How to do Gemstone Cutting?

Techniques, Common Abrasives and Tools Used in Gem Processing and Cutting of Gem Materials

Εισαγωγή:

This comprehensive article covers the essentials of gemstone processing, including common abrasives and their functions, the design of frequently used abrasive tools, and the principles of cutting. It delves into cutting techniques, equipment, saw blade selection, and the intricacies of gem cutting technology. From size calculations to measurement tools, it’s a valuable guide for anyone in the jewelry industry involved in crafting and polishing gemstones.

Large Blade Cutting Machine and Schematic Diagram

Πίνακας περιεχομένων

Section I Common Abrasives and Tools Used in Gem Processing

1. Commonly Used Abrasives in Gemstone Processing

1.1 Basic Properties of Abrasives

Abrasives are materials that play a role in grinding, polishing, and honing. The granular or powdered materials used for grinding, polishing, or honing gemstones are called abrasives.

Abrasives are the main raw materials that makeup grinding tools. Abrasives are natural or synthetic materials with a granular shape and cutting function, and they should possess the following basic properties.

(1) Hardness

The ability of a material to resist the penetration of hard objects into its surface. During the grinding process, the greater the hardness of the abrasive, the easier it is for the abrasive particles to cut gemstones, as shown in Table 3-1.

Table 3-1 Hardness of various abrasives commonly used in gemstone processing

| Όνομα | Microhardness | Σκληρότητα Mohs |

|---|---|---|

| Natural diamond | Slightly higher than synthetic diamond | 10 |

| Synthetic diamond | 86000 ~ 106000 | 10 |

| Brown corundum | 19600 ~ 21600 | 9.0 ~ 9.2 |

| Zircon corundum | 14700 | 9.0 ~ 9.2 |

| Green Silicon Carbide | 31000 ~ 34000 | 9.2 ~ 9.3 |

| Boron Carbide | 40000 ~ 45000 | 9.3 ~ 9.5 |

| Cubic Boron Carbide | 73000 ~ 100000 | Close to 10 |

| Chromium Corundum | 21600 ~ 22600 | 9.0 ~ 9.3 |

The classification of abrasive hardness in gem processing is as follows.

Soft abrasives: Mohs hardness 1~5 (chalk).

Medium-hard abrasives: Mohs hardness 6〜7 (agate powder, ferric oxide).

Hard abrasives: Mohs hardness 8 to less than 10 (silicon carbide, boron carbide).

Superhard abrasives: Mohs hardness 10 to close to 10 (diamond, cubic boron carbide).

(2) Toughness

The performance of abrasive particles being tough and not breaking.

(3) Strength

Refers to the ability of a material to resist damage. The ability of abrasive particles to withstand mechanical forces; the higher the compressive strength, the better the grinding performance.

(4) Thermal fracture performance

The phenomenon of abrasive particles breaking under thermal stress.

(5) Chemical stability

The reduction or loss of cutting ability of abrasive particles in chemical reactions.

(6) Uniformity

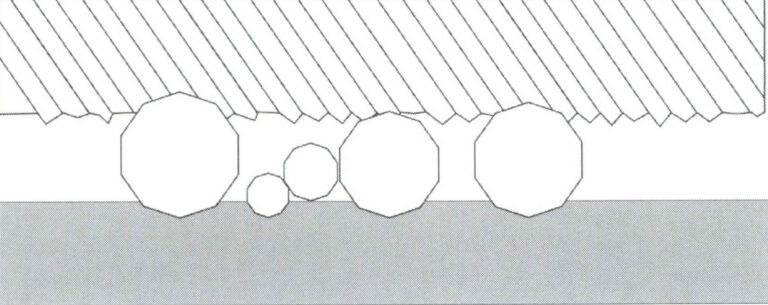

Refers to the degree of uniformity in size of abrasive particles of the same specification. Figure 3-1 shows the impact of uneven particle morphology on grinding.

(7) Self-sharpening

Abrasive particles still have new sharp edges and tips after breaking.

1.2 Classification of abrasives

1.3 Common abrasives used in gemstone processing

The model of abrasives is expressed by particle size; a larger particle size indicates a coarse abrasive, resulting in a rough surface on the processed gemstone; a smaller particle size indicates a fine abrasive, resulting in a smooth surface on the processed gemstone. Common abrasive models used in gemstone processing are shown in Table 3-2.

Table 3-2 Common Abrasive Models Used in Gem Processing

| Particle Size Classification | Japan (JIS6002.63) | China (GB 1182-71) | ||

| Particle Size Number | Particle size (μm) | Particle Size number | Particle size ( μm ) | |

| Abrasive particle | 46# | 420-350 | 46# | 400-315 |

| 60# | 290-250 | 60# | 315-250 | |

| 70 # | 250-210 | 70 # | 250-200 | |

| 80# | 210-177 | 80# | 200-160 | |

| 90# | 177-149 | |||

| 100# | 149-125 | 100# | 160-125 | |

| 120# | 125-105 | 120# | 125-100 | |

| 150# | 105-88 | 150# | 100-80 | |

| 180# | 88-73 | 180# | 80-63 | |

| 220# | 73-63 | |||

| 240# | 63-53 | 240# | 63-50 | |

| 280# | 53-44 | 280# | 50-40 | |

| Particle Size Classification | Japan (JIS6002.63) | China (GB 1182-71) | ||

| Particle Size Number | Particle size (μm) | Particle Size number | Particle size ( μm ) | |

| Microparticle | 320# | 44-37 | W40 | 40-48 |

| 400# | 37-34 | |||

| 500# | 34-28 | |||

| 600# | 28-24 | W28 | 28-20 | |

| 700# | 24-20 | |||

| 800# | 20-16 | W20 | 20-14 | |

| 1000# | 16-13 | |||

| 1200# | 13-10 | W14 | 14-10 | |

| 1500# | 10-8 | W10 | 10-7 | |

| 2000# | 8-6 | W7 | 7-5 | |

| 2500# | 6-5 | |||

| 3000 # | 5-4 | W5 | 5-3.5 | |

| 4000 # | 4-3 | |||

| W3.5 | 3.5-2.5 | |||

| W2.5 | 2.5-1.5 | |||

| W1.5 | 1. 5-1 | |||

| W1 | 1-0.5 | |||

| W0.5 | ≤ 0.5 | |||

2. The Role of Common Abrasives in Gem Processing

Abrasives are important materials in gem processing. Abrasives are the main materials that can perform grinding operations. The choice and quality of abrasives directly affect the efficiency and quality of processing in gem work. The roles of abrasives in gem processing are as follows.

2.1 Abrasives can be used to make various gemstones and tools

(1) The grinding wheel is vertically placed on the outer ring of different steel wheels. Various types or shapes of grinding wheels and discs can be made for gemstone grinding using the electroplating abrasive method, as shown in Figure 3-2.

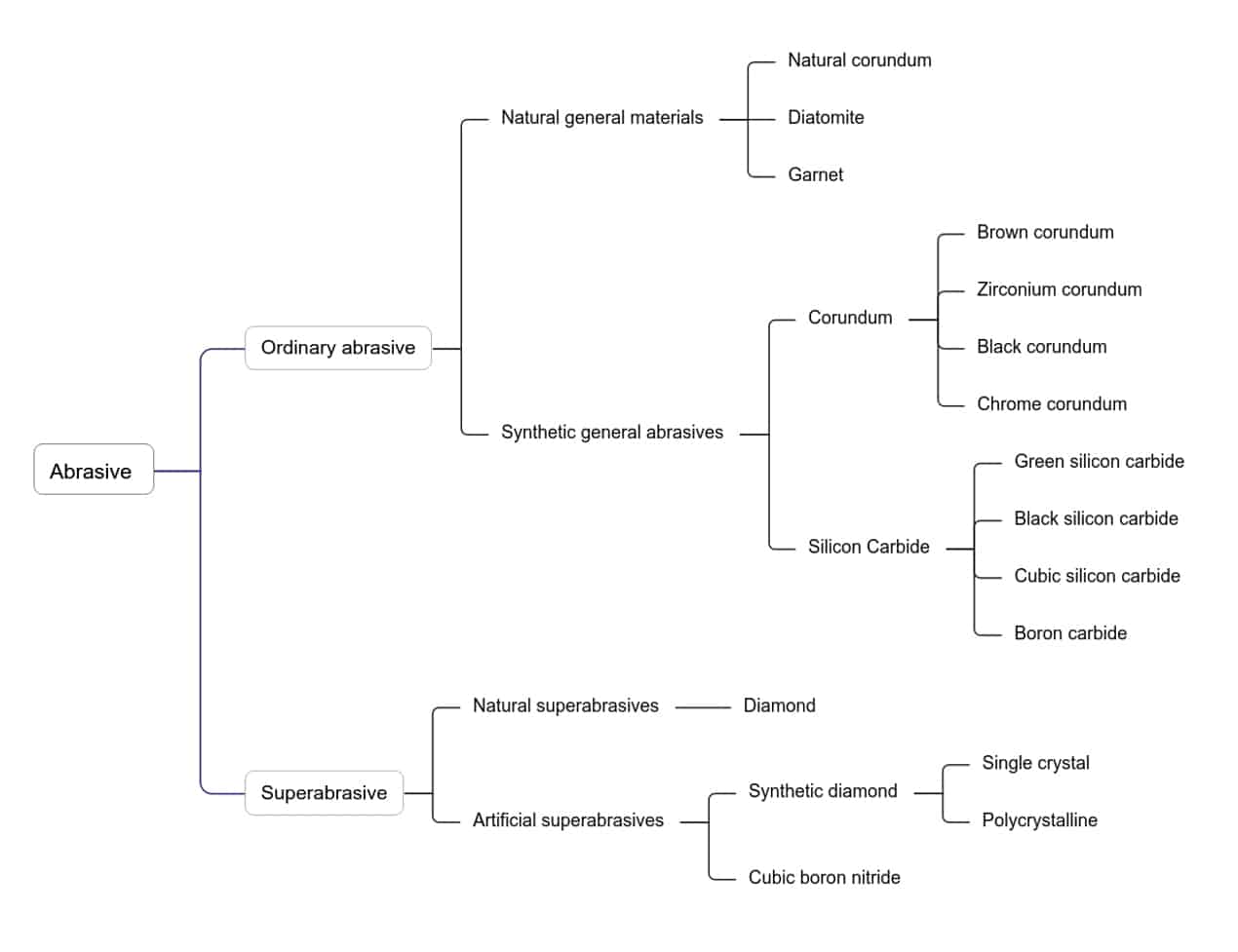

(2) Various sizes of saw blades can be made for cutting gemstones on the outer ring of a metal disc substrate using the electroplating abrasive method, as shown in Figure 3-3.

Figure 3-2 Grinding Wheel

Figure 3-3 Saw Blade

(3) Abrasives are adhered to specialized materials such as cloth and leather to create sandpaper, as shown in Figure 3-4.

2.2 Abrasives for Direct Processing of Gemstones

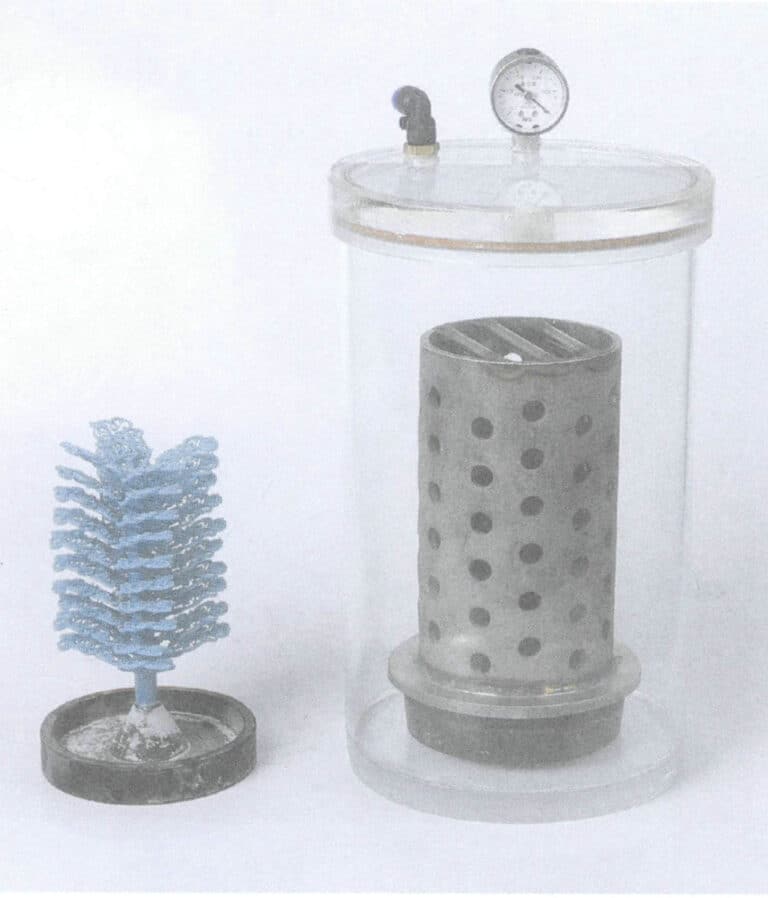

(1) Abrasives can grind and polish gemstones in a vibrating polishing machine. Place an appropriate amount of gemstones to be processed along with the abrasives into the vibrating barrel, start the machine to create vibrations that generate friction between the gemstones and abrasives, achieving grinding and polishing effects (Figure 3-5).

(2) Abrasives can be attached to polishing wheels to grind and polish gemstones. The gemstones to be processed come into contact with the polishing wheel coated with abrasives, generating friction to achieve grinding and polishing effects (Figure 3-6).

Figure 3-5 Vibratory Polishing Machine

Figure 3-6 Polishing Cloth Wheel

3. Common Abrasives Tools Used in Gem Processing

Abrasives are tools that bond abrasives of different particle sizes with binders and molds to create various shapes and sizes. They are used for grinding and polishing and have a certain strength and rigidity.

In gem processing, abrasives are divided into bonded and coated abrasives.

Bonded abrasives mainly include saw blades, diamond grinding wheels, diamond grinding discs, diamond grinding heads, sandpaper, etc.

Coated abrasives mainly include polishing discs, cloth wheels, polishing powder, and paste.

3.1 Bonded Abrasives Tools

(1) Saw Blades

It is made by electroplating abrasives onto the outer diameter of a metal substrate ring.

Common specifications for gemstone saw blades: 110 mm, 150 mm, 200 mm, 300 mm, 400 mm, 500 mm. Blade thickness 0.18- 3 mm, as shown in Figure 3-7.

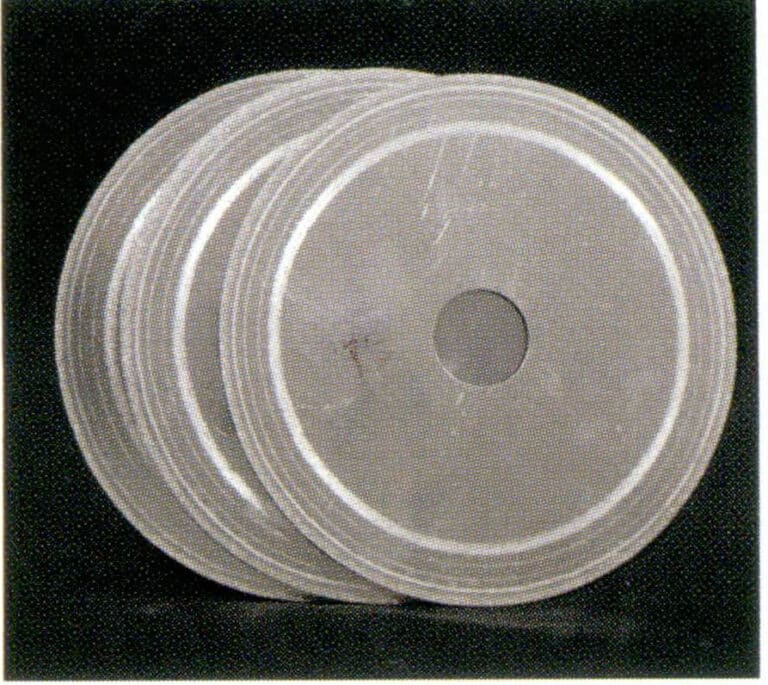

(2) Diamond grinding wheel

① Arc wheel

The shape ground on the gemstone’s surface is called an arc wheel if it is arc-shaped. It is made by coating the outer diameter surface of an arc-shaped metal wheel with diamond abrasive. The arc wheel designed according to the product shape is shown in Figure 3-8.

② Straight wheel

The linear shape ground on the gem’s surface is called a straight wheel, and the linear metal wheel is made by coating the outer diameter surface with diamond abrasive material. Figure 3-9 shows the grinding wheel (or lapidary wheel).

Selection of grinding wheels in production: The coarser the abrasive particles on the grinding wheel, the higher the efficiency of gem grinding, but the surface finish becomes rougher. According to the fineness of the abrasive particles, there are coarse grinding wheels, medium coarse grinding wheels, and fine grinding wheels. Coarse grinding wheels 60-180 #, medium coarse grinding wheels 220-320 #, fine grinding wheels 400-600 #.

According to the diameter size of the wheel, 50-150 #, and according to the thickness of the wheel, 5〜50 #.

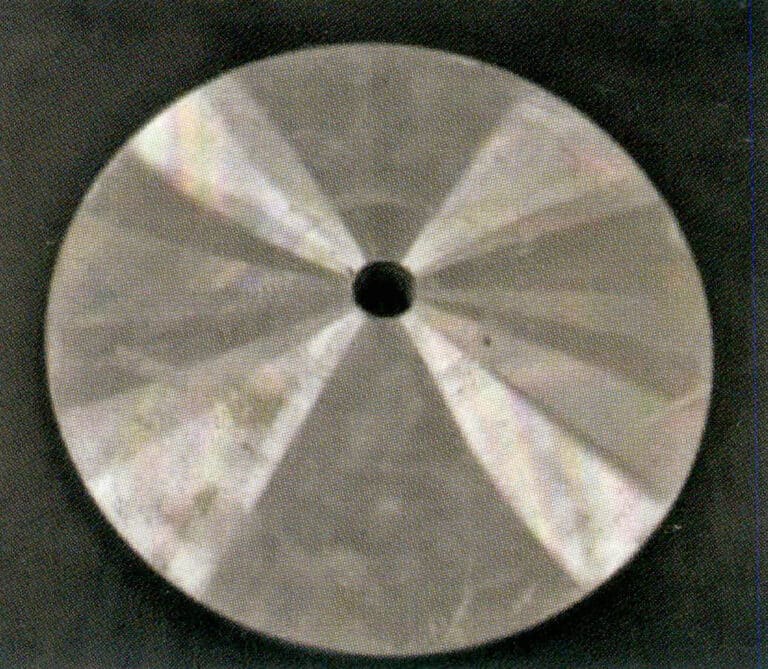

(3) Diamond Grinding Disc

Electroplating diamond abrasives make the diamond grinding disc onto the surface of a circular metal substrate. The coarser the abrasive particles on the grinding disk, the more efficient the grinding of gemstones and the rougher the machined surface. The main types of diamond grinding discs on the market are as follows.

① Ordinary diamond grinding disc:

Thickness 1.5-2 mm, divided into coarse sand disc 120-180 #, medium sand disc 220-320 #, fine sand disc 400~800 #, and extra fine sand disc 1000~2000 #, as shown in Figure 3-10.

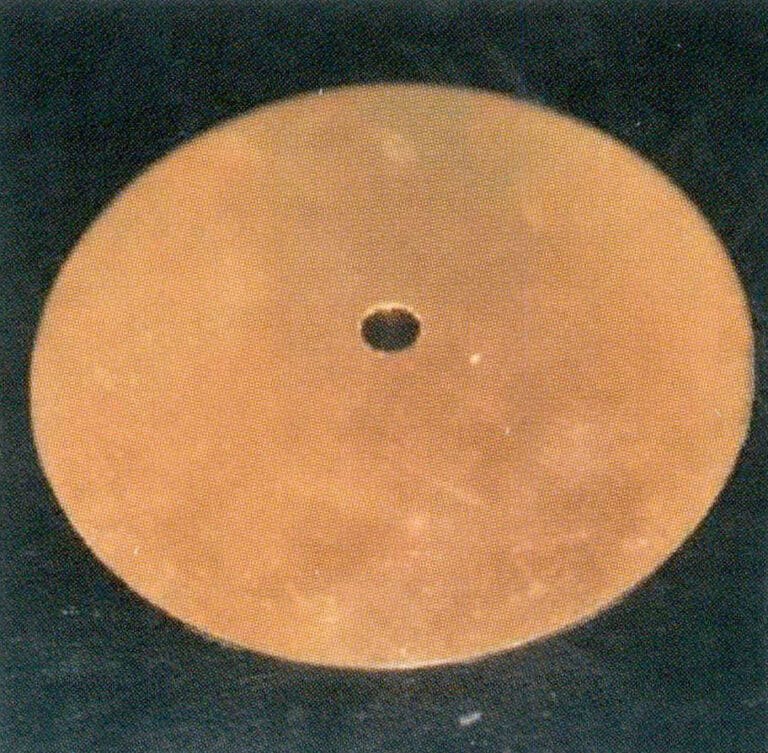

② Mixed grinding disc:

To improve processing efficiency and reduce the number of reverse grinding cycles during the gemstone processing, a 320 # coarse grinding material is plated on the outer ring of the disc, and a 1000 # fine grinding material is plated on the inner ring to create a mandarin duck sand disc, as shown in Figure 3-11.

③ Diamond spherical disc:

Pits are made on the metal disc base according to the size of the gemstones being processed, and diamond grinding materials are electroplated onto it. Figure 3-12 shows diamond spherical discs with different sizes of pits, and Figure 3-13 shows examples of diamond spherical disc processing.

(4) Diamond grinding heads

Diamond abrasive is electroplated on metal substrates of different shapes and sizes, which can be used for gemstone carving. Various shapes of grinding heads are made according to the design pattern requirements (Figure 3-14).

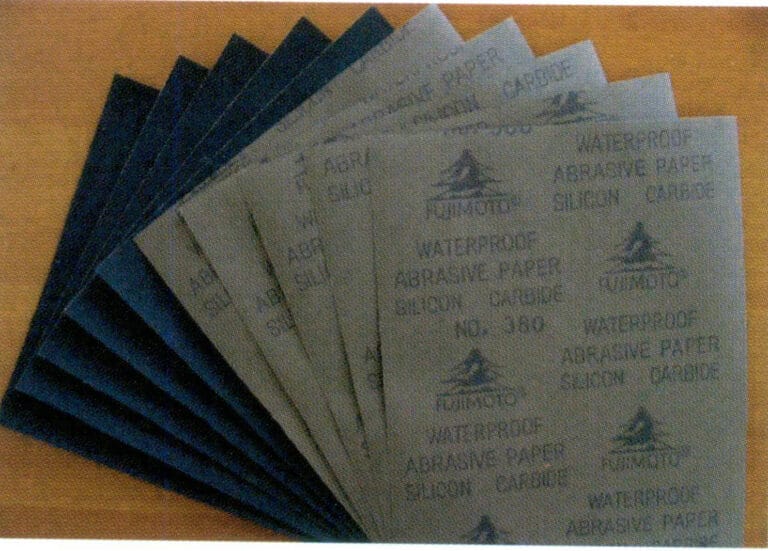

(5) Sandpaper

The main role of sandpaper in gemstone processing is grinding, polishing, and shaping.

- The types of sandpaper include diamond sandpaper, artificial diamond sandpaper, glass sandpaper, etc. Additionally, sandpaper can be divided into two categories based on its water resistance: dry grinding sandpaper and water-resistant sandpaper, and it needs to have both dry grinding and water-resistant properties. The commonly used sandpaper in gemstone processing is diamond sandpaper and corundum sandpaper.

- Commonly used models:150 #, 280 #, 320 #, 300 #, 500 #, 600 #, 800 #, 1000 #, 1200 #, 1500 #, 2000 # [The number represents the grit size, which refers to the number of particles contained in the area of lin x lin (lin = 2.54 cm) ], as shown in Figure 3-15.

(6) The application of abrasives in production

The principles for selecting grinding tools are shown in Table 3-3.

- According to the size of the gemstone being processed.

- According to the shape and length of the gemstone.

Table 3-3 Applications of various grinding tools in production

| Coarse | Μεσαίο | Fine | Extra fine | Κοινά μεγέθη | ||

| Diameter | Thickness (mm) | |||||

| Lapidary Wheel | 60~180 # | 220~320 # | 400~600 # | ¢ 50~¢ 150 | 5~50 | |

| Sand Plate | 60~180 # | 220~320 # | 400~800 # | 1000~2000 # | ¢150~¢500 | Thickness 1.5~5 |

| Large rough stone | Small rough stone | |||||

| Grind gems above ¢10 | Grind ¢4 to ¢10 gems | Grind ¢3 to ¢4 gems | Grind ¢2〜 ¢3 Gemstone | |||

3.2 Coated Abrasives

Polishing is the most important step in gemstone processing, and the brilliance of the gemstone reflects the quality of the polishing. A perfectly polished gemstone can sparkle with dazzling brilliance. In principle, the polishing of gemstones is not greatly related to the choice of polishing disc materials, but it is significantly related to the sharpness of the facet edges.

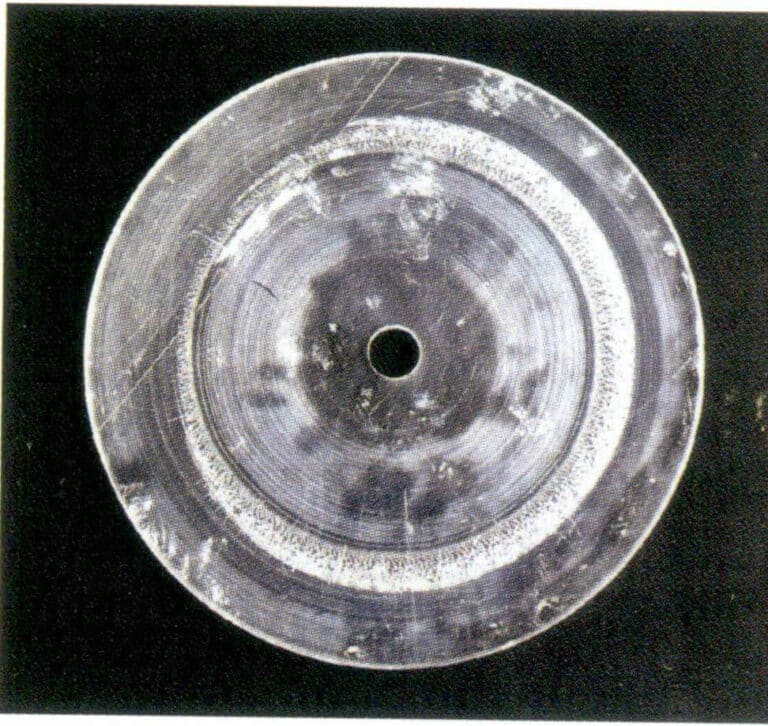

(1) Hard polishing disc

Hard polishing discs are made of alloys with a certain hardness. Common types of hard discs used in faceting gemstones include cast iron discs, often used for polishing diamonds or various high-hardness gemstones as shown in Figure 3-16; composite polishing discs, with an outer ring made of cast iron and an inner ring made of various alloys, commonly used for polishing various high-hardness gemstones, as shown in Figure 3-17; zinc alloy discs, often used for polishing gemstones with a hardness greater than 7, as shown in Figure 3-18: lead-tin alloy discs (green powder polishing discs), commonly used for polishing gemstones with a hardness below 7, such as polishing crystals, agates, etc., as shown in Figure 3-19; copper discs, often used for polishing rubies and sapphires, as shown in Figure 3-20; diamond abrasive resin bond polishing discs, as shown in Figure 3-21.

Figure 3-16 Cast Iron Tray

Figure 3-17 Composite Polishing Disc

Figure 3-18 Zinc Alloy Disk

Figure 3-19 Lead-Tin Alloy Disk

Figure 3-20 Purple Copper Plate

The characteristics of diamond abrasive resin bond polishing discs are as follows.

- Diamond abrasives mixed in a resin binder do not require the application of polishing abrasives when polishing gemstones; they are cooled with water during use, which also helps wash away polishing residues.

- Compared to ordinary polishing discs, there is no need to add polishing powder when polishing gemstones; this type of polishing disc can accelerate the efficiency of automated gemstone processing and is commonly used in automatic gemstone grinding machines.

- The disadvantage is that it cannot polish gemstones above 2A.

(2) Medium Hardness Polishing Disc

Polishing discs made from medium hardness materials are commonly used for polishing gemstones with a hardness of less than 6; they have high polishing efficiency, but the facets of the gemstones are not sharp. Common medium-hardness polishing discs include organic glass discs (Figure 3-22), plastic discs (Figure 3-23), and wooden discs (Figure 3-24).

Figure 3-22 Acrylic Plate

Figure 3-23 Plastic Plate

Figure 3-24 Wooden Plate

(3) Soft Polishing Pad

Polishing pads are made of soft materials. Especially suitable for polishing curved gemstones, where sharp edges are not required for faceted gemstones. Hard materials can be bonded with machine pumps, for example, using soft pads to polish glass, which greatly improves polishing efficiency. The felt pad is shown in Figure 3-25, the leather pad in Figure 3-26, the canvas pad in Figure 3-27, and the polyester pad in Figure 3-28.

Figure 3-26 Leather Disc

Figure 3-27 Canvas Disc

Figure 3-28 Polyester Disc

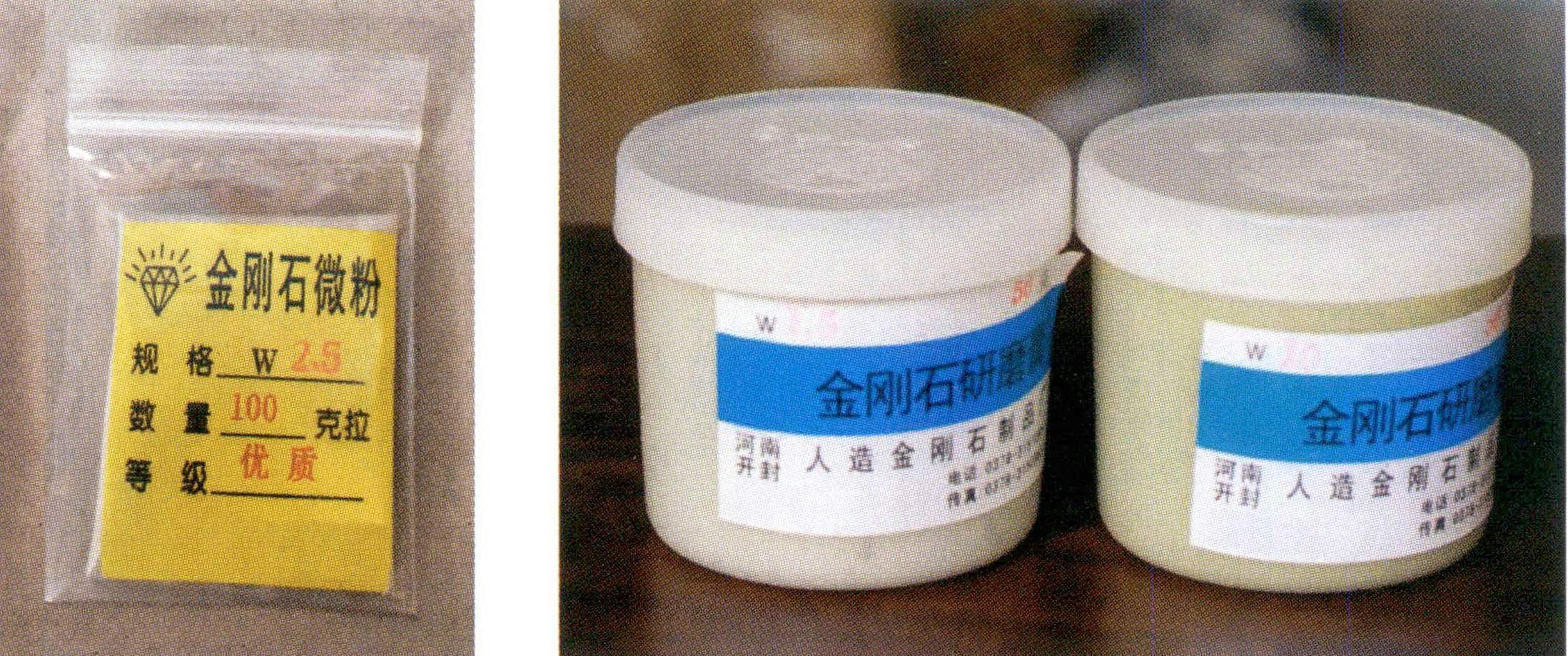

3.3 Application of Polishing Powder and Polishing Paste in Coated Abrasives

All ultra-fine abrasives can be used as polishing powder. Polishing paste is made by mixing polishing powder with materials like petroleum jelly. Gem processing includes coarse polishing and fine polishing. W5-W3.5` Abrasives are used for coarse polishing, and W2.5 the following are used for fine polishing. Figure 3-29 shows these are polishing powder and polishing paste. There are many types of polishing powder, which can be selected according to different processing materials. The range of use and performance are shown in Table 3-4.

Table 3-4 Common Types and Uses of Gem Polishing Powder

| Όνομα | Χημική σύνθεση | Scope of Application |

|---|---|---|

| Natural diamond powder | C | The hardest, processed diamond |

| Synthetic diamond powder | C | Slightly lower hardness than natural, polishing of all gemstones |

| Chromium oxide Green powder | Cr3O3 | Jade, crystal, turquoise, malachite, various gemstones, emerald, moonstone, garnet |

| Aluminum oxide Ruby Powder | Al2O3 | Low Hardness Gem Polishing |

| Cerium Oxide | Ce2O3 | Crystal, Olivine, Aquamarine, Tourmaline, Fluorite, Glass, Garnet, Agate |

| Silica Diatomaceous Earth | SiO2 | Ruby, Sapphire, Aquamarine, Coral, Amber |

| Ferric oxide Red lead | Fe2 O3 | Low-grade gemstones, Glass |

4. Design of Common Grinding Tools for Gem Processing

The processing of single gemstone shapes is done by hand. Mass production requires semi-automatic shaping machines in conjunction with shaping wheels. The curve of the outer diameter of the grinding wheel is the shape curve of the produced product, as shown in Figure 3-30. Examples of various shapes are shown in Figures 3-31 to 3-33. The bead plate is designed according to the size of the beads (commonly used bead sizes are 1 to 10 mm), as shown in Figure 3-34.

Figure 3-30 Sizing Wheels of Various Shapes

Figure 3-31 Design of Five Star Wheel

Figure 3-32 Design of the flower wheel

Figure 3-33 Design of the heart-shaped wheel

Figure 3-34 Design of the bead plate

Copywrite @ Sobling.Jewelry - Κατασκευαστής προσαρμοσμένων κοσμημάτων, εργοστάσιο κοσμημάτων OEM και ODM

Section II Cutting of Gem Materials

1. Principles of Diamond Saw Blade Cutting

Natural gemstone processing technology: Arm splitting method and cutting method to remove cracks and impurities—raw material cutting—shaping—gluing stone—polishing the crown— reverse stone—polishing the pavilion—polishing the waist—cleaning, packaging, and storage.

Artificial gemstone processing technology: Raw material cutting—shaping—polishing (waist and table polishing)—gluing stone—polishing the crown—reverse stone—polishing the pavilion—cleaning, packaging, and storage.

From the processing technology of natural and artificial gemstones, cutting is the first process after the raw materials are procured. Cutting in the gemstone processing process (commonly known as rough shape cutting) refers to cutting the diamond saw blade of raw gemstone materials into stone blanks of a certain shape according to design or customer requirements. The essence of this cutting is to divide large materials into small ones and remove impurities or cracks, which is technically referred to as cutting.

1.1 Cutting principle of bonded abrasives

(1) Structure of diamond saw blades (Figure 4-1)

The structure of the diamond saw blade indicates that it bonds diamond abrasives to the outer ring of the metal blade substrate. Its principle is similar to that of a thin diamond grinding wheel. The hardness and heat resistance of the diamonds on the saw blade are very high, and each diamond particle can be seen as a small tooth. The entire diamond layer of the saw blade can be regarded as a multi-edged tool with countless teeth.

(2) Principle of Diamond Saw Blade Cutting

When the diamond saw blade is in operation, the diamond particles on the surface or end face around the blade, in contact with the gemstone material as the motor drives the saw blade to rotate at high speed, are pressed tightly against the gemstone material by the feed force, causing both to be compressed and deformed. When the force applied by the abrasives exceeds the bonding force between the molecules of the gemstone material, some gemstone chips will be separated from the whole material. The entire process is a “plowing” action, cutting off fine chips, which are washed away with the participation of water, completing the entire cutting process.

(3) Precautions for Using Gem Cutting Blades

① Why is coolant used when cutting gemstone materials?

During cutting, the average temperature in the grinding area is within 400℃, and the temperature at which the abrasive contacts the gemstone is 1000-2000℃. This creates significant thermal stress in localized areas. Poor cooling during gemstone cutting can lead to sparks, and cracks may appear for brittle gemstone materials. When cutting, as the abrasive passes through the cutting area, the high temperature and pressure contact can cause gemstone debris to adhere to the abrasive, leading to clogging of the cutting blade. When adhesion is severe, the cutting saw blade can quickly lose its cutting ability, resulting in cracks in the gemstone. To reduce adhesion, it is essential to select and use coolant correctly.

② Why is a new saw blade’s cutting efficiency faster than an old saw blade?

Due to the inconsistent arrangement of abrasives on the saw blade, new saw blades have sharper abrasives. After cutting for a period, the edges of the abrasives become dull. Dull abrasives are not conducive to cutting, resulting in a very shallow cutting depth, and can only create scratches on the surface of the gemstone material.

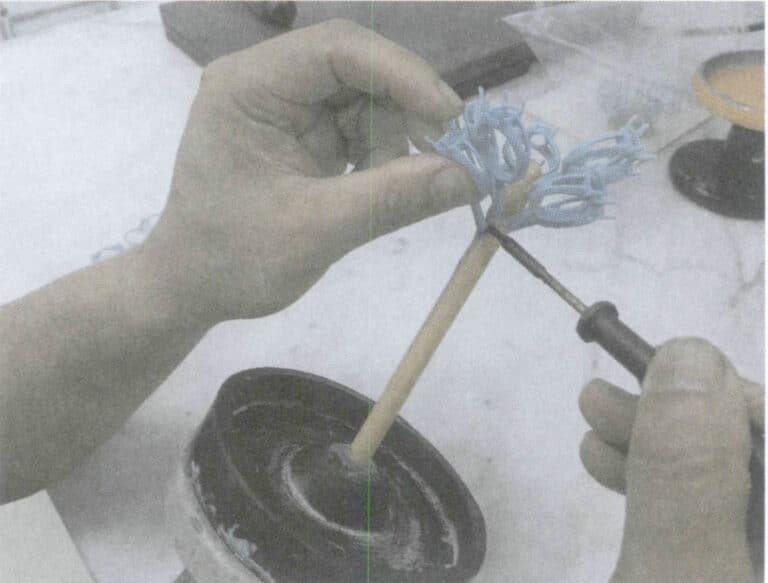

1.2 The principle of cutting with loose abrasives

The cutting principle of abrasive grain cutting is the same as that of fixed abrasive cutting, with the difference being that the abrasive grains are not pressed into the matrix of the abrasive grain cutting saw blade. Instead, the rotating saw blade carries the abrasives adhered to the teeth from the material groove to the cutting area. When cutting gemstones with abrasive grains, the abrasives adhere to the iron saw blade and press against the gemstone surface, causing small fragments to form on the gemstone surface under the “plowing” action of the abrasives. As the abrasives continue to move, with the participation of water, these fragments are “excavated” from the gemstone and “pushed away,” completing the cutting process.

This cutting method is still used in the processing of diamonds. Its advantage is that the saw blade is very thin, resulting in a small cut, thus saving raw materials. However, due to the slow cutting efficiency, this method is no longer used for cutting natural and synthetic gemstones.

2. Cutting Technology for Natural Gemstone Materials

Natural or synthetic gemstone materials share a common point before cutting and grinding; they need to be cut to transform large pieces of material into sizes required by the customer or according to order specifications. The characteristics of natural precious gemstones require cutting to maximize yield and remove impurities, processing rough materials into the shape of gemstones through certain cutting skills.

2.1 Gemstone Material Cutting Methods

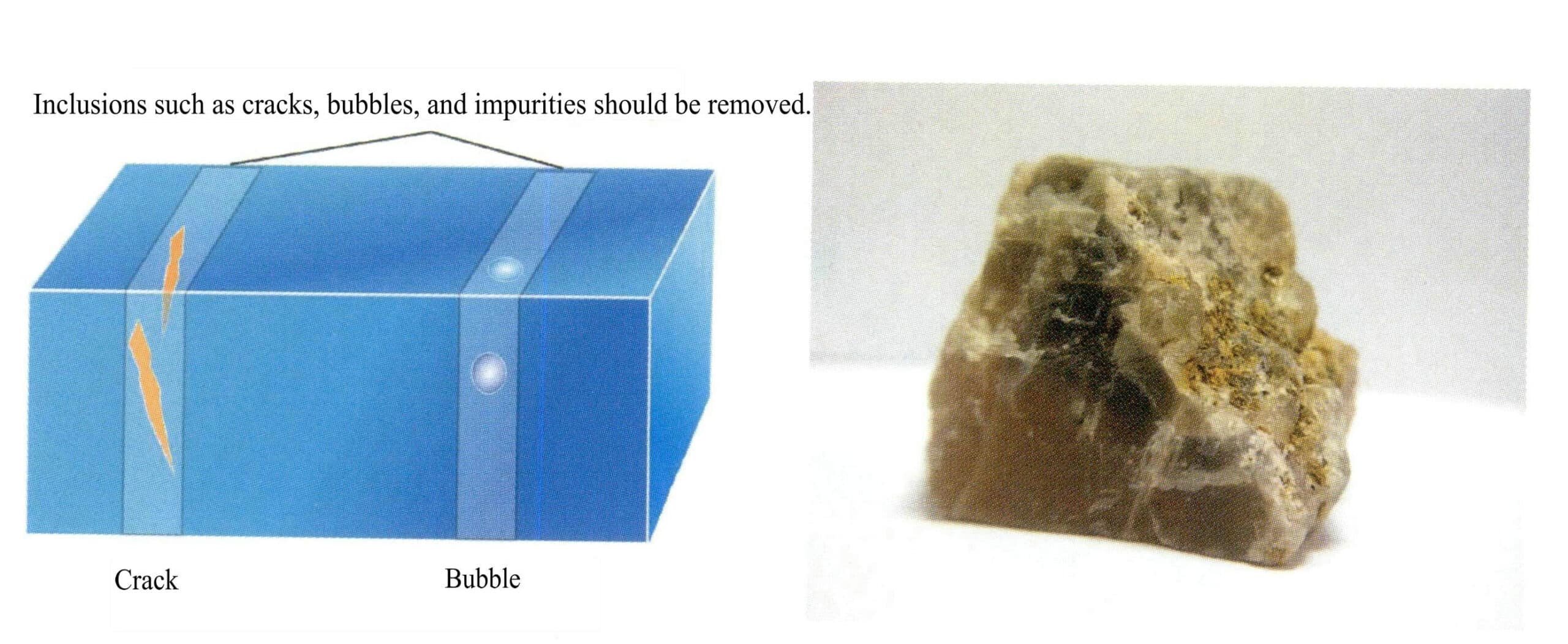

If there are cleavage or cracks in the raw gemstone material, they must be removed before processing. Suppose the cracks and cleavages are not removed. In that case, the following situations may occur during the processing of gemstone products: they may crack due to stress during rough shaping or contouring, crack during the heating process of adhesive stones, crack due to friction and heat during grinding, crack due to collisions during processing, and crack during cleaning.

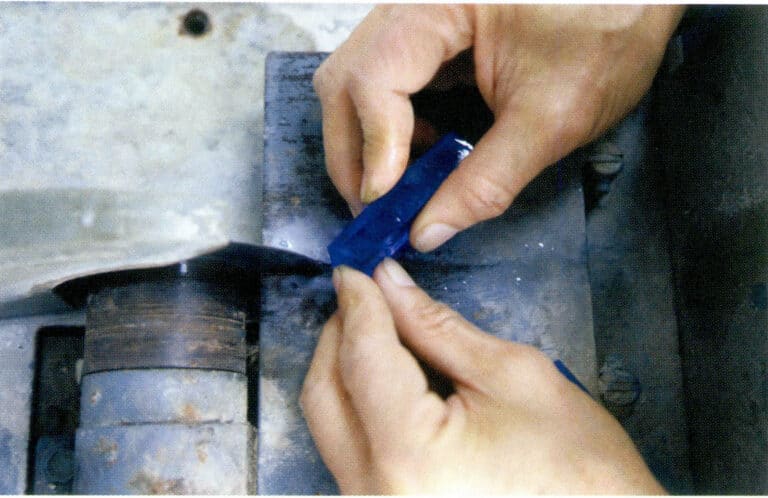

(1) Splitting method

The method for handling cleavages and cracks is to strike along the direction of the crack or cleavage with a pointed hammer or to strike with a wedge-shaped knife and hammer, as shown in Figure 4-2.

(2) Cutting method

The method for removing cleavage, bubble impurities, and initial shaping-commonly used diamond saw blades, as shown in Figure 4-3.

2.2 The purpose of gemstone cutting

(1) Before processing gemstones, it is necessary to cut them into several small pieces without cracks along the original cleavage direction to design and process them, as shown in Figure 4-4.

(2) Remove cleavage, cracks, and bubble impurities, leaving the necessary clean material without impurities and bubbles. The principle of impurity removal cutting is shown in Figure 4-5.

(3) According to the designed shape, remove some unnecessary parts and cut out qualified material sizes. The principle of removing edge scraps cutting is shown in Figure 4-6.

(4) Use the inclusions of natural stones to design and cut distinctive crafts, as shown in Figure 4-7.

3. Commonly Used Gem Cutting Equipment

3.1 Single Blade Gem Cutting Machine

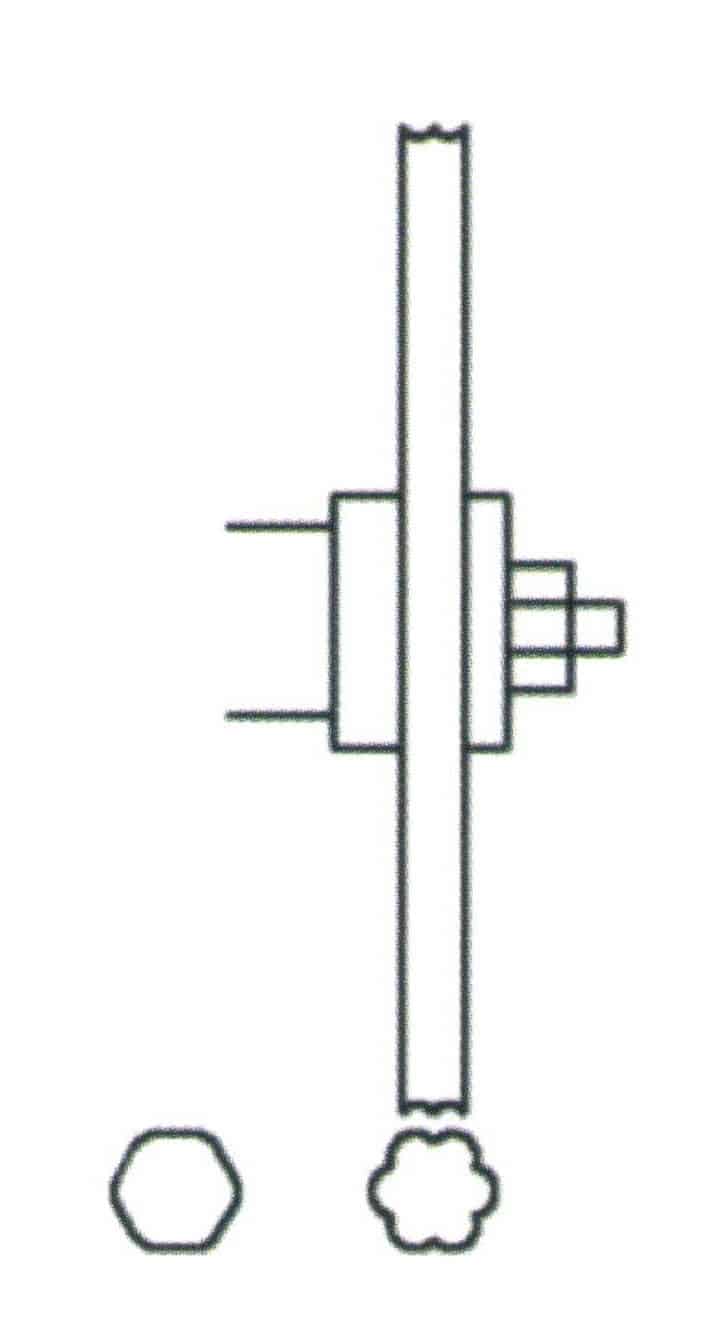

(1) Single saw blade cutting machine and schematic diagram (Figure 4-8)

1. Motor; 2. Large pulley; 3. Small pulley; 4. Spindle; 5. Diamond saw blade; 6. Water tank; 7. Frame

(2) Equipment structure and principle

The power of the equipment is output by the motor (1) of 250 W, 2800 r/min, installed on the frame (7), the large pulley (2) on the motor (1) drives the small pulley (3) on the spindle (4) through a V-belt, and under the speed change of the pulley, the spindle speed reaches 5600 r/min. A diamond saw blade (5) is installed at the other end of the spindle, and the spindle (4) is mounted on the panel of the water tank (6) through a spindle sleeve. The water tank panel (6) is also equipped with a waterproof cover and a stone-cutting machine workbench. When cutting materials, the raw material is placed on the workbench and pushed toward the saw blade.

(3) Equipment Application Range

The single-saw blade cutting machine is suitable for cutting gemstones below 30 mm.

3.2 Multi-saw Blade Gemstone Cutting Machine

(1) Multi-saw Blade Gemstone Cutting Machine and Principle Diagram (Figure 4-9)

1. Motor; 2. Large pulley; 3. Small pulley; 4. Spindle; 5. Multi-blade diamond saw blade; 6. Water tank; 7. Frame

(2) Equipment Structure and Principle

Multi-blade cutting machine differs from single-blade cutting machine in the spindle ③ the length of the head of the mounted saw blade is extended, and the extension size is designed according to the length of the cut material. There is a spacer between each saw blade, and the thickness of the spacer determines the cutting width.

(3) Equipment applicability range.

The multi-blade cutting machine is suitable for automated cutting production of large quantities of gemstone products.

With the installation of a saw blade automatic feeding mechanism, the equipment can complete the automatic cutting of sheet materials; with the installation of strip cutting and granule cutting automatic feeding mechanisms, it can complete the cutting of gemstones into strips and granules.

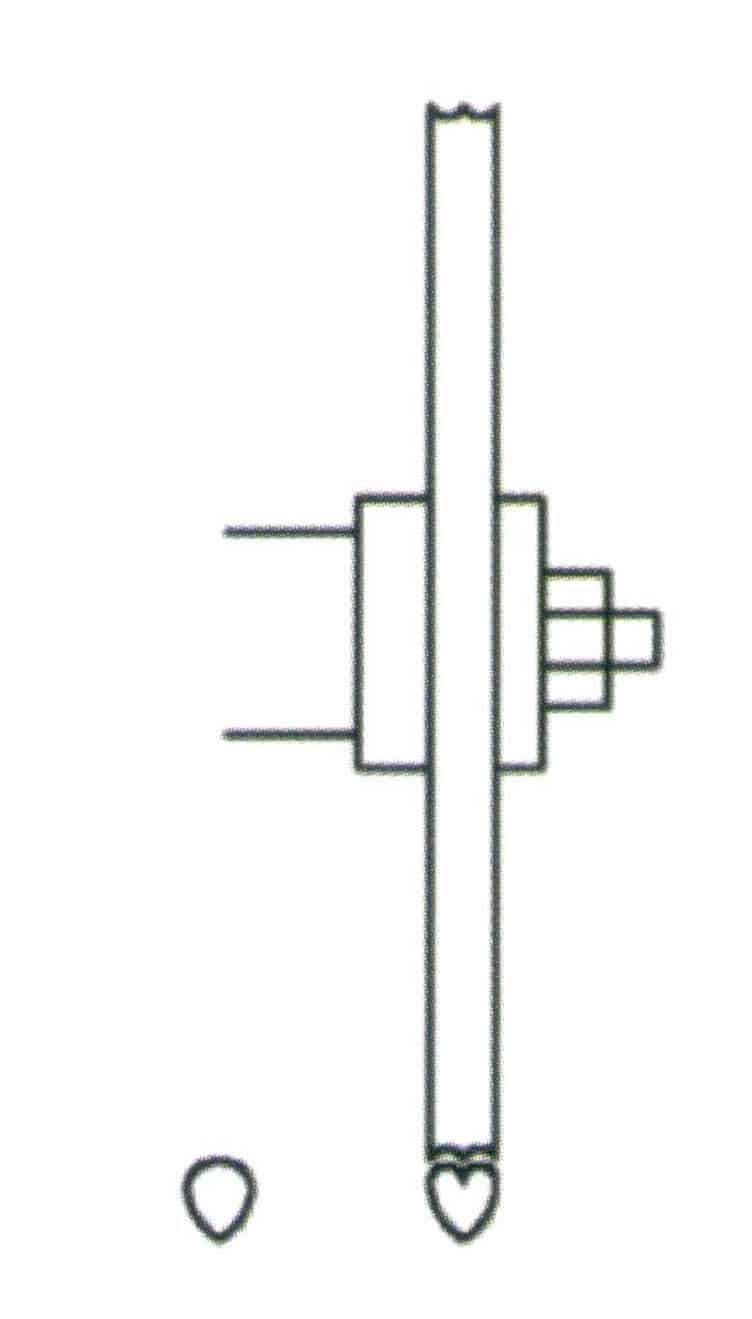

3.3 Large Blade Gemstone Cutting Machine

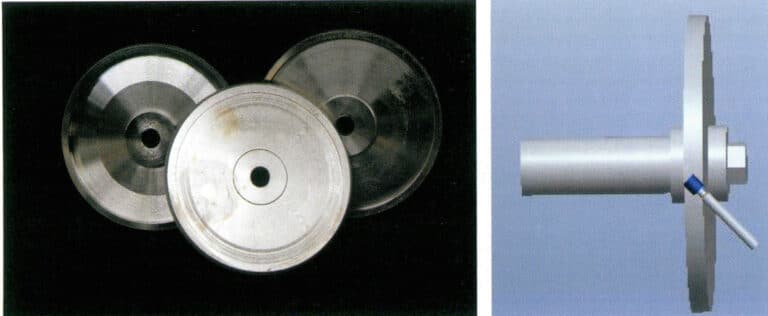

(1) Equipment Structure and Principle (Figure 4-10)

1. Small pulley; 2. Large pulley and motor; 3. Spindle; 4. Water tank; 5. Frame; 6. Handwheel; 7. Parallel cylindrical guide rails; 8. Workbench; 9. Screw; 10. Handle; 11. Material clamping screw; 12. Material clamping pliers

Similar to the principle of a single saw blade cutting machine. Difference: The large saw blade cutter cuts large pieces of raw material with high power input requirements. The power is output by a 550 W motor installed on the frame (5) with a speed of 1400r/min, and a large pulley (2) is installed on the motor shaft, which drives the small pulley (1) to rotate through a V-belt. The small pulley (1) is installed at one end of the spindle (3), and a saw blade is installed at the other end. The spindle (3) is mounted on the side of the water tank (4) through a bearing seat, and the water tank (4) is welded to the frame (5). Two parallel cylindrical guide rails (7) are also installed on the water tank, and the workbench (8) is mounted on the parallel guide rails (7), which moves the workbench (8) back and forth through the screw (9) and handwheel (6). The workbench (8) is also equipped with material clamping pliers (12) that clamp the raw materials through the material clamping screw (11) and handle (10).

The device has two types: manual feeding and automatic feeding.

(2) Scope of application of the equipment.

This equipment is suitable for cutting 50-200 mm gemstone materials.

3.4 The role of coolant in gemstone cutting

Gemstone cutting is performed under the high-speed rotation of diamond cutting blades, and the cutting process generates very high temperatures. If not cooled in time, it can cause cracks in the raw materials. The functions of the coolant are as follows.

- To carry away the heat generated by grinding.

- To clean the chips produced during grinding.

- Wedge cracking action: When gemstones are subjected to abrasive action, cracks appear on the surface. The coolant penetrates the cracks, creating high pressure, resulting in wedge-cracking action.

- Lubricating action.

4. Types and Selection of Gemstone Cutting Saw Blades

4.1 Types of Saw Blades

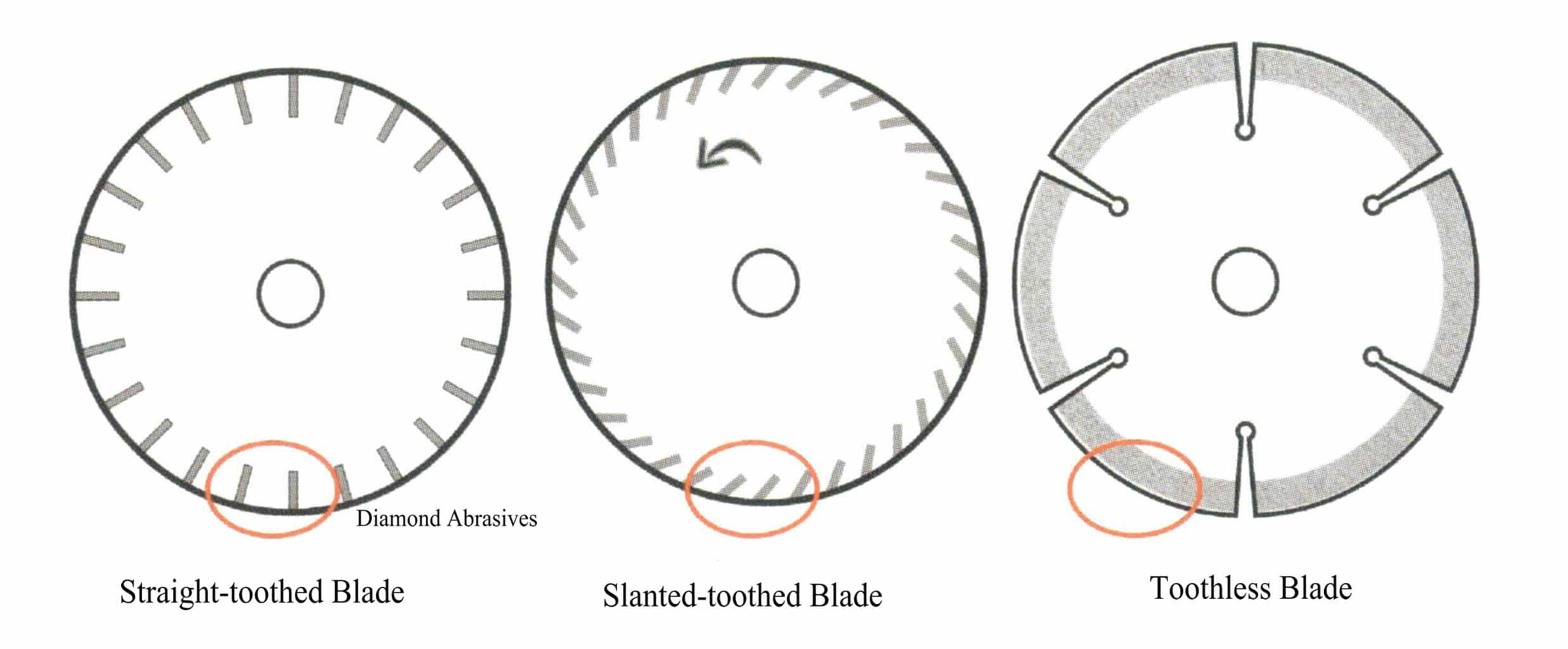

Currently, three main types of diamond ultra-thin cutting blades are available on the market.

(1) Resin-bonded diamond ultra-thin cutting disc

Using resin as a binder, the diamond micro-powder is bonded together. This diamond ultra-thin cutting disc type generally has a short lifespan, is not very sharp, and is prone to deviation.

(2) Electroplated diamond ultra-thin cutting disc (Figure 4-11)

A layer of diamond micro-powder is electroplated around the metal edge of the saw blade, which fundamentally addresses the strength deficiency of the ultra-thin substrate and compensates for some shortcomings of the resin method. It is currently a commonly used cutting disc in gemstone processing.

(3) Metal-bonded diamond ultra-thin cutting disc

Mixed with metal powder and diamond micro-powder, it sintered to form; although there are some breakthroughs in lifespan and overall strength, its thickness can only be made above 0.3 mm, and it cannot be made below 0.3 mm, which is also one of the reasons why metal-bonded diamond ultra-thin cutting discs are expensive.

4.2 Technical performance and selection of diamond cutting saw blades

(1) Requirements for saw blade technical performance

The diamond powder particle size on the saw blade cutting edge must be uniform and firmly adhered to, and the flatness of the blade base must be good enough to ensure that there is no jumping during cutting.

(2) Principles for Selecting Saw Blades

- For small particle natural gemstones and precious stones, it is advisable to choose saw blades with a thin base and a small amount of diamond powder with a short lifespan and narrow blade gaps.

- For jade, low-grade gemstones, and large materials, it is advisable to choose saw blades with a thick base and a large amount of diamond powder, which have a longer lifespan and wide blade gaps.

Commonly used saw blade models for gemstone cutting are:¢110mm, ¢150mm, ¢200mm, ¢300mm, ¢400mm, ¢500mm. Thickness 0.15-3 mm. Common hole diameters ¢25mm, ¢20mm.

5. Gem Cutting Techniques and Technology

Artificial Gem Cutting Case

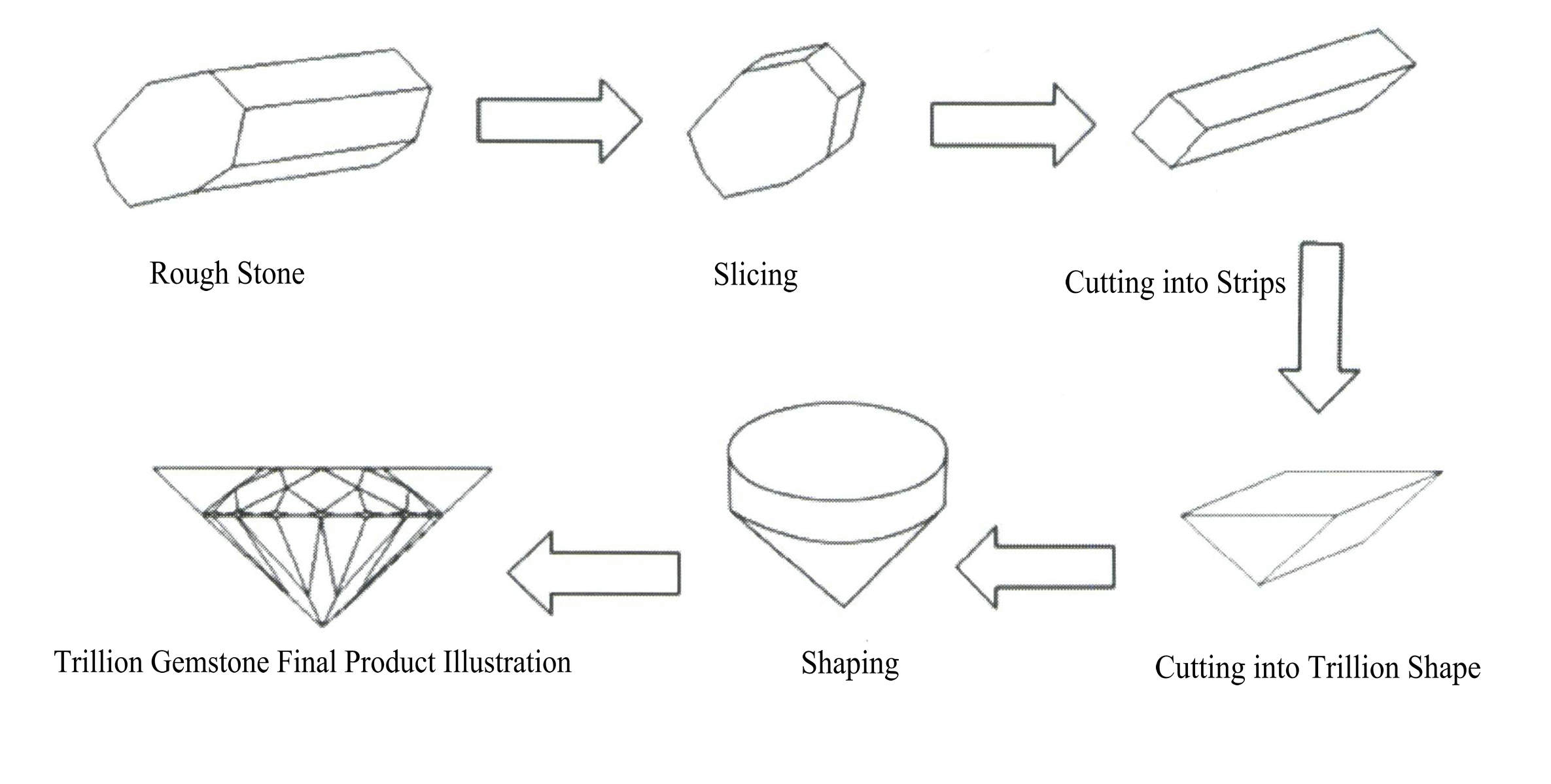

(1) Triangle Tile Cutting Process Flow

The main process of triangle tile cutting is slicing, cutting strips, and cutting triangle particles into a certain shape, as shown in Figure 4-12. The stone waste produced from triangle tile material is shown in Figure 4-13.

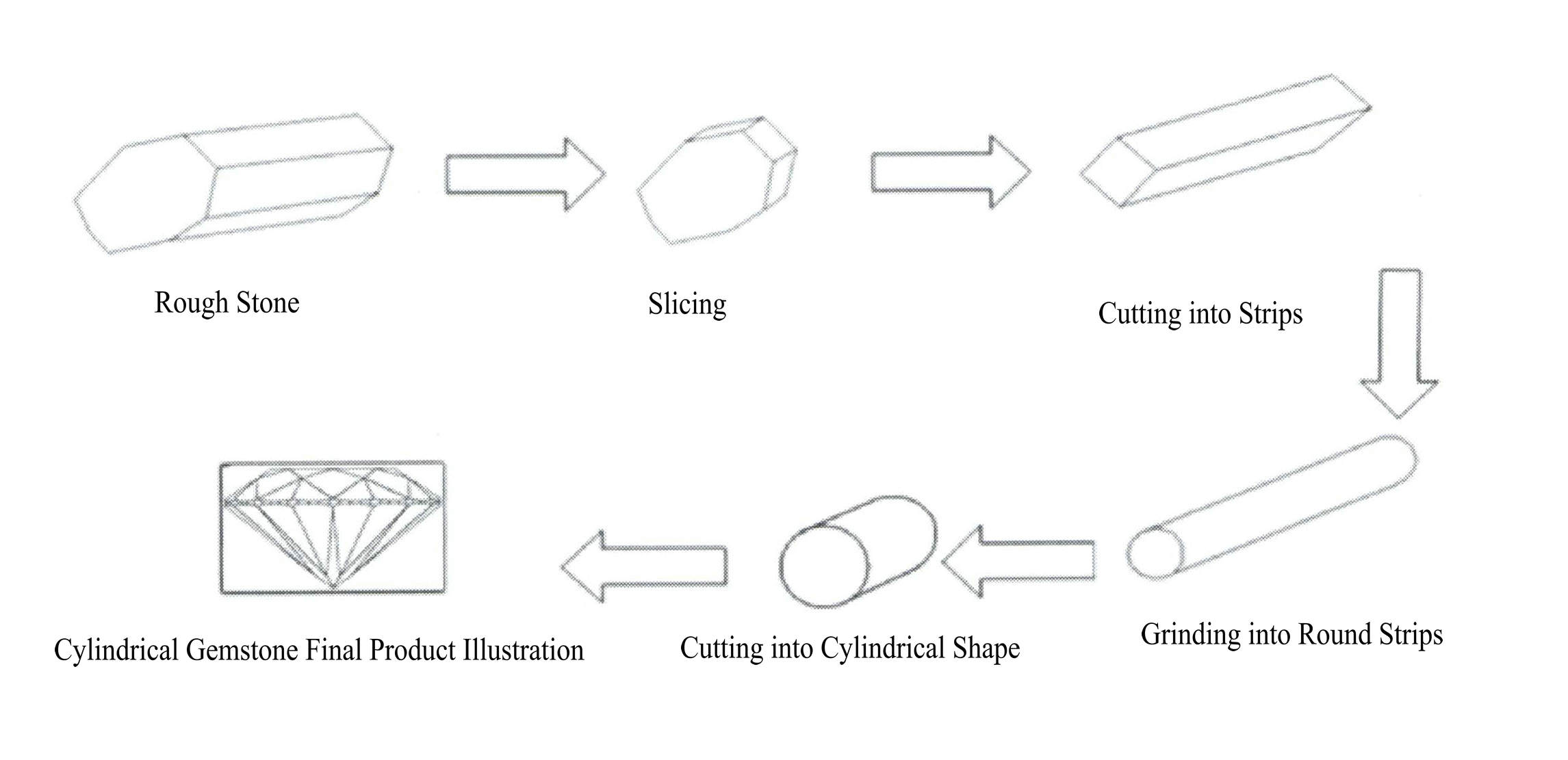

(2) Cylinder Blank Cutting Process Flow

The main process of cutting cylinder blanks is slicing – cutting strips – grinding round bars – cutting cylinder particles, as shown in Figure 4-14. The completed cut cylinder blank is shown in Figure 4-15.

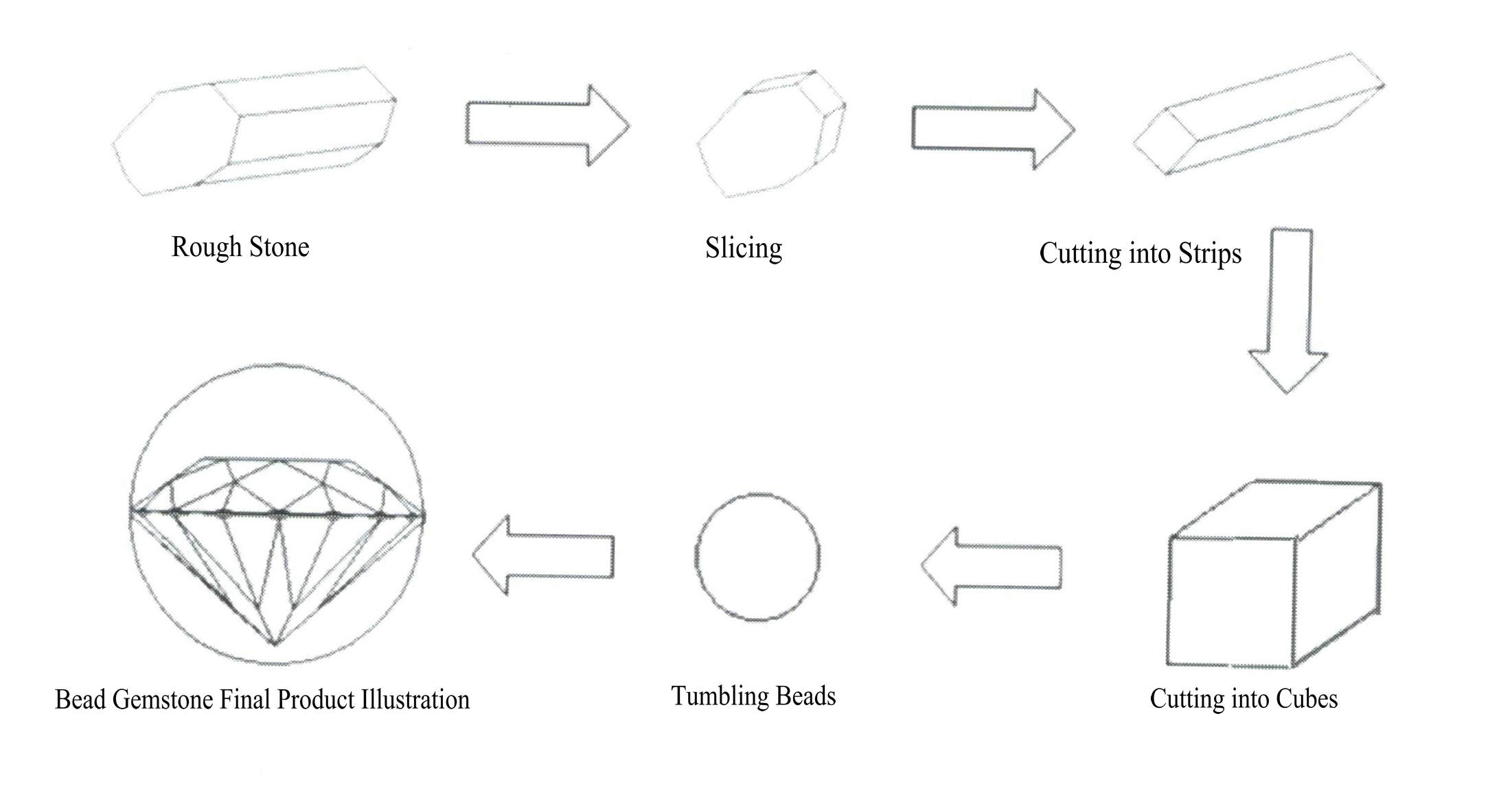

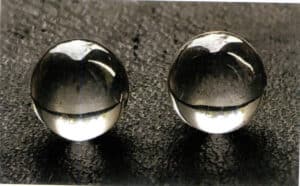

(3) Rounded Beads Blank Cutting Process Flow

The main process of the round bead blank cutting technology is slicing – cutting strips – cutting cubes into a batch of round beads, as shown in Figure 4-16. The completed cut round beads are shown in Figure 4-17.

6. Calculation of Gem Cutting Dimensions

6.1 Calculation and Requirements for Gem Cutting Dimensions

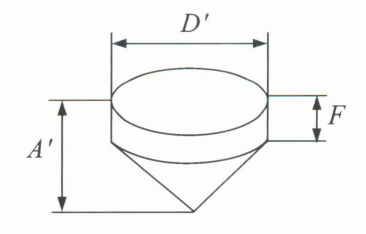

The designer determines the size of the finished gemstone products based on the size of the jewelry. During the actual processing, each step must also reserve processing allowances, such as in the stone cutting process, the stone shaping process, the stone waistline and tabletop polishing process, the gemstone grinding and polishing process, etc. Table 4-1 lists the cutting technology data for synthetic gemstone products, detailing the processing allowances for each step, which can also be referenced for natural gemstones.

Table 4-1 Cutting technology data for synthetic cubic zirconia products

| Υπόμνημα |

|

|

|

||||

| Diameter D | Product Size | Stone Cut Size | Half-Finished Stone Size | ||||

| Total Height A | Crown Height B | Belt width C | Total Height A’ | Width D’ | Total Height A’ | Above Girdle Height F | |

| 2 | 1.2〜1.3 | 0. 46 | 0.04 | 1. 5〜1. 6 | 2.3 | 1. 5〜1. 6 | 0.53 |

| 2.25 | 1. 35〜1. 46 | 0.52 | 0.045 | 1. 65〜1. 76 | 2.6 | 1. 65〜1. 76 | 0.60 |

| 2.5 | 1. 5〜1. 63 | 0.58 | 0.5 | 1. 8〜1. 93 | 2.8 | 1. 8〜1. 93 | 0.66 |

| 2.75 | 1. 65〜1. 79 | 0.63 | 0.055 | 1. 95〜2. 09 | 3.1 | 1. 95〜2. 09 | 0. 72 |

| 3 | 1. 8〜1. 95 | 0.69 | 0.06 | 2. 1〜2. 25 | 3.4 | 2. 1〜2. 25 | 0.8 |

| 3.5 | 2. 1〜2. 28 | 0.81 | 0.07 | 2. 4〜2. 58 | 3. 8〜4 | 2. 4〜2. 58 | 0.93 |

| 4 | 2. 4〜2. 6 | 0.92 | 0.08 | 2. 7〜2. 9 | 4. 3〜4. 5 | 2. 7〜2. 9 | 1.05 |

| 4.5 | 2. 7〜2. 93 | 1.04 | 0.09 | 3〜3. 32 | 4. 8〜5. | 3〜3. 32 | 1.15 |

| 5 | 3〜3. 35 | 1.15 | 0.1 | 3. 3〜3. 55 | 5. 3〜5. 5 | 3. 3〜3. 55 | 1.2 |

| 5.25 | 3. 15〜3. 41 | 1.2 | 0.105 | 3. 45〜3. 71 | 5. 55〜5. 75 | 3. 45〜3. 71 | 1.36 |

| 5.5 | 3. 3〜3. 58 | 1.27 | 0.11 | 3. 6〜3. 88 | 5.8 〜6 | 3. 6〜3. 88 | 1.45 |

| 6 | 3. 6〜3. 9 | 1.38 | 0.12 | 3. 9〜4. 2 | 6. 3〜6. 5 | 3. 9〜4. 2 | 1.55 |

| 7 | 4. 2〜4. 55 | 1.61 | 0.14 | 4. 5〜4. 85 | 7. 3〜7. 5 | 4. 5〜4. 85 | 1.0 |

| 8 | 4. 8〜5. 2 | 1.84 | 0.02 | 5. 1〜5. 5 | 8.3〜 8.5 | 5. 1〜5. 5 | 1.92 |

Note: This table is calculated based on synthetic cubic zirconia materials; other materials can be referenced.

6.2 Gemstone cutting yield

In enterprise production, the cost of gemstone products mainly depends on the yield and the cost of polishing. Natural gemstones are calculated based on the number of rough stones mined per kilogram of raw material. Natural gemstone cutting requires the removal of cracks and impurities, with yields varying from 5% to-30%. The yield of manual cutting mainly depends on the skill level of the stone cutter, while the yield of mechanized cutting mainly depends on the performance of the equipment. Wire-cutting equipment has the highest yield, followed by multi-blade cutting machines, and the yield of manual gemstone cutting is calculated based on how many pieces of the same specification can be cut from one kilogram of raw material (Table 4-2).

Table 4-2 Combined Mining Rate of Cubic Zirconia Cutting Tool

Unit: Grain/kg

| Circular specifications | Quantity | Irregular specifications (mm x mm ) | Quantity |

|---|---|---|---|

| ¢1 | 23000 | 2x4 | 3000 |

| ¢1.5 | 13000 | 3x5 | 1500 |

| ¢ 2 | 7000 | 4x6 | 1200 |

| ¢ 2.5 | 5000 | 5x7 | 800 |

| ¢ 3 | 3200 | 6x8 | 550 |

| ¢ 3.5 | 2400 | 7x9 | 400 |

| ¢ 4 | 1700 | 8 x 10 | 290 |

| ¢ 4.5 | 1500 | 9 x 11 | 210 |

| ¢ 5 | 1300 | 10 x 12 | 160 |

| ¢ 5.5 | 870 | 12 x 14 | 100 |

7. Common Measuring Tools for Gem Processing

7.1 Structure and Use of the Vernier Caliper

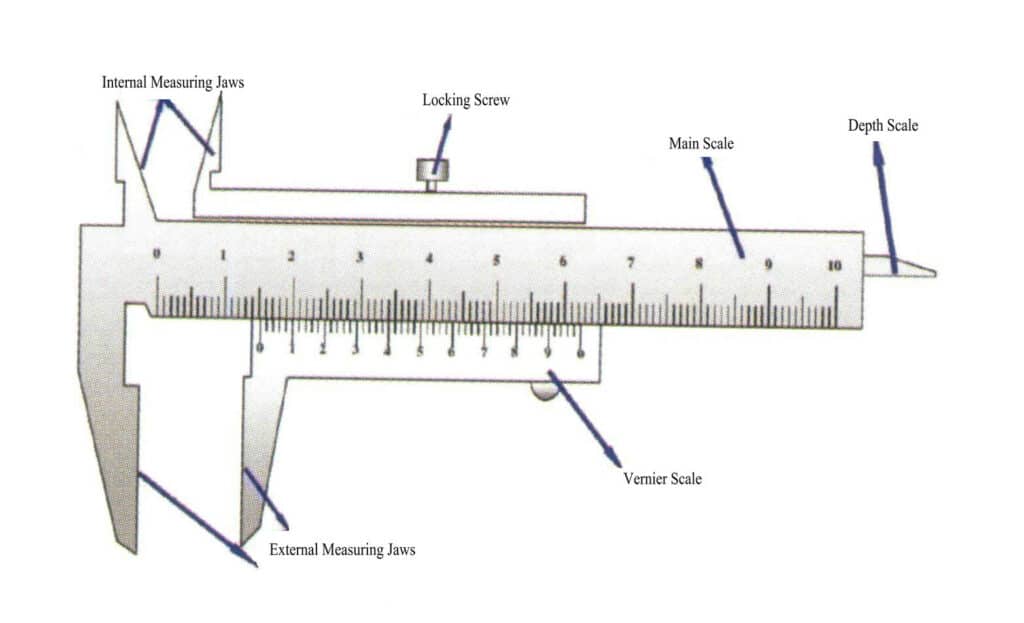

(1) Structure of the Vernier Caliper (Figure 4-18)

The Vernier Caliper consists of a main scale, a sliding scale, a depth gauge, a locking screw, external measuring jaws, and internal measuring jaws.

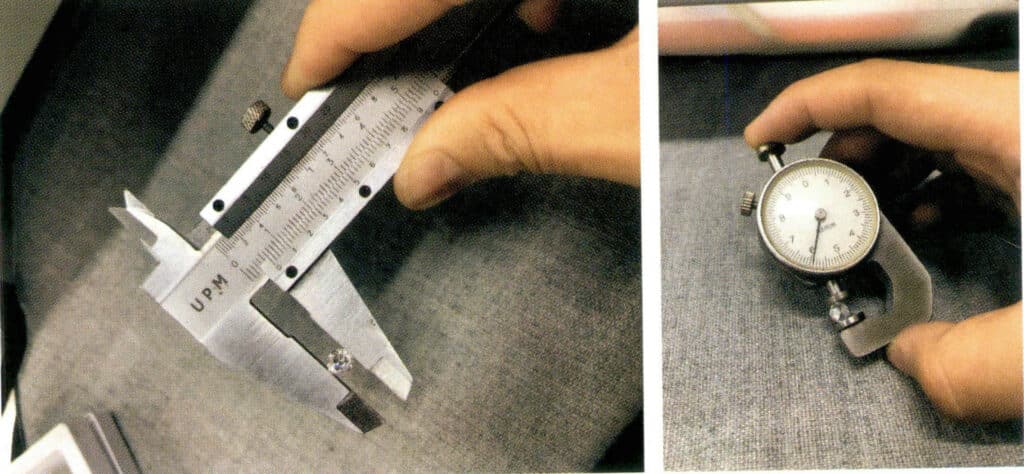

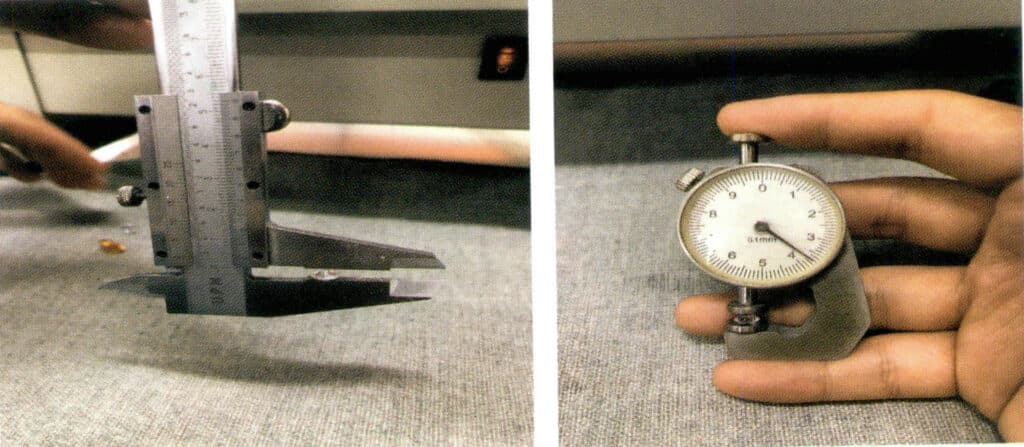

(2) Use of the Vernier Caliper in Gem Processing

Measure the inner and outer diameters of the gem, as shown in Figure 4-19. Measure depth, height, and various other measurement purposes, as shown in Figure 4-20.

(3) Reading of the vernier caliper and measurement error

Both the main scale and the vernier scale have graduations. Taking a vernier caliper accurate to 0.1 mm as an example, the smallest division on the main scale is 1 mm, and the vernier scale has ten small equal divisions, with a total length of 9 mm, each division being 0.9 mm, which differs from the smallest division on the main scale by 0.1 mm. When the measuring jaws are closed, the zero graduation lines of the main scale and the vernier align, with their first graduation line differing by 0.1 mm, the second graduation line differing by 0.2 mm, and the 10th graduation line differing by 1 mm, meaning the 10th graduation line of the vernier aligns exactly with the 9 mm graduation line of the main scale.

(4) Precautions for Using a Caliper

- A caliper is a precision measuring tool and should be handled gently to avoid collisions or falls from heights. It is unsuitable for measuring rough objects to prevent damage to the measuring jaws, and when not in use, it should be stored in a dry place to prevent rust.

- When measuring, first loosen the fastening screws, and do not apply excessive force when moving the caliper. The two measuring jaws should not be too tight when clamping the object to be measured, but the object should not move within the jaws.

- When reading the measurement, the line of sight should be perpendicular to the scale. If a fixed reading is needed, the caliper can be secured to the scale body with fastening screws to prevent sliding.

- During actual measurements, the same length should be measured multiple times, and the average value should be taken to eliminate random errors.

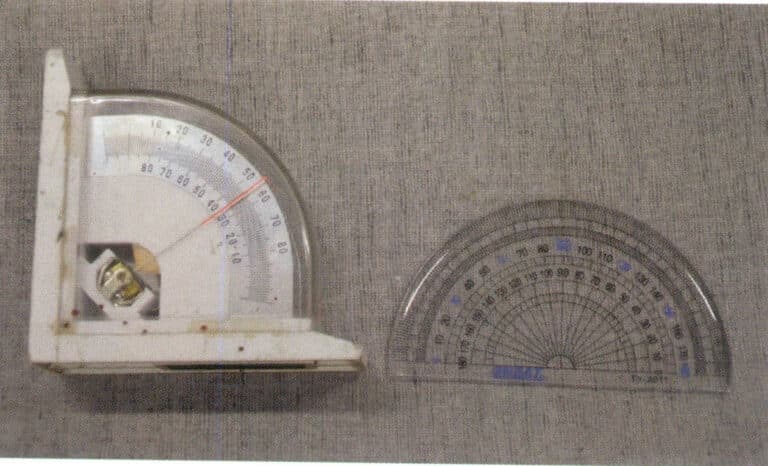

7.2 Angle Measurement Tools

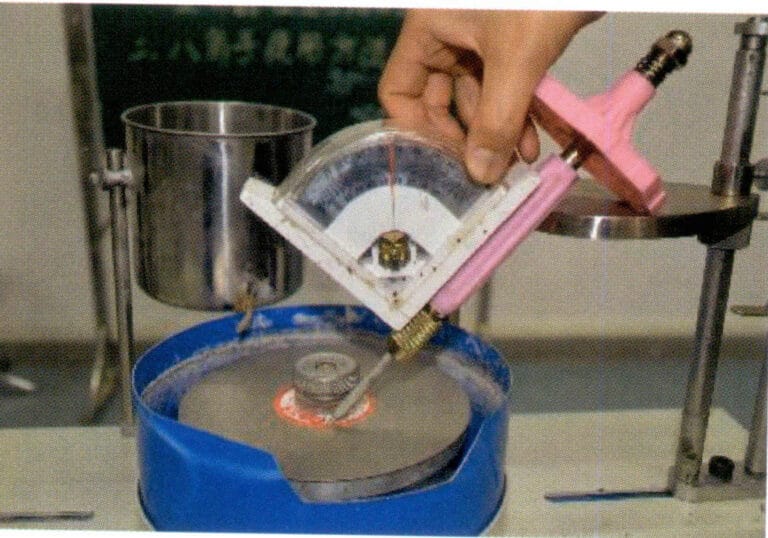

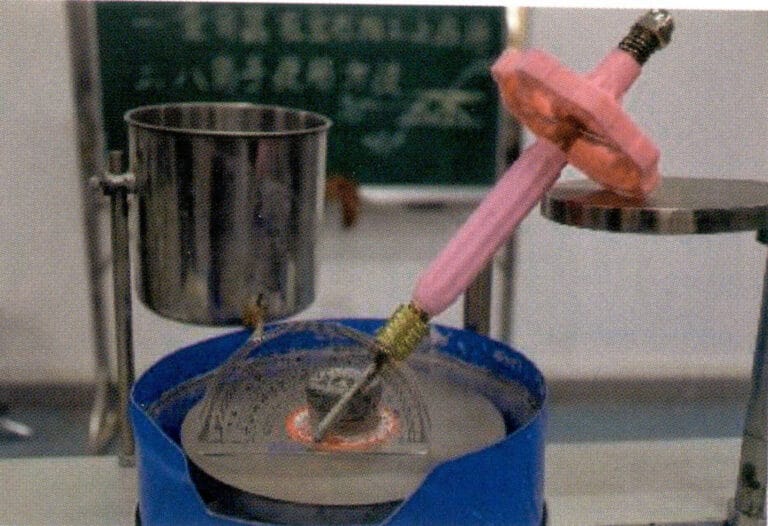

The design angle of the gemstone is measured using angle measurement tools during gemstone processing. Commonly used measuring tools include magnetic pointer protractors and angle measurement tools (Figure 4-21).

(1) How to Use the Magnetic Pointer Protractor

Insert a non-adhesive iron rod into the octagonal hand, then place the octagonal hand on the lifting platform of the gemstone machine. Adjust the height of the lifting platform until the protractor indicates the polishing angle designed for the gemstone, as shown in Figure 4-22.

(2) How to use a protractor

A standard protractor is shown in Figure 4-23. Align the center of the protractor with the centerline of the iron rod, then place the octagonal handle on the lifting platform of the gem machine, and adjust the lifting platform’s height until the iron rod’s central axis is consistent with the angle designed for the gem.

8. Examples of enterprise gem cutting production

(1) Single Blade Cutting of Gemstone Materials Example (Figure 4-24)

Single Blade Gem Cutting Tutorial Video

(2) Multi-Blade Cutting of Gemstone Examples

Multi-Blade Gem Cutting Tutorial Video

2 Απαντήσεις

Me gustó mucho el artículo sobre el trabajo con Gemas, Muy instructivo, gracias.

Saludos desde Córdoba, Argentina.

Muchas Gracias.

Olá Córdoba, Fico feliz por saber que este artigo é útil para si. Desejo-lhe sempre boa sorte.