the mold, helping to improve the balance of molten metal flow and preventing the molten metal from preferentially flowing into the pouring channel wall in the reverse rotation direction.

Figure 7-18 Appearance of the vacuum centrifugal casting machine

Figure 7-19 Variable arm of the vacuum centrifugal casting machine

(2) Crucibles for Centrifugal Casting

To ensure the purity and metallurgical quality of the molten metal, it is essential to avoid introducing impurities during the melting process, making the choice of crucible material critical. In jewelry production, the working conditions for crucibles are harsh, repeatedly subjected to high-temperature erosion, metal liquid scouring, and alternating heating and cooling. Therefore, the crucible must meet the following performance requirements: first, high refractoriness to withstand the high temperatures of the molten metal without melting or softening; second, good thermal shock resistance to endure rapid heating and cooling during induction melting and casting without cracking; third, good chemical inertness to avoid chemical reactions with the molten metal and prevent perforation under its erosion; fourth, sufficient mechanical strength to withstand the impact of metal charge and the external forces during centrifugal pouring, making it resistant to cracking and peeling.

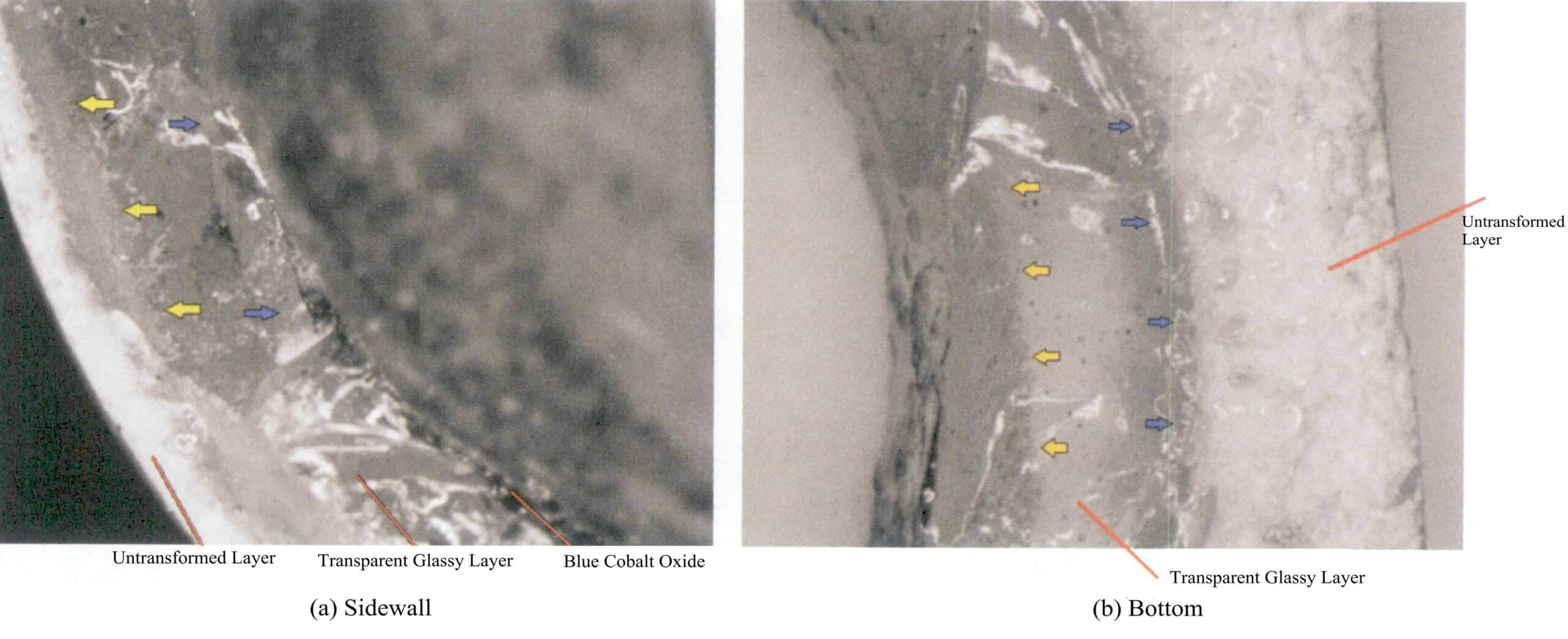

The crucibles used for centrifugal casting can be divided into two main material categories: graphite and ceramic. Graphite crucibles have advantages such as high refractoriness, good thermal shock resistance, and certain mechanical strength. When used for jewelry materials like gold, silver, and copper, the wettability of the molten metal on graphite is low, and the resistance when the molten metal flows out of the crucible is small. Therefore, graphite is the preferred crucible material for this type of jewelry casting. However, for precious metal jewelry materials like platinum and palladium, carbon can dissolve in platinum at high temperatures, and the solubility increases with temperature. When cooling, carbon precipitates, making the properties of platinum and palladium brittle, a phenomenon known as carbon poisoning. Therefore, when melting platinum and palladium, graphite crucibles cannot be used; only high melting point ceramic crucibles can be used. When melting materials like stainless steel and cobalt alloys, carbon reacts with the molten metal to form carbides, so these jewelry materials also cannot use graphite crucibles.

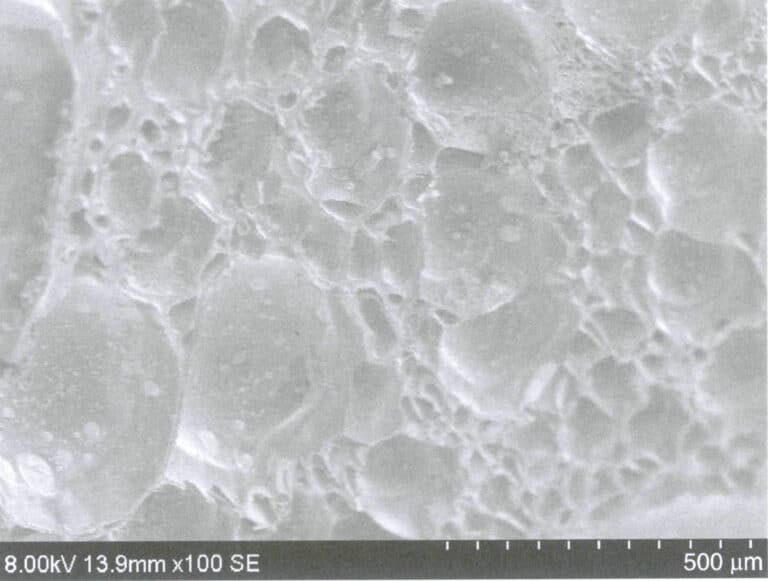

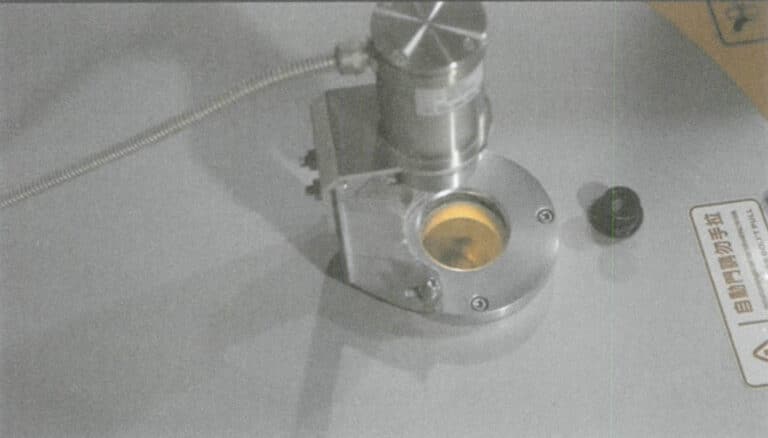

Graphite crucibles are generally not used alone but in conjunction with a quartz outer shell. Figure 7-20 shows a vertical crucible kit used for centrifugal casting, where the crucible has a larger top and a smaller bottom, with a pouring hole opened at the upper part of the crucible. When pouring begins to rotate, the molten metal rises along the inner wall of the crucible under the action of centrifugal force and accelerates outward at the pouring hole.

Many types of ceramic crucibles are used in industrial applications, such as alumina, zirconia, magnesia, beryllia, calcium oxide, and silicon carbide. Their melting points and refractoriness are significantly higher than those of quartz. Still, their thermal shock resistance is poor and cannot meet the rapid heating and cooling requirements in jewelry casting. Therefore, the melting of platinum, palladium, stainless steel, and other jewelry materials has primarily been done using quartz crucibles.

The high melting point jewelry materials such as platinum and palladium have the characteristics of high melting temperature, short time of keeping liquid state, and easy to be polluted by metal liquid, and their melting difficulty is far more than that of gold and silver alloys. The melting point of pure quartz is 1750℃. Still, in actual production, the crucible material is inevitably mixed with some impurities, which reduces its melting point to 1650~1700℃, while the melting temperature of platinum is generally above 1850℃; therefore, as far as the melting point is concerned, quartz is not the preferred crucible material for melting platinum. However, because quartz has a fine structure, low thermal conductivity, small thermal expansion, good thermal shock resistance, good electrical properties, good chemical resistance, etc., to meet the requirements of jewelry casting production, so become platinum, palladium, and other jewelry casting of the main crucible material. The problem of low melting point is generally solved by small capacity and rapid heating and melting, which can shorten the single melting time and increase the number of times the crucible is used accordingly.

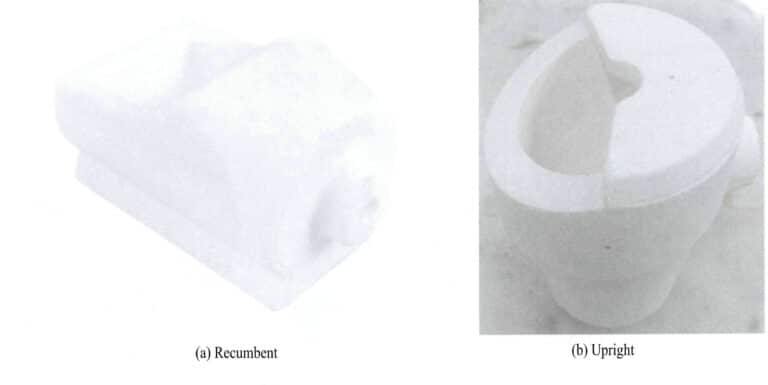

The quartz crucibles used for platinum melting come in two types: recumbent and upright, as shown in Figure 7-21. The recumbent crucible is relatively more advantageous for the flow of molten metal.

2. Görev Uygulaması

This task uses a vacuum centrifugal casting machine to melt and pour Pt950 jewelry.

(1) Verifying Material and Product Structure

Before melting and pouring, determine the product’s material to be poured, check the prepared Pt950 pre-melt and recycled materials, and inspect the cleanliness of the charging materials to avoid contamination. At the same time, verify the type and structure of the product inside the mold and set the pouring temperature to 1900℃.

(2) Melting and Pouring Preparation Work

Set the angle to 150°between the casting mold center axis and the swing arm. Check the quartz crucible for any residual metal beads; if present, they must be cleaned out to avoid contaminating the metal liquid. Wipe the infrared temperature measurement window of the melting room with a soft cloth and anhydrous alcohol. Raise the induction coil and place the crucible inside the induction coil, ensuring that the pouring hole aligns with the center of the mold support. Turn on the chiller, switch on the casting machine power, and check if the operation panel displays normally.

Enter the operation interface, select the preset Pt 950 casting program, choose manual operation mode, and check each preset process parameter for suitability.

(3) Melting Charging Materials

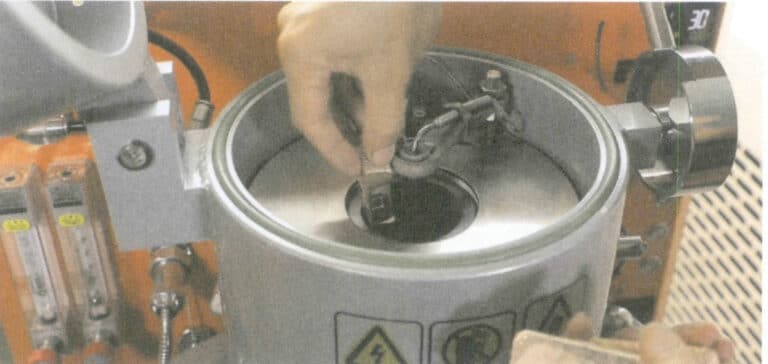

Add the charging materials into the crucible as shown in Figure 7-25, ensuring that the materials are not packed too tightly to avoid the “material jamming” issue. Press the heating button and increase the power to melt the materials quickly. Continue adding the remaining materials into the crucible; once all materials are melted, use a dedicated glass rod to stir the metal liquid to ensure uniform composition, as shown in Figure 7-26, then lower the power to reduce the metal liquid temperature to near the melting point.

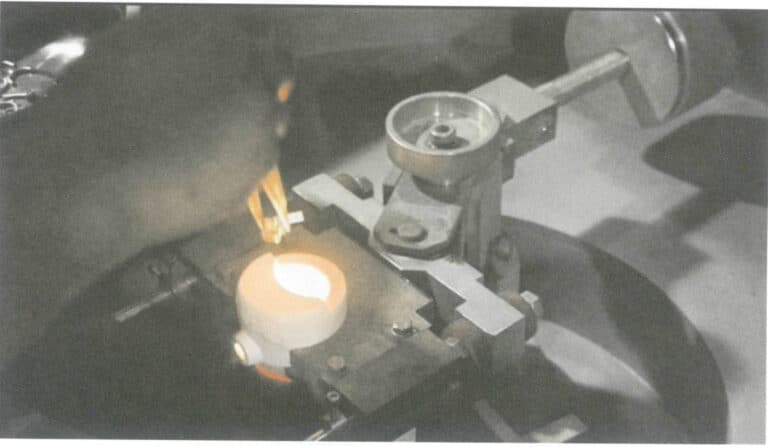

(4) Placing the Casting Mold

Use a steel flask clamp to hold the crucible, remove it from the burnout furnace, and place it horizontally on the mold support, with the mold pouring cup facing the crucible pouring spout, as shown in Figure 7-27. Close the furnace lid, turn on the vacuum extractor, and simultaneously increase the heating power to raise the temperature of the molten metal.

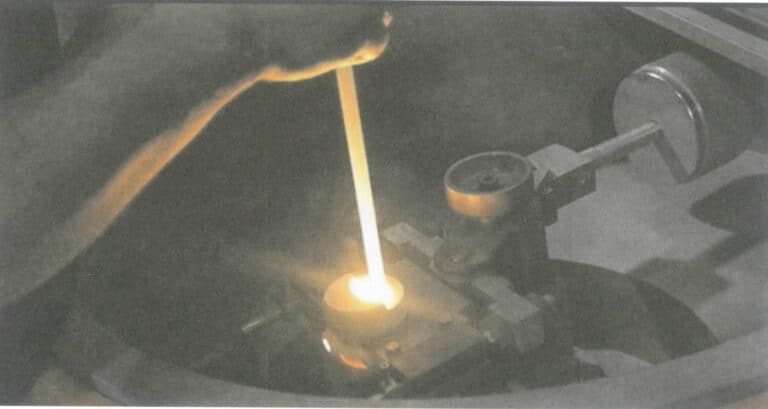

(5) Vacuum Centrifugal Casting

When the temperature of the molten metal reaches and stabilizes at the pouring temperature, press the pouring button, the induction coil descends, and the rotating arm immediately spins at high speed, filling the mold cavity with molten metal under the action of centrifugal force, as shown in Figure 7-28.

(6) Removing the Casting Mold

After reaching the predetermined rotation time, the system automatically rotates the motor. Once the rotation speed drops to zero, the vacuum extractor is turned off and started the exhaust function to break the vacuum in the casting chamber. Open the furnace cover, use a steel flask clamp to hold the steel flask, and vertically lift the mold out, placing it in the designated position to cool, as shown in Figure 7-29.

(7) End of Work

After pouring all casting molds, place the crucible in the designated position and cover it with refractory cotton. Continue to supply cooling water to the induction melting furnace, which can only be shut down after 30 minutes. Use tools such as brooms and tweezers to collect fallen metal debris, clean the casting chamber with a vacuum cleaner, wipe the observation window with a cloth soaked in anhydrous alcohol, and clean the exterior of the casting machine and the workplace.

Section V Vacuum Continuous Casting

1. Arka Plan Bilgisi

1.1 Principle of Continuous Casting

In jewelry production, in addition to using precision casting for shaping, CNC machining technology is also widely applied, which requires the production of various shapes of profiles such as bars, plates, and tubes. The traditional method of profile production involves manually pouring cast blanks and then performing rolling and pressing. This production method inevitably allows the molten metal to be in contact with air for a long time, increasing the chances of oxidation and oxygen absorption. Additionally, inclusions and surface pitting can occur in the cast blank due to the impact and splashing of the molten metal flow. Furthermore, defects such as shrinkage, holes, cracks, and surface cold shuts often exist in the cast blank. The quality issues present in traditional cast blanks make it difficult to manufacture high-quality products; thus, improving the casting process of the blanks becomes crucial.

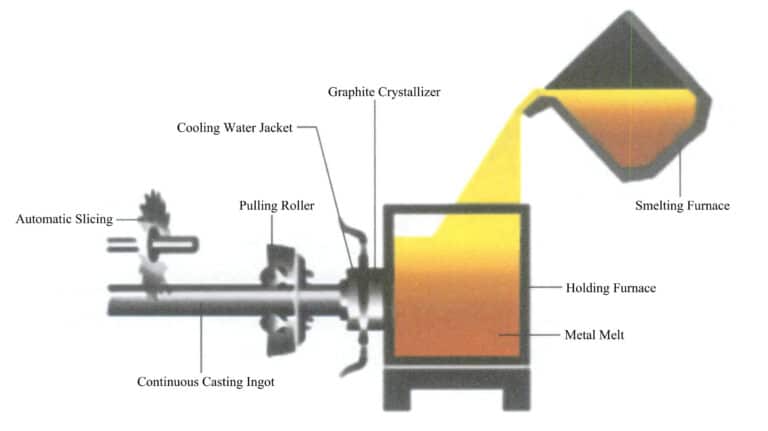

Due to its advantages, continuous casting technology has replaced the traditional manual ingot mold casting technology, becoming an important means of processing gold and silver profiles. In the 1990s, continuous casting technology was widely applied to produce non-ferrous metal profiles and was introduced into producing precious metal profiles. Continuous casting is an advanced casting method, the principle of which is to continuously pour molten metal into a special metal mold (crucible), and the continuously solidified (shell) profiles are drawn out from the other end of the crucible, allowing for the production of profiles of any length or specific length. The crucible’s internal structure determines the cast profile’s cross-sectional shape.

The continuous casting process is mainly divided into two categories based on the movement of the profile: vertical continuous casting and horizontal continuous casting. Among them, the former is the earliest developed continuous casting process for jewelry alloys, which is still widely used in producing various profiles, especially those with larger cross-sections. Depending on the method of throwing, it is further divided into two categories: bottom-pulling and top-pulling.

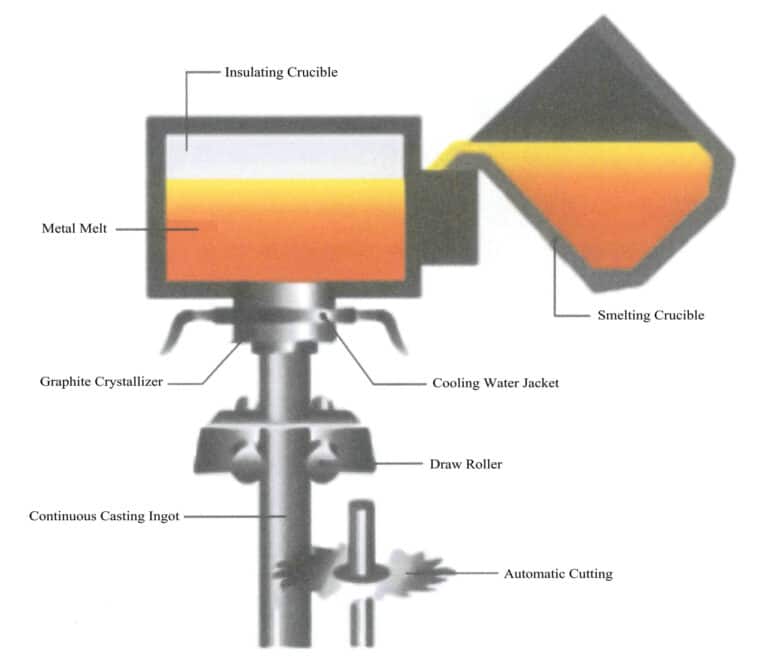

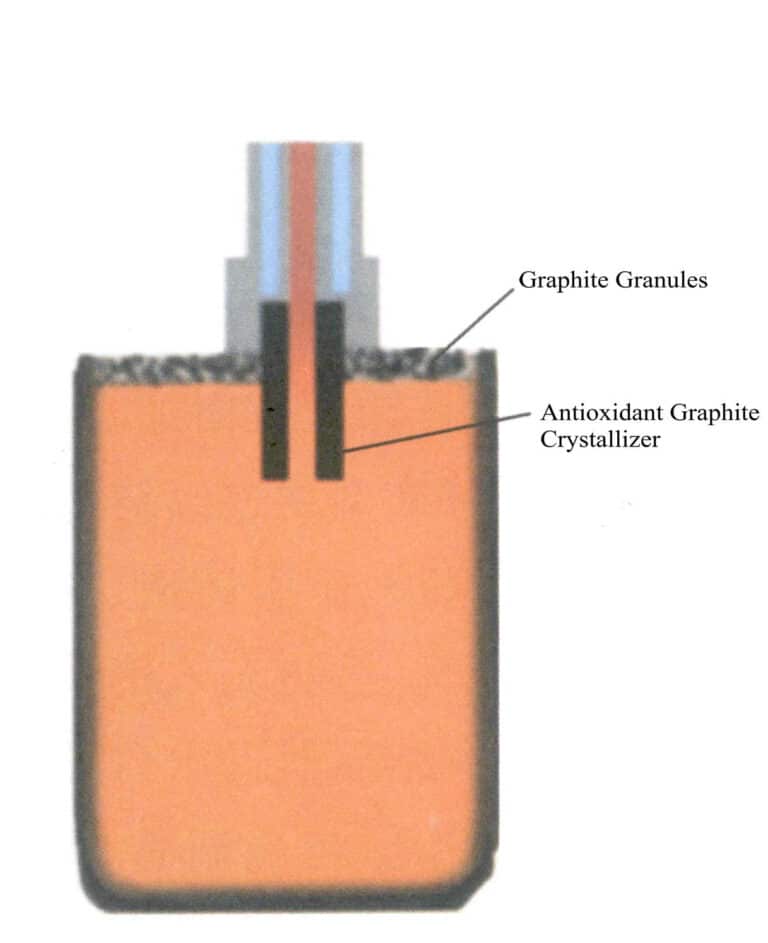

(1) Bottom-Drawing Continuous Casting

The working principle of bottom-pulling continuous casting is shown in Figure 7-29. It is carried out in a closed melting furnace, where the metal is melted and continuously poured into the crystallizer. After cooling, the traction rollers continuously pull down the solidified metal profile. The bottom-pulling casting method takes advantage of the metal’s gravity to pull down, resulting in higher production efficiency, and is beneficial for increasing the density of the cast profile and reducing shrinkage voids. The continuous casting profiles for jewelry metals such as gold, silver, and copper generally use the bottom-pulling method.

(2) Üstten Çekmeli Sürekli Döküm

Üstten çekmeli sürekli döküm yöntemi, Şekil 7-30'da gösterildiği gibi, metal eriyiğini aşağıdan aynı vakum cihazına bağlı bir kristalizatöre çeker, katılaştırır ve şekillendirir. Üstten çekmeli sürekli döküm makinesi, yalıtım fırınının tepesine monte edilmiş, soğutucuya sabitlenmiş (alt ucu belirli bir derinliğe kadar metal sıvısına daldırılmış) bir kristalleştirici, külçe için bir çekme mekanizması ve külçeyi yanlara doğru büken bir kılavuz mekanizmasından oluşur. Üstten doldurmalı sürekli döküm makinesi döküm yaparken, metal eriyiği kristalleştiriciye negatif basınç altında girer ve eriyiğin kristalleşme cephesi, yalıtım fırınındaki metal eriyiğinin sıvı seviyesinden biraz daha yüksektir. Bunun nedeni, kristalleştiricinin, basıncın atmosferik basınçtan daha düşük olduğu aynı vakum cihazına bağlı bir soğutucuya monte edilmiş olmasıdır. Üstten çekmeli sürekli döküm yöntemi, yüksek üretim verimliliği, daha kısa üretim döngüleri, basit kullanım ve düşük iş gücü yoğunluğu ile şeritler, çubuklar ve borular gibi farklı kesit şekillerine sahip metal külçeler üretebilir; ekipman basittir, küçük bir alanı kaplar, düşük yatırım gerektirir ve yüksek ekonomik faydalara sahiptir. Bununla birlikte, üretilen profillerin merkezi yapısı gevşekliğe yatkındır, bu da onu yüksek mukavemetli ürünler ve küçük seri üretim için uygun hale getirmez.

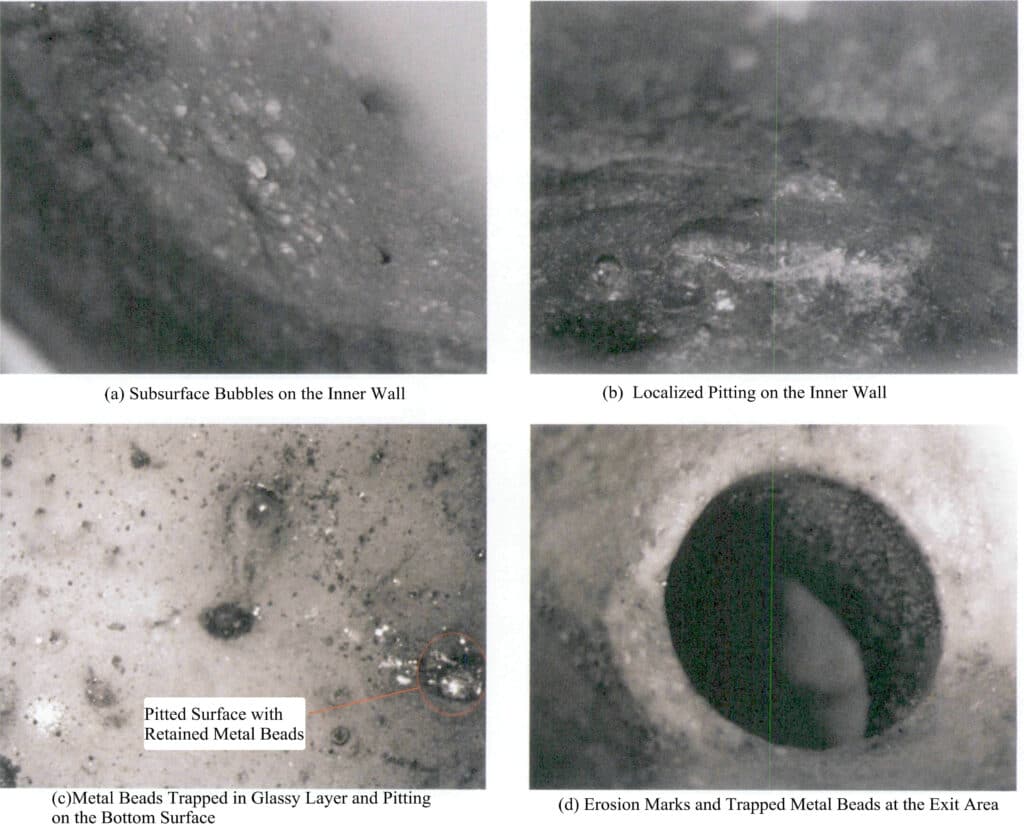

(3) Yatay Sürekli Döküm

Yatay sürekli dökümde, metal sıvı yalıtım fırınının yan duvarından yatay olarak yerleştirilmiş bir grafit kristalleştiriciye akarak katı bir kabuk oluşturur ve bu kabuk yatay olarak dışarı çekilir ve profil Şekil 7-31'de gösterildiği gibi sabit bir uzunlukta kesilir. Dikey sürekli dökümle karşılaştırıldığında, yatay sürekli döküm basit ekipman, derin kuyu ve vinçlere gerek olmaması, daha kısa süreçler, daha yüksek üretim verimliliği ve sürekli üretim gibi avantajlara sahiptir. Bununla birlikte, nispeten dar bir alaşım çeşidi aralığı için uygundur, kristalleştiricinin iç kovanının büyük bir tüketimi vardır ve ingotun enine kesitinin kristal yapısının homojenliğinin kontrol edilmesi kolay değildir. Külçenin alt kısmı, yerçekiminin etkisiyle kristalizatörün iç duvarına karşı sürekli olarak soğutulur ve daha ince taneler elde edilir; üst kısım, gaz boşluklarının oluşması ve daha yüksek eriyik sıcaklıkları nedeniyle daha geç katılaşır ve bu da soğutma hızını yavaşlatır. Külçelerin daha büyük özellikleri için kristal yapı daha iridir. Bu nedenle, bu yöntem yalnızca küçük boyutlu profillerin üretimi için uygundur.

1.2 Vakumlu Sürekli Döküm Takı Profilleri

Kuyumculuk üretiminde kullanılan profillerin özellikleri genellikle küçüktür ve tek bir işlemde dökülen metal miktarı da nispeten düşüktür, ancak profiller için kalite gereksinimleri yüksektir. Değerli metal takıların inceliğine ilişkin katı gereklilikler nedeniyle, tüm profil parçalarının standart gereklilikleri karşıladığından emin olmak çok önemlidir. Bu nedenle, değerli metal malzemelerin eritme ve döküm işlemi sırasında, metal-sıvı bileşiminin homojenliğini sağlamak gerekir. Buna ek olarak, mücevherat genellikle yüksek parlatma ve yüzey kaplaması gerektiren yüksek yüzey kalitesi gereksinimlerine sahiptir. Profilin metalürjik kalitesi, mükemmel yüzey efektleri elde etmenin temelidir. Profilin oksidasyon kalıntıları, gözenekler, büzülme veya pullar (yüzeydeki halka desenleri) gibi belirgin kusurlara sahip olduğunu varsayalım. Bu durumda, mücevherin yüzey işleme etkisini önemli ölçüde etkileyecektir. Bu nedenle, sürekli döküm sırasında profilin metalürjik kalitesini iyileştirmek için çaba gösterilmelidir.

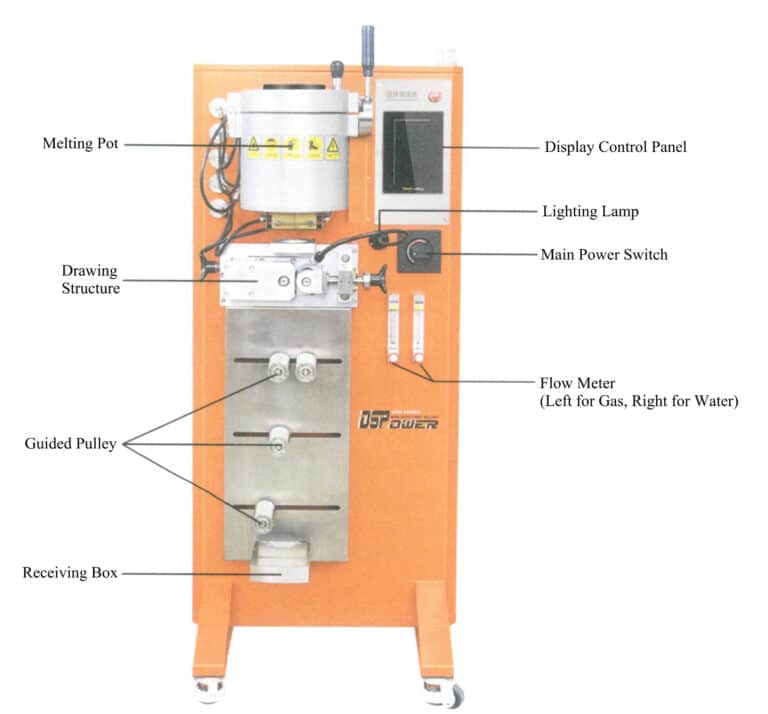

Şu anda, mücevher profillerinin sürekli döküm üretiminde, Şekil 7-32'de gösterildiği gibi tipik bir görünüme sahip indüksiyon ergitme, elektromanyetik karıştırma, vakum koruma, çekme döküm ve kontrol sistemlerini entegre eden aşağı doğru çekmeli vakumlu sürekli döküm makinesi kullanılmaktadır. Ergitme sırasında, ergitme odası önce boşaltılabilir ve ardından metal sıvıyı oksidasyondan korumak için inert gaz verilir. Grafit tapaya bir termokupl yerleştirilmiştir ve sürekli döküm işlemi sırasında sıcaklık değişikliklerini çevrimiçi olarak izlemek için kristalleştiricinin çıkışına yakın bir başka termokupl yerleştirilmiştir, bu da sürekli döküm işleminin istikrarlı kontrolünü sağlamak için sıcaklık ve çekme hızında ilgili ayarlamalara izin verir. Elektromanyetik karıştırma hareketi, metal sıvının sıcaklığını ve bileşimini daha homojen hale getirir. Yönlü kasnaklar çekme yönünü kontrol eder ve presleme tekerleğinin presleme uyumu ve kasnakların ve presleme tekerleklerinin yüzeylerindeki yuvarlanan bıçak deseni sayesinde sürekli döküm işlemi sorunsuz bir şekilde ilerler. Ekipmanın genel yapısı kompakttır, küçük bir alanı kaplar ve yüksek çalışma verimliliğine sahiptir.

2. Görev Uygulaması

Bu görevde 18 ayar pembe altın çubuklar üretmek için alttan çekmeli vakumlu sürekli döküm makinesi kullanılır.

(1) Hazırlık Çalışması

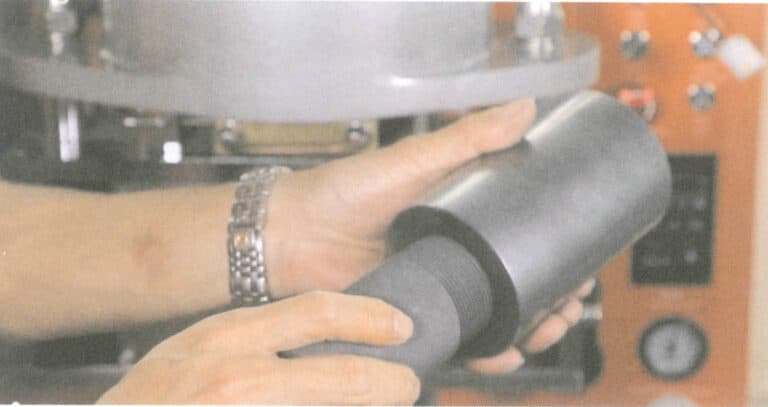

Grafit potanın ve kristalleştiricinin durumunu kontrol edin ve iç duvardaki metal kalıntılarını, cürufu vb. temizleyin. Şekillendirme kalıbını ve eritme potasını Şekil 7-34'te gösterildiği gibi bir ünite oluşturacak şekilde sıkın. Çekme çubuğunun düzlüğünü ve yüzey durumunu ve çekme ucundaki halka şeklindeki oluğun durumunu kontrol edin. Dökümden sonra döküm profilli malzemenin çekme çubuğundan düzgün bir şekilde ayrılmasını kolaylaştırmak için çekme ucuna grafit bulamacı uygulayın. Fırına sorunsuz bir şekilde girebildiğinden emin olmak için fırın şarjının kalitesini ve boyutsal durumunu kontrol edin. Gözlem penceresini susuz alkole batırılmış yumuşak bir bezle silin.

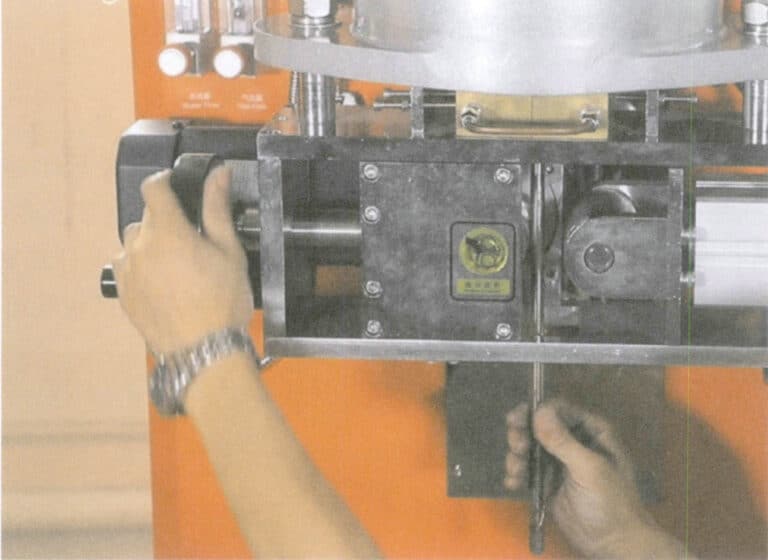

(2) Eritme Sistemi Tertibatı

Kuvars dış kabuğu indüksiyon bobininin içine yerleştirin, ardından kroze-kalıp tertibatını kuvars dış kabuğun içine yerleştirin, kalıp su soğutmalı kristalizatöre girecek ve dış duvarı kristalizatörün iç duvarına dayanacaktır. Mika kapağı potanın üstüne yerleştirin. Grafit tapa çubuğunu kaldırma mekanizmasının kirişine takın ve potanın dökme deliğini tamamen tıkamak için tapa çubuğu aşağı düğmesine basın. Termokuplu Şekil 7-35'te gösterildiği gibi grafit tapa çubuğunun orta deliğine yerleştirin. Çekme çubuğunu, çekme ucu tapa çubuğunun ucuna dayanacak şekilde kristalizatörün deliğine yukarı doğru yerleştirin. Çekme cihazındaki yönlü kasnağın konumunu, çekme çubuğu düz olacak ve Şekil 7-36'da gösterildiği gibi yönlü kasnağın yüzeyine sıkıca yapışacak şekilde ayarlayın. Sıkma tekerleğinin çekme çubuğuna sıkıca bastırdığından emin olmak için "Sıkma" düğmesine basın.

(3) Erime Yükü Malzemesi

Eritme sırasında "malzeme sıkışması" sorunlarına yol açabilecek aşırı sıkıştırmadan kaçınmak için yükü eşit olarak dağıtmaya çalışarak yükü Şekil 7-37'de gösterildiği gibi potaya ekleyin. Şarjı ekledikten sonra fırın kapağını kapatın, alanı 20 Pa'nın altına boşaltın ve atmosfer basıncına yakın saf argon gazı ile doldurun. Isıtma sıcaklığını 1050°C'ye ayarlayın, ısıtmaya başlayın ve ısıtma gücünü artırın. Metal yükü tamamen eridiğinde, erimiş metalin bileşiminde ve sıcaklığında homojenliği sağlamak için elektromanyetik karıştırma başlatılır.

(4) Çekişli Döküm

Erimiş metalin sıcaklığı ayarlanan sıcaklıkta sabitlendiğinde, grafit tapa çubuğu kaldırılır ve erimiş metal çekme çubuğu kafasına temas eder. Çekiş cihazı çalıştırılır ve çekiş çubuğu, yön tekerleği ve baskı tekerleğinin sürtünmesi altında sürekli olarak aşağı doğru hareket eder ve erimiş metal çekiş çubuğu ile birlikte aşağı akar. Kristalleştiricinin grafit kalıp üzerindeki soğutma etkisinden etkilenen kalıp içindeki erimiş metal katılaşır ve katı-sıvı arayüzü belirli bir yükseklikte stabilize olarak Şekil 7-38'de gösterildiği gibi sürekli döküm işleminin sürekli ve istikrarlı bir şekilde ilerlemesini sağlar.

(5) Profil Malzemelerinin Kesilmesi ve Çıkarılması

Sürekli döküm çubuğu malzemesinin uzunluğu yaklaşık 500 mm'ye ulaştığında, çekme işlemi sırasında sürekli döküm çubuğu malzemesinin engellenmemesini sağlamak için kesmek için büyük bir cıvata kesici kullanın. Baskı çarkını serbest bırakın ve erimiş metal döküldüğünde kalan profili çıkarın. Çubuğun çekme çubuğunun etrafına sarılmış kısmı için, birkaç güçlü sarsıntı ayrılmasını sağlayacaktır.

(6) End of Work

Tüm döküm kalıpları döküldükten sonra, kapatmadan önce sıcaklığı 100°C'nin altına düşene kadar indüksiyon ergitme ocağına soğutma suyu vermeye devam edin. Düşen metal parçalarını toplamak için süpürge ve cımbız gibi aletler kullanın, ergitme odasını elektrikli süpürge ile temizleyin, gözlem penceresini susuz alkole batırılmış bir bezle silin ve döküm makinesinin ve çalışma alanının dışını temizleyin.