Co dělá dřevěné ozdoby tak jedinečnými: Jaké vzácné dřevo a řemeslné zpracování zdobí ozdoby?

Objevte kouzlo dřevěných ozdob: Vyzkoušejte si, jak se z přírody vytváří krása

Dřevo pochází z přírody a odjakživa se používalo při výrobě řemeslných výrobků. S návratem lidí k jednoduchosti a obdivu k přírodě se dřevo začalo používat k výrobě doplňků, čímž se dosáhlo dobrého tržního efektu. Tyto doplňky, vyrobené výhradně z přírodních dřevěných materiálů, jsou estetické a vyhovují snaze lidí o ochranu životního prostředí, módu a individualitu, a stávají se tak na trhu nově oblíbenými.

Existuje mnoho druhů dřeva a dřevo používané na ozdoby se obvykle vybírá z méně obvyklých a vzácnějších druhů, jako je agarové dřevo, palisandr, tmavé dřevo, santalové dřevo, čínské nanmu a zkamenělé dřevo.

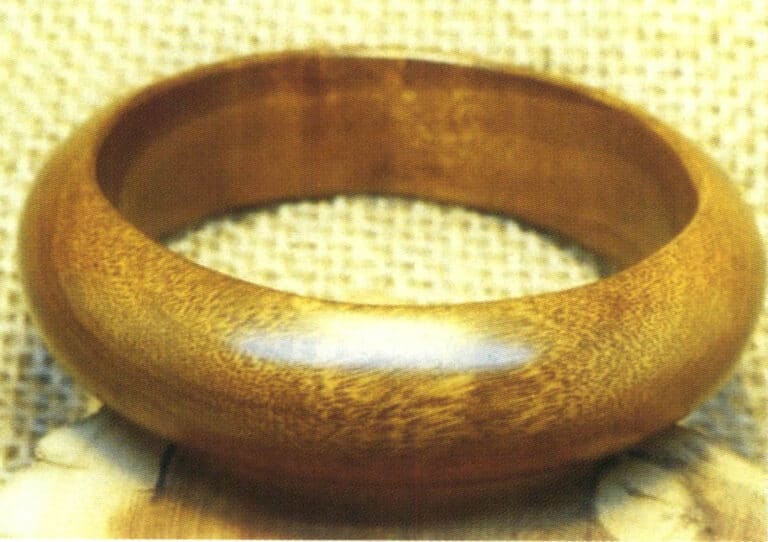

Náramek z agarového dřeva

Obsah

Sekce I Agarwood a příslušenství

1. Úvod do dřeva agarwood

Agarwood je známý jako "diamant mezi rostlinami". Shromažďuje duchovní energii nebe a země, spojuje v sobě esenci Slunce a Měsíce a je zušlechtěno časem, neboť je od pradávna považováno za nejvýznamnější mezi všemi vůněmi. "Sandálové dřevo, agarové dřevo a dračí krev", o nichž se často zmiňují starověcí lidé, se vztahují k agarovému dřevu. Jako nositel tradiční čínské kultury dnes agarové dřevo přitahuje stále více lidí, kteří ho oceňují a studují. Může být dekorativním doplňkem pro zvýšení osobního kouzla a může se používat do kadidla pro zklidnění mysli a zmírnění stresu. Je také velmi cenným léčivým materiálem.

Agarwood a agarwoodový strom jsou dva různé pojmy. Agarwood tree označuje hostitele agarwood, který patří do čeledi dvouděložných rostlin Thymelaeaceae a je stálezelený strom. Na některých místech se tento strom nazývá přímo agarové dřevo a část, která nevytvořila pryskyřici, se nazývá agarové dřevo. Agarwoodové stromy rostou především v subtropických oblastech, jako je Guangdong, Guangxi, Hainan a Taiwan, a také v Číně a v zemích jihovýchodní Asie, jako je Vietnam, Malajsie, Indonésie a Filipíny. Když se na povrchu nebo uvnitř stromu agarwood vytvoří rána, kolem poraněného místa se nahromadí pryskyřice, která ho chrání. Když koncentrace nahromaděné pryskyřice dosáhne určité úrovně, může být tato část sklizena jako použitelné agarové dřevo. Rány však nejsou jediným důvodem hromadění pryskyřice; pryskyřice z agarového dřeva se může přirozeně tvořit také v nitru stromu a na ztrouchnivělých místech. Agarwood je směs dřevních složek, která obsahuje agarwoodovou pryskyřici a tukovou složku známou jako "agarol". Ve staré Číně bylo agarové dřevo klasifikováno jako "dřevo" a označováno jako "medové dřevo" nebo "vonné dřevo".

2. Podmínky pro vznik agarového dřeva

Vznik agarového dřeva je velmi vzácný a požadavky na přírodní podmínky jsou velmi přísné; musí být splněny alespoň následující podmínky.

(1) Aby mohlo vzniknout agarové dřevo, musí nejprve existovat agarové stromy, což je předpokladem pro tvorbu pryskyřice.

Čtyři hlavní druhy stromů z čeledi burseraceae, lauraceae, thymelaeaceae a euphorbiaceae mohou produkovat agarové dřevo, z nichž nejkvalitnější agarové dřevo často pochází z agarového stromu z čeledi thymelaeaceae. Většina agarového dřeva, které je dnes na trhu, pochází z agarového stromu z čeledi thymelaeaceae. Proces vzniku agarového dřeva ve stromu agarwood je dlouhý a nároky na podmínky vzniku agarového dřeva jsou obzvláště vysoké. Proto je podíl tvorby agarového dřeva u tohoto druhu stromu poměrně nízký.

Dřevina agarwood z čeledi thymelaeaceae má velmi vysoké nároky na prostředí, ve kterém roste, včetně půdy, teploty a vlhkosti. Pro jeho růst jsou vhodné pouze teplé a vlhké oblasti jihovýchodní Asie. Jakmile teplota v jeho prostředí klesne pod -2 ℃, bude přežití agarového dřeva ohroženo a bude pro něj obtížné přežít i v případě přesazení na jiná místa. Tento druh stromu má navíc křehké dřevo a jeho větve se snadno lámou, což může vést ke zranění nebo dokonce smrti, takže je obtížné přežít v oblastech se silnými větry a pískem. Aby strom agarwood mohl produkovat uspokojivé agarwoodové dřevo, musí mít výše zmíněné životní podmínky a musí mít zralé a dobře vyvinuté pryskyřičné žlázy, které se obvykle vyskytují pouze u stromů, které rostou již několik desetiletí. Kvůli špatné přizpůsobivosti prostředí se stromy agarwood ve volné přírodě obvykle dožívají jen jednoho až maximálně dvou set let.

(2) Složitý proces výroby pryskyřice - rány v kombinaci s dlouhým procesem stárnutí.

To je začátek, kdy strom agarwood najde vhodné prostředí pro svůj růst a zrání. Poté musí čekat na různé náhody v přírodě, které mu dají šanci produkovat pryskyřici.

Po poškození se na stromu agarového dřeva vytvoří rány. Mezi tato poškození patří úder blesku, eroze způsobená větrem a pískem, kousnutí hmyzem a mravenci, řezné rány od nože či sekery nebo poranění zvířaty. Při těchto zraněních může mít agarové dřevo možnost produkovat vůni, ale není to absolutní. Pokud se tyto rány rychle nezahojí, může se okolní tkáň infikovat bakteriemi. Pokud dojde k poranění, začne stromová míza v agarovém dřevě fungovat podobně jako lidský imunitní systém, který mutuje. aby se vytvořila olejová hmota podobná pastě. To má zabránit hnilobě dřevní tkáně v důsledku poškození. Tato olejová hmota se průběžně šíří podél dřevních cév agarového dřeva a po určité době zrání vytvoří směs oleje a dřeva. Tento proces je procesem tvorby agarového dřeva.

(3) Pokračování kadidla - různé změny aromatické části

Olej z agarového dřeva (agarol) v agarovém dřevě je aktivní a v průběhu času se mění a se změnami prostředí se mění i jeho vlastnosti. V důsledku toho dojde poté, co agarové dřevo úspěšně produkuje pryskyřici, především k následujícím situacím.

- Olej z agarového dřeva ulpívá uvnitř agarového dřeva a vytváří vůni a agarové dřevo jako nosič poskytuje různé podmínky pro nepřetržitý růst a šíření agarové vůně, například živiny. Proto se agarový olej uvnitř agarového dřeva neustále šíří a kvalita oleje se zlepšuje.

- Aromatická část opustila agarové dřevo a spadla do bahnité vody nebo půdy. V tomto okamžiku již není tělo stromu, které by aromatické části poskytovalo živiny, aromatická část se přestane šířit a s prostředím se změní i její tvar, barva atd. Zůstane-li agarové dřevo v takovém prostředí delší dobu, zkazí se nebo zvětrá a nakonec zmizí. Pokud má však opadaná aromatická část vysoký obsah oleje, může skořápka po zvětrání chránit vnitřní oleje a zachovat je.

- Aromatická část stále ulpívá na agarovém dřevě, ale to nakonec odumře a rozpadne se. Zbytky aromatické části v těle stromu mohou ještě nějakou dobu růst nebo přímo přestat růst v závislosti na různých podmínkách rozkladu agarového dřeva. Bez ohledu na aromatickou část se aktivní oleje uvnitř po určitou dobu zachovají, během níž agarwood s vyšším obsahem oleje průběžně mění svůj vzhled a vytváří různé vůně v průběhu času a se změnami prostředí.

3. Klasifikace agarového dřeva

Různé metody klasifikace agarového dřeva lze rozdělit na základě způsobu jeho tvorby, kvality, původu, vůně a dalších aspektů.

(1) Klasifikace na základě změn aromatické části

Aromatická část živého agarového dřeva je "zelené agarové dřevo". Naproti tomu vonná látka získaná z kůry agarového stromu nebo mrtvého agarového stromu se nazývá "zralé agarové dřevo", známé také jako "vyzrálé kadidlo" nebo "mrtvé kadidlo". Obvykle se mezi nimi rozlišuje na základě vůně a vzhledu.

Vůně "zeleného agarového dřeva" má svěží sladkost a chladivost, ale vzhledem ke krátké době, za kterou se kadidlo vytvoří, vnitřní vlhkost ještě nevyschla a stáří pryskyřice je příliš nízké; často nese určitý stupeň svíravé chuti a nadměrnou vlhkost. Vůně "zralého agarového dřeva" se přiklání spíše k bohaté medové a mléčné chuti, ale protože jeho tělo bylo dlouho v půdě, obsahuje více nečistot nebo dřevité složky uvnitř kadidla prošly plísňovými změnami v prostředí, často nese určitý stupeň plesnivé a kyselé chuti.

Olej ze "zeleného agarového dřeva" se rozptyluje a roste podél dřevěných kanálků, takže jeho olejové linie jsou výraznější, blíže ke dřevu, a když se oholí nožem, působí dřevěnějším dojmem. Doba růstu "zralého agarového dřeva" je obecně delší a je značně ovlivněna prostředím; jeho povrchové olejové linie nejsou příliš výrazné a obvykle má křehčí strukturu, která při holení nožem působí drobivým dojmem.

(2) Klasifikace jakosti pryskyřičných olejů

Předpokládejme, že vnitřní míza dřeva je hojná a bohatá na živiny, když rána na dřevě agaru zasahuje hluboko do dřeva. V takovém případě je často snazší získat agarové dřevo s tmavší barvou a bohatším obsahem oleje, označované jako jádrové olejové agarové dřevo. Jádrové olejové agarové dřevo má husté olejové linie, většinou černý olej. Když obsah oleje dosáhne určité úrovně, klesne do vody, což je považováno za vysoce kvalitní agarové dřevo. Různá poloha agarwood, doba a velikost poranění, mimo jiné vnější faktory, mohou ovlivnit podobu dřevěného olejového agarwood.

Pokud je strom poškozen pouze na povrchu kůry, olej z agarového dřeva stéká po povrchových cévách kůry a zůstává na povrchu kůry, což se označuje jako agarwood s okrajovým olejem. Agarwood s olejem z okrajové kůry má často tenčí vrstvu oleje, která se objevuje v tenkých vrstvách, což ztěžuje tvorbu silné aromatické části. Po zahřátí se olej rychle zcela odpaří. Agarwood s olejovou kůrou na okrajích lze také rozdělit na agarwood s olejovou výpustí a agarwood s kůrou a pryskyřicí, přičemž agarwood s olejovou výpustí se nachází v blízkosti dřevní části a agarwood s kůrou a pryskyřicí se tvoří přímo na kůře.

(3) Klasifikace na základě morfologických vlastností rostliny

Vlivem různých vnějších faktorů může mít agarové dřevo různé fyzikální vlastnosti, které lze rozdělit na následující typické odrůdy.

① Pařezové dřevo. When sekery nebo pily poranily agarové dřevo, nebo bylo tělo stromu zlomeno příčně, výsledné rány jsou často plošné. Takové velkoplošné rány vytvářejí tenké, husté, olejovité aromatické tělo, které se nazývá pařezové agarové dřevo. Mezi jeho vlastnosti patří nepravidelný tvar a ploché aromatické tělo. Protože rány pařezového agarového dřeva mají příčný průřez vůči tělu stromu, jeho olejové linie se nerozkládají lineárně podél cévního systému stromu, ale jeví se jako bodové, rovinné rozložení podobné průřezu cév.

② Hmyzem navrtané agarové dřevo. Voňavé tělísko, které vzniká z ranek agarového dřeva způsobených bodnutím hmyzem, se nazývá agarové dřevo, které má jedinečný tvar a zpravidla se spirálovitě stáčí. Rány po kousnutí hmyzem mají obvykle jeden hmyzí otvor, kterým hmyz vodorovně nebo šikmo prokousne kanálky agarového dřeva, což způsobí, že se kolem hmyzí cesty vytvoří agarový olej. U každého kusu agarového dřeva s hmyzími otvory lze nalézt alespoň jeden hmyzí otvor, což je významná charakteristika agarového dřeva s hmyzími otvory.

Agarwood pařezový

Agarwood napadený hmyzem

③ Agarwood s padlým kmenem. Termín "agarwood s padlým kmenem" pochází ze zvláštní situace při sběru agarwoodového dřeva pěstiteli kadidla. Strom agarového dřeva je již dávno mrtvý, leží v půdě nebo v bažině, ale samotné aromatické tělo ve stromě stále existuje. Dřevité složky stromu se působením mikroorganismů a vnějších vlivů prostředí rozpadly a zvětraly. Přesto se aromatické tělo zachovalo neporušené a svým tvarem připomíná spadlý stojan. Proto se mu říká agarwood padlého kmene.

④ Agarwood ponořený do vody (známý také jako Water Pattern Agarwood, Water Grid Agarwood). Jedná se o termín vytvořený pěstiteli kadidla, který označuje aromatickou část, jež se oddělila od stromu a dostala se do vlhkého bahna nebo bažin, kde dozrála a vytvořila agarové dřevo. Ve vodě ponořené agarové dřevo má často tmavou barvu a díky vlhkému prostředí v pozdějších fázích je méně ovlivněno povětrnostními vlivy, díky čemuž jsou viditelné olejové vzory. Ve vodě potopené agarové dřevo má tvrdou strukturu a velkou houževnatost a aromatické tělo je obvykle poměrně husté.

Agarwood s padlým kmenem

Agarwood potopený vodou

⑤ Zemní agarové dřevo. Je to také druh vyzrálého agarového dřeva. Když aromatické tělo opadá nebo agarové dřevo přirozeně odumře, aromatické tělo padá do sušší půdy. Poté je aromatické tělo značně ovlivněno zvětráváním a vytváří sypkou a pórovitou strukturu, která se nazývá agarwood zemního stáří. Když je pohřbeno v půdě, jeho barva bude ovlivněna kvalitou půdy a barvou jejích příměsí. Vzhled agarového dřeva zrajícího na zemi se liší v závislosti na stupni zrání a zvětrávání. Dřeva s menším zvětráváním mají tvrdý vnější povrch a husté aromatické tělo; dřeva se silným zvětráváním mají obvykle porézní povrch a křehkou strukturu.

⑥ Mravenčí hnízdo agarwood. Je velmi podobný hmyzímu agarovému dřevu, které také vzniká po bodnutí hmyzem a včelím žihadlem, ale mravenčí agarové dřevo se obecně vztahuje na dřevo s vyšším obsahem oleje a je starší. Vůně agarového dřeva z mravenišť je obecně sladší a bohatší než vůně agarového dřeva z hmyzích děr, zatímco vůně agarového dřeva z hmyzích děr je chladnější.

Agarwood zrající na zemi

Mravenčí hnízdo agarwood

⑦ Ultimate agarwood. Jedná se o nejvyšší třídu agarového dřeva a nejzářivější hvězdu mezi kořením. Barva oleje Kyara je velmi bohatá, převážně zelená, ale obsahuje také černý olej, žlutý olej, červený olej a fialový olej. Podle barvy jej lze rozdělit na Kyara zelená, Kyara orchidejová, Kyara zlatožilná, Kyara cukrově hnědá, Kyara železitě černá atd.

Ultimate agarwood

Vrcholná řezba Guanyina z agarového dřeva

(4) Umělé agarové dřevo

S rostoucí oblibou trhu s agarovým dřevem se přírodní divoce rostoucí agarové dřevo ve velkém těží, čímž se přírodní zdroje stávají stále vzácnějšími. V jihovýchodní Asii je sběr agarového dřeva jednou z prací domorodých obyvatel žijících v lesích, kteří na stromu agarového dřeva náhodně způsobují rány vonným nožem, aby uměle vytvořili podmínky pro produkci pryskyřice, která může poskytnout více zdrojů a podmínek pro budoucí těžbu. Toto chování nepatří k umělému agarovému dřevu; vyrobená pryskyřice je stále divoká, protože pouze spouští podmínky pro výrobu pryskyřice, ale proces tvorby pryskyřice je stále přirozený, bez umělé katalýzy nebo zásahů. Tento tradiční a neefektivní způsob výroby pryskyřice však již nemůže uspokojit požadavky trhu s agarovým dřevem a obrovské komerční zájmy vedly k rozšíření "umělého agarového dřeva". Výroba umělých vonných látek zahrnuje umělé vrtání otvorů do stromu agarového dřeva, zatloukání hřebíků, vypalování, aplikaci hub a používání látek vyvolávajících agarwood na podporu produkce pryskyřice. Samozřejmě ne všechno umělé agarové dřevo je nekvalitní; některé mají slušný obsah oleje. Někteří bezohlední obchodníci však používají velmi špatné metody výroby vůně, využívají chemické vonné látky k vytvoření pryskyřice a některé mají pouze povrchovou vrstvu pryskyřice. Zároveň je uvnitř celé dřevo bílé. Tento typ umělého agarového dřeva nejenže nepříjemně voní, ale je také škodlivý pro tělo a jeho cena je mnohem nižší než cena čistě přírodních výrobků z agarového dřeva.

4. Řemeslné ozdoby z agarového dřeva

Vysoce kvalitní agarové dřevo se často používá na náboženské obětiny a řezby. Vzhledem k nárokům na objem a kvalitu suroviny jsou téměř všechna vyřezávaná díla nádhernými uměleckými díly s vysokou sběratelskou hodnotou, která mají v oblibě obchodníci a náboženské osobnosti, jako jsou například agarwoodové řezby Guanyin.

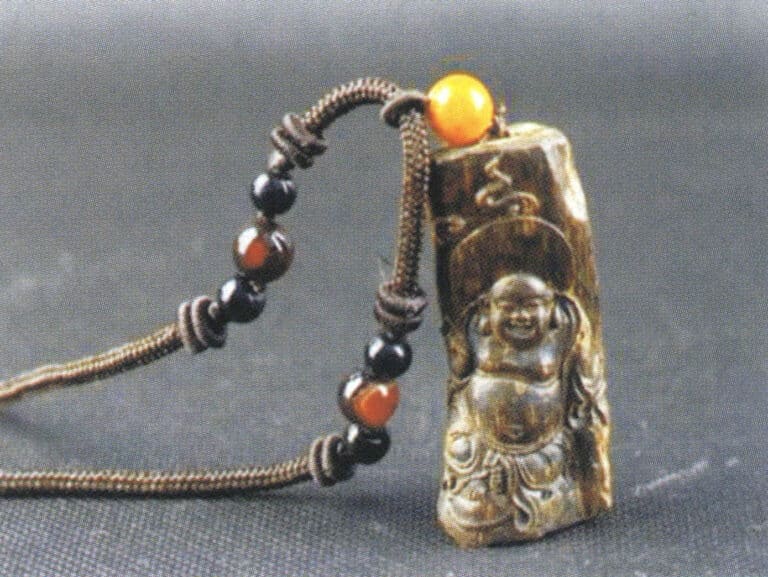

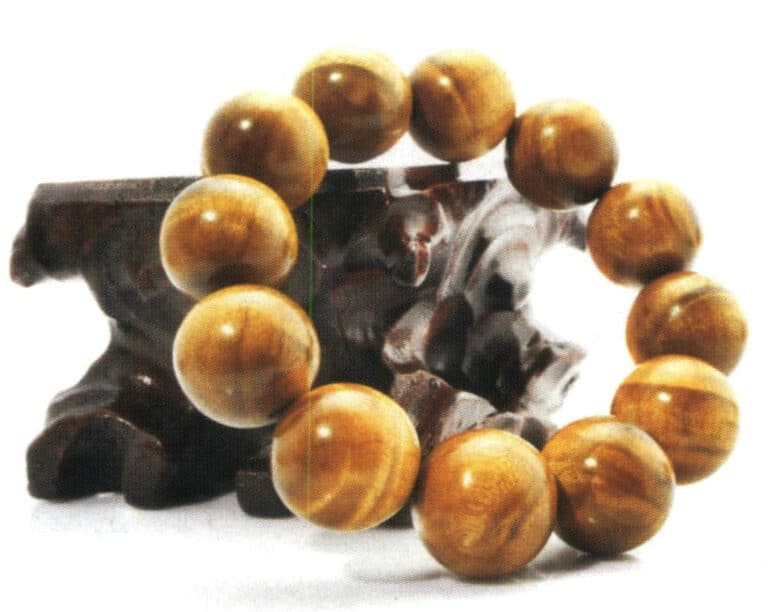

S rozvojem buddhismu a snahou lidí o módu a vkus se do života běžných lidí dostaly také doplňky z agarového dřeva, jako jsou přívěsky a náramky z agarového dřeva. Je třeba poznamenat, že vzhledem k tomu, že agarové dřevo je klasifikováno jako regulovaná rostlina, jsou pravé doplňky z agarového dřeva velmi drahé. Ačkoli má podobný vzhled a vydává vůni, většina levných doplňků z agarového dřeva prodávaných na trhu má ve srovnání s pravým agarovým dřevem značné rozdíly ve výběru materiálu a řemeslném zpracování.

Přívěsek z agarového dřeva

Náramek z agarového dřeva

Oddíl II Dřevo Huanghuali a jeho ozdoby

1. Úvod do Huanghuali

Huanghuali, vědecky známá jako Dalbergia odorifera, má odrůdy podle svého původu, včetně hainanské Huanghuali, vietnamské Huanghuali, laoské Huanghuali, africké Huanghuali a brazilské Huanghuali, přičemž nejcennější je hainanská Huanghuali. Struktura dřeva Hainan Huanghuali připomíná plynoucí mraky a vodu, má hladkou strukturu, elegantní a jemnou barvu a osvěžující vůni. Jeho jádrové dřevo je tvrdé a husté a dobře se zpracovává. Pro svou vzácnost je známé jako "panda velká mezi rostlinami" a těší se pověsti "nejdražšího dřeva v Číně". Je vysoce ceněno historicky i v moderní době a vedle červeného santalového dřeva, dřeva wenge a cejlonského železného dřeva patří mezi čtyři slavné dřeviny staré Číny. Hodnota hainanského dřeva Huanghuali začala stoupat již v době, kdy bylo poplatné dynastii Tang, a za dynastie Ming se proslavilo po celém světě, přičemž nábytek z něj vyrobený byl v té době velmi drahý. Většina špičkového nábytku vyrobeného za dynastie Ming a na počátku dynastie Qing byla vyrobena ze dřeva Huanghuali. V důsledku nadměrné těžby dřeva v předchozích dynastiích se však dostupnost dřeva Huanghuali prudce snížila a před polovinou dynastie Qing se blížila jeho vyhynutí, což vedlo k pozdějšímu používání mahagonu jako náhrady. Po dynastii Qing se toto mimořádně obtížně dostupné dřevo Huanghuali stávalo stále vzácnějším a mimořádně cenným.

Hainan Huanghuali je vonná dřevina z čeledi bobovitých, patřící do rodu Dalbergia. Je jedním z 33 druhů sekvojovce podle národního standardu pro sekvojovec, který je zařazen do pěti rodů a osmi kategorií. Jeho jádrové dřevo se nazývá "ge", což je podstata dřeva Hainan Huanghuali. Ačkoli se dřevo Huanghuali snadno pěstuje, není snadné z něj získat použitelné dřevo. Rčení "500 let roste do šířky mísy" se vztahuje k jádrovému dřevu. Říká se, že dřevo Huanghuali roste 30 let, než vyroste jen tolik, aby stačilo na malou kuličku, což zdůrazňuje obtížnost výroby dřeva. V současnosti je hainanské Huanghuali zařazeno mezi vzácné a ohrožené rostliny prvního stupně.

2. Charakteristika dřeva Huanghuali

Dřevo Huanghuali má mimořádně stabilní vlastnosti, nedeformuje se, nepraská ani se neohýbá bez ohledu na chlad nebo teplo a má určitý stupeň houževnatosti, díky čemuž je vhodné pro výrobu různého nábytku nepravidelných tvarů, jako jsou například stoly se třemi nohami, které vyžadují značný stupeň zakřivení, kterého může dosáhnout pouze dřevo Huanghuali; s jinými druhy dřeva se pracuje poměrně obtížně. Vlastnosti dřeva Huanghuali jsou dosti podobné vlastnostem jiných dřev a lze je snadno zaměnit, zejména s palisandrovým a červeným santalovým dřevem. Toto palisandrové a červené santalové dřevo pochází hlavně z oblastí Guangdong a Guangxi a z ostrova Hainan, přičemž na některých místech je označováno jako hainanské červené santalové dřevo. Jinde ho naopak nazývají vietnamským santalovým dřevem, protože tento strom roste také ve Vietnamu a okolních zemích.

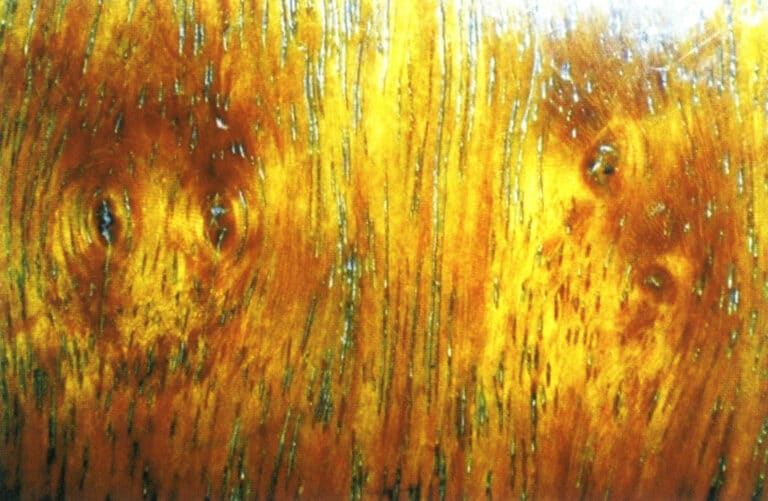

Dřevo Huanghuali je zlatožluté a teplé, jádro je tmavší červenohnědé nebo tmavě hnědé a má strukturu podobnou nosorožčímu rohu, který časem tmavě zčervená. Dřevo Huanghuali má relativně nízkou hustotu a je možná lehčí než sekvoj (palisandr). Po vložení do vody je polopotopitelné, což znamená, že se ani zcela nepotopí, ani neplave. Růstové letokruhy dřeva Huanghuali jsou zřetelné, s jasnou a zřetelnou kresbou vláken, která se přirozeně prolínají a připomínají plynoucí mraky a vodu, díky čemuž je dřevo velmi dekorativní, má jemný lesk a voní. Nejpozoruhodnější je, že kresba dřeva často obsahuje mnoho suků, které jsou zpravidla velmi hladké, nepraskají a vykazují vzory připomínající liščí hlavu, hlavu starce a vlasy starce, které jsou jedinečné a krásné, běžně označované jako "tváře duchů".

3. Klasifikace Hainan Huanghuali

(1) Klasifikace podle dřeva

Jádrové dřevo dřeva Hainan Huanghuali se průběžně mění z bělového dřeva a má bohatou škálu barev, které se liší hloubkou a velikostí. Jádrové dřevo se běžně označuje jako "zrno", přičemž větší jádrové dřevo se nazývá "pryskyřicí nasycené zrno" a menší jádrové dřevo "porézní zrno". Jádrové dřevo má různé barvy: světle žlutou, zlatožlutou, oranžově žlutou, červenohnědou, purpurově červenou a tmavě hnědou. Obvykle se pryskyřicí nasycená zrna jeví jako tmavě hnědá, zatímco porézní zrna jako červenohnědá nebo purpurově hnědá. Různé barvy také odpovídají relativní hustotě dřeva, olejnatosti a variacím vůně. Čím hlubší je barva, tím vyšší je relativní hustota; čím větší je olejnatost, tím silnější je vůně santalového dřeva; naopak, pokud je barva jádra světlejší, relativní hustota a olejnatost jsou nižší a vůně santalového dřeva je relativně slabá.

(2) Klasifikace podle olejnatosti

Rozdíly v barvě a olejnatosti Hainan Huanghuali lze rozdělit do tří kategorií: Žluté Huanghuali, Huanghuali s máslovým tukem a Huanghuali nasycené pryskyřicí.

Žluté Huanghuali je ve skutečnosti to, co lidé běžně označují jako "porézní Huanghuali". Když je staré Huanghuali nasycené pryskyřicí ponecháno delší dobu, vlivem oxidace se olej a vlhkost uvnitř dřeva postupně zmenšují. Přestože pryskyřicí nasycené Huanghuali lze stále nejasně identifikovat podle kresby, dřevo se stává drsným a ztrouchnivělým. Tento druh Hainan Huanghuali je porézní Huanghuali. Většina žlutého Huanghuali má světlejší barvu a vyšší obsah oleje, a aby se odlišila od tmavšího porézního Huanghuali, nazývá se žluté Huanghuali. Hlavními charakteristikami žlutého Huanghuali jsou jasná a hladká zrna a světlá barva, především s kruhovými vzory.

Termín Butterfat Huanghuali se používá teprve v posledních stoletích a vznikl díky aktuálnímu trhu se sekvojí. Butterfat Huanghuali si zachovává jas a půvab žlutého Huanghuali, pokud jde o strukturu a linie, ale jeho celková barva se přiklání ke žlutohnědé a na některých místech se zdá být tmavě hnědá. Největší rozdíl mezi Butterfat Huanghuali a Yellow Huanghuali spočívá v tom, že Butterfat Huanghuali se vyznačuje především duchovitými tvářemi s okouzlující a hlubší strukturou a je také bohatší na olejnatost ve srovnání se Yellow Huanghuali. Mnoho nádherných vzorů tygřích pruhů pochází z máslového Huanghuali.

Žlutá Huanghuali

Máslový tuk Huanghuali

4. Dřevěné ozdoby Huanghuali

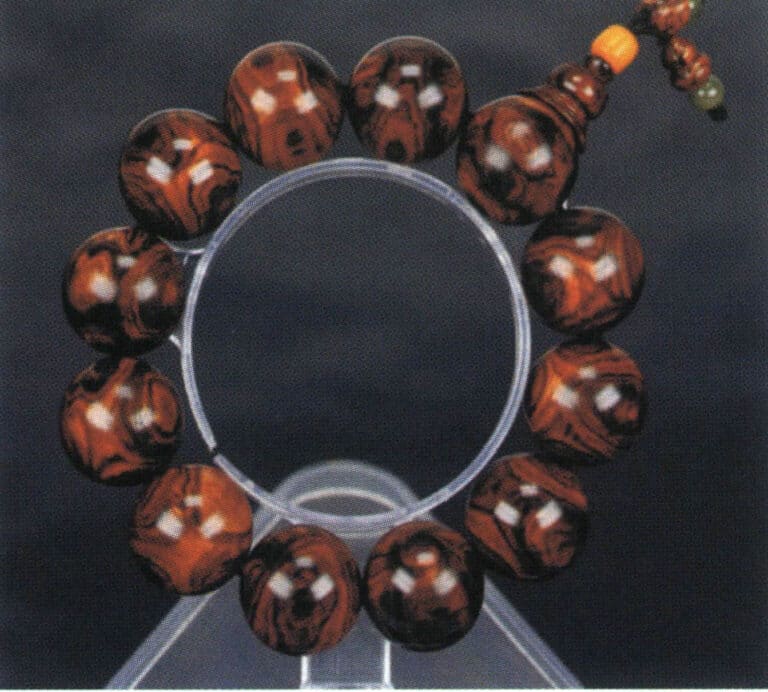

Náramek z Hainan Huanghuali

Řemeslné výrobky z Hainan Huanghuali

Oddíl III Starobylé potopené dřevo a jeho ornamenty

1. Úvod do starobylého potopeného dřeva

Starověké potopené dřevo neoznačuje pouze jeden druh dřeva, například cedr, ale je to souhrnný název pro různé druhy dřeva pohřbeného pod zemí a nerozloženého, které lze použít k výrobě předmětů. K mnoha druhům starobylého potopeného dřeva patří cypřiš, čínská jedle, nanmu, divoké liči, hořké tzu, zelené nanmu a železné dřevo. Termín "prastaré potopené dřevo" je v různých oblastech znám pod různými názvy; v povodí řeky Songhua v severovýchodní Číně se mu říká "vlnové dřevo" nebo "potopené říční dřevo", zatímco v Sečuánu je označováno jako "černé dřevo" (barva potopeného dřeva je obecně tmavá). Tyto druhy dřeva mají společné vlastnosti: jsou tvrdé, odolné proti vlhkosti, hmyzu, hnilobě, voňavé a mají vysoký obsah oleje. Jejich barvy se liší v důsledku různého stáří a stupně karbonizace; staré potopené dřevo je černé a lesklé, velmi luxusní.

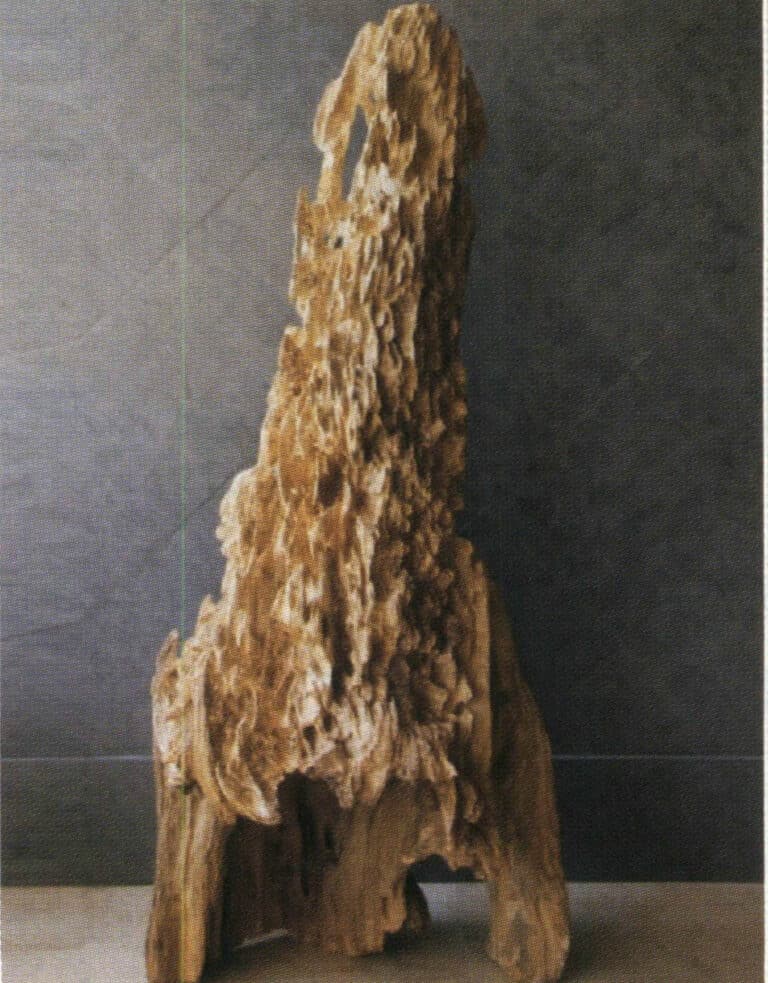

Obecně se má za to, že příčinou vzniku dávných potopených lesů jsou přirozené změny na nebeských tělesech, kdy zemětřesení, záplavy a sesuvy půdy pohřbívají veškerý suchozemský rostlinný život do dávných říčních koryt a jiných nízko položených oblastí. Některé stromy pohřbené v nánosech bahna procházejí během tisíců nebo dokonce desetitisíců let procesem karbonizace za anaerobních a vysokotlakých podmínek, kterému napomáhají bakterie a další mikroorganismy. Proto se jim také říká "karbonizované dřevo". Starobylé potopené dřevo odolalo proměnám času, bylo vystaveno různým vnějším i vnitřním přírodním silám a výsledkem jsou jeho bizarní, starobylé a elegantní přírodní tvary. Není divu, že jej cizinci po návštěvě obdivují jako "posvátné dřevo Východu".

2. Starobylé dřevěné řemeslné ozdoby z potopeného dřeva

Podstata starého potopeného dřeva je tvrdá, často se projevuje v tmavě hnědých, černočervených, zlatavých a žlutohnědých barvách. Jeho broušený povrch je hladký, s jemnou kresbou dřeva, a pokud je správně vyleštěn, může dosáhnout zrcadlového lesku. Některé starobylé potopené dřevo je ve své podstatě téměř podobné červenému santalovému dřevu.

Protože staré potopené dřevo je neobnovitelný zdroj, jeho vývoj se snižuje a některá přirozeně tvarovaná umělecká díla ze starého potopeného dřeva mají značnou sběratelskou hodnotu. V průběhu historie se starobylé potopené dřevo používalo jako talisman a vyráběly se z něj řemeslné výrobky, sošky Buddhy, amulety a další předměty. Staří lidé říkali: "Mít doma půlku kusu černého dřeva je lepší než truhla s pokladem." Vynikající vlastnosti prastarého potopeného dřeva vedly také k jeho využití při výrobě šperků. Některé příklady řemeslných šperků ze starověkého potopeného dřeva jsou následující.

18K náušnice z potopeného dřeva vykládané diamanty

Stříbrný prsten 925 vykládaný starobylým potopeným dřevem

Kopírování @ Sobling.Jewelry - Výrobce šperků na zakázku, továrna na šperky OEM a ODM

Oddíl IV Palisandr a jeho ozdoby

1. Úvod do palisandru

Čína si palisandrového dřeva cení již od starověku a je jednou z prvních zemí, která jej začala uznávat a rozvíjet. Název "palisandrové dřevo" se poprvé objevil za dynastie Jin před 1500 lety, což je zaznamenáno ve "Starověkých a moderních poznámkách" Cui Baoa, kde se uvádí: "Palisandrové dřevo, vyráběné ve Funanu, má purpurovou barvu a je také známé jako černé santalové dřevo." Znak "purpurový" symbolizuje příznivý vývoj a v kombinaci s jedinečnými vynikajícími vlastnostmi dřeva a vzácností palisandrového dřeva byl vysoce ceněn královskou rodinou v období dynastií Ming a Qing. Císaři obou dynastií nešetřili a sháněli zručné řemeslníky z celého světa, aby vytvořili různý nábytek a ozdoby z palisandrového dřeva. Na konci dynastie Ming a na začátku dynastie Čching se naprostá většina palisandrového dřeva vyrobeného po celém světě shromáždila v Číně a uskladnila v Kantonu a Pekingu.

Palisandrové dřevo se dělí především na černé a červené santalové dřevo. Černé palisandrové dřevo je běžně známé jako Louvelovo palisandrové dřevo, které patří mezi černé kyselé dřevo. Má větší a hrubší póry než druhé jmenované a jeho růstové kruhy nejsou zřejmé. Z hlediska fyzikálních vlastností jsou jeho hustota za sucha, pevnost v ohybu, modul pružnosti a podélná pevnost v tlaku nižší než u červeného santalového dřeva. Červené santalové dřevo, obecně známé jako palisandr, je jedním z nejvzácnějších dřev na světě, které se těží především v Indii, na Malajském poloostrově, na Filipínách a v menší míře v provinciích Hunan, Guangdong a Yunnan v Číně. Červené santalové dřevo roste pomalu a dlouho dozrává, takže jeho průměr je obvykle malý, obvykle do 20 cm; větší kusy bývají duté a nepoužitelné. Mezi různými druhy tvrdého dřeva má indické červené santalové dřevo nejjemnější strukturu a nejtěžší hmotnost, ve vodě se potápí. Existuje přísloví: "Devět z deseti červených santalových dřev je dutých", což poukazuje na jeho vzácnost. Na obrázku 10-2 je příklad kmenů červeného santalového dřeva.

Vzhledem k tomu, že svět dává přednost červenému santalovému dřevu, přimíchává se do něj mnoho dalších druhů dřeva, z nichž nejvýznamnější je černé palisandrové dřevo, které se vydává za indické červené santalové dřevo. Červené santalové dřevo má odlišné vlastnosti a hlavní způsoby, jak je rozlišit, jsou následující.

- Nádoby z červeného santalového dřeva jsou naplněny červenou pryskyřicí a santalovou esencí, zatímco nádoby z černého palisandru mají tmavší barvu a větší kontrast s původní barvou.

- Červené santalové dřevo má vysokou hustotu a ve vodě se potápí, zatímco černé palisandrové dřevo se někdy ve vodě potápí a někdy plave.

- Povrchový materiál červeného santalového dřeva je většinou fialově červený nebo tmavě fialově červený, zatímco čerstvě nařezaný povrch černého palisandrového dřeva je oranžově červený a po delší době se stává tmavě fialovým nebo tmavě kávovým.

- Červené santalové dřevo má fluorescenční reakci (obrázek 10-3), zatímco černé palisandrové dřevo ne.

- Červené santalové dřevo má silnější olejovitou strukturu, ale olejovitá struktura černého palisandru, který je lehčí, je slabší.

- Červené santalové dřevo nemá žádnou vůni nebo je velmi slabá, zatímco černé palisandrové dřevo má kyselou vůni.

- Struktura červeného santalového dřeva je poměrně rovná s menším množstvím vzorů, zatímco černé palisandrové dřevo má zřetelné vzory a je lokálně zvlněné.

2. Řemeslné ozdoby z palisandru

Červená spona do vlasů ze santalového dřeva

Stříbrný prsten vykládaný červeným santalovým dřevem

Náramek z červeného santalového dřeva

Přívěsek z červeného santalového dřeva

Oddíl V Zlaté nanmu a jeho ozdoby

1. Úvod do Golden Nanmu

Zlatý nanmu je obecné označení pro typ nanmu se zlatými nitkami a saténovým leskem mezi některými materiály. Jedná se o vzácné dřevo, které je v Číně jedinečné a je zařazeno mezi národní rostliny chráněné druhým stupněm. Vyskytuje se hlavně v subtropických oblastech Sečuánu, Kuej-čou, Hubeje a Hunanu v Číně, zejména ve vlhkých údolích, v nízko položených oblastech a podél řek v nadmořské výšce 1000 ~ 1500 m. Podnebí je zde teplé a vlhké, bez prudkých větrů a sněhových bouří v oblastech vysokých nadmořských výšek a spalujícího horka v tropických deštných lesích, což z něj činí typické subtropické monzunové klima. Jedinečné přírodní prostředí a klimatické podmínky dávají zlatému nanmu teplé, jemné a ani suché, ani vlhké vlastnosti dřeva. Zlaté nanmu je stabilní, nedeformuje se ani nepraská, je trvanlivé a má svěží a příjemnou vůni. Již od pradávna se říká, že "voda ho nenasákne a mravenci se do něj nemohou zavrtat".

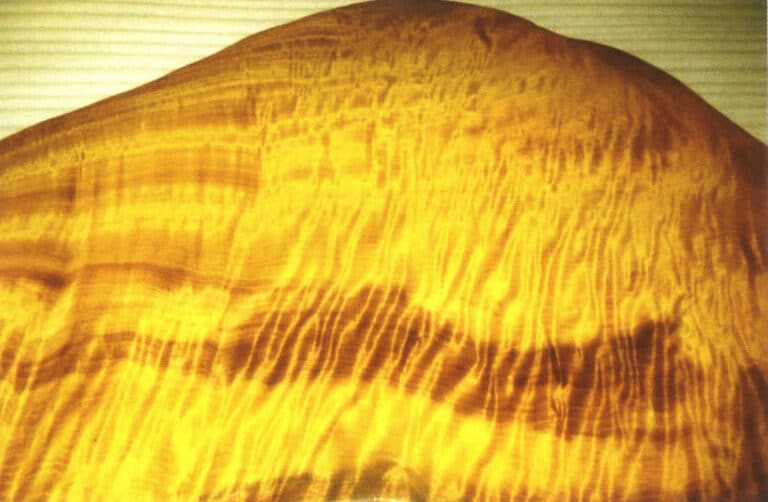

Barva zlatého dřeva nanmu je obvykle žlutá s nádechem do světle zelené. Po oxidaci však může mít různé barvy, včetně zlatožluté, světle žluté, zelené, purpurově červené a černé. Zlaté hedvábí ve zlatém dřevě nanmu je krystalická látka, která vzniká z buněčné šťávy dřeva nanmu po delší oxidaci. Tato krystalická látka může odrážet světlo z různých úhlů, takže se povrch dřeva na slunci třpytí, objevuje se zlaté hedvábí a vyzařuje jemná vůně. Ačkoli tedy mnoho dřev nanmu může obsahovat různé množství zlatého hedvábí, ne všechna dřeva nanmu splňují standardy, aby mohla být klasifikována jako zlaté dřevo nanmu. Aby se dřevo nanmu mohlo označit za zlaté dřevo nanmu, musí splňovat následující požadavky: na světle musí být struktura křišťálově čistá nebo poloprůhledná; kvalita zlatého hedvábí musí být velmi vysoká, míra krystalizace celého kusu dřeva musí dosahovat nebo přesahovat 80% a na světle by měl být vidět fantastický efekt měnící se scenérie při každém kroku; struktura dřeva musí vykazovat příznivé vzory, jako jsou vzory tygří kůže, vzory fénixe, růžové mraky, moře mraků, vlny, vrcholy atd.

2. Textura zlatého nanmu

Struktura zlatého nanmu je bohatá a rozmanitá. Díky jedinečným proměnlivým stínům (dřevo má dvě strany jin a jang, které v různých úhlech ukazují různé barvy) je jeho hodnota úměrná jeho struktuře; čím krásnější a vzácnější je zrno, tím vyšší je jeho hodnota. Dělí se na čtyři úrovně: obyčejné, střední, jemné, špičkové a vzácné.

- Mezi běžné vzory patří zlaté hedvábné vzory, kostkované vzory a vrcholové vzory.

- Textury střední úrovně zahrnují běžné vzory vodních vln, vzory černé tygří kůže z nového materiálu, zlaté vrcholové vzory a vrcholové vzory, které vytvářejí obrazový efekt.

- Prémiové textury zahrnují vzor staré černé tygří kůže, vzor zlaté tygří kůže, vzor zlaté čáry, vzor zlatého slitku, vzor mraků, vzor vodních kapek, vzor bublin atd.

- Prémiové textury zahrnují prémiové vodní vlnění, prémiový vzor vln, vzor fénixova ocasu, husté vodní kapky, vzor zlaté chryzantémy, sezamové tečkované dřevo, vzor mraku ding ding nan atd.

- Mezi vzácné textury patří vzor hořce, vzor dračích šupin, vzor zlatého nefritu v plné síni, vzor růže, vzor hroznového dřeva a textury krásných scenérií a vzory ptáků a zvířat.

Vynikající vzor vodních vln zlatého nanmu

Zlatý nanmu s hroznovým vzorem

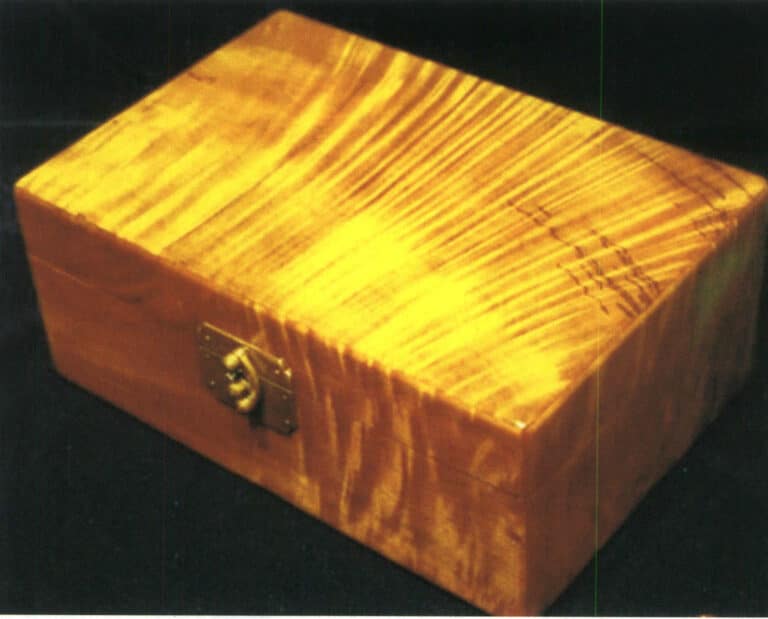

3. Zlaté řemeslné ozdoby Nanmu

Zlatý náramek nanmu

Zlatý náramek nanmu

Oddíl VI Zkamenělé dřevo a jeho ozdoby

1. Úvod do zkamenělého dřeva

Zkamenělé dřevo je stejně jako jiné zkameněliny rostlin a živočichů velmi cenným geologickým paleobiologickým reliktem, který patří k neocenitelnému a neobnovitelnému přírodnímu dědictví, jež nám příroda zanechala. Vzhledem ke svému významnému vědeckému výzkumu, populárně-naučnému vzdělávání a turistické hodnotě přitahuje zkamenělé dřevo stále větší pozornost vědecké komunity a různých společenských vrstev. Čína je jednou z oblastí na světě, kde je zkamenělé dřevo široce rozšířeno, a v téměř 20 provinciích a autonomních oblastech po celé zemi byly objeveny a hlášeny zkameněliny zkamenělého dřeva. Jeho rozšíření zahrnuje Liaoning, Heilongjiang, Jilin v severovýchodní Číně; Vnitřní Mongolsko, Peking, Hebei, Shanxi v severní Číně; Xinjiang, Gansu, Shaanxi v severozápadní Číně; Sichuan, Chongqing, Yunnan v jihozápadní Číně; Hubei, Hunan, Guangdong, Guangxi v jižní Číně; a Zhejiang a Shandong ve východní Číně. Z hlediska rozsahu a stavu zachování zkamenělého dřeva patří k nejreprezentativnějším lokalitám Qitai v Sin-ťiangu, Yanqing v Pekingu, Xinchang v Če-ťiangu a Shehong v Sečuánu, které byly schváleny jako národní geologické parky.

Proces vzniku zkamenělého dřeva je velmi dlouhý. Asi před 1,5 až 3 sty miliony let, v období pozdních prvohor a druhohor, byla zemská pevnina pokryta hustou vegetací s bohatou rozmanitostí kapradin a gymnospermových lesů. Zejména v období pozdní jury, asi před 150 miliony let, vzkvétaly vysoké a bujné gymnospermy a staly se dominantním typem vyšších suchozemských rostlin na Zemi.

Vlivem geologických činností, jako jsou sopečné erupce způsobené tektonickými pohyby, lesní požáry, rozsáhlé transgrese a regrese, přívalové deště a povodně a rozsáhlé sesuvy půdy, však byly některé lesy pohřbeny v podzemních vrstvách, které je na dlouhou dobu izolovaly od vzduchu. Dlouhým procesem zkamenění z nich vznikly tzv. prastaré kamenné stromy, které představují kmeny rostlin. Petrifikace se týká především silicifikace, kterou lze dále rozdělit na mineralizací zkřehlé dřevo a karbonizací zkřehlé dřevo. Bez ohledu na typ je veškeré zkamenělé dřevo závislé na působení oxidu křemičitého.

Když jsou stonky a další části rostlin dlouho pohřbeny pod zemí, dostává se do trubicovitých molekul uvnitř dřeva vodný roztok bohatý na křemík. Veškerá vlhkost a živiny ve vnitřní struktuře dřeva jsou nahrazeny SiO2 prostřednictvím procesu výměny. Anatomická struktura dřeva, morfologie buněk, vnější kůra a kořeny stromu se mohou po silicifikaci zachovat po dlouhou dobu a vytvořit zkamenělinu dřeva s tvrdou strukturou, která se běžně označuje jako "zkamenělé dřevo".

Zkamenělé dřevo se obvykle zachovává ve velkých kmenech zkamenělých stromů a v některých se zachovává i kořenový systém a další výživné orgány rostlin. Kmeny zkamenělých dřev se často nacházejí v padlém stavu, některé rovnoběžně s okolními vrstvami, přičemž dochovaná délka je velmi různá, od několika centimetrů až po několik metrů; některé kmeny jsou zachovány vzpřímeně na zemi, především spodní část stromu v blízkosti kořenů, často jako pařezy nebo základy stromů. Ve většině případů jsou menší dřevní fosilie zachovány ve fragmentární podobě v důsledku transportu na velké vzdálenosti nebo migrace vodou. Kromě toho se při příznivých podmínkách pohřbívání a uchovávání může zachovat i vnější morfologie zkamenělých kmenů, připomínající otisky "kůry" moderních stromů.

2. Řemeslné ozdoby ze zkamenělého dřeva

Náramek ze zkamenělého dřeva

Náramek ze zkamenělého dřeva

Zkamenělé dřevo

Ozdoba ze zkamenělého dřeva

Oddíl VII Výrobní proces dřevěných řemeslných výrobků

1. Obecný postup výroby dřevěných řemeslných ozdob

Výroba dřevěných řemeslných ozdob obecně prochází asi 10 procesy.

(1) Design. Profesionální designéři vytvářejí podle potřeb zákazníků a trhu vzorky šperků a prototypy a výrobní technici navrhují průběh procesu a výrobní operace.

(2) Výběr materiálu. Zvolte vhodné dřevo podle potřeb uměleckého návrhu.

(3) Řezání. Vybrané dřevo předběžně zpracujte, nařežte na desky nebo drátěné výrobky a poté materiál vytvarujte.

(4) Tvarování. Existuje mnoho druhů dřeva a mnoho druhů dřeva je náchylných k deformaci v důsledku faktorů, jako je struktura vláken, materiál a vlhkost po prvotním zpracování. Různé materiály vyžadují odpovídající metody tvarování, přičemž mezi hlavní metody patří namáčení ve vodě, lisování na plocho, pražení, napařování a nastavování. Některé dřeviny vyžadují také procesy, jako je odstranění cukru a dezodorizace; například bambus a bříza obsahují vysoký obsah cukru, takže jsou náchylné k poškození hmyzem, takže je nutné odstranění cukru, zatímco materiály jako borovice a kafr vyžadují extrakci kalafuny a kafrového oleje; jinak by vůně kalafuny a kafrového oleje v doplňcích byla příliš silná a nevhodná k nošení.

(5) Dokončovací práce. Tvarované dřevo nařežte podle požadavků technologického návrhu a zpracujte jej kus po kusu do základních uměleckých tvarů. Mezi metody zpracování patří především řezání, řezání, broušení, frézování, vrtání, vyřezávání a ražba.

(6) Leštění. Povrchová úprava prvotně vytvořených šperků zahrnuje tři hlavní kroky: první je odstraňování otřepů, při němž se na prvotních špercích odstraňují otřepy, ostré hrany, dřevěné třísky atd.; druhý je hrubé leštění, při němž se k leštění šperkových komponentů používají hrubé pískové materiály, takže povrch je hladký; třetí je jemné leštění, při němž se k leštění používají jemné pískové materiály, vlasy, hedvábí, bavlna, len a další materiály z jemných vláken, které zajišťují vysoký lesk.

(7) Zpracování povrchové úpravy. Komponenty příslušenství s povrchovou úpravou jsou vyráběny umělecky, zejména pomocí kresby, transferového tisku, barvení, gravírování a ražby, čímž vznikají umělecké komponenty příslušenství.

(8) Montáž. Sestavovat ozdobné doplňky a různé pomocné součásti, jako jsou korálky, hroty, řetízky, nitě, dráty, uzly, spony, náramky, spony, háčky atd., podle výkresů řemeslného návrhu za použití různých metod, jako je vázání, spojování, navlékání, zapínání, svařování a lepení, a sestavovat je do hotových šperků.

(9) Kontrola. Při každém procesu, od výtvarného návrhu až po montáž, je třeba kontrolovat různé technické požadavky. Kromě standardních kontrol se musí provádět také technické kontroly v oblasti zdraví, ochrany životního prostředí a bezpečnosti.

(10) Balení. Balení hotových šperků.

2. Výrobní proces dřevěných korálkových náramků

Vezmeme-li si jako příklad náramek z červených santalových korálků, výrobní postup je následující.

(1) Výběr materiálu. V průmyslu zpracování dřevěných korálkových náramků, zejména při zpracování červeného santalového dřeva, je nejdůležitější výběr materiálu. Existuje rčení: "Devět z deseti červených santalových dřev je dutých," takže při nákupu dřeva je třeba zvážit vzhled a zohlednit vzhled a odhadnout, zda je dřevo duté, na základě jeho objemu, hmotnosti, hustoty a dalších faktorů.

(2) Krájení. Krájejte podle velikosti vyráběných dřevěných korálků, přičemž při krájení ponechte rezervu na zpracování (obrázek 10-4).

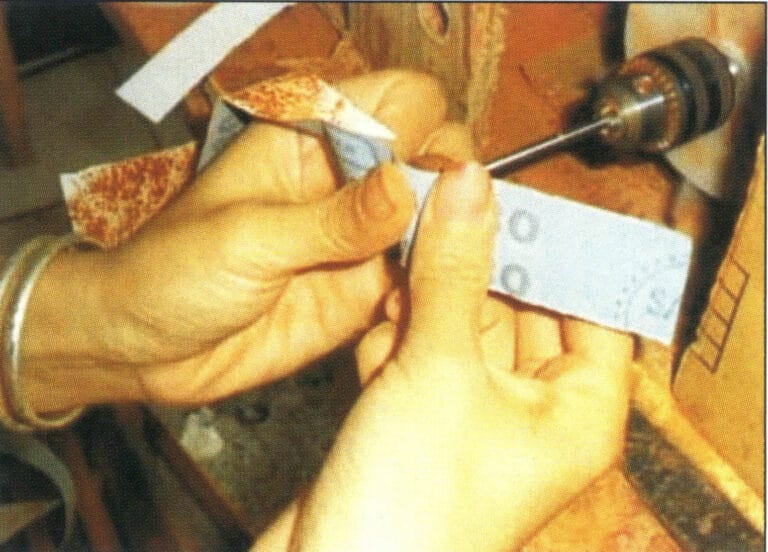

(3) Nalepování kulatých dílků nebo kreslení kruhů. Podle tvaru každého dřevěného dílku nakreslete na dřevěný dílek kolečka nebo nalepte kulaté kousky papíru jako vodítko pro řezání (obrázek 10-5). Při kreslení kruhů zvažte jejich rozložení, abyste maximalizovali počet kruhů a zlepšili využití dřeva. U vadného dřeva se suky, dutinami, prasklinami atd. se při kreslení kruhů těmto vadám vyhněte, abyste neovlivnili kvalitu dřevěných korálků. Zároveň nezapomeňte mezi jednotlivými kružnicemi ponechat určitou vzdálenost jako rezervu pro řezání.

Obrázek 10-4 Krájení dřeva

Obrázek 10-5 Kreslení kružnic na dřevěné díly pro řezání

(4) Řezání surovin. Velký dřevěný kus rozřežte podle naznačeného kruhu na malé dřevěné sloupky (obrázek 10-6). K řezání lze použít nástroje, jako jsou pásové pily, rotační řezací nástroje se zahnutými čepelemi a zubaté ocelové trubky, přičemž každý z nich má své vlastnosti. Pásové pily se obvykle používají pro hromadné zpracování, protože jejich kotouče jsou tenčí než ostatní metody, což vede k nejvyšší výtěžnosti dřeva při stejné hmotnosti. Principy rotačních řezacích nástrojů se zahnutými čepelemi a ocelových trubek jsou podobné; oba používají rotační techniku řezání, která dřevěný kus přemění na malé sloupky nebo korálky, což usnadňuje operaci. Výhodou řezacího nástroje je, že může přímo vyrábět korálky, čímž odpadá krok broušení sloupku na korálky. Sloupky vyrobené ocelovou trubkou jsou velmi pravidelné, což usnadňuje další krok zpracování. Nástroje používané při těchto dvou metodách však mají svou pevnou tloušťku, takže dojde k většímu plýtvání surovinami.

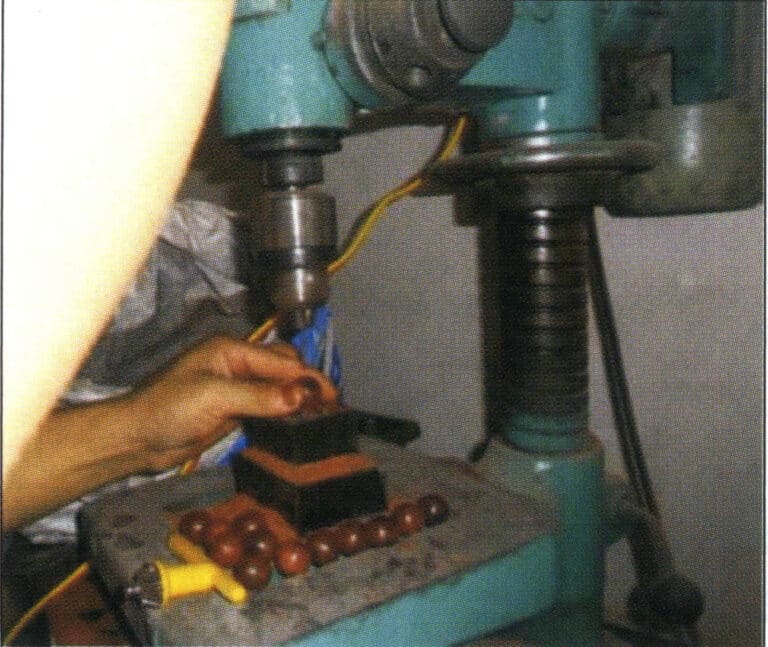

(5) Vrtání. K vrtání otvorů do malých dřevěných sloupků lze použít jednoduché vrtací nástroje, přičemž velikost otvorů je dána tloušťkou a počtem lan. Při vrtání je důležité kontrolovat svislost dřevěného sloupku, aby se zabránilo špatnému nastavení otvorů.

(6) Vysoustružení dřevěných korálků. Zvolte vhodnou velikost soustružnického nástroje podle požadované velikosti korálků, přičemž hrana nástroje musí být obloukovitá. Připevněte malý dřevěný sloupek vodorovně na zařízení a spusťte stroj, aby se dřevěný sloupek otáčel určitou rychlostí. Sousední soustružnický nástroj se naopak otáčí nepřetržitě a řeže dřevěný sloupek na korálky (viz obrázek 10-7). Kontakt mezi dřevěným sloupkem a soustružnickým nástrojem bude při řezání nevyhnutelně vytvářet teplo, proto je nutné přidávat nad dřevěný sloupek kapky vody. Tím lze snížit teplotu kuliček a doplnit vlhkost odpařenou z povrchu kuliček v důsledku vysokých teplot, čímž se zabrání vzniku trhlin způsobených nestejnou hustotou napětí uvnitř a vně dřevěných kuliček.

Obrázek 10-6 Řezání a dělení materiálu

Obrázek 10-7 Odšroubování korálků

(7) Výroba třícestné hlavy Buddhy. Každý korálkový náramek je třeba spárovat s třícestnou hlavou Buddha, kterou lze vybrat z hromady korálků, a na vrtačce se vyvrtá třícestný otvor (obrázek 10-8).

(8) Leštění. Povrch dřevěných korálků vyleštěte hrubým až jemným smirkovým papírem (obrázek 10-9). Čím jemnější je leštění, tím více oleje se dostane dovnitř dřevěných korálků.

Obrázek 10-8 Vrtání třícestného otvoru

Obrázek 10-9 Leštění povrchu korálku

(9) Hotové kulaté korálky. Jak je znázorněno na obrázku 10-10.

(10) Provlékání dřevěných korálků elastickým provazem a výroba náramku.

Kopírování @ Sobling.Jewelry - Výrobce šperků na zakázku, továrna na šperky OEM a ODM