Optimization Processing, Identification And Maintenance Of Pearls

Pearl Enhancement Techniques: A Guide for Jewelers and Designers

Introducere:

Discover the art of pearl enhancement with our comprehensive guide, perfect for jewelry stores, studios, and designers. Learn about the latest bleaching, dyeing, and irradiation treatments that can elevate the beauty of your pearls. Gain insights into polishing, waxing, and engraving techniques to create stunning jewelry pieces. Our guide also covers identification of natural vs. cultured pearls and the secrets to maintaining their luster. Whether you’re a retailer, e-commerce seller, or crafting custom celebrity pieces, this resource is a must-read. Understand the impact of pearl treatments on luster, color, and surface defects, and how to select the best pearls for your creations. Enhance your pearl jewelry collection today with expert advice from industry leaders.

Tabla de conținut

Section Ⅰ Optimization Processing of Pearls

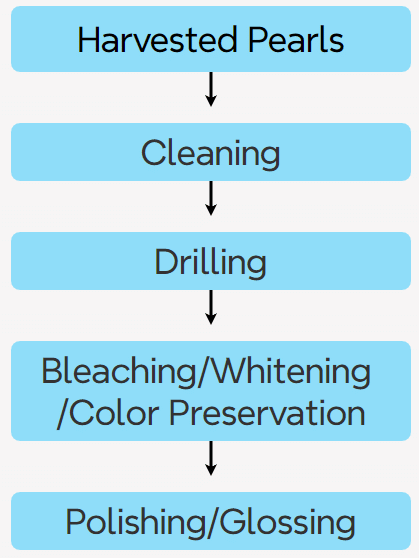

The optimization processing of pearls mainly includes bleaching or color preservation after cleaning, polishing, dyeing, “heat treatment,” irradiation treatment, coating, waxing, etc.

In addition, there are also processes such as drilling and engraving.

1. Bleaching, Whitening, Color Preservation, and Polishing

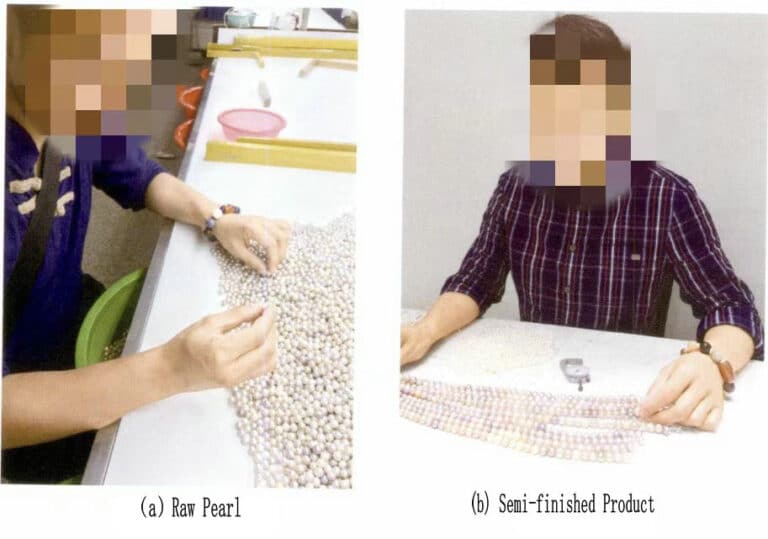

After harvesting, pearls need to undergo cleaning, sorting, bleaching for enhancement or color preservation, polishing, and other processes. The optimization treatment techniques and processes vary among different types of pearls, countries, and companies. Figure 1-5-1 shows the processing methods and workflows of some manufacturers of freshwater cultured pearls in Zhuji, Zhejiang.

(1) Cleaning and drilling of pearls

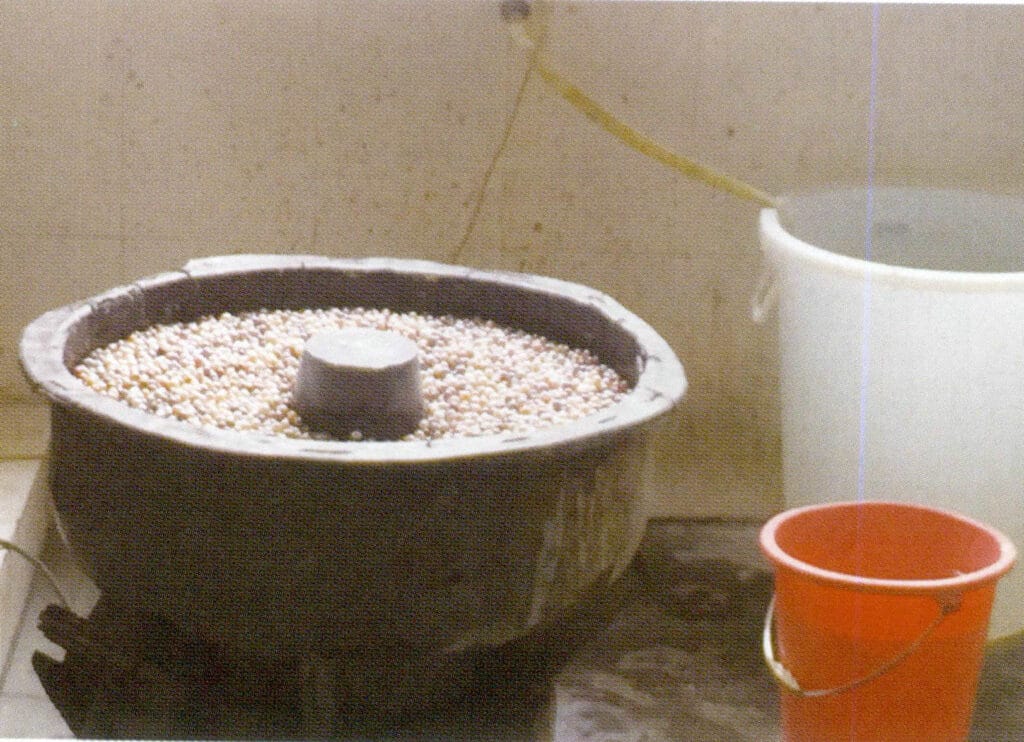

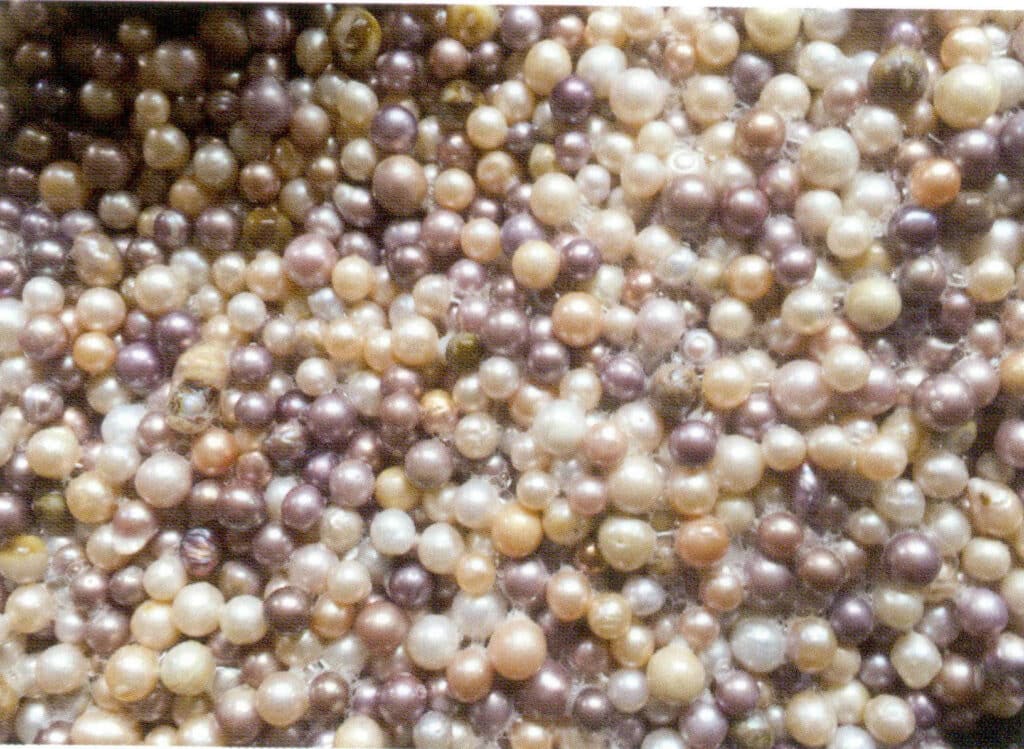

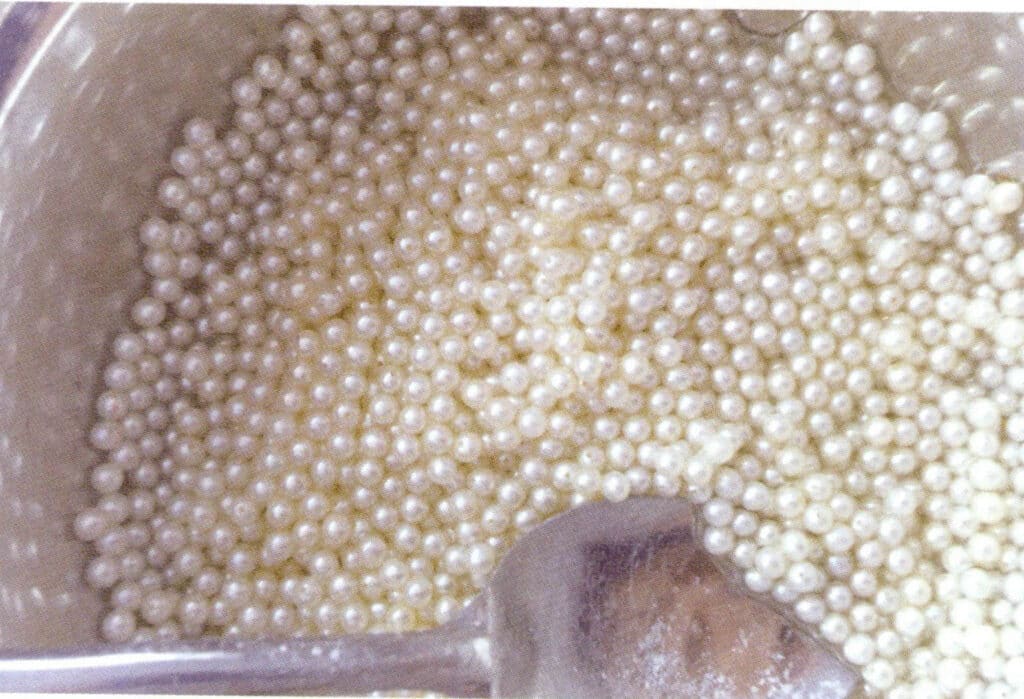

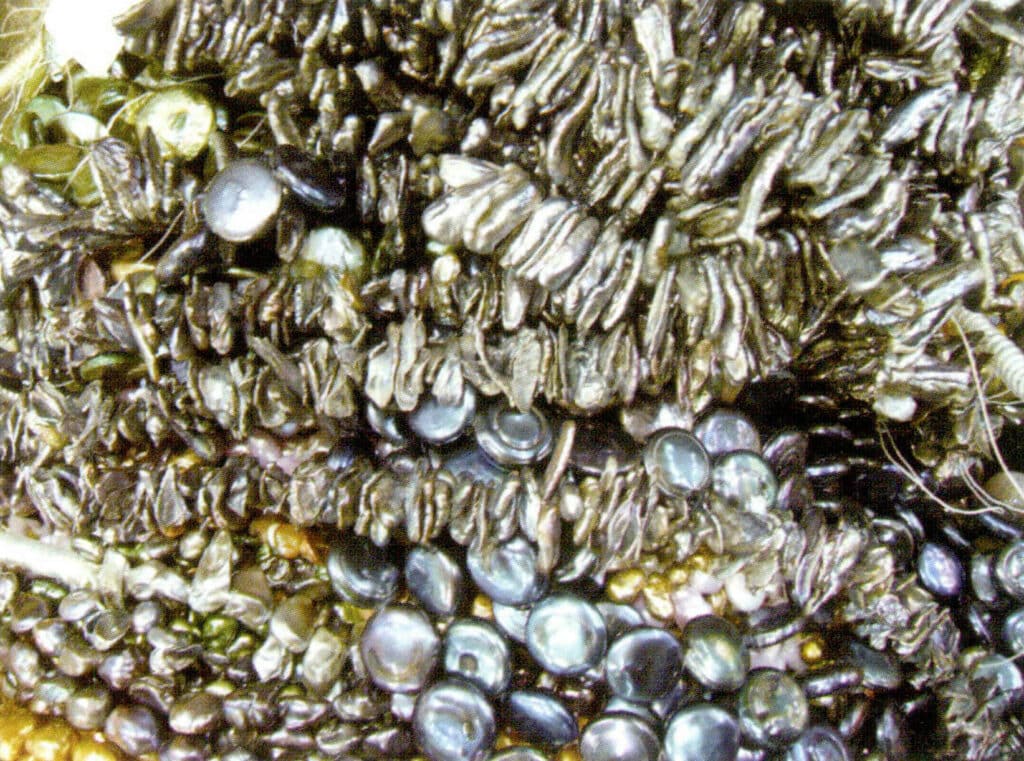

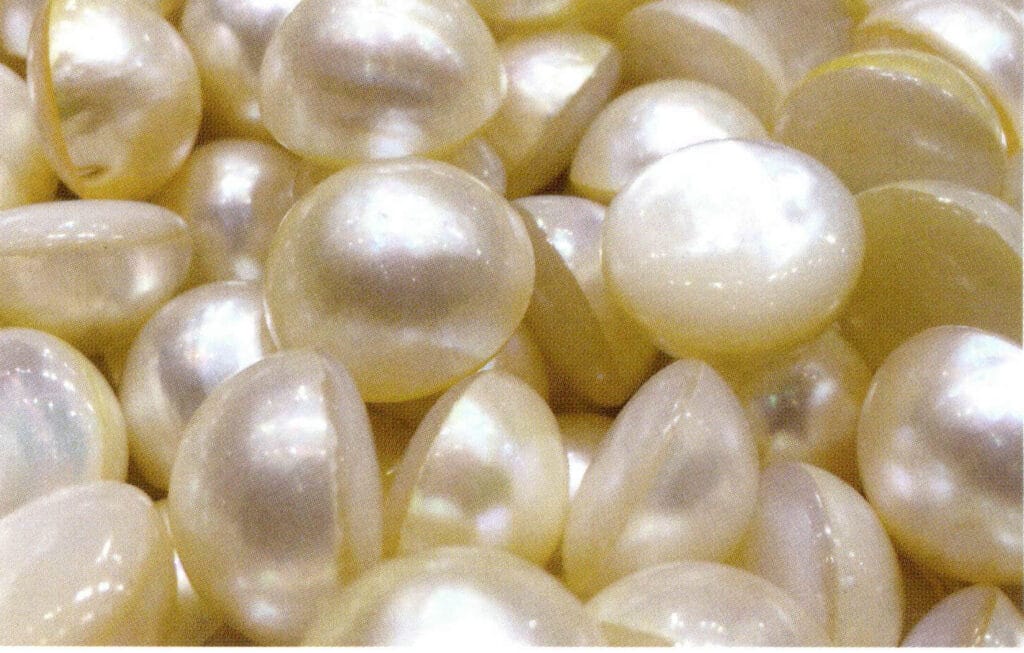

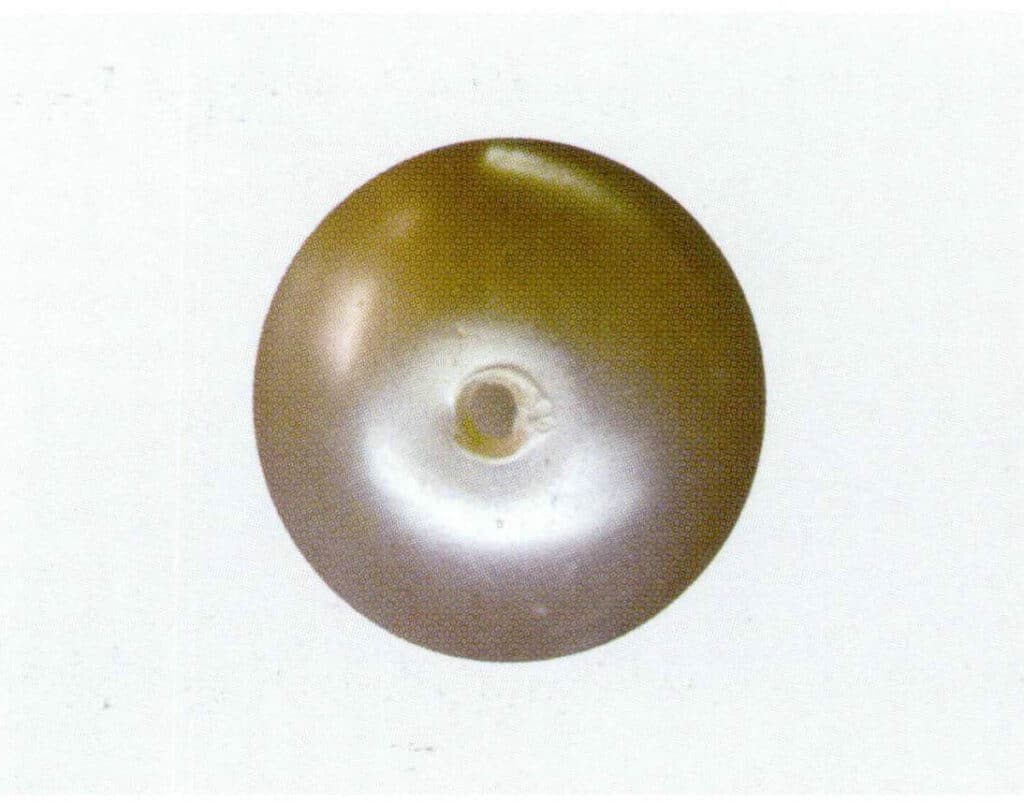

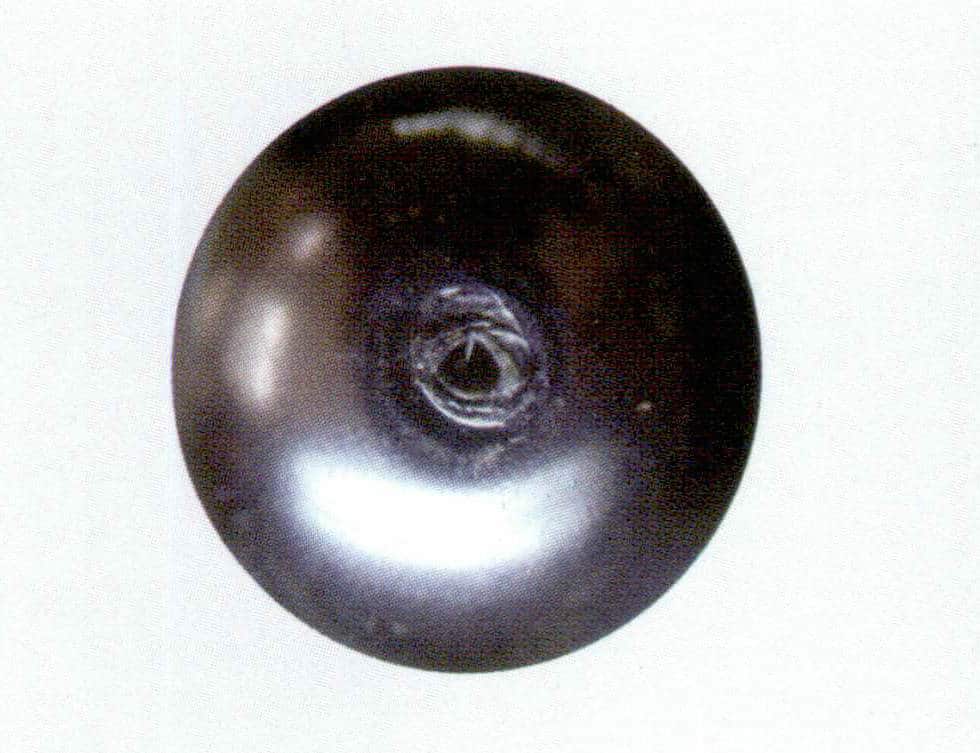

Pearls are wrapped in organic tissue within bivalve mollusks, so freshly harvested pearls will also have organic tissue and other stains on their surface, as seen in Figures 1-5-2 and 1-5-3.

Figure 1-5-2 Freshly harvested pearls (1)

Figure 1-5-3 Freshly harvested pearls (2)

Pearls should be washed immediately after collection to clean off surface dirt. If the harvested pearls are not cleaned promptly and effectively, the mucus from the mollusks will stain the surface of the pearls, as shown in Figures 1-5-4 and 1-5-5.

Figura 1-5-4 Perle nespălate și cochilii de nucă de perlă

Figure 1-5-5 Unwashed pearls

Generally, harvested pearls are soaked in a cleaning agent for a few days, then rinsed with distilled water and air-dried. Different processing plants use different cleaning agents and processes. The cleaning of pearls is shown in Figures 1-5-6 and 1-5-7.

Figure 1-5-6 Cleaning Pearls (1)

Figure 1-5-7 Cleaning Pearls (2)

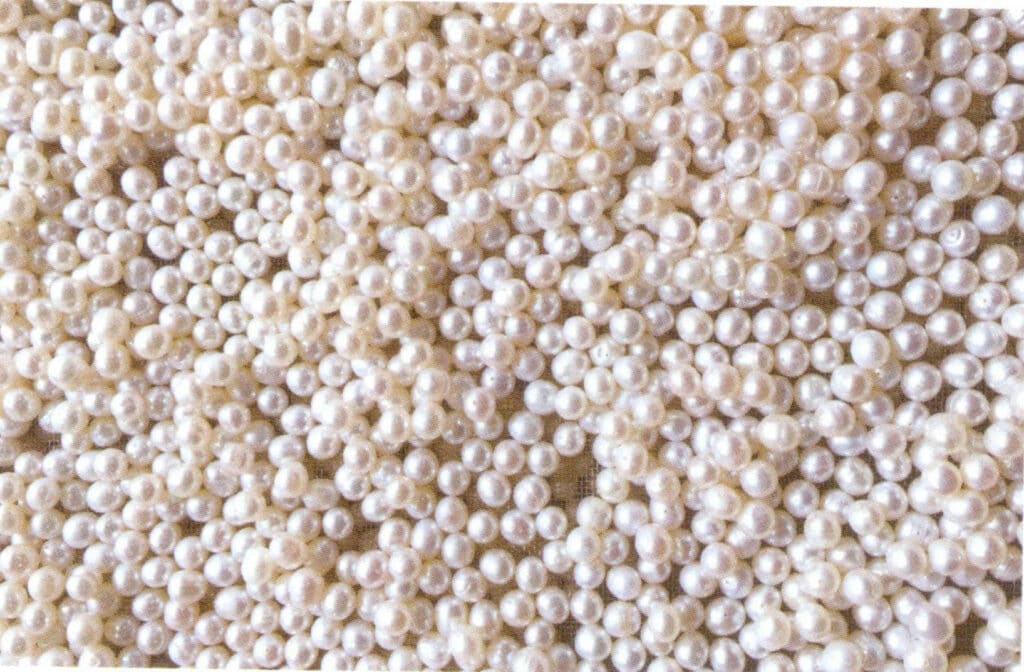

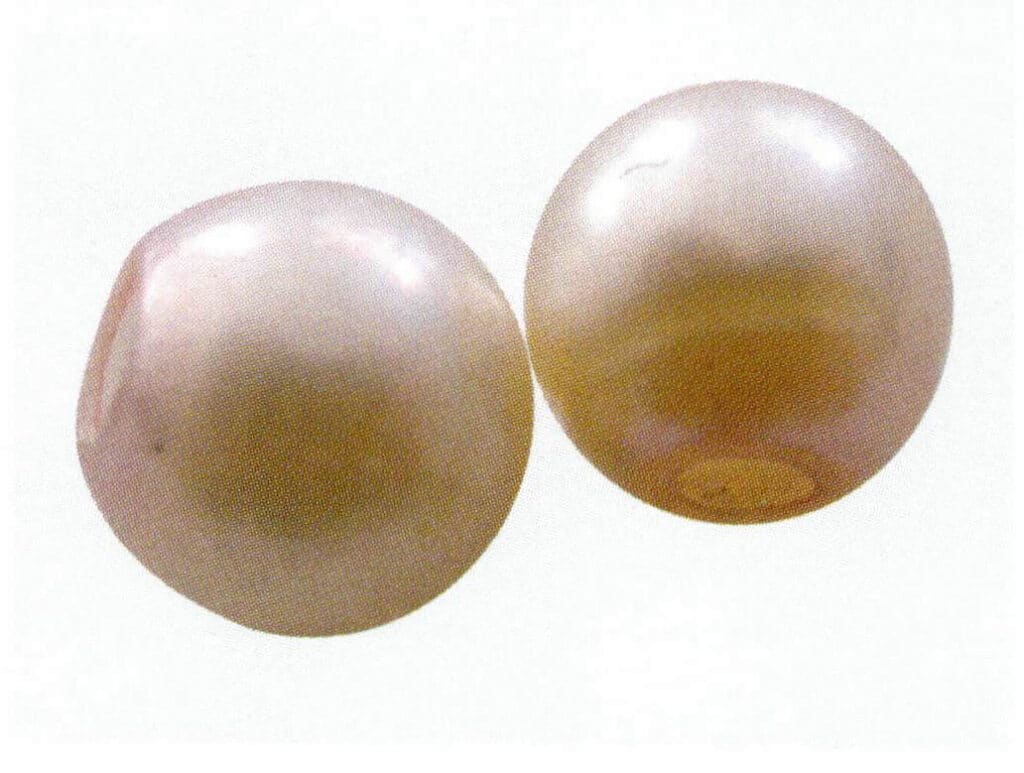

Simply cleaning pearls does not completely remove the organic slime and other substances that penetrate the fine pores on the surface. After a short time, the color and luster of the pearls may be affected, as seen in Figures 1-5-8 and 1-5-9. Therefore, pearls must also undergo bleaching, whitening, or color preservation treatments.

Figure 1-5-8 Pearls that have only undergone regular cleaning 1

Figure 1-5-9 Pearls that have only undergone regular cleaning (2)

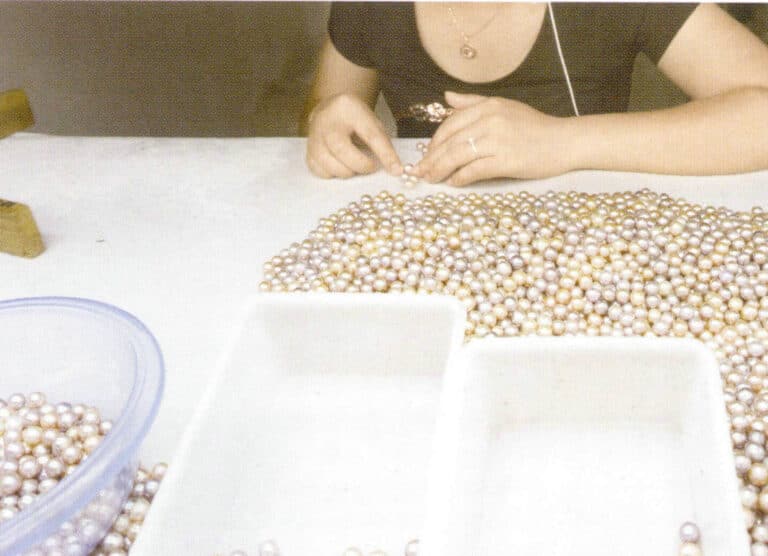

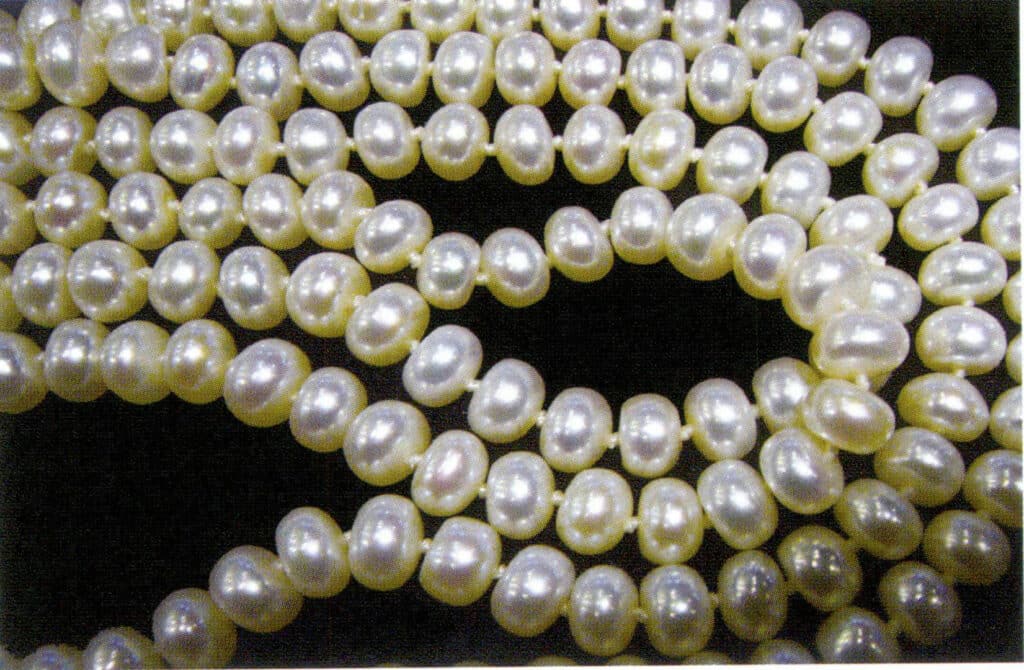

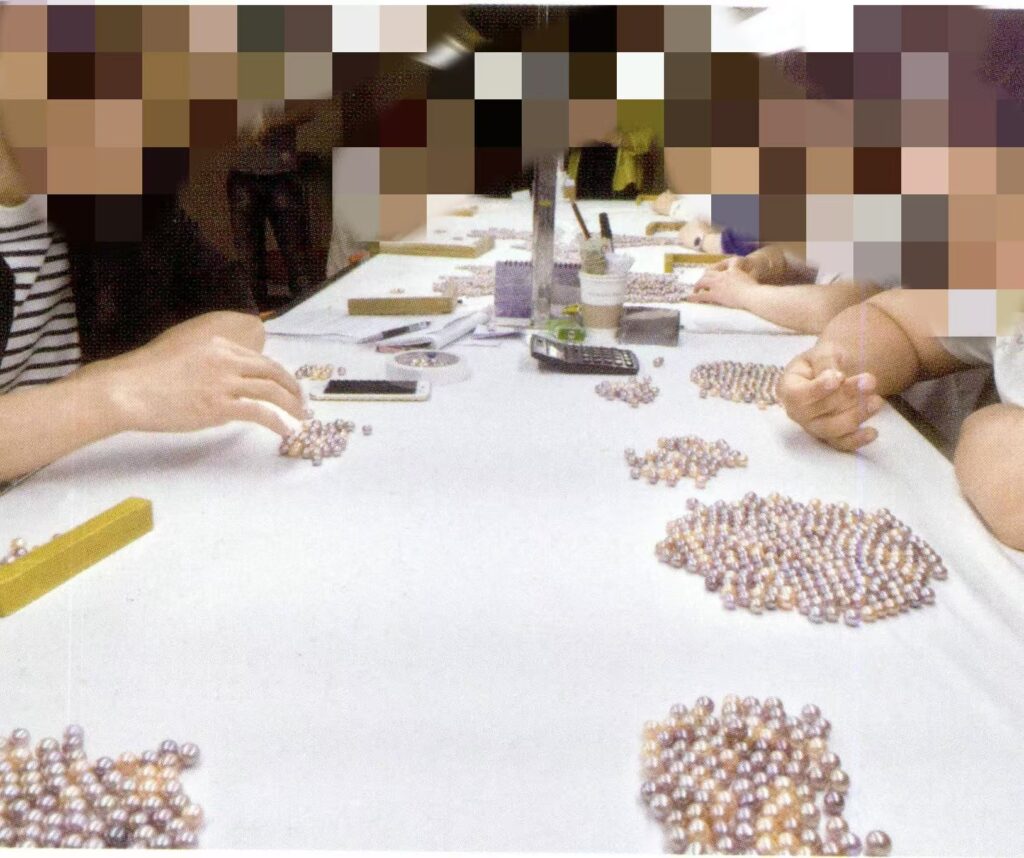

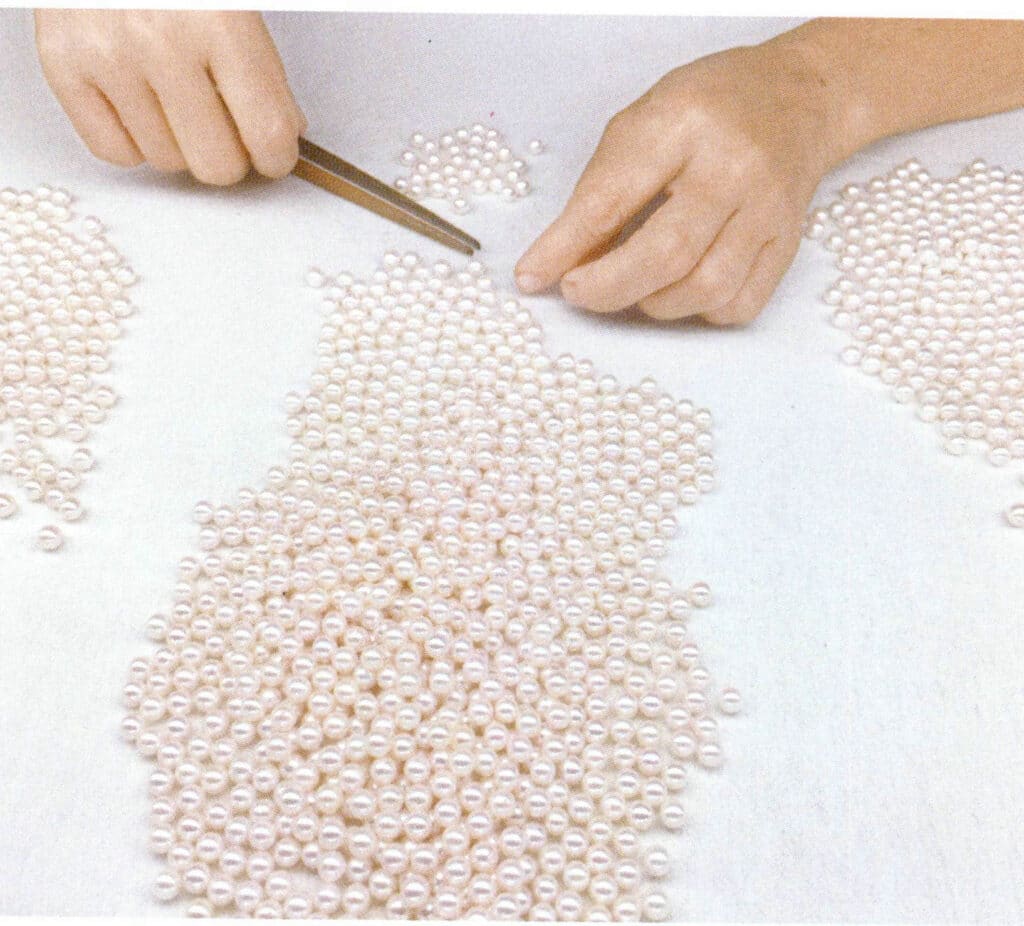

After cleaning, pearls are generally sorted by size, color, luster, shape, and flaws, as seen in Figures 1-5-12

The sorted pearls can be drilled first or directly enter optimization processes such as bleaching and enhancing luster.

High-quality pearls with perfect surfaces and large grains do not need to be drilled first and can go directly into bleaching, whitening, or color preservation. Such pearls are usually drilled when made into jewelry and can be used for pendants, earrings, etc.

Pearls that are sorted and have heavier flaws are usually drilled first, generally for use in necklaces. Drilling aims to enhance the penetration of the bleaching solution’s dye. Without drilling, the bleaching solution cannot easily penetrate through the thin layer of gaps into the pearl’s interior.

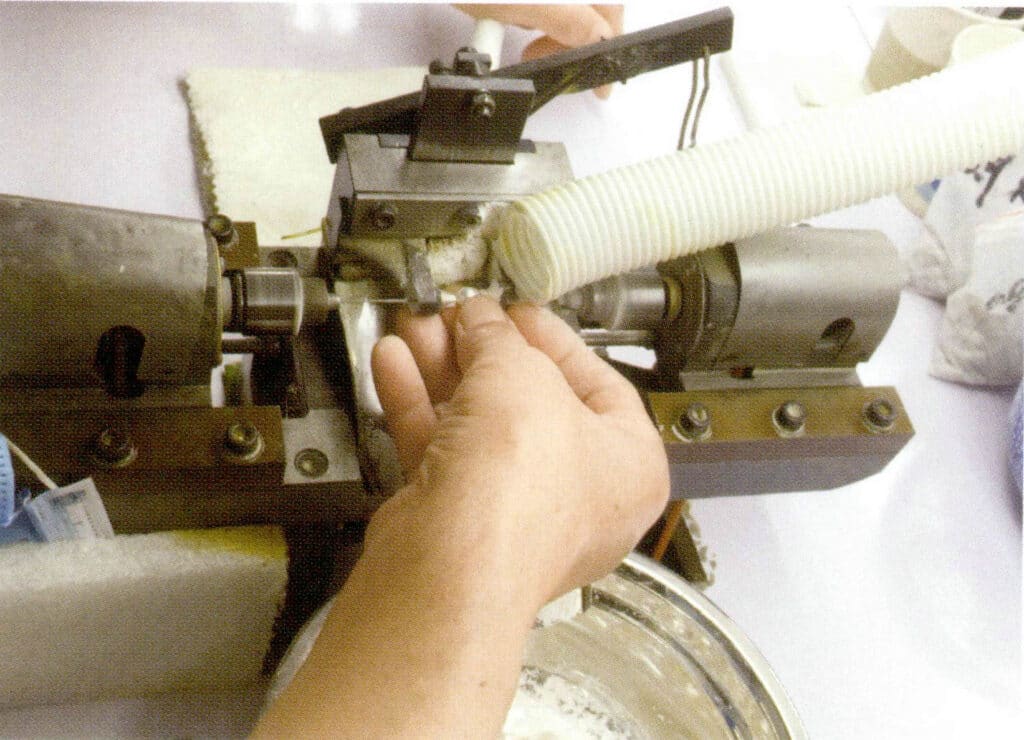

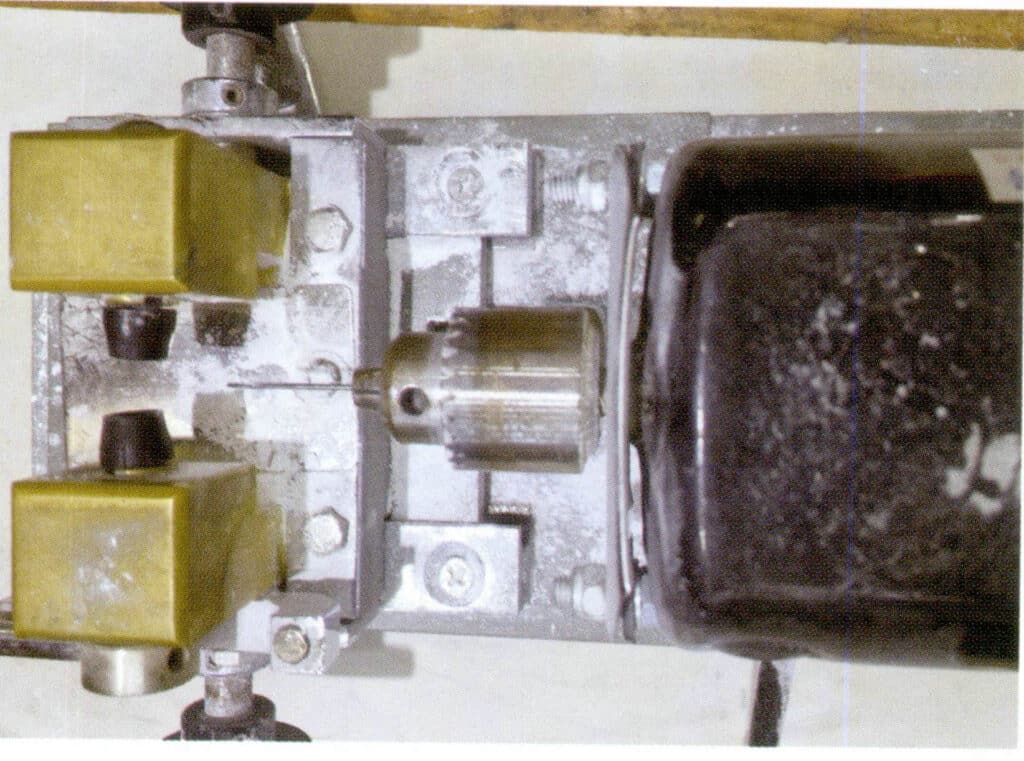

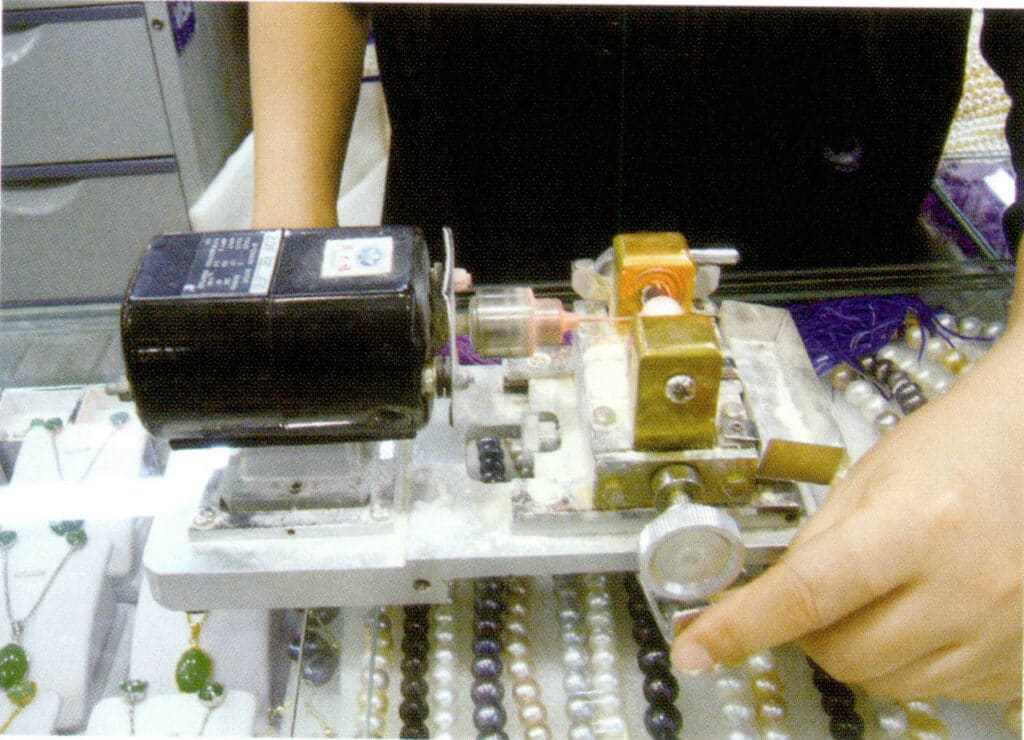

Before drilling, a mark is made at the drilling point, usually at the location of the heaviest flaw. If used for necklaces, the pearl is drilled through, meaning the hole goes through the pearl; if used for pendants, ear studs, etc., only a half-hole is drilled, leaving it for gem setting. The factory drilling before processing is shown in Figures 1-5-14 and 1-5-15, and the drilling machine for single pearls after processing is shown in Figures 1-5-16 and 1-5-17.

Figure 1-5-14 drill holes in factory

Figure 1-5-15 drill holes in factory 2

Figure 1-5-16 Single Pearl Drilling Machine

Figure 1-5-17 Drilling a Single Pearl

(2) Bleaching and Whitening of Pearls

Even after cleaning, newly harvested pearls cannot completely remove some impurities and yellow-brown chromophores that enter during growth, affecting the pearls’ beauty. In addition, many light-colored pearls, uneven white, and light-colored pearls are not as popular as white in terms of color and are relatively difficult to match into necklaces. At the same time, bleaching can turn these pearls into the more popular white, making them more valuable commercially. As early as 1924, bleaching methods were widely used on natural and cultured pearls.

The bleaching of pearls includes pretreatment, pretreatment, bleaching, and whitening. The processes vary among different processing factories and are kept strictly confidential; even within the factory, only a few people can access them.

The main targets of bleaching are white, light-colored, and unevenly colored pearls.

Pretreatment is an important step in pearl bleaching, directly affecting the effectiveness of subsequent processes. According to publicly disclosed information, a mixture of ammonia and benzene is used for the swelling treatment of pearls to make the structure “looser.” After the swelling treatment, anhydrous ethanol or pure ethanol is used. Glycerin acts as a dehydrating agent to remove the interstitial water and adsorbed water from pearls; or use boiling (steaming) for several hours to expand the pearl layer or pre-illuminate with strong light at high temperatures for several hours to lighten the color.

Bleaching refers to treating pearls in a bleaching solution composed of a specific formula, using appropriate processing techniques. Japan, China, and Southeast Asian countries have conducted extensive research on this technology, with Japan having the most advanced research techniques and having adopted third and fourth-generation bleaching technologies, while China mainly uses a liquid-phase bleaching method with H2O2 as the bleaching agent.

Generally, hydrogen peroxide is diluted and used as a bleaching agent. The concentration ratio of hydrogen peroxide should be appropriate; if the amount is too small, it will not be effective, and if it is excessive, it will damage the structure of the pearls. Adding compounds like ammonia makes the bleaching solution weakly alkaline in the end.

The factors affecting the bleaching effect mainly include the composition of the bleaching agent formula and the bleaching process conditions. For white and light-colored pearls, the whiter they are bleached, the better the quality of the pearls appears and the higher the price. In this process, the ratio of the bleaching solution is crucial. The bleaching solution mainly consists of bleaching agents, surfactants, stabilizers, solvents, and other components, each playing a different role in the bleaching process. The bleaching agent plays the main role, while the other components act as auxiliaries, effectively promoting bleaching, improving the bleaching effect and process, and ensuring that various indicators of the bleached pearls achieve satisfactory results.

The previously published optimal bleaching solution formula and bleaching process involve mixing 30% of H2O2, ethanol, and water in a volume ratio of 1:3:6, adding 0.25% of sodium dodecyl sulfate as the active agent, and 0.25% of sodium silicate as the stabilizer; after cleaning, the original pearls undergo a water boiling pretreatment of 2-6 hours, then under sunlight, a water bath constant temperature of 40℃, Ph value 8-8.5, followed by 24-60 hours bleaching, which can achieve a relatively ideal bleaching effect.

The cooking time for pearls depends on the size and color depth; larger and darker pearls require longer. The bleaching time varies due to factors such as the size and color depth of the pearls, cooking time, and the content of H2O2 in the bleaching solution. Extending the cooking and bleaching times can increase the number and depth of micropores, causing some calcium crystals to detach from the shell proteins, which leads to a decrease in the strength of the pearls. Ultimately, this can make the pearls brittle and even loose, resulting in spots, peeling, and loss of luster on the surface, causing the pearls to completely lose their value. Therefore, controlling the cooking and bleaching times is also crucial.

The whitening process is the most critical step in the bleaching and whitening process. Different manufacturers use different formulas and processes. For manufacturers, this part is the highest technical secret. Whitening not only improves the whiteness of pearls but can also enhance their luster to a some extent, creating a brighter visual effect. High-quality whitening agents are characterized by their ability to be absorbed by the fine pores of the pearl layer, are not easily washed away immediately, and can enhance the whiteness of the pearl layer, making the pearls whiter and brighter.

After bleaching the pearls, wash them with distilled water, and an ultrasonic cleaner can also be used to improve efficiency. Place the pearls in a filter and create a vacuum inside, then open the piston and pour in the whitening solution. Next, move the pearls and the whitening solution into a wide-mouth glass bottle and soak for a some period. During the soaking process, observe the color changes of the pearls; the soaking time and frequency depend on the whiteness of the pearls.

The bleaching and whitening of pearls can be seen in Figures 1-5-18 to 1-5-27.

Figure 1-5-18 Light-colored pearls waiting to be bleached and whitened

Figure 1-5-19 Bleaching and Whitening Agents for Pearls

Figure 1-5-20 Pearls being bleached and whitened (1)

Figure 1-5-21 Pearls being bleached and whitened (2)

Figure 1-5-22 Pearls being bleached and whitened (3)

Figure 1-5-25 Pearls being bleached and whitened (6)

Figure 1-5-26 Pearls drying after bleaching and whitening

Figure 1-5-27 Pearls after bleaching and whitening

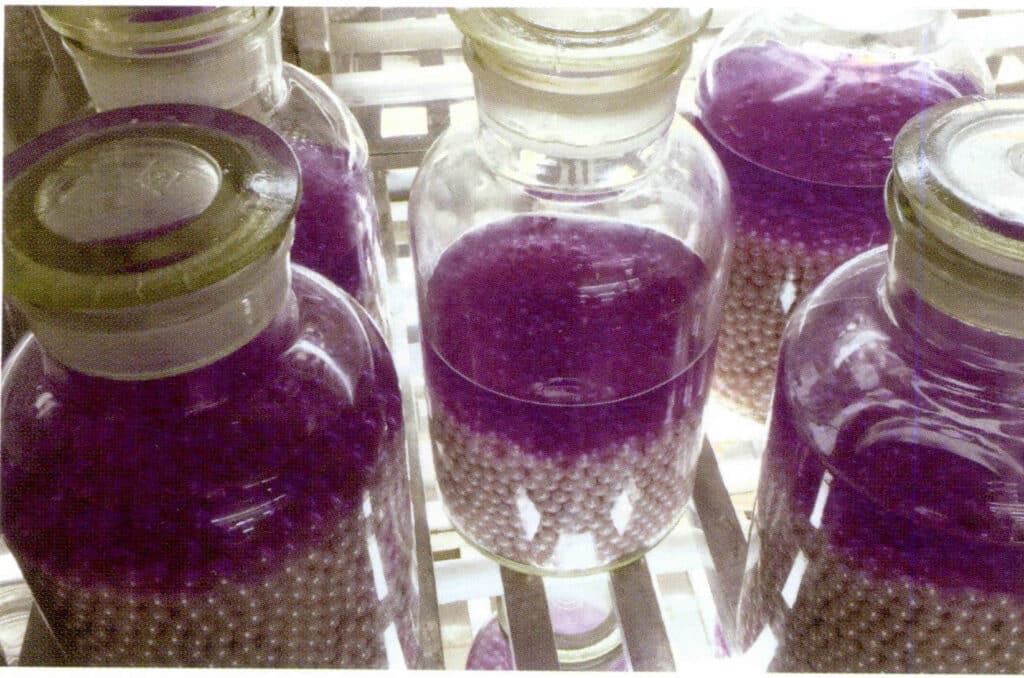

(3) Color preservation

If the color of colored pearls is darker or in demand in the market, they are not bleached but undergo another process called “color preservation.” This process solidifies the color of the pearls, which is why manufacturers commonly refer to it as “color preservation.” The main targets for color preservation are dark-colored pearls and large-grained colored pearls.

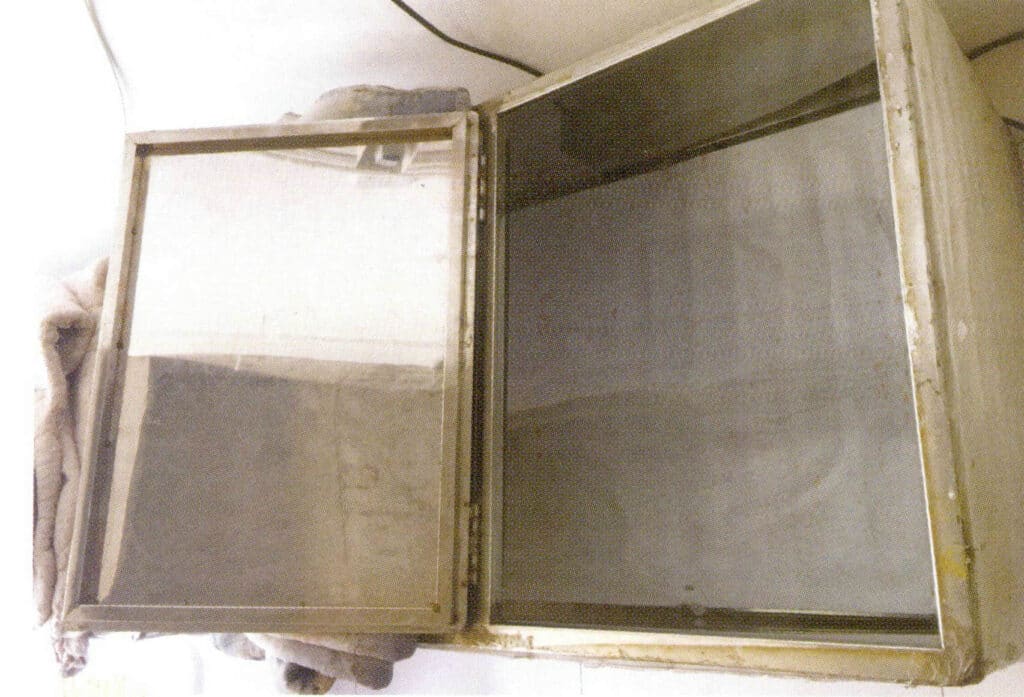

Color-preserving reagents and processes are also among manufacturers’ most important technical secrets have. Generally, the cleaned pearls are placed in a wide-mouth bottle with the color-preserving reagent, kept away from light, and stored in a constant temperature water bath iron box for a some period before being taken out and dried. The color-preserving reagents, devices, and the color-preserving process for pearls are shown in Figures 1-5-28 to 1-5-35.

Figure 1-5-28 Color-preserving reagent

Figure 1-5-29 Constant temperature water tank used for color preservation

Figure 1-5-30 Pearls to be preserved in color

Figure 1-5-31 Preservation of Pearl Color (1)

Figure 1-5-34 Preservation of Pearl Color (4)

Figure 1-5-35 Drying after color preservation

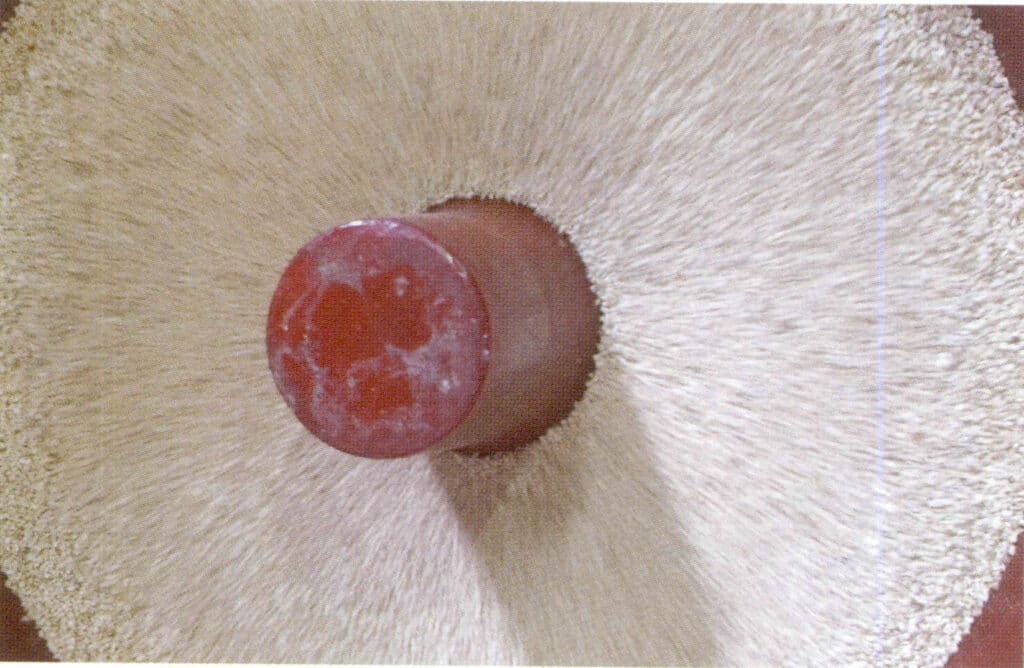

(4) Glossing

Polishing, also known as glazing, is the final process after completing the whitening and color preservation techniques. Good polishing can enhance the effects of bleaching and whitening.

Different manufacturers’ polishing materials vary slightly. Common polishing materials include jade wood core and wax; smooth walnut shells and wax; small bamboo green triangular pieces, wooden blocks, walnut shells, small pieces of tanned sheepskin, etc., soaked in liquid wax to remove moisture; small bamboo pieces, small stones, and paraffin; there are also materials like sawdust, coarse salt, and diatomaceous earth. Polishing materials from different manufacturers are shown in Figures 1-5-36 and 1-5-37.

Figure 1-5-36 Polished Materia

Figure 1-5-37 Polished Materia 2

Place the polishing material into the polishing machine, and also put the bleached, whitened, dyed, and sun-dried pearls into the polishing machine to rotate together, polishing the surface of the pearl layer to enhance the smoothness and luster of the pearls, as shown in Figures 1-5-38 and 1-5-39.

Figure 1-5-38 Polishing of Pearls 1

Figure 1-5-39 Polishing of Pearls 2

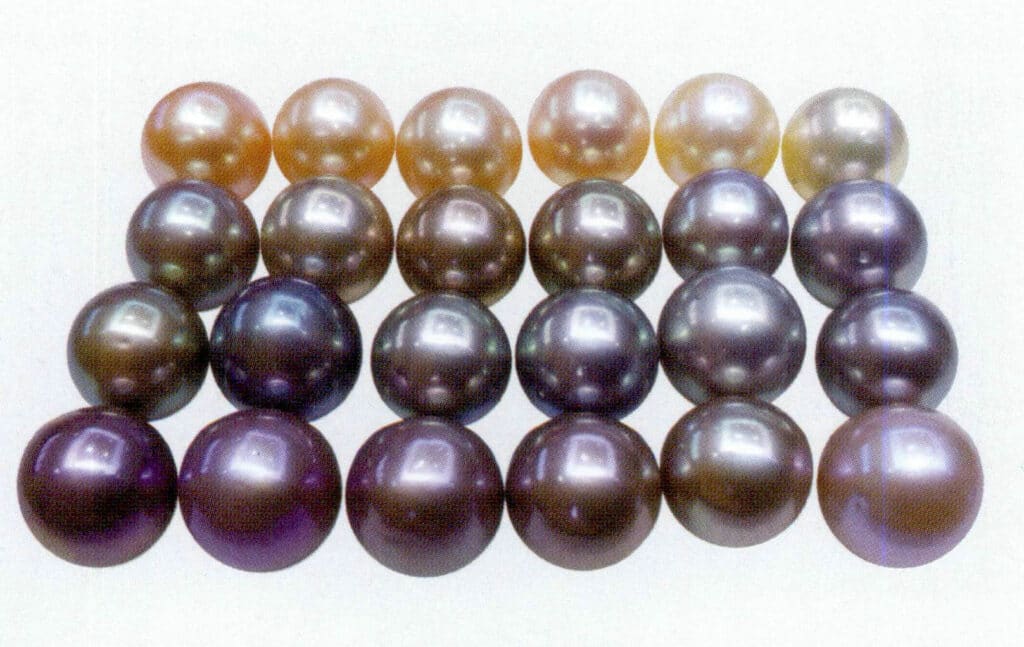

2. Dyeing

Due to the limited natural colors of seawater and freshwater pearls, they cannot meet the market and decorative needs. Among the methods to change the color of pearls, dyeing is relatively the simplest and, therefore, the most widely used. Dyeing can deepen light colors using organic or inorganic dyes and dye white pearls into various colors. Dyeing can be applied to various types of pearls.

(1) Dyeing method

After preprocessing, pearls can be soaked in special chemical coloring solutions. By using different colored dyes, pearls can be dyed in various colors.

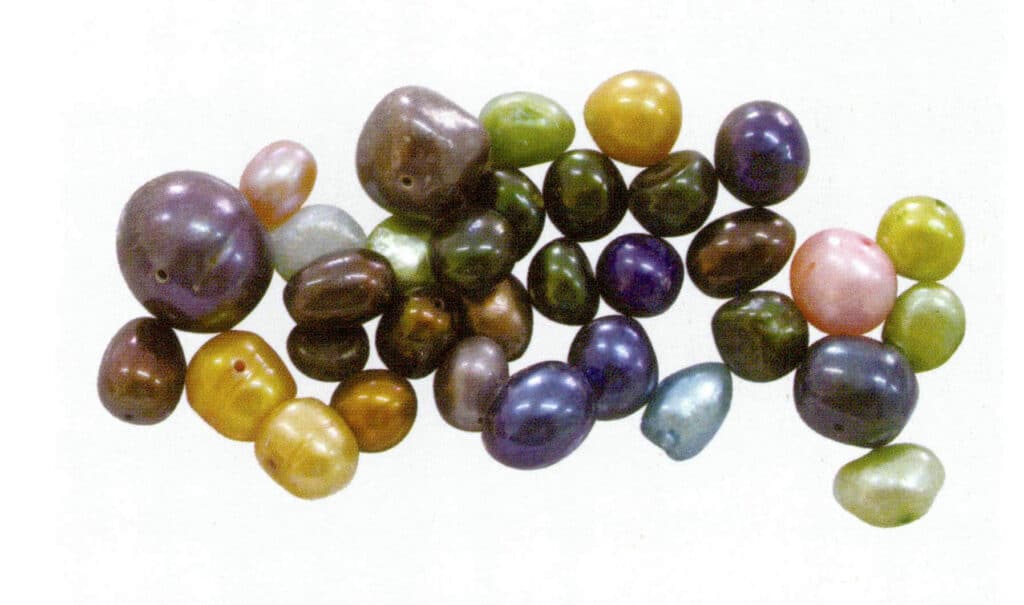

If cold potassium permanganate is used as a dye, it can dye pearls brown; by using cobalt (Co) salts and other dyes, seawater pearls can be dyed gray to imitate the natural color of gray Japanese seawater cultured pearls. Other inorganic or organic dyes can also be used to dye pearls in different colors. Dyed pearls of various colors are shown in Figures 1-5-40 to 1-5-49.

Figure 1-5-40 Dyed freshwater cultured pearls and mother-of-pearl shells

Figure 1-5-41 Dyed freshwater cultured pearls (1)

Figure 1-5-42 Dyed freshwater cultured pearls (2)

Figure 1-5-43 Dyed freshwater cultured pearls (3)

Figure 1-5-44 Dyed freshwater cultured pearls (4)

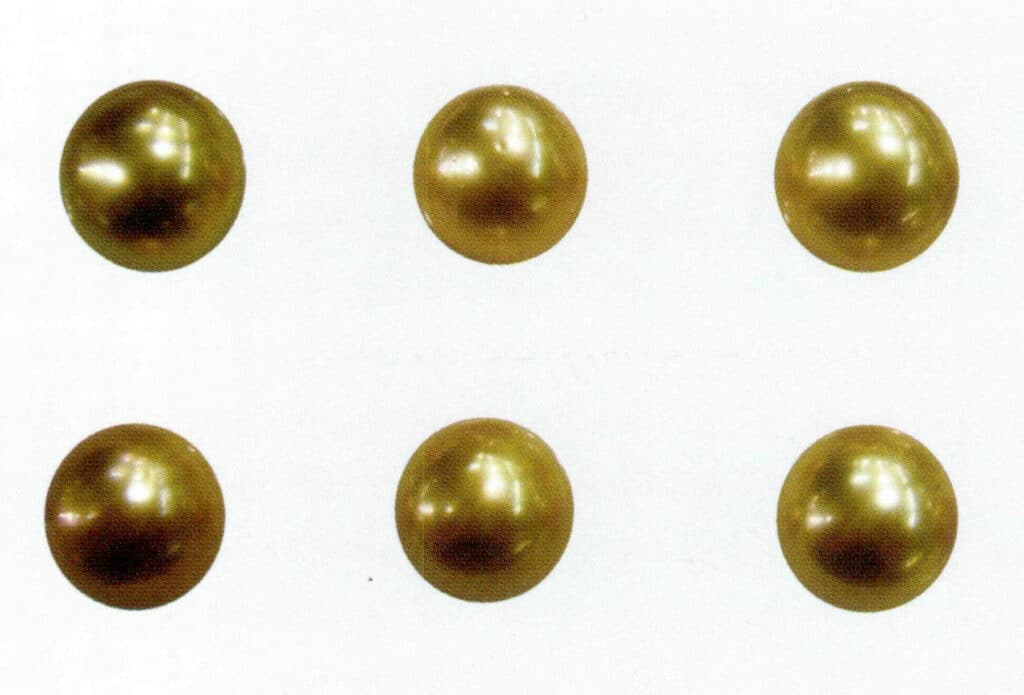

Figure 1-5-45 Dyed South Sea Aquaculture Pearls

Figure 1-5-46 Staining Chinese sea water cultured pearls (1)

Figure 1-5-47 Dyed Chinese Sea Aquaculture Pearls (2)

Figure 1-5-48 Stained Japanese sea water cultured pearls (1)

Figure 1-5-49 Dyed Japanese Sea Farmed Pearls (2)

To allow the dye to enter the interior through the gaps in the pearl layer, the pearl can be pre-drilled, and the dye can be injected into the holes for coloring.

The most common type on the market is dyed black pearls, which are treated with silver salts to dye the pearl layer a completely opaque pure black. The pearls are usually soaked in dilute silver nitrate and ammonia solution, and then the samples are placed in sunlight or reduced in hydrogen sulfide gas to turn black. Dyed black pearls are stable under light and heat conditions. Some pearls require multiple dyeing processes to achieve the desired effect. The black dyeing treatment of pearls is shown in Figures 1-5-50 to 1-5-55.

Figure 1-5-50 Workshop for dyeing seawater cultured pearls

Figure 1-5-51 Dried seawater cultured pearls after the first dyeing

Figure 1-5-52 Sea-farmed pearls after secondary dyeing

Figure 1-5-53 Completed dyed seawater cultured pearls

Figure 1-5-54 Stained freshwater cultured pearls (1)

Figure 1-5-55 Dyed freshwater cultured pearls (2)

(2) Identification Characteristics

- Naked eye and magnified inspection The raw materials for pearl dyeing treatment are generally pearls with poor drilling, luster, or color, and drilling before dyeing facilitates the diffusion of the dye. However, except for black, it is generally difficult to achieve uniform color across the entire pearl layer for other colors, as seen in Figures 1-5-56 and 1-5-57.

Figure 1-5-56 Cross-section of dyed freshwater cultured pearls (1)

Figure 1-5-57 Cross-section of dyed freshwater cultured pearls (II)

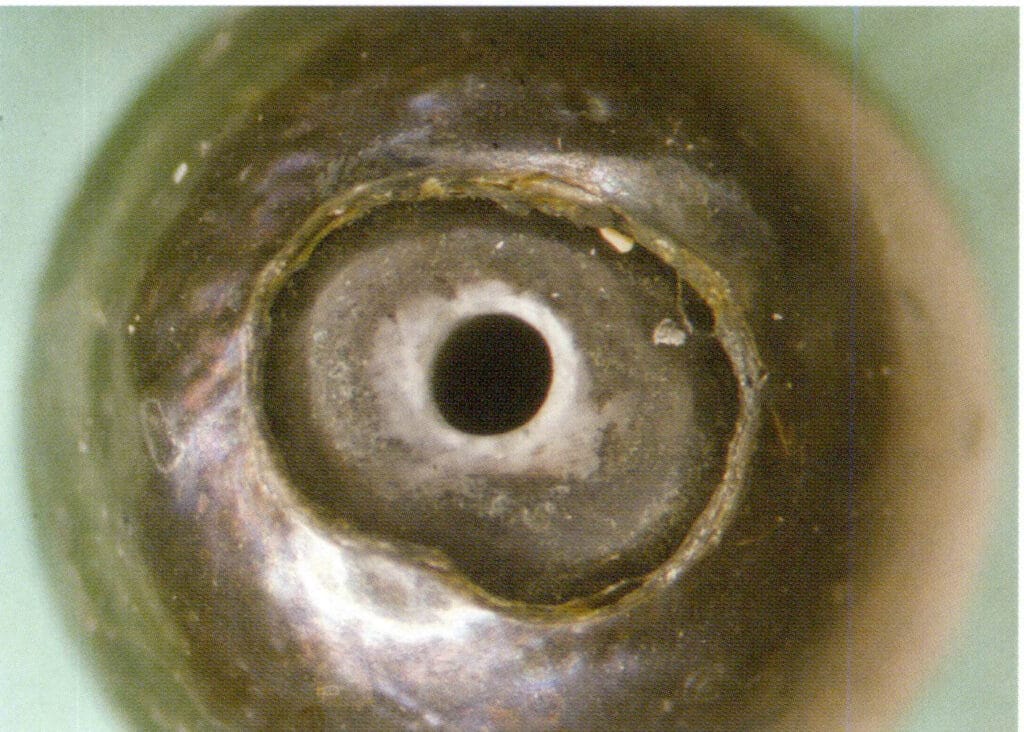

One of the most important identification features of dyed pearls is the characteristics of the drilled hole. This is because the dye generally seeps in along the drill hole, making it easy to accumulate in this area. Additionally, there will be a deposit of colorant at the surface’s flaw pits, which is darker than the color of the other smooth layers of the pearl.

A magnified inspection of dyed pearls reveals color spots and point-like precipitates on the surface; the pearl layer is often corroded, showing signs of corrosion, fine wrinkles, and unnatural spots or powder, and there may even be peeling of the pearl layer.

Dyed black pearls are generally pure black, with uniform color, poor luster, unnatural overtones, and accompanying colors, and they often exhibit abnormal metallic luster or overtones. Traces of chemical treatment can often be seen near the drilled holes, with yellowing or other colors differing from other areas frequently appearing around them.

The identification features of dyed pearls observed with the naked eye and under magnification are shown in Figures 1-5-58 to 1-5-69.

Figure 1-5-58 Characteristics of the drilling site for dyed seawater cultured pearls (1)

Figure 1-5-59 Characteristics of the drilling holes in dyed seawater cultured pearls (II)

Figure 1-5-60 Characteristics of the drilling area of dyed seawater cultured pearls (under a microscope)

Figure 1-5-61 The color of dyed freshwater cultured pearls deepens at the drilled holes and blemishes

Figure 1-5-62 The luster and accompanying colors of black dyed freshwater cultured pearls

Figure 1-5-63 Metallic luster of black dyed freshwater cultured pearls c

Figure 1-5-64 Unnatural spots on the surface of black-dyed freshwater cultured pearls

Figure 1-5-65 Signs of corrosion on the surface of black-dyed freshwater cultured pearls, including the peeling of the pearl layer

Figure 1-5-66 Common colors of non-freshwater cultured pearls (1)

Figure 1-5-67 Common colors of non-freshwater cultured pearls (II)

Figure 1-5-68 Shows Common Colors of Non-Japanese Sea Water Cultivated Pearls

Figure 1-5-69 Common colors of non-Chinese seawater cultured pearls (excluding white)

- Under long-wave ultraviolet light, natural black pearls can exhibit dark red-brown and red fluorescence, while the fluorescence of dyed black pearls is inert or dark green.

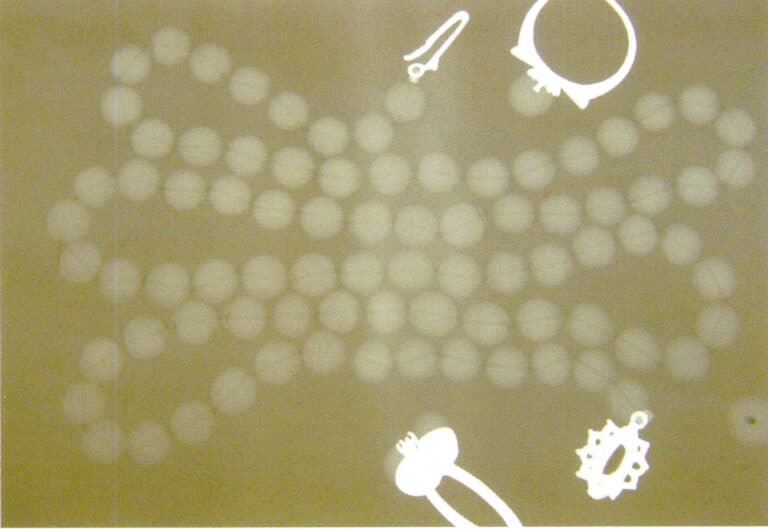

- Photographic method

(1)X-ray photography uses materials such as pearl nuclei, organic matter, and aragonite, which have different degrees of transparency to X-rays. The property that silver does not transmit X-rays is used to distinguish different colors on X-ray photographic film: the pearl can be seen on natural black pearl X-ray photographic film. A distinct connection band exists between the layer, hard protein, and the nucleus; dyed pearls treated with silver salts usually have silver deposited in the organic hard protein layer between the pearl layer and the nucleus, resulting in only white stripes appearing in the photograph.

(2) Infrared photography method utilizes the different reflective properties of natural black pearls and dyed black pearls to infrared light. The film shows a bluish image for natural pearls, while dyed black pearls display a bluish-green to yellow image.

- Micro-damage identification: Use a cotton swab dipped in dilute hydrochloric acid or acetone to wipe inconspicuous areas. Natural pearls do not lose color, while dyed pearls will leave black stains. Scraping at the drilling site, natural black pearls produce a white powder, while dyed black pearls produce a black powder.

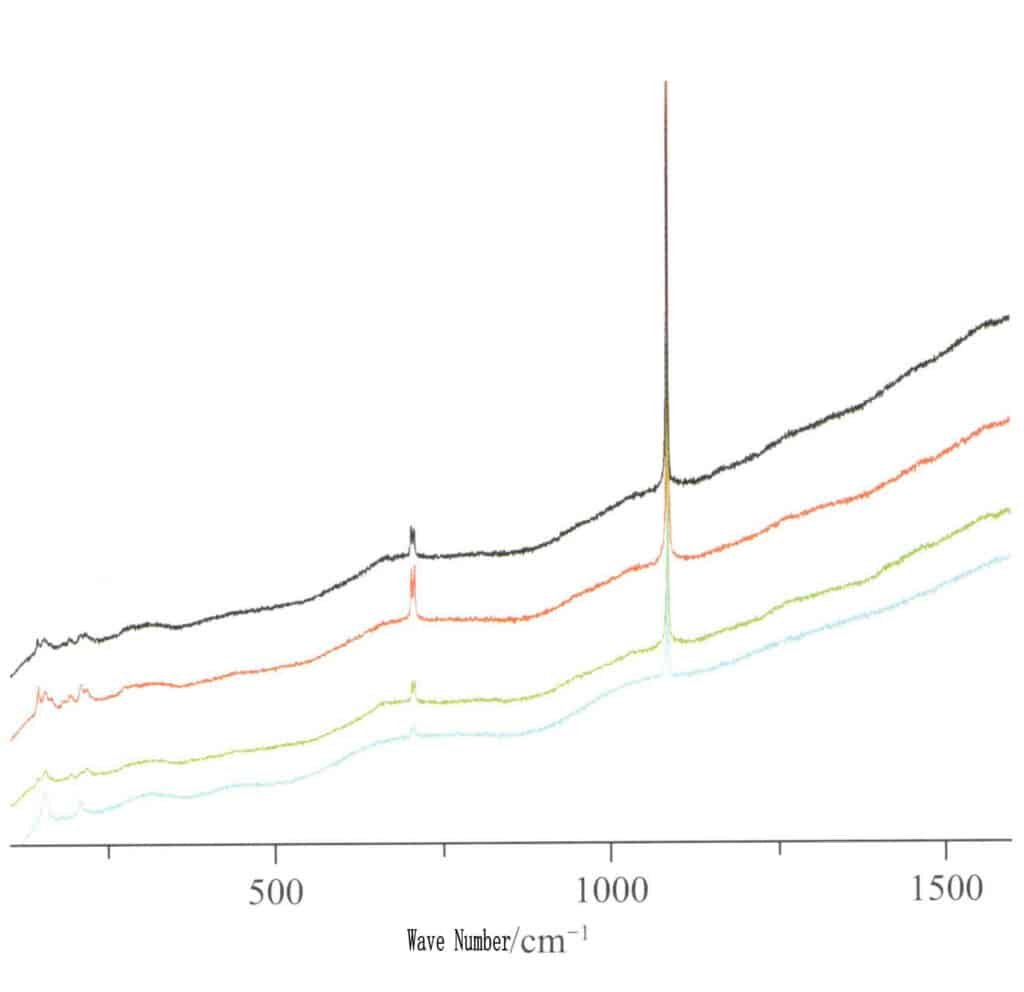

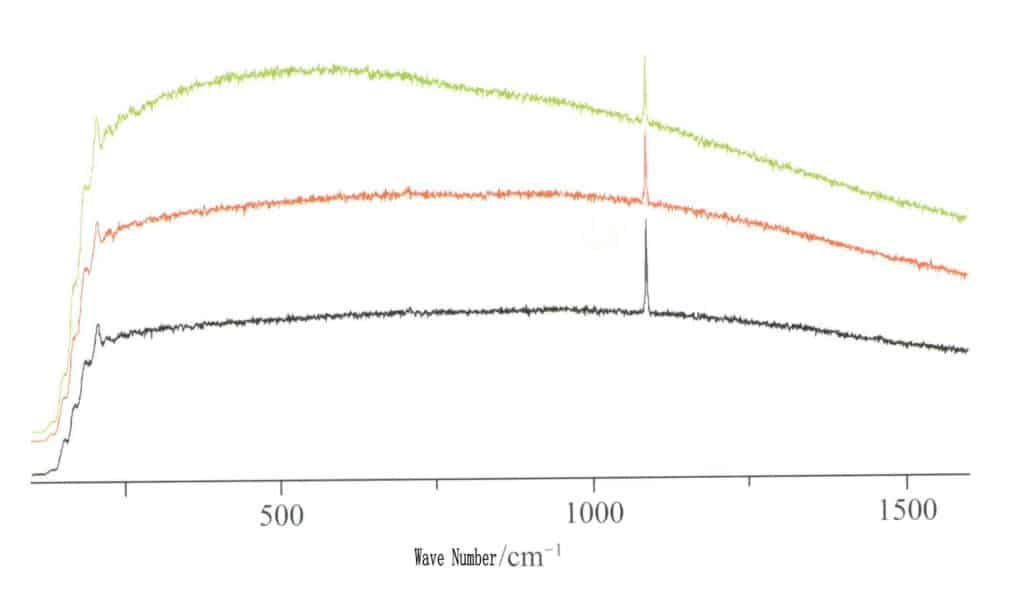

- Raman spectroscopy Although black pearls treated with different dyeing processes have different Raman spectral peaks, there are generally very strong calcite peaks near 1084cm-1, medium intensity peaks at 702cm-1, and dye peaks, etc.

3. Irradiation

(1) Method

The pearl irradiation treatment generally uses the Y radiation method, which has existed since 1960. The radiation source used in the Y-ray radiation method is 60Co, with an intensity equivalent to 100Ci (1Ci = 3.7 x 1010 Bq), a radiation distance of about 1cm, and an irradiation time of 20 minutes.

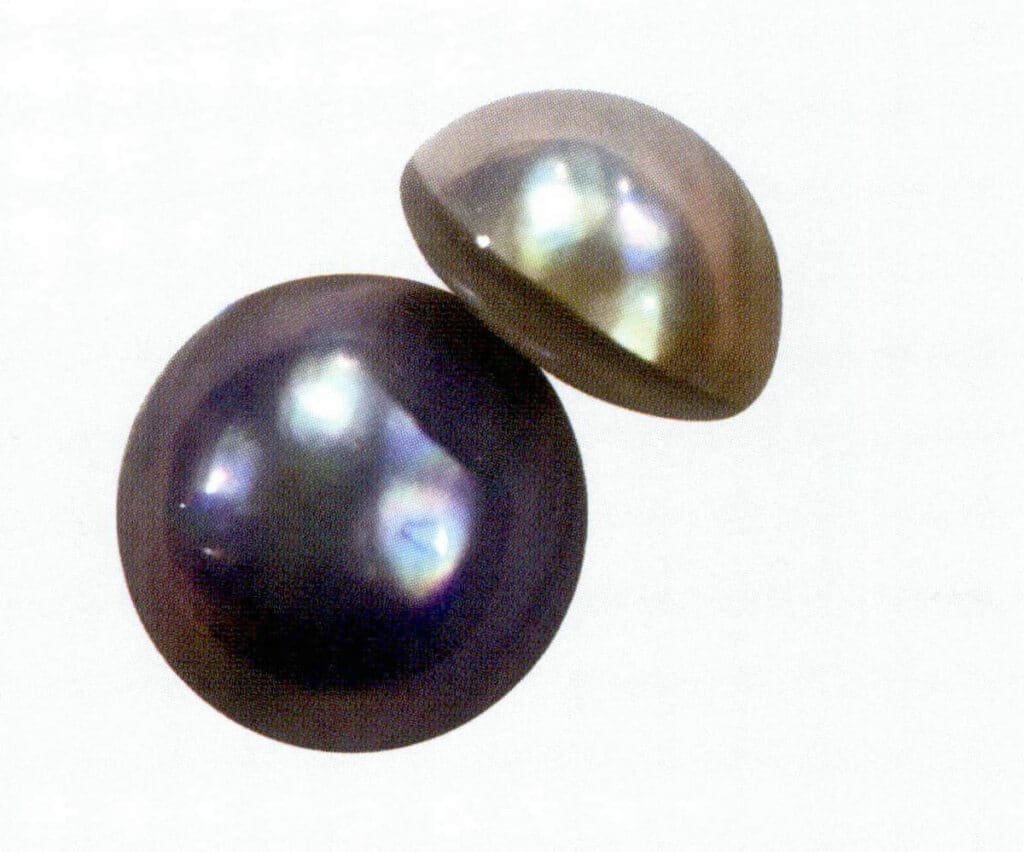

Freshwater cultured pearls can turn into black pearls with body colors of black and silver-gray, accompanied by bright colors such as green, blue, and red after irradiation. The pearl layer of seawater pearls does not change color after irradiation, but the color of the nucleus deepens when freshwater mussel shells are used as the pearl nucleus.

The dosage and time of irradiation should be appropriate. If the dosage or time is insufficient, the pearls will only turn gray and not achieve the ideal black color. Generally, the dosage and time of irradiation are positively correlated with the deepening of the pearl sample’s color; however, when exceeding a some point, that is, when the dosage is too high and the time is too long, the luster of the irradiated pearls will weaken. Even the pearl layer may flake off.

After irradiation, pearls are stable under ultraviolet light and sunlight. When irradiated pearls are exposed to sunlight and ultraviolet light separately, there is no noticeable change in color after several hours. After being stored under general conditions for more than six months, the color of the irradiated pearls also remains unchanged.

(2) Identification Characteristics

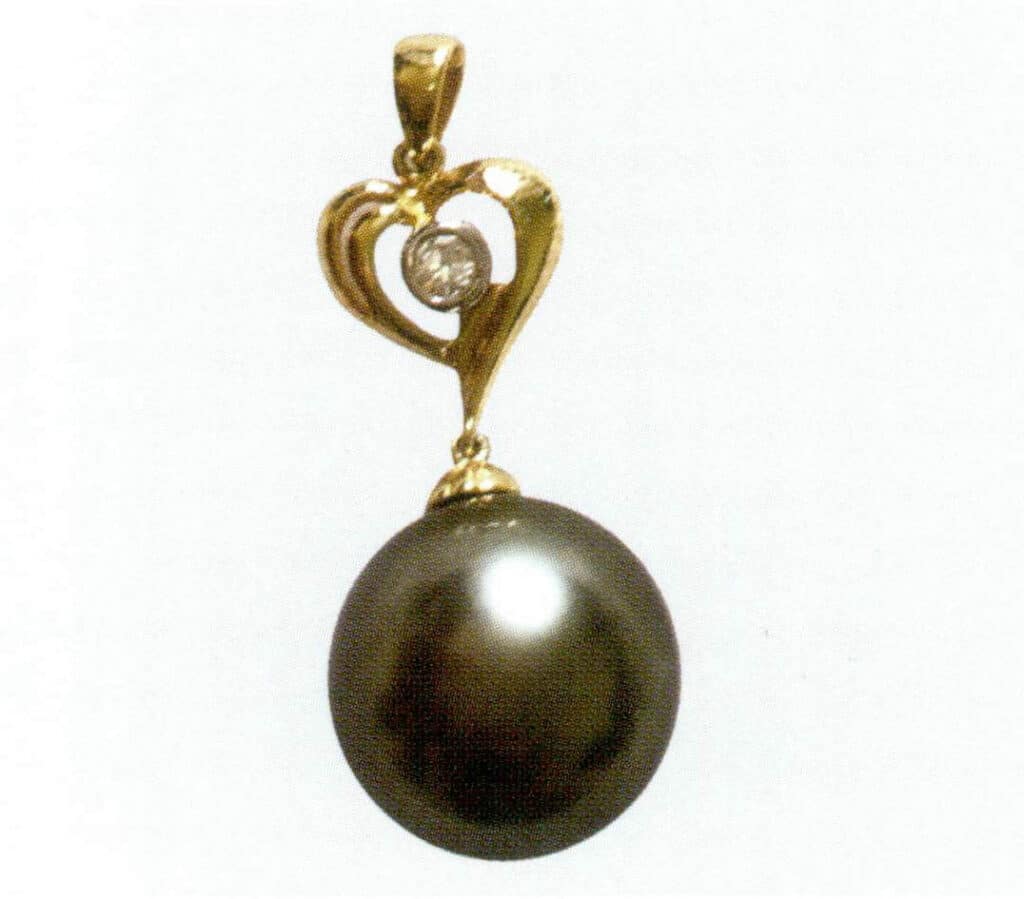

Since seawater pearls are unsuitable for irradiation color change, freshwater non-nucleated cultured pearls are generally treated, see Figure 1-5-70 and Figure 1-5-71.

Figure 1-5-70 Irradiated freshwater cultured pearls

Figure 1-5-71 Irradiated freshwater cultured pearls (under microscope)

The identification characteristics are as follows:

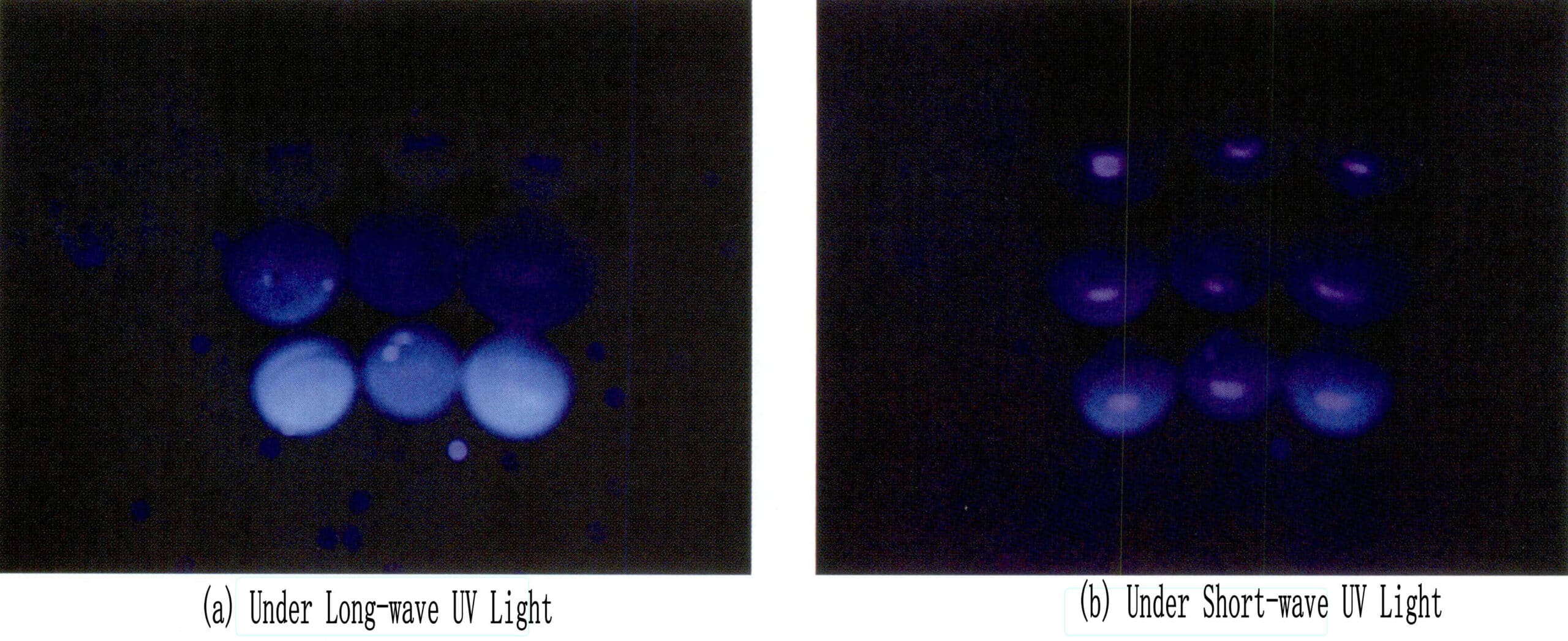

(a) Magnified inspection is similar to cultured pearls.

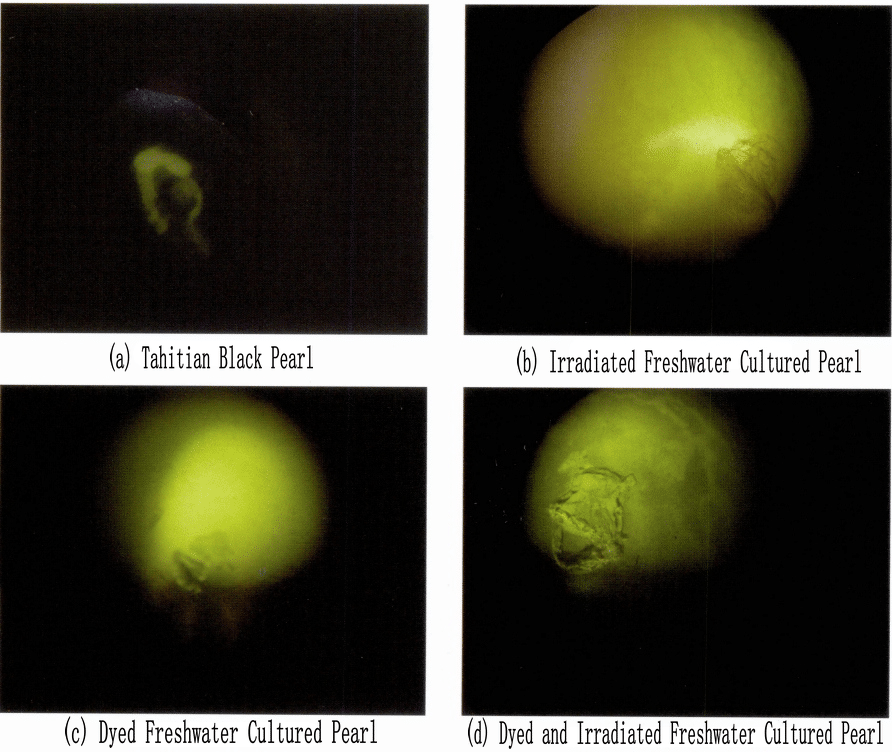

(b) Fluorescent characteristics Under long-wave ultraviolet light, freshwater cultured pearls treated with Y-ray irradiation exhibit extremely strong green fluorescence; two unknown source irradiated freshwater cultured pearls purchased from the market also emit strong green fluorescence, slightly weaker than that of the Y-ray irradiated freshwater cultured pearls. Irradiated seawater pearls show medium to strong blue-white fluorescence; natural black pearls generally emit red to brown-red fluorescence. Under short-wave ultraviolet light, irradiated pearls exhibit medium to weak green fluorescence, while natural black pearls generally do not emit light.

(c) Cathode ray luminescence characteristics Under cathode rays, the structure of irradiated pearls appears rougher, with poorer transparency, reduced luster, and a noticeable “dry” appearance compared to the former; some pearls show surface cracks and other damages. Dyed irradiated black pearls have similar cathode luminescence characteristics to uncolored irradiated pearls, but their luminescence is uneven, revealing internal cracks. Additionally, larger areas of damage appear on the surface. The freshwater pearls purchased from the market, irradiated by an unknown source, show internal cracks more clearly under cathode luminescence, similar to the cathode luminescence characteristics of the dyed irradiated black pearls mentioned above. For seawater pearls, the layers of irradiated pearls do not emit light or only weak blue-white light under cathode rays, while the exposed black shell parts emit green light; natural black pearls do not emit light under cathode rays.

(d) Infrared and Raman spectral characteristics The infrared spectrum of irradiated pearls shows no significant difference from freshwater cultured pearls, but there are differences from natural black pearls.

The Raman spectrum shows differences between dyed and natural black cultured pearls. The Raman peaks of irradiated pearls are easily identifiable, with strong fluorescence causing the peak positions to be too high, generally only showing a weakened 1083cm -1 calcite peak; the Raman peaks of dyed and irradiated black pearls are similar to those of generally irradiated freshwater cultured pearls. Natural black pearls, apart from the calcite peak, generally show many accompanying peaks, such as 1168.54cm-1, 1262.85cm-1, 1472.23cm-1,1563.34cm-1, 1604.89cm-1 and so on.

(e) Micro-damage testing: Use a small knife to scrape powder in inconspicuous areas during micro-damage identification because the amount of powder is very small; the powder from irradiated pearls is the same as natural, also showing white. Sometimes, the micro-powder from dyed black pearls and dyed plus irradiated black pearls can also be white.

(f) Another characteristic of Tahitian black pearls is nucleated seawater pearls. Generally, the color change effect of seawater pearls is not ideal. Therefore, if freshwater pearls exhibit the appearance of Tahitian black pearls, it can serve as one of the auxiliary identification criteria for irradiation treatment.

4. Heat Treatment

The heat treatment process began to appear in the 1990s, mainly targeting lighter-colored golden South Sea pearls. The specific details of the heat treatment process are kept confidential.

This process mainly targets un-drilled pearls. After drilling, the color inside the pearl hole is noticeably lighter than the surface. The diagnostic identification feature is the ultraviolet-visible spectroscopic characteristics. Naturally colored golden South Sea pearls have a strong absorption peak at 330-385nm, and the deeper the color, the stronger the peak, while heat-treated pearls are the same as naturally colored white South Sea pearls, showing no characteristic absorption peaks in this range.

5. Fading

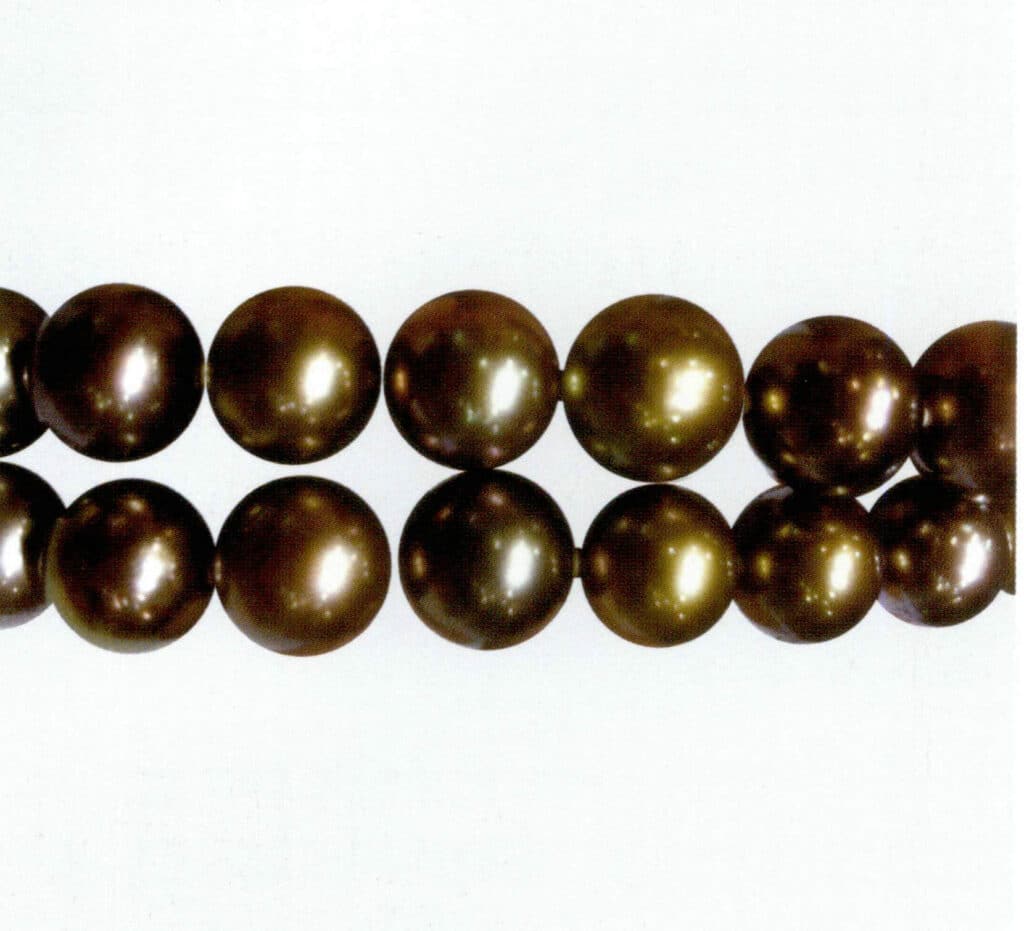

Fading treatment, also known as bleaching, mainly refers to Tahitian black pearls. Tahitian black pearls can be bleached through an undisclosed process to fade to a chocolate color.

The color tone of pearls treated with this fading process is difficult to control, making it hard to ensure that each pearl has the same tone, see Figure 1-5-72 to Figure 1-5-75.

Figure 1-5-72 Fading treatment of seawater cultured pearls 1

Figure 1-5-73 Fading treatment of seawater cultured pearls 2

Figure 1-5-74 Fading treatment of seawater cultured pearls 3

Figure 1-5-75 Fading treatment of seawater cultured pearls4

6. Film Coating

Such methods are mainly applied to low-quality freshwater non-nucleated pearls and are not widely seen in the market and laboratories.

(1) Polymer Coating

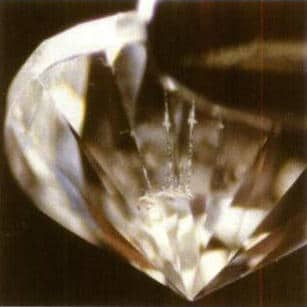

A thicker layer of colorless polymer (mainly plastic) is applied to the surface of low-luster black nucleated cultivated pearls from the Taqi Dike; freshwater pearls can also be coated with a thick film and cut into small facets.

During identification, it can be found that the luster of the pearl does not come from the surface like natural pearls but from beneath the polymer layer. The color of the pearl also varies in tone when observed from the top and the side.

Additionally, bubbles trapped in the colorless plastic layer, uneven surfaces, scratches on the covering layer, sharp objects that can leave marks on its surface, and other “dressing” characteristics can all serve as identification criteria.

(2) Coated Silica Pearls

A layer of polydimethylsiloxane is applied to the surface of the pearl to improve its luster.

The surface of the pearl is particularly glossy and has a some sticky feel when touched. Upon magnified inspection, the edges of the pearl’s layered crystals are difficult to see, and sometimes, the colorless covering layer and surface scratches are visible.

( 3 ) “Electroplated” Pearls

The surface of the pearls is “electroplated” with a layer of Ti-rich material to improve their luster. This treatment is mainly applied to white freshwater pearls. The luster intensity of the treated pearls is generally positively correlated with the Ti content.

Identification features: The luster of “electroplated” coated pearls is generally stronger than that of white freshwater pearls and conventional brightening bleached pearls (Figure 1-5-76), with a relative density comparable to freshwater pearls; the ultraviolet fluorescence of white “electroplated” coated freshwater pearls is mostly light blue, weaker than that of conventional brightening bleached freshwater pearls. Under microscopic observation, the surface of white “electroplated” freshwater pearls may show scratches and patchy wear (Figure 1-5-77). Trace element testing shows high Ti levels, differing from ordinary cultured pearls.

Figure 1-5-76 Untreated pearls (left) and coated treated pearls (right)

Figure 1-5-77 Scratches on the surface of coated pearls (under microscope)

7. Peeling

Currently, this method is rarely used abroad and is not used domestically.

Peeling treatment involves carefully removing the unattractive outer layer of the pearl with extremely fine tools, hoping to find a better layer underneath. This operation is difficult, and sometimes, one peeling can lead to another peeling until no pearl layer remains. This

method is often used for pearls that have been worn for a long time and have yellowed skin or damaged outer layers.

Peeling treatment is mainly used for natural pearls and seawater cultured pearls, primarily due to their high value, and the difficulty of peeling is not as great as that of freshwater cultured pearls. This may be related to the single-layer thickness of seawater cultured pearls (about 0.3-0.6µm ) being thicker than that of freshwater cultured pearls (about 0.2-0.4µm) and having little variation in thickness.

8. Surface Crack Filling

This type of processing technology is not widely seen in the market or laboratories.

The tiny cracks on the surface of the pearl must be healed promptly to ensure the luster and beauty of the pearl’s appearance. The specific method is to soak the pearl in hot olive oil, using the oil’s penetration to gradually “heal” the cracks on the pearl’s surface, then raise the temperature to 150℃, resulting in a deep brown color on the pearl’s surface.

9. Wax Filling

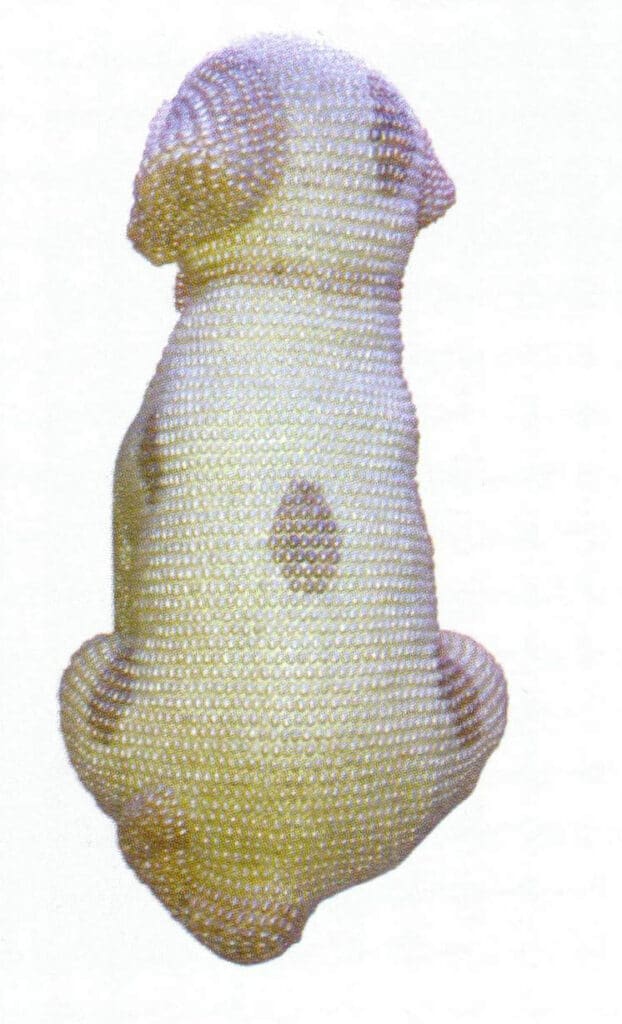

Wax is mainly used for freshwater cultured pearls with holes on the surface, and wax is used to seal the holes, as seen in Figures 1-5-78 and 1-5-79.

Differences in luster between the wax and the pearl layer can be observed during identification.

Figure 1-5-78 Pearls with holes awaiting treatment

Figure 1-5-79 Freshwater nucleated pearls treated with wax

10. Nucleated pearl dyeing

Seawater pearls can also have their nuclei dyed, achieving a colorful pearl effect visually through the thin white layer of the pearl.

In addition, the outer mantle implanted during nucleation can also be dyed to intervene in the color of the pearl layer. Colored outer mantles of black-lipped and gold-lipped oysters can also be implanted, showing silver-gray or light golden yellow through the thin layer of the pearl, but the pearl layer remains white, see Figure 1-5-80 and Figure 1-5-81.

Figure 1-5-80 Gray treated pearls

Figure 1-5-81 The color of the inner and outer mother-of-pearl layers is inconsistent

11. Splicing

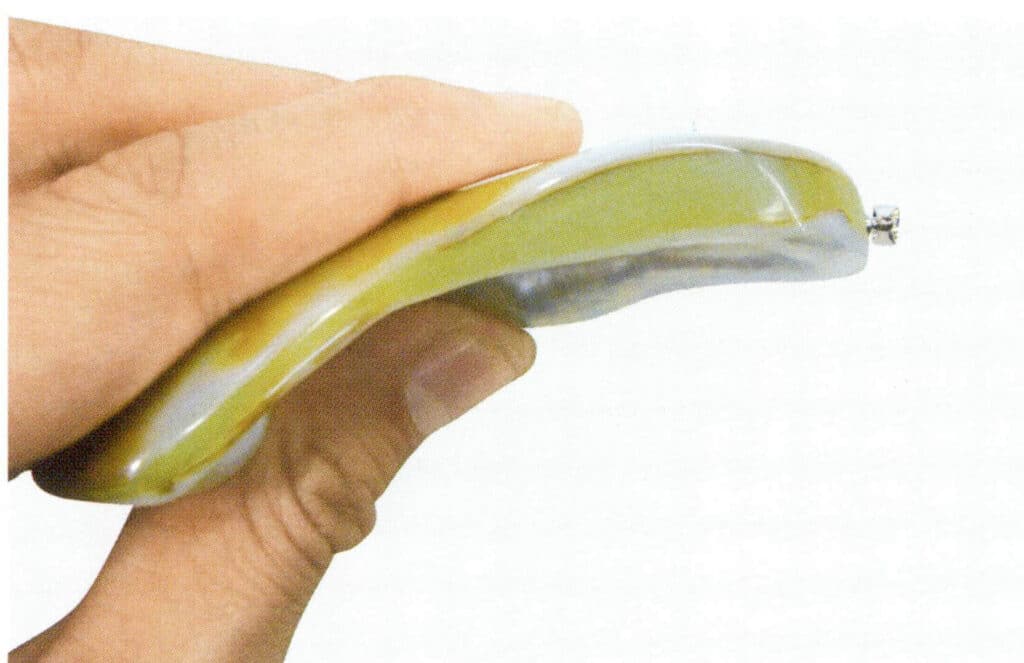

Mabe pearls are the most common two-layer, or three-layer spliced pearls.

Since the semi-spherical and other shapes of the Mabe pearl nucleus are not inserted into the outer membrane of the mother shell but are glued to the inner shell of the mollusk, the pearl layer of the Mabe pearl is relatively thin, and the nucleus of the Mabe pearl is very easy to separate from the pearl layer covering it. Therefore, it must be spliced before it can be used as jewelry.

Semi-spherical and semi-oval Mabe pearls are generally three-layer spliced. The outer or upper part is the cultured pearl layer, the middle is filled with wax or shell material, and the bottom is glued with the pearl layer of the bead-producing shell. Patterns that are flatter, such as images, are generally two-layer spliced.

During identification, a clear boundary can be seen from the side, with differences in color, luster, etc. In addition, the shape of the assembled pearls is also the most important identification feature: they are semi-circular, semi-elliptical, etc., with larger sizes and flatter bottoms; the setting form of assembled pearl jewelry is mainly bezel setting, which is different from bead setting. See Figures 1-5-82 to 1-5-91.

In addition, there will also be inlaid shells with pearls, which combine shell pearls and mother-of-pearl with shells.

Figure 1-5-82 Cultured shell and Mabe pearl (1)

Figure 1-5-83 Cultured Zhu Pearls and Mabe Pearls (2)

Figure 1-5-84 Three-layer assembled Mabe pearl (1)

Figure 1-5-85 Three-layer Assembled Mabe Pearls (2)

Figure 1-5-86 Two-layer assembled portrait Mabe pearl

Figure 1-5-87 Side View of Three-layer Assembled Mabe Pearls

Figure 1-5-88 Front view of three-layer assembled Mabe pearl

Figure 1-5-89 Back View of Three-layer Assembled Mabe Pearls

Figure 1-5-90 Mabe Pearls with Bezel Setting

Figure 1-5-91 Inlay with Pearls

12. Carving and Inlay

The carving of pearls includes faceting, inlaying, and other techniques.

Faceting refers to polishing facets on the pearl layer; see Figure 1-5-92 and Figure 1-5-93.

Figure 1-5-92 Faceted Pearl (1)

Figure 1-5-93 Faceted Pearl (2)

Carving refers to engraving a specific pattern on the pearl layer. The nucleus used to cultivate pearls can also be replaced with colored gemstones. After the pearls have grown, the carving is done on the surface of the pearls, allowing the colors of the internal colored gemstones to emerge from the hollow patterns, creating a special visual effect. See Figure 1-5-94 and Figure 1-5-95.

Inlaying refers to polishing the depressions in the pearl layer and then inlaying gemstones.

Figure 1-5-93 Faceted Pearl 1

Figure 1-5-95 Carved Pearls 2

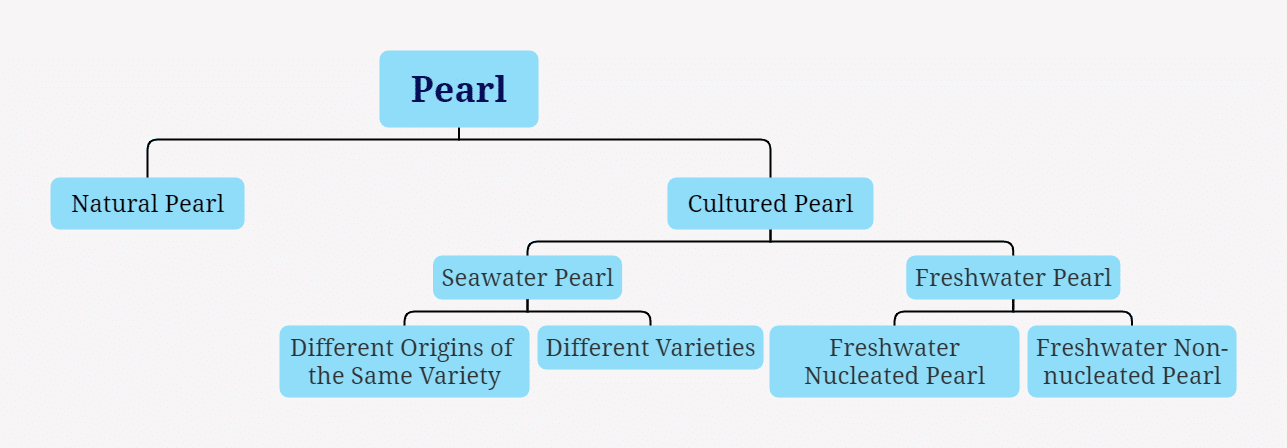

Section II Identification of Pearls

For the identification of pearls, the first step is to determine whether it is a pearl or a faux pearl; once confirmed as a pearl, it is necessary to identify whether it is a natural pearl or a cultured pearl; for cultured pearls, it must be determined whether they are saltwater cultured pearls or freshwater cultured pearls and whether they have undergone dyeing or other enhancement treatments.

1. Distinguishing Pearls from Faux Pearls

Imitation pearls have a long history. The pearls that are part of the adornments on the clothing of Queen Elizabeth I of England are imitation pearls. Artificial imitation pearls are made with a core of plastic, glass, or shell beads, coated with a layer of “pearl liquid” to achieve an appearance similar to real pearls.

(1) Glass core imitation pearls

For imitation pearls with a glass core, see Figure 1-6-1.

The glass core imitation pearls produced by the Spanish company Majorica are the most famous in this category. Majorica pearls are made by applying a special bioluminescent coating with an iridescent sheen to the glass bead core, followed by a protective layer.

Majorica pearls have a strong luster, with a distinct rainbow color on the smooth surface. They feel warm and smooth to the touch, and when pricked with a needle at the drilled hole, they can flake off in pieces; they have a low refractive index of only 1.48; under a microscope, they do not exhibit the characteristic growth spiral lines of real pearls, only uneven edges; when lightly scraped with a tooth, they feel smooth. In X-ray photographs, Majorica pearls appear opaque.

(2) Plastic core imitation pearl

For imitation pearls with a plastic core, see Figure 1-6-2.

Upon careful observation, its color is monotonous and dull, its size is uniform, and it has good roundness. There are depressions at the drilling points, and it feels light with a warm sensation.

(3) Shell core imitation pearl

For imitation pearls with a shell core, see Figure 1-6-3.

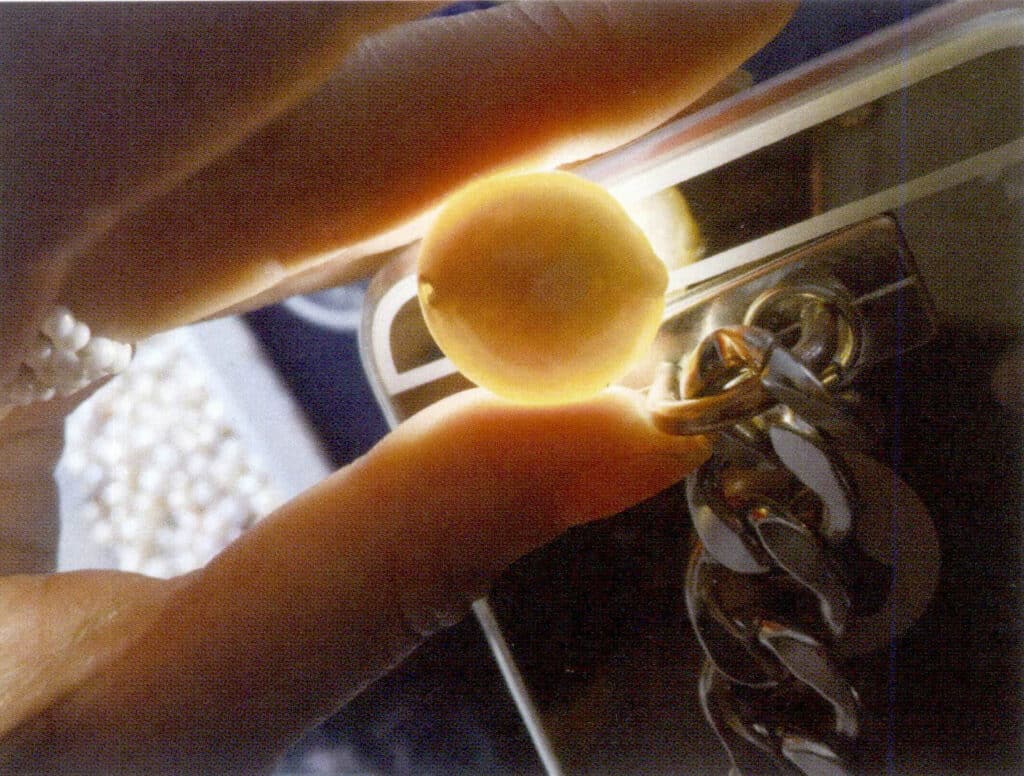

This imitation pearl is made by applying extremely fine synthetic resin along with some tiny crystals, layer by layer, onto small round balls made from shells (the nucleus used for cultured seawater pearls), creating an effect similar to that of cultured seawater pearls. Shell pearls appear very close to cultured seawater pearls in appearance, and they are large and round, with excellent luster, making it easy for people to mistake them for high-quality pearls.

The main difference between shell nucleus imitation pearls and real pearls is that when observed under magnification, the unique growth spiral lines on the surface of real pearls cannot be seen, and instead, it resembles the surface of an eggshell; under transmitted light, the stripes of the inner nucleus and the “pearl layer” membrane attached to it can be seen.

(4) Identification features of pearls and imitation pearls

The identification features of pearls and imitation pearls can be found in Table 1-6-1 and Figures 1-6-4 to 1-6-17.

Table 1-6-1 Identification features of pearls and imitation pearls

| Caracteristici | Perla | Imitation pearl |

|---|---|---|

| Culoare | White, pink, orange, purple, black, golden yellow, gray | Diverse culori |

| Formă | Round, teardrop, oval, irregular, connected irregular, cabochon | Usually regular round and teardrop shapes |

| Hand¬held weight | Moderat | Glass core: Heavy |

| Hand¬held weight | Moderat | Plastic core: Light |

| Hand¬held weight | Moderat | Shell core: Similar to pearls |

| Drilling | Smooth; visible nucleus in the pearl | Wrinkled |

| Caracteristici de suprafață | Smooth; may have pits, no shiny spots, growth lines, wrinkles, and other growth defects | Surface similar to eggshell; scratches |

Figure 1-6-4 Surface characteristics and drilling of imitation pearls (1)

Figure 1-6-5 Surface characteristics and drilling of imitation pearls (2)

Figure 1-6-6 Surface characteristics and drilling of imitation pearls (3)

Figure 1-6-7 Drilling of imitation pearls (1)

Figure 1-6-8 Drilling of imitation pearls (2)

Figure 1-6-9 Surface characteristics of imitation pearls (1)

Figure 1-6-10 Surface characteristics of imitation pearls 2

Figure 1-6-11 Surface characteristics of imitation pearls 3

Figure 1-6-12 Surface characteristics of non-nucleated freshwater cultured pearls

Figure 1-6-13 Drilling characteristics of freshwater cultured pearls (microscopic observation)

Figure 1-6-14 Drilling characteristics of seawater cultured pearls

Figure 1-6-15 Drilling characteristics of seawater cultured pearls (microscopic observation)

Figure 1-6-16 Smooth surface of seawater cultured pearls (microscopic observation)

Figure 1-6-17 The smooth surface of freshwater cultured pearls (microscopic observation)

2. Identification of natural pearls and cultured pearls

The traditional methods for distinguishing between natural and cultured pearls mainly involve determining whether there is a nucleus, X-ray diffraction, and X radiography (see Figures 1-6-18 and 1-6-19).

Figure 1-6-18 X-ray radiography (GIT Laboratory, Thailand)

Figure 1-6-19 X-ray observation of pearl jewelry

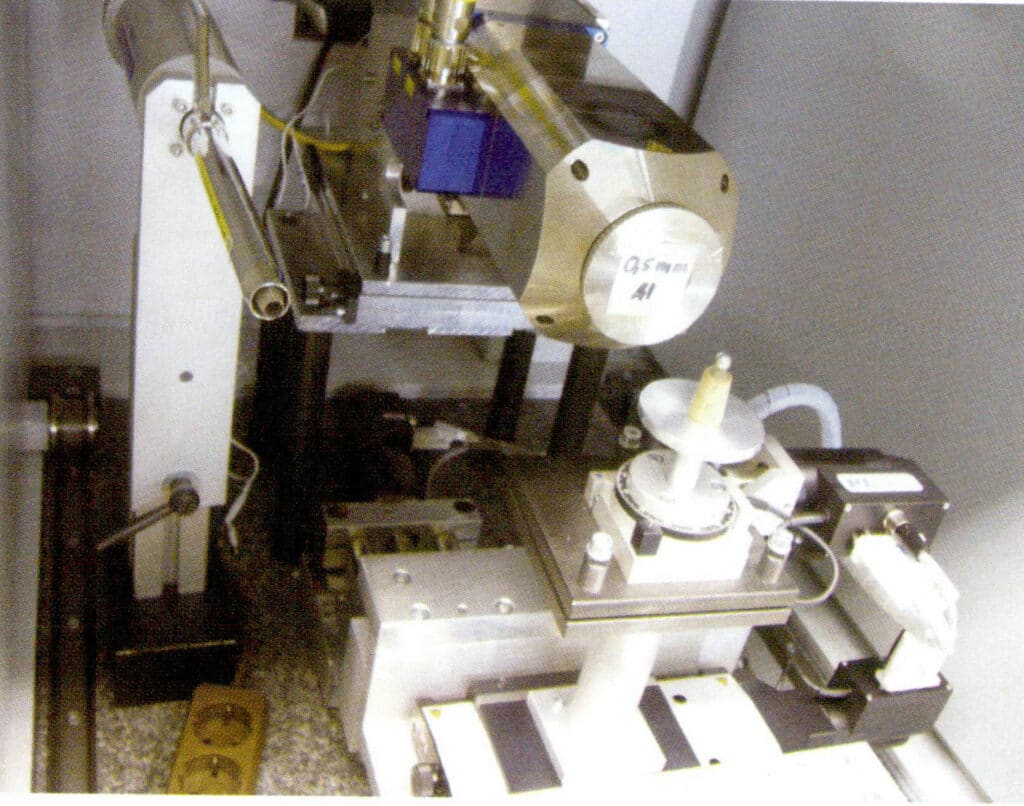

In recent years, X-ray microtomography technology (or X-ray-uCT ), also known as X-ray tomography, has been developed, allowing for clearer observation of the interiors of natural pearls, cultured pearls, and nucleated freshwater pearls compared to traditional X radiography. In the center of nucleated freshwater cultured pearls, curled voids left by the mantle absorption can be seen. In contrast, such voids are rarely found inside natural pearls, which generally exhibit concentric growth structures from the center. The instruments and images of X-ray microtomography of pearls are shown in Figures 1-6-20 to 1-6-23.

Figure 1-6-20 X-ray micro-CT scanner (Mainz University, Germany)

Figure 1-6-21 X-ray micro-tomography (local)

Figure 1-6-22 X-ray tomography observing seawater cultured pearls

Figure 1-6-23 X-ray tomography observing non-nucleated freshwater cultured pearls

Copywrite @ Sobling.Jewelry - Producător de bijuterii personalizate, fabrică de bijuterii OEM și ODM

Neutron scattering imaging technology can also better observe the interiors of pearls.

Since the main mineral component of pearls is calcium carbonate, many natural pearls are set in antique jewelry with a history of several hundred years, while non-nucleated cultured pearls have only a history of a few decades. Pearls can be dated using an ultra-sensitive accelerator mass spectrometer (AMS). A gem laboratory in Switzerland successfully used this technology to identify pearls from a shipwreck that are 970 years old, with an error range of 3 years.

The distinguishing features of natural and cultured pearls are shown in Table 1-6-2.

Table 1-6-2 The distinguishing features of natural and cultured pearls

| Caracteristici de identificare | Perle naturale | Cultivation of Pearls |

|---|---|---|

| Nucleus and Water Body | Nucleus-free | Nucleus-free freshwater cultured pearls: Nucleus-free, as the outer membrane often leaves gaps at the center of the pearl. |

| Nucleus and Water Body | Nucleus-free | Nucleated freshwater cultured pearls: Nucleated |

| Nucleus and Water Area | Nucleus-free | Seawater Cultivated Pearl: With Nucleus |

| Densitate relativă | Natural Seawater Pearl: 2.61 ~ 2.85 | Sea water cultured pearls: 2.72 ~ 2.78 |

| Densitate relativă | Natural freshwater pearls: 2.66 ~ 2.78, Rarely exceeds 2.74 | Freshwater cultured pearls: lower than most natural freshwater pearls |

| Indice de refracție | 1.530 ~ 1.685 | 1.500 ~ 1.685, mostly 1.53 ~ 1.56 |

| Ultraviolet light | Black: Long wave, weak to moderate, red, orange-red other colors: none too strong, light blue, yellow, green, pink, etc. | None to strong, light blue, yellow, green, pink |

| Naked eye identification | Shape mostly irregular; texture fine, structure uniform; pearl layer thick, mostly | Mostly round; pearl layer thin, relatively good transparency |

| Inspecția măririi | Concentric radiating layered structure; surface growth texture | Nucleated cultured pearls: with a nucleated layered structure, the nacre layer presents a thin concentric radiating structure, with fine surface textures; the nucleus can present parallel layering, and the nucleus shows a whitish cold light |

| Fotografii cu raze X | The structure shows concentric layering from the center to the shell, with the film displaying alternating light and dark ring patterns or arc shapes near the center | Nucleated cultured pearls: The boundary between the nucleus on the base and the pearl layer is distinct. |

| Fotografii cu raze X | The structure shows concentric layering from the center to the shell, with the film displaying alternating light and dark ring patterns or arc shapes near the center | Non-nucleated cultured pearls: Present a hollow or irregular void at the core, and an external concentric layered structure. |

| X Diffraction | Six-fold symmetric diffraction image | Four-fold symmetric diffraction image; special directions present a six-fold symmetric diffraction image |

| X-ray computed tomography | Concentric radiating layered structure starting from the core | Irregular voids or cavities left by the curled outer membrane visible inside freshwater non-nucleated pearls |

| Neutron scanning and imaging | Concentric radiating layered structure starting from the core | Irregular voids or cavities left by the curled outer membrane visible inside freshwater non-nucleated pearls |

| Carbon isotope dating | Often lasts for hundreds of years | From a few years to several decades |

3. Identification of freshwater cultured pearls and seawater cultured pearls

Freshwater and seawater cultured pearls can be easily distinguished by the naked eye based on color, size, shape, and nucleus characteristics.

Both freshwater cultured pearls with nuclei and seawater cultured pearls with nuclei have freshwater shell nuclei and exhibit the same nucleus characteristics. Naked-eye, microscopic observation, and Raman spectroscopy can distinguish nucleated pearls from white ones. For white nucleated pearls, Raman spectroscopy makes it difficult to differentiate whether they are seawater or freshwater cultured pearls. However, they can be distinguished through trace elements, cathodoluminescence, and other characteristics.

The distinguishing features of freshwater and seawater cultured pearls are shown in Tables 1-6-3, 1-6-4, and Figures 1-6-24 to 1-6-28.

Figure 1-6-24 Freshwater non-nucleated cultured pearls

Figure 1-6-25 Freshwater nucleated cultured pearls

Figure 1-6-26 Seawater nucleated cultured pearls

Figure 1-6-27 Transmission light observation of nucleated cultured pearls' nuclei

Table 1-6-3 Identification characteristics of Freshwater cultured pearls and seawater beautiful cultured pearls

| Caracteristici | Freshwater cultured pearls | Seawater Cultivated Pearls | |

|---|---|---|---|

| Caracteristici | Nucleolus-free freshwater cultured pearls | Nucleated freshwater cultured pearls | Seawater Cultivated Pearls |

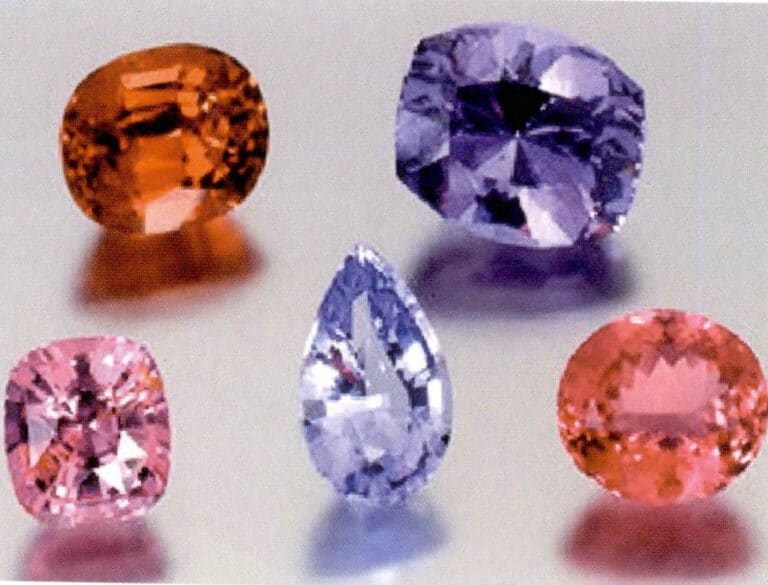

| Culoare | White, pink, orange, purple | White, pink, orange, purple, occasionally bronze | White, black, gray, light yellow to golden yellow |

| Mărime | Commonly 3 to 15mm | Commonly 11 to 17mm | Common 5 -17mm |

| Shape and size | Round, teardrop, oval, button shape, irregular, connected irregular shapes, etc. | Round, flat button-shaped, bar ¬shaped, cross-shaped, or other irregular shapes; some may have protrusions resembling "tails." | Below 9mm is round, above 13mm visible irregular shapes |

| Pearl hole observation | Nucleus-free | Nucleated | Nucleated |

| Strong transmitted light observation | Partia lly visible concentric ring structure | The visible core part shows a layered structure of the core | The visible core part shows a layered structure of the core |

| Cathood luminescence | Yellow green to green light | Yellow-green to green light | Non-luminescent |

| Radiographic | Nucleus-free | Nucleated | Nucleated |

| X Ray leigh scattering spectrum | Rich in Mn, poor in Mg, Sr, Fe and others | Rich in Mn, poor in Mg, Sr, Fe and others | Poor in Mn, rich in Mg, Sr, Fe, etc. |

| Spectroscopia Raman | Pink, orange, and purple freshwater pearls generally exhibit 1132cm-1 and 1528cm-1 organic vibration peaks | Do not exhibit 1132cm-1 and 1528cm-1 organic vibration peaks | |

Table 1-6-4 Comparison of Raman vibration spectrum peaks of nucleated freshwater pearls and seawater cultured pearls (Unit:cm-1)

| Sample | Aragonite | Organic peak | ||

|---|---|---|---|---|

| Sample | V1 | V4 | Lattice mode | Organic peak |

| Nucleated freshwater pearl (white) | 1089 | 702,705 | 141,152,161,179,190,209,216 | - |

| Natural freshwater pearls (orange, purple) | 1089 | 702,705 | 141,152,161,179,190,209,216,272,283 | 1132,1528 |

| Cultured seawater pearls (white) | 1087 | 702,705 | 141,152,179,190,206,272,283 | - |

4. Identification of natural color pearls and treated black pearls

The Tahitian black pearl is “a cultured pearl with a natural color.” The most common enhancement method for Freshwater cultured pearls is to dye them black to mimic Tahitian black pearls. Freshwater cultured pearls irradiated with y rays can also exhibit similar appearance characteristics to Tahitian black pearls. Additionally, dyed and irradiated Freshwater cultured pearls are occasionally seen. The identification features of these four types of black pearls are shown in Table 1-6-5 and Figures 1-6-29 to 1-6-35.

Table 1-6-5 Comparison of the basic characteristics of four types of black pearls

| Caracteristici | Tahitian black pearl | Y Freshwater cultured pearl | Dyed freshwater black pearl | Dyed irradiated black pearls |

|---|---|---|---|---|

| Pearl type | Seawater Cultivated Pearls | Mainly freshwater cultured pearls without nuclei | Freshwater cultured pearls | Freshwater cultured pearls |

| Coloration mechanism | Organic pigment porphyrin coloration | Changes in trace elements, calcite, and organic matter and their combinations | Dyes have a some binding force with kaolinite and keratin. | The dual effects of dyeing and irradiation. |

| Naked eye observation. | Black to silver-gray, generally deep blue¬black with slight rainbow-like luster or with a bronze tint. | Black and silver-gray as the base colors, with bright accompanying colors such as green, blue, and red | Metallic luster, pure black, uniform color, halo effect, accompanying colors are unnatural | Accompanying colors can be brighter than irradiated freshwater pearls |

| Trace powder | Alb | Light brown | Grayish brown | Gray-brown |

| Observație microscopică | The surface is fine and smooth, or has growth textures | The surface is delicate and smooth, with occasional visible micro¬damage. Under strong transmitted light, black layered structures may sometimes be seen | Visible surface color spots, dot-like precipitates, or traces of surface nacre corrosion, and fine wrinkles | Visible surface localized layer peeling |

| Ultraviolet Fluorescence (long wave) | Dark reddish-brown, or strong reflection only visible on the surface | Strong green fluorescence | Fluorescent inert to medium intensity green fluorescence | Strong green fluorescence, uneven fluorescence - |

| Ultraviolet Fluorescence (short wave ) | General tendency | Weak to medium green fluorescence | General tendency | Weak to medium green fluorescence |

| cathode luminescence | Non-luminescent | Strong green light emission | Yellow green to strong green light emission | Strong green light emission |

| Spectroscopia Raman | Extremely strong peaks, porphyrin and other organic pigment peaks | The spectral lines are too high due to strong light, and are generally seen only in the attenuated 1083cm-1 aragonite peak. | Extremely strong calcite 702.50cm-1 | Generally only weak 1083cm-1 is observed |

Figure 1-6-29 irradiated freshwater cultured pearls (top), Taqi black pearls (left), and dyed freshwater cultured pearls (right)

Figure 1-6-30 Taixi black pearl (left), irradiated freshwater cultured pearl (middle), dyed freshwater cultured pearl (right) and its powder

Figure 1-6-33 Raman spectral characteristics of Taqi black pearls

Figure 1-6-35 Raman spectral characteristics of irradiated freshwater cultured pearls

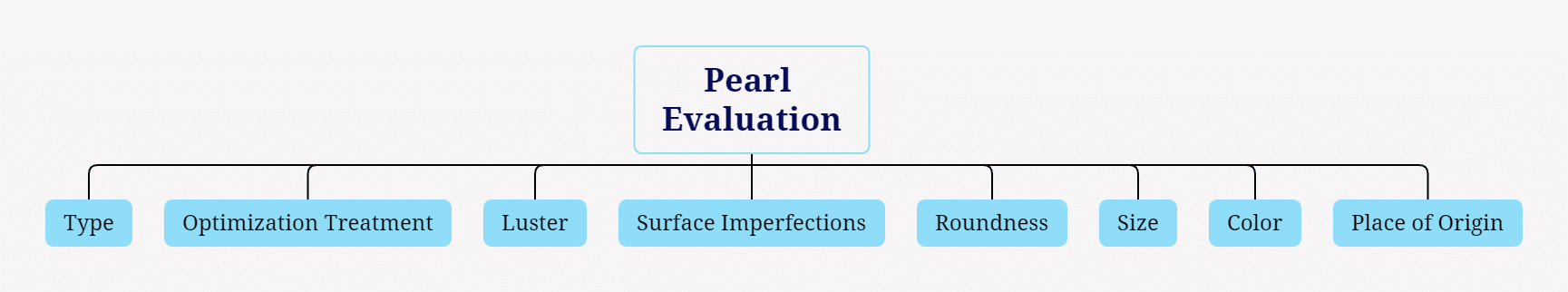

Section III Quality Evaluation of Pearls

Before evaluating the quality of pearls, it is necessary to determine the type of pearl and whether it has undergone any optimization treatment. For pearls of the same size and quality, natural pearls are far more valuable than cultured pearls, and seawater pearls are more valuable than freshwater pearls.

After determining the type of pearl, the quality can then be evaluated. In the commercial field, standards such as A to AAA or D-A are sometimes used. Still, the quality evaluation of pearls does not have an internationally recognized grading system and standard samples like diamonds do, so the 3A or D-A standards of different laboratories and commercial enterprises may vary. Even the standards of the same institution may differ. To establish a globally accepted evaluation standard, it is necessary to create reference samples to determine the grading factors for cultured pearl quality, known as master pearls. The difficulty in establishing pearl reference samples is that pearls are organic gemstones, and their color and luster may change slightly over time due to differences in post-harvest processing, storage conditions, and other factors.

The quality evaluation factors of pearls include luster, color, shape, size, thickness of the nacre layer, surface defects, etc., which are mainly determined by the composition and structure of the pearls; for cultured pearls, the type of mother-of-pearl, growth conditions, cultivation techniques, and post-harvest optimization technology level all have a some impact. The evaluation factors of pearls are shown in Figure 1-7-1 and Table 1-7-1.

Table 1-7-1 Quality evaluation of pearls

| Factori de evaluare | Conținutul evaluării calității |

|---|---|

| Types | Under the same quality conditions, natural pearls have the highest value, followed by seawater cultured pearls, freshwater cultured pearls with nuclei, and freshwater cultured pearls without nuclei. |

| Lustru | The stronger, the better; the reflected light should be particularly bright, sharp, and uniform, with a surface like a mirror, and a very clear image is the best. |

| Netezimea suprafeței | The fewer pits, grooves, spots, protrusions, and blemishes on the surface of the pearl, the better; it is best if the surface appears smooth and delicate to the naked eye, making it extremely difficult to observe any blemishes. |

| Culoare | Among yellows, a bright, rich, and saturated golden yellow is preferred; among blacks, a greenish undertone is preferred; among whites, a pinkish undertone is preferred; for colors like pink, orange, and purple, a rich and vibrant color is preferred |

| Formă | Generally, a perfect circle is preferred, with a diameter difference percentage of <= 1.0% being the |

| Mărime | Cu cât este mai mare, cu atât este mai mare valoarea. |

| Pearl layer thickness | A pearl layer thickness of >= 0.6mm for nucleated pearls is ideal; the thicker, the better; if too thin, the pearl layer is prone to falling off. |

| Compatibility of jewelry | Quality factors such as shape, luster, and smoothness are consistent; color and size are harmonious and aesthetically pleasing, or show a gradual change; the holes should be centered and straight for the best result. |

| Place of Origin | Golden South Sea pearls: origins such as Australia and the Philippines are generally superior to those from Myanmar; black Tahitian pearls: origins such as Tahiti are generally superior to those from the Gulf of Mexico. |

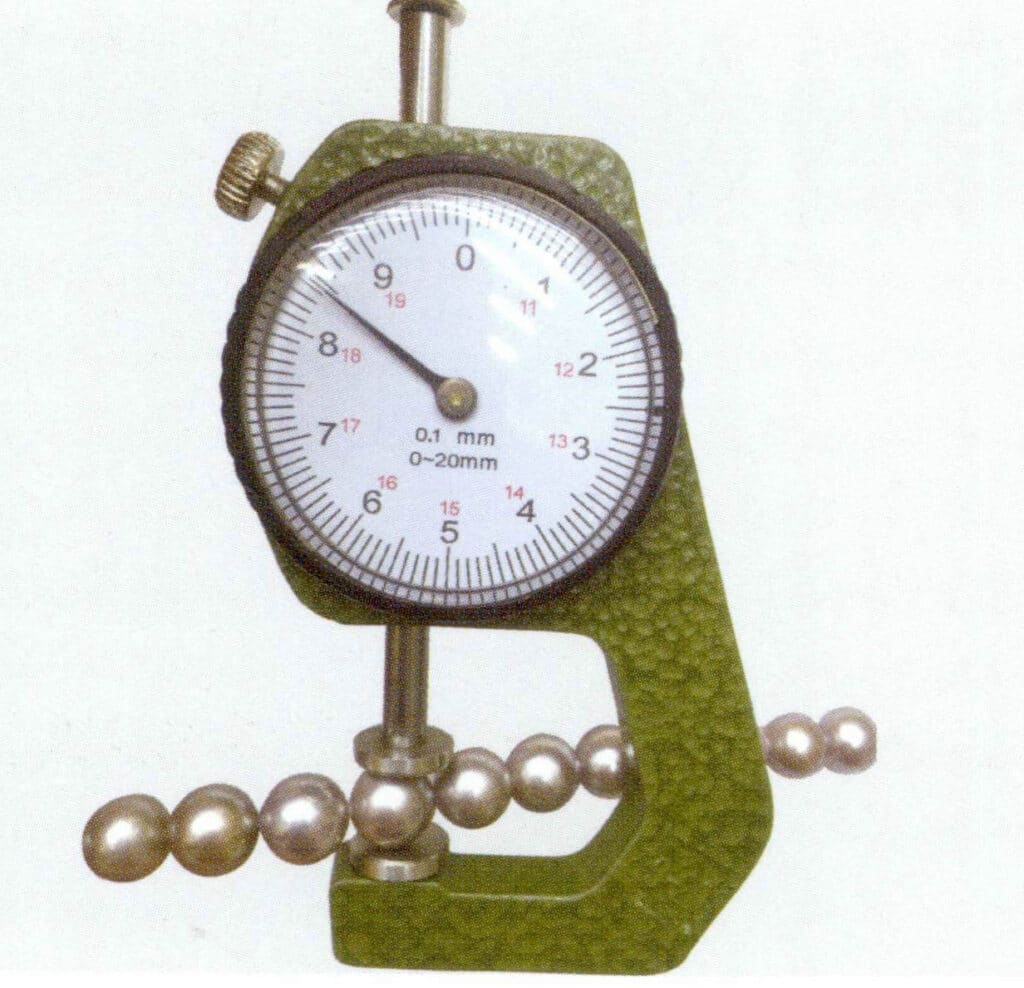

When conducting quality evaluations, the main method is visual observation, placing the pearls against a non-reflective white or gray background, and some pearls can also be placed against a black background; the distance from the eyes to the pearls is 20-50cm, which can be adjusted according to personal observation habits, but should not be too close to the pearls and the light source; the light source is generally north-facing sunlight or daylight lamps with a color temperature of 5500-7200K. The size and roundness of the pearls are often measured using a pearl caliper (also known as a “thickness gauge”). The methods for evaluating pearl quality factors are shown in Figure 1-7-2.

1. Types

The Classification of types of pearls has a significant impact on their value, as shown in Figure 1-7-3. The value of natural pearls is much higher than that of cultured pearls. Even though many natural pearls may have inferior luster, shape, and size compared to cultured pearls, their rarity, history, and emotional value far exceed that of cultured pearls. Therefore, natural pearl jewelry currently holds the highest auction prices for pearls. For natural pearls, the older the history, the higher the historical value; if they are worn or collected by historical figures, their value can increase significantly.

Under the same size and quality conditions, the value of saltwater cultured pearls is generally higher than that of freshwater pearls, and the value of round-nucleated pearls is higher than that of non-nucleated pearls.

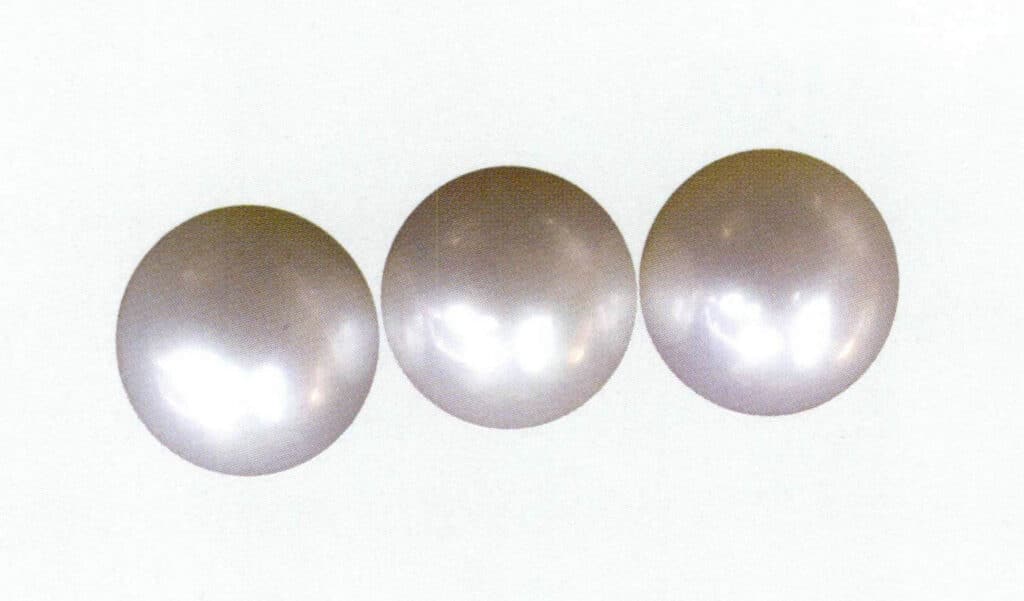

2. Luster

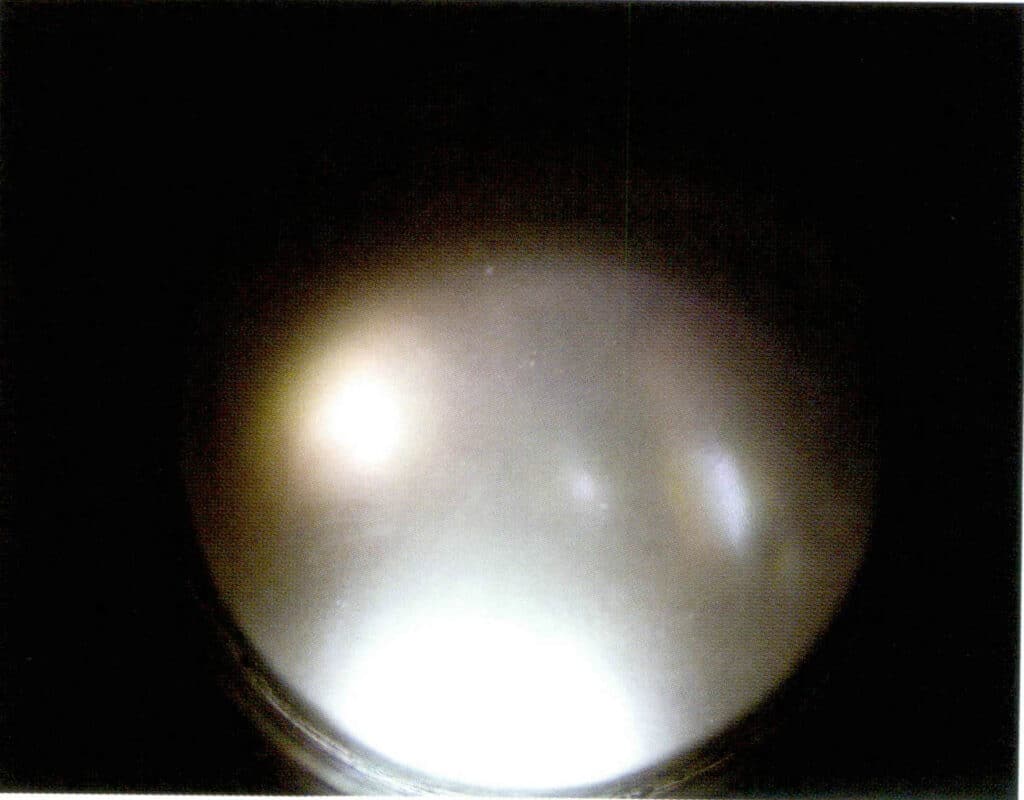

The luster of pearls is one of the most important characteristics that make pearls beautiful. Thus, luster occupies a very important position in evaluating pearl quality. The luster of a pearl refers to the intensity of light reflected from the cultured pearl’s surface and the image’s clarity.

The strength of pearl luster is observed with the naked eye, and there is no clear quantitative standard between its strengths. The common levels of pearl luster strength internationally can be seen in Table 1-7-2 and Figures 1-7-4 and 1-7-15.

Table 1-7-2 Classification of common pearl luster levels.

| Nivel de luciu | Quality requirements |

|---|---|

| Extrem de puternic | The reflected light is very bright, sharp and uniform, and the image is very clear, similar to a mirror-like reflection |

| puternic | The reflected light is bright, the surface can see the object's image, and the image is moderately clear |

| Mediu | The reflected light is not bright; the surface can reflect objects, but the image is dark, weak, and blurry. |

| Slab | The reflected light is entirely diffuse; the surface has a dull sheen and almost no reflection. |

| No light. | Milky or chalky appearance, with almost no reflection on the surface |

Figure 1-7-4 Medium to Strong Luster (South Sea Pearl)

Figure 1-7-5 Strong luster increasing from left to right (South Sea Pearl)

Figure 1-7-6 Extremely Strong Luster (South Sea Pearl)

Figure 1-7-7 Very High Luster (Akoya Pearls)

Figure 1-7-8 Slightly Different Extremely Strong Luster (Akoya Pearl)

Figure 1-7-9 High Luster (Akoya Pearls)

Figure 1-7-10 Extremely Strong Luster (Nucleated Freshwater Cultured Pearl) (One)

Figure 1-7-11 Very High Luster (Nucleated Freshwater Cultured Pearls) (II)

Figure 1-7-12 Medium Luster (Nucleated Freshwater Cultured Pearls) (I)

Figure 1-7-13 Medium luster (nucleated freshwater cultured pearls) (II)

Figure 1-7-14 Weak to Medium Luster (Nucleated Freshwater Cultured Pearls)

Figure 1-7-15 Strong to medium luster diminishing from left to right (South Sea pearls)

3. Surface blemishes

The surface blemishes of pearls refer to defects that cause the surface of the pearl to be uneven and unattractive. Common surface blemishes on pearls include banding, bumps (papules, tails), depressions (flat tops), wrinkles (grooves), damage, chips, spots (black dots), needle marks, scratches, peeling marks, cracks, and pearl scars.

The surface perfection of a pearl refers to the overall degree of smoothness and cleanliness determined by the size, color, location, and quantity of blemishes on the pearl’s surface. The fewer the blemishes, the higher the quality of the pearl. Common levels of surface blemishes in pearls can be seen in Table 1-7-3 and Figures 1-7-16 and 1-7-23.

Clean and dry the sample, roll the sample, observe with the naked eye, record the types, quantity, and distribution of surface flaws, refer to standard samples, and determine the sample’s smoothness level.

Table 1-7-3 Classification of Common Pearl Surface Defect Levels

| Surface Defect Levels | Cerințe de calitate |

|---|---|

| Flawless | The surface appears smooth and delicate to the naked eye, making it extremely difficult to observe any defects; such pearls are generally not drilled beforehand and are drilled only after sale |

| Extremely minor flaw | The surface has one or two clustered pinpoint flaws; after drilling, the pearl is of flawless grade; or can be covered after setting |

| Minor flaw | The surface has very few flaws, such as scattered pinpoint flaws, which cannot be completely covered after drilling and setting, but are not easily observed |

| Few flaws | There are fewer flaws, easily observable to the naked eye, but not very obvious. |

| Flaw | Flaws are obvious, such as pits, rings, etc., easily observed by non-professionals. |

| Major flaw | The flaw is very obvious |

Figure 1-7-16 Flawless (South Sea Pearl)

Figure 1-7-17 Slight Flaw (South Sea Pearl) (I)

Figure 1-7-18 Slight Flaw (South Sea Pearl) (II)

Figure 1-7-19 Minor Flaw (South Sea Pearl) (III)

Figure 1-7-20 Minor Flaw (Freshwater Non-Nucleated Cultured Pearl)

Figure 1-7-21 Flaw (Taki Black Pearl)

Figure 1-7-22 Major Flaw (Freshwater Non-Nucleated Cultured Pearl)

Figure 1-7-23 Major Flaw (Freshwater Cultured Pearl)

4. Color

The color of a pearl is composed of body color, overtone, and orientation. For pearls, body color is not as important to the quality as luster and roundness.

The body color of pearls is generally in the series of white, golden yellow, black, orange, pink, purple, etc., with pink, purple, and orange often appearing in combination. For white series pearls, the whiter the color, the more pronounced the pink overtone, and the higher the value. For colored pearls in the golden, orange, purple, and pink series, the more uniform and intense the color, the higher the value. For the black series, the blacker the body color, the more pronounced the green overtone, and the higher the value. See Figures 1-7-24 and 1-7-35.

Figure 1-7-24 shows uneven yellow (South Sea pearl).

Figure 1-7-25 Light yellow (South Sea pearl)

Figure 1-7-26 Medium to deep golden yellow (South Sea pearl)

Figure 1-7-27 Vivid golden yellow (South Sea pearl)

Figure 1-7-28 Gray to dark black (Taqi Ti black pearl)

Figure 1-7-29 Black with peacock green undertones (Taqi Ti black pearl)

Figure 1-7-30 Light to medium orange (freshwater cultured pearls)

Figure 1-7-31 Light to deep pink, pink-purple (freshwater cultured pearls)

Figure 1-7-32 Light to deep orange and purple

Figure 1-7-33 Medium to deep orange, purple, and metallic colors

Figure 1-7-34 Deep pink-purple (freshwater cultured pearls)

Figure 1-7-35 Deep Purple (Freshwater Cultured Pearls with Nuclei)

Under the same conditions of other quality factors, golden yellow is the most valuable among seawater pearls; among freshwater pearls, white and deep purple, orange, and pink are equally popular, while light purple, orange, and pink have slightly lower values.

Overtone and orient are important factors in the appreciation of pearls. Generally speaking, the stronger the overtone and the more pronounced the colors of the orient, the stronger the luster and the higher the value.

The accompanying colors of pearls include pink, purplish-red, blue, green, and others. For white pearls, pink is preferred over green and other accompanying colors; for black pearls, green is preferred over red and blue. The different levels of accompanying colors of pearls are shown in n in Figures 1-7-36 to 1-7-45

Figure 1-7-36 Subtle Accompanying Color (Taqi Black Pearl)

Figure 1-7-37 Noticeable Accompanying Color (Taqi Black Pearl)

Figure 1-7-38 Obvious Accompanying Color (Taqi Black Pearl)

Figure 1-7-39 Strong accompanying color (Taqi Black Pearl)

Figure 1-7-40 Strong red, green, and other accompanying colors (Taqi Black Pearl)

Figure 1-7-41 Strong red and green accompanying colors (Taqi Black Pearl)

Figure 1-7-42 Strong pink accompanying color (Akoya Pearl)

Figure 1-7-43 Strong powder, green and other accompanying colors (Akoya pearls)

Figure 1-7-44 Strong green accompanying color (except for the left three) (Freshwater nucleated cultured pearl)

Figure 1-7-45 Strong purple-red accompanying color (freshwater cultured pearls with nuclei)

5. Size

The larger the pearl, the higher the value. The longer a pearl grows inside a mollusk, the larger it becomes; however, as the pearl grows larger, the uncertainty regarding the health of the mollusk and the pearl’s luster, color, shape, and surface flaws increases. In particular, diseases and aging of the mollusk can greatly affect the quality of the pearl. The probability of perfection for large pearls is much lower than that for small pearls. For cultured pearls, the longer the growth time, the more uncontrollable and uncertain situations arise, leading to higher risks and costs of cultivation.

Round, spherical, and near-spherical pearls are generally represented by the smallest diameter, while the product of the maximum and minimum sizes represents other shapes of cultured pearls.

Individual or strings of pearls can be measured using a pearl caliper (thickness gauge) or a vernier caliper, see Figure 1-7-46; bulk loose pearls can be measured using a pearl sieve, see Figure 1-7-47, with their diameter represented by the aperture range of the pearl basket. Different diameters of Freshwater cultured pearls with nuclei are shown in Figure 1-7-48 and Figure 1-7-49.

Figure 1-7-46 Pearls and Pearl Thickness Gauges

Figure 1-7-47 Measuring pearl diameter with a pearl basket

Figure 1-7-48 Freshwater cultured pearls with nuclei, diameter 14-17mm

Figure 1-7-49 Freshwater cultured pearls with nuclei, diameter 18-19mm

6. Shape

The shapes of pearls can be divided into round, near-round, oval, flat-round (such as button-shaped, cabochon, etc.), irregular, and other shapes, see Figure 1-7-50 to Figure 1-7-55. The round shape has the highest value; larger water droplet shapes are easier to make into pendants, and the irregular shapes are symbolic Shapes that are easy to design can also have high value.

A method combining visual observation of pearl rolling and multi-directional diameter measurement can be used. The percentage difference in diameter ≤1% is for perfectly round pearls. Calculate the percentage difference in diameter X(%) based on the measurement data.

Figure 1-7-50 Water droplet shape (South Sea pearl)

Figure 1-7-51 Water droplet shape, flat-round, and round shape (South Sea pearl)

Figure 1-7-52 Oval shape (South Sea pearl)

Figure 1-7-53 Flat round and round shapes (South Sea pearls)

Figure 1-7-54 Flat-round shape (freshwater non-nucleated cultured pearl)

Figure 1-7-55 Perfectly round (Akoya pearls)

7. Pearl layer thickness

The thickness of the nacre does not affect the luster of the pearl, but a layer that is too thin is prone to damage and shedding, which affects the lifespan of the pearl, see Figure 1-7-56.

The thickness of the layer in a non-nucleated pearl is its radius. For nucleated pearls, the core is inside, and the pearl layer is outside the core.

Non-destructive testing methods include X-radiographic methods, tomography, etc.

The destructive testing method is the direct measurement method. The sample is cut open and polished in the middle, and the thickness of the nacre layer is measured using a measuring microscope. This method measures at least three maximum and three minimum thicknesses of the pearl layer and takes the average to determine the thickness level of the pearl layer.

Figure 1-7-56 Thin pearl layer

Figure 1-7-57 Thickness of the pearl layer in nucleated and non-nucleated pearls

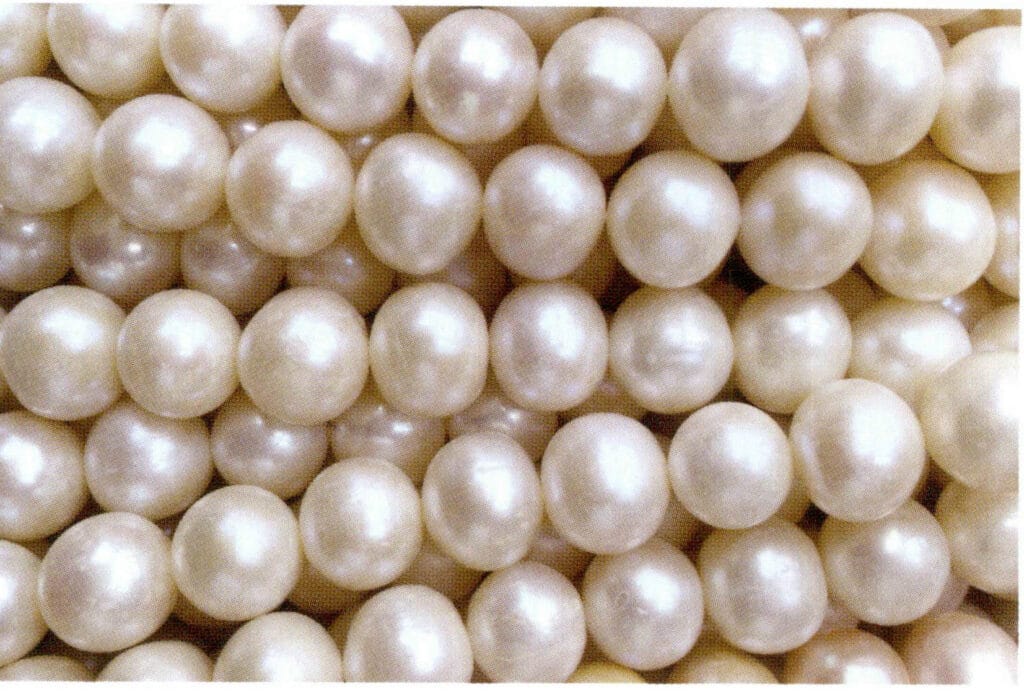

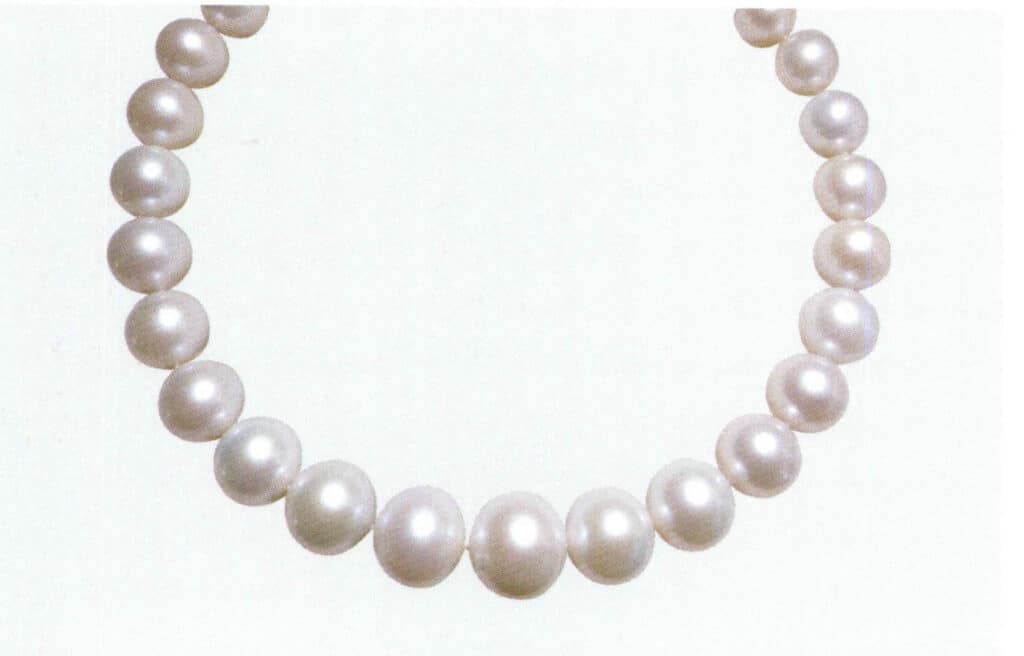

8. Matching

For multi-bead pearl jewelry such as pearl necklaces, matching attribute is also one of the factors in evaluating pearl quality.

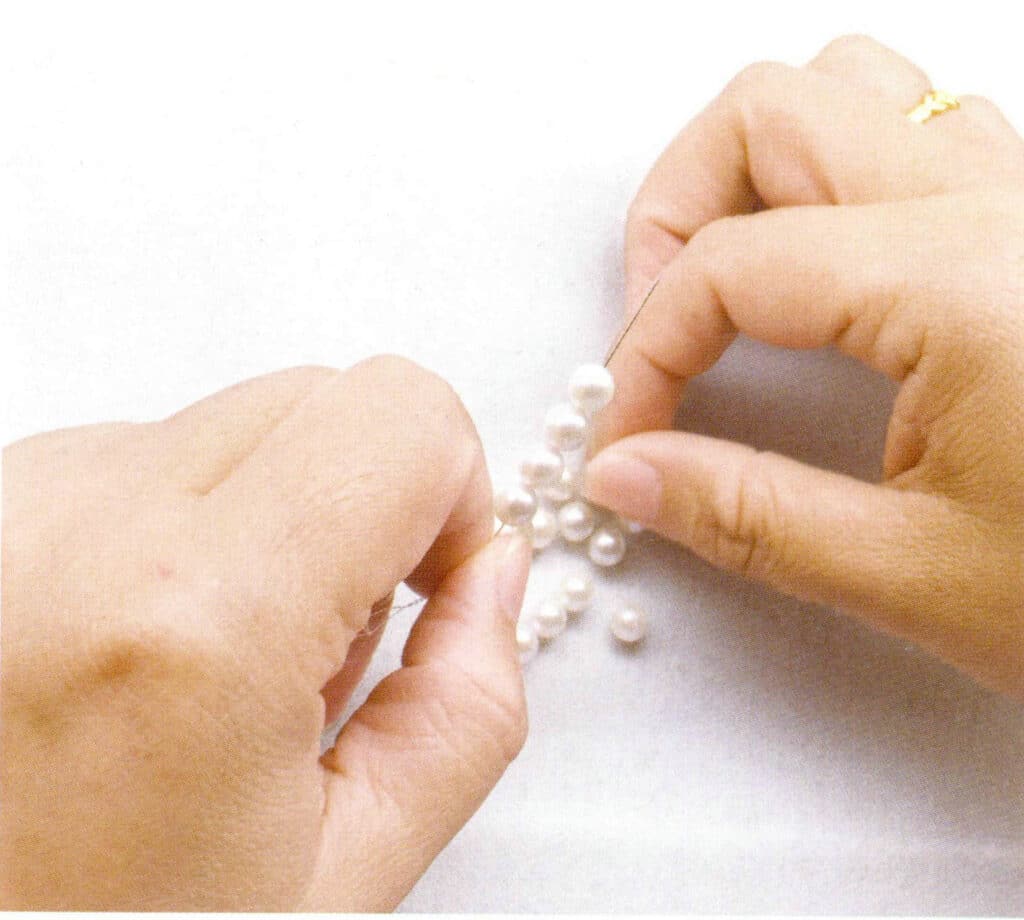

After harvesting and polishing, perfect pearls are selected individually without drilling; pearls with minor flaws or more significant defects are drilled before or after bleaching and polishing, matched according to quality factors such as color, luster, shape, and size, and strung together to a standard necklace length to be sold as semi-finished products. See Figures 1-7-58 to 1-7-65.

Figure 1-7-58 Sorting of pearls in a freshwater pearl processing factory.

Figure 1-7-59 Matching of pearls in freshwater pearl processing plant

Figure 1-7-60 Matching and stringing of pearls in freshwater pearl processing plant(1)

Figure 1-7-61 Matching and stringing of pearls in freshwater pearl processing plant (2)

Figure 1-7-62 Sorting of pearls in seawater pearl processing plant (1)

Figure 1-7-63 Sorting of pearls in a seawater pearl processing factory (2)

Figure 1-7-64 Beading of pearls in a marine pearl processing plant (1)

Figure 1-7-65 Stringing of pearls in a seawater pearl processing factory (2)

Matching refers to the degree of coordination among cultured pearls in multi-bead pearl jewelry in shape, luster, surface flaws, color, and size. Pearls with good Matching have consistent quality factors such as shape, luster, and surface flaws; color and size should be harmoniously unified or show a gradual, aesthetically pleasing change; the drill holes should be centered and straight, smooth without burrs. For high-quality multi-bead pearls, perfect Matching should also consider accompanying colors; see Figures 1-7-67.

When observing, one should consider various quality factors such as shape, luster, surface flaws, color, size, drilling, and accompanying color, observing both the overall piece and individual pearls, first the overall and then the details, to evaluate the quality of Matching. The overall observation of Matching can be seen in Figures 1-7-68 and 1-7-69. Generally, the quality level of multiple pearl jewelry is evaluated based on the level of pearls above 90%.

Figure 1-7-68 Akoya pearl necklace matching in size, accompanying color, and flaw level

Figure 1-7-69 South Sea pearl necklace matching in color, size, and flaw level

9. Origin

The origin identification of pearls is not as mature and widespread as that of rubies, sapphires, and emeralds. Due to factors such as price, the industry and consumer market for cultured pearls do not have urgent requirements for origin identification. Currently, the identification of pearl origin is more applied in natural pearls, cultural relics, and archaeology. Nevertheless, some cultured pearls from traditional origins still outperform those from other origins regarding quality and acceptability, and their value is correspondingly higher.

Golden South Sea pearls from origins such as Australia and the Philippines are generally superior to those from Myanmar. In contrast, black pearls from Tahiti and the Cook Islands are generally superior to those from the Gulf of Mexico. The quality of seawater cultured pearls harvested or processed in Japan is often better than those harvested in China, and the price of Japanese freshwater cultured pearls with the same appearance is higher than that of Chinese Freshwater cultured pearls.

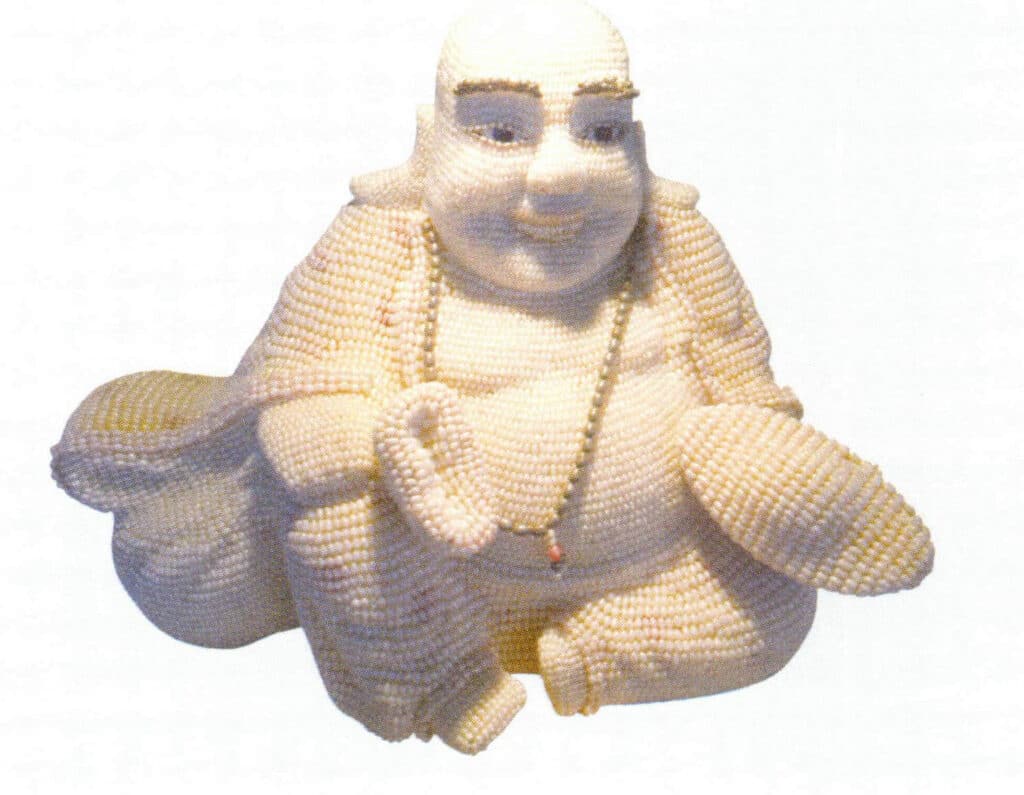

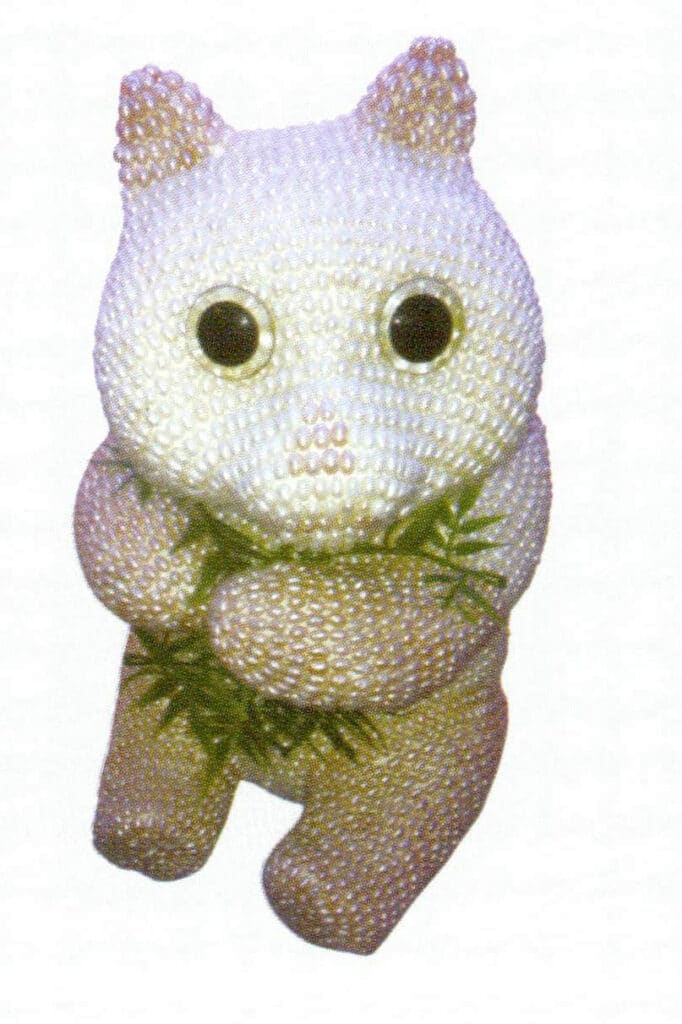

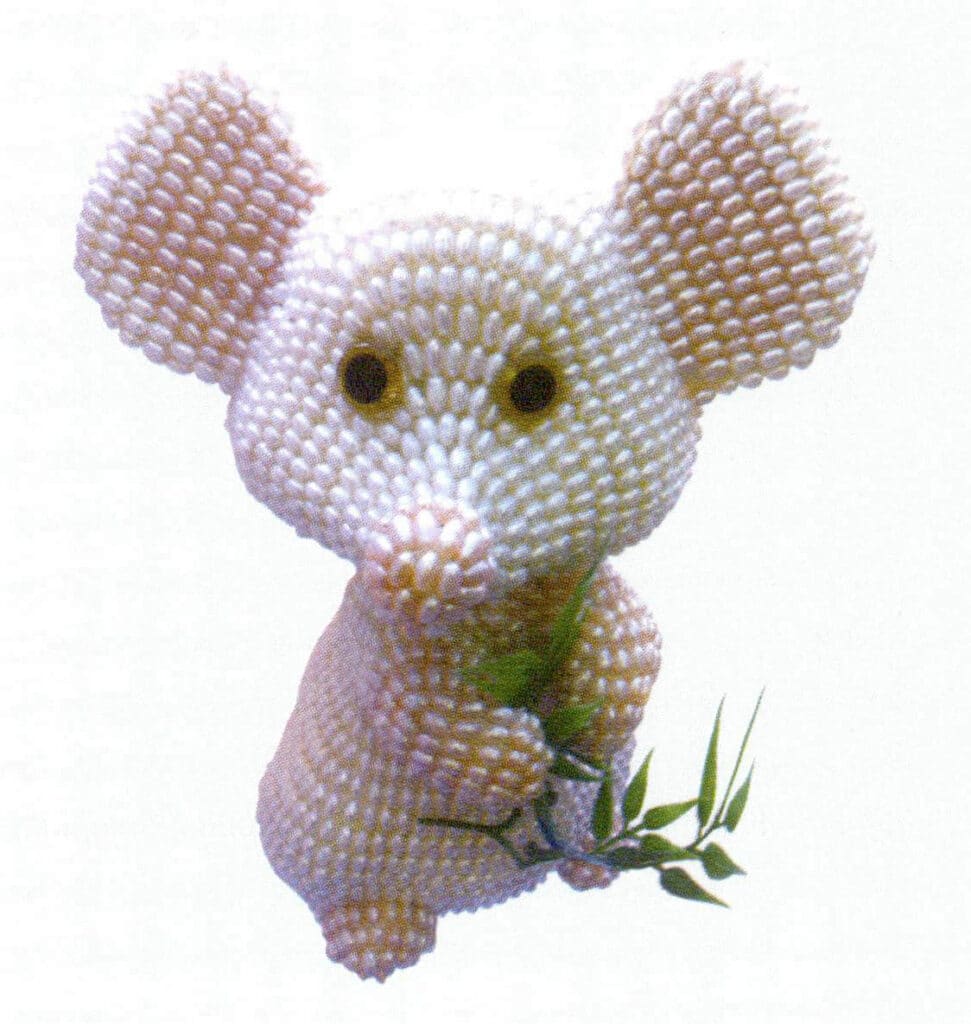

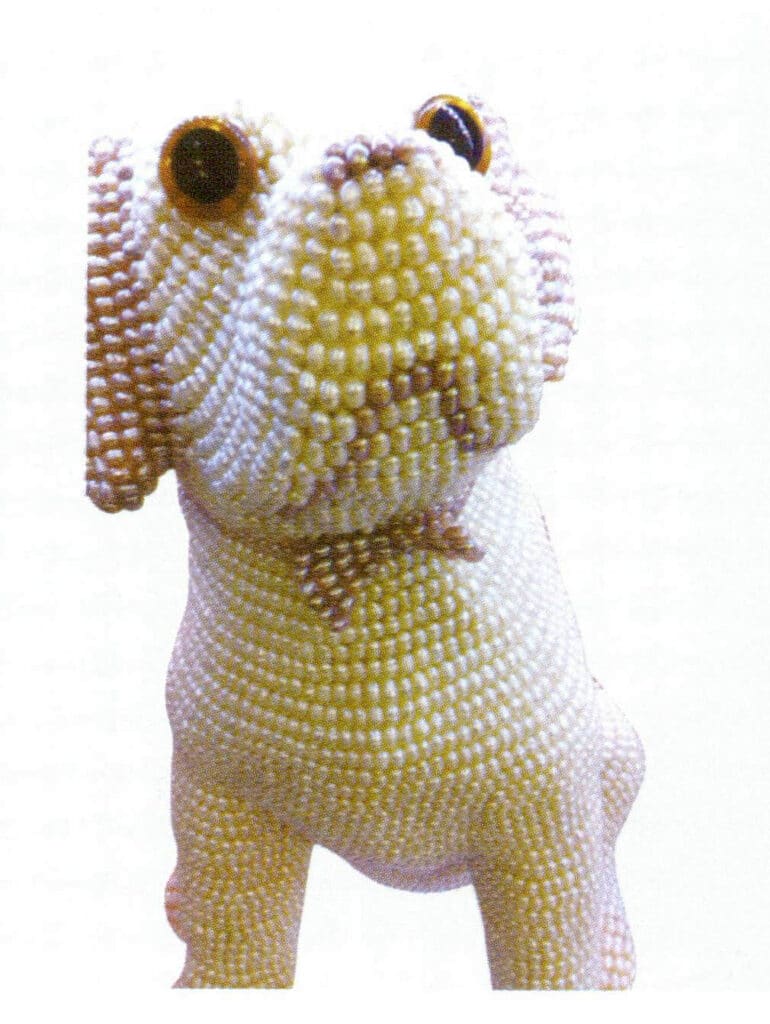

10. Craft-grade Pearls

When pearls do not meet the quality requirements for jewelry grade, they are often used in crafts or ground into pearl powder for use in beauty and other fields. The craft pearls are shown in Figures 1-7-70 to 1-7-75.

Figure 1-7-70 Pearl Crafts(1)

Figure 1-7-71 Pearl Crafts (2)

Figure 1-7-72 Pearl Crafts Arts and Crafts (3)

Figure 1-7-73 Pearl Crafts (Four)

Figure 1-7-74 Pearl Crafts (Five)

Figure 1-7-75 Pearl Crafts (Six)

Section IV Maintenance of Pearls

Pearls are composed of two parts: organic and inorganic. The inorganic part of pearls is mainly carbonate, which is easily eroded by acids, damaging the organic gemstone; the organic part is easily eroded by organic solvents such as alcohol, ether, and acetone.

Pearls are sensitive to acids and chemicals such as lotions, perfumes, hair sprays, nail polish, and detergents when worn or stored, and should be kept away from them.

Avoid contact with sweat and other substances. Sweat can corrode pearls to some extent, so wiping them clean with a soft cloth after use and when storing is best. If exposed to a large amount of sweat, rinse immediately with clean water, dry with a soft cloth, and air dry in a cool place.

Avoid exposure to sunlight and prevent prolonged constant temperature baking. Pearls contain a small amount of water, which can cause discoloration and loss of luster due to dehydration.

Avoid contact with hard objects, especially metals, and prevent friction with other inorganic gemstones and jade when wearing pearls.

After wearing a pearl necklace, it is best to clean the pearls with a soft cloth and store them separately in a jewelry box.

It is best to restring pearl necklaces every few years. When stringing, tie a knot between each pearl to prevent friction between them and the pearls from scattering if the string breaks.