How Does Sobling Do Quality Control For Your Jewelry?

6 Must Steps To Ensure You Receive The Best Quality.

Introducere:

Jewelry production is all about quality, from raw materials like gold and silver to the final product. This guide helps you check your gems, avoid casting flaws, and ensure your pieces look great. Whether you’re a store, designer, or just making custom jewels, this is your go-to for making beautiful, lasting jewelry.

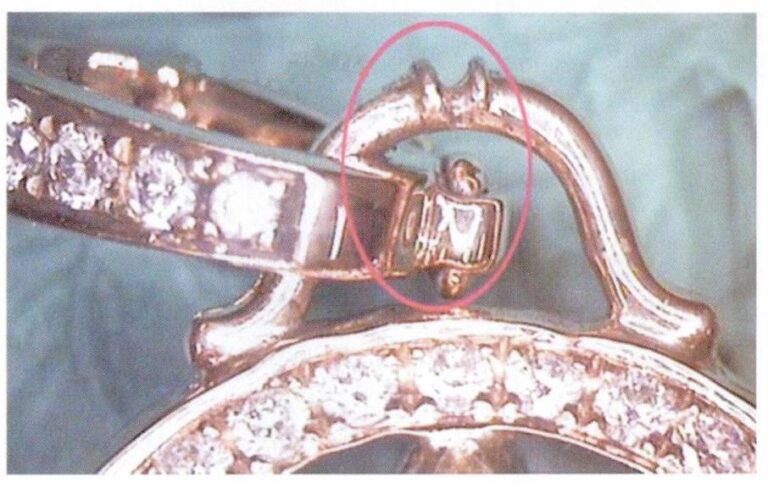

The ring head is not straight

Tabla de conținut

Section I Jewelry Production Raw and Auxiliary Materials Inspection and Common Defects

More details list here: https://sobling.jewelry/how-to-inspect-quality-of-jewelry-raw-materials/

Various raw materials and auxiliary materials are needed in jewelry production, and their performance directly affects the quality and cost of production. Therefore, it is essential to strictly control the inspection of raw and auxiliary materials during production to avoid the use of unqualified materials.

Overall, the materials used for jewelry production mainly include precious metals such as gold, silver, platinum, and palladium; filler materials for various alloy compositions; gemstones such as diamonds, rubies, sapphires, and jade; and auxiliary materials used in key processes such as mold making, casting, setting stones, polishing, and electroplating, some of which have a direct impact on the quality of jewelry products.

1. Quality Inspection of Precious Metal Raw Materials

1.1 Pure Gold Ingots

Gold is one of the most widely used raw materials in the production of precious metal jewelry. Enterprises generally purchase pure gold ingots from refining plants, precious metal suppliers, and other channels, which can be used to formulate 24K gold, 18K gold, and various other gold alloys.

(1) Purity requirements for pure gold ingots

The purity of pure gold ingots is the foundation for ensuring the quality of gold jewelry. ASTM B562-95 “Standard Specification for Refined Gold” is the only standard used for high-purity gold ingots.

Impurities in pure gold are divided into metallic, non-metallic, and radioactive. Metallic impurities like platinum are not listed in standards due to their value and benign impact on gold’s performance. Non-metallic impurities from purification processes are also not listed. Radioactive impurities are negligible and unlisted. ASTM B562 only considers certain metallic elements, and manufacturers can negotiate to list additional elements for quality assurance.

(2) Analysis methods for impurity elements in pure aur ingots

The cupellation method is the earliest and most accurate for determining gold content but is limited in detecting impurities in pure gold ingots; alternative methods like spectroscopic analysis and scanning electron microscopes (SEM) with energy dispersive spectroscopy (EDS) are more effective for impurity detection.

(3) The impact of impurity elements in pure gold bars on a quality of jewelry production

Certain impurity elements in pure gold bars, such as lead, bismuth, and arsenic, can severely deteriorate the performance of gold, while other elements like silicon and iron can sometimes also have harmful effects, like brittle fracture and hard point defect.

(4) Purification of gold

When excessive harmful impurities appear in pure gold or gold alloy materials, it is necessary to consider purifying the materials. There are various methods for purifying gold, such as Mercury amalgamation method, Aqua regia purification method, Electrolytic method, Pearl granulation method, Ammonium chloride method,

1.2 Pure silver ingots

According to chemical composition, pure silver is divided into three grades: IC – Ag99.99, IC – Ag99.95, and IC – Ag99.90. The national standard “GB/T4135-2002 Silver” clearly specifies the impurities in pure silver ingots.

Impurities like lead, bismuth, arsenic, and silicon in pure silver can cause brittleness due to their minimal solubility and tendency to form low-melting intermediate phases at grain boundaries, while trace impurity detection is crucial for assessing pure silver quality, with inductively coupled plasma atomic emission spectrometry offering a more efficient analysis method.

1.3 Pure Platinum Ingot

The international standard “ASTM B561:2005 Specification for Refined Platinum” specifies the purity and impurity element requirements for pure platinum, and the “GB/T1419-2004 Sponge Platinum” standard also adopts similar provisions.

1.4 Inspection methods for precious metal materials

After jewelry companies purchase precious metal materials from the market, they need to conduct incoming material inspection.

2. Quality inspection of filling materials

In jewelry making, the quality of alloy “filler” materials significantly impacts the final product, necessitating thorough testing of new fillers for properties such as physical, chemical, mechanical, processing characteristics, safety, and economics.

(1) Physical Properties

K gold jewelry requires careful consideration of material properties like density, color, magnetism, and melting point to optimize both its precious metal quality and surface decorative appeal.

- Density: The choice of filler alloy elements in jewelry impacts the alloy’s density, with substitutions like zinc for silver reducing density, thereby allowing for lighter-weight jewelry with the same gold content.

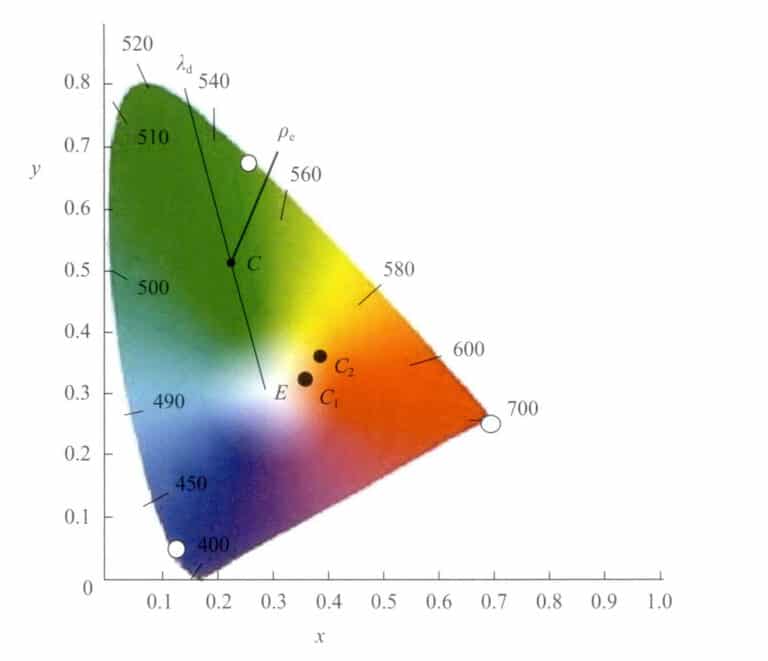

- Color: The most commonly used colored K gold includes three series: K yellow, K white, and K red. To quantitatively describe the color and color stability of gold alloys, the jewelry industry has introduced the CIELab system for color measurement based on colorimetry principles. This system uses L*, a*, b* three coordinates to describe color, providing stable and reliable results.

- Magnetism: As a type of precious metal jewelry, K gold jewelry generally does not want the alloy to exhibit magnetism, to avoid consumer doubts and complaints about the authenticity of the material.

- Melting point: The melting point of K gold alloys, particularly white gold containing nickel and palladium, significantly affects the gypsum investment casting process, with higher melting points risking gypsum decomposition and necessitating more expensive casting materials to ensure quality.

(2) Chemical Properties

The chemical properties of K gold alloys, particularly their resistance to tarnish and corrosion, depend on their composition, with higher karat golds exhibiting better resistance, while the addition of beneficial alloying elements can enhance the protective film and microstructure, improving anti-tarnish ability, especially in K red gold.

(3) Mechanical Properties

K gold alloys enhance mechanical properties like strength, hardness, and toughness to meet jewelry wear resistance and structural requirements, with specific considerations for the balance of these properties in different types of K gold, such as nickel-bleached K platinum and K red gold.

(4) Processing Properties

Processing performance is mainly considered from aspects such as casting performance, plastic processing performance, polishing performance, welding performance, and recycling performance.

(5) Safety

Jewelry must be safe, avoiding harmful elements and allergens like nickel to prevent skin reactions.

(6) Economy

The choice of filler in K gold alloys should be cost-effective, using widely available and inexpensive materials to minimize production costs, especially for lower karat golds that require more filler.

(7) Inspection Method of Filled alloys

3. Quality Inspection of Auxiliary Materials

A large amount of auxiliary materials is used in jewelry production, which affects the quality of jewelry products to varying degrees. Among them, the impact of casting powder, boric acid/borax, crucibles, and other auxiliary materials is signficant.

(1) Casting powder:

a critical material in jewelry molding, must replicate wax mold details precisely, maintain stable thermal-chemical properties, and have suitable thermal expansion to ensure dimensional stability, with uniform particle size.

(2) Boric acid and borax:

Borax and boric acid are used in jewelry making to prevent diamond oxidation, prevent gemstone discoloration, act as flux in welding, and as a slagging agent in metal smelting.

(3) Crucibles:

Commonly used crucibles include: graphite crucibles, which consist of high-purity graphite crucibles and ordinary graphite crucibles; ceramic crucibles, which include quartz crucibles, corundum crucibles, magnesium oxide crucibles, mullite crucibles, lead oxide crucibles, silicon carbide crucibles, etc. The requirements for crucibles in smelting mainly focus on fire resistance, density, thermal stability, and reactivity with molten metals.

(4) Silicone rubber:

Silicone rubber, favored in jewelry lost-wax casting for its inertness, high surface finish, and self-lubricating properties, has become the primary material for soft molds, surpassing natural rubber, and is available in high-temperature and room temperature vulcanized forms, each with distinct advantages and limitations.

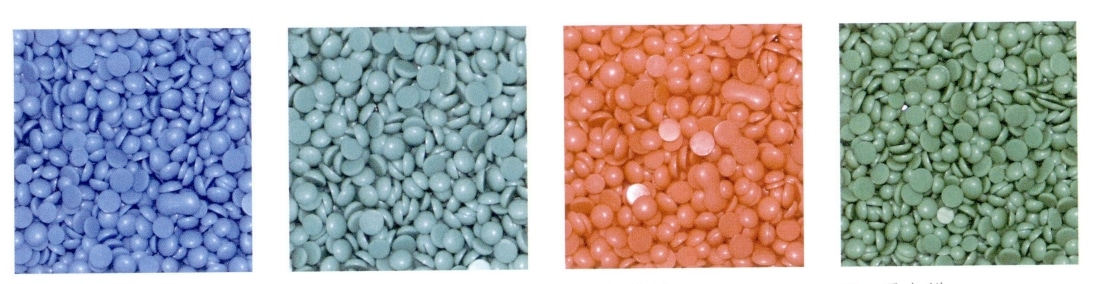

(5) Jewelry Wax Material:

Wax molds for jewelry must have a moderate melting point, thermal stability, minimal shrinkage, surface hardness, and flexibility to ensure high-quality casting.

(6) Electroplating Solution:

The electroplating solution’s composition, including various salts and agents, is key to determining the coating properties in jewelry electroplating.

Section II Master Mold Quality Inspection and Common Defects

More details list here: https://sobling.jewelry/how-to-control-jewelry-molds-quality/

The master mold version is the first process in the jewelry processing process. It is generally made by the following methods:first, hand-made master mold version, that is, through sawing,filing, welding, chiseling, etc., to create a sharp-edged, clear-lined, and smooth-surfaced master mold version. Second, carve a wax model by hand, and then cast it into an master mold version. Third, use various rapid prototyping methods to make wax or resin models, and then cast them into silver versions, or directly make master mold versions with metal. The master mold version is the basis for ensuring that jewelry products meet customer quality requirements, and it is necessary to strengthen the quality inspection and process testing of the master mold version.

1. Master mold quality inspection content

The main content of the master mold version quality inspection includes: shape, size, weight, structure, surface quality, water lines, etc.

(1) Shape:

Jewelry master molds must precisely match the design’s appearance and intent, requiring operators to think three-dimensionally and maintain aesthetic integrity.

(2) Dimension Inspection:

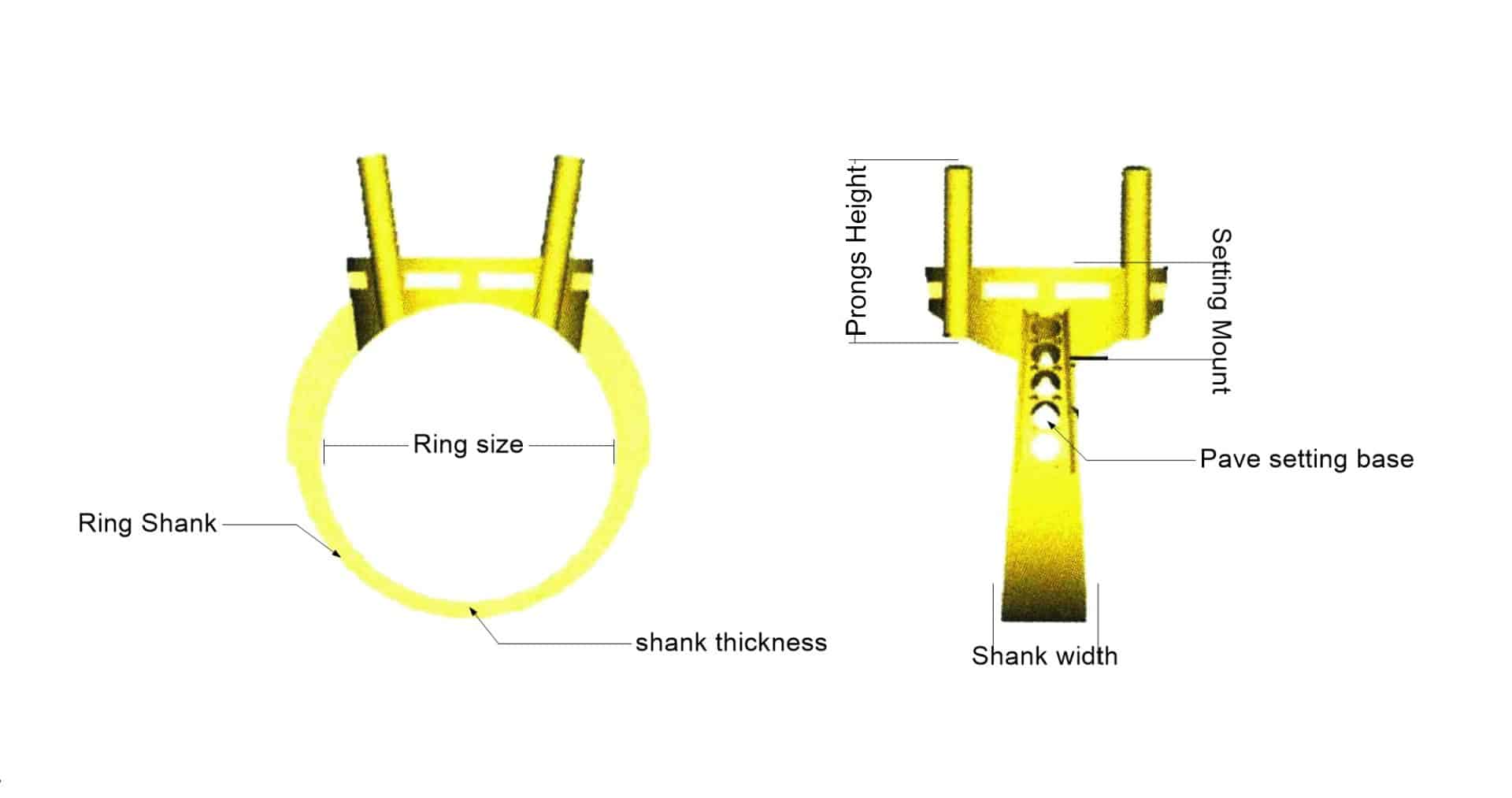

Different types of jewelry have both common size requirements and specific sizes for each type that need to be considered when making the first version.

(3) Weight:

The master mold weight largely determines the weight of the product. When the master mold materials and product materials are determined, there is an approximate proportional relationship between their weights. Therefore, the weight of the product can be controlled by controlling the weight of the master mold.

(4) Original Plate Structure:

The structure of the master mold plate includes the main body, sub-parts, inserts, accessories, process attachments and etc.

(5) Master mold surface quality:

The master mold version surface should be smooth and delicate, without obvious sand eyes, holes, scratches, uneven edges, and other defects.

(6) Waterline:

In jewelry casting, the sprue’s design, including its position, number, shape, size, and connection method, is crucial for ensuring high-quality castings by allowing efficient flow and compensation for shrinkage during the filling process.

2. Quality Inspection Personnel and Methods

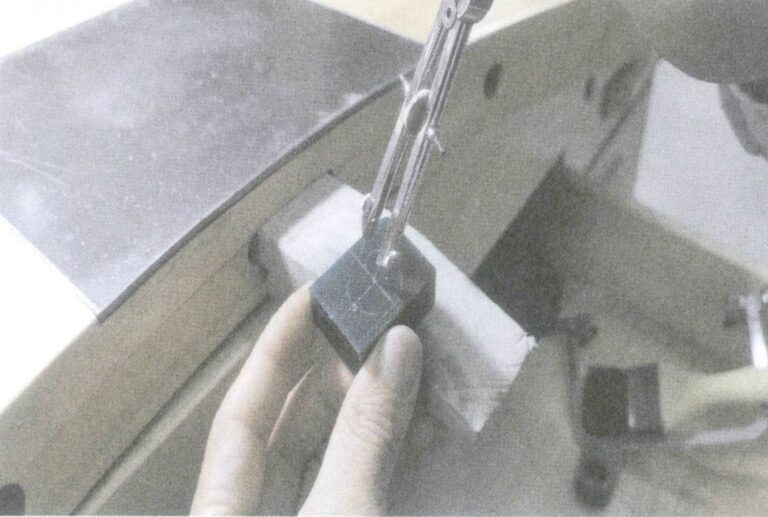

Master mold quality inspectors in jewelry making, known as “viewers” or “reviewers,” require extensive knowledge of design, production processes, materials, and craftsmanship to ensure the quality of CAD drawings, prototypes, and silver plates through visual inspection and dimensional measurements.

3. Common defects of the master mold

(1) Shape inconsistency

Jewelry master molds generally have design drawings, sketches, or customer requirements for appearance. After the master mold version is completed, it should be checked against the drawings or confirmed by the customer.

For the master mold version deformation problem, there are generally several solutions. One is to make necessary adjustments to the master mold structure to avoid being too thin or having too large a plane; the second is to set up process pull rods, connecting each isolated operating handle with pull rods, greatly reducing the probability of operating rod deformation; the third is to choose materials with better performance to make the silver plate. In recent years, some manufacturers in the industry have made beneficial attempts in developing high-hardness silver alloys, significantly improving the strength and hardness of the alloy by adding some trace alloy elements and manufacturing processes. Additionally, for animal master mold versions, using computer drawing for rapid prototyping often appears mechanical and rigid. It is recommended to prioritize manual wax carving or use computer drawing to create the main body model, and then process it manually.

(2) Dimensional Inconsistency

Jewelry does not require the same strict dimensions as mechanical parts, but when it comes to wearing, setting, and assembling, such as ring size, bracelet ring size, bracelet length, necklace and melon seed ear coordination, inlay and base coordination, accurate master mold dimensions are required.

(3) The master mold weight does not match

For precious metal jewelry, considering cost and market acceptance price, it is necessary to control the weight of gold. This needs to be ensured from the plate-making stage to hollow out hidden parts such as the back and concave parts as much as possible to reduce the product weight while meeting the jewelry’s external dimensions and structural strength.

(4) The structure of the master mold is unreasonable

The master mold version’s structure critically affects downstream production quality, requiring a design that balances customer specifications with production feasibility to minimize defects and processing challenges.

(5) Poor master mold surface quality

The surface quality of the master mold version determines the surface quality of the product. It must achieve a smooth and clean master mold surface to reduce the workload of polishing and repairing in subsequent processes.

(6) Issues with the master mold version’s water lines

The water line serves as both the channel for the metal liquid to enter the mold cavity and the channel for supplementing metal liquid for solidification and shrinkage of the casting. Whether the water line is set reasonably or not is related to the integrity of the casting, the density of the surface, etc., and must be taken seriously.

Section III Quality Inspection and Defect Analysis of Pouring Mold

More details list here: https://sobling.jewelry/jewelry-quality-inspection-and-defect-analysis-of-thewax-lost-casting/

The lost wax process is widely used in mass jewelry production, involving many processes including pressing rubber molds, wax injection, wax tree setting, plaster mold casting, wax dewaxing and baking, and metal casting. Analyzing each step of the process reveals that each successful step is built on the previous one, and any problem in a previous step may affect the quality of the entire workpiece.

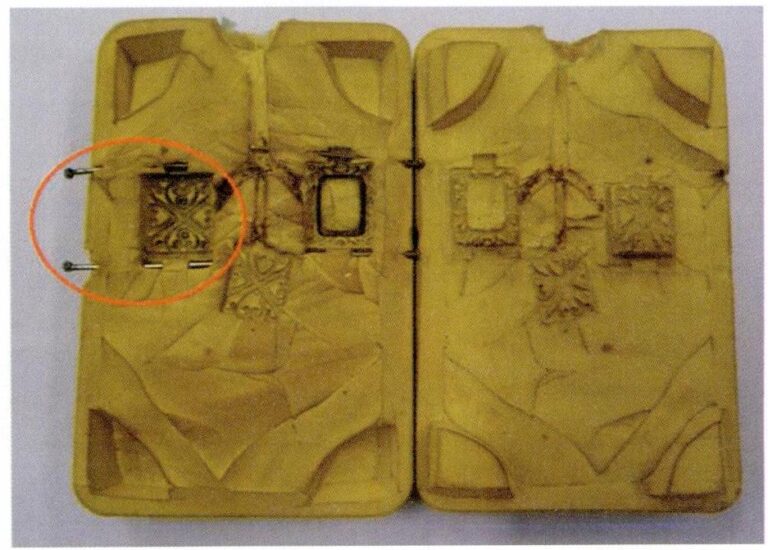

1. Quality Inspection and Common Defects of Rubber Mold

Jewelry rubber molds are made of natural rubber, high-temperature vulcanized rubber, and room temperature vulcanized rubber.

(1) Quality Inspection Content of Rubber Mold

To evaluate the quality of a rubber mold, it should mainly be assessed from aspects such as rubber mold structure, inner cavity surface quality, mechanical properties of rubber molds (Including the elasticity, hardness, tear strength, etc., of the rubber mold), and rubber mold process measures (Including whether the pouring system and the setting of inserts are reasonable).

(2) Common Rubber Mold Defects

- In the lost wax casting of jewelry, when making wax molds with silicone rubber molds, it is not necessary to part from the largest cross-section like metal molds to demold smoothly because silicone rubber molds are easily bent and deformed. Therefore, to reduce the damage of the parting surface to the appearance of the workpiece front, the parting surface is generally selected at the edge of the ring, placing most of the ring on one side of the mold.

- When pressing the mold, the positioning method of the mold should be considered first, and sufficient space should be reserved when arranging the original version. There are generally two commonly used positioning methods for molds, one is the four-corner protrusion positioning; the other is the edge sawtooth-like mating line positioning.

- Only by smoothly exhausting the air in the rubber mold cavity during wax injection and avoiding the resistance to wax filling can a wax model with clear contours be obtained. The rubber mold should not only have air vent holes, but also pay attention to the position and direction of the openings.

- Before wax injection, check the nozzle of the rubber mold. If there is accumulation of wax material, impurities, etc., clean it first before injecting wax.

- The rubber mold must have good elasticity, cannot stick to the wax mold, have high tensile strength, otherwise the details will not be clear, and the life of the rubber mold will be shortened. When the rubber mold becomes soft and sticky, it is mainly due to insufficient rubber vulcanization, which is caused by short curing time or low temperature. Therefore, it is necessary to appropriately increase the working temperature of the mold and extend the molding time.

- Determine the appropriate vulcanization temperature, vulcanization time, and mold pressure based on the specific structure of the rubber mold to solve the issue of the rubber mold is too hard, cannot be leveled, and the two halves of the rubber mold cannot be closed.

- Use clean and dry adhesive material

- Add a large pin as an insert and assemble it into the rubber mold. After waxing, simply pull out the pin to obtain a regular through hole.

- To ensure the inner wall of the rubber mold cavity is smooth.

- When cutting the rubber mold, consider whether it is convenient to remove the wax mold.

2. Quality Inspection and Common Defects of Wax Mold

(1) Quality Inspection Content of Wax Mold

To evaluate the quality of a wax mold, it is generally assessed from the following aspects:

- Shape and size. The wax mold should accurately reflect the shape of the original model, without obvious deformation. It should meet the size requirements, not soften or deform easily, and be easy to weld.

- Appearance quality. The wax pattern surface should be smooth, fine, clean, without obvious surface shrinkage, cracks, wrinkles, bulges, or other defects.

- Intrinsic quality. The wax pattern should be dense, without obvious air bubbles inside, and leave little ash residue when burned.

- Mechanical properties. The jewelry wax pattern should have good strength, flexibility, and elasticity, with sufficient surface hardness at room temperature to prevent surface abrasion in subsequent processes after wax loss casting. The wax pattern should be able to bend without breaking when taken out of the rubber mold, and automatically return to its original shape after removal. The wax pattern and wax core should be securely welded during wax tree planting and not easy to fall off.

(2) Common Wax Mold Defects

- Flash: Adopt measures to optimize wax injection molding, including adjusting air pressure, wax temperature, clamping force, and rubber mold quality.

- Incomplete or cold shut, flow marks on the wax piece: Enhance wax injection molding by increasing air pressure, wax liquid temperature, adjusting mold clamping force, cleaning nozzles, venting molds, and preheating in cold weather.

- Air bubbles appear in the wax mold: Ensure proper wax injection by adjusting air pressure, wax quantity, temperature, nozzle alignment, and maintaining vent line clearance.

- Cracks or complete fractures occur in some parts of the wax piece: Improve wax injection by using more new wax, reducing mold quantity during recycling, opting for higher quality wax, refining mold cutting methods, and exercising caution in mold removal.

- Wax mold deformation: To prevent wax deformation, solutions include cooling wax pieces adequately in molds, selecting harder wax for high-temperature conditions, ensuring proper mold alignment, and adding support to delicate original versions.

- Wax Mold Surface Roughness: Maintain mold quality and cleanliness by using release agents sparingly, inspecting and cleaning molds regularly, ensuring wax quality, and using a neutral pickling solution for thorough cleaning.

- Wax piece overweight: Ensure consistent wax piece weight and quality using an automatic wax injection machine with mechanical clamping and precise temperature control.

3. Quality Inspection and Common Defects of the Casting Mold Blanks

(1) Quality Inspection Content of Casting Mold Parts

The quality inspection of the mold blank mainly focuses on the following aspects:

- Appearance: Check the integrity of the blank, whether the dimensions meet the requirements, and whether there are any defects such as defects, deformations, cracks, etc. Check if the color meets the requirements.

- Surface quality: Whether the surface of the casting is smooth and dense, and whether there are defects such as sand holes, metal shrinkage, air holes, etc.

- Internal quality: Whether the poured metal is correct, whether there are any wrong colors or insufficient colors, and whether the mechanical properties such as hardness, strength, and plasticity meet the requirements.

- Other aspects: Such as whether it is magnetic, whether it can meet the requirements of metal release, etc.

(2) Factors affecting the quality of investment casting molds

There are many process factors involved in the jewelry reverse mold process, such as physical properties of metal materials, melting process parameters, mold process parameters, pouring process parameters

(3) Common defects of investment casting molds

Common defects of investment casting molds are such a pinholes with segregation in castings, entrapment porosity in castings, shrinkage porosity defects, surface roughness, flash, sand hole, slag inclusion, cold shuts defects, metal beads, fracture and so on.

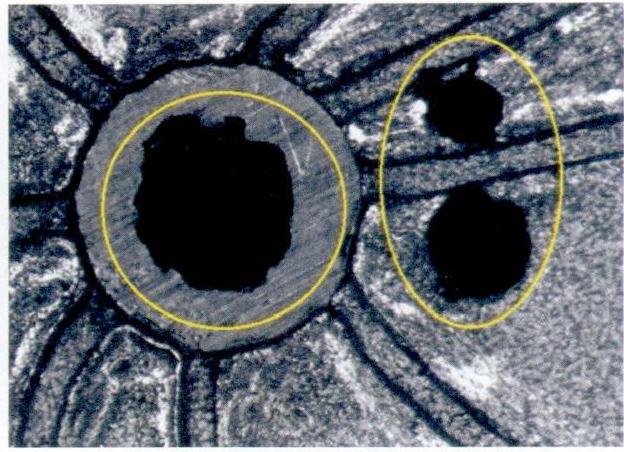

① Porosity Defects:

- Use clean, dry metal materials and control the proportion of new to old metals.

- Ensure effective degassing treatment of metal liquid and control temperature and atmosphere during smelting.

- Improve mold strength and control pouring pressure to prevent gas entrapment.

② Shrinkage Porosity Defects:

- Select alloys with a small solidification range and control the temperature and atmosphere during smelting.

- Design the casting system to facilitate sequential solidification and use proper mold temperatures.

③ Surface Roughness:

Improve the quality of patterns used for casting and control the quality of casting powder and mold-making processes.

④ Flash (Pi Feng):

Increase mold strength, ensure proper storage of casting powder, and avoid rapid temperature changes during firing.

⑤ Sand Holes:

Enhance mold quality and casting processes to prevent the inclusion of foreign matter in the metal.

⑥ Slag Eye (Clinker):

Clean the metal furnace charge and crucible, and improve slag removal methods before pouring.

➆ Incomplete and Cold Shut:

Ensure complete filling of the mold cavity by using appropriate pouring temperatures, mold temperatures, and casting system designs.

➇ Gold Beads:

Improve the dewaxing process by controlling the water-to-powder ratio and the operation time.

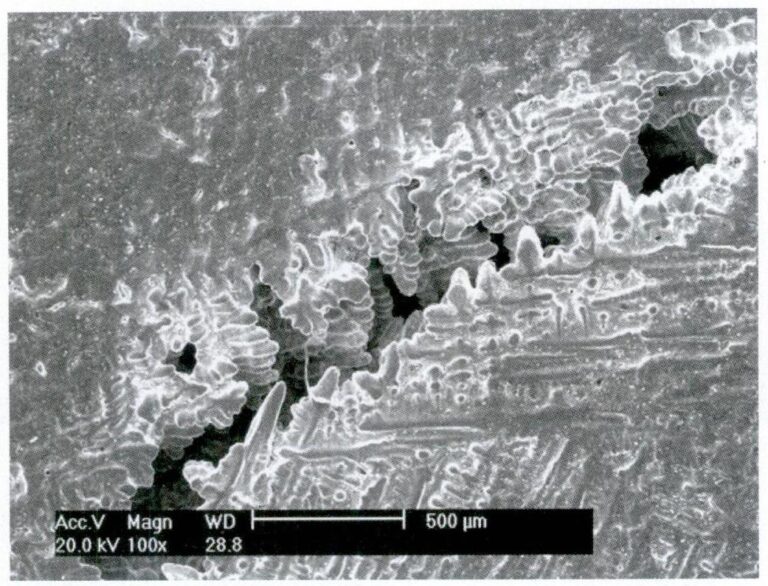

➈ Fracture:

Avoid external mechanical stress during handling, control the cooling rate after casting to minimize thermal shock, and ensure proper alloy composition to avoid brittleness due to microstructural transformations.

➉ Measures for Specific Fracture Cases:

- For composition-induced brittleness, refine and remix old gold to remove impurities.

- For mechanical stress fractures, ensure gentle handling and avoid concentrated forces on the workpiece.

- For thermal shock fractures, determine appropriate quenching times based on alloy properties and casting size.

- For structural transformation fractures, control the cooling rate and minimize thermal and organizational stress.

Copywrite @ Sobling.Jewelry - Producător de bijuterii personalizate, fabrică de bijuterii OEM și ODM

Section IV Quality Inspection of Finishing and Analysis of Common Defects

More details list here: https://sobling.jewelry/jewelry-quality-inspection-and-defect-analysis-of-stone-settings/

1. The model quality inspection content

In the jewelry making process, the model making process is a very important process. It is the process of integrating, fastening, welding, and rough finishing the jewelry blanks made by pouring or stamping using manual techniques and equipment.

The purpose of model making is to restore the original shape. Poor model making of jewelry blanks will directly affect the final quality of the jewelry.

Different types of jewelry have their own special requirements during modeling. For example, rings require coordinated and uniform setting, round and full claws, perforation if needed; earrings require symmetry, uniform size, equal length, elasticity on the back to hold the earring in place; necklace or bracelet chains should be straight, flexible in chain joints, appropriate tightness of chain clasps for easy wearing without automatic detachment; pendant seed ear size should be appropriate; brooch pin welding should be appropriate, with moderate length.

2. Common Defects in Finishing

(1) Common Finishing Defects in Various Types of Jewelry

① Filing-related defects:

In the process of filing, a large number of tools such as steel files and sandpaper are used to process the surface of the workpiece. The processing effect is directly related to the skill, carefulness, assessment method of the operator. When the processing is not done well, file-related defects are prone to occur, such as incomplete filing, over-filing, and uneven filing.

② Defects in Gold Materials:

Such defects refer to the poor quality of the metal, which is not generated during the die forging stage but brought about by previous processes, for example: Obvious shrinkage is observed on the surface of the jewelry die forging after water removal; After jewelry finishing, sand holes are exposed in a certain area; Residual flash remains after jewelry workpiece is finishing; Cracks appeared during jewelry finishing.

③ Welding defects:

When jewelry is being modeled, welding is often used to assemble components, repair defects, etc. The main welding methods used are laser welding and flame brazing. Improper welding operation can easily lead to welding sand holes, incomplete penetration, weak welding, and other defects.

(2) Defects of various types of jewelry finishings

In addition to common mold problems, corresponding category-specific mold defects often occur for different types of jewelry.

① Defects in bracelet and necklace finishing:

For bracelet and necklace jewelry blanks, the shape of the workpiece blank needs to be corrected to meet the design requirements, then the chain links are connected, and through processes such as filing, buckling, welding, holding, and saving, they are combined into a perfect piece of jewelry. It is required that the chain links fit tightly, the combination is flexible, the distances are uniform, the overall balance of the chain is maintained, and there are no uneven sections. Some common defects in bracelet and necklace finishings are such as the sizes of the fastening rings are not consistent; the fastening lines between chain links are too long; the tightness between different chain links is inconsistent; weak welding position; use welding (The occurrence of virtual welding, missing welding, and the inability of solder to penetrate at the welding site); Welding death; the ring was not welded properly; the bottom of the link socket is deformed; the length of the chain does not meet the requirements; the duck lever assembly tolerance is poor.

② Defects in holding the ring:

The holding of the ring generally goes through processes such as filing water mouth, shaping, assembling components, welding, boiling water, filing, sandpaper saving, and leak passing machine. In these operations, in addition to common generic holding problems, holding problems specific to the ring category often occur, such as refusal to follow the rules; the inner ring of the ring is not rounded; the ring shoulder is too thin; the ring size does not match; the bottom of the ring network base is deformed; ring net bottom hole deformation; ring claw deformation; Men’s Ring Side Without Angle; cheshuikou Injured the Ring; the flower head of the ring is not aligned.

③ Earring holder defects:

The earring holder must go through processes such as filing water mouth, shaping, buckling thread, welding, preserving water, filing, sandpaper saving, and leak machine. In this process, common earring holder defects are such as the earring position is too tight, and the ear pin cannot match the needle hole; ear needle too long; ear needle burnt; earrings are not matching; the earring opening is deformed; the ear clip is too tight, and the movement is not smooth; the ear pin is not straight; the ear flap button line is too long

④ Defects in pendant modeling:

The pendant is a pendant used in conjunction with a chain. The modeling process includes filing the water mouth, checking the shape, welding the melon seed ear, filing, saving sandpaper, and water outlet. In addition to common modeling defects, the common defects of pendant modeling are such as the suspension ring is not round; the suspension ring does not match the melon seed ears; the melon seed ear hole is too small to pass through the chain; the pendant is not hung properly; the corner position of the pendant has been filed off; pendant back perforation; inconsistent sizes of decorative holes on the pendant; pendant stud incomplete.

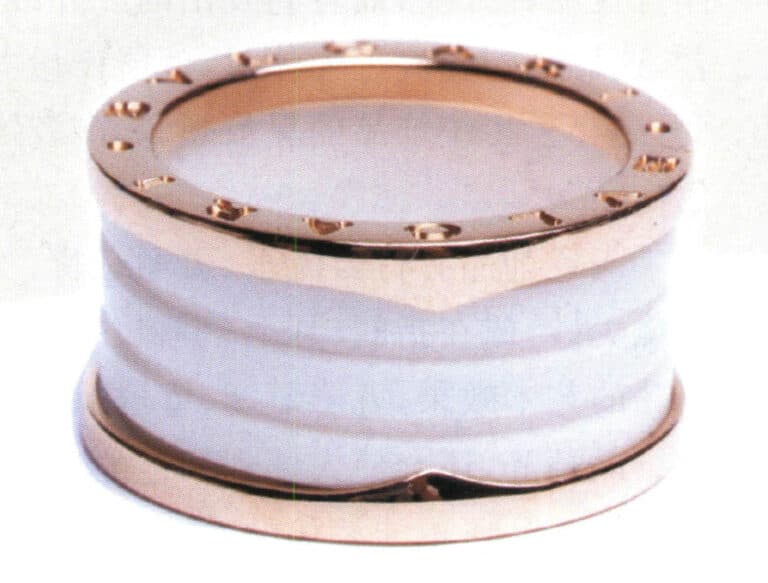

⑤ Hand gong holding model defects:

Such as duck lever box collapse edge; the duck lever is not tight enough; the duck lever positioning is too tight, leading to the head of the finishing breaking; bracelet compared to the tube welded to death; bracelet compared to the tube position detached; bracelet “8” character made too loose; the inner circle of the bracelet is not round; the bracelet modeling requires smoothness and no abrupt thickness changes; in order to reduce the weight of gold and highlight the gemstone effect, sometimes a bottom hole is opened in the bracelet, requiring its shape to be round. When problems such as deformities and uneven edges occur, they should be trimmed to the required shape by modeling.

Section V Inlay Quality Inspection and Common Defect Analysis

More details list here: https://sobling.jewelry/quality-inspection-and-common-defect-analysis-of-jewelry-finishing/

The most dazzling part of inlaid jewelry is the gemstones of various shapes and colors inlaid in it. The quality of the inlaying process directly affects the appearance and grade of the jewelry. However, inlaying is mainly done by manual operation, and the quality of inlaying is closely related to the work attitude, skill level, and proficiency of the operator. Therefore, it is necessary to strengthen the inspection of the quality of inlaying during the production process.

1. Inlay quality inspection content and quality requirements

(1) Inlay quality inspection content

The inspection and control of inlay quality mainly focus on the quality of gemstones and inlay work. Gemstone quality inspection in jewelry making involves checking stones for weight, color, clarity, and defects before setting, using tools like magnifying glasses and electronic scales, to ensure they match order specs, while inlay work inspection focuses on the setting quality and gem integrity, using tools such as magnifying glasses and steel needles.

(2) Quality requirements for inlaying

Common inlaying methods mainly include prong inlaying, claw inlaying, bezel setting, pit inlaying, flying edge inlaying, prong setting, forcing inlaying, edgeless inlaying, etc. According to the types of gemstone settings, it can be divided into wax inlaying and gold inlaying. Each inlaying method has its own characteristics, but many quality issues are common, generally divided into gemstone issues and setting issues, requiring intact gemstones, firm setting, no loose stones, oblique stones, high and low stones, twisted stones, crooked stones, etc., claws, pits, prongs, edges, holding, scraping smooth, good appearance.

Quality requirements for various inlaying methods include symmetrical claws for claw inlaying, consistent pit depth for pit inlaying, uniform gold edges for forcing inlaying, round and symmetrical prong heads for prong settings, and uniform prong positions for flying edge settings, all ensuring proper fit and appearance of the gemstones.

2. Common Inlay Problems

(1) Problems with Gemstone Texture:

During the production of inlaid jewelry, various gemstone texture problems are often encountered, mainly including issues related to gemstone material, gemstone grade, gemstone cutting, gemstone size, gemstone color, gemstone quantity, etc.

- The gemstones to be set do not match the material requirements of the order: Natural crystals with artificial zircon mixed in; Diamonds were swapped during the setting process.

- Gemstone Grade Issue: Gemstones are generally graded based on color, clarity, cut or processing characteristics, single crystal size or size of jade blocks, etc. The grading standards for different types of gemstones are not the same, and different international organizations or large companies may not have the same standards for grading the same type of gemstone. For diamonds, GIA, the Gemological Institute of America, pioneered the diamond grading standards currently recognized in the industry, including color, clarity, cut, and carat weight, known as the standard.

(2) Stone Matching Issues:

Stone matching is an important link to ensure the quality of setting and production efficiency. Here are some common stone matching issues:

- The diamond shape does not match the setting: One basic requirement for gemstone setting is to match the shape, that is, the shape of the gemstone should basically match the size and shape of the setting, which should be paid attention to from the beginning of the stone setting which means when setting the stones, the size of the diamond should be reasonably selected, and if necessary, the diamond should be cut and polished to better fit the setting.

- Incorrect stone setting angle during stone setting: When setting stones, it is necessary to consider the overall effect rather than just the arrangement of individual stones.

- The diamond is too long: This makes it easy to damage the diamond when setting the tiger claw stone.

- The diamond is too short, resulting in obvious gaps between the gold and the stones, affecting the stability and appearance of the diamonds.

- There is a large contrast in gemstone colors: When matching stones, it is necessary to select gemstones with similar colors from the materials.

(3) Setting Issues:

Setting issues involve both the setting effect of gemstones and the handling effect of metal claws (edges). Setting is one of the important indicators to measure the grade of a set-inlaid product. Different setting methods encounter common setting issues, as well as issues specific to the setting method.

① Common Setting Issues in Pave Setting:

Pave setting is usually not used for setting main stones, but for setting smaller (diameter less than ) side stones or clusters of small diamonds. It fully utilizes the good ductility of precious metals, uses special tools to dig out small metal teeth, catches the girdle of the gemstone, and thus secures the gemstone. Pave setting is widely used for setting small granular gemstones, and can be divided into two-prong setting, three-prong setting, four-prong setting, and close-prong setting according to the number of prongs.

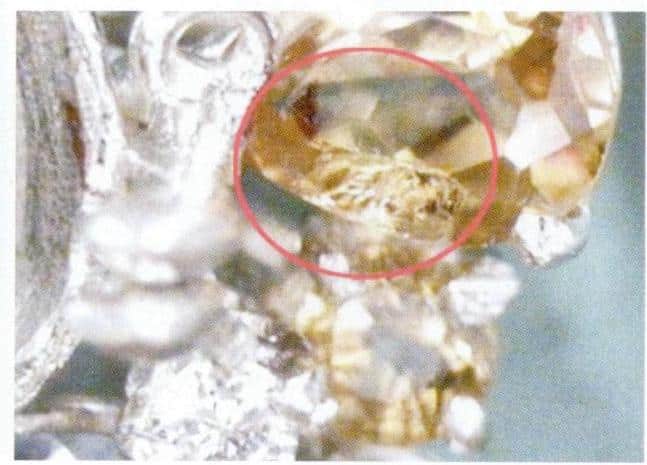

To inspect the quality of pave setting work, it should be examined from aspects such as the flatness, fastening condition, intactness, and treatment of the prong head of the gemstone. The set gemstone should not have phenomena such as slanted stones, uneven stones, used stones, loose stones, or rotten stones; the light gold position around the gemstone and the gold edge should not be scratched; the prong head should be round, not flattened, and no gold chips should appear on the prong edge; the prong should not be too long or too short, and so on.

② Common setting problems with claw setting:

Claw setting is a representative of traditional craftsmanship. It tightly holds the gemstone with long metal claws (columns), with minimal metal covering the gemstone, allowing a large amount of light to enter from all directions, revealing the dazzling brilliance, making it appear larger and more sparkling. Claw setting is suitable for gemstones of different sizes, even large main stones can be securely fixed, becoming a popular single-grain diamond jewelry inlay craft in the market. Claw setting claws come in various forms such as round claws, square claws, triangular claws, finger claws, figure-eight claws, six claws, four claws, three claws, two claws, single claws, and common claws.

Good claw setting worker, should ensure that the claws are tightly attached to the gemstones; the gemstones must be flat, without phenomena such as slanted stones, high and low stones, loose stones, rotten stones, or used stones; the length of the claws should be consistent and symmetrical, not crooked; the claw heads should be regular, not pinched on the back of the claw; the gripping position of the claws should be consistent in depth, shallowness, height, and lowliness.

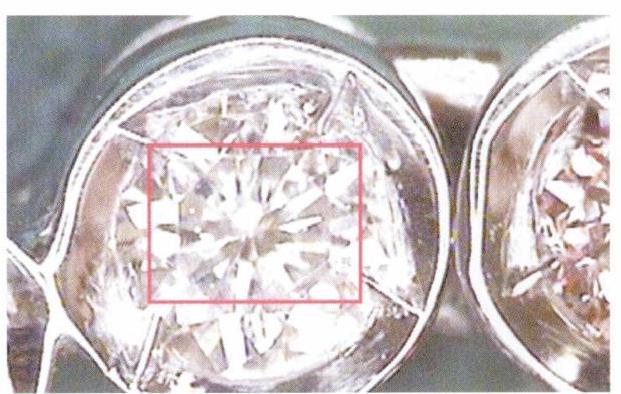

(4) Common Setting Issues in Channel setting:

Channel setting, also known as forcing setting or clamping setting, is a setting method where a groove is carved on the side of the setting, the gemstone is placed into the groove, and firmly pressed. This method is commonly used for setting secondary stones in high-end jewelry. Additionally, some square and trapezoid diamonds are set using channel setting, resulting in a better visual effect.

Common channel setting methods include prong setting and channel setting. Prong setting uses the tension of metal to secure the waist or the waist and bottom tip of the gemstone, exposing more of the gemstone to showcase its brilliance. Channel setting involves carving grooves on the precious metal mount, then placing the gemstone into the groove. In this method, gemstones are set one after another in a continuous line within the metal channel, utilizing the metal on both sides to support the gemstones, creating a smoother appearance on the jewelry surface. Channel setting is suitable for round brilliant-cut gemstones of the same diameter as well as for varying trapezoid-cut gemstones.

The setting of gemstones should be flat, consistent in height, density, without loose stones, swinging stones, rotten stones, or tilted stones; reasonable control of the spacing of gemstones based on the shape, quantity, and length of the setting position; the gold edge should be closely attached to the gemstone edge; after setting the gemstones, there should be no deformation or unevenness on the gold surface, etc.

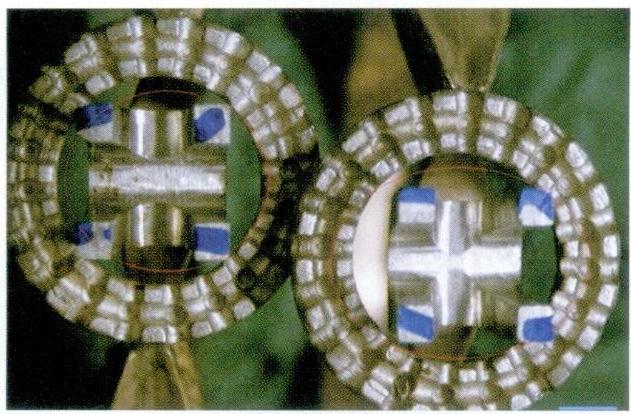

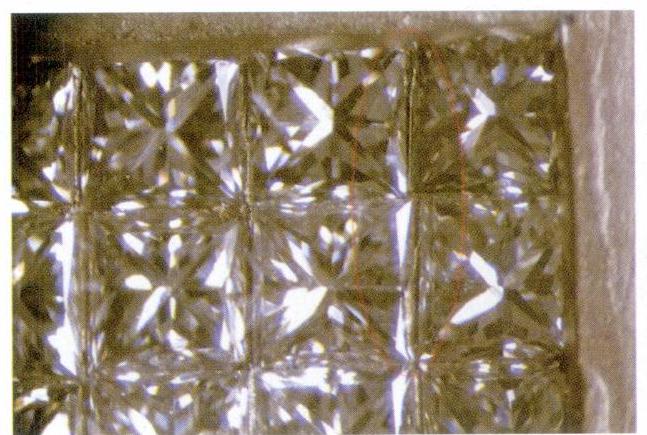

(5) Problems with Invisible setting:

Invisible setting is a new type of gemstone setting method, which is deeply welcomed in the market for its attractive gemstone appearance effect. The basic principle is that when setting multiple rows of gemstones, shallow grooves are opened on the bottom side of the gemstones, transferring the metal fixing the gemstones from the stone surface to the bottom groove, and using external force to force the metal into the groove to secure the gemstones. Therefore, only the outermost metal of the gemstone is visible, and no metal can be seen between the gemstones, commonly known as “seeing the stone but not the metal.” Invisible setting technology breaks the traditional setting technique, allowing diamonds to have no metal obstruction above the waist, ensuring the best light penetration at the crown and waist, making the gem’s fire color more perfectly shine, thus ensuring that the diamond presents the most perfect optical effct and further enhancing the appearance of the entire jewelry. Especially for cluster-set diamonds, since there are no metal prongs or edges around the diamonds, the joining and color transition between diamonds are more perfect and natural, creating more elegant patterns. Without the traditional metal prong obstruction, light can propagate more widely between diamonds, making the diamonds more brilliant and dazzling.

The requirements for Invisible setting craftsmanship are as follows: the gemstones must be flat, tight, and consistent in height, with no gaps visible to the crossbar, and no loose, rotten, misused, or slanted stones should appear. The gemstones must align with each other, and the cross positions must be correct. However, Invisible setting is a high-demand manual craftsmanship setting method, prone to setting problems.

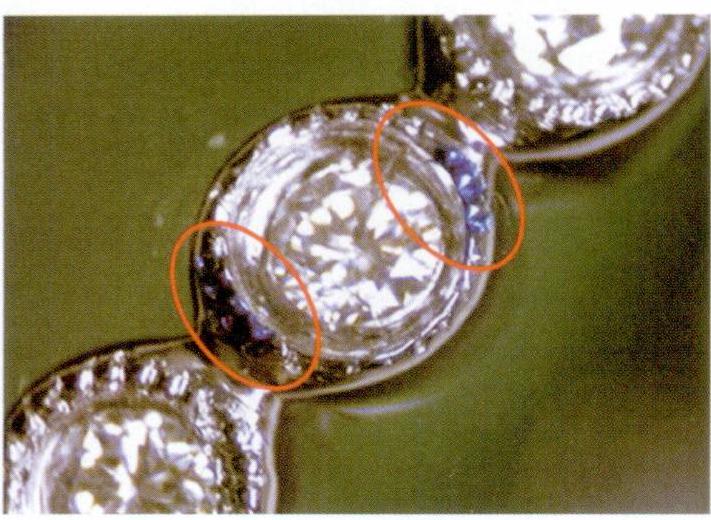

(6) Common setting problems in bezel setting:

Bezel setting is a method of tightly setting gems surrounded by metal. It can be divided into edged bezel setting and edgeless bezel setting. Edged bezel inlay has a metal edge wrapped around the gemstone, technically called a “stone bowl,” which is a common gemstone setting; edgeless bezel setting wraps the gemstone with metal without a circular edge, mainly used for inlaying small granular gemstones or side stones. In addition, according to the size of the metal edge surrounding the gemstone, it can be further divided into full bezel setting, half bezel setting, and tooth bezel setting, among which tooth bezel setting is a method of setting cabochon gemstones, only wrapping the top corner of the gemstone, also known as “corner setting.”

Bezel setting securely sets gemstones and is suitable for inlaying gemstones with large grains, high prices, and bright colors, such as large diamonds, faceted or saddle-shaped jadeite jade ring faces; but due to the metal edge wrapping, the light passing through the gemstone is relatively less, and the visible area of the gemstone is also reduced compared to the original stone. Therefore, it is not suitable for transparent gemstones, those desiring to highlight fire color, and inlaying gemstones with small grains.

Bezel setting is a inlaying craft with certain difficulty, requiring the gemstones to be flat after inlaying, in the center of the setting, without slanting stones, loose stones, rotten stones, high and low stones, etc. The workpiece cannot deform after pressing, the gold edge should be smooth, the surface gold should retain a certain thickness, not too thick or too thin.

(7) Common setting problems for aperture inlays:

Gypsy inlay, also known as smear inlay, is similar to bezel setting in craftsmanship. The gem is deeply embedded in a circular metal stone bowl, and the edge is tightly wrapped and embedded by metal wrapping. There is a recessed metal ring edge around the periphery of the gemstone, which looks like a halo under light, hence the name Gypsy inlay. According to whether there is a metal hook in the metal stone bowl, it can be divided into Gypsy inlay and prong Gypsy inlay. prong Gypsy inlay, also known as flying edge inlay, batch wire inlay, or Italian inlay, is to carve out several metal small prongs by hand on the metal ring edge to set the gemstone. Due to the presence of the metal halo, the Gypsy inlay visually gives the impression that the gemstone has increased significantly, and the circular halo also has a certain decorative effect.

Good Gypsy inlay work quality should ensure that the gemstone is flat and tight, without phenomena such as rotten stones, oblique stones, or missing stones; the nest edge should be flat, uniform in thickness, and bright without scratches; the prong head should not be too long or too short, the prong direction should be consistent, the prongs should be symmetrical, uniform in size, and the prong head should fit snugly.

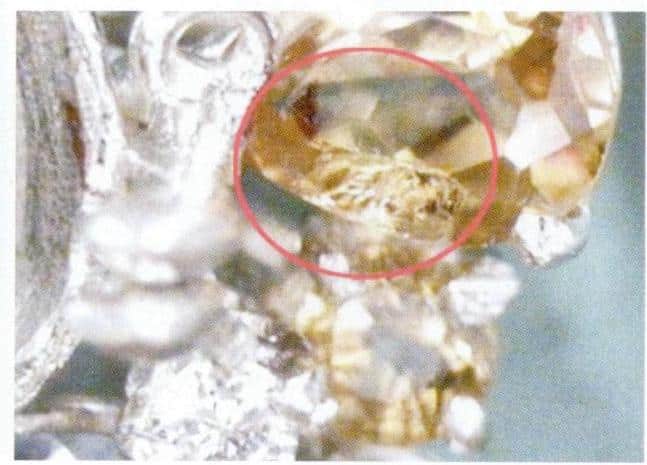

(8) Inlay problems in wax-inlaid casting:

Wax inlay is a widely used inlay method in the jewelry making industry, especially in the production of jewelry with a large number of inlaid gemstones. The wax inlay process has become an important way to reduce production costs, improve production efficiency, and increase product competitiveness. The so-called wax inlay is in contrast to gold inlay. It is to pre-inlay gemstones in wax models before casting. After preparing the plaster mold, dewaxing, and firing, the gemstones are fixed on the plaster wall of the mold cavity. When the metal liquid is poured into the cavity, the gemstones are wrapped by the metal liquid and firmly fixed in the metal inlay after cooling and shrinking. The wax inlay technology is based on the traditional investment casting process, but it has its own uniqueness and difficulty in each production process. While bringing efficiency to jewelry processing enterprises, it also carries certain risks. Only with a full understanding and strict operation of the wax inlay process can the stability of wax inlay quality be ensured and the advantages of wax inlay technology be truly brought into play.

Wax inlay casting technology is a comprehensive technology that integrates knowledge of casting technology, gemology, metallurgy, jewelry making technology, aesthetics, and other aspects. It has a wide range of knowledge and many influencing factors. Any change in factors may affect the wax inlay casting effect, leading to quality problems in the final product, or even scrapping. Therefore, if this process is not effectively controlled, the cost of wax inlay casting may be higher than that of conventional jewelry casting.

Common problems in wax inlay include: cloudy stones, rotten stones, black spots, loose stones, uneven or misaligned stones, and gold-covered stone surfaces

Section VI Electroplating Production Quality Inspection and Defect Analysis

More details list here: https://sobling.jewelry/how-to-inspect-quality-of-finished-products/

Different jewelry production enterprises have different organizational structures, with most of them integrating the jewelry polishing, electroplating, or other surface treatment processes after casting and setting into the electroplating department. Electroplating belongs to the semi-finished product process and is the final process for products to become finished goods. Thus, the inspection of goods covers both semi-finished and finished product inspections, with higher inspection requirements. In jewelry production, although each batch of goods has been inspected and approved by inspectors from various departments before reaching the electroplating department, inspections are often carried out only partially at a particular process, leading to incomplete inspections and omissions. Therefore, jewelry production enterprises are expected to face disruptions and accumulate reworked products in the electroplating department.

1. Electroplating Quality Inspection Contents and Methods

According to the surface decoration requirements of goods, the production process of the electroplating department can be divided into several types:

1st type is the polished surface goods that only require Polishing, with the process flow as follows: grinding– cleaning – finished product.

2nd type is goods that require single-color electroplating, with the process flow as follows: grinding – cleaning-electroplating —finished product.

3rd type is goods that require electroplating, surface sandblasting, etc., with the general process flow as follows: grinding – cleaning – applying protective paper – sandblasting – degreasing – etching-electroplating – finished product.

After wax removal and cleaning, a polishing QC is set up, usually to a semi-finished product QC, and a finished product QC is set up after electroplating. As the final process, the electroplating quality inspector must possess comprehensive inspection capabilities, be familiar with the production processes of various goods and departmental work procedures, take inspection work thoughtfully and responsibly, promptly inspect products transferred from the previous process, and quickly provide feedback on any issues found to relevant personnel; strictly inspect finished product quality according to company product standards or customer requirements, strictly control product quality, and prevent non-conforming products from leaving the factory.

The content and methods of quality inspection for electroplating are as follows:

① Understand the requirements of the production work order.

After the QC staff checks the number of goods received, they should then read the order to understand the general situation of the batch of goods, such as the quality of the goods, the required engraved inscriptions, the size of the goods (hand size), the stone data, whether it needs edge grinding, sanding, whether it involves color separation and the desired effect of the goods. The QC staff should know the products’ general quality standards and consider each customer’s requirements.

② Check the quality of the stones and the stone setting.

The quality inspector should master the basic identification methods of common gemstones, compare the stone data and setting requirements on order, and carefully inspect each Stone to see if the quality, size, cutting, color, etc., are to the order requirements. According to the characteristics and requirements of different setting methods, carefully check the setting quality to see if there are problems such as scratch stones, broken stones, loose stones, slanted stones, uneven stones, twisted stones, and tilted stones, and whether the prongs, mounts, and prongs are polished to a bright shine.

③ Check the size and characters of the goods.

If the order specifies the size of the goods, the actual size must be measured during inspection to see if it matches the order requirements. Check for missing or incorrect inscription, whether the position is correct, and if the inscription is clear.

④ Check the functionality of the goods.

For example, when inspecting earrings, please pay attention to whether the ear pins are straight, the flexibility, elasticity, and tightness of the ear clips; the function of the bracelet clasp and hinge, whether it moves smoothly when worn; whether the gaps between the two sides are too long; whether the chain buckle is flexible; in addition to paying attention to the elasticity and flexibility of the brooch clasp pin, also note the direction of the pin (fasten from right to left); the bail of the pendant should be flexible, and the loops should be round.

⑤ Check the metal quality.

Carefully inspect the goods for any metal-related issues. Common metal quality problems include metal withering, sand holes, metal cracks, lack of smoothness, metal inclusion residue, and other defects. When these problems exist, rework is required. For milgrain and sandblasting goods, thorough grinding and Polishing must be done after migraine and sandblasting so that incomplete polishing defects can be ignored before milgrain and sandblasting. Still, it must be ensured that the goods have no issues with the setting, size, movement function, metal quality, etc., before milgrain or sandblasting. After milgrain, pay attention to whether the milgrain edges are uniform, whether there are broken stones or collapsed edges; after sand pushing, the sand should be neat and in place without crossing the boundaries or forming wrinkles. Before electroplating, check again for loose stones, wax crumbs, and metal crumbs at the bottom of the stones, and before and after electroplating, ensure that the goods are kept clean and tidy.

⑥ Inspect the overall quality of the goods.

According to the order requirements or reference samples, inspect the overall quality of the goods. Check whether there are any problems with the metal edge lines, angles, and levels, ensuring smooth lines, precise angles, distinct levels, roundness where it should be round, and squareness where it should be square. The gemstone settings should be secure and positioned correctly, and the stone holes should be transparent. The metal content should meet the requirements, and the metal surface and edges should be smooth, without deformation, obvious sand holes, withering cracks, or clean interlayers. No positive and negative surfaces in electroplating should exist, and no gray-black, yellow spots, or haze should be present in rhodium plating.

Pay attention to the specific requirements of different types of goods. For example, for ring-type goods, the ring size and ring shank should be consistent, and the ring size should be correct round; for earring-type goods, the earring length should match the order, the ear pins should be straight, soldered through, the loops should be asymmetrical, and the ear clips should be flexible; for pendant-type goods, the bail should be adaptable, soldered through, and the loops should be round; for necklace and bracelet-type goods, the links should be smooth, and the angles should be consistent. Since the chain’s metal is relatively thin, special attention should be paid to whether there are any signs of breakage in the movable joints. The soldering of the connected position should be complete and clean, without noticeable marks of soldering for bracelet-type goods. The higher function should be flexible, and when closed, the clasp should touch closely, without gaps.

➆ Methods for dealing with issues.

After the inspector identifies the defects in the goods, different techniques are adopted based on the severity of the problems. Generally, a repair team is set up in the electroplating department. In addition to metal base trays with metal withering, cracks, lack of smoothness, and sand holes, there are also issues such as ring size being not round due to improper processing, ring shank not being smooth, hinges being too loose or too tight, clasps not being soft or flexible, missing engravings, broken chains, over-polishing, inconsistent prong sizes, etc., which can all be handed over to the repair team for rework. All issues must be addressed before electroplating to avoid repairing or grinding the goods after electroplating, as this can cause significant damage to the items.

2. Common Electroplating Defects Problems

(1) Common Electroplating Defects in Various Types of Jewelry:

These defects can be encountered in various types of jewelry, mainly covering aspects such as metal quality, setting quality, electroplating quality, or other surface treatment effects.

① Jewelry Metal quality:

The content does not meet the standard requirements, welding should use materials with the same content as the body; Rose metal is prone to discoloration, production companies should make reasonable choices and conduct necessary tests, they can also use artificial sweat immersion and electrochemical tests to infer the alloy’s anti-discoloration ability; Sand holes are exposed after the goods are polished, repair sand holes in jewelry by cleaning, laser welding, and polishing, avoiding heat damage to gemstones; The product shows severe shrinkage after polishing, it is necessary to strengthen the casting process’s control and improve the casting quality for such defects; After polishing, metal slag appears on the metal surface, complex spot defects in jewelry arise from issues like nickel segregation, silicon-related reactions, and foreign material inclusions, requiring meticulous smelting and material handling to prevent; Cracks appeared in 18K red metal, to solve this problem, in addition to selecting appropriate mixed alloys, when hot working jewelry, it is necessary to reduce the total thermal stress and structural stress to the lowest level rather than just adopting a slow cooling method to reduce thermal stress; Cracks appeared on the 18K white mesh bottom.

② Jewelry Shape issues:

Final products not follow original sample; Product deformation; Bottom support pole not removed; Abnormal bottom hole of the product; The edge is not smooth; The edge size is unsmooth; Metal edge collapse.

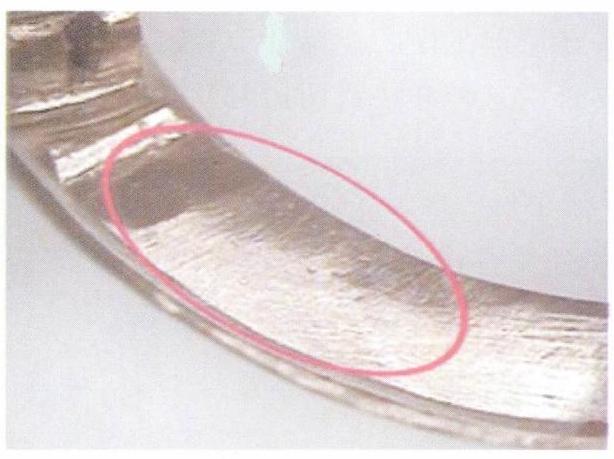

③ Jewelry Polishing issues:

The polishing work is insufficient because some parts of the product have not been thoroughly polished, and the previous process’s original surface state or processing traces still need to be retained; The product inscription is unclear; Metal surface perforation; Uneven metal surface; Excessive Polishing; Scratches on the Polished Surface; Poor Electrolytic Polishing Effect.

④ Jewelry Settings issues:

Glue not removed; Stones falling off during Polishing; Pearl surface scratched; Jewelry pieces are thrown away with great force in Polishing, causing diamond fractures; Stone drop off during ultrasonic cleaning; Uneven height of gemstones; Gemstones turning dark; High prong scratching hand; The Prong is not round; The prong head is not smooth; The prong of the gypsy setting is broken; The metal edge of the channel setting is uneven.

⑤ Jewelry Plating Issues:

The polishing wax removal is not clean; The oil removal needs to be more thorough; The inspection of the coating color is not standardized, and the client has objections to the inspection results; The Rhodium plating color is not bright enough; The white color of the Stone turns yellow after plating; The jewelry surface turns cloudy after plating; The bottom of the Earring is not plated, and the diamond appears black; The bottom of the caged back is dull; Color change during electrolytic oil removal; Coating pinholes and pitting.

(2) Defects of various types of jewelry in electroplating

① Defects of pendant electroplating:

The bail and the jump ring cannot be fastened; The bail is too small, and the chain is complex; Defect in the welding position of the bail; The jump ring is not round, and the pendant is not aligned; Loose shrinkage on the inner wall of the bail; Bail and Jump ring welded together, unable to move.

② Defects of finger ring electroplating:

Improper position of the inscription; The ring shank is asymmetric; The decorative pattern is deformed; Inlaid parts skew; Stress Corrosion Cracking of 14 KW Ring’s Prong; Ring shank too thin; The ring size does not meet the requirements.

③ Defects in bracelet and necklace electroplating:

Excessive gap and chain breakage; Non-uniform connected gaps; Welding incomplete; Chain breakage; Chain specifications do not match; Pendant is not centered; The chain length does not meet the requirements; The leather cord is not securely fastened and comes loose from the leather cord clasp.

④ Defects in earrings electroplating:

The position of the earring pin welding is incorrect; Earring edge is not symmetrical; Earring face is not symmetrical; The jump ring is deformed & incomplete; The support pole of the Earring clap is too thin; Earring post with sanding marks; The ear back pressure is too loose; The ear pin is crooked and deformed; The ear pin is broken; The earring hinge pivot falls off; There is a crack at the welding position of the earring hinge pivot; Skin Scratches on the earring hinge pivot; The earring clap does not sit in the center of the ear pin; Ear back sizes are inconsistent; The bracelet is not smooth; The bracelet is uneven and deformed; The bracelet opening clasp is not flexible; The Security Latch is not tight; The size of the open bangle does not meet the requirements; Wearing the bangle at the clasp part causes hand scraping.