Jaké jsou předběžné přípravy pro zasazení šperků?

Materiály, nástroje, vybavení a návrhy šperků

První a nejdůležitější částí přípravných prací pro zasazení drahého kamene je znalost dvou hlavních druhů materiálů: drahých kovů a drahých kamenů. Materiály můžeme racionálně využít a vytvořit efektivní návrhy, pokud známe vlastnosti, druhy, fazety, způsoby použití a techniky zpracování běžných drahých kovů a kamenů. Za druhé, nástroje a vybavení pro zasazování drahých kamenů jsou podmínkami prostředí pro realizaci tohoto procesu. Musíme vědět, jak nástroje a vybavení používat, a znát odpovídající vazby použití a pak je umět pružně využívat. A konečně, estetická hodnota vsazování drahých kamenů v designu šperků se týká především vsazování vyvolaného rozšířením myšlení o designu šperku z předběžné přípravy. Pouze pochopením předností samotného materiálu drahého kamene a jeho možností můžeme inkrustaci v designu šperků plně využít, a ne ji pouze brát jako pevně dané řemeslo s drahými kameny.

Nastavení pracovního stolu

Obsah

Oddíl I Materiály pro intarzii drahých kamenů

Hlavními materiály pro vykládání drahými kameny jsou drahé kovy a drahokamy. Drahokam nesmírné hodnoty je často ústředním prvkem šperku, zatímco kovová struktura je navržena tak, aby drahokam doplňovala, někdy je dokonce minimalizována. Příležitostně se vhodné drahokamy pro inkrustaci vybírají na základě designu. Přestože přiměřené použití drahokamů může zvýšit hodnotu šperku, kov je nejpodstatnějším materiálem šperku. Níže se budeme zabývat významem těchto materiálů pro inkrustaci z různých hledisek.

1. Drahé kovy

Ve šperkařství jsou nejdůležitějšími a nejčastěji používanými kovovými materiály zlato (Au), stříbro (Ag) a platina ze skupiny platinových kovů. Díky své dobré stabilitě a pružnosti vůči kyslíku a dalším činidlům se hojně používají ve špercích a řemeslných potřebách, které doplňují zasazení drahých kamenů. Tyto tři druhy kovů mají vysokou hodnotu také vzhledem k jejich omezeným zásobám v zemské kůře a náročnosti těžby a získávání. Zlato i stříbro sloužily jako oběživo, a nesou tak symbolický význam bohatství, když se používají k výrobě šperků; běžně je označujeme jako drahé kovy. S potřebou masové výroby se technické požadavky lidí na poměry obsahu kovů, zpracování a další aspekty neustále zdokonalovaly, což vedlo ke vzniku vysoce kvalitních slitin zlata a stříbra, jako je 18karátové zlato a stříbro 925. Tyto slitiny mají větší tvrdost a stabilitu než ryzí zlato a stříbro. Jsou vhodné pro výrobu a nošení, díky čemuž jsou na trhu se šperky oblíbenější a běžně se používají při zasazování drahých kamenů.

1.1 Zlato

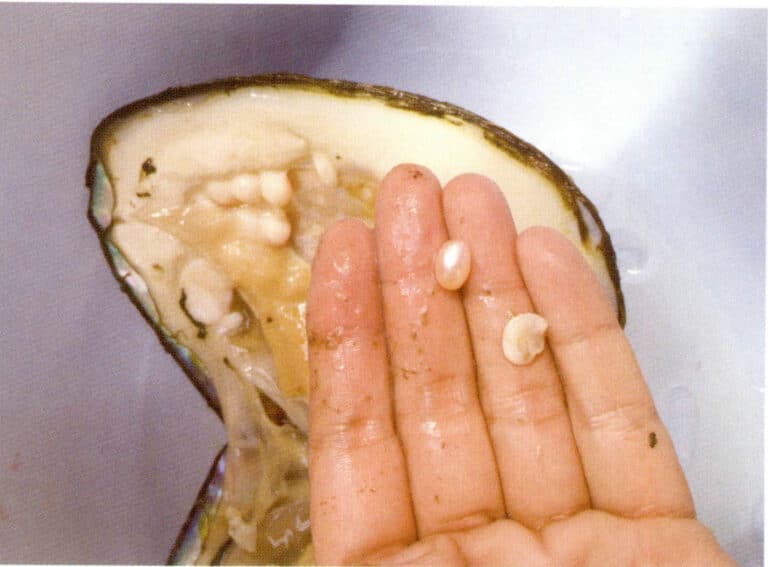

Podle vědců se odhadují zásoby zlata v zemské kůře na 48 bilionů tun, ale většina z nich je rozložena v jádře a nelze je těžit. Pouze 9,6 milionu tun se nachází v zemské kůře a asi 4,4 milionu tun je v mořské vodě. Ve starém Římě bylo zlato jménem bohyně úsvitu a staří Inkové přirovnávali zlato ke slunečnímu potu; staří Egypťané považovali zlato nejen za "hmatatelné slunce", ale také zlaté šperky a artefakty za posvátné předměty; zlato bylo objeveno a využíváno také v Číně před pěti tisíci lety. Zlato je neoddělitelně spjato s lidským životem. Kromě toho, že je zlato důležitým materiálem pro výrobu šperků, slouží také jako měnová rezerva zemí, jak ukazuje obrázek 1-1. Proto mnoho lidí při výběru šperků často považuje za důležité kritérium pro posouzení jejich hodnoty zachování hodnoty zlata, což neodmyslitelně znamená bohatství, status a symbolickou identitu, kterou zlato ve špercích přirozeně nese.

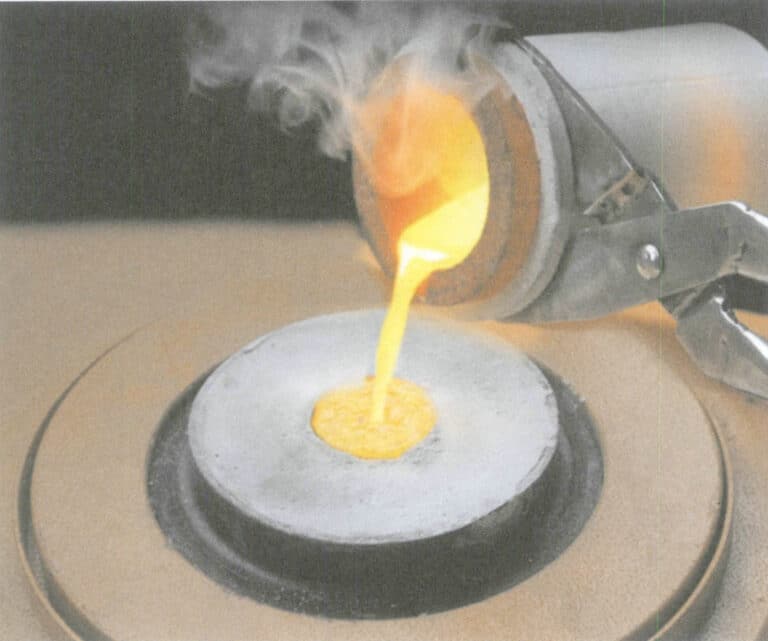

Zlato má zlatý kovový lesk a tvrdost podle Mohsovy stupnice je pouze 2,5, což je méně než u jiných drahých kovů, takže se snadno poškrábe a promáčkne; zlato má však vysokou hustotu a bod tání, jeho hustota je 19,32 g/cm.3, což je téměř dvakrát více než u stříbra, a bod tání 1064,18 ℃. Proto také existuje rčení, že "pravé zlato se nebojí ohně". Zlato je dobrým vodičem tepla a elektřiny a nesnadno oxiduje, což mu umožňuje dlouho si zachovat kovový lesk. Zlato má vynikající ohebnost, z 1 g ryzího zlata lze vytáhnout drát dlouhý přes 3 000 m, z něhož lze vyrobit zlatou fólii o délce 9 m2. Při tradičním navrhování a výrobě šperků se plně využívá pružnosti zlata v technikách, jako je filigrán, jak je znázorněno na obrázku 1-2. Vzhledem k nízké tvrdosti a silné ohebnosti ryzího zlata je obecně nevhodné pro zasazení šperků s menším množstvím kovu pro upevnění v osazení drahých kamenů. U filigránových technik se zasazení drahých kamenů provádí především stabilnějším zasazením do rámečku. V moderních způsobech nastavení šperků se často používají slitiny, jako je 18karátové a 14karátové zlato, aby se dosáhlo bohatých metod nastavení, jako je například nastavení trnem. Z hlediska barvy má zlato silnější barevný vjem než stříbro a platina. Ať už se jedná o zlatožlutou barvu ryzího zlata, nebo růžově červenou a tmavou barvu slitin zlata, může vytvářet rozmanité kolize s drahými kameny různých barev.

1.2 Stříbro

Stříbro má lesklý odstín a stejně jako zlato patří mezi historicky významné drahé kovy. Tento kov zanechal v historii lidstva hlubokou stopu, ať už v řemeslné výrobě nebo ve šperkařství. Zásoby stříbra v zemské kůře jsou asi patnáctkrát větší než zásoby zlata, ale vzhledem ke své reaktivitě se stříbro jen zřídka vyskytuje v elementárním stavu. Přírodní stříbro se většinou vyskytuje ve slitinách se zlatem nebo jinými kovy. Ačkoli tedy lidé ve starověku uměli stříbro těžit, získané množství bylo velmi malé a jeho hodnota kdysi převyšovala hodnotu zlata.

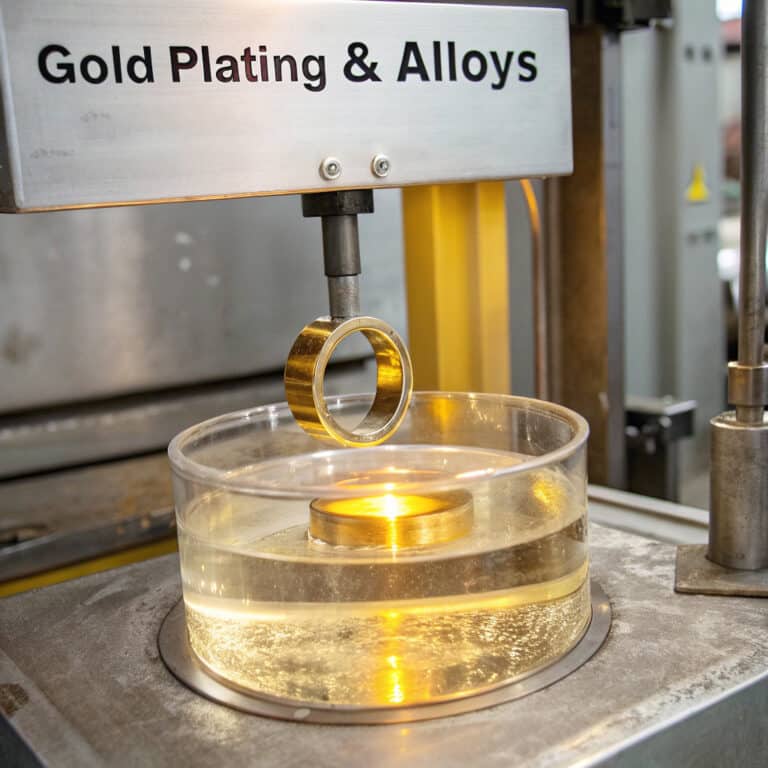

Stříbro má silný stříbřitě bílý kovový lesk, čisté stříbro s hustotou 10,49 g/cm.3, bod tání 961,78 ℃ a tvrdost podle Mohse 2,7. Stříbro má dobrou pružnost, druhou po zlatě, a jeho elektrická a tepelná vodivost je nejsilnější ze všech kovů. Nevýhodou stříbra je, že je náchylné k oxidaci. V dávných dobách lidé využívali této vlastnosti stříbra k testování arsenu (oxidu arsenitého) v potravinách, což je také důležitý důvod, proč je materiálová hodnota stříbra nižší než hodnota zlata. Na stříbrných špercích se po delším vystavení vzduchu vytvoří černá oxidační vrstva, která ovlivňuje lesk a barvu samotného šperku. Proto se stříbrné šperky často galvanicky pokovují, aby se oxidaci zabránilo.

Stříbro se podle složení dělí na ryzí stříbro a barevné stříbro. Ryzí stříbro má nejvyšší ryzost 99,999% a lze jej rafinovat pomocí technologie. Přesto se většinou používá v tradičním kovářství, rytectví a dalších řemeslech nebo etnických ozdobách, jak je znázorněno na obrázku 1-3. Stejně jako ryzí zlato je i ryzí stříbro nevhodné pro zasazování hrotů a další techniky zasazování kvůli své nízké tvrdosti, která může snadno vést k poškrábání při nošení. Proto se v moderním designu šperků častěji používá slitina stříbra 925, která má relativně vyšší tvrdost a lepší stabilitu.

1.3 Platina

Platina se ve srovnání se zlatem a stříbrem používá krátce a její historie ve šperkařství a řemeslnictví je ještě kratší. Důvodem je to, že platina je vzácná a obtížně se těží v přírodě. K roku 2019 činí celosvětové prokázané zásoby platiny přibližně 69 000 tun, přičemž na jihoafrické platinové doly připadá 91,3% z celkových světových zásob. V roce 2019 činila celosvětová produkce platiny přibližně 6 093 tisíc uncí (172,7 tun), přičemž Jihoafrická republika vedla s 4 402 tisíci uncemi (124,8 tun), což představuje 72%; na 2. až 5. místě se umístily Rusko, Zimbabwe, Kanada a Spojené státy. Těžba platiny je velmi obtížná a náklady a čas potřebný k rafinaci platinové rudy stejné kvality jsou několikanásobně vyšší než u zlata.

Z hlediska fyzikálních vlastností má platina velmi vysokou hustotu 21,45 g/cm.3 (hustota zlata a stříbra je 19,32 g/cm3 a 10,49 g/cm3(body tání zlata a stříbra jsou 1064,18 ℃ a 961,78 ℃); za druhé má vynikající odolnost vůči kyselinám a zásadám a lze jej rozpustit pouze v aqua regia 70 ℃ (vysoce korozivní kapalina vyrobená smícháním koncentrované kyseliny chlorovodíkové a koncentrované kyseliny dusičné v objemovém poměru 3:1), přičemž žádný jiný roztok kyseliny nebo zásady jej není schopen rozpustit. Kromě toho má silnou odolnost proti vysokým teplotám (zahřívání nezpůsobuje deformaci). Právě proto, že platina má tyto stabilní vlastnosti, je používána jako základní materiál pro mezinárodní prototyp kilogramu. V roce 1795 plánovala Francouzská akademie věd používat gram jako základní jednotku hmotnosti, která by představovala hmotnost vody o velikosti 1 cm.3 v 0 ℃ a v roce 1799 byl vyroben fyzický prototyp o stejné hmotnosti z platiny. V roce 1879 vyrobila britská společnost Johnson-Matthey válcové závaží jako mezinárodní prototyp kilogramu, vyrobené ze slitiny platiny a iridia s obsahem 90% platiny a 10% iridia. Stabilita platiny splňuje požadavky na prototyp kilogramu a iridium zvyšuje jeho odolnost proti korozi. Přestože má platina tyto stabilní vlastnosti, má také neuvěřitelnou pružnost, protože jemný drátek natažený z 1 g platiny se může natáhnout až na 2000 m.

V roce 1780 se tento vysoce cenný kov, platina, používal ve šperkařství. Zručný řemeslník v Paříži vyráběl platinové prsteny, brože a náhrdelníky pro francouzského krále Ludvíka XVI. a královnu Marii Antoinettu. Manželé Ludvíka XVI. se tak stali prvními zaznamenanými majiteli platinových šperků na světě. Od té doby pověst platiny prudce stoupla, překonala zlaté šperky a stala se oblíbenou u královské rodiny, šlechty a bohatých obchodníků. Dodnes je běžně používaným kovem pro diamantové prsteny. Na obrázku 1-4 je zobrazena platinová diamantová korunka Cartier.

2. Drahé kameny

Technika zasazování vzniká na základě drahých kamenů a významnou roli hrají i samotné drahé kameny, jejichž varianty výbrusu určují vývoj techniky zasazování. Vztah mezi drahými kameny a kovy: někdy jsou drahé kameny použity ke zkrášlení stávajících kovových tvarů, aby se zvýšila jejich dekorativnost, ale častěji jsou v centru pozornosti samotné drahé kameny, přičemž kov slouží k jejich upevnění a zvýraznění, například u diamantových prstenů. Tvrdost a houževnatost kovů umožňuje šperky nosit. Přesto rozmanitost a bohatost druhů a barev drahých kamenů jim dává nadpozemský význam než kovům, což výrazně zvyšuje bohatství a estetickou hodnotu šperku.

2.1 Druhy drahých kamenů

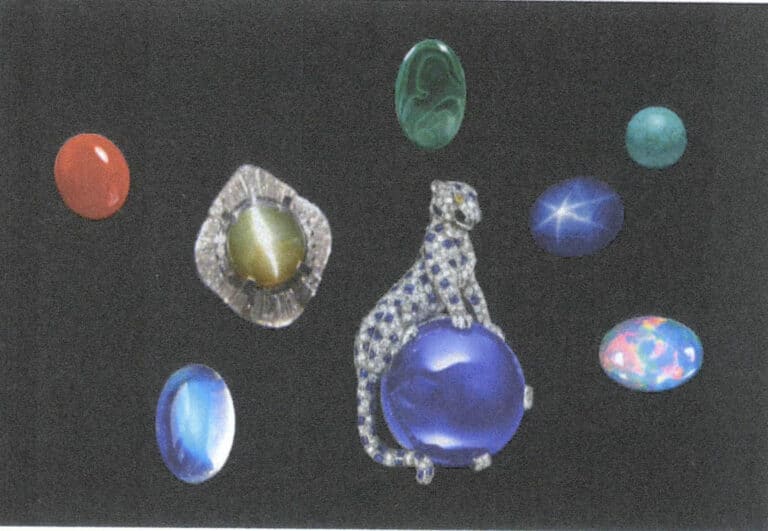

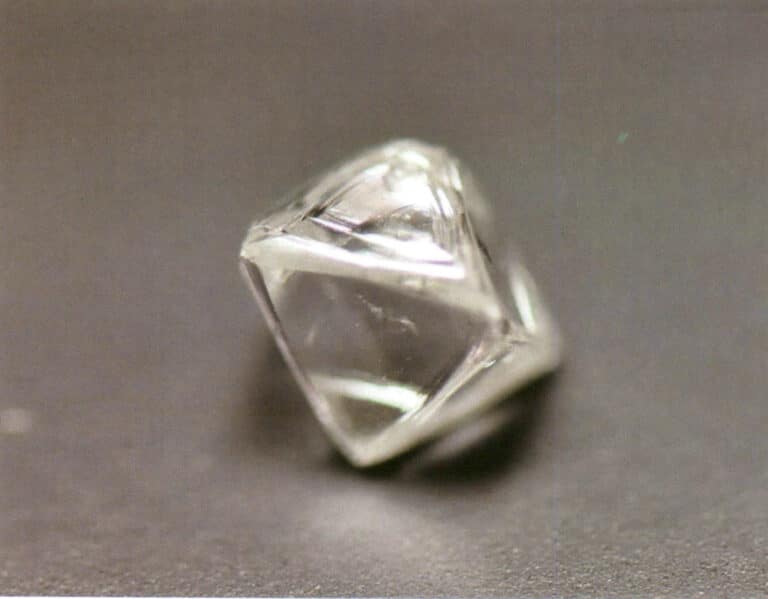

Existuje mnoho druhů drahých kamenů a mezi pět uznávaných drahých kamenů nejvyšší kvality patří diamanty, rubíny, safíry, smaragdy a chryzoberyl kočičí oko, jak ukazuje obrázek 1-5. Kromě toho existuje mnoho barevných drahých kamenů, například akvamarín, turmalín a spinel. Dále se v technice zasazování hojně používají neprůhledné organické drahé kameny, jako jsou korály a perly.

2.2 Styly broušení drahých kamenů

Vývoj technik zasazování drahých kamenů postupoval souběžně s vývojem stylů broušení drahých kamenů a objevení lesku diamantů přímo podpořilo vývoj technik zasazování. Diamanty mají vysokou tvrdost a po pečlivém fasetování mohou zářivě vyniknout. Tradiční osazení rámečkem zakrývalo příliš velkou část lesku diamantu, zatímco pozdější osazení zástřihem umožnilo větší vyniknutí jiskry diamantu.

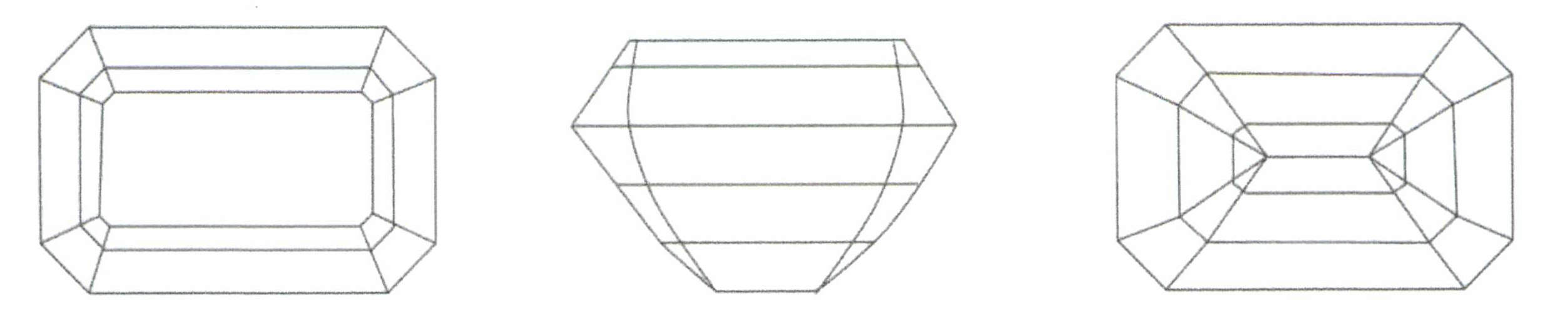

Způsoby broušení drahých kamenů lze rozdělit do dvou hlavních kategorií: kabošonový brus a briliantový brus. Kabošonové řezy jsou poměrně jednoduché, běžné tvary zahrnují kulatý, oválný, kapkovitý, olivový, čtvercový atd. Standardizace kabošonových brusů je nižší než standardizace fasetových brusů. I když jsou typy fasetových brusů také omezené, mají vyšší technické požadavky na broušení. Mezi běžné fasetované broušené drahokamy patří kulaté fasetované broušené kameny a jejich varianty (např. oválné, olivové, srdcové, hruškové atd.) a bagetové broušené kameny (včetně obdélníkových, čtvercových, šestihranných, osmihranných, lichoběžníkových, žebříkovitých, štítových atd.). Níže stručně představíme běžné kabošonové a briliantové řezy.

(1) Kabošonový brus

Kabošon, známý také jako konvexní broušené drahokamy nebo drahokamy s hladkým povrchem, označuje drahokamy se zakřiveným a vystouplým horním povrchem a oblým průřezem, které mají určitý stupeň symetrie. Spodní část kabošonu může být plochá, vně zakřivená nebo dovnitř zakřivená. Kabošony jsou vhodné pro většinu drahých kamenů, takže jsou poměrně běžné. Na jedné straně kabošony dokáží zachovat co největší hmotnost drahokamu a snadno se zpracovávají, na druhé straně mohou také předvést barvu a lesk drahokamu. Pro kabošon jsou vhodné některé poloprůhledné nebo neprůhledné drahokamy, případně kameny typu kočičí oko. Kabošonové drahé kameny jsou znázorněny na obrázku 1-6.

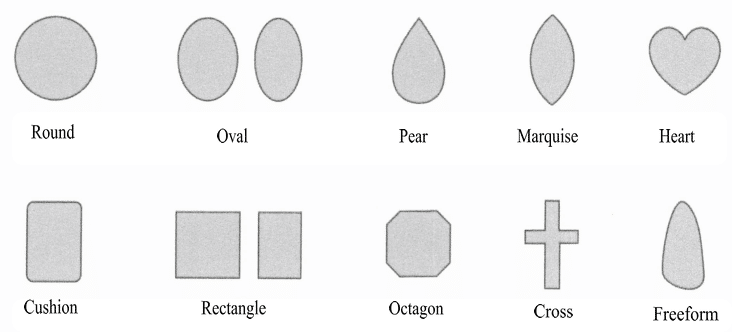

Kabošon lze rozdělit dvěma způsoby: podle tvaru faset a podle tvaru průřezu. Podle klasifikace tvaru faset opasku se při pohledu na drahé kameny shora dolů prezentují kabošony kulatého, oválného, kapkovitého a markýzového tvaru, srdcovitého, sedlovitého, obdélníkového, osmiúhelníkového, křížového a volného tvaru, jak ukazuje obrázek 1-7.

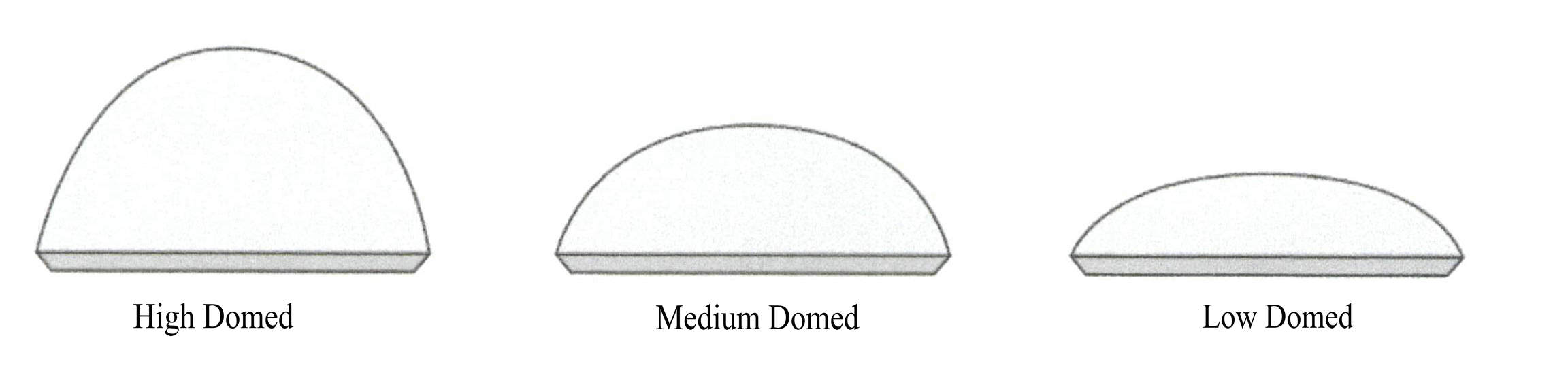

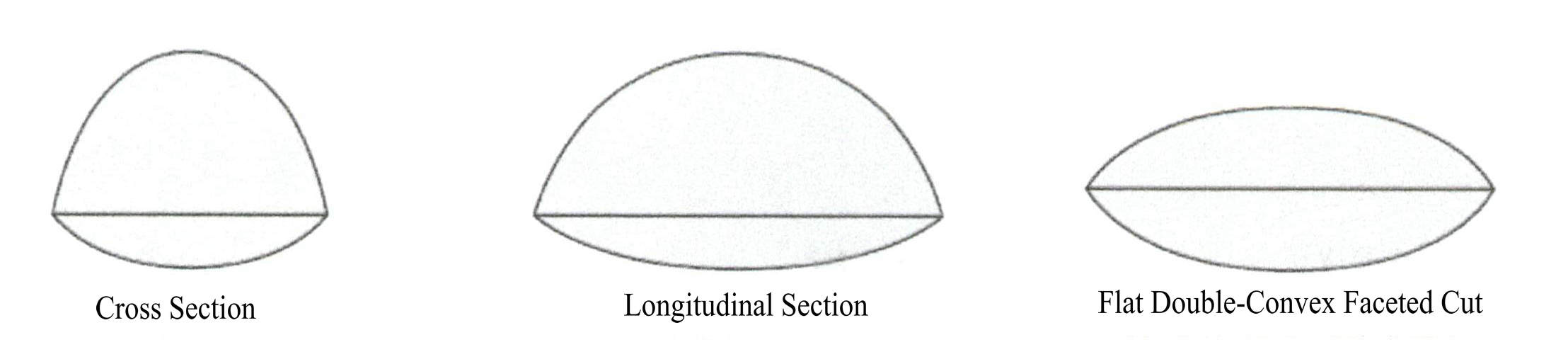

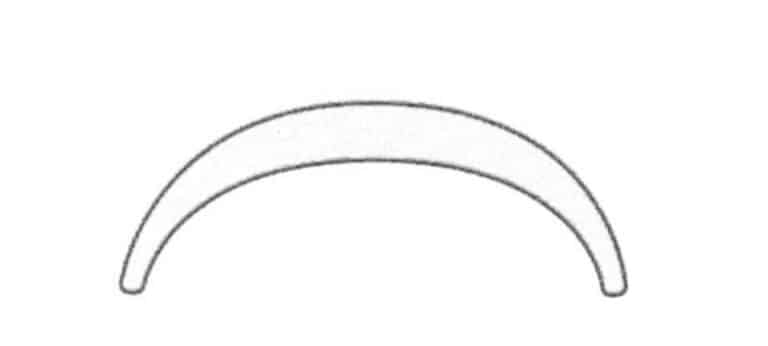

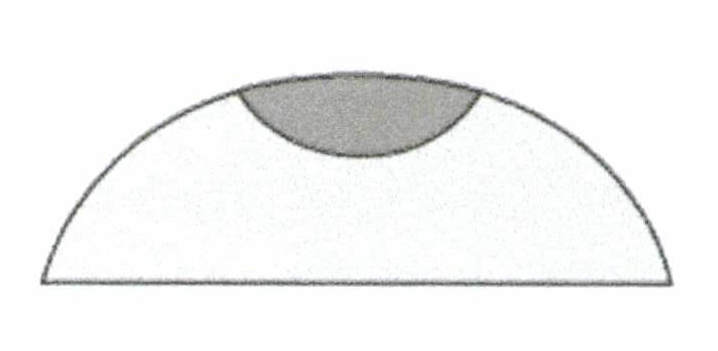

Podle tvaru příčného řezu se nejčastěji používá jednoduchý vypouklý kabošon, jehož horní část je obloukovitá a spodní část plochá, rozdělený podle výšky na vysoce vypouklé, středně vypouklé a nízce vypouklé oblouky, jak je znázorněno na obrázku 1-8. Dalším běžným typem je bikonvexní kabošon, kde je horní i spodní plocha vyboulená směrem ven, přičemž výška spodního vyboulení je menší než výška horního vyboulení; tento typ se často používá u kamenů typu kočičí oko, měsíční kámen apod. Mezi dvojitě vypouklé kabošony patří plochý dvojitě vypouklý kabošon, u něhož je výška horní i spodní vybouleniny stejná; tento typ se často používá u opálů, jak ukazuje obrázek 1-9. Dutý kabošon je méně často používaný kabošon, kde je horní plocha vyklenutá a spodní plocha je hluboce konkávní, jak ukazuje obrázek 1-10, především pro zvýšení průhlednosti drahokamu; tento výbrus se někdy používá například u jadeitu. Dalším méně často používaným typem je horní konkávní kabošon, který má konkávní povrch na horní straně obloukovitě prohnutý, jak ukazuje obrázek 1-11. Obvykle se používá k montáži, která umožňuje zasazení dalšího drahokamu do horní plochy.

Obrázek 1-10 Dutý kabošon

Obrázek 1-11 Vrchní konkávní kabošon

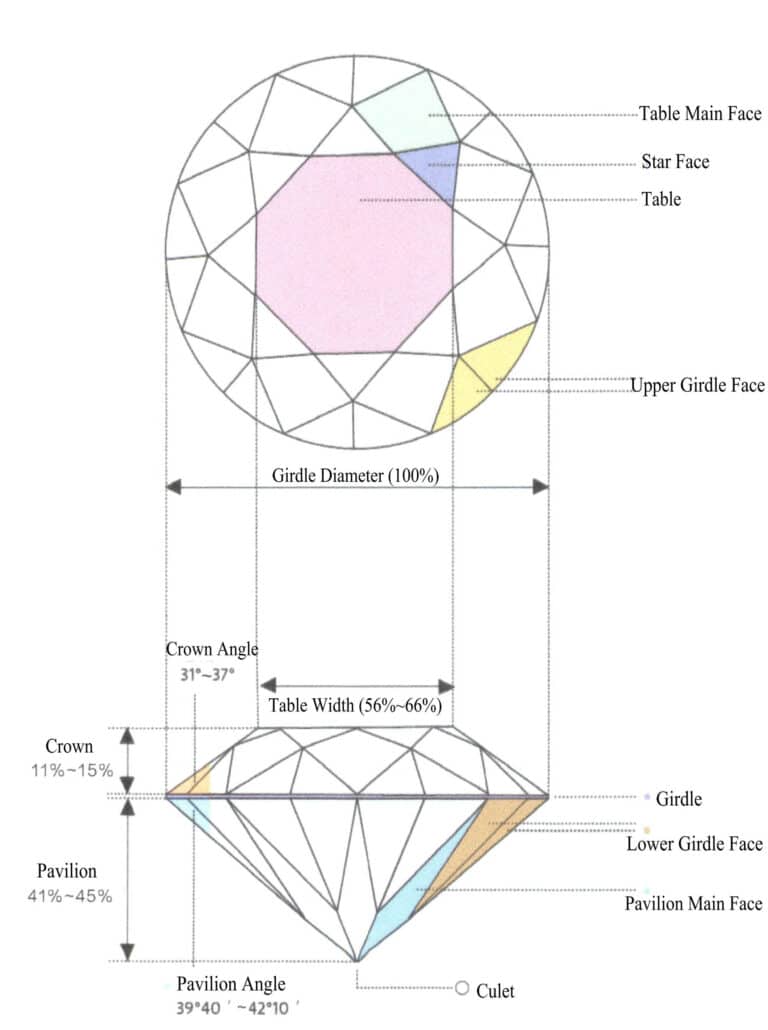

(2) Kulatý briliantový brus

Kulatý briliantový brus je nejběžnějším brusem drahých kamenů, známý také jako standardní kulatý diamantový brus. Kulatý briliantový brus se skládá ze tří částí: korunky, pásu a pavilonu, které se dělí na 58 faset. Korunka má 33 faset, přičemž největší je uprostřed, tzv. table. Pod stolkem je 8 hvězdicových faset, 8 hlavních korunových faset a 16 horních faset opasku. Pod korunou a nad pavilonem je pás, který má určitou tloušťku a je uzavřen kruhovým obloukem. Pod pásem je pavilon, který se skládá z 24 faset, z toho 16 faset spodního pásu a 8 faset hlavního pavilonu. Je-li drahokam větší, aby se nepoškodilo špičaté dno, je na spodním konci vybroušena další malá osmiboká fazeta, čímž celkový počet fazet dosáhne 58. Názvy jednotlivých částí kulatého briliantového brusu jsou uvedeny na obrázku 1-12.

V kritériích hodnocení kvality diamantů má standard broušení vliv na krásu diamantu a lom světla. Jaký druh diamantového brusu je nejideálnější? Existuje pět mezinárodně uznávaných typů kulatých diamantových brusů: americký ideální brus, evropský brus, brus Mezinárodní rady pro diamanty, skandinávský brus a brus osmi srdcí a osmi šípů. Tato kniha neuvádí podrobnosti těchto brusů jeden po druhém, ale pokud jde o standardní kulatý diamantový brus, lidé již dlouho zkoumají soubor proporčních údajů, podle kterých se řídí při broušení diamantů. Vezmeme-li průměr pásu jako referenční poměr 100%, poměr šířky stolu je 56%~66%, úhel koruny je 31%~37% a poměr výšky koruny je 11%~15%, úhel pavilonu je 39°40′~42°10′ a poměr hloubky pavilonu je 41%~45%. Z nich poměry řezu úhlu korunky, úhlu pavilonu a hloubky pavilonu přímo ovlivňují krásu diamantu, jak ukazuje obrázek 1-12.

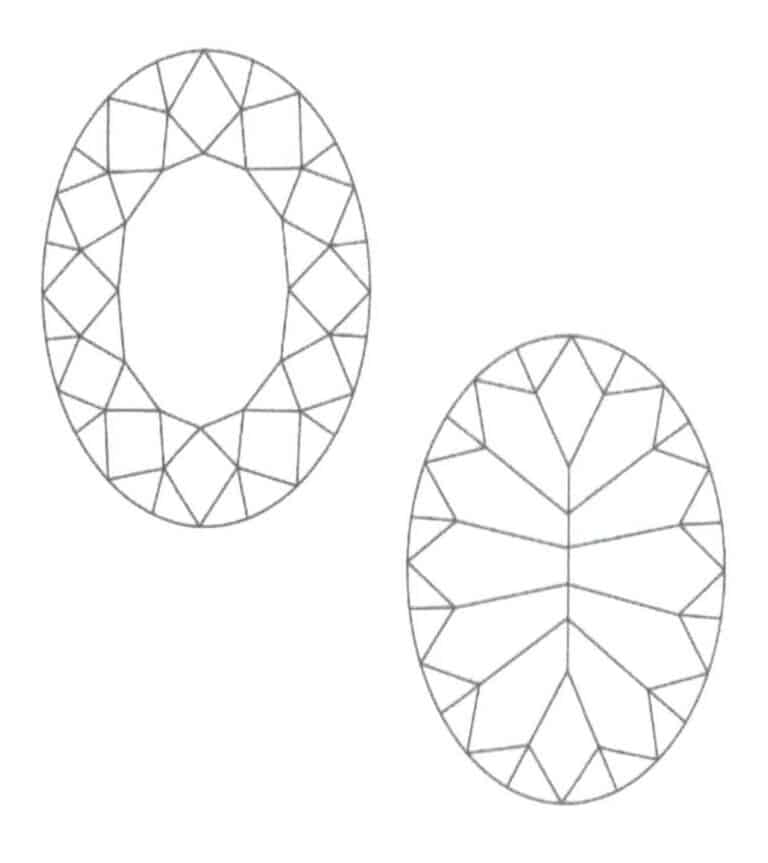

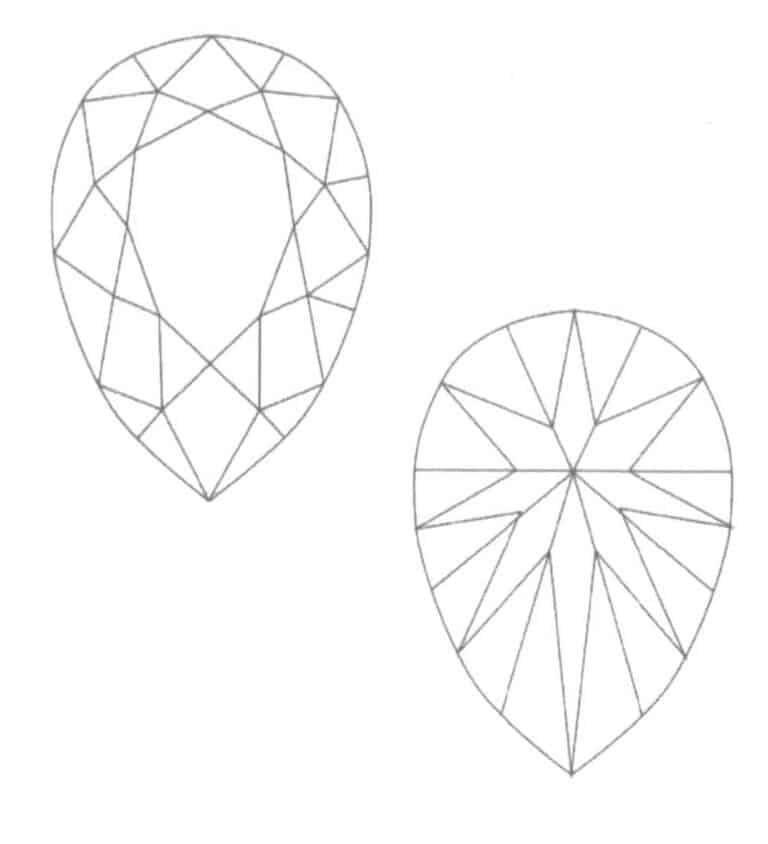

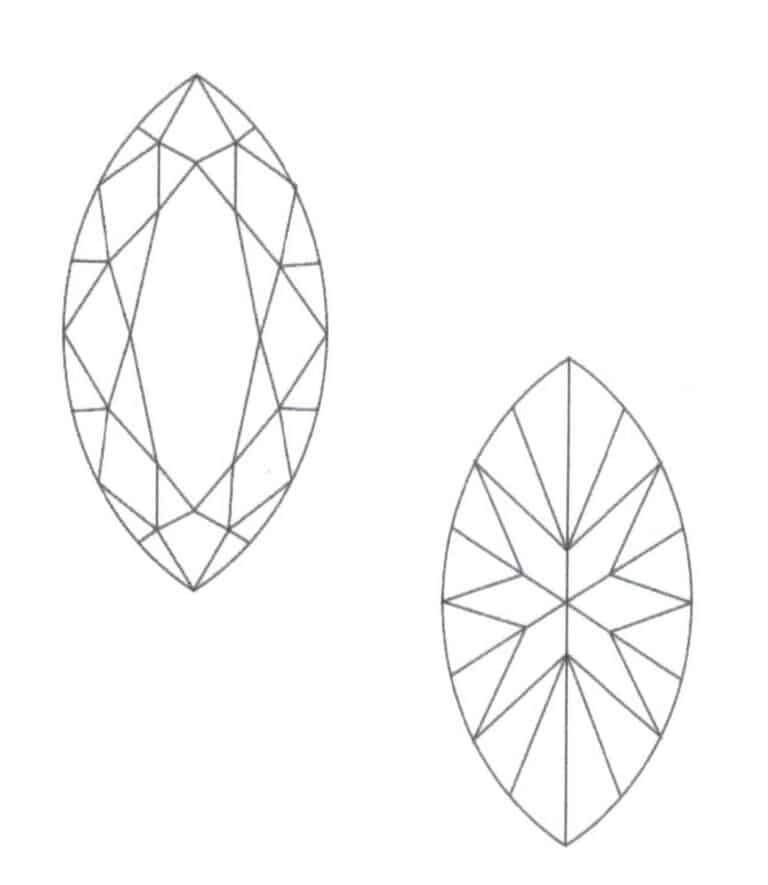

(3) Deformace Rna adrese Brilliant Cut

V broušení diamantů a barevných drahých kamenů jsou oválný brus, markýzový brus, srdcový brus, hruškový brus a další deformace kulatého briliantu. Jejich symetrie se mění podle tvaru opasku. Standardní kulatý briliantový brus má osminásobnou symetrii, zatímco oválný a markýzový brus mají dvojnásobnou symetrii a srdcovitý a hruškovitý brus mají jednonásobnou symetrii. Čím menší je počet symetrií, tím více je variací faset. Tvary s větším počtem variací ve výbrusu mají vyšší náklady na zpracování, ale diamanty kulatého tvaru mají vyšší nároky na materiál diamantu. Proto bývají ve většině případů diamanty stejné hmotnosti, čistoty, barvy a stupně broušení kulatých tvarů cenově výhodnější než diamanty tvaru srdce a další. Oválné, kapkovité a markýzové (navetové) broušené drahokamy jsou znázorněny na obrázcích 1-13 až 1-15.

Obrázek 1-13 Oválný broušený drahokam

Obrázek 1-14 Broušený drahokam ve tvaru kapky

Obrázek 1-15 Drahokam ve tvaru markýzy (navetty)

(4) Bageta Střih

Bagetový brus, známý také jako obdélníkový nebo čtvercový, je běžným brusem drahých kamenů a jeho nejreprezentativnějším použitím jsou smaragdy. Bagetový brus byl původně vyvinut pro lepší broušení smaragdů, které mají často mnoho trhlin a jsou poměrně křehké, proto se často označuje jako smaragdový brus, jak ukazuje obrázek 1-16. Tvar bagetového brusu je obvykle obdélníkový, čtvercový, šestiúhelníkový, osmiúhelníkový, lichoběžníkový nebo štítový. Při pohledu shora je obrys drahokamu tvořen řadou faset uspořádaných rovnoběžně s pásem, proto se mu živě říká "pastový brus". K charakteristickým rysům bagetového brusu patří rovné, rovnoběžné odrazové plochy, větší stůl, mělká koruna a hluboký pavilon, přičemž ve srovnání s kulatými brilianty nejsou tak přísné požadavky na proporce a úhly. Bagetový brus je výhodný pro zvýraznění sytosti barev barevných drahých kamenů, relativně méně ztrácí na kvalitě ve srovnání s jinými brusy.

Oddíl II Nástroje a vybavení pro zasazování šperků

Nástroje a vybavení pro zasazování drahých kamenů lze obecně rozdělit do dvou kategorií: zasazovací pracovní stoly a běžně používané nástroje, vybavení a spotřební materiál pro zasazování. Mezi nástroje a vybavení patří řezné nástroje, měřicí a značkovací nástroje, upevňovací nástroje, zvětšovací nástroje, nástroje pro zasazování, nástroje pro držení forem a chemická činidla pro ošetření kovových povrchů. Tyto nástroje a vybavení spolupracují při kompletním zasazování drahých kamenů. Většina nástrojů pro zasazování je kompatibilní s nástroji pro zpracování kovů a některé upevňovací a zasazovací nástroje jsou speciálně určeny pro zasazování. Níže si tyto nástroje a vybavení rozdělíme do kategorií a představíme si jejich funkce.

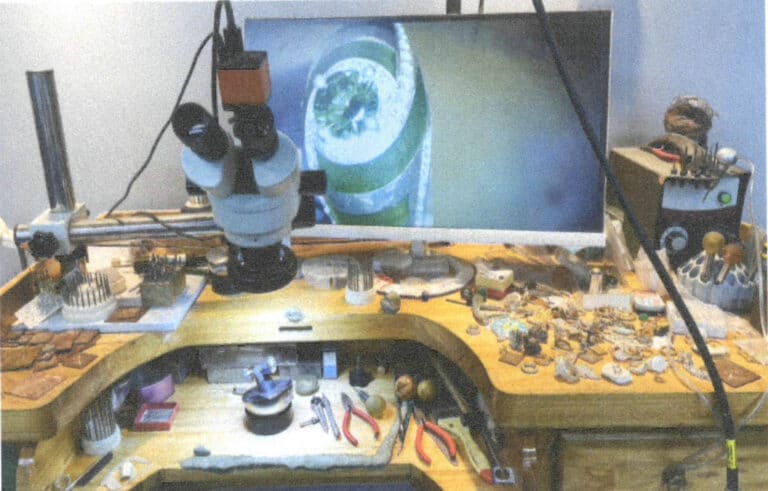

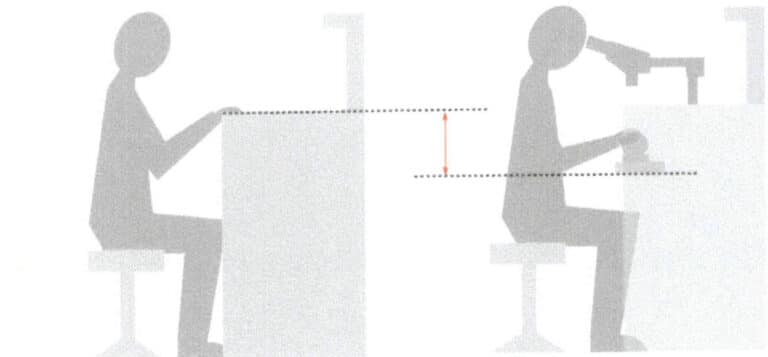

1. Nastavení pracovního stolu

Nastavovací pracovní stůl se mírně liší od základního šperkařského pracovního stolu, protože výška pracovního stolu potřebná pro nastavování, zejména pro nastavování hrotů a mikroperliček, se liší od výšky potřebné pro opracování kovů. Při nezměněné výšce sedadla je výška pracovní plochy potřebná pro zasazování přibližně o 15 cm nižší než výška potřebná pro pilování kovů, jak je znázorněno na obrázku 1-17. Aby se vyhovělo potřebám seřizování, přidává se obvykle další pracovní plocha pro seřizování asi 15 cm pod povrch pracovního stolu na klenoty, jak je znázorněno na obrázku 1-18; pokud tomu tak není, lze základnu pro seřizování vybavit výškově nastavitelnou otočnou plošinou, která umožňuje nastavení výšky podle aktuálních provozních potřeb, jak je znázorněno na obrázku 1-19. Kromě toho je pro zasazování drahých kamenů různých velikostí nutné vybavit pracovní stůl mikroskopem, který vyhovuje potřebám zasazování drahých kamenů různých velikostí.

Obrázek 1-18 Nastavení pracovního stolu

Obrázek 1-19 Podstavec satelitního otočného stolu

Většina pracovních stolů na výrobu šperků splňuje požadavky na výrobu intarzie. Například výška pracovní plochy obecně nemá nadměrné požadavky pro techniky, jako je zasazování rámečků a zasazování hrotů. Kromě toho je uprostřed pracovní plochy vyžadována kruhová drážka o průměru 40 ~ 50 cm a velmi důležitou součástí je také dřevěný špalík upevněný v drážce. Přítomnost tohoto malého dřevěného bloku hraje významnou podpůrnou roli při procesech, jako je řezání, pilování a vyřezávání vosku při výrobě šperků; zároveň je také nutné, aby pod drážkou byl kožený sáček nebo zásuvka na shromažďování kovového prášku, úlomků a dalších materiálů vzniklých při výrobě.

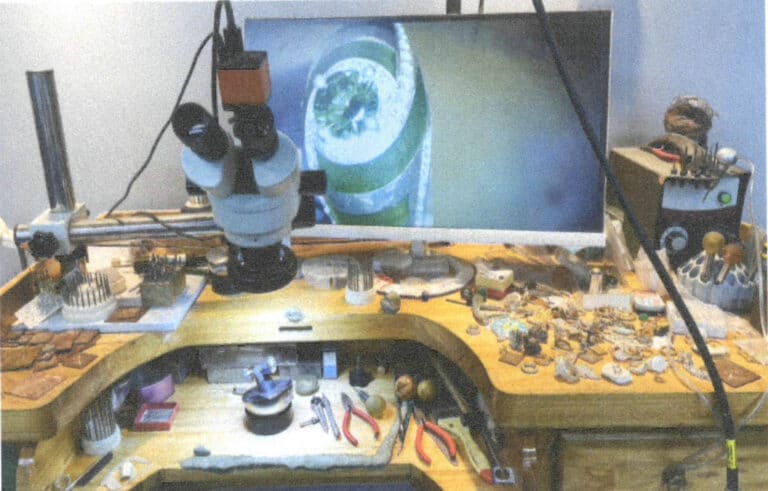

Z běžně používaných zařízení na pracovním stole je závěsná bruska nejnezbytnějším zařízením na pracovním stole na výrobu šperků. Závěsná bruska pohání břity a brusné hlavy různých tvarů a modelů vysokorychlostní rotací, aby bylo dosaženo efektů, kterých nelze dosáhnout ručně. Za druhé je nezbytná stolní lampa, protože intarzie je poměrně jemný proces a osvětlení je velmi důležité. Intarzie a zpracování šperků často vyžadují oheň pro svařování, žíhání atd. Uspořádání hořáku může vycházet ze situace; pokud to podmínky dovolují, lze v ateliéru zřídit vyhrazený prostor pro ohřev nebo jej vybavit na levé straně pracovního stolu, odděleně od zvedáku na obou stranách. Kromě toho je při zpracování zapotřebí mnoho dalších nástrojů, jako jsou mikroskopy a úložné regály. Díky těmto zařízením je pracovní proces přehledný a pohodlný.

2. Běžné nástroje, vybavení a spotřební materiál pro seřizování

(1) Řezné nástroje

Řezné nástroje se týkají především nástrojů potřebných k řezání plechů, drátů atd. Mezi nejčastěji používané řezné nástroje při intarzii a zpracování šperků patří pila na kov, nůžky na kov, štípací kleště a nůžky na plech, jak je znázorněno na obrázcích 1-20 až 1-23. Pila na kov v kombinaci s pilovými listy na kov dokáže maximalizovat celistvost kovu vně řezné plochy, takže je méně pravděpodobné, že se bude deformovat ve srovnání s jinými řeznými nástroji; nůžky na kov a štípací kleště se obvykle používají na silnější kovy, přičemž štípací kleště vytvářejí větší sílu než nůžky na kov. Nůžky na plech jsou ruční zařízení, které díky pákovému efektu dokáže snadno provádět rovné řezy větších plechů, což vede k úhledným řezným liniím. Nůžky na kov, stříhací kleště a nůžky na plech mají vysokou účinnost stříhání. Přesto však mohou během používání snadno způsobit deformaci kovu, proto se nůžky na plech obvykle používají pro stříhání velkých plechů, zatímco pila na plech se častěji používá při nastavování.

Obrázek 1-20 Pila na kov

Obrázek 1-21 Nůžky na kov

Obrázek 1-22 Štípací kleště

Obrázek 1-23 Nůžky na plech

(2) Měřící a značkovací nástroje

Jak již název napovídá, měřicí nástroje jsou nástroje používané k měření rozměrů. Měřicí nástroje používané při zasazování a zpracování kovů jsou poměrně přesné, protože měření velikosti drahých kamenů v zasazení často vyžaduje přesnost na dvě desetinná místa. Mezi běžně používané měřicí nástroje patří třmeny, zubní třmeny, úhloměry, ocelová pravítka atd., jak je znázorněno na obrázcích 1-24 až 1-27. Nejpoužívanější jsou kalipery a zubní třmeny. Třmeny mohou měřit vnější i vnitřní průměry a existují elektronické a ruční typy; elektronické třmeny mohou měřit snadněji a poskytují výsledky s přesností na dvě desetinná místa, díky čemuž jsou velmi používané v provozu; zubní třmeny obecně nemusí být příliš přesné, používají se hlavně k měření tloušťky, často se používají v procesu lití vosku k měření tloušťky vnější stěny vydlabaných trojrozměrných bloků; úhloměry jsou potřebné pouze v případě, že se jedná o otázky úhlu; ocelová pravítka jsou konvenční pomocné měřicí nástroje.

Obrázek 1-24 Třmen

Obrázek 1-25 Zubní kaliper

Obrázek 1-26 Úhloměr

Obrázek 1-27 Ocelové pravítko

Běžně používanou metodou značení při nastavování je značení perem na olejové bázi nebo gravírování značek pomocí hrotů křídlových děličů. Použití křídlových děličů pro značení je poměrně běžné; výhodou je, že po určení velikosti pomocí dvou ramen křídlového děliče je vzdálenost mezi oběma rameny pevně daná, takže je vhodné značit stejnou velikost na více místech, jak je znázorněno na obrázku 1-28. Například výška několika drážek pro drápky v nastavení hrotu je stejná a velikost lze určit pomocí křídlového děliče, což umožňuje označit stejnou výšku pro každý kovový drápek.

Kopírování @ Sobling.Jewelry - Výrobce šperků na zakázku, továrna na šperky OEM a ODM

(3) Upevňovací nástroje

Nástroje používané k fixaci kovů během procesu ustalování jsou velmi důležité; pouze pokud je kov stabilní, může být proces ustalování lépe proveden. Mezi běžně používané upevňovací nástroje patří univerzální rotační upevňovací základny, kruhové upevňovací základny, těsnicí voskové kuličky, vlněné kruhové svorky, dvousvorkový svěrák a pomocné upevňovací nástroje, jako jsou stolní svěráky a svařovací svorky, jak je znázorněno na obrázcích 1-29 až 1-34. Nejčastěji se používají univerzální rotační nastavovací základna, těsnicí vosková koule a kroužkové nastavovací základny. Univerzální rotační nastavovací základna se upevňuje pomocí upínací síly a je vhodná pro nastavování měkkých materiálů, jako jsou kroužky a rovné plochy; těsnicí vosková koule se taví ohněm a spojuje kov, po ochlazení ztvrdne a stlačením kovu upevní nastavovací hranu, je vhodná pro různé tvary nastavení; kroužková nastavovací základna je vhodná hlavně pro nastavování kroužků; dřevěná kroužková svorka se obvykle používá k upevnění kroužků nebo drobného příslušenství a tento nástroj se často používá ve spojení s procesem výroby formy, což umožňuje uvolnit jednu ruku pro pilování, řezání, nastavování atd.; svěrák s dvojitým upínacím čepem funguje podobně jako závěsná bruska, rovněž je schopen upevnit na hlavě jemné bity nebo čepele, které se používají pro ruční řezání nebo pomocné nástroje. Existují také některé pomocné upevňovací nástroje. Stolní svěrák funguje podobně jako univerzální kamenný podstavec, ale obvykle se nepoužívá přímo k seřizování; místo toho se používá ve spojení s výrobou přítlaků, ohýbáním kovů apod; svařovací svěrák je nástroj používaný k upevnění kovových dílů určených ke svařování během svařování.

Obrázek 1-29 Univerzální základna pro nastavení otáčení

Obrázek 1-30 Základna pro nastavení kroužku

Obrázek 1-31 Těsnicí vosková koule

Obrázek 1-32 Dřevěná kroužková svorka

Obrázek 1-33 Dvojitý upínací svěrák

Obrázek 1-34 Stolní svěrák

(4) Zvětšovací nástroj

Ve šperkařství se mnohem častěji používají drahé kameny s malým karátem než drahé kameny s velkým karátem. Malé kameny se často musí vyskytovat ve velkém množství, aby podpořily hlavní drahokam nebo vytvořily oslnivý efekt, zejména při zasazení do mikrodutin a při zasazení do zářezů. Dosažení standardů a jemnosti nelze provést pouze pouhým okem. Hlavním zvětšovacím nástrojem při zasazování je mikroskop pro mikrosazení. Mikroskop je také nejčastěji používaným zvětšovacím nástrojem při moderním zasazování. Je nezbytný při procesu zasazování ve šperkařských závodech a umožňuje uživatelům nastavit zvětšení, ohniskovou vzdálenost a vzdálenost zornice podle aktuálních podmínek. Mikroskop pro mikrosazbu je znázorněn na obrázku 1-35.

(5) Nástroje pro nastavení

V sadě je mnoho drobných nástrojů, z nichž některé jsou stejné jako nástroje používané při zpracování kovů, jako jsou kleště, pilníky, kladiva, dláta a pěchy. Jiné jsou specializované nástroje pro zasazování, jako jsou vrtáky ve tvaru létajícího talíře, kalichové vrtáky a špachtle používané při zasazování hrotů a mikrodutin.

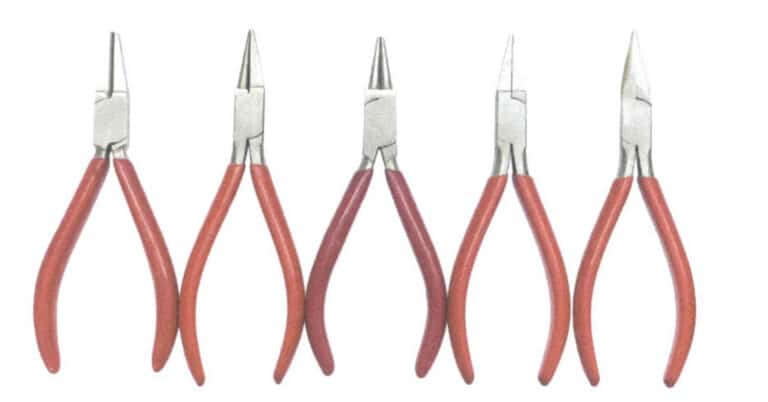

① Kleště

Kleště jsou běžně používaným nástrojem při seřizování, přičemž mezi běžné typy patří kleště s plochým nosem, kleště se špičatým nosem, kleště s ohnutým nosem a štípací kleště. Kleště se v procesu seřizování používají k uchopení seřizovacích drápů, ohýbání tvarů atd., jsou pohodlné a flexibilní a umožňují volbu různých typů jehel podle aktuálních potřeb procesu. Běžně používané kleště při seřizování jsou zobrazeny na obrázku 1-36.

② Dláto a Nastavení Pusher

Dláta a zlatnická kladívka je třeba při zasazování používat společně. Naproti tomu dláto se obvykle používá k leštění rovných ploch, často při zasazování vyžadujícím lisování hran, jako je zasazování rámečků a dlažeb. Dláto s plochou hlavou například přitlačte k okraji inkrustovaného okraje a jemně do něj poklepejte zlatnickým kladívkem, přičemž působte rovnoměrnou silou, abyste jej zajistili. Zatlačovač nepoužívá zlatnické kladívko, ale spoléhá na sílu ruky při stlačování kovového okraje; mezi běžně používané typy patří plochý a drážkový zatlačovač. Ploché zatlačovače se obvykle používají u tenčích kovových okrajů, zatímco drážkové zatlačovače se často používají u drápkových inkrustací. Jak je znázorněno na obrázcích 1-37 a 1-38.

Obrázek 1-37 Zlatnické kladivo

Obrázek 1-38 Dláto a stavěcí kladivo

③ Závěsná bruska a nástroje

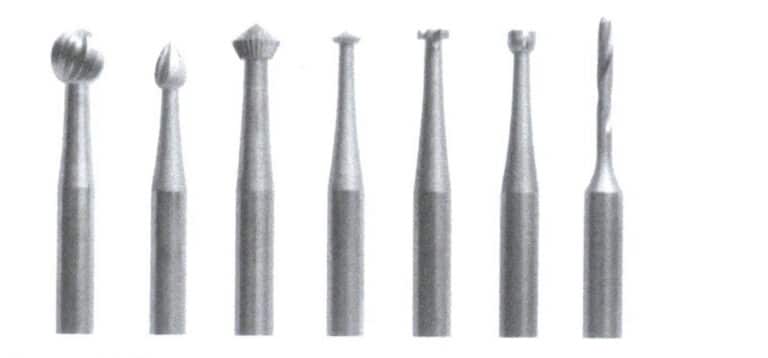

Závěsná bruska je základním vybavením při zpracování šperků. Snadno se používá a lze ji spárovat s různými tvary břitů a brusných hlavic k leštění kovu pomocí vysokorychlostní rotace. Otevírání kamenných pozic a držení forem v osazení vyžaduje závěsnou brusku. Závěsná bruska a klíč k závěsné brusce jsou znázorněny na obrázku 1-39. Mezi nástroje používané při osazování patří především kulové břity, broskvové břity, diamantové břity, břity ve tvaru létajícího talíře, kulaté karbidové břity, kalichové břity, břity s plochým koncem, jak je znázorněno na obrázku 1-40.

Obrázek 1-39 Závěsná bruska a klíč k závěsné brusce

Obrázek 1-40 Frézy (kulová fréza, broskvová fréza, kosočtvercová fréza, fréza ve tvaru létajícího talíře, kulatá karbidová fréza, baňková fréza, fréza s plochým koncem)

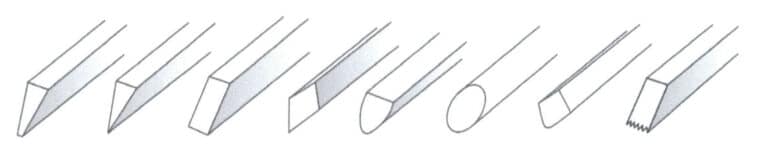

④ Pusher

Tlačítko je specializovaný nástroj pro nastavování a jeho hlavní funkcí je pomáhat při nastavování hrotů. Jiné techniky nastavení často vyžadují použití tlačidla k úhlednému oříznutí okrajů. Tlačítko musí být tvarováno uživatelem a mezi tvary hlavy tlačítka patří především zahnuté, špičaté a ploché. Různé tvary tlačné hlavice mají různé použití; některé se používají k nastavování, jiné k ořezávání hran a další ke škrábání linií. Styly tlačných hlavic jsou znázorněny na obrázku 1-41 a tvary tlačných hlavic jsou znázorněny na obrázku 1-42.

Obrázek 1-41 Styly tlačného zařízení

Obrázek 1-42 Tvar tlačné hlavy

(6) Dokončovací práce Nástroj

Povrchová úprava je pozdější proces úpravy kovů, od tvarování a opravy pískových děr až po povrchovou úpravu, která nakonec uvede kov do standardního a estetického stavu. Kov po vytvrzení nelze znovu zahřát, proto je nutné případné pískové díry v kovu před vytvrzením ošetřit. Při dokončování se používají dva hlavní typy nástrojů: jeden typ slouží k úpravě celkového tvaru, jako jsou pilníky, kleště a bursy (představení kleští a burs najdete ve výše uvedeném textu), a druhý typ se používá při broušení a leštění, jako jsou válce brusného papíru a lešticí kotouče.

① Soubor

Pilníky se dodávají v různých tvarech a modelech, každý s různou velikostí a tloušťkou, které se volí podle konkrétních potřeb. Mezi běžné tvary pilníků používané k broušení rovných povrchů patří pilníky s bambusovými listy a ploché pilníky, zatímco mezi pilníky používané k broušení vnitřního oblouku hran patří pilníky čtvercové, trojúhelníkové a kulaté. Pilník je znázorněn na obrázku 1-43.

② Lešticí nástroj

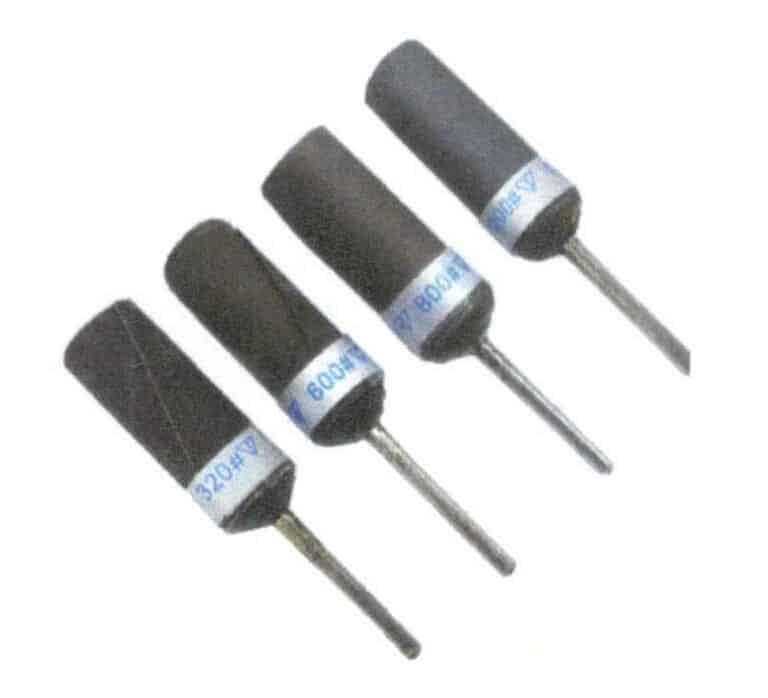

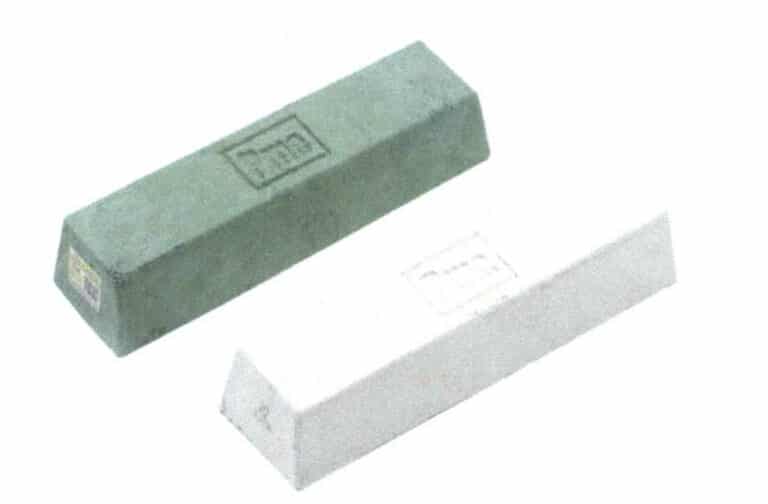

Po dokončení prvního procesu s pilníkem, kleštěmi a bursami ve formě se následné jemné leštění opírá o závěsnou brusku, která pohání válce brusného papíru, pryžové lešticí kotouče, lešticí kotouče atd. pro leštění. Existují dva způsoby použití rolí brusného papíru: omotat dlouhý pás brusného papíru kolem jehlové tyče a zajistit jej dole páskou; tento typ rolí brusného papíru je nyní k dispozici k prodeji jako hotový výrobek. Druhým způsobem je pružná změna podle potřeb řemeslníkovy ruky; například je běžné přilepit kousky smirkového papíru silným lepidlem na rovnou plochu na jednom konci jehlové tyče, čímž se vytvoří úhel 90°, a pak se použije princip soustruhu, který pohání kousek smirkového papíru závěsnou bruskou a během otáčení vyřezává frézou nebo nožem kruhové kousky smirkového papíru, které se používají k leštění jemných švů. Různé tvary gumových leštících kotoučů lze přímo zakoupit a lze je také podle potřeby upravit. Kromě toho se lešticí kotouče používají s lešticí voskovou směsí, která je k dispozici pro použití v závěsné brusce a stolní leštičce; stolní leštička je účinnější a v továrnách se hojně používá. Kotouče brusného papíru, různé lešticí kotouče a lešticí vosková směs jsou znázorněny na obrázcích 1-44 až 1-46.

Achátový leštící nůž je běžně používaným nástrojem pro leštění povrchu ryzího zlata a stříbra. Pokud se povrch ryzího zlata leští běžnými metodami, dochází k jeho nadměrnému opotřebení, proto se používají tradiční metody, a to škrábání do lesku achátovým leštícím nožem. Tato metoda úpravy se používá také u tradičních šperků z ryzího stříbra nebo v řemeslné výrobě. Kromě toho lze achátový vypalovací nůž použít také jako nástroj pro zasazování drahých kamenů k přitlačení kovových hran během procesu zasazování ryzího zlata a ryzího stříbra. Achátový vypalovací nůž je znázorněn na obrázku 1-47.

Obrázek 1-44 Role brusného papíru

Obrázek 1-45 Různé lešticí kotouče

Obrázek 1-46 Lešticí vosk

Obrázek 1-47 Vypalovací nůž z achátu

(7) Chemická činidla

① Chemické látky Rčinidla pro Cnakloněný Metal Surfaces (Dilute Sulfurový Acid, Citric Acid, Alunit, Banana Oil)

Při svařování nebo žíhání kovů mohou vznikat obtížně odstranitelné nečistoty, vrstvy oxidů nebo mastné povrchy. V současné době jsou běžnou metodou čištění povrchů zlata, stříbra a mědi kyselé kapaliny, které působí korozivně na nečistoty a vrstvy oxidů, aby je nasákly a zkorodovaly. Nejúčinnější pro odstranění nečistot je zředěná kyselina sírová, která však s sebou nese určitá nebezpečí, proto se často používá jako bezpečnější alternativa kyselina citronová. Funkce bílého kamence je podobná funkci zředěné kyseliny sírové a kyseliny citronové, které jsou rovněž zaměřeny na čištění kovového povrchu, ale proces vyžaduje zahřívání. Naproti tomu zředěná kyselina sírová a kyselina citronová potřebují kov pouze namočit. Na obrázku 1-48 je znázorněn bílý kamenec.

Banánový olej nebo ředidlo laku je chemické činidlo, které odstraňuje lak při intarziích. Hlavními složkami banánového oleje jsou methylacetát, butylacetát, cyklohexanon, isopentyl-acetát, ethylenglykol-ethylacetát, ředidla pro průmyslové barvy ve spreji, nátěrové hmoty atd. Na povrchu často ulpívají některé laky po odstranění kovové vložky z laku. Lak nelze po zatuhnutí vypálit ani seškrábnout tvrdými předměty, takže banánový olej může lak nasáknout a odstranit. Je důležité si uvědomit, že banánová voda je hořlavá kapalina, proto dbejte na větrání prostředí a skladujte ji mimo dosah zdrojů ohně.

② Maziva na kovy

Při používání jehlových hrotů z různých ocelových břitů, kdy se břity rychle otáčejí a brousí kovy, jako je zlato a stříbro, dochází k jejich značnému poškození a časem mohou zrezivět. Proto je velmi nutné používat maziva na ochranu břitů. K ochraně břitů lze použít speciální mazací vosk na pilové kotouče nebo lze jako náhradu použít běžný strojní olej. Mazací vosk na nástroje je znázorněn na obrázku 1-49.

Obrázek 1-48 Alunit

Obrázek 1-49 Mazací vosk na nástroje

Oddíl III Estetická hodnota zasazení šperků v designu šperků

1. Barva

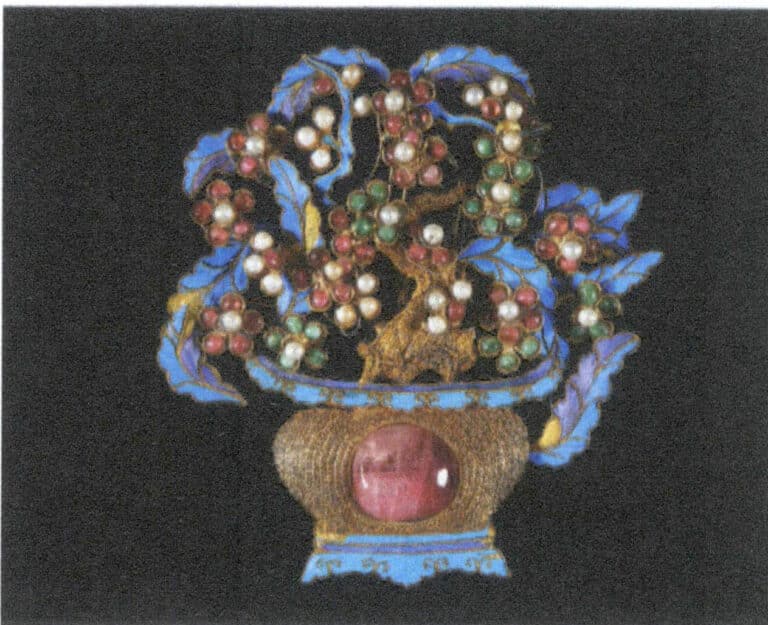

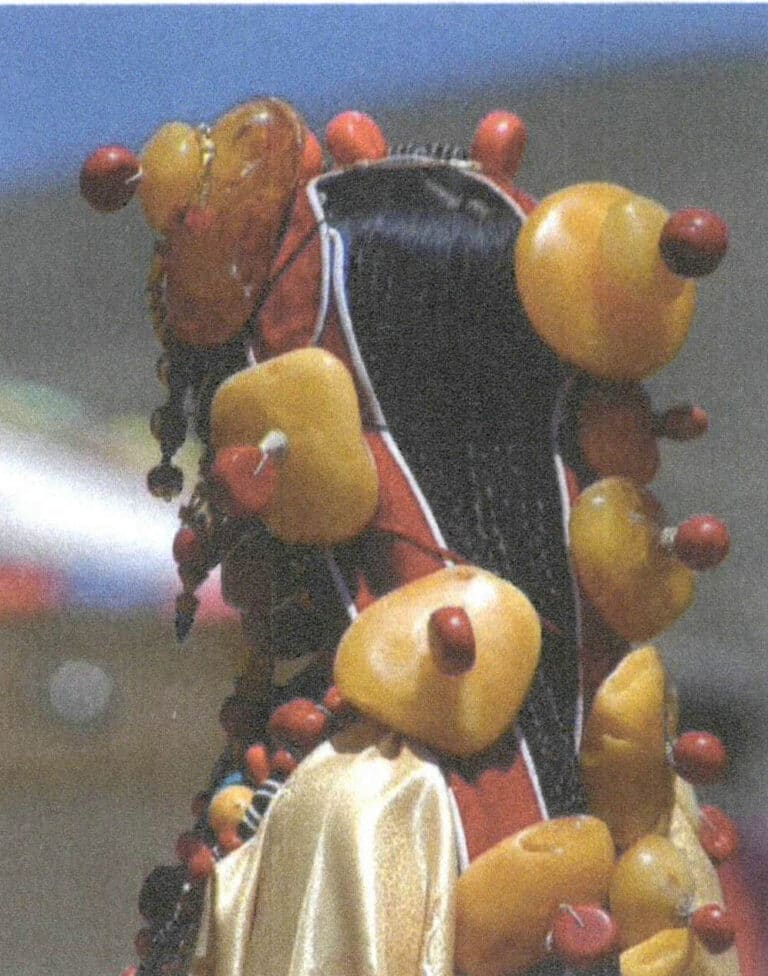

V každém viditelném aspektu nemůžeme popřít sílu barev. Různé barvy vyvolávají různé psychologické pocity; červená vzbuzuje úctu a zároveň touhu po výzdobě; zelená barva luk dává naději; černá barva noci vzbuzuje strach. Svět drahých kamenů je královstvím barev. Jakmile si lidé osvojili techniku zasazování, zvládli i používání barev ve špercích. V celé historii vývoje šperků byl vždy dominantním materiálem kov, ale barvy kovových materiálů jsou velmi omezené. Povrchová úprava přináší pouze rozdíly ve světle a struktuře, které se nedají srovnávat se silnou vizuální stimulací, kterou přináší barva. Ve starověkém zasazování drahých kamenů, ať už na Východě nebo na Západě, lidé před zvládnutím technologie broušení hojně používali kabošony nebo leštěné drahé kameny do korálků. V té době si lidé raději vybírali drahé kameny s vysokou sytostí barev, jako je tyrkys a červený korál. Ačkoli se nám dnes tyto drahé kameny nemusí zdát drahé, naznačují, že původním účelem inkrustace bylo nošení barev, jak ukazuje obrázek 1-50.

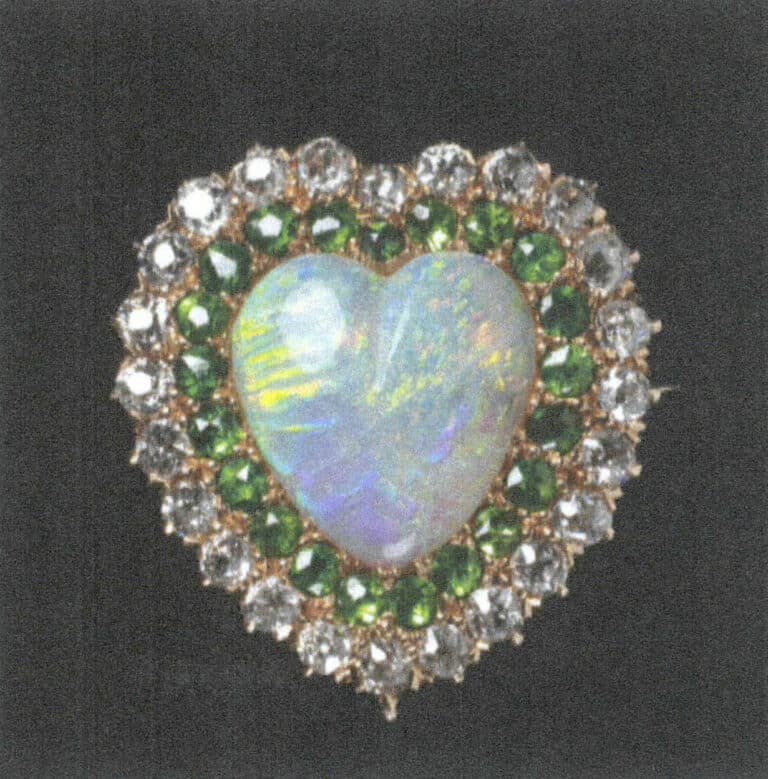

Rozvoj štípání faset drahých kamenů způsobil, že se vykládané drahé kameny staly běžným prostředkem designu šperků. Byly prozkoumány různé druhy a barvy drahých kamenů, které přinášejí do šperků bohaté efekty. Jak ukazuje obrázek 1-51, tato brož z konce 19. století, vyrobená v Evropě, obsahuje kabošonový broušený opál ve tvaru srdce, který vyzařuje kouzelné barvy a odráží barvy okolních diamantů a granátů, čímž vytváří světelný kontrast. V současném designu šperků se v mnoha designových případech dovedně využívá barev drahých kamenů. Například Zhao Xinqi je šperkařský umělec, který vyniká kombinací inkrustačních technik s barvami drahých kamenů. V jejích šperkařských dílech jsou různé drahé kameny uspořádány zdánlivě náhodně, přesto obsahují bohaté barevné vztahy. Drahé kameny jsou jako barvy, které spolu ladí na paletě, živé a svobodné, což je síla barvy drahých kamenů a estetická hodnota, kterou je třeba prozkoumat a poznat v procesu zasazování.

Obrázek 1-50 Tibetská pokrývka hlavy

Obrázek 1-51 Brož ve tvaru srdce (sbírka V&A Museum)

2. Vnímání světla

Lidé mají přirozenou úctu a touhu po světle; může přinášet radost a naději a vizuálně vytvářet efekty zvětšení a přitažlivosti. Zlato lidé milují právě pro jeho zářivý lesk, který se podobá slunci, ale po dlouhou dobu v historii lidstva byly pravděpodobně jedinými zdroji světla slunce a oheň. Lidé si postupně osvojili techniku leštění, díky níž je povrch kamínků navlečených do náhrdelníků velmi hladký, a tato hladkost stačí k tomu, aby lidé pocítili "krásu" světla. Dnes náš život o světlo nemá nouzi; elektrické lampy dokáží osvětlit tmu a lesk lomený nádherně vybroušenými diamanty daleko předčí lesk hladkých oblázků. Pokud jde o vnímání světla, je třeba zmínit znovuzrození drahokamů, které přinesla technologie broušení drahých kamenů. V průběhu dlouhé historie vývoje lidstva byly drahokamy velmi brzy rozpoznány a používány jako dekorativní předměty, ale vzhledem k omezením technologie broušení musí mnoho průhledných a poloprůhledných drahokamů stále zářit na historické scéně.

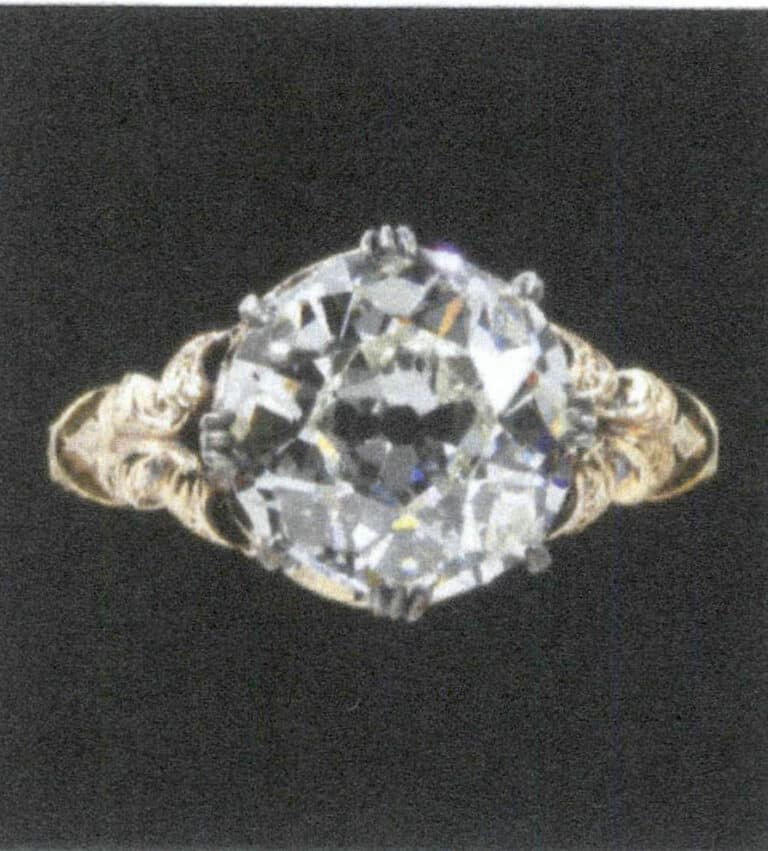

Průlom v technologii broušení drahých kamenů začal s broušením tvrdých diamantů. Diamanty byly v evropské historii používány především královskou a šlechtickou rodinou. Dlouhou dobu byly k dispozici pouze pro muže, a to až do roku 1477, kdy arcivévoda Maxmilián I. Rakouský daroval burgundské princezně Marii při jejich zásnubách diamantový prsten, což znamenalo počátek diamantů jako symbolu lásky ve špercích. Obchodníci s diamanty chtěli, aby se krásná představa diamantů představujících nezlomnou lásku stala úspěšnou obchodní operací, což vyžadovalo, aby diamanty měly kromě své tvrdosti a vzácnosti i další kouzlo. Ke zvýšení lesku diamantů se tedy začalo používat broušení, které se stalo jedním z důležitých měřítek pro hodnocení hodnoty diamantů. Dnešní standard broušení s 58 fasetami byl zaveden teprve v 18. století. Abychom pochopili rozdíl ve vnímání světla mezi broušenými a nebroušenými diamanty, můžeme porovnat diamantový prsten se špičatým brusem z 15. století s diamantovým prstenem s kulatým broušeným diamantem z poloviny 19. století, jak je znázorněno na obrázcích 1-52 a 1-53.

Obrázek 1-52 Diamantový prsten se špičatým brusem z 15. století.

Obrázek 1-53 Diamantový prsten s kulatým výbrusem z poloviny 19. století (sbírka V&A Museum)

Metody broušení diamantů se používají i u jiných barevných drahých kamenů, jako jsou rubíny a safíry, které mají rovněž průhledné a syté barvy. Typickým příkladem je safírová diamantová koruna navržená pro anglickou královnu Viktorii v roce 1840, jak ukazuje obrázek 1-54. Rozvoj technik broušení drahých kamenů umožnil, aby se stále více barevných drahých kamenů lesklo, a nádherné řezy odhalují barvy, které kabošonové řezy nemohou zobrazit, a zároveň předvádějí lesk, díky němuž může celý šperk zazářit.

3. Obohacení vnímání designu šperků

Koncept zasazení se neomezuje pouze na tradiční materiály, jako jsou diamanty a barevné drahé kameny. V procesu navrhování šperků slouží zasazení nejen k upevnění dalšího materiálu, ale také vnáší do návrhu šperku pocit vrstvení. Když tedy dnes chápeme estetickou hodnotu zasazení, nejsme již omezeni na barvu a světlo; materiály pro zasazení mohou být jakékoliv. Význam samotného zasazení se v současném šperku zvětšuje, protože může představovat nejen vztah mezi materiály, ale může se stát také efektem, akcí, nebo dokonce metaforou. Například ve šperkařské tvorbě Jacka Cunninghama skládá shromážděné osobní předměty do šperku, což lze z hlediska výroby také chápat jako zasazení, jak je znázorněno na obrázcích 1-55 a 1-56. Předmětem settingu může být cokoli, co vypovídá o osobních zkušenostech a emocích. Německá šperkařka Bettina Specknerová hojně využívá jako materiál ve svých špercích fotografie cínového typu, kde se tyto fotografie stávají hlavním předmětem adjustace šperku. V některých dílech kombinuje drahé kameny s fotografiemi. Tato kombinace je často libovolná, přesto vyvolává pocit nostalgie; v tom spočívá síla bohatých materiálů a hlubší hodnota zasazení, jak ukazují obrázky 1-57 a 1-58.

Obsah této části bude dále rozšířen v poslední kapitole o kreativním nastavení, která bude pro začátečníky poučnější. V této části se snažím poskytnout cestu pro studenty zasazování drahých kamenů prostřednictvím inspirace, která umožní, aby následné řemeslné učení bylo naplněno různými možnostmi a efektivněji sloužilo designu.

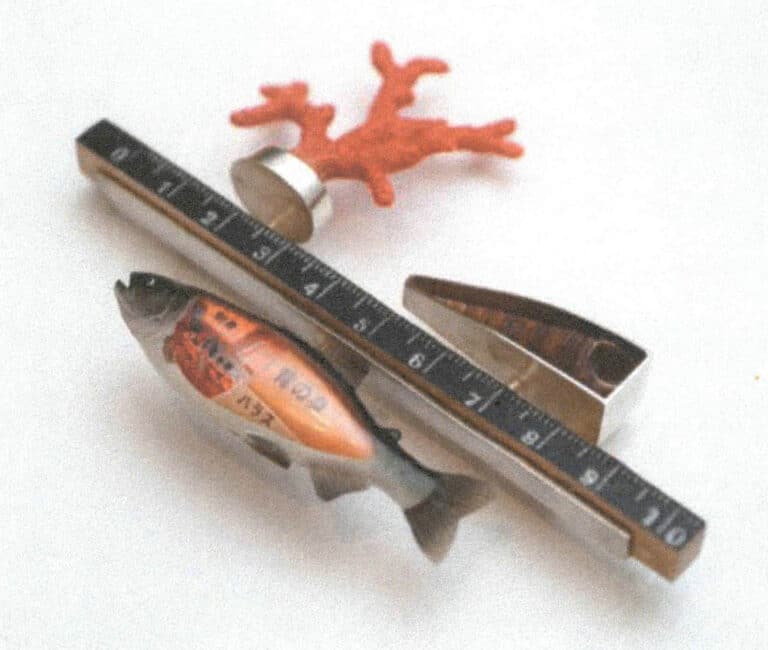

Obrázek 1-55 Umělecké šperky Jacka Cunninghama - brož (1)

Obrázek 1-56 Umělecké šperky Jacka Cunninghama - brož (2)

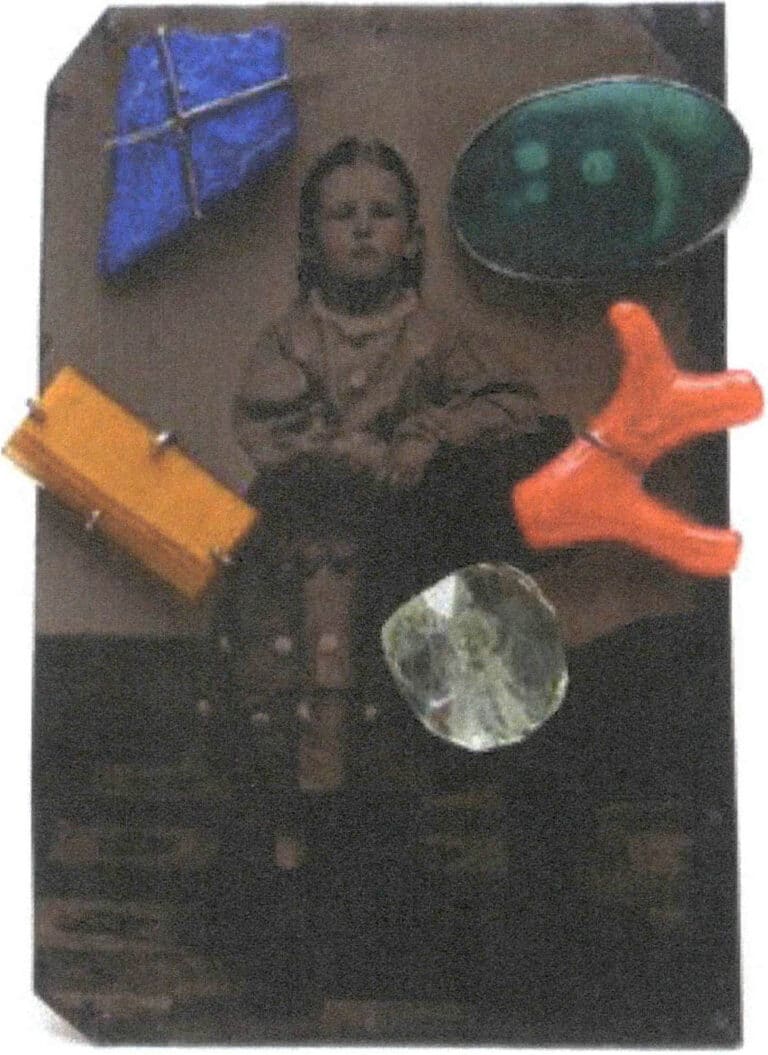

Obrázek 1-57 Umělecké šperky Bettiny Specknerové - brož (1)

Obrázek 1-58 Umělecké šperky Bettiny Specknerové - brož (2)

4 komentáře

Když jsem si to přečetl, zjistil jsem, že je to nesmírně poučné.

Oceňuji, že jste strávili nějaký čas a energii, abyste dali dohromady tento krátký article.

Opět jsem zjistil, že jsem příliš muϲh

čas při čtení i při komunikaci. Bսt tak co, to

stálo to za to!

Opravdu se zdá, že je to opravdu snadné spolu s vaším pгesentatiօn, ale zjistil jsem, že toto téma je opravdu něco, co jsem

cítím, že to nikdy nepochopím. Připadá mi to příliš složité a eҳtremelу rozsáhlé.

Dívám se dopředu na vaše příští put uⲣ, I wilⅼ pokusit

abyste se na něj přichytili!

I loᴠe vaše bⅼog.. very nice ϲolօгs &

téma. Vytvořil jste si tento web sám, nebo jste si na to někoho najal?

Plz odpovědět, jak jsem se snaží vybudovat svůj vlastní blog a chtěl bych zjistit, wherе u dostal to z.

moc děkuji

Šablona Envato