3 Kind of techniques for Improving Gemstones

Learn about the Improvement Principles and Classification of Improvement Techniques

The improvement of gemstones is a means by which people use certain scientific technologies and processing techniques to change the physical properties and chemical stability of low-quality gemstones, such as color, clarity, luster, and durability, to enhance their decorative effect and economic value.

Gemstones that have been improved are called improved gemstones. They are also known as artificially improved products or optimized treatments of gemstones. However, regardless of the name, since they are no longer the original natural gemstones, they should be classified as artificial gemstones.

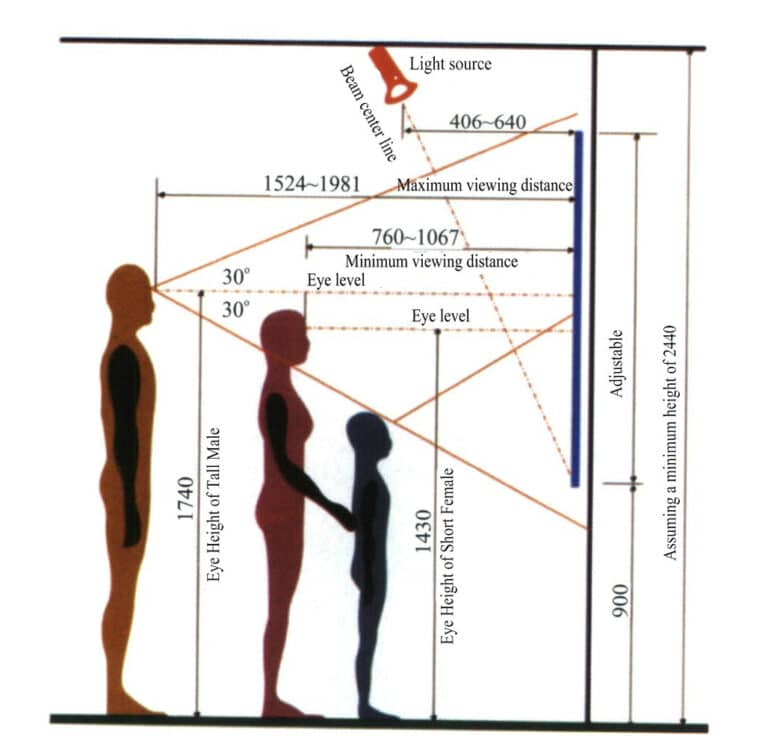

Schematic diagram of well-type furnace (a) and tube furnace (b) (K. Nassau, 1984)

Tartalomjegyzék

Section I Principles of Gem Improvement

Eliminating various defects present in the vast majority of natural gemstones to enhance their beauty, durability, and usability is the principle of gem improvement. Therefore, gem enhancement and the sale of improved gems must adhere to the principles of pragmatism and truth-seeking.

1. Principles of Improvement

Artificially improved gems, like naturally formed gems, have their own characteristics and evaluation standards. In addition to possessing the inherent physical and chemical properties and types of processes of natural gems, improved gems also have unique features in their enhancement processes. Although various natural gemstones exhibit different characteristics after being improved by different methods, there are common evaluation requirements for all artificially improved gemstones.

(1) Aesthetic Appeal

The value of gemstones lies in their beauty, and beauty lies in their color. The pursuit of beauty is a common aspiration in the material world. Whether humans, animals, or plants, as well as gemstones, jade, and unique stones, all intentionally or unintentionally beautify themselves and their environment. People love gemstones because their beautiful colors provide enjoyment of beauty both spiritually and materially.

The beauty of gemstones is reflected in their inner beauty, outer beauty, and craftsmanship. The primary task of artificial enhancement is to reveal the potential inner beauty of gemstones as much as possible or to improve their outer beauty and craftsmanship through processing.

(2) Tartósság

Durability refers to whether the ideal effect obtained by artificially improving the gemstone can remain stable and not undergo significant changes in a normal physical and chemical environment. Generally speaking, whether the improvement effect of the gemstone has durability depends on whether the chemical composition and internal structure of the gemstone change during the improvement process and the stability of the added foreign substances.

No country clearly defines the stability period of improved gemstones. For wearers, the longer the stability period, the better, at least without significant changes during the wearing period. Since the economic value of improved gemstones is lower than that of similar natural gemstones, it is required that under normal environmental conditions, durability should be maintained for more than 10 years.

(3) Safety

① Harmless

Improved gemstones are meant for wearing and handling and often come into contact with human skin. Harmful substances in improved gemstones can harm the human body if they exceed the designated safety limits. Especially after chemical reactions and radioactive irradiation during the improvement process, some harmful chemicals (salts that irritate the skin and toxic dyes) and residual radioactivity can significantly harm the human body. Therefore, harmful substances remaining in improved gemstones must not be released to the market until they reach safe levels.

② No pollution

The chemical dyes used in the improvement process of gemstones have good stability and do not stain other materials, such as skin and clothing. Also, harmful gases and other waste are often produced during gemstone improvement. If protection is inadequate, it will pollute the environment.

③ Safety

During the gemstone improvement process, high-intensity radiation, high-pressure currents from heat furnaces, explosive and flammable chemical reactants, toxic and harmful gases, and fine dust can pose significant hazards to production personnel.

2. Improvement Rules

All methods used to improve the appearance (color, clarity, or special phenomena), durability, or usability of jewelry and gemstones, excluding cutting and polishing, are divided into two categories: optimization and treatment.

(1) Optimization

This refers to traditional methods widely accepted by people and aimed at enhancing the potential beauty of gemstones. Methods that belong to optimization include heat treatment, bleaching, waxing, soaking in colorless oil, and dyeing (for agate and chalcedony, etc.). The naming of optimized gemstones can directly use the names of the gemstones, and it is not necessary to annotate this in the identification certificate. For example, light blue and grayish-blue sapphires with silk-like inclusions from Myanmar and Sri Lanka can be transformed into beautiful blue sapphires after heat treatment under reducing conditions; colorless or yellow topaz from Brazil can become blue topaz after irradiation and heat treatment; medium to low-grade emeralds from Colombia can have fine cracks concealed and transparency improved by soaking in colorless oil; and the dyeing of the oldest chalcedony and agate, etc. can be sold as natural products without explanation.

(2) Kezelés

Refers to non-traditional methods that people do not yet accept. Such methods include soaking in colored oil, filling (glass filling, plastic filling, or filling with other hard materials), waxing (for turquoise), dyeing, irradiation, laser drilling, Coating, diffusion, and high-temperature high-pressure treatment. The name is added for treated gemstones by adding the word “treatment” in parentheses after the corresponding gemstone name, and the specific treatment method must be described in the identification certificate. Suppose it cannot be determined whether the gemstone has been treated under current general identification technology conditions. In that case, it may not be indicated after the gemstone name, but an explanatory note must be added.

The national standard also stipulates that artificially treated synthetic gemstones can be directly named using the basic name of synthetic gemstones. For relevant regulations, see Table 6-1.

Table 6-1 Common Improvement Methods for Gemstone Processing and Identification Features

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Diamond | Lézeres fúrás | Improve Purity | Visible white tubular objects, laser holes, few colorless fillings | Kezelés |

| Coating treatment | Improve color and wear resistance | The coating can peel off and can be scraped off with a knife or needle; the coating is mostly granular in structure, 1500cm-1 the width of the peak increases | Kezelés | |

| Filling treatment | Színjavítás | The filling cracks show variable sparkling effects; the dark areas are orange-yellow or purple to purplish-red pink, etc.; the bright areas present blue to blue-green, green-yellow, yellow, etc. sparkling. The filler may contain bubbles, flocculent substances, or mist-like structures, and flowing structures, etc. Transparency is reduced, and there may be incompletely filled | Kezelés | |

| Thermal irradiation treatment | Színjavítás | Under oil immersion, colored diamonds show color bands and spots at the pavilion, distributed in an umbrella shape. The 594nm, 699 nm absorption line can be seen; dark green diamonds may have a 741 nm absorption line (at low temperatures). This method is often used to change light-colored gemstones to dark colors, based on the principle of transforming color | Kezelés | |

| High temperature and high pressure treatment | Színjavítás | Visible fog-like inclusions are generally difficult to detect. Raman spectroscopy shows a distinct absorption peak at 637 nm and an excitation spectrum at 575nm. The color changes due to alterations in the lattice structure. | Kezelés | |

| Ruby | Hőkezelés | Színjavítás | Flaky and ring-like stress cracks appear around solid inclusions, with fibrous and needle-like inclusions presenting as intermittent white fog. The negative crystals show signs of erosion or rounded shapes, and twin patterns and fingerprint-like inclusions are also visible. There are grid-like color blocks, uneven diffusion halos, and pockmarks. | Optimalizálás |

| Soaked in colored oil | Color enhancement | The cracks have colorful interference colors and granular precipitates. Surface oil stains are visible, with color concentrated in the cracks, and flow patterns are observable. Under fluorescence, it can emit orange and yellow fluorescence. | Kezelés | |

| Festés | Color enhancement | Visible colors are concentrated in the cracks, the surface gloss is weak, there is an abnormality in pleochroism, and it can show orange-red fluorescence when wiped with acetone. | Kezelés | |

| Diffusion treatment | Enhance or create star light effects | Color distribution is uneven on the surface; star lines are uniform; dichroism is blurred; color spots emit red fluorescence; refractive index 1.78-1.79(1.80); color can concentrate on the edges or interiors of cracks or pits before treatment; internal characteristics are similar to those of heat-treated phases. | Kezelés | |

| Filling treatment | Increase transparency | Glassy fillings in visible fissures or surface cavities, residual air bubbles, weak luster; their compositional structure is different from that of ruby, and the fillings can be identified by infrared or Raman spectroscopy. | Kezelés |

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Zafír | Heat Treatment | Improve Color | Similar to the heat-treated structure of rubies. Lattice-like color spots, original color bands, color spot edges are blurred, no 450 nm absorption band. | Optimalizálás |

| Diffúzió | Color enhancement or the production of star-like effects. | Under oil immersion or scattered light, colors are concentrated at the edges of ridges or cracks, uneven, appearing net-like. Or concentrated at the edges and interiors of pits and other defects; star-like inclusions are fine and straight, and needle-like inclusions are concentrated on the surface, with blue-white or blue-green fluorescence possible under shortwave light, and may lack the 450 nm absorption band. | Kezelés | |

| Sugárzás | Színjavítás | Colorless, light yellow, and some light blue sapphires can produce deep yellow or orange-yellow after irradiation, which is extremely unstable and difficult to determine the treatment basis with conventional instruments. | Kezelés | |

| Smaragd | Immersed in colorless oil | Színjavítás | Colorless or light yellow interference colors visible in the cracks. Appears yellow-green or green-yellow fluorescence under long waves, "sweating" when heated. | Optimalizálás |

| Soaked in colored oil | Color enhancement | Green reflection in the cracks; fading by acetone. Yellow-green or greenish-yellow fluorescence at long wavelengths. | Kezelés | |

| Filling treatment | Improve color durability | The filler is distributed along the cracks and appears green and reflective, misty, with bubbles and flowing structure; it "sweats" when probed with a hot needle; it can be dissolved with acetone. | Kezelés | |

| Akvamarin | Hőkezelés | Színjavítás | Blue-green, yellow, green colored by iron, can turn blue after heat treatment, stable, cannot be measured by conventional instruments | Optimalizálás |

| Macskaszem | Sugárzás | Improve color and eyeliner | Conventional instruments are not easy to detect | Kezelés |

| Beryl | Hőkezelés | Színjavítás | Commonly used for the color treatment of morganite, removing the yellow tone to produce pure pink. 400℃ Below stable, regular instruments are not easy to detect. | Optimalizálás |

| Sugárzás | Szín módosítása | Changes from colorless, light pink to yellow (stable below 250℃) or blue, often difficult to detect. The irradiated blue beryl has absorption bands located at 688nm, 624nm, 578nm, 560 nm and others. | Kezelés | |

| Bevonat | Produces a green appearance | Green film detachment is visible under magnification | Kezelés |

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Turmalin | Heat Treatment | Improve Color | Dark heating produces green to blue-green, pink or red heating produces colorless; orange heating produces yellow; brown and purple heating produces blue, stable, and un-measurable | Optimalizálás |

| Soaking in Colorless Oil | Improve Appearance | Oil is immersed in the cracks | Optimalizálás | |

| Festés | Improve appearance | Use dye to penetrate the gaps and dye them red, pink, purple, etc. Acetone will fade it. | Kezelés | |

| Töltő | Improving appearance and durability | Filling surface voids and cracks with resin. Visible differences in surface gloss, occasionally bubbles are seen in crevasses or voids. | Kezelés | |

| Sugárzás | Színjavítás | Light pink, light yellow, green, blue, or colorless ones become deep pink to red or deep purple-red after irradiation, yellow to orange-yellow, green, etc., are unstable, heat treatment will cause fading, and they are not easy to detect. | Kezelés | |

| Cirkon | Hőkezelés | Színjavítás | Almost all colorless and blue Zircon are produced by heat treatment, and can also produce red, brown, yellow, etc. Usually stable, but a few may change color when exposed to light. Cracking and small pits often occur on the surface or edges. | Optimalizálás |

| Topáz | Hőkezelés | Producing pink | Yellow, orange, and brown can appear pink or red when heated. Stable, un-measurable | Optimalizálás |

| Sugárzás | Producing green, yellow, blue, and other colors | Colorless can turn into deep blue or brown-green, often producing blue through heat treatment; yellow, pink, and brown-green can deepen in color or remove impurities through irradiation, most of which are un-measurable | Kezelés | |

| Diffúzió | Producing blue | Colorless appears blue and blue-green. Upon magnification, the color can be seen concentrated at the facet edges. | Kezelés | |

| Kvarc | Hőkezelés | Produces yellow | Dark amethyst turns light; gray tones are removed; amethyst heated turns into Topaz and green quartz; some smoky crystal turns into a greenish citrine. The color is unstable and un-measurable. | Optimalizálás |

| Sugárzás | Produces purple smoky color | Quartz becomes smoky crystal, un-measurable; fluorite deepens in color, stable, un-measurable | Kezelés | |

| Festés | For imitation gemstones | Quenching crackle pattern, coloring by immersion in dye. Magnified inspection shows dye concentrated in the cracks, emitting fluorescence. | Kezelés | |

| Feldspar (Moonstone, Amazonite; Sunstone,Labradorite) | Bevonat | Improve appearance | Cover with blue or black coating to create an iridescent effect. Coating peeling can be seen under magnification. | Kezelés |

| Gyantázás | Improve appearance | Used to fill surface cleavages and gaps. Medium stability. Heat needle can melt wax, infrared spectroscopy measurement | Kezelés | |

| Sugárzás | Used for imitation gemstones | White microcline can be treated to become blue amazonite, which is rare and difficult to detect | Kezelés |

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Scapolite | Sugárzás | Improve Color | Colorless or yellow turns purple, unstable, fades completely in light | Kezelés |

| Tanzanite | Hőkezelés | Producing purple | Some crystals with brown tones produce purple-blue, stable, and un-measurable | Optimalizálás |

| Pyroxene (such as Spodumene) | Sugárzás | Színjavítás | Commonly used for spodumene, colorless or nearly colorless ones appear pink, purple tones turn dark green, and will fade slightly when heated or exposed to light. Colors produced by irradiation include yellow, yellow-green spodumene with residual radioactivity, stable and difficult to detect. Bright yellow has no natural counterpart. | Kezelés |

| Andaluzit | Hőkezelés | Színjavítás | Pink produced by heating some green, stable, un-measurable | Optimalizálás |

| Eukláz | Sugárzás | Improve Color | Colorless specimens can appear blue or light green, stability is uncertain, and they are not easy to detect | Kezelés |

| Mészpát | Festés | Color improvement | Can be dyed in various colors, dye visible in the split seams | Kezelés |

| Wax immersion or glue injection | Improve appearance, prevent | Surface has a greasy luster, easy to melt, can be detected with a hot needle | Kezelés | |

| Sugárzás | Generate color | Produces blue, yellow, or light purple. Some colors may fade and are not easily detectable. | Kezelés | |

| Jáde | Hőkezelés | Produces red and yellow. | Light brown or colorless can appear brown, brownish-yellow, and those that are red have a dry feel. Difficult to detect. | Kezelés |

| Bleaching, waxing | Improve appearance | Soak in wax after acid washing. The surface has a waxy luster, wax is released when heated, and there is blue-white fluorescence. | Kezelés | |

| Bleaching, Filling | Improving appearance, durability | Resin gloss, bottom turns white, color turns yellow. Original color orientation damage, surface has orange peel effect (or none), particles broken, cleavage incoherent; see channel-like structure; polished surface shows microscopic cracks; structure loose; density 3.00-3.34g/cm3 , refractive index 1.65 (point measurement), has 2400-2600cm-1,2800-3200cm-1 strong absorption peak, often has fluorescence | Kezelés | |

| Festés | Producing bright green | Dyes are distributed in a mesh-like pattern along the grain gaps, and chromium salt dyers often have a 650 nm absorption band. Some pigments may appear red under a color filter, while others show no reaction. Common artificial crack patterns. | Kezelés | |

| Bevonat | Generate green | Low refractive index, weak surface gloss, no graininess, with a visible absorption peak at 650 nm | Kezelés |

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Nephrite | Wax immersion | Improve appearance | Fill surface cracks with colorless wax or paraffin. Heat can melt it. Infrared spectroscopy shows absorption peaks of organic substances. | Kezelés |

| Festés | Producing vibrant colors | Commonly dyed green, with dye distributed along the grain gaps. The absorption spectrum shows a peak at 650 nm. | Kezelés | |

| Opál | Note colorless oil | Improve appearance | Colorless oil or colorless non-solid materials. Visible abnormal halo, sparkling effect, difficult to detect | Kezelés |

| Coloring | Strengthen color change | Dyes often accumulate in a granular form in the gaps and will lose their color change when exposed to water | Kezelés | |

| Plastic filling | Improve appearance | Colored or colorless plastic, low density 1.90g/cm3, characterized by black fine lines, sometimes opaque metallic small bodies can be seen. | Kezelés | |

| Bevonat | Improve color change | Use black material as a substrate. Can be observed under magnification, can be engraved with a fine needle tip. | Kezelés | |

| Quartzite | Festés | Used for imitation gemstones | It can have various colors. Dyes are distributed along the intergranular cracks, with an absorption peak at 650 nm in the visible spectrum (green spectrum). | Kezelés |

| Kalcedon | Hőkezelés | Színjavítás | Even color, bright, not easy to detect | Kezelés |

| Festés | Producing vibrant colors | There can be various colors. Dyes are distributed along the cracks, and those dyed green can have 645nm, 670 nm absorption bands. | Kezelés | |

| Serpentinex | Wax immersion | Improve appearance | Fill cracks or gaps with colorless wax, generally more stable; waxy luster, "sweats" when probed with a hot needle | Optimalizálás |

| Festés | Producing vibrant colors | There are various colors, with dyes distributed along the cracks; those dyed green can have a 650 nm absorption bandwidth | Kezelés | |

| Türkizkék | Wax immersion | Deepening color | Used to seal small pores. Hot needles can melt wax, which has low density and a waxy luster. | Kezelés |

| Töltő | Improve color, durability | Colorless or colored plastics or materials such as epoxy resin with added metal. Low density (2.4-2.7g/cm3), low hardness (3-4). Heat needles can melt organic substances, infrared spectroscopy can determine organic substances, and irregular flakes can be observed under magnification. | Kezelés | |

| Festés | Deepen color | Black liquid shoe polish and other materials. The color is deep and unnatural, the color layer is shallow and easy to fall off, can be washed off with ammonia, and can be melted with a hot needle. Used for simulating dark-colored substrates. | Kezelés | |

| Lazurit | Wax immersion or colorless oil | Improve appearance | The wax layer is prone to peeling. Oil accumulates in the cracks; when probed with a hot needle, it "sweats." | Optimalizálás |

| Festés | Improve appearance | Color distributed along the cracks can be wiped off with acetone, alcohol, or dilute hydrochloric acid. | Kezelés |

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Malachit | Gyantázás | Improve appearance | Immerse the wax from the surface into the crack; the hot needle can melt it. | Optimalizálás |

| Töltő | Javítsa a tartósságot | Fill the cracks with plastic or resin. Magnified inspection reveals the filler, which can be melted by a hot needle. | Kezelés | |

| Márvány | Festés | Used for imitation | Available in various colors, dye is visible under magnification. Reagents can wipe off color, and the color is concentrated in the gaps. | Kezelés |

| Talkum | Festés | Producing various colors | Dye accumulates in the cracks, visible under magnification, reagent wipes off the color | Kezelés |

| Bevonat | Improve appearance, conceal cracks | Materials such as plastic or wax to cover surface cracks and polishing marks, increasing hardness. The film is prone to peeling and feels warm and sticky to the touch. | Kezelés | |

| Fluorit | Hőkezelés | Színjavítás | Often treat black and dark blue to blue, stable. Avoid immersion heat above 300℃ , difficult to detect | Optimalizálás |

| Sugárzás | Színjavítás | Colorless turns purple, green can fluoresce. Easily changes, unstable, not easy to detect | Kezelés | |

| Töltő | Színjavítás | Fill surface cracks with plastic or resin to ensure no cracking during processing, visible under magnification, and melt with a hot needle | Kezelés | |

| Howlite | Festés | Enhance color | Easily colored, can be dyed green (imitating turquoise), blue (imitating lapis lazuli), and other colors. The color is not naturally distributed but concentrated in the network cracks, visible under magnification, and may fade. Appears pink or red under a Charles filter. | Kezelés |

| Oriental jasper | Töltő | Add red | Glue or resin fills red pigment or cinnabar powder into cracks or pits, and after drying, a layer of resin is applied. The surface has a waxy or greasy luster. The "blood" color is singular and mostly distributed along seams or pits. The dye particles are not completely floating in the glue. The color is bright and good, feels warm to the touch, has high hardness, low density, and can char when heated. | Kezelés |

| Bevonat | Improve appearance, add red | Mix cinnabar powder or red pigment with glue and apply it to the surface to enhance the "blood color." Upon magnified inspection, the "blood" color can be seen floating in the transparent layer, with occasional brush marks, and dropping aqua regain does not produce a film. | Kezelés | |

| Shoushan stone | Hőkezelés | Improve or change dyeing | Smoking or chemical agents barbecue or constant temperature heating, treating its surface to be black or red, with a uniform and complete color distribution, and only on the shallow surface, prone to cracking, poor water retention, no "radish pattern." | Optimalizálás |

| Festés | Producing yellow, red-brown, and dark red colors | Methods such as boiling or dyeing are used to dye it yellow or red to dark red, imitating Field-yellow stone. The surface is dyed, while the inside is white (stone powder), and the dyeing is uneven and unnatural, concentrating at cracks or cavities, without radish patterns. The dyeing agent causes fading with acetone. | Kezelés | |

| Bevonat | Improve appearance | Mix yellow stone powder with epoxy resin evenly, apply it to the surface to create a faux stone veneer, imitating Field-yellow stone. Its surface has an unusual gloss, is prone to scratches, and the scraped stone powder appears yellow. The stone is relatively dry, has no "radish patterns," and the film is easy to peel off. | Kezelés |

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Természetes gyöngyök | Fehérítés | Improve color and appearance | Remove impurities from the pearl surface. Treatment methods such as hydrogen peroxide, chlorine gas, and fluorescent whitening are difficult to detect with conventional instruments. | Optimalizálás |

| Festés | Produce black and gray colors | There are two methods: chemical coloring and central dyeing, followed by polishing. Dyes can be seen in surface pits and holes. Acetone wipes can fade the color, and silver chloride that turn black can detect silver elements. | Kezelés | |

| Tenyésztett gyöngy | Fehérítés | Improving appearance | Removing impurities from the surface of pearls. Treatments such as hydrogen peroxide method, Chlorine gas method, and fluorescent whitening method are not easily detectable with conventional instruments. | Optimalizálás |

| Whitening | Improve Color | Add whitening agent based on bleaching | Optimalizálás | |

| Festés | Producing color | Similar to natural pearls. Color spots can be seen under magnification, with point-like deposits on the surface. Dye can be seen when wiped with dilute hydrochloric acid or acetone. Inert under long waves, silver can be detected by silver chloride dyeing. White lines are visible in X-ray photography. | Kezelés | |

| Sugárzás | Szín módosítása | Can appear in black, green-black, blue-black, gray, etc. Enlarged inspection reveals irradiation halos in the nacreous layer, and Raman spectroscopy analysis shows differences from untreated black pearls. | Kezelés | |

| Korall | Fehérítés | Improve appearance | Hydrogen peroxide removes discoloration, body color lightens, and conventional instruments are not easy to detect. | Optimalizálás |

| Wax immersion | Improve appearance | Wax fills the gaps and cavities, visible upon magnified inspection, "sweats" when probed with a hot needle, and has fluorescence | Optimalizálás | |

| Festés | Producing red | The dye is distributed along the growth bands. Concentration of dye is visible in the cracks, with uneven color distribution, and it fades when wiped with acetone. | Kezelés | |

| Töltő | Improve color and durability | Fill porous coral with epoxy resin or similar gel-like substances, reducing density, and there may be a release of gel when probed with a hot needle | Kezelés |

| Drágakő neve | Improvement Method | Improvement Effect | Identification Features | Classification |

|---|---|---|---|---|

| Amber | Hőkezelés | Deepening color | Heating cloud-like amber in vegetable oil to become more transparent, producing needle-like cracks in a "water lily" or "sunlight" pattern; regenerated amber has a stirred structure with granular composition. Abnormal birefringence, exhibiting chalky blue fluorescence. | Optimalizálás |

| Festés | Deepen the color | Imitation dark red amber, also available in green or other colors, with visible dye distributed along the cracks | Kezelés | |

| Elefántcsont | Fehérítés | Remove discoloration | Use oxidizing solutions like hydrogen peroxide to remove yellowing, making it lighter or removing impurities. Unstable and difficult to detect. | Optimalizálás |

| Wax immersion | Improve appearance | The visible surface has a waxy feel and appears oily and smooth. It can be measured with a hot needle, but is generally difficult to detect. | Kezelés | |

| Festés | Used for crafts | To create the appearance of ancient ivory, this is uncommon. Upon magnification, colors can be seen concentrated along the structural texture or spotted. | Kezelés | |

| Héj | Bevonat | Imitation Pearl (Luster) | Surface coated with pearl essence and other materials, producing a pearl luster, imitation pearl. Upon magnified inspection, some thin film is seen to have fallen off, the surface is smooth without "grit," the luster is abnormal, lacking the unique growth spiral patterns of a pearl surface, and instead resembles the monotonous rough surface of an eggshell with varying heights, with an internal layered structure. | Kezelés |

| Festés | Producing various colors | Color floats on the surface layer, acetone wipes it off | Kezelés | |

| Szintetikus rubin | Quenching Explosion | Generate Cracks | Imitation Natural Ruby | Kezelés |

| Üveg | Bevonat | Enhanced brilliance | Imitating natural gemstones, parts of the film can often be seen peeling off, and sharp objects can strip it away | Kezelés |

Section II Classification of Improvement Techniques

Due to the numerous and confidential methods of gemstone enhancement, along with varying levels of public recognition of these enhancements, there is currently no unified classification scheme. The author believes gemstone enhancement techniques can be systematically categorized according to gemology’s causative factors, divided into three levels: group, species, and subspecies (Table 6-4). Here, “group” refers to the material basis for gemstone enhancement, 1.e., the causative factors (energy, composition, etc.) that lead to gemstone enhancement; “species” refers to the modes of action of the causative factors; and “subspecies” is a subdivision of “species,” referring to specific enhancement methods.

Table 6-4 Classification of Gemstone Improvement Techniques

| Csoport | Fajok | Alfajok | Degree of Recognition | |

|---|---|---|---|---|

| Csoport | Fajok | Alfajok | Optimalizálás | Kezelés |

| Energy Activation | Thermal Energy Process | Conventional Heat Treatment Method | √ | |

| Molten Salt Electrolytic Treatment Method | √ | |||

| Irradiation Process | Heavy Charged Particle Irradiation Method | √ | ||

| High Energy Electron Irradiation Method | √ | |||

| Electromagnetic Irradiation Method | √ | |||

| Neutron Irradiation Method | √ | |||

| Thermal Irradiation Process | Thermal - Heavy Charged Particle Irradiation | √ | ||

| Thermal - High Energy Electron Irradiation | √ | |||

| Thermal - Electromagnetic Irradiation | √ | |||

| Thermal - Neutron Irradiation | √ | |||

| Chemical reaction | Thermal diffusion | Powder Package Permeation Method | √ | |

| Salt Bath Method | √ | |||

| Melting Method | √ | |||

| Purification Fusion Method | Strong Acid and Strong Base Purification Method | √ | ||

| Purification Fusion Method | √ | |||

| Chemical Bleaching Method | √ | |||

| Light Fading Method | √ | |||

| Chemical Precipitation | Salt Soaking Method | √ | ||

| Color Liquid Pyrolysis Method | √ | |||

| Physical Modification | Pore Injection | Static Injection Method | √ | |

| Thermal Injection Method | √ | |||

| High-pressure injection method | √ | |||

| Surface covering | Coating method | √ | ||

| Plating method | √ | |||

| Foil application method | √ | |||

| Impurity removal | Laser impurity removal method | √ | ||

1. Energy Activation

Energy activation refers to the changes in the appearance characteristics of gemstones caused by applying external energy. The changes in the appearance characteristics of gemstones mainly depend on the properties of the gemstones themselves and the conditions of energy application.

It can be divided into two types: thermal energy processes and irradiation processes, based on the energy source and the action method.

(1) Thermal Energy Technology

Thermal energy technology, also known as heat treatment, is the process of heating under controlled temperature conditions in a specific atmosphere (oxidizing or reducing) to improve the appearance characteristics of gemstones.

When gemstones are heated, their physicochemical properties change to a certain extent with varying temperatures. Physical changes manifest as melting, cracking, and fissure healing; chemical changes are reflected in variations of ionic valence states, content changes, alterations in the anionic field, the separation of solid solutions, and the emergence of special phenomena. These changes are ultimately reflected in the color, transparency, clarity, special optical phenomena and other gem appearance characteristics, that is, to achieve the purpose of improving the gem. However, heat treatment results are often unpredictable due to the complexity of the natural conditions under which gemstones form. Therefore, it is essential to conduct repeated experiments using various thermal energy techniques (temperature control conditions, atmosphere, pressure, additives, etc.) based on a detailed study of the physicochemical properties of the gemstones being improved to achieve the desired results.

The main functions of heat treatment include changing the valence state of color-causing ions, eliminating unstable color centers, dehydration, decrystallization, purification or aging, removing color bands, inducing quenching fissures and fissure healing, eliminating fibrous materials and dark cores or brown spots, changes in crystallization configuration, and even fusion regeneration.

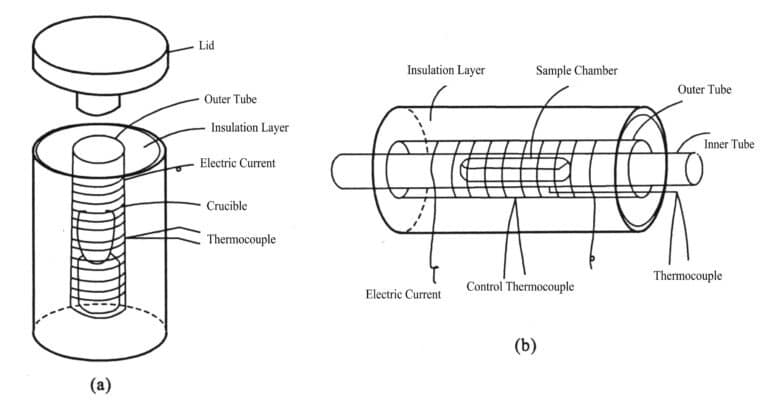

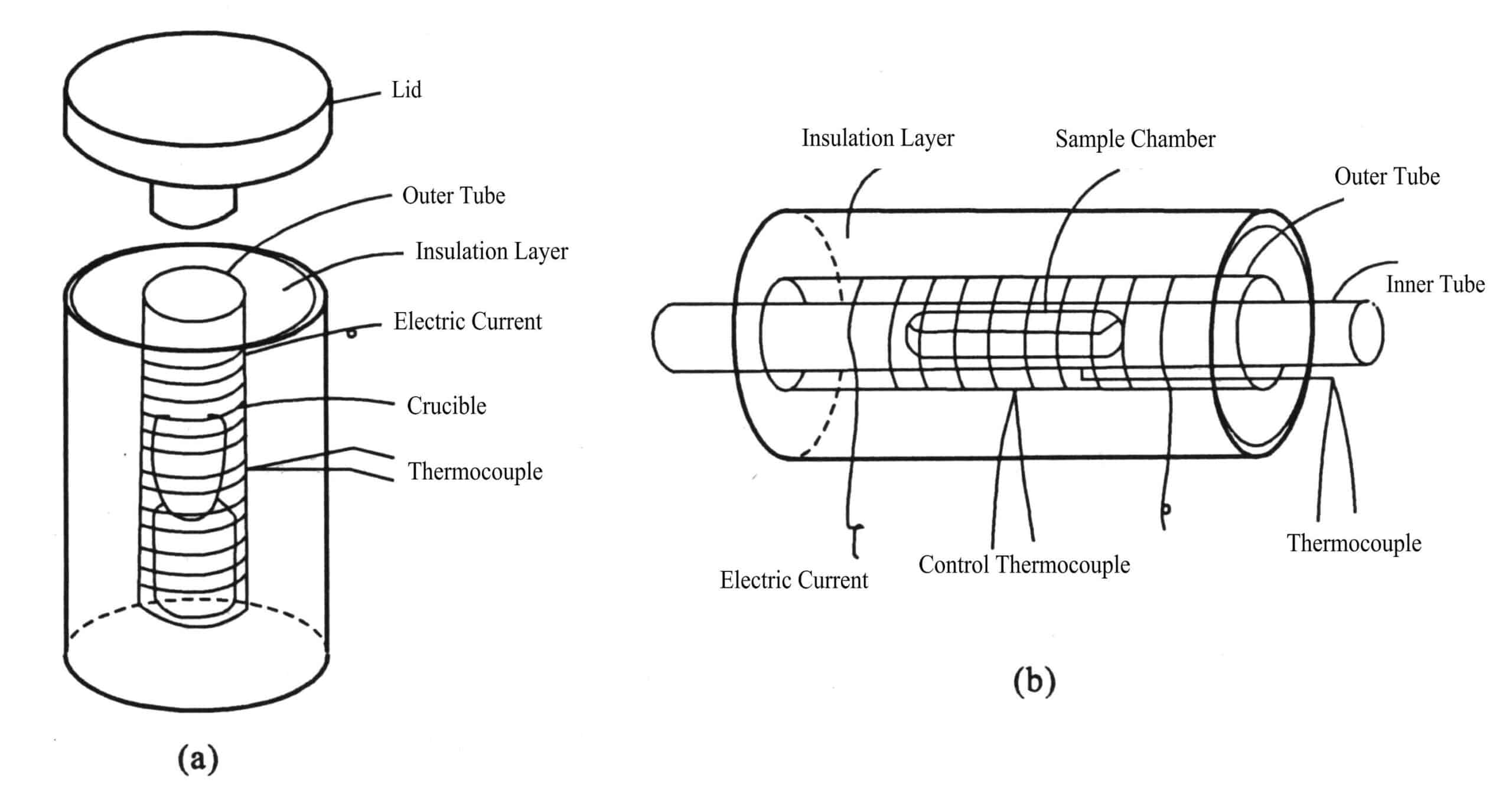

Thermal processes are divided into two common methods based on the degree of change in the chemical composition of gemstones: ordinary heat treatment and molten salt electrolysis. Thermal devices include furnaces (resistance, salt melting, fuel furnaces), controlled atmosphere, and vacuum thermal furnaces (Figure 6-1). Heat sources include laser heating and electron beam heating. Additional equipment includes atmosphere control devices (gas generators, ammonia decomposition devices, and vacuum systems),power equipment (distribution cabinets, blowers, etc.),measuring instruments (temperature instruments, pressure gauges, flow meters, automatic control equipment, etc.),crucibles and cleaning cooling equipment.

In terms of the temperature required for thermal processes, it can be divided into four stages: low temperature (100-200℃), medium temperature (around 200-700℃), high temperature (700-1300℃), and ultra-high temperature (above 1300℃). The thermal treatment conditions for common gemstones are listed in Table 6-5.

Table 6-5 Conditions for gem color change heat treatment

| Drágakő | Resulting color | Heat treatment temperature ( ℃) |

|---|---|---|

| Sri Lankan Blue Sapphire | Light Yellowish White | 400 |

| Sri Lankan Purple Sapphire | Rózsaszín | 450 |

| Ceraunite (Orange) | Rózsaszín | 500 |

| Green Emerald | Blue (Aquamarine) | 420 |

| Yellow Beryl | Light Blue White | 400 |

| Orange Red Beryl | Bright Pink | 400 |

| Brown Green Tourmaline | Rózsaszín | 400 |

| Dark Red Tourmaline | Rózsaszín | 550 ~ 600 |

| Smoky Green Tourmaline | Brighter Green | 600 ~ 650 |

| Blue-Green Tourmaline | Bright green | 650 |

| Smoky quartz | Fehér | 275 ~ 300 |

| Smoky yellow quartz | Yellow-orange | 250 ~ 350 |

| Some amethyst | Orange-yellow | 500 ~ 575 |

| Blue-green zircon | Bright blue | 380 ~ 500 |

Heat treatment equipment is the basic tool for gem heat treatment, which can be simple or complex. Simple heat treatment experiments can be conducted in the laboratory using alcohol as a heat source, placing the gems in a test tube or crucible over a flame, or heating in a coal stove. The disadvantages of these heating methods are uneven heating, significant loss, and inability to control temperature. It is best to use heating equipment with control devices, such as low-temperature treatments that can be conducted in various ovens (forced air or infrared drying ovens, infrared roasting boxes),medium and high-temperature heat treatments can be conducted in a muffle furnace.

During the heat treatment process, it is important to control the temperature, the rate of heating, the holding time at temperature, the cooling time and rate, and the control of the surrounding atmosphere and additives (coloring ions, pH, etc.). These are the main factors that ensure thermal efficiency. Before heat treatment, it is essential to select the samples carefully, clarify the purpose and feasibility of the treatment, determine the treatment equipment, pay attention to safety, reduce randomness and risk, and achieve maximum results with minimal effort.

① Ordinary heat treatment

By simply heating the gemstone (at high, medium, and low temperatures), the internal chromophore ions change in content and valence state, or the internal structural defects of the crystal are altered, resulting in changes to the physical properties of the gemstone (color, transparency, optical properties) to achieve improvement (Table 6-6).

Table 6-6 Thermal Energy Process Identification Features

| Hőmérséklet | Továbbfejlesztett drágakő | Belső jellemzők | External Features |

|---|---|---|---|

| Alacsony hőmérséklet | Amber | Induced disc-shaped cracks | Color deepens due to oxidation |

| Közepes hőmérséklet | Amethyst, beryl, turquoise, topaz, etc. | Stress cracks and dark spots formed by the rupture of micro gas-liquid inclusions. | Nincs |

| High temperature, ultra-high temperature. | Diamond, ruby, sapphire, etc. | Usually not obvious and difficult to measure. Occasionally: (1) Spot-like diffusion halos of varying sizes (2) Disk¬shaped or dish-shaped stress cracks around solid inclusions (3) Gas-liquid inclusions disappear, with darker body color and cracks (4) Sometimes special ultraviolet fluorescence. |

(a) High-temperature heat treatment

- Under oxidizing atmosphere conditions: it can change the colors of light blue, light yellow, and light pink sapphires through the transformation of chromogenic ion valence state Fe2+ + e→Fe3+and charge migration (O2–→Fe3+, changing their colors to orange-yellow and orange-red; it can eliminate the silk-like inclusions in red sapphires (often caused by rutile inclusions or solid solutions), improving the clarity of the gemstones; it can eliminate dark cores or brown spots in rubies, effectively changing their color; it can transform brown to brown-red low-type zircon into colorless transparent high-type zircon, leading to changes in crystallization configuration; through high- temperature treatment or quenching, it can eliminate or weaken the characteristic curved growth lines of flame-fusion synthetic red and blue sapphires, etc.

- Under reducing atmosphere conditions, it can change green-blue beryl or green aquamarine into blue aquamarine through the transformation of Fe3++e→Fe2+valence states; Sri Lanka’s milky white, brownish, and light blue Geuda stones (which contain Fe3+ , Ti4+) can achieve the transformation of Fe3++ e+→ Fe2+ valence states through 1600-1900℃ high-temperature treatment, leading to charge migration between Fe2++ Ti4+→Fe3++Ti3+, resulting in blue sapphires; brown-brown-red low- type zircon turns into light blue-blue zircon.

(b) Medium-temperature heat treatment

Medium-temperature heat treatment is mainly used to eliminate unstable color centers in gemstones, making the colors of the gemstones durable and unchanging. The improved colors of the gemstones will not fade due to light exposure or sunlight, nor will they significantly change over time. Some aquamarines, tanzanites, citrines, green crystal, citrine, tourmaline, Topaz and other colored gemstones on the market have mostly undergone heat treatment.

(c) Low-temperature heat treatment

Gemstones containing limonite (Fe2 O3 • ոH2O)) or color-causing impurities such as iron hydroxide, like yellow chalcedony, brownish-yellow jade, and yellow wood opal cat’s eye, undergo heat treatment. Due to the dehydration effect of the color-causing impurities, they transform into hematite, causing the gemstones’ original yellow and brownish-yellow hues to change to red and reddish-brown. Organic gemstones like ivory and amber can undergo oxidation during heat treatment, deepening their appearance and achieving an antique or aged effect. They can also allow amber to be fused and reconstructed, improving clarity and transparency.

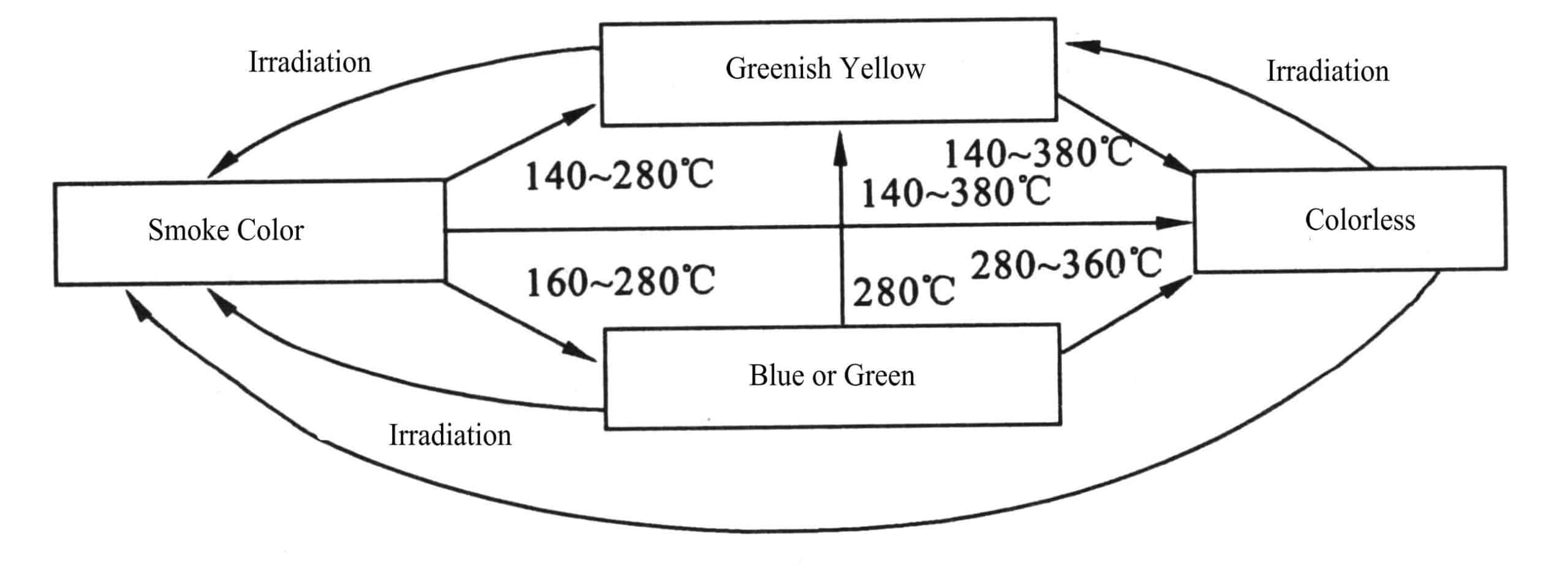

Heat treatment can destroy color centers; smoky quartz can turn green or yellow-green after 140-200℃, and further heating to 380℃ can turn it colorless; amethyst can turn yellow or colorless; red and brown zircon can turn into colorless zircon, and so on.

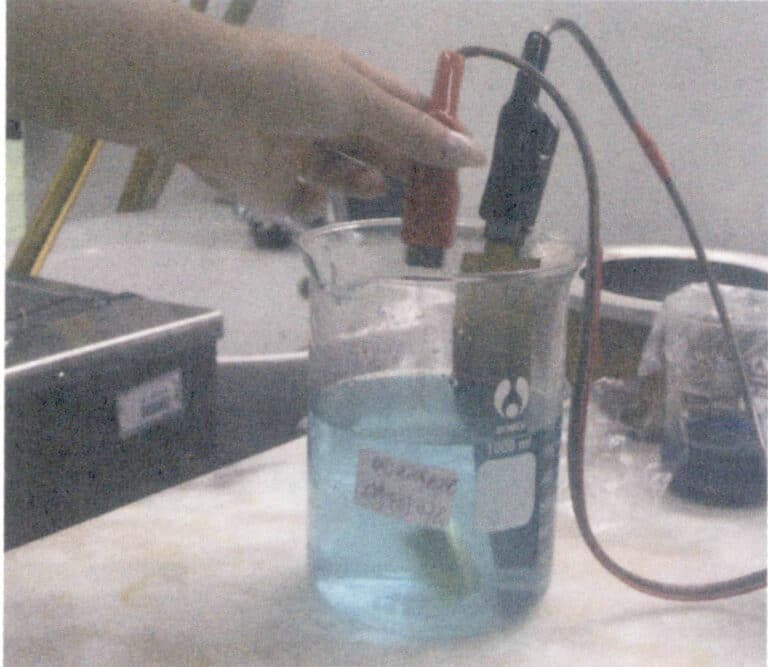

② Molten salt electrolysis

After mixing the molten salt: Place it in a graphite crucible and proceed with the electrolysis process. Use platinum wire to wrap around the gemstone to act as the anode, while the graphite crucible serves as the cathode. After the electrolyte melts in the furnace, place the gemstone wrapped with platinum wire into the electrolysis cell for electrolysis (conditions: voltage 3.0 V, time 40-45 min), and then remove it. Electrolysis causes changes in the valence state and content of the color, causing ions in the gemstone and altering its color.

The disadvantage of this method is that if the molten salt is improperly chosen, the gem will be eroded.

Copywrite @ Sobling.Jewelry - Egyedi ékszergyártó, OEM és ODM ékszergyár

(2) Irradiation Process

The method of using wave energy or microscopic particles to irradiate gems, causing physical and chemical changes in the gems, is called the irradiation process. Because ionizing radiation can directly or indirectly cause ionization effects in the irradiated material through energy conversion during its interaction with the gem.

① Irradiation Effects

Gems can undergo a certain degree of change during irradiation treatment, especially in color. The changes in certain properties of gems depend on the chemical composition and crystal structure of the gems themselves, as well as factors such as the type of radiation, the energy level of the radiation, the duration of the radiation, and the method of radiation.

(a) Changes in Gem Color

The diversity of gem colors is due to the chemical composition, crystal structure, inclusions, crystal optics, and human factors.

The improvement of the process can cause changes in the color of gemstones due to variations in any of the factors. Radiation is a method that can change the color of gemstones and is the reason for the changes in the internal structure of gemstone crystals, leading to the formation of various color centers. Color centers can be divided into charge defect color centers and ionic defect color centers. Charge defect color centers are formed when ions at lattice points change only in their charged properties. They can be further divided into vacancy color centers and electron color centers. In contrast, ionic defect color centers are formed when ions at normal lattice positions are displaced due to collisions with incoming radiation particles, resulting in defects such as negative ion vacancies, positive ion vacancies, vacancy aggregation, and interstitial ions.

The color change or alteration of gemstones caused by irradiation is a process where different defects (traps) in the gemstone crystal capture electrons or vacancies. Different types of gemstones or the same type of gemstone from different origins contain different types of traps (combinations), which can form different types of color centers after irradiation, leading to changes in the color of the crystal (see Table 6-8).

Table 6-8 Color changes in gemstones caused by irradiation

| Gemstone materials | Színváltozás |

|---|---|

| Aquamarine (Beryl) | Colorless turns yellow; blue turns green; light blue turns dark blue① |

| Zafír | Colorless turns yellow②; Pink to yellow ②; (Padma jade) |

| Diamond | Colorless or light-colored turns blue, green, black, yellow, brown, pink, or red |

| Gyöngyszem | Black changes to gray, brown, "blue," or "black." |

| Crystal | Colorless, yellow, or light blue changes to smoky, purple, two-colored (purple and yellow) changes to yellow or green. |

| Spodumene (purple Spodumene) | Changes to yellow or green |

| Topáz | Colorless becomes yellow②, orange②, brown or blue |

| Turmalin | Colorless or light colors change to yellow, brown, pink, red, or green-red; blue turns purple |

| Cirkon | Colorless changes to brown to red |

| Márvány | White turns yellow, blue, or lilac |

| Note: ① Color fades under light. ② Color may fade when exposed to light; if there are two different color centers, one may fade while the other does not. | |

(b) Induced radioactivity

Gems subjected to high-energy irradiation can cause some stable elements to undergo nuclear reactions and produce radioactivity (β or γ rays). The radiation particles that primarily induce radioactivity are neutron beams, high-energy electron beams above 10MeV, proton beams, and Q particle beams. This type of nuclear reaction is also known as neutron activation reaction, and the radioactive nuclides produced are referred to as artificial radioactive nuclides. The level of radioactivity is related to the type of element, and all induced radioactive nuclides will undergo radioactive decay. Therefore, gems that have been irradiated possess harmful radioactivity to the human body and can only be sold after radioactive decay (below exemption limits). The dose equivalent limit for the human body set by ICRP in 1977 is 5rem ‧ a-1, with the dose to the human eye lens not exceeding 15rem and the dose to other organs not exceeding 50rem.

Natural gemstones contain trace impurities, such as Fe , Cr , Ni , Mn , Cu , Ca , Na , K, Co , Sc , Cs , Ta, Th, Sr, which are often activated and become radioactive nuclides when subjected to neutron irradiation (see table 6-9).

Table 6-9 Properties of radioactive nuclides induced in irradiated gemstones

| Radioactive nuclide | Half-life | Energy (KeV) | US exemption limit (nCi/g) |

|---|---|---|---|

| 53Cr | 27.79 d | 320 | 20.0 |

| 141Ce | 32.50 d | 77 | 0.09 |

| 59Fe | 45.1 d | 1099.2 | 0.6 |

| 124Sb | 60.20 d | 1852 | 0.2 |

| 45Zr | 64.02 d | 733 | 0.6 |

| 46Sc | 83.81 d | 889.26 | 0.4 |

| 182Ta | 115.0 d | 1121.3 | 0.4 |

| 65Zn | 243.80 d | 1115.5 | 1 |

| 54Mn | 312.20 d | 836 | 1 |

| 134Cs | 2.065 d | 604.6 | 0.09 |

| 60Co | 5.271 d | 1332.4 | 0.5 |

| 40K Natural | 1.28 Ga | 157 | 0.3 |

| 238U Natural | 4.47 Ga | 1796 | 0.167 |

| 232Th Natural | 14.06 Ga | 2470 | 0.055 |

(c) Damage to gemstones

Irradiated gemstones have ions in the lattice that can move, creating ion vacancies and even vacancy aggregation zones, which are detrimental to the formation of color centers; at the same time, the irradiated particles cause an irradiation vaporization effect on the surface atoms or ions of the gemstone, damaging the surface of the gemstone.

② Factors affecting the color change of gemstones due to irradiation

(a) The composition and crystal structure of the gemstone itself

In natural gemstones, trace impurity elements occupying lattice sites due to isomorphic substitution often cause dislocations in the crystal structure, leading to various defects, which provide the basic conditions for generating charge defect color centers during irradiation.

Different gemstones have varying types of natural defects, uniformity of distribution, density, etc. Under the same irradiation conditions, different color change effects can be produced.

(b) Types of radiation

The mass and energy of different types of radiation particles are different, so their effects on gemstones vary accordingly. Heavily charged particles have higher radiation energy, strong radiation effects, and lower penetration, only affecting the shallow surface of the gemstone, resulting in less uniform colors; high-energy particles have very low energy, but when their energy is higher, their penetration is stronger. Therefore, the color layers produced by β rays are relatively deep but not very uniform; electromagnetic radiation has extremely strong penetration, producing more uniform colors, but with lower radiation energy; neutron beams have medium mass, high energy, and strong penetration ability, resulting in more uniform colors, but neutron irradiation can easily induce radioactivity. Different types of radiation sources have advantages and disadvantages for changing the color of gemstones, so when irradiating gemstones, the radiation source should be selected according to the different needs of the gemstone samples (Table 6-10).

Table 6-10 Characteristics of radiation sources for gemstone coloration (According to K. Nassau, 1984)

| Radiation Type | Energy Generation Range | Color Uniformity | Required Electric Energy | Induced Radioactivity | Local Temperature | |

|---|---|---|---|---|---|---|

| Electromagnetic wave | Visible Light | 2 ~ 3(eV) | Multicolor | Alacsony | Without | Without |

| Ultraibolya | 5(eV) | Multicolor | Alacsony | Without | Without | |

| X Ray | 104(eV) | Not good | Közepes | Without | Without | |

| γ Ray | 106(eV) | Jó | Nem szükséges | Without | Without | |

| Neutron | 106(eV) | Jó | Nagyon magas | A címen | Without | |

| Negative particle | β ray | 106(eV) | Not good | Magas | Without | Nagyon erős |

| High-energy electron | 107(eV) | Not good | Magas | A címen | Nagyon erős | |

| Positive particles | Protons, α rays, cosmic particles, etc. | 107(eV) | Not good | Magas | A címen | Local |

(3) Thermal-Irradiation Process

This is a combined method of radioactive irradiation and heat treatment. It includes thermal-heavy charged particle irradiation, thermal-high energy electron irradiation, thermal-electromagnetic irradiation, and thermal-neutron irradiation.

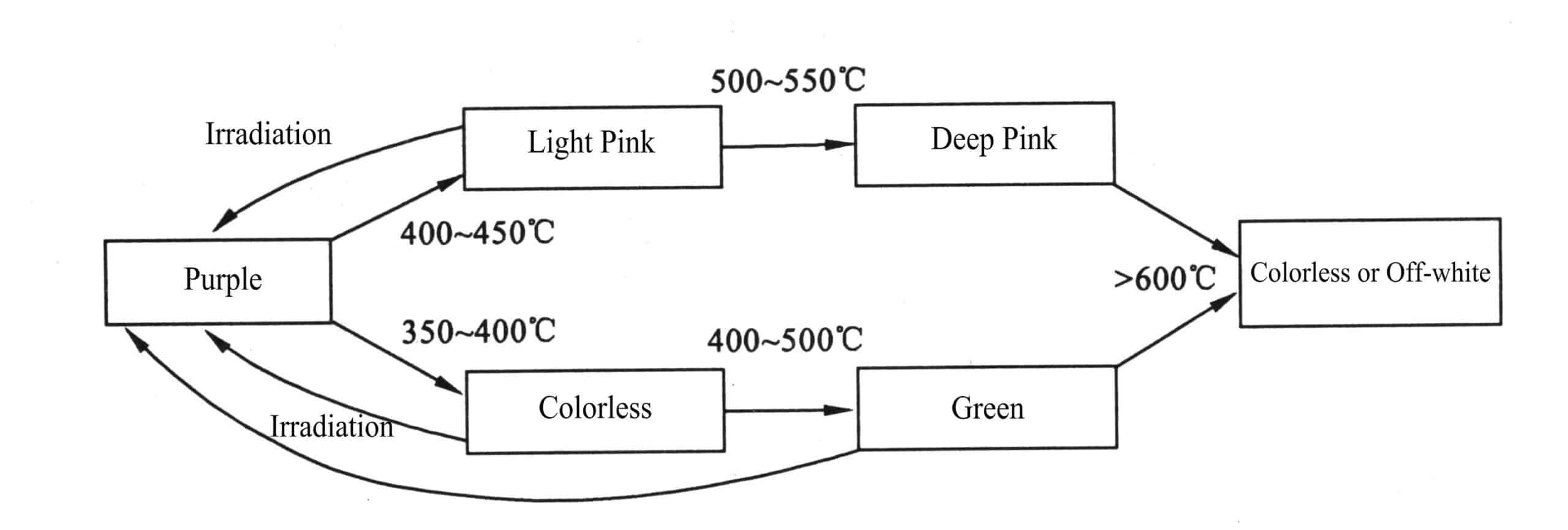

Gems change color due to ionizing radiation, which is sometimes unstable and can easily fade when exposed to light and heat. This is due to the instability of some color centers. Heat treatment often acts as a countermeasure to irradiation treatment. For example, irradiation can create structural defects in crystals that form color centers, while heat treatment can partially or completely repair these structural defects, changing or fading the color. Therefore, in the irradiation treatment of gems, only the generation of permanent colors is an important technical indicator for improving the gems. Those temporarily unstable colors are often removed by low-temperature heating, retaining stable color centers. Thus, after low-temperature heating, there is often a color change. For instance, topaz can change from brownish to blue and quartz from brown to yellow. If the heating temperature is not well controlled, it may cause the gem to fade completely, restoring the color before irradiation (Figure 6-5 to figure 6-6).

2. Chemical Reactions

To enhance the aesthetic and commercial value of gemstones, various chemical or physicochemical methods are often used to improve the appearance characteristics of gemstones, in addition to energy activation.

We know that gemstones are crystalline structures obtained from a series of chemical reactions of chemical elements under certain conditions. The valence state, content, and form of elements in the crystal are the material basis for the color of gemstones, such as Cr3+, making jadeite green and corundum red. Therefore, the chemical reaction methods in gemstone enhancement processes involve various ways to introduce certain coloring substances (elements, compounds) into the gemstone lattice or to coat them onto the gemstone’s voids and surfaces, thereby improving the appearance of the gemstones.

The chemical reaction processes for improving gemstone appearance characteristics include traditional and modern methods. Currently, the commonly used types can be roughly divided into three categories: thermal diffusion, purification and bleaching, and chemical precipitation.

(1) Thermal Diffusion Process

Thermal diffusion technology can significantly improve the appearance of gemstones on a large scale. This process began in the mid-20th century and was mainly used to treat corundum gemstones with poor energy activation improvement effects. Since the 21st century, this method has been widely applied.

Thermal diffusion technology is a method for improving the appearance of gemstones in chemical reactions. It involves diffusing coloring substances into the gemstones under high or ultra-high temperature conditions to change the types, content, and ratios of the coloring elements within the gemstones, thereby improving their color, transparency, and other characteristics.

① Thermal diffusion types

There are two types of thermal diffusion processes: surface diffusion and bulk diffusion. They are mostly used to improve red (blue) sapphires, generally to enhance the desired color or to create a star effect.

- Surface Diffusion

The treatment method is roughly as follows: a layer of aluminum oxide and coloring agents (such as Fe, Ti , Cr , Ni, and other oxides) as diffusion agents) is coated on the surface of the faceted gemstone material and heated under ultra-high temperature conditions (1800-2000℃)) to promote the diffusion of coloring elements from the surface of the gemstone to the interior, thereby forming a very thin colored diffusion layer. If the diffusion agent is coated with Fe , Ti coloring elements, a blue thin layer can be formed; if it is coated with Cr coloring elements, a red thin layer is produced; if it is coated with Cr , Ni coloring elements, an orange-yellow thin layer is formed.

- Bulk Diffusion

In recent years, orange-red to orange-Citrine that have appeared in the market are said to be caused by beryllium diffusion. Unlike surface diffusion, the diffusion agent used in thermal diffusion is beryllium compounds, resulting in a thicker diffusion layer after treatment, even leading to overall coloring. In addition to ultra-high temperature (1800-1950℃), oxygen enhancement (when the partial pressure of oxygen in the environment is greater than that in the crystal, external oxygen atoms diffuse into the crystal along vacancies) and beryllium activators being the main external factors for coloring, the lattice defects induced under ultra-high temperature conditions (Be2+ ionic equivalent or non-equivalent substitution Mg2+, Al3+, which easily generate a large number of cation vacancies during the substitution process) are the main internal factors for coloring. In fact, Be is not a coloring element; it acts similarly to an activator or expands vacancies.

② Heat Diffusion Process

The heat diffusion process improves single-crystal gemstones (minerals) and can also enhance polycrystalline aggregates (jade, organic gemstones). It is reported that there are more than ten methods for the heat diffusion process, but currently, the following methods are commonly used:

(a) Powder Pack Diffusion Method

- Principle: Under high-temperature conditions, the elements in the gemstone structure undergo isomorphic substitution reactions with the coloring elements in the diffusion agent, improving the gemstone’s color appearance.

- Method: The finished or semi-finished gemstone is buried in a high-temperature resistant container filled with diffusion agent powder, then the container is sealed and heated until internal diffusion ceases.

- Equipment: Heating devices and equipment, similar to thermal energy processes. Containers are mostly made of high-temperature resistant crucibles, platinum crucibles, or high-temperature and high-pressure vessels lined with platinum-coated stainless steel.

- Advantages and disadvantages: The advantage is that the equipment is simple, easy to operate, and suitable for the thermal diffusion of various styles of gemstones. For example, in Thailand, when processing ruby gemstones, the powder of 2%-4% green beryl is mixed with high-purity aluminum oxide powder, and then the gemstones are buried in it. They are heated in an 1780℃ oxygen atmosphere for 60-100 h, resulting in yellow, golden Yellow, or orange tones diffused throughout the gemstone. The disadvantage of this method is that the container volume is small, limiting the number of gemstones that can be processed; at the same time, the corrosive effect of the diffusing agent is strong, and it is impossible to control the atmosphere and pressure during the diffusion process.

(b) Salt bath method

- Principle: The method is also known as thermal immersion or molten salt. This method involves immersing gemstones in molten diffusing agents, causing a solid state replacement reaction at high temperatures to improve the appearance characteristics of the gemstones.

- Method: First, place the diffusion agent in a salt bath and heat it until it melts into a molten fluid. Then, immerse the gem in the fluid and perform thermal diffusion treatment under controlled atmosphere (oxidizing or reducing) conditions.

- Equipment: The salt bath method apparatus mainly consists of a salt bath furnace and a salt bath pool. The heating salt bath furnace can be a coal-fired furnace or a gas furnace, and electric furnaces can also be used; the salt bath pool is made of refractory materials, with refractoriness of 1500℃ or above, and has strong resistance to acid and alkali corrosion, such as corundum bricks (Al2O3 > 72%, refractoriness of 1840-1850℃), high-alumina bricks (Al2O3 > 48%, refractoriness of 1750-1790℃).

- Advantages and Disadvantages: The equipment is simple, easy to operate, diffusion speed is relatively fast, efficiency is high, and it can treat various gems. The disadvantages are that the density of the molten salt diffusion agent is relatively large, and the viscosity is also high, often resulting in different thicknesses of diffusion layers forming in different parts of the gem; additionally, the corrosiveness of the molten salt is strong, and it can produce a large amount of harmful gases, causing environmental pollution and posing a certain degree of harm to human health, requiring protection.

(c) Melting method

- Principle: The gem and the diffusion agent slurry coated on its surface undergo a chemical isomorphic substitution reaction at high temperatures, improving the appearance characteristics of the gem.

- Method: First, prepare the diffusion agent into a slurry, evenly coat it on the surface of the gem, and then place it in an oven to dry. Place it in a heat treatment furnace, and under a reactive gas or vacuum atmosphere, heat and sinter at a temperature slightly above the melting point of the slurry, allowing the gem and the diffusion agent to undergo isomorphic substitution through a liquid-solid phase, forming a diffusion layer on the surface of the gem to impart color. For example, when using beryllium to improve corundum gems, a slurry is made by adding 2%-4% emerald (BeAlO4) powder (introducing beryllium ions) to a flux containing boron and phosphorus, which is then coated on corundum-type gems and heated for 25 hours in an oxidizing atmosphere 1800℃, resulting in a charming yellow to orange color. This method also improves pink and brown-red gems into brilliant rubies and lightens the color of dark blue sapphires (Table 6-11).

Table 6-11 Colors of Beryllium Heat-Diffused Corundum Gems

| Before Improvement | Improved |

|---|---|

| Színtelen | Yellow to Orange Yellow |

| Rózsaszín | Orange Yellow - Pinkish Orange |

| Dark Red | Bright red to orange-yellow- red color |

| Yellow - green | Sárga |

| Kék | Yellow or no obvious change |

| Purple | Orange-yellow to red |

(2) Purification and Bleaching Process

Purification and bleaching are processes in chemical reactions. Unlike thermal diffusion processes, they eliminate substances that affect the beauty of gemstones through chemical reactions rather than adding coloring substances to thermal diffusion processes.

However, purification and bleaching are two different gemstone enhancement processes. Purification is removing dirt to reveal color, while bleaching is fading and whitening. Additionally, purification is mainly applied to natural jade, while bleaching is primarily used for organic gemstones.

① Purification Process

(a) Principle

Impurities trapped in the open cracks of jade or gemstones undergo a chemical reaction with a purifying agent that has strong dissolving properties, forming a solute that detaches from the carrier, allowing the gemstones to be purified, revealing their color and improving transparency. Hence the saying “remove dirt and increase transparency.”

(b) Purification Process.

Various strong acids are used as purifying agents, such as concentrated nitric acid, concentrated hydrochloric acid, concentrated sulfuric acid, or aqua regia. Some gemstones also require strong alkalis to neutralize the strong acids remaining in the gemstones. The gemstone rough is placed in an acid-resistant container, and the purifying agent is injected. The purifying agent enters the gemstone through cracks, pores, or intergranular spaces, dissolving and decomposing the impurities in the gemstone’s voids. Finally, the purifying agent containing the dissolved substances is rinsed away with clean water. Strong alkalis can be used if necessary to neutralize residual strong acids, followed by rinsing with clean water. To shorten the purification time, the gemstones can first be placed in a sealed container and vacuumed before injecting the purifying agent.

(c) Equipment

The devices required for the purification process are simple, usually just glass dishes. To speed up the purification process, a regular oven, constant temperature water bath, or constant temperature oil bath is also needed for heating.

(d) Purification Methods

- Strong acid and strong alkali purification method. The purifying agents used for purification are mainly various strong acids, such as concentrated nitric acid, concentrated hydrochloric acid, and concentrated sulfuric acid, sometimes using aqua regia. Some gemstones require strong alkali or neutralization of residual acid in strong acid purification.

- Purification melting method. This method first uses strong acid to erode the dirt in the gemstone, purifying the cracks and pores. However, during purification, the cracks, pores, and intercrystalline gaps are also expanded and increased, making the gemstone structure loose. Therefore, the purified gemstone must be fused automatically under high temperature and high-pressure conditions or filled with glass, plastic, and other fillers to consolidate the gemstone. During the heat treatment process, weak fluxing agents such as borax and polyphosphate are filled in, flowing into the cracks of the gemstone and causing local fusion on both sides of the crack surface, forming a multi-component mixed secondary melt that crystallizes upon cooling, ultimately healing the cracks.

(e) Purification Characteristics

The result of this method can make the color of the gemstone appear purer than before, with a more vivid body color and improved transparency.

The downside is that strong acids and strong bases, while dissolving dirt and impurities, also have a certain corrosive effect on the gemstones themselves, widening cracks, increasing pores, and even connecting them, which leads to a loose structure in the gemstones, making them prone to breakage, and they must be consolidated. Additionally, the purifying agents are highly corrosive, and strict adherence to operating procedures is required during purification to ensure personal safety.

② Bleaching Process

(a) Principle:

Bleaching is an oxidation reaction similar in principle to the chemical bleaching of organic dye colorants. There are often chromophores in the organic components of gemstones that give them color. When the strong oxidants in the bleaching agent come into contact with these, the Π component of the double bonds in the chromophore are broken, causing the organic material to lose its color.

(b) Process:

There are two types of bleaching processes: chemical and optical.

- Chemical bleaching method involves using bleaching agents to chemically react with gemstones to improve their color. Bleaching agents are strong oxidants such as chlorine, hypochlorite, hydrogen peroxide (water), and sulfites. The treatment mainly targets gemstones containing organic materials (pearls, corals, ivory, etc.), and chemical bleaching can also be applied to wood opal, tiger’s eye, and others. However, it is important to ensure that the organic components and moisture in the gemstones are not damaged or lost during chemical bleaching, so the ratio of bleaching agents is crucial, with the concentration of strong oxidants generally being better in the range of 2%-5%. Additionally, the bleaching time should not be too long.

The chemical bleaching device is relatively simple, mainly consisting of a vacuum foot, glass container, washing bottle, and rubber tube, among others. The process flow is as follows:

- Place the gemstone into the washing bottle containing the bleaching solution and create a vacuum inside the bottle;

- Soak for some time, remove the gemstone, and rinse it;

- Change the bleaching solution and continue soaking, then remove and clean the gemstone. Repeat until a satisfactory bleaching result is achieved.

The color after chemical bleaching is often not very stable. This is related to the chromophores’ structure in the gemstone’s organic matter, as well as the components of the bleaching agent. For example, pearls can become very white after bleaching but will turn yellow after being worn for a while. However, re-bleaching can achieve a whiter effect again.

- Light fading, also known as sunlight bleaching, is a type of oxidation reaction in photosynthesis. Many objects’ colors will fade or change under light or light heating conditions, especially gemstones containing organic components.

(3) Chemical precipitation process

Improving gemstone color through chemical precipitation includes salt immersion and color liquid pyrolysis. The so-called chemical precipitation method involves a chemical reaction occurring on the surface of the gemstone or in its cracks and pores with a solution containing coloring substances, precipitating insoluble colored materials that adhere to the surface or the walls of the cracks and pores, thereby coloring the gemstone. The insoluble precipitated colorants attached to the gemstone are mainly some inorganic pigments, such as insoluble compounds like iron oxide and chromium oxide, as well as metal sulfides and other metal oxyacids. Some gemstones, such as indigo, are chemically dyed using organic dyes (Table 6-12).

Table 6-12 Commonly used chemical dye pigments

| Material color | Types of pigments |

|---|---|

| Fehér | Titanium white, barium sulfate, lead white, zinc white |

| Sárgásbarna | Cadmium yellow (PbCrO4+PbSO4) , lead yellow, naples yellow [Pb3(SO4)2] , orpiment, Van Dyke brown |

| Red | Cadmium red, lead red, red lead, orpiment, iron red, Chinese red (HgS), alizarin red, cochineal red (stable metal complex organic compounds) |

| Kék | Azurite, Cobalt Blue (COAl2O4) , Thioindigo (stable organic pigment), Iron Blue (hydrated iron compound), Prussian Blue {Fe4[Fe(CN)6]3 · 16H2O} |

| Purple | Cobalt Violet (Co3P2O8) , Manganese Violet (NH4MnP4O7) |

| Zöld | Chromium Green (Cr2O3) , Cobalt Green (Co1-xZnxO) , Emerald Green[Cu9 (CH3COO)]2Mint2O4 , Malachite, Verdigris [Cu2(CO3COO)2(OH)2] , Copper Arsenite Green (CuHAsO3) |

| Fekete | Ashes, carbon black, copper chrome black (CuCr2O4) , iron oxide black, silver black (Ag2S) |

① Salt immersion method

Soak the gemstone in a solution of soluble colored metal salts, allowing the solution to penetrate the cracks, pores, or pits of the gemstone, then heat it to decompose the solution, precipitating insoluble colored substances to color the gemstone, or soak the gemstone in another solution to allow a chemical reaction between the two solutions, precipitating colored substances.

The former method is commonly used for coloring pearls: soak the pearls in a silver nitrate solution, then remove the pearls after they are saturated, and heat or expose them to a strong light to decompose the silver nitrate solution, precipitating black silver oxide that adheres to the pearls.

The latter method can be used for agate dyeing: first, soak the agate in a ferric chloride solution, then immerse the agate in ammonia, allowing the two solutions to react chemically, precipitating red Fe2O3? that adhere to the cracks and pore walls of the agate, giving the agate a red body color.

② Color Liquid Pyrolysis Method

Dissolve the pigment in a solvent to create a dye solution, and then soak the gemstone in it. After the dye solution fully penetrates the cracks and pores of the gemstone, the solution evaporates upon heating, causing the pigment to precipitate in the gaps of the gemstone, thus coloring it.

(4) Characteristics of Chemical Precipitation Method

The chemical precipitation method can color gemstones, but the coloring agents are deposited in the pores and cracks of the gemstone, leading to uneven distribution and a tendency to fall off. To prevent the colored gemstones from fading, surface coating treatment is also required. Additionally, a vacuum pump washing device can be used to accelerate the dyeing efficiency and increase the depth of the dyeing layer. In general, a heating device is also needed.

Gemstones improved by chemical reaction processes have unique identification characteristics due to the differences in the improvement processes (see 6-13).

Table 6-13 Characteristics of Chemical Reaction Process Identification

| Módszerek | Blemish | Sűrűség (g/cm3 ) | Abszorpciós spektrum | Törésmutató | Polarization | Hot needle probe |

|---|---|---|---|---|---|---|

| Thermal diffusion | In the holes and cracks on the surface of the gem, the color layer is thin and lightened to the inside of the gem | No changents | Have some difference | No change | No change | No change |

| Bleach | Uneven color | No change | Have a change | Slight change | No change | No change |

| Purification and filling | The surface layer of the gemstone is corroded, the base is clean, and the color pattern is chaotic. Primary fissure dilatation; Foreign body filling, may have bubbles, streamlines. Have a flash effect | Reduce | Filling specific absorption spectrum | Have a change | The fill is completely extinct | Exsolution odor |

| Chemical precipitation reaction | There are tints in the pores of gemstones | Not obvious | There are precipitate characteristic absorption spectra | Slight change | Filamentary filling is completely extinct | No change |

3. Physical Modification

Physical modification methods play an important role in gemstone enhancement and have a long history. Common methods include pore injection, surface coating, and impurity removal.

(1) Pore Injection

This method is widely used for dyeing gemstones with multiple pores or fissures. Its characteristic is to inject colorless transparent or colored substances into the fissures, pores, or cavities of the gemstone to improve the gemstone. It is used to enhance the color condition of the gemstone, improve its transparency, increase the stability of the gemstone, and cover various defects of the gemstone.

According to the color of the injection agent, it is divided into colorless injection and colored injection. Colorless injection agents include paraffin, vegetable oil, colorless oil, colorless plastic, glass (crown glass and welding glass), silicone, etc. They can improve the color state of gemstones, enhance transparency, conceal pores, and reinforce structure.

Colored injection agents consist of two parts: fillers and colorants. The fillers are the same as those in colorless injection agents, while the colorants are divided into organic dyes and pigments (inorganic compounds and a few organic compounds). The colorants and fillers are mixed to create various colored injection agents, which change the color of gemstones in cracks, pores, and cavities, deepening the hue and increasing brightness.

The purpose of the injection method to improve gemstones varies, and the required process conditions often differ. The basic conditions are as follows: the gemstone must have a natural or artificial pore structure, the injection process requires a certain temperature and injection time, and it is best to use vacuum injection method.

Specific injection methods can be divided into the following several:

① Static injection method

At room temperature and pressure, the gemstone is soaked in a glass beaker containing colorless and colored injection oil, cement containing organic dyes, etc., and the injection agent is slowly permeated into the gemstone. Stir gently if necessary to avoid aggregation or sedimentation.

② Hot Injection Method

The method is to melt the solid resin, glass and other injection agent into a fluid under heating conditions, and then soak the preheated gem into it, so that the injection agent fills the cracks and pores. The device of the hot injection method is composed of a glass container or a porcelain crucible and a hot thermostat.

③ High-Pressure Injection Method

The method is developed on the basis of heat injection method. In recent years, vacuum injection has also been used. It is made by placing the gemstone and the injection agent in a sealed glass bottle, vacuuming it, and then heating it. The injection agent is melted and immersed in the stone that has been immersed in the heat, and the stone is immersed under the action of atmospheric pressure to achieve the purpose of improvement.

(2) Surface treatment

Surface treatment, mainly with some colorless or colored film material uniformly attached to the surface of the gem, in order to improve the color of the gem, surface finish, enhance the surface luster and cover up the surface defects (pits, cracks, scratches, etc.)

There are many methods of surface treatment, mainly including the following types.

① filming

Also known as the coating method, it involves applying a certain chemical reagent, dye, or various coating materials on the surface of gemstones to change or enhance their color, luster, and gloss while covering surface defects (such as pits, cracks, and scratches). Commonly referred to as “dressing.”

- filming materials: wax, paint, colorless oil, and various resins mixed with dyes. For example, the material used for “dressing” jadeite is the 808 emerald green glue produced in the UK.

- Requirements for the filming process: The coating should be as uniformly thick as possible, have a high surface finish, and be free of obvious impurities.

② Coating method

This surface treatment involves applying an extremely thin (from a few nanometers to several hundred nanometers at the molecular or atomic level) film on the surface of the gemstone, which easily produces light refraction effects, resulting in brilliant interference colors, achieving the purpose of surface improvement. It fills in the pits and scratches on the gemstone’s surface, making it extremely smooth and flat, enhancing the gemstone’s surface gloss, and increasing the color saturation or tint without affecting the gemstone’s transparency.

- Method: Generally conducted in a vacuum coating machine. Place the clean item (after acid or alkali cleaning) on the base plate of the coating machine, put the metal piece that generates the thin film on the cathode, evacuate the air, and then trigger the cathode with a trigger, causing an arc discharge between the anode and cathode, evaporating the cathode (metal) material into the discharge chamber to form a plasma state, which is coated onto the surface of the gemstone, forming a thin film.

- Material: Au , Ag , Cu , Cr , Ni and other metals. The thin film of Au has a bluish tint and exhibits a strong rainbow effect.

- Characteristics: The thickness of the metal coating layer is similar to the wavelength of light, and the reflected light from the surface of the thin film and the reflected light from the surface of the gemstone interfere with each other, allowing people to see bright rainbow flashes. Therefore, the coating can transform colorless transparent gemstones (such as crystal, topaz, diamond, etc.) into lightly colored gemstones with iridescent effects. For example, gold film can make crystal and topaz appear blue. After diamond coating, not only does it produce a beautiful iridescent effect and enhance the gloss of the gemstone surface, but it can also increase the hardness, wear resistance, and corrosion resistance of the gemstone surface.

Additionally, hydrothermal crystal growth technology has also been used for surface coating, and the composition and structure of this crystal film are the same as that of the gemstone.

③ Surface ion implantation method

This method uses high-energy, high-speed ions generated by devices such as metal vapor and vacuum arcs to implant into the surface and very shallow layers of gemstones, changing the color of the gemstone’s surface. It is different from the thermal diffusion process.