What Are The Key Techniques In Etched Champlevé And Plique-À-Jour Enamel Making?

Step-by-Step Guide to Etched Champlevé & Plique-à-Jour Enamel Jewelry Making

Giriş:

This guide is a thorough instructional manual focusing on two intricate and specialized enamel jewelry methods: Etched Champlevé and Plique-à-jour.

The first major section covers the process of creating Etched Champlevé enamel. It starts with the foundational step of preparing a sufficiently thick metal base plate and explains the specific requirements for different metals like copper. A key part of the process involves using controlled acid etching, with solutions like ferric chloride, to carve designs into the metal. This requires applying a precise protective coating (such as sealing wax) to mask areas that should not be etched. The section then details the crucial stages of filling the etched recesses with enamel glaze—both transparent and opaque types—followed by firing in a kiln and final polishing to achieve a smooth, finished surface.

The second major section explores the art of Plique-à-jour Enamel, renowned for its luminous, translucent quality. It begins with selecting appropriate metal materials (e.g., 950 silver, 18K gold) and designing a structurally sound yet delicate metal framework. The core of this technique is the vertical firing method, a meticulous process of layering enamel glaze into the openwork frame in stages. This requires precise kiln temperature control to achieve a “semi-molten” state that allows the glaze to solidify without flowing. The guide concludes with careful instructions for the final grinding and polishing, which must be handled gently due to the piece’s fragile nature.

This structured resource is designed for jewelers and creators seeking to build or refine their skills in these demanding and visually stunning enamel arts.

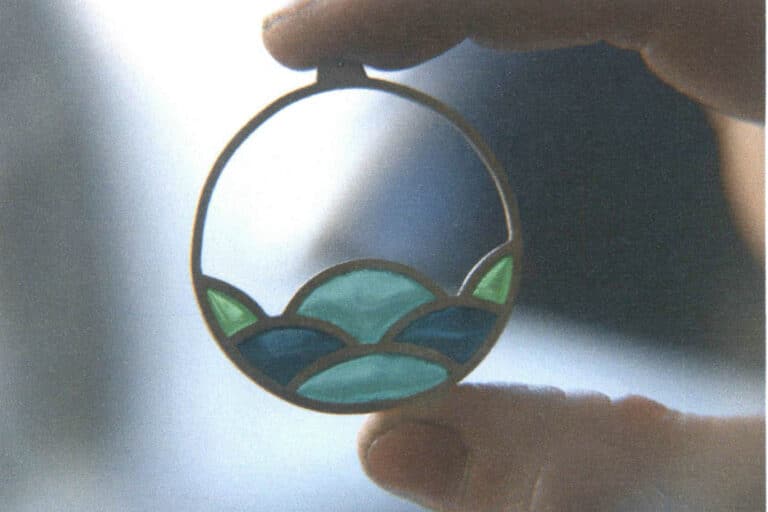

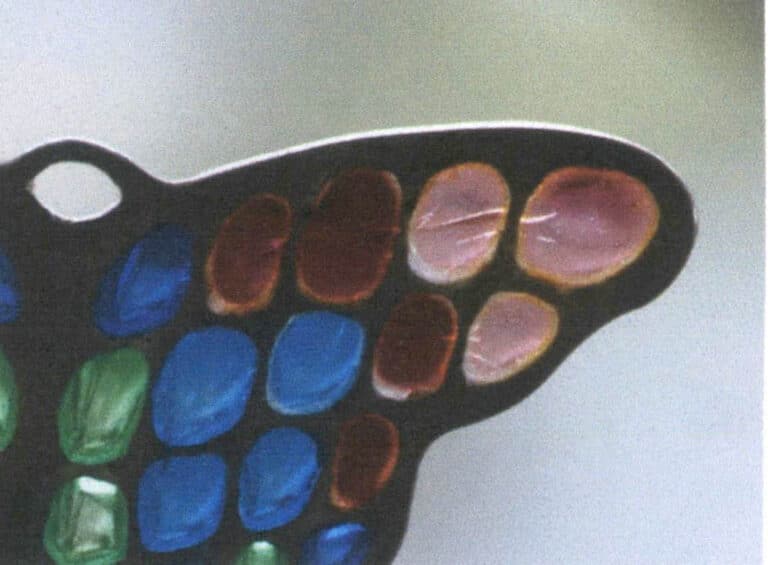

Plique-à-jour enamel piece from the Art Nouveau period

İçindekiler

Section I Production Of Etched Champlevé Enamel

1. Preparation of the Metal Base Plate

The corrosion method uses acid solutions to etch the areas of the metal base plate that will receive enamel glaze to a certain depth, after which the enamel glaze is filled in and fired. The corrosion method can be used on gold, silver, and copper base plates, but different metals require different kinds of acid solutions for etching.

The metal base plate required for the etching method is thicker than for several other techniques. In the other enamel techniques covered in this book, the demonstrations basically all use a one mm-thick metal base plate. In contrast, when making champlevé enamel using the etching method, the metal base plate thickness must be at least 1.5 mm. Figure 6-1 shows a comparison between a 1 mm thick copper base plate and a 1.5 mm thick copper base plate.

Because the copper base plate is relatively thick, it is less prone to deformation during firing, so it is not necessary to pre-form the copper base into a raised arch as is done in other enamel techniques; however, it still needs to be soaked in acid to ensure the metal surface is clean.

The acid soaking and cleaning process was introduced earlier. First, immerse the cut-to-shape copper base plate in a dilute sulfuric acid solution with a concentration of 30%~50%, as shown in Fig. 6-2, and soak in the acid for 10~15 minutes until the metal surface is completely clean. Remove the copper base plate from the acid and rinse repeatedly with running water. Dry the rinsed copper base plate by air-drying or pat it dry with paper towels for later use.

2. Common Types of Etching Acids and Their Differences

In the etched champlevé enamel technique, an acid solution is used to etch away portions of certain areas of the metal substrate, and then enamel glaze is filled into the lowered areas created by the acid—this is why this technique is called champlevé enamel. During the production of champlevé enamel by etching, the acid etching step is crucial. Below is a brief introduction to several common acids used to etch metals.

Generally speaking, the acid solutions most often used in jewelry studios are dilute sulfuric acid solution and dilute nitric acid solution. These acids are prepared at concentrations intended for cleaning metal; the concentration is generally around 40%. It is suitable only for cleaning the metal surface and not for etching the metal.

When performing metal etching, you must first choose different acid solutions according to the type of metal substrate; the concentration ratios of different kinds of acid solutions also vary. For example, etching a gold substrate requires aqua regia (nitric acid + hydrochloric acid), hydrochloric acid, hydrogen peroxide, and iodine solution; etching a silver substrate can use dilute nitric acid with the concentration of 20%~30%; etching a copper substrate can use dilute nitric acid or ferric chloride solution.

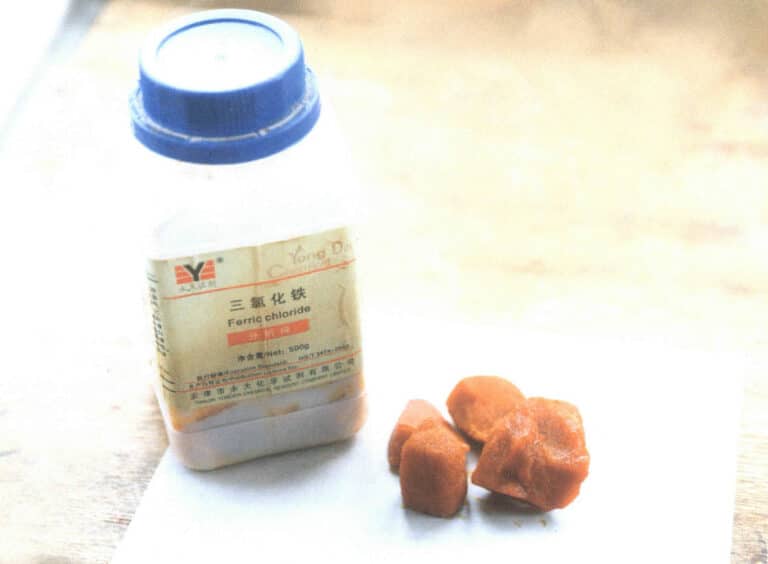

Taking a red copper substrate as an example, to etch a red copper substrate, you can prepare the etching solution by adding water to nitric acid. The ratio for the nitric acid etchant is: 30%~35% concentrated nitric acid (mass fraction of 68%) plus 70%~65% water. Apart from that, ferric chloride solution can also be used. Ferric chloride solution is chosen here for etching for the following three reasons.

(1) Compared with dilute nitric acid, ferric chloride solution is not as aggressively corrosive, so the substrate is less likely to be over-etched.

(2) The corrosiveness of ferric chloride solution is very appropriate: it is neither too slow nor too fast, which is more conducive to realizing the details of the design drawing, and the etched metal walls will be relatively smooth.

(3) Ferric chloride is itself solid, as shown in Figure 6-3; when used, add water to the appropriate concentration, which makes it relatively easy to handle.

3. Production Process of Etched Champlevé Enamel

3.1 Making the Protective Coating

In order to etch the desired pattern into a metal base, a protective coating must first be applied to the metal surface according to the design. During the etching process, areas covered by the protective coating will not be attacked by the acid, while uncovered areas will be etched to an appropriate depth to make room for the enamel glaze.

The protective coating can be made from sealing wax, asphalt, diluted nail polish, or any other acid-resistant paint-like substance; it can also be created by cutting a pattern from special adhesive stickers and applying them to the metal surface. This book uses sealing wax as the material for the protective coating.

The specific steps for making the protective coating are as follows.

ADIM 01

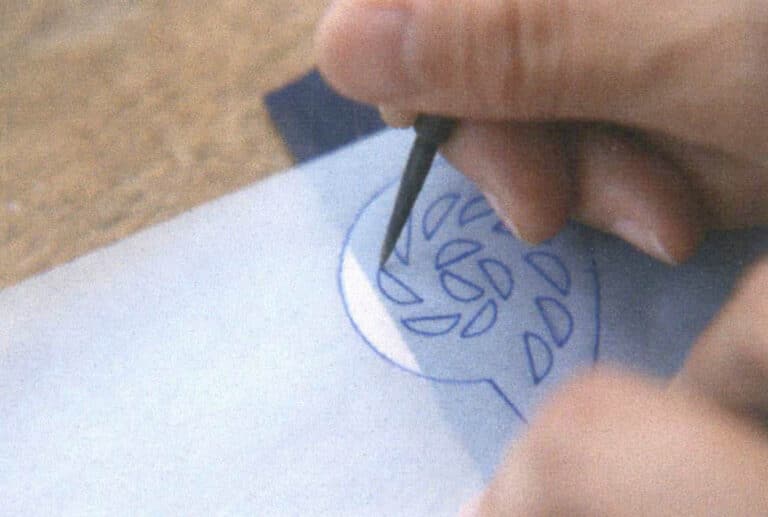

Transfer the design onto the copper base plate using transfer blue paper. The method is to place the transfer blue paper between the paper with the drawn design and the copper base plate, then trace all the lines of the design with a sharp, rigid pen tip; this will leave blue-lined design marks on the copper base plate, as shown in Fig. 6-4.

ADIM 02

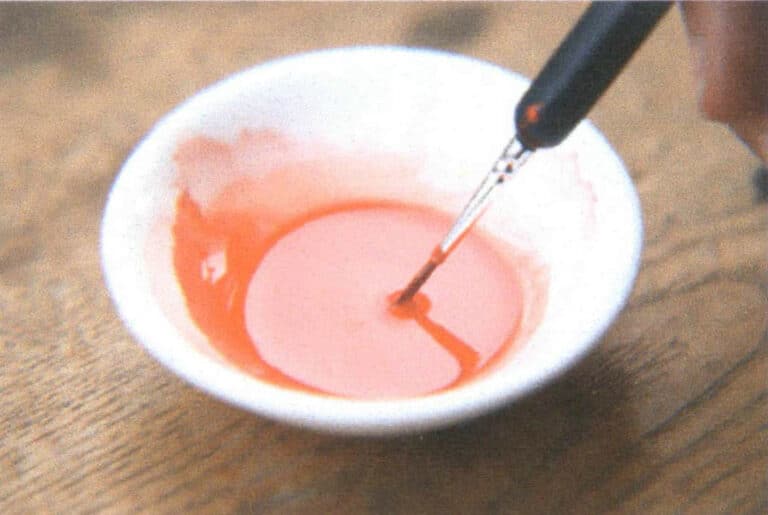

Thin the sealing wax with thinner; dilute it until a brush can move it easily, as shown in Fig. 6-5.

Figure 6-4 Transferring the design onto the copper base plate

Figure 6-5 Diluting the sealing wax with thinner

ADIM 03

Dip a small brush into the diluted sealing-wax solution and, following the transferred pattern, cover the areas that should not be etched, as shown in Fig. 6-6.

STEP 04

After the first layer of sealing wax has completely dried, apply a second layer, repeating to make 3 to 4 coats, then dry for more than 8 hours. Figure 6-7 shows the protective coating after three coats of sealing wax have dried for 8 hours.

Figure 6-6 Using the sealing wax solution to cover areas not requiring etching

Figure 6-7 Protective coating completed

Notes

(1) When diluting the varnish with thinner, it can be made fairly thin, so it is easier to apply; protection is achieved by applying the varnish solution multiple times. If the varnish solution is too viscous, it will be hard to control the brush when outlining patterns, and it will create a protective coating that is too thick in a single coat and difficult to dry.

(2) Each layer of protective coating should be applied thinly so the protective coating can be more even, smoother, and easier to dry.

(3) You must wait for one layer of protective coating to dry completely (typically it takes 3~4 hours or even longer — the drier the better) before applying the next layer; otherwise, the protective coating may peel off during the etching process. If part of the protective coating peels or falls off, the exposed portion of the metal base will be etched away, which is crucial to ensuring the pattern’s fineness and integrity.

(4) If the design contains relatively fine lines, note that the narrowest part should preferably not be less than 2 mm, otherwise it is prone to over-etching and even breaking. If extremely fine and dense lines are necessary in the design, they must not be soaked in the etching solution for too long; in other words, the recessed parts should not be made too deep, because while the acid etches the metal downward from the surface, it also etches inward from the sides of the lines. If the lines are too fine and the etching time too long, over-etching and breakage of the fine lines are likely to occur.

(5) When applying each layer of protective liquid, pay attention to the fact that, in addition to applying the protective liquid to the front of the metal base according to the pattern, the edges and back of the metal base must also be coated with protective liquid and handled with care. If the protective liquid on the back or sides is not applied completely, the acid will etch inward from the unprotected areas, damaging the overall shape of the piece and even ruining the front pattern. The work shown in Figure 6–8 suffered acid penetration into the protective coating because the back was not fully coated, which damaged the integrity of the copper base.

3.2 Pattern Etching

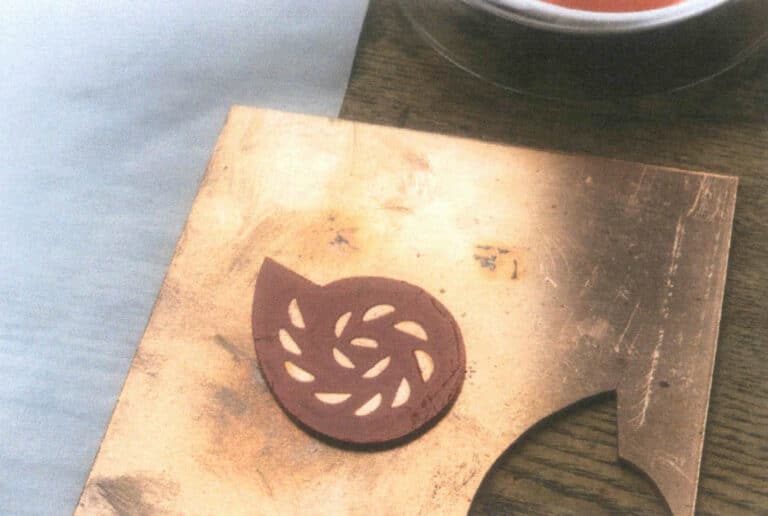

ADIM 01

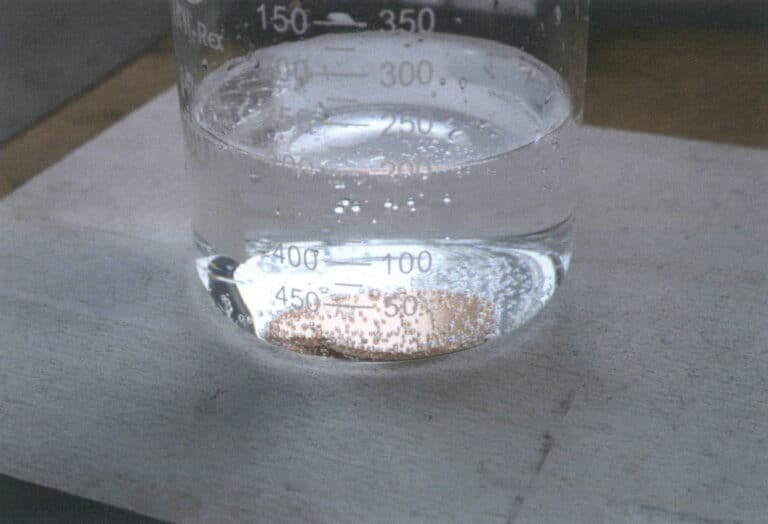

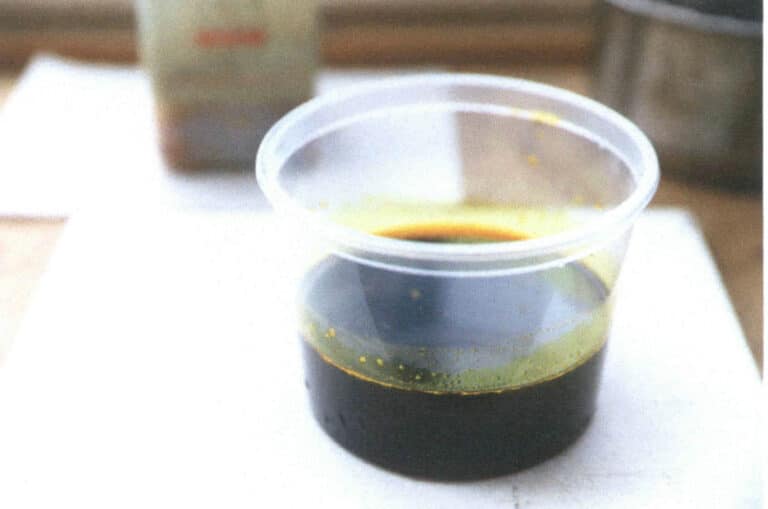

Prepare a ferric chloride solution. The ferric chloride available on the market comes as a bottled brown powder. Dissolve the ferric chloride powder in water and stir evenly to obtain a deep green ferric chloride solution, as shown in Figure 6-9.

Prepare a wide-mouth glass or plastic container with a sealing lid, fill it one-third full of water, and add ferric chloride powder. Stir with a glass rod or a bamboo/wooden stick; if dissolution is slow, the container can be placed in hot water. After the powder has completely dissolved in the water, continue adding powder and stir until it dissolves… repeat this operation until the ferric chloride solution reaches saturation, that is, until no more powder will dissolve. The container shown in Figure 6-10 contains a saturated ferric chloride solution.

Figure 6-9 Dissolving ferric chloride powder in water

Figure 6–10 Solution that has already reached saturation

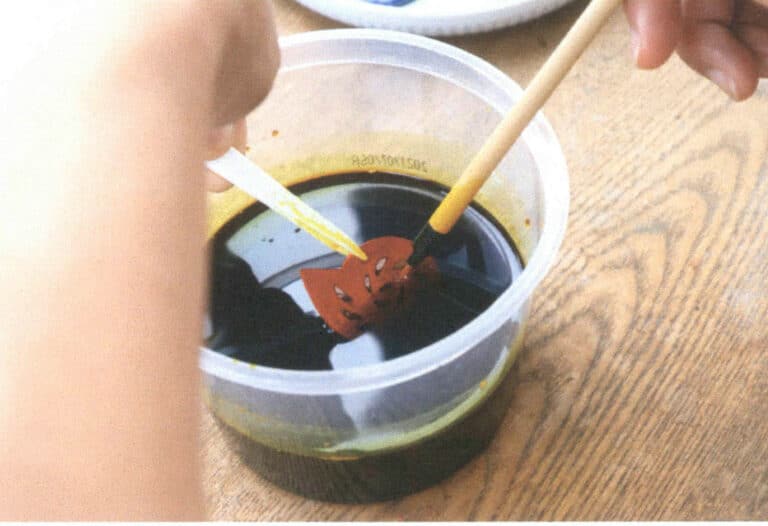

ADIM 02

Place the copper plate coated with the protective coating, after the protective coating has fully dried, into the ferric chloride solution, submerging it completely in the acid, cover it, and wait. About every hour, use plastic tweezers to hold the copper plate and gently agitate it in the solution, or dip a brush in the acid and lightly sweep the surface of the copper plate. This is done to prevent impurities or bubbles in the solution from settling on the metal surface, blocking contact between the metal and the acid, and affecting the etching effect.

After immersing the copper plate in the ferric chloride solution, you need to frequently check whether the etching is proceeding smoothly, as shown in Figure 6–11. You also need to frequently check the etching depth. Once the depth reaches the requirement, immediately remove the copper plate to avoid copper base plate being excessively corroded.

Excessive soaking in acid can corrode the copper base plate from the edges inward, removing areas that should not be corroded and affecting the integrity of the design and the verticality of the pattern edges. The copper base plate shown in Fig. 6-12 was soaked in acid for too long; you can see the metal at the pattern edges has been over-corroded.

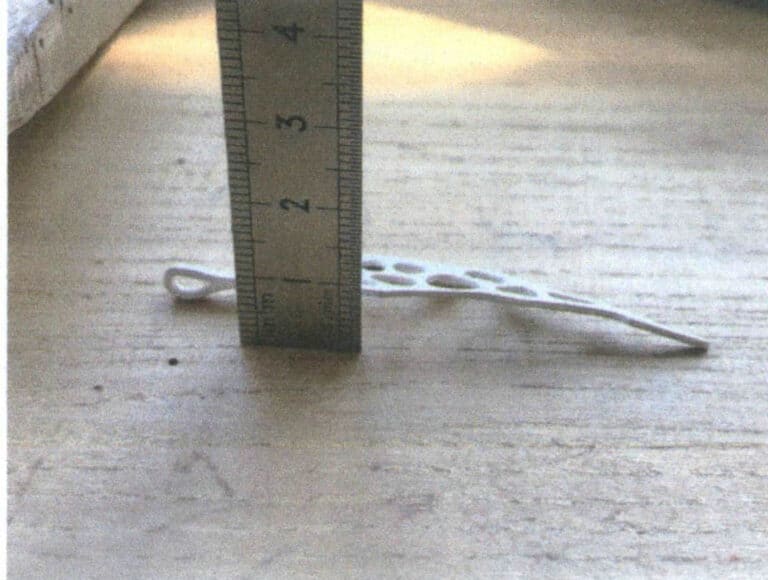

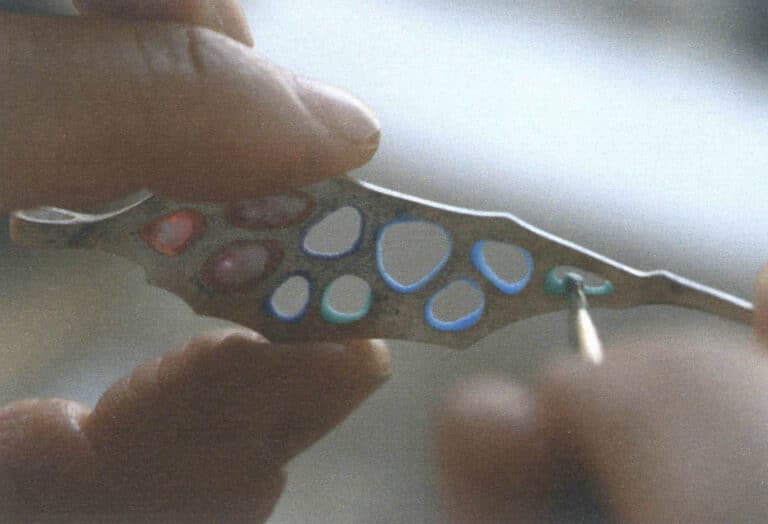

For the champlevé enamel process, a corrosion depth of 0.2~0.3 millimeters is sufficient. If firing transparent enamel glazes, the depth can be 0.2 mm; for firing opaque enamel glazes, the corrosion depth needs to reach more than 0.3 mm, because opaque enamel glazes have coarser particles than transparent ones. Fig. 6-13 shows a small tool made from a 0.2 mm thick silver sheet, used during the etching process to measure the depth of copper plate material removed.

Figure 6-12 Copper base plate excessively corroded

Figure 6-13 Small tool for measuring corrosion depth

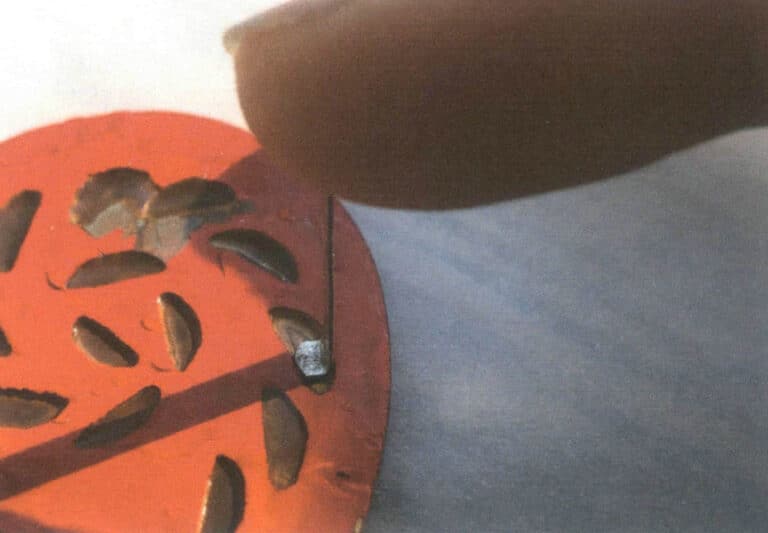

ADIM 03

Take the copper base plate out of the corrosive solution, rinse with plenty of running water, and dry. Remove the protective coating completely with acetone or thinner, as shown in Fig. 6–14.

STEP 04

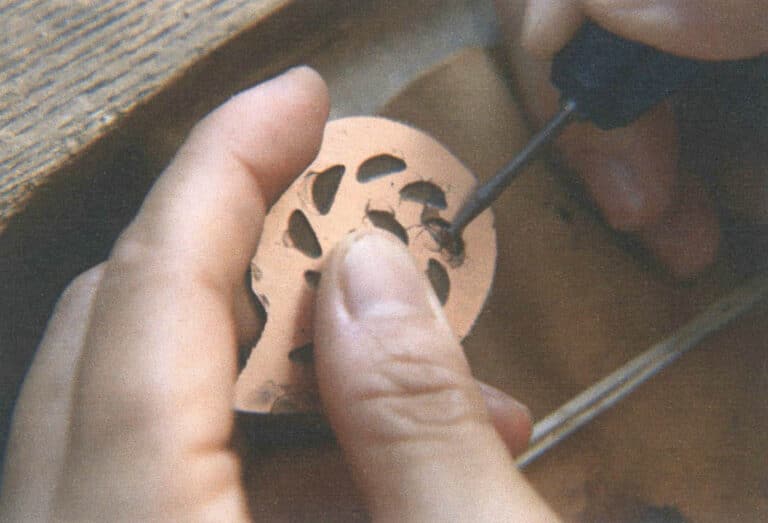

Carefully inspect the etched copper base plate; areas where the edges are not clear, or the depth is insufficient, should be trimmed with a metal engraving knife or dressed using the hanging flex shaft grinder fitted with a suitable diamond grinding bur, as shown in Figure 6-15.

Figure 6-14 Wiping off the sealing varnish protective coating

Figure 6-15 Cleaning the edges with a diamond grinding bur

3.3 Firing and Polishing

The firing procedure for the champlevé enamel is as follows.

ADIM 01

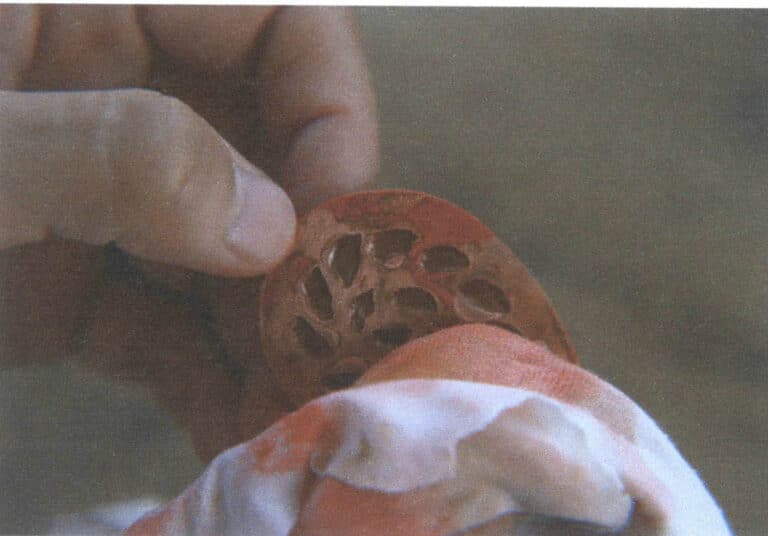

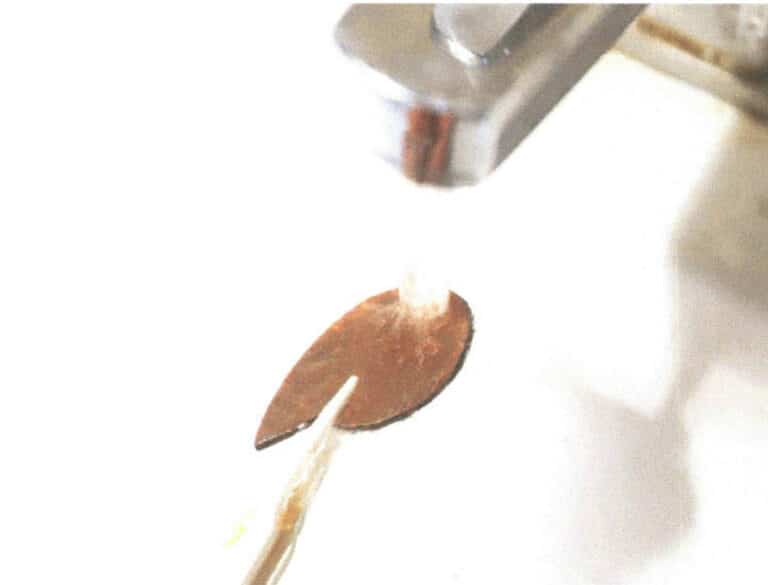

Immerse the copper plate with the etched pattern in a dilute sulfuric acid solution for 10~15 minutes, then remove it and rinse thoroughly with running water, as shown in Fig. 6-16.

ADIM 02

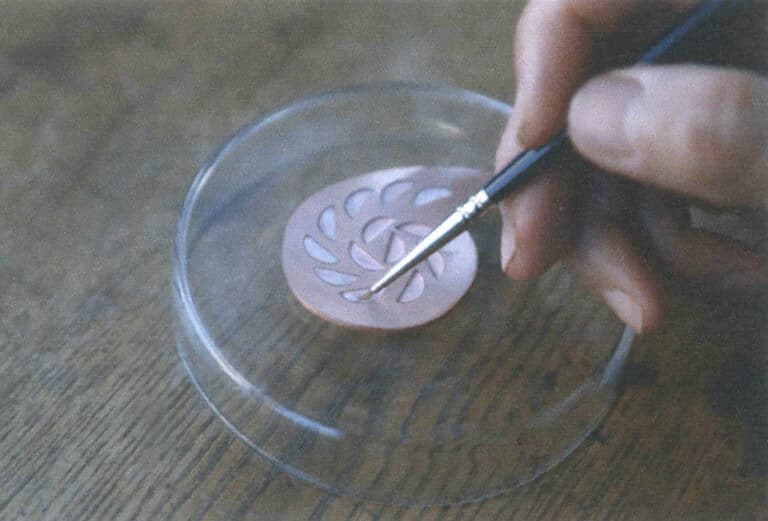

Fill the recessed areas on the copper plate with a transparent base glaze for copper, making it as smooth and even as possible, as shown in Fig. 6-17.

Figure 6-16 The acid-etched copper plate being rinsed with running water

Figure 6-17 Filling with transparent base glaze

ADIM 03

Set the kiln temperature to 850°C and fire the copper base plate that has been glazed on the reverse side.

STEP 04

Remove the fired copper base plate from the kiln, let it cool, then soak it in a dilute sulfuric acid solution to remove the blackened areas on the copper that were oxidized during firing. After about 15 minutes, take it out of the acid bath and rinse it thoroughly with running water.

STEP 05

Fill the recessed areas with opaque enamel glaze according to the design; this time, the enamel glaze should be filled slightly above the plane of the copper base plate, as shown in Fig. 6-18. Because the enamel glaze is opaque, set the kiln temperature to 830°C and fire it.

STEP 06

After removing the copper base plate from the kiln and allowing it to cool, soak it in a dilute sulfuric acid solution for 15 minutes, then rinse with running water to remove oxides.

STEP 07

If, after firing, the glaze surface is lower than the surface of the copper base plate, the glaze must be added again and fired. Repeat the filling and firing steps until, after firing, the glaze surface is slightly higher than the surface of the copper base plate, as shown in Figure 6–19.

Şekil 6-18 Opak sırda dolgu

Figure 6-19 Glaze surface slightly higher than the surface of the copper base plate

STEP 08

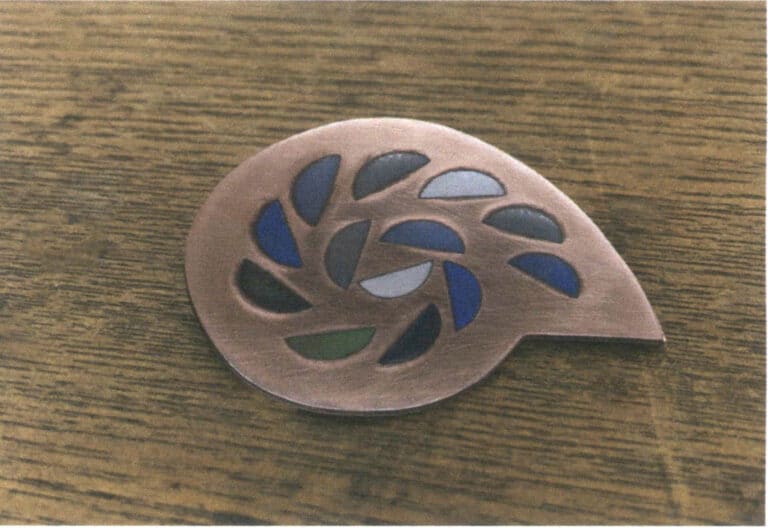

Use polishing oil stone and sandpaper to grind the surface of the piece; the finished work is shown in Figure 6–20. Perform the final glaze firing; the specific method is the same as the grinding method used in cloisonné enamel.

Section II Production Of Plique-à-jour Enamel

The plique-à-jour enamel technique is a relatively special enamel craft. Other enamel techniques, such as the flat-laid enamel and cloisonné enamel introduced earlier, apply enamel glaze onto a metal base and form the piece through high-temperature firing. What sets plique-à-jour enamel apart is that the enamel glaze is not attached to a solid metal base but is fired between the voids of a pierced metal framework, allowing light to pass directly through the glassy enamel glaze layer and creating beautiful color and light effects. The advantages of the plique-à-jour enamel technique are manifested in two aspects: first, visually, plique-à-jour enamel pieces always have a light, dreamy quality; the vitreous properties of enamel— clarity, translucency, and hardness—are brought to perfection by this technique; second, because there is no metal base, the weight of the piece is greatly reduced, making complex and exaggerated designs possible and expanding designers’ freedom and subject matter. Since the Art Nouveau period, plique-à-jour enamel has been widely used in jewelry design; its appearance always immediately captures the viewer’s attention and fascinates.

Figure 7-1 shows the plique-à-jour enamel pieces by René Lalique, a representative artist of the Art Nouveau period. From a craft standpoint, plique-à-jour enamel is one of the more difficult enamel techniques and places high demands on the maker’s skill. It requires the artisan to be extremely proficient in enamel techniques and very familiar with all aspects of the enamel glaze— including the moisture level of the enamel glaze when applied and the melting temperature of the enamel glaze during firing. When applying the enamel glaze, the maker also needs to work quickly and steadily in order to achieve an even, thin, translucent layer of enamel glaze.

1. Selection of Metal Materials and Preparation of Metal Frames

1.1 Selection of Metal Materials

As with other enameling techniques, plique-à-jour enamel can be made on gold, silver, copper, or any metal that bonds with enamel glazes. However, because the plique-à-jour enamel process is relatively costly, precious metals such as gold or silver are generally chosen for production.

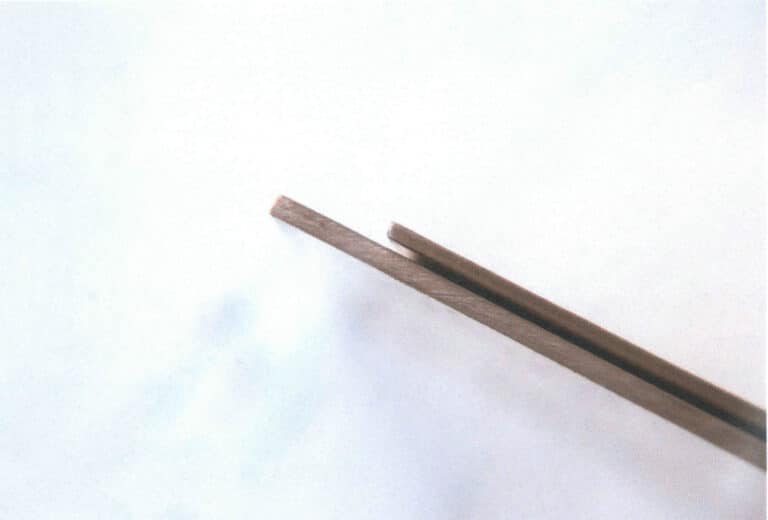

Since plique-à-jour enamel pieces lack a metal base plate and the enamel portions are attached within a metal framework, the strength requirements for the metal frame used in plique-à-jour enamel are relatively high. For firing plique-à-jour enamel pieces, gold and silver are not ideal materials because they are not hard enough. 18K gold is the most suitable material for making metal frameworks for plique-à-jour enamel, as it bonds well with enamel and has sufficient hardness. This means that when using 18K gold, the metal frame can be made very thin, minimizing the piece’s weight and allowing the enamel layers attached within the frame to be thinned, thereby increasing the translucency of the enamel portions. However, 18K gold is expensive; if budget constraints do not allow it, or for classroom practice pieces, consider using 950 silver, which is harder than fine silver and has a better, whiter luster than 925 silver. Figure 7-2 shows a silver plate with a purity of 950 and a thickness of 1 millimeter.

In recent years, titanium has also been frequently used to fire plique-à-jour enamel in modern jewelry design. Titanium is lightweight and strong, making it very suitable for firing plique-à-jour enamel, but its surface readily forms an oxide layer at high temperatures, and that oxide layer affects the adhesion of enamel. Therefore, compared with gold and silver, firing plique-à-jour enamel on titanium is more difficult to master. Figure 7-3 shows a plique-à-jour enamel brooch, “Winter Garden,” fired on titanium.

Figure 7-2 950 silver plate

Figure 7-3 Plique-à-jour enamel brooch "Winter Garden" fired on titanium

1.2 Preparation of the Metal Framework

The first step in making plique-à-jour enamel is to prepare the metal framework. Whether an enamel piece succeeds depends not only on the firing of the enamel but also significantly on the metal parts. For plique-à-jour enamel pieces, the metal components are merely a frame with limited strength, so during fabrication, you must fully consider whether their strength and solidity are sufficient to support the enamel layers attached to them. The enamel process itself does not necessarily cause problems that arise during the firing of plique-à-jour enamel; often, they stem from issues with the metal framework.

First, when finalizing the design pattern, you need to take into account the craft characteristics of plique-à-jour enamel. Here are several points to note.

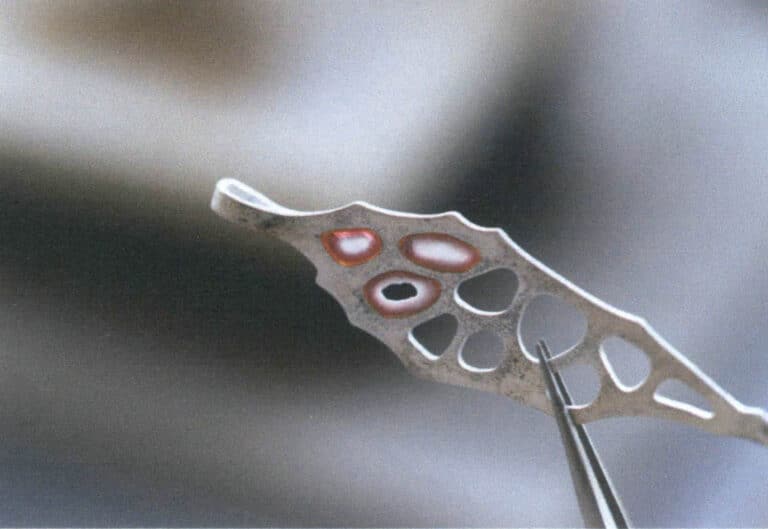

(1) The void area of each open section should be neither too large nor too small. If the void area is too large, firing becomes difficult. Generally speaking, the larger the hole, the more difficult the firing and the harder it is to achieve a thin, translucent enamel layer. Figure 7-4 shows an unfinished earring made with plique-à-jour enamel; because the designed void area is too large, the firing difficulty increased, and even if firing succeeds, a thicker layer of glaze will impair the piece’s translucency.

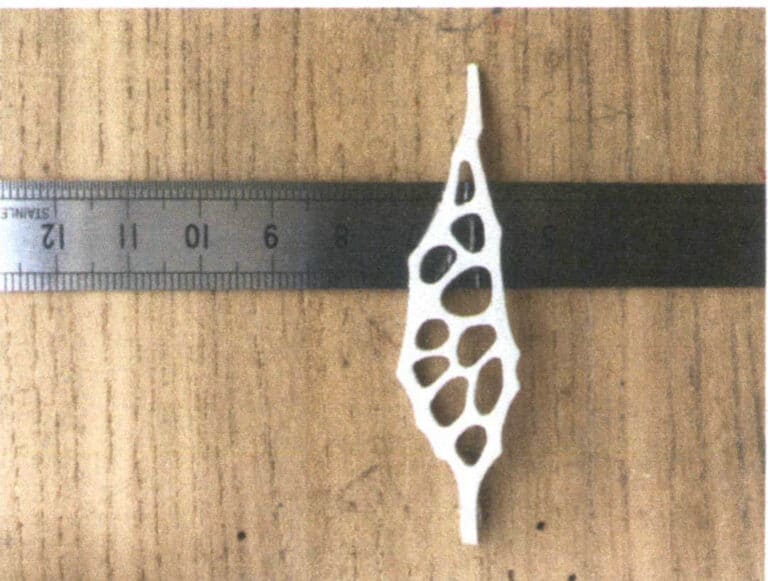

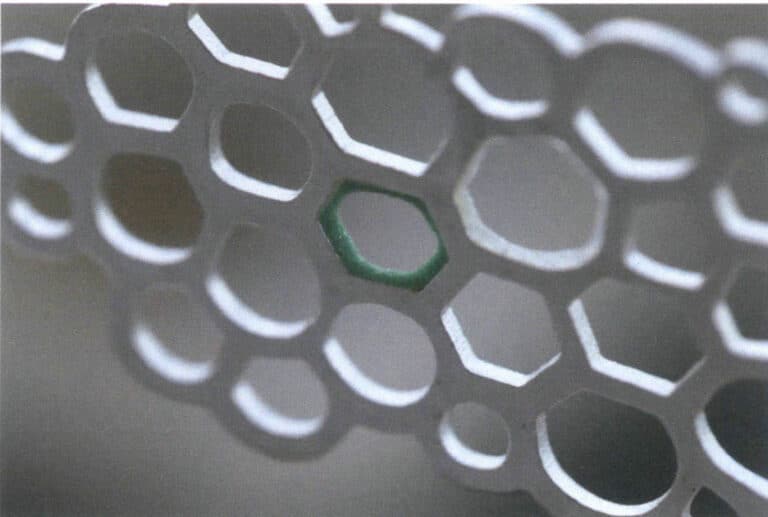

But if the void area is too small, it will also affect translucency and the way the enamel color presents. In the design shown in Figure 7-5, because the void area was too small, the fired piece did not exhibit a noticeable translucency, thereby losing the advantages of plique-à-jour enamel.

Figure 7-4 Excessive void area causing excessive glaze thickness

Figure 7-5 Void area too small affecting light transmission

(2) When designing patterns, consider the thickness and width of the metal framework. Suppose the metal framework is too thin or the framework lines are too fine. In that case, significant deformation can occur during high-temperature firing and cooling, and deformation of the metal framework usually causes the enamel layer attached to it to crack. In some museum-quality translucent plique-à-jour enamel works, one can even observe areas where the enamel has cracked or partially detached. The solution is to appropriately increase the thickness and line width of the metal framework. Considering that each metal has a different strength, if silver is chosen as the metal for the framework, the thickness should not be less than 0.9 mm. The silver frame shown in Fig. 7-6 is made of 950 silver and is 1 mm thick. The narrowest line width on the plane should not be less than 0.9 mm, as shown in Fig. 7-7; otherwise, the enamel areas on the piece are likely to crack, as in the test piece shown in Fig. 7-8, where it is clearly visible that the enamel cracks occur precisely where the silver framework is too thin. Suppose 18K gold is chosen as the frame material, because 18K gold has higher strength. In that case, the limits on frame thickness and line width can be reduced to 0.7 mm or even 0.6 mm, so 18K gold is a relatively ideal metal for making plique-à-jour enamel, best achieving a thin, delicate visual effect. As for the minimum dimensions of a metal framework that can ensure the enamel layer does not crack, besides being affected by the strength of different materials, it also depends on the actual size and shape of the work; makers need to judge based on experience and the specific circumstances during production.

Figure 7-6 Thickness of the silver framework

Figure 7-7 Width of the silver framework

Copywrite @ Sobling.Jewelry - Özel takı üreticisi, OEM ve ODM takı fabrikası

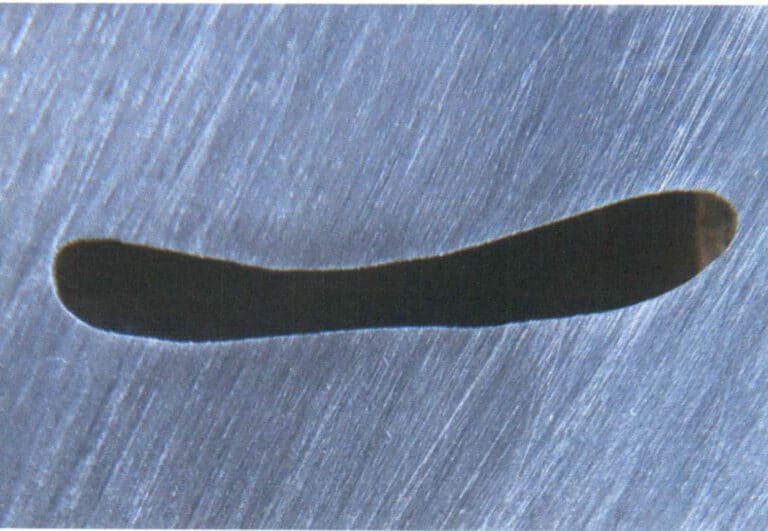

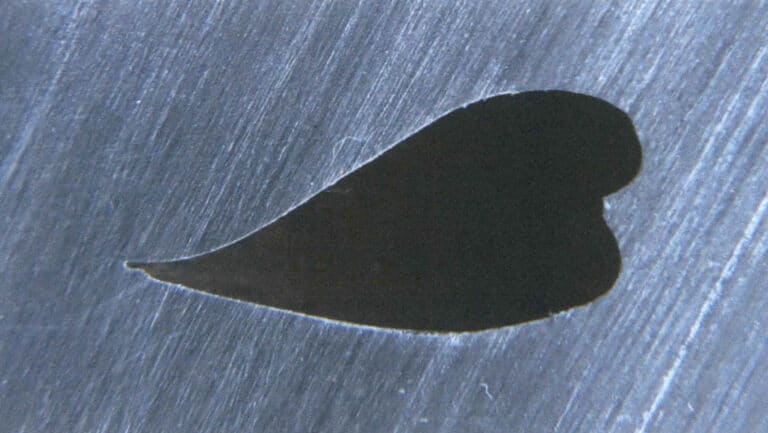

(3) In design, try to avoid long strip-shaped holes as shown in Figure 7-9, and also avoid cavities with very sharp corners as shown in Figure 7-10, because both shapes are prone to cracking during or after firing. The reason long strip-shaped holes tend to crack after firing plique-à-jour enamel is that the metal at the two ends of the hole deforms unevenly and, after twisting, causes cracking in the enamel. There are different explanations for why sharp-cornered cavities cause enamel cracking: one is that the metal on both sides of the sharp corner is squeezed inward; another is that the inside of the sharp corner cannot be fully filed smooth. In any case, cracking of the enamel layer is a common problem for plique-à-jour enamel pieces, so designs that may lead to cracking should be avoided from the design stage.

Figure 7–9 Long, narrow holes are not suitable for firing plique-à-jour enamel

Figure 7–10 Overly sharp, acute corners are not suitable for firing plique-à-jour enamel

(4) Besides the risk of cracking in the enamel layer, the metal frame itself can also fail if it lacks sufficient strength. For example, the piece shown in Fig. 7–11 uses 950 silver, with a thickness of 1 mm and a frame line width of 1 mm. Because the openings intended to be filled with enamel in this design are relatively large, once the enamel is filled and fired, it produces a considerable inward pulling force, resulting in cracking of the outermost silver frame. Therefore, in designing plique-à-jour enamel works, when the area of an opening is large, the metal border line width should be increased accordingly, and the outermost border lines should be wider than the internal ones, because the outermost metal has enamel on only one side and is subjected to a unidirectional pull, making it more prone to cracking.

(5) For a plique-à-jour enamel piece with openwork, the light-transmitting effect is its greatest highlight and the design focal point of the piece. Generally, when the enamel layers are successfully fired, the larger the area of the openings, the better the light transmission, and the thinner the metal framework, the better the light transmission. However, suppose the design pursues light transmission by indiscriminately enlarging the openings and reducing the thickness of the metal framework. In that case, this comes at the cost of increased difficulty in firing and a higher risk of firing failure. There is a balance point between pursuing light transmission and ensuring smooth firing; accurately grasping this balance requires the designer to have sufficient technical knowledge and experience.

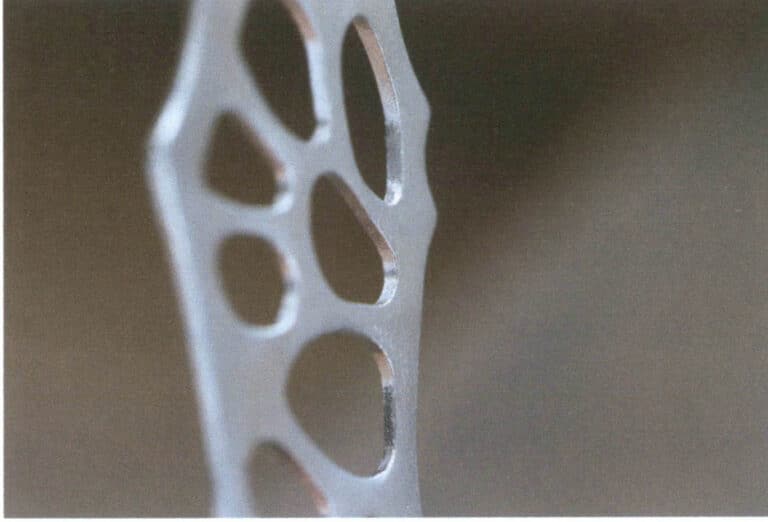

Once the design pattern is finalized, you can begin making the metal framework. The following plique-à-jour enamel production example uses 950 silver as the material for the metal framework; the specific production steps are as follows.

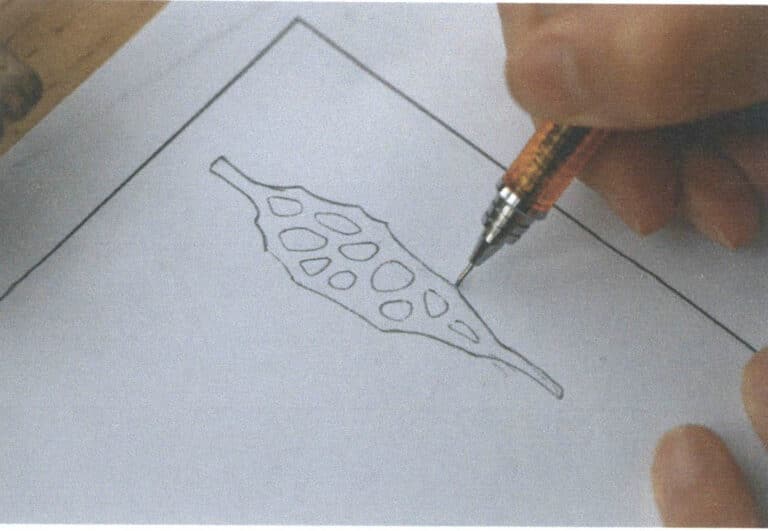

ADIM 01

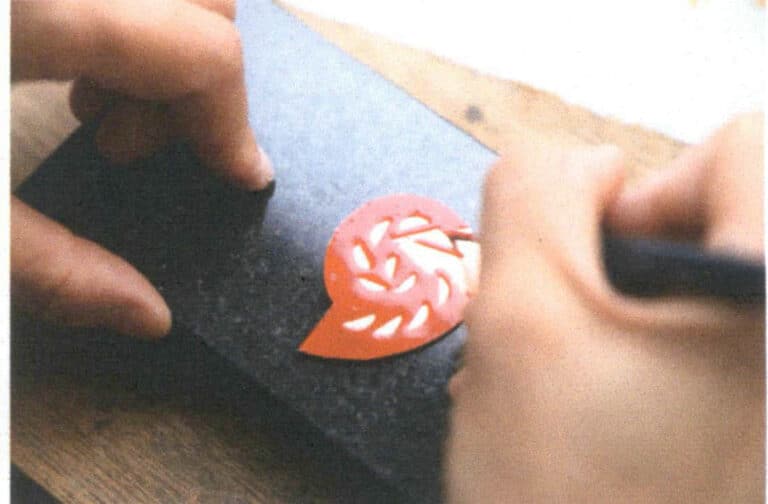

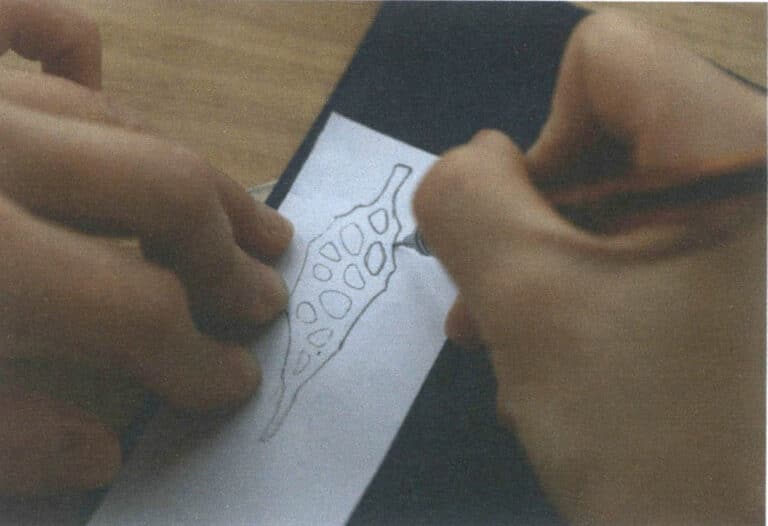

Draw the design at 1:1 scale on paper, as shown in Figure 7–12. What is needed here is not a design sketch but an accurate graphic confirmed after the design stage, which will be used in the next step for sawing and filing the metal.

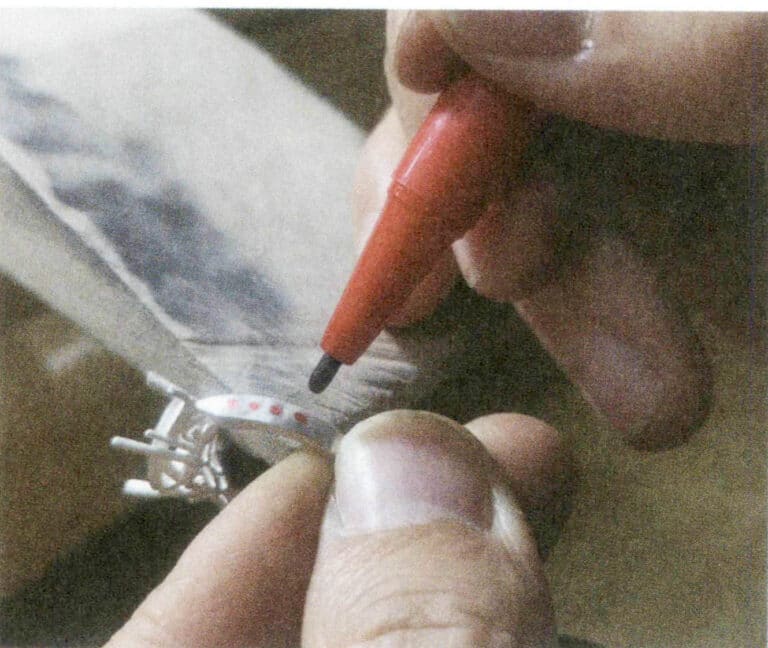

STEP 02

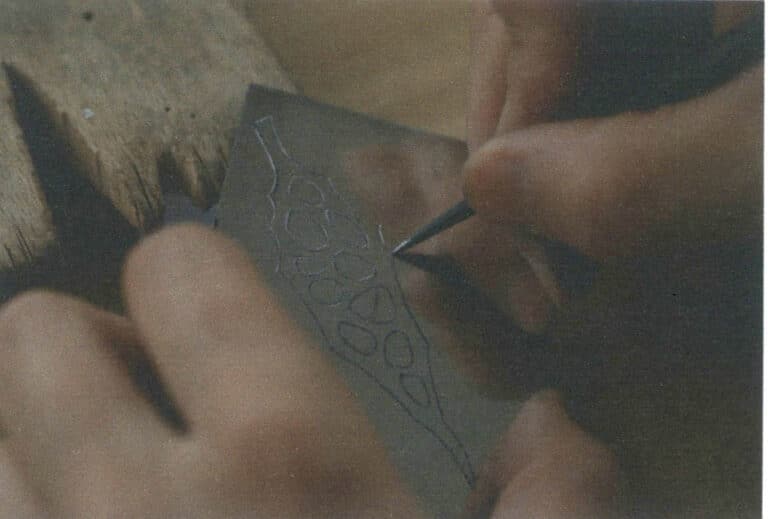

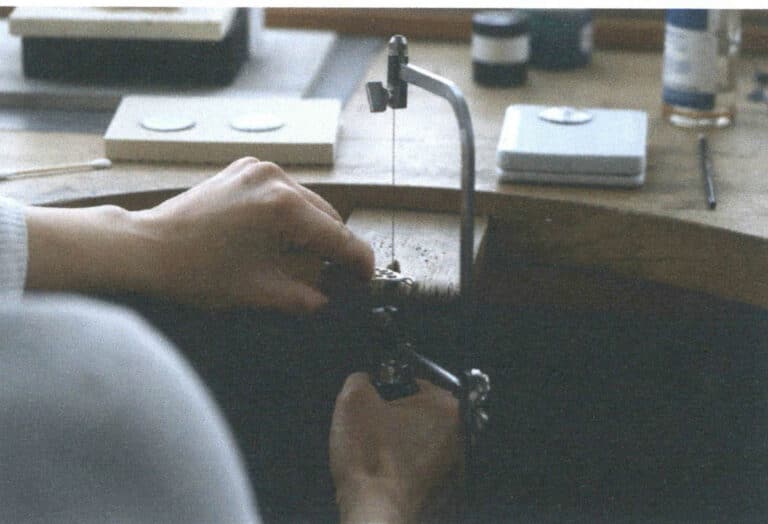

Select a 1mm-thick 950 silver sheet. Use tracing paper to copy the design from the paper onto the metal surface, as shown in Figure 7-13. Then, use a scribing tool to engrave all the lines according to the blue marks left by the tracing paper. Figure 7-14 shows the scribing tool engraving the pattern lines on the silver sheet. This step is taken to prevent the lines transferred onto the metal surface from being rubbed off during the sawing process. During sawing, it is crucial to ensure that the cut surface is perpendicular to the surface of the workpiece—meaning the saw blade must be perpendicular to the surface being cut, as illustrated in Figure 7-15. This point is vital for the successful firing of plique-à-jour enamel. If the cut results in a slanted surface, the enamel glaze may flow along that incline during the firing process.

Figure 7-12 Outlining the design

Figure 7-13 Transferring a pattern onto tracing paper

Figure 7-14 Drawing pattern lines on the silver base plate with a metal stylus

Figure 7-15 Saw blade perpendicular to the silver base plate

ADIM 03

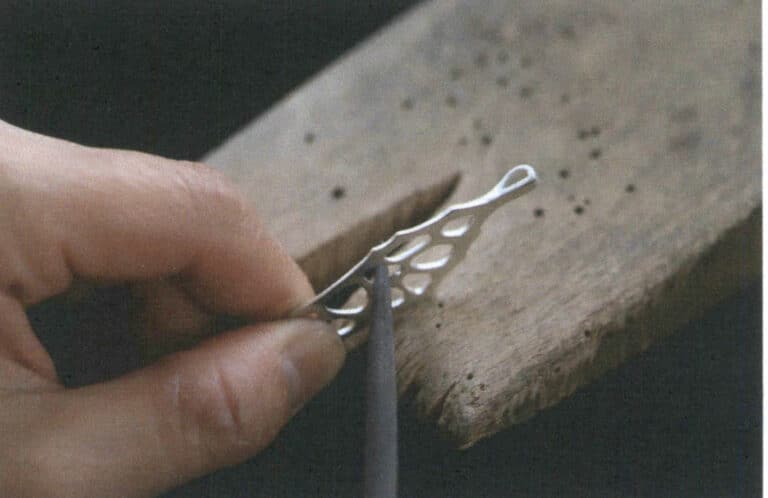

Use a small file to trim the metal edges on the inside of the holes; the inner sides of the holes must still be kept perpendicular to the surface of the piece. In addition, the inner edges of the holes need to be very smooth, as tiny flaws on the metal frame often cause cracks in the enamel. This work can be done with a file, and no sanding is required afterwards. Figure 7-16 shows the situation of filing the inner sides of the holes with a small file and the inner sides of the holes after filing is completed, and Figure 7-17 shows the completed metal frame, where the inner sides of the holes appear smooth and even.

Figure 7-16 Trimming and smoothing the inner side of the hole

Figure 7-17 The edge of the hole after filing is completed

STEP 04

After the metal on the inner side of the hole has been trimmed and smoothed, the metal on the surface of the piece must also be treated, including filing and sanding. Here, 280-grit and 600-grit sandpaper are used for sanding. Fig. 7-18 shows the piece after sanding is finished and ready to begin firing the 950 silver frame for the plique-à-jour enamel. The reason for sanding to a polishable degree before firing is that plique-à-jour enamel pieces are relatively fragile and cannot withstand strong impacts or collisions after firing. If further sanding is done afterward, the piece can easily crack accidentally during the process, so it is necessary to sand the piece as thoroughly as possible before firing; then, after firing, only slight cleaning is required before polishing the piece.

2. Firing of Plique-à-jour Enamel

2.1 Methods for Filling Glaze

There are the following methods for filling glaze in plique-à-jour enamel.

The most common method is to lay the metal frame flat on a mica sheet, fill the frame’s holes with enamel glaze, and fire the piece together with the mica sheet repeatedly. Figure 7-19 shows the situation of placing a metal frame flat on a mica sheet and filling it with enamel glaze. Once the holes are filled after firing, the piece is removed from the mica sheet and polished, completing a plique-à-jour enamel piece with openwork. Mica is a natural mineral that is resistant to high temperatures and does not bond with enamel. The advantage of this method is that it is relatively simple to operate; the disadvantage is that the fired enamel areas are relatively thick and have poor light transmission. If a mica sheet cannot be found, other high-temperature materials that do not bond with enamel can be used instead.

Figure 7-20 Positioning for firing openwork enamel using the vertical firing method

Figure 7-21 Works fired by the vertical firing method

The plique-à-jour enamel example in this article uses the second method; for convenience of description, it is called the “vertical firing method.”

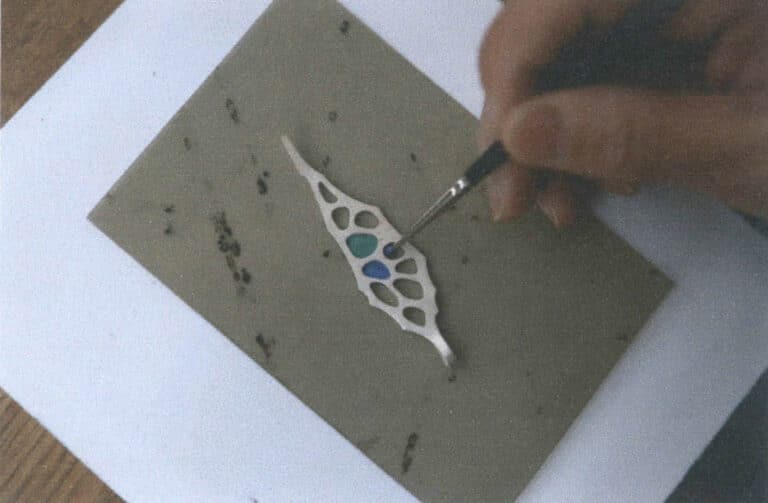

In the vertical firing method, a very small amount of glue is added to the cleaned and ground enamel glaze to give the enamel glaze a certain tackiness so it will not fall out when filled into upright pieces and will be less likely to drip downward during firing. It should be noted that the amount of glue added to the enamel glaze must be very small; too much glue can cause bubbles in the enamel layer and sometimes affect the final color presentation of the enamel glaze. Figure 7–23 shows the situation of adding glue to the enamel glaze, and you can see that the amount added is very small.

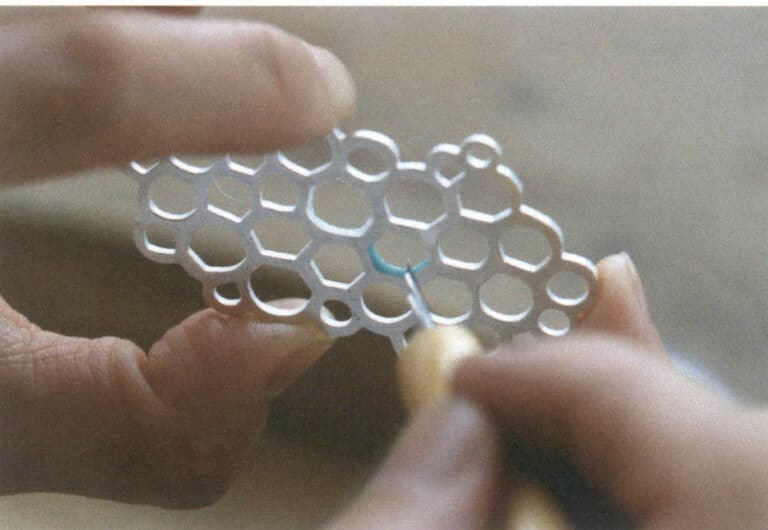

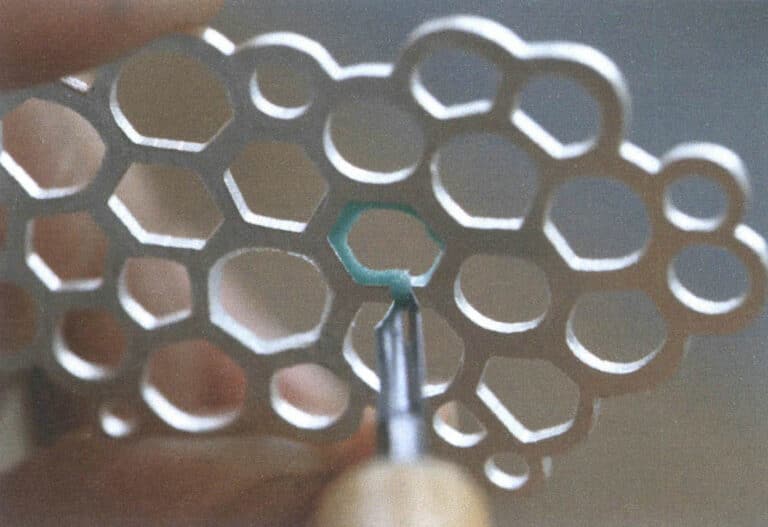

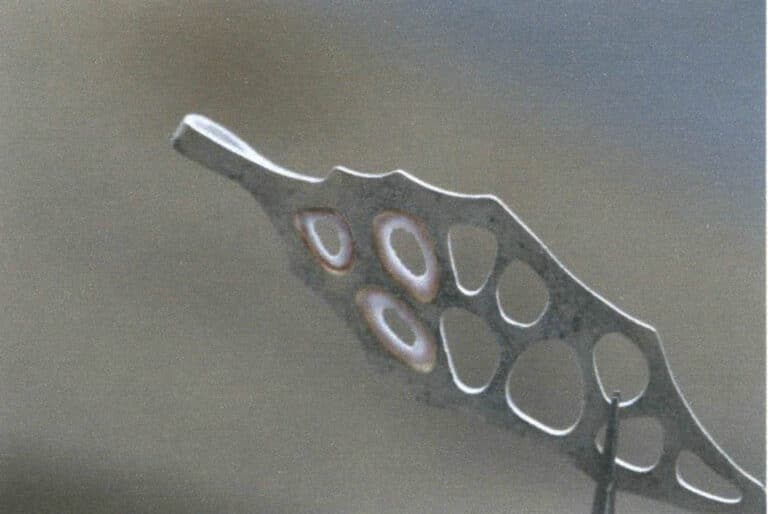

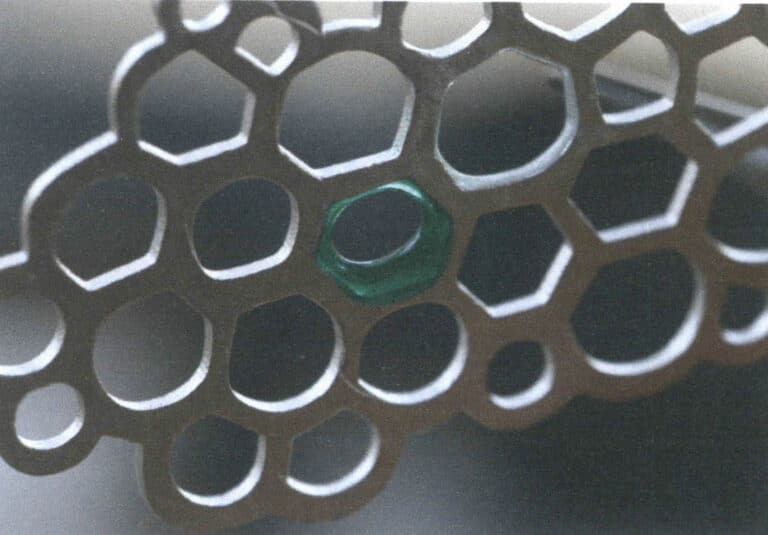

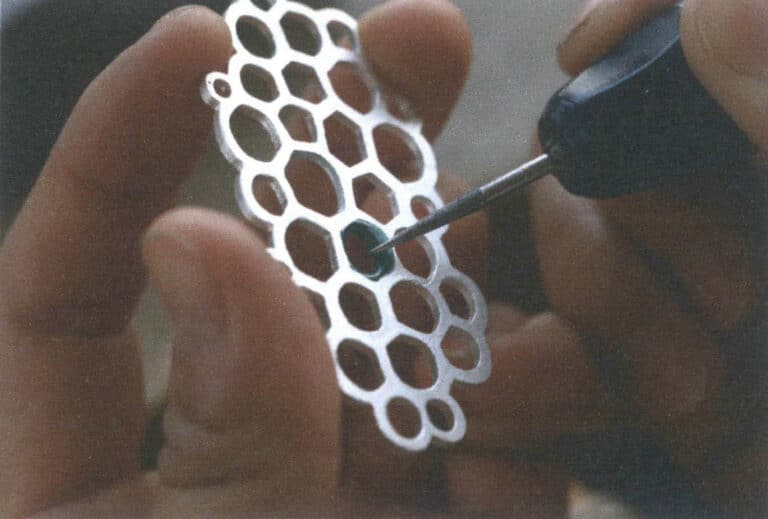

In the vertical firing method, the way enamel glaze is filled is also rather special. First, use the nib of a water-dipped fountain pen or a very fine brush to apply a very thin ring of enamel glaze evenly along the inner edge of each cavity, as shown in Figure 7– 24. After firing, apply another ring of enamel glaze inward from the first fired ring, as shown in Figure 7–25, then fire again… and so on, filling and firing ring by ring toward the center; the cavity in the center of the enamel glaze becomes progressively smaller, as shown in Figure 7–26, until it closes.

Figure 7-23 Adding a very small amount of glue to the enamel glaze

Figure 7-24 Applying the first ring of enamel glaze

Figure 7-25 Applying the second ring of glaze

Figure 7-26 The voids in the glaze become progressively smaller

Notes

(1) If the hole area is relatively large (for example, a circular hole with a diameter of 0.8 cm or more, or an approximately circular hole), first apply glaze to the lower half of the circumference, as shown in Fig. 7-27. After firing, invert it and then apply glaze to the other half of the circumference, as shown in Fig. 7-28. If you fill the entire circumference with glaze at once, the upper half of the glaze will sag downward during firing, as shown in Fig. 7-29.

Figure 7-27 Placing glaze on half the circumference

Figure 7-28 Filling the remaining half circle of enamel

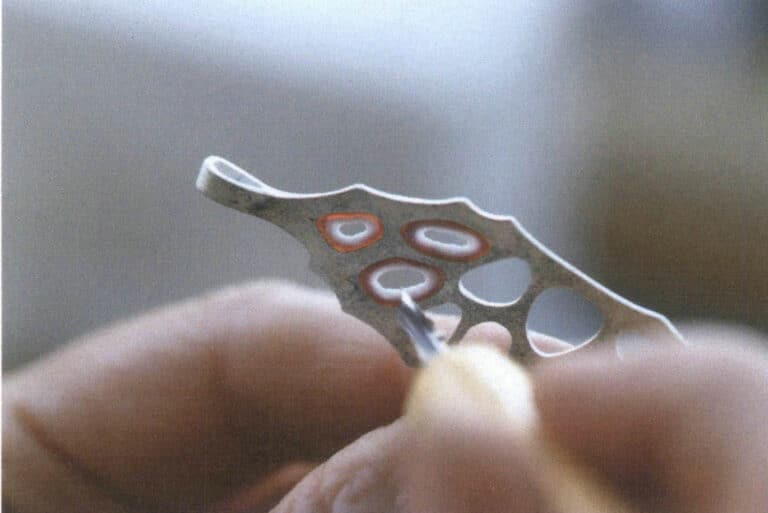

(2) When firing plique-à-jour enamel in a silver frame, if warm-colored glazes such as red or yellow are to be filled, the first round should apply a colorless transparent base glaze as protection, and warm-colored glazes should only be filled from the second round onward, as shown in Fig. 7-30. This prevents the glaze from reacting with the silver and affecting the color.

(3) If, according to the design, some cavities contain warm glazes of the red and yellow families while others contain cool blue-green glazes, then the red-family glazes should be fired first, as shown in Fig. 7-31; after the red glazes are fully fired, all the blue-green and yellow glazes can be filled and fired together.

Figure 7-30 Transparent base enamel layer beneath the red glaze

Figure 7-31 Continuing to add other colored glazes onto a test piece filled with red glaze

(4) During the filling process, the metal surface must be kept as free of glaze as possible; if glaze does get on it, it should be removed promptly. This prevents damage caused by removing residual glaze from the metal surface after firing, which is especially important when using K-gold materials. In Fig. 7-32, you can see many traces of residual glaze on the surface of the fired piece; these traces must be slowly ground away with a jeweler’s file, which is time-consuming and increases material loss. Therefore, be very careful when filling to avoid getting excess glaze on the surface of the piece.

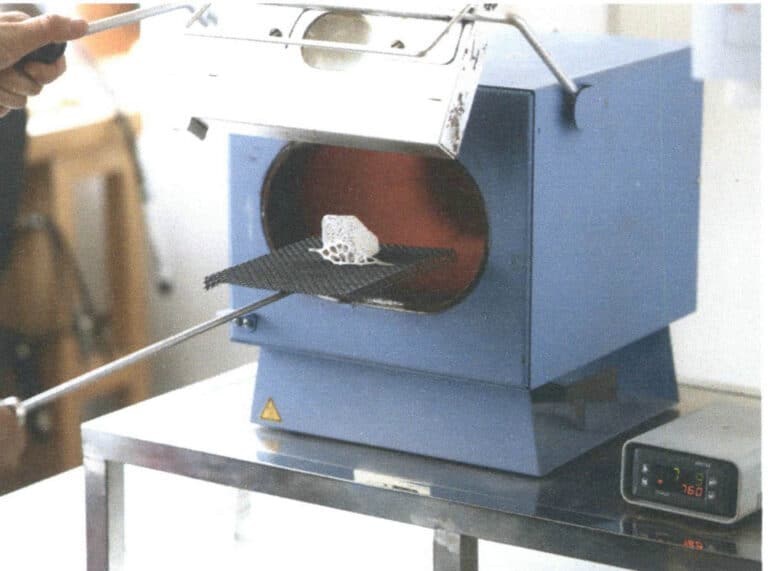

2.2 Firing Process of the Vertical Firing Method

Compared with the other two firing methods for plique-à-jour enamel with hollow areas, the firing process of the vertical firing method is relatively special. Because the piece is fired in the kiln in an upright position, the enamel glaze must not be fired to a fully molten state; otherwise, the enamel glaze will flow downward or drip. During the vertical firing process, each circle of enamel glaze from the metal framework inward is only fired to a semi-molten degree until the enamel glaze fills the void; then the temperature is raised to fully melt the enamel glaze and make it transparent. At that point, the enamel glaze has filled the entire void, and after melting, due to the surface tension of the liquid, it will not drip downward even though it has melted.

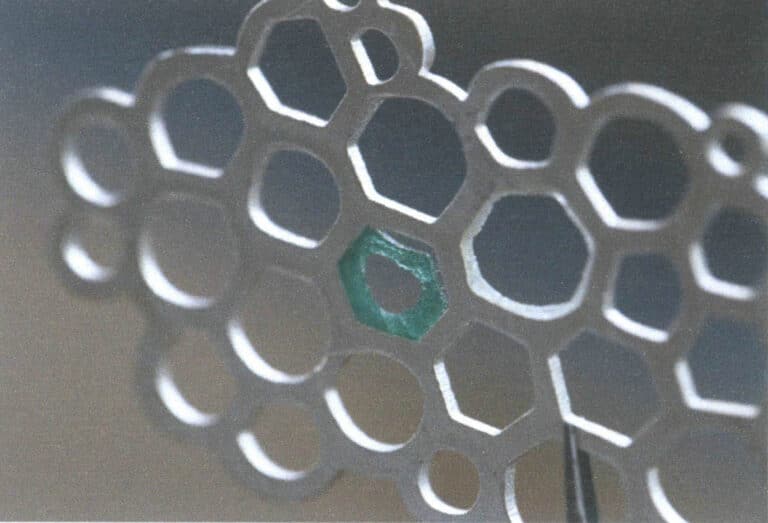

So how can one judge when the enamel glaze is in the semi-molten state? From the firing processes of other enamel techniques, we can see that when the enamel glaze is fully molten, its surface appears very smooth, like a water surface. In the vertical firing of plique-à-jour enamel, the enamel glaze only needs to be fired to a semi-molten state, at which the enamel glaze surface appears opaque and not smooth—like “granulated sugar.” This means the enamel glaze powder has begun to melt but has not yet completely liquefied. Figure 7-33 shows the enamel glaze in this semi-molten “granulated sugar” state during the vertical firing process. Learning to observe the melting state of the enamel glaze is key to firing plique-à-jour enamel.

Firing the glaze only to a semi-melted state has the following two advantages.

(1) During vertical firing in the kiln, the glaze will not flow downward.

(2) Because each ring is fired into a “granulated sugar” semi-melted state, when applying a second ring of glaze, the glaze powder can more easily accumulate on top of the first ring. If the outer ring of glaze were fired to an almost fully melted state and the surface had already become smooth, then when placing the second ring, the glaze powder would tend to slide downward, resulting in more time required to fill each void and producing a thicker plique-à-jour enamel.

The specific steps for the vertical firing method are as follows.

ADIM 01

Fill the outermost rim of each hollow with enamel glaze, set the kiln temperature to 750°C, and fire it in the kiln, as shown in Figure 7–34.

ADIM 02

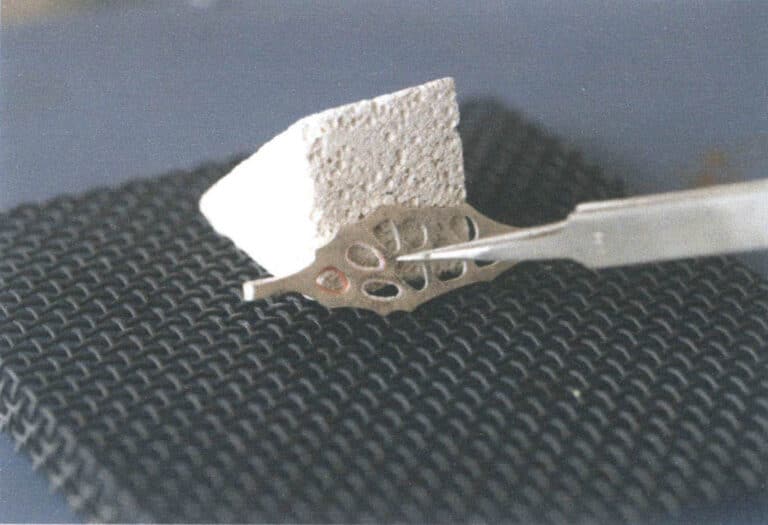

Observe the state of the enamel glaze through the viewing window of the enamel kiln. When the color of the enamel glaze begins to darken, take it out to inspect it. If the enamel glaze appears semi-transparent and “granulated sugar”-like, you can let it cool and then fill the next inner ring of enamel glaze. Another situation can sometimes occur: although the enamel glaze has not reached the “granulated sugar” appearance and still looks powdery, it may already have solidified enough to allow the next ring to be added. In cases where this is difficult to judge by appearance, you can, as shown in Figure 7–35, gently touch a local area of the enamel glaze with the tip of tweezers to check the degree of melting. If the enamel glaze has solidified, you can let it cool and continue filling the next inner ring; if the enamel glaze is still loose and powdery and falls off when touched with the tweezers, it needs to be returned to the kiln for further firing.

Figure 7–34 Fired in the kiln at 750°C

Figure 7–35 Checking the enamel glaze condition with the tip of tweezers

ADIM 03

Continue filling the second ring of glaze inward and place it in the kiln for firing. Figure 7-36 shows the hole after the second ring of glaze has been applied. Repeat the above steps; the hole in the center of the glaze will become progressively smaller, as shown in Figure 7-37. At that point, one more application will fill it.

Figure 7-36 Appearance after applying the second ring of glaze

Figure 7-37 The hole in the center of the glaze is getting smaller and smaller

STEP 04

After the hole is filled with glaze, the kiln temperature can be raised to 800°C for firing. This time, the glaze should be fired until it is completely molten. Due to the surface tension of the liquid, after the glaze melts, it will be stretched by the surrounding metal frame like a thin film, becoming thin and transparent. Figure 7-38 shows the piece after firing at 800°C; you can see that the glaze in the hole has already become transparent.

Notes

(1) When filling the glaze, the dryness/wetness of the glaze is very important; it must be neither too dry nor too wet. If there is insufficient moisture in the glaze, it will not adhere to the metal frame; if there is too much moisture, the glaze will run downward.

(2) Before raising the kiln temperature to 800°C, carefully inspect the enameled parts that have been filled with glaze to confirm that every area is filled with glaze and there are no small holes or gaps. Otherwise, even a pinpoint hole can instantly expand into a larger hole during heating.

(3) During firing at 800°C, the process must be monitored continuously through the observation window. Because the temperature is high at this time, closed enamel layers can easily be burned through; once a hole is seen, the piece should be removed from the kiln immediately to prevent the hole from enlarging. The enamel layer shown in Figure 7–39 was burned through during the heating process. If a hole occurs, reduce the kiln temperature back to 750°C and refill the glaze according to step one until the glaze fills the hole again, then raise the temperature to 800°C for firing.

(4) After firing, the enamel within the cavities should be thicker around the edges and thinner in the center, not flush with the metal frame. The fired enamel should be stretched by the metal frame like a thin film; only then can a good light-transmitting effect be achieved. Figure 7-40 shows the completed test piece, where the enamel layer appears like a tightly stretched plastic film—thin in the middle and thick at the edges.

Figure 7-39 Holes appearing in the enamel layer during the firing process

Figure 7-40 The enamel layer is thicker at the edges and thinner in the middle

(5) If the firing temperature is too high, the glaze in the cavities will melt and continually accumulate toward the lower part of the cavity, and in severe cases may even form droplet-like masses; this should be avoided as much as possible. In Figure 7-41, the glaze has accumulated into droplet-like forms. Once the accumulated glaze thickness exceeds that of the metal frame, the congregated glaze must be ground off with a diamond bur and refilled, as shown in Figure 7-42.

Figure 7-41 Glaze accumulated into droplet-like forms

Figure 7-42 Removing aggregated glaze with a diamond grinding bur

3. Grinding of Plique-à-jour Enamel

The grinding steps for plique-à-jour enamel differ somewhat from other techniques; the following precautions apply.

(1) For a successful plique-à-jour enamel piece, the enamel glaze within the cavities should be slightly recessed, and the enamel thickness should be lower than the metal framework. Therefore, if you grind carefully, you can completely avoid grinding into the glaze. Figure 7-43 shows the process of grinding an plique-à-jour enamel piece with an polishing oil stone. Exercise caution during this process: use the polishing oil stone to grind off enamel glaze adhered to the metal surface, and do not touch the plique-à-jour enamel inside the holes. Doing so can eliminate the need for a final glaze firing; after polishing the metal frame, the plique-à-jour enamel piece is complete.

(2) Because there is only a metal frame and no metal base plate, plique-à-jour enamel pieces tend to be relatively fragile, so polishing after firing should be minimized as much as possible. A safer approach is to file and sand the metal frame thoroughly before beginning firing. The inside of the holes can be filed flat only, while the other parts (for example, the front and back surfaces of the piece, as well as the sides) should be sanded to a level ready for immediate polishing. In this way, once the enamel firing is successful, only simple cleaning of the metal surface is needed before the final polishing. Figure 7–44 shows the polishing of an plique-à-jour enamel piece with a polishing machine and a cloth polishing wheel.

Figure 7–43 Filing an plique-à-jour enamel piece with a polishing oil stone

Figure 7–44 Polishing an plique-à-jour enamel piece with a polishing machine and cloth polishing wheel