How To Make Bezel Setting? Focus On Cabochon And Faceted Gemstone Techniques

Bezel settings's overview, making methods and applications in Jewelry design

From the production point of view, the craft of bezel setting is relatively low in difficulty, easier for beginners to learn and grasp, and can be used as an introductory learning content of setting. At the same time, the bezel setting has strong material inclusiveness, can adapt to cabochon gemstones and faceted gemstones, and is most of the integrated material inlay. It is a very strong application of a kind of setting!

Inlaying with Gemstones

Tabla de conținut

Section I Overview of Bezel Setting

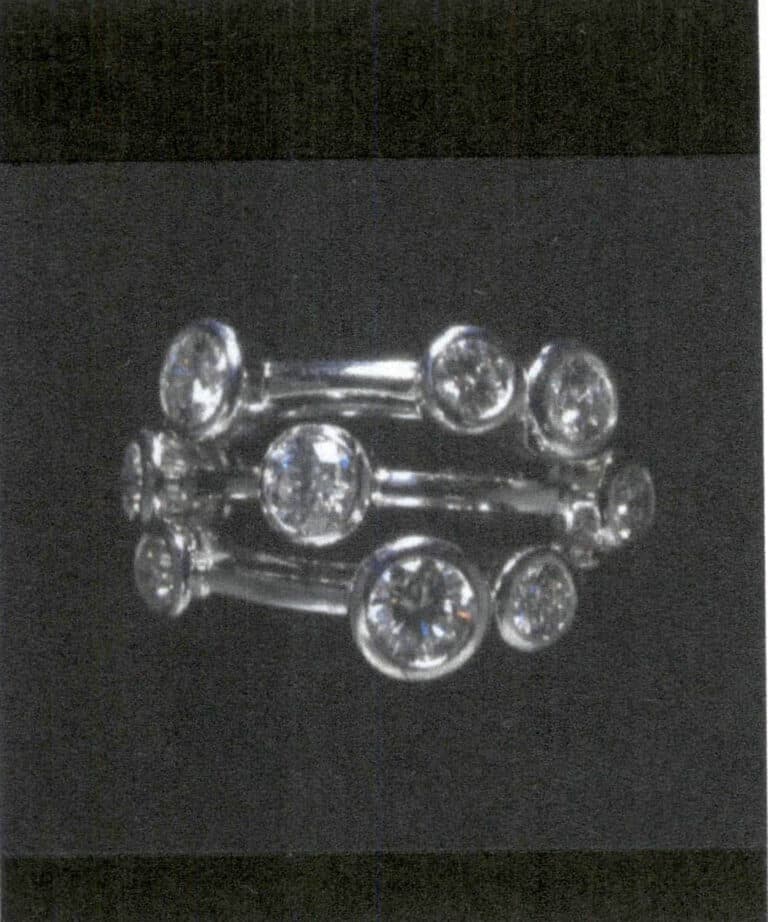

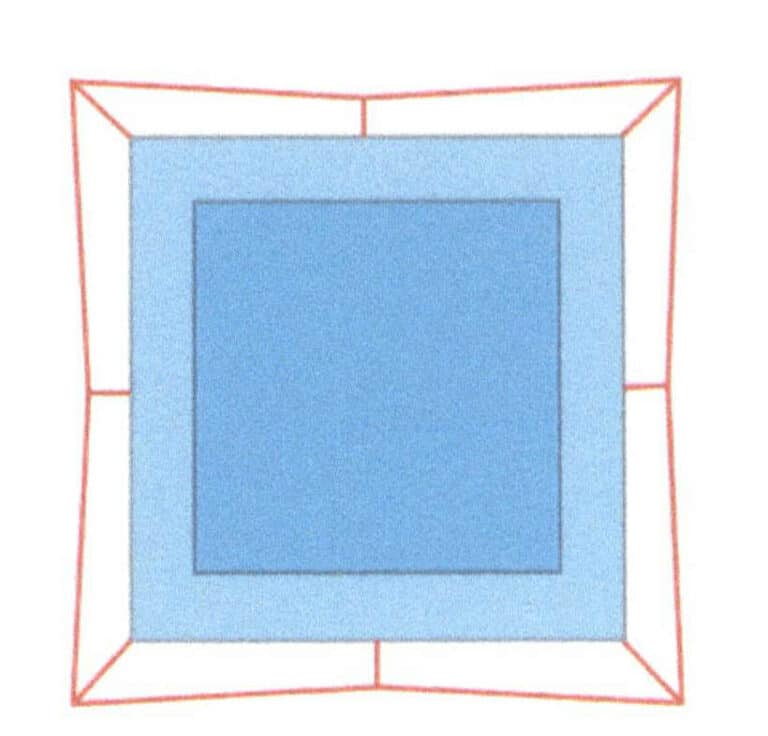

Bezel setting refers to securing a gemstone by pressing a metal rim around it, which holds it in place from its girdle. Its structure consists of a base and a metal rim standing on the base. This setting method is one of the most widely used ways to set gemstones in traditional and modern jewelry, especially for cabochon gemstones. Its widespread application is due to its flexibility and great inclusiveness, as most shapes and composite materials of gemstones can be secured using the bezel setting method. Due to its strong fixation, it also has a strong adaptability to metals, allowing soft metals like pure gold and pure silver to be used for setting gemstones. Bezel setting jewelry is shown in Figure 2-1.

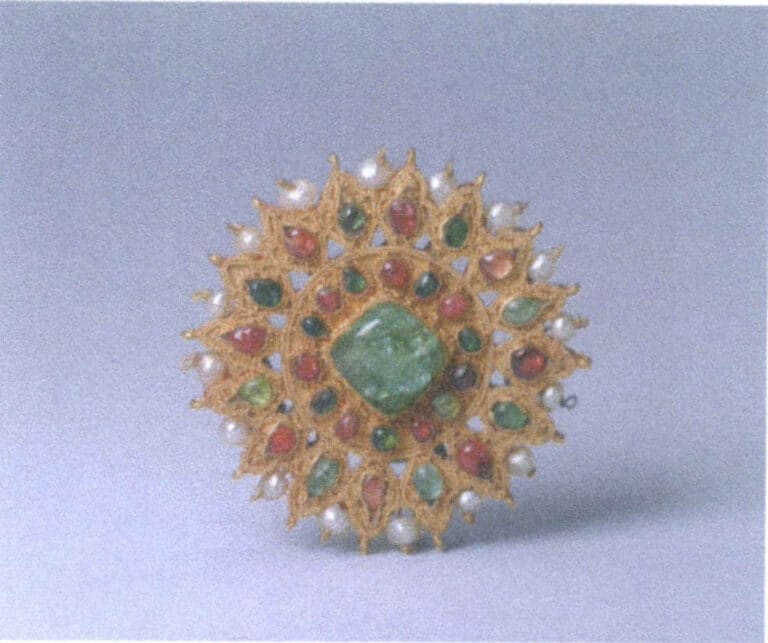

Compared to other methods, the bezel setting gives a visually simple impression, as the metal rim surrounds the gemstone, providing greater stability. Although the bezel setting is suitable for most gemstones, it is only suitable for some. Single gemstone bezel settings are mostly used for larger cabochon gemstones. The ring face of cabochon gemstone can also be combined with other setting methods or techniques. For example, bezel setting gemstones are embellishments in filigree, as shown in Figure 2-2.

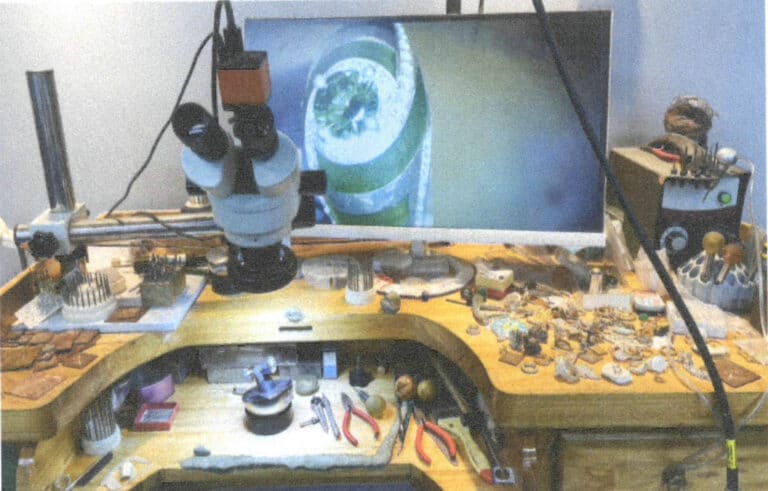

Figure 2-1 Inlaying with Gemstones

Figure 2-2 Filigree setting

Section II Method of Making Bezel setting

The gemstones used for bezel setting are primarily larger cabochon and faceted stones, with cabochon stones being more common. The classification of setting is first divided into two main categories based on the type of stones: the common cabochon bezel setting and the faceted stone bezel setting. The differences in the cutting styles of the gemstones result in certain structural and operational differences in the bezel setting process, so the two types of gemstone bezel setting will be introduced separately. Additionally, some bezel setting methods are designed for specific gemstone shapes or special applications; the following text will summarize representative cases of these special bezel setting methods and explain the key points and difficulties in the production process.

1. Method for Making a Cabochon Gemstone Bezel Setting

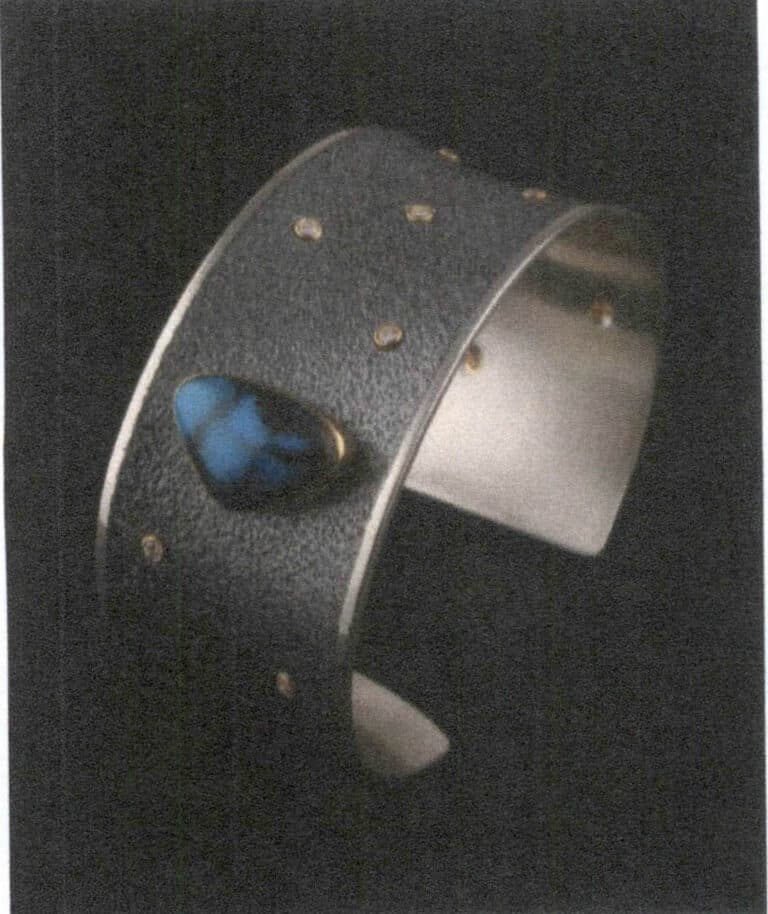

Among cabochon gemstones, oval-shaped are the most basic gemstone shapes, followed by drop-shaped with pointed corner, rectangular-shaped, heart-shaped, and others. For faceted gemstone bezel settings, since the bottom surface differs from that of cabochon gemstones, having a conical angle and slope, the treatment of the setting stone position will also vary. The following will introduce the production steps for setting oval-shaped cabochon gemstones and drop-shaped cabochon gemstones as the main cases and provide key points for the bezel setting methods of other shapes of cabochon gemstones. As shown in Figures 2-3 and 2-4.

Figure 2-3 Irregular cabochon gemstone bezel setting bracelet

Figure 2-4 Multi-gemstone setting ring (V&A Museum Collection)

1.1 Steps for Setting Oval-shaped Cabochon Gemstones

(1) Pregătirea materialului

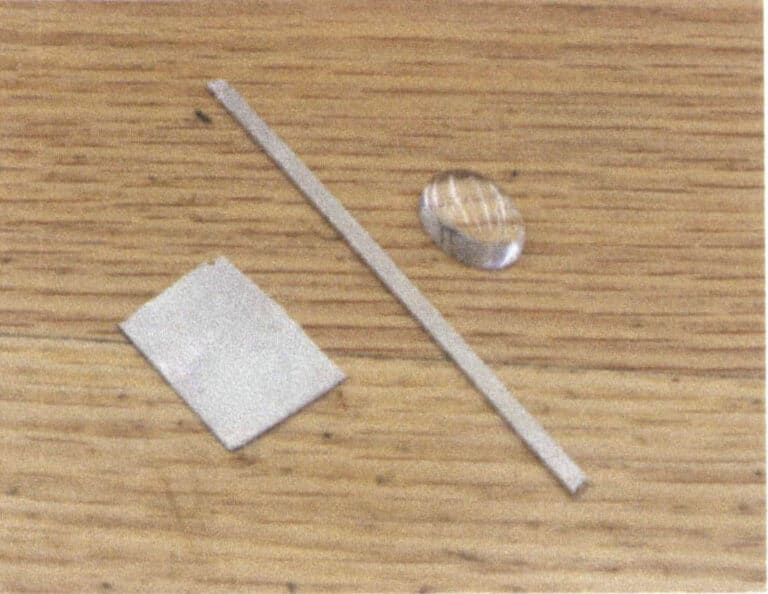

First, select the gemstone and the appropriate thickness and size of 13mm×18mm. In this case, a cabochon cut type of white transparent glass is used for demonstration, with the metal being 925 silver, as shown in Figure 2-5.

(2) Determine the Thickness and Height of the Metal Edge

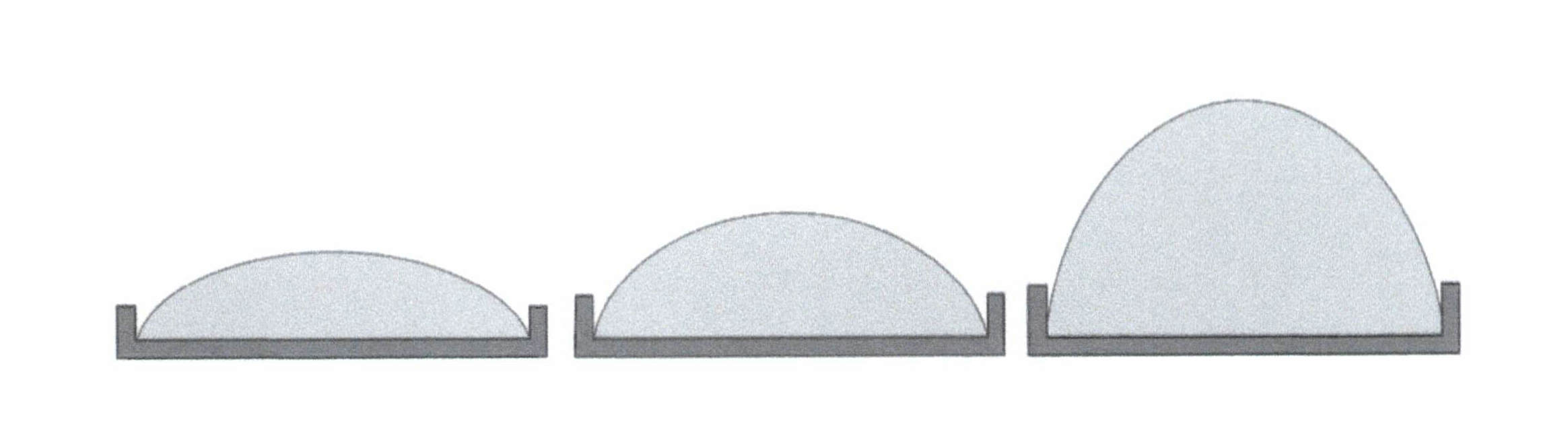

The thickness, width, and length of the metal edge used for bezel setting depend on the gemstone’s size. Therefore, in most cases, the gemstone is observed first, and then the metal is determined based on the gemstone, following the principle of suitability. A larger gemstone will appear more harmonious with a thicker metal edge, while a smaller one will not; the thickness of the metal edge is not absolute and may vary slightly in later processing. The height of the metal edge can be determined by observing the sloped position on the side of the gemstone and its proportion. If the metal edge is too high, it will obscure the gemstone surface; if it is too low, it will not be securely set. The above is the principle for preparing metal materials. The height of the metal edge is shown in Figure 2-6. In this case, the thickness of the metal used for the edging is 1 mm, and the height is 4 mm.

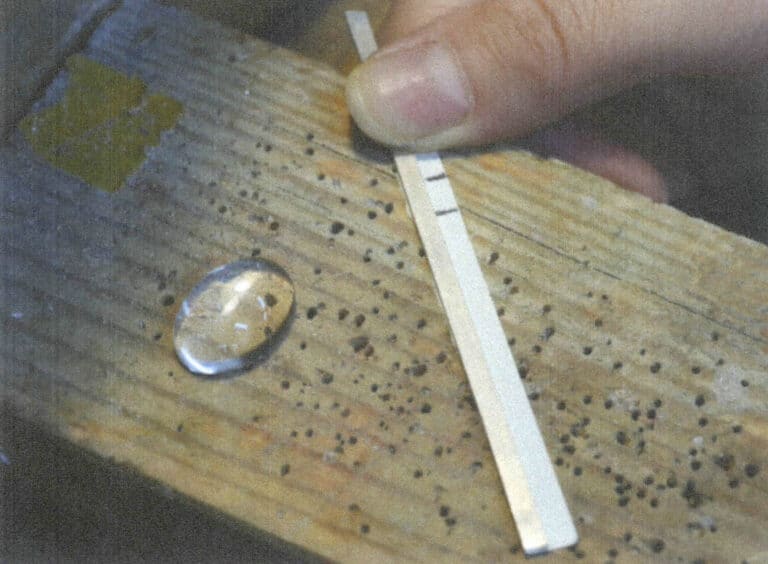

(3) Determine the Length of the Metal Edge

To calculate the circumference of the gem approximate circumference of a round-shaped gem can be calculated based on the diameter (Circumference = Pi ×Diameter), but the required dimensions for the metal should include a certain allowance. Since the cut of an oval-shaped gem may not necessarily be a standard oval shape, a strip of paper can be cut to encircle the gem to obtain an intuitive length, as shown in Figure 2-7. The required dimensions for the metal edge should add more than three times the thickness dimension on top of the gem’s circumference; in this case, the thickness of the metal edge is 1 mm, so the length of the metal edge should be at least increased by 3 mm. The allowance includes twice the thickness of the metal edge and the loss from sawing and filing to prevent insufficient dimensions, so leaving more allowance is safer, as shown in Figure 2-8. This method mainly ensures that the length of the metal edge is at least the required circumference. If there is enough of a long metal edge, this step can be omitted, and the metal edge can be directly wrapped around the gem and cut at the appropriate position.

Figure 2-7 Measuring the circumference of the gem with a strip of paper

Figure 2-8 Determining the length of the metal edge

(4) Bending the Metal Edge

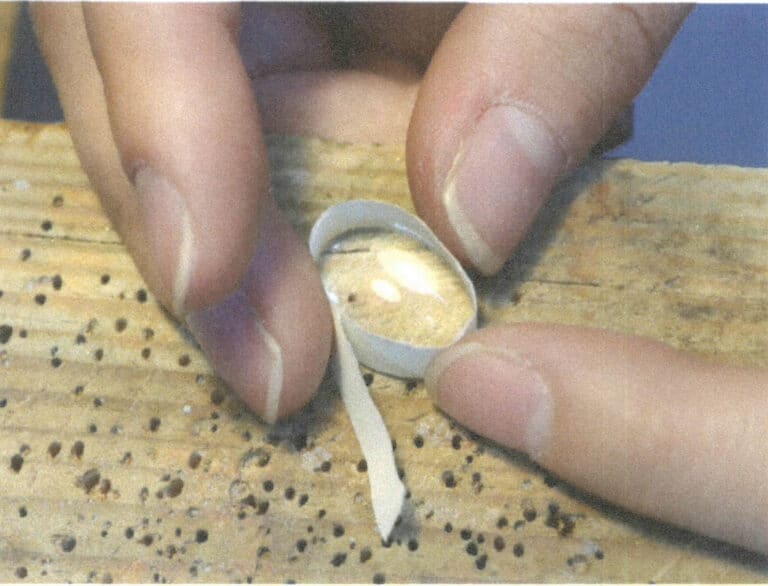

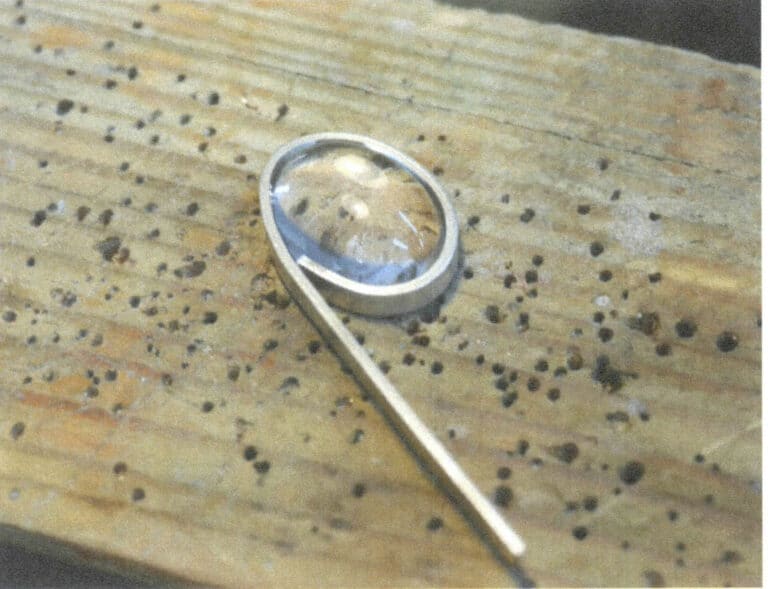

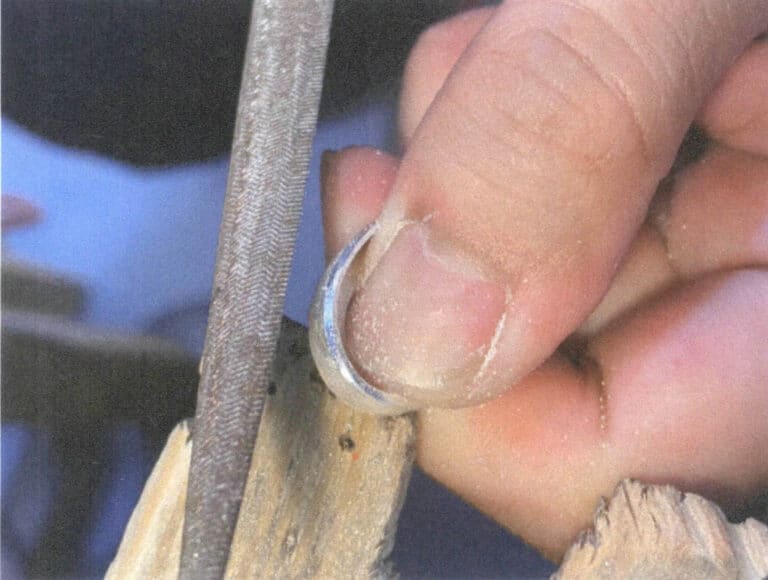

After the metal edge is annealed and softened, wrap it as tightly as possible around the gemstone to determine the final length of the metal edge, as shown in Figure 2-9.

(5) Cutting the Metal Edge

After ensuring the metal edge tightly wraps around the gemstone, use a metal saw to cut the metal edge to the determined length, ensuring the cut is as straight as possible, as shown in Figure 2-10.

Figure 2-9 Bending the metal edge

Figure 2-10 Cutting the metal edge

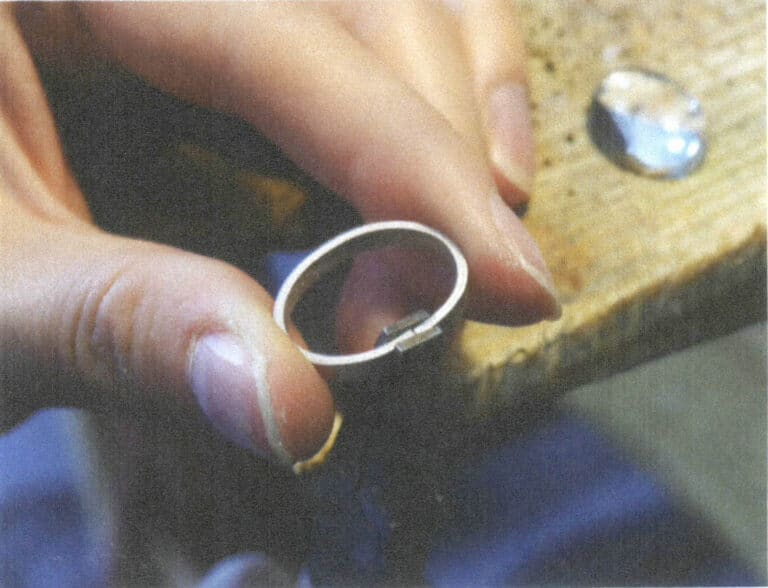

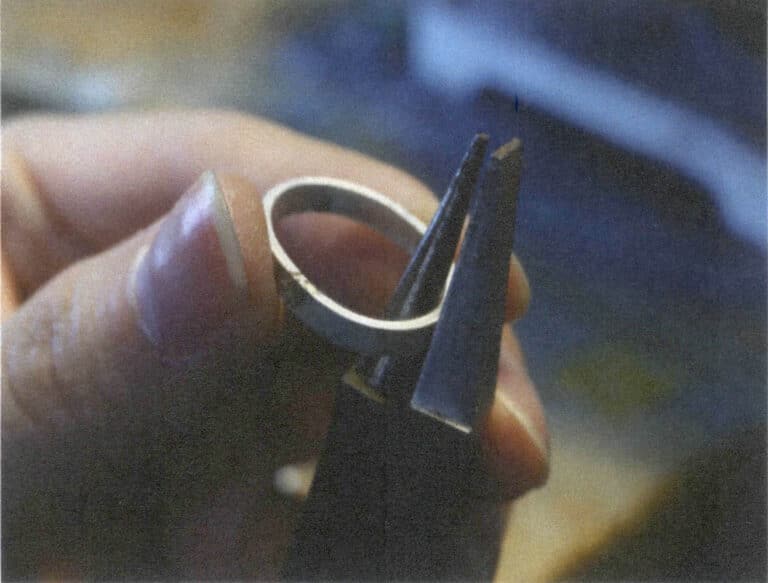

(6) Tightening the Joint

If the cut metal edge joint is not straight, it should be trimmed with a file first. Once the joint is straight, use pliers to adjust and tighten the joint, as shown in Figure 2-11.

(7) Welding the Joint

Ensure the joint is tightly fitted before welding the metal edge interface, as shown in Figure 2-12.

Figure 2-11 Tightening the joint

Figure 2-12 Welding the joint

(8) Adjust the Shape of the Metal Edge

After welding, pliers adjust the shape of the metal edge to match the shape of the gemstone, as shown in Figure 2-13.

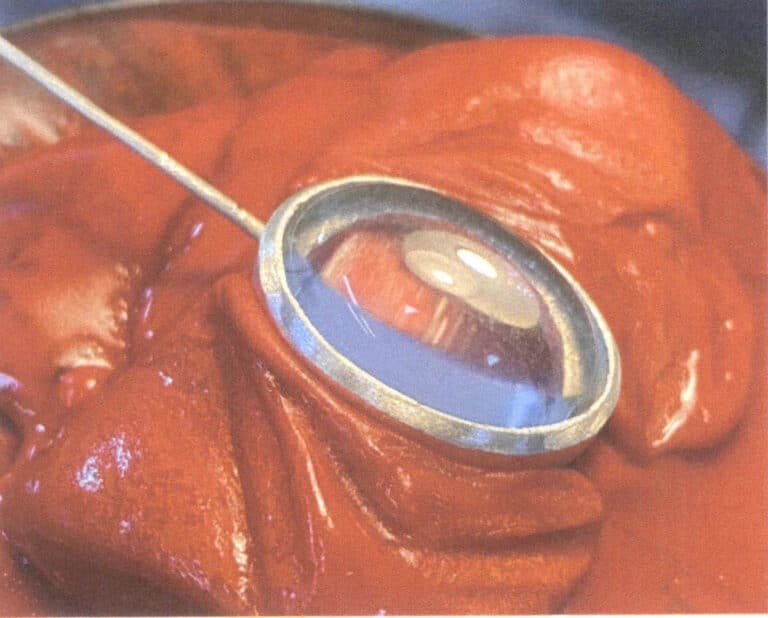

(9) Testing the Setting Mount

Press the gemstone into the welded metal edge and observe for any gaps. If there are obvious gaps, it must be sawed open and tightened again. During the setting mount testing process, a tightly fitting metal edge will achieve the desired shape by pushing the gemstone edge against the metal, requiring minimal manual adjustment. The setting mount testing is shown in Figure 2-14.

Figure 2-13 Adjusting the shape of the metal edge

Figure 2-14 Testing the Setting Mount

(10) Welding the Base

Once the suitable metal edge has been adjusted to the desired shape through stone trialing, it is ready to prepare the welded metal base (see Figure 2-15). The prepared base should encompass the entire metal edge, and after welding the base, any excess parts need to be trimmed.

(11) Sawing off the Excess Metal Base on the Outside

After welding the metal edge on the metal base, saw off the excess metal base on the outside, as shown in Figure 2-16.

Figure 2-15 Welding Base

Figure 2-16 Sawing off the excess metal base surface on the outside

(12) Grinding the Edges

After sawing off the excess metal base on the outside, use a file to smooth the edges, as shown in Figure 2-17.

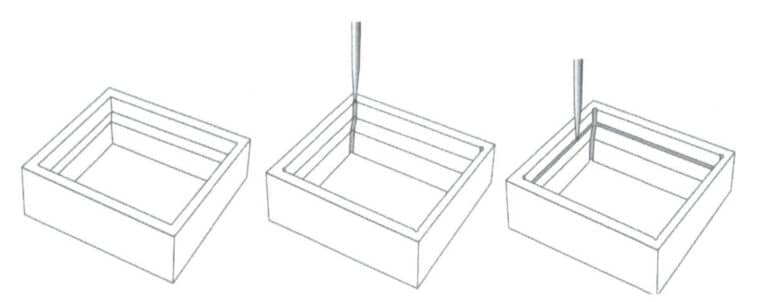

(13) Hollowing the Metal Base

In addition to sawing off the excess metal from the outer base, the inner side can also be hollowed out, but it is not mandatory. This should be chosen based on specific circumstances while ensuring the base’s support strength. Hollowing can reduce weight, lower metal loss, and enhance design aesthetics. If the material is transparent or semi-transparent gemstones, light can also pass through. The cutting for the inner hollowing needs to be done by first drilling holes at the edges of the hollowed shape with a drill bur, then inserting a saw wire into the hole to saw off the metal base, and finally polishing it smooth, as shown in Figures 2-18 and 2-19.

(14) Adjustment of Metal Edges

Before setting the stone, confirm the height of the metal edge one last time and grind off the excess, as shown in Figure 2-20. For thicker bezels, a bevel can be ground to reduce the thickness of the top edge, making it easier for the metal edge to be pressed under force during stone setting, as shown in Figures 2-21 and 2-22.

Figure 2-17 Grinding the edges

Figure 2-18 Hollow Base

Figure 2-19 Trimming Hollow Edges

Figure 2-20 Processing the height of the metal edge

Figure 2-21 Method for handling thicker bezels

Figure 2-22 Grinding the slanted surface of the metal edge

(15) Welding Metal Fittings

For decorative items such as jewelry with inlays, it is best to weld the metal fittings like necklace clasps, ring bands, and ear pins before setting the stones, as all fire-related steps must be completed before stone setting. Only spot welding can be used if you want to add metal fittings after the inlay. In this case, the metal fitting is an ear hook, so first weld the straight metal wire, and to avoid interfering with subsequent production, bend it into the shape of the ear hook at the end, as shown in Figure 2-23.

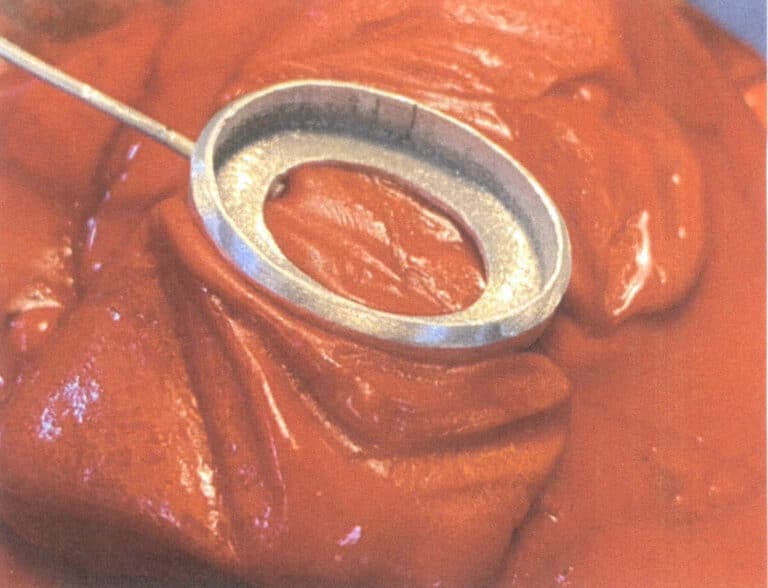

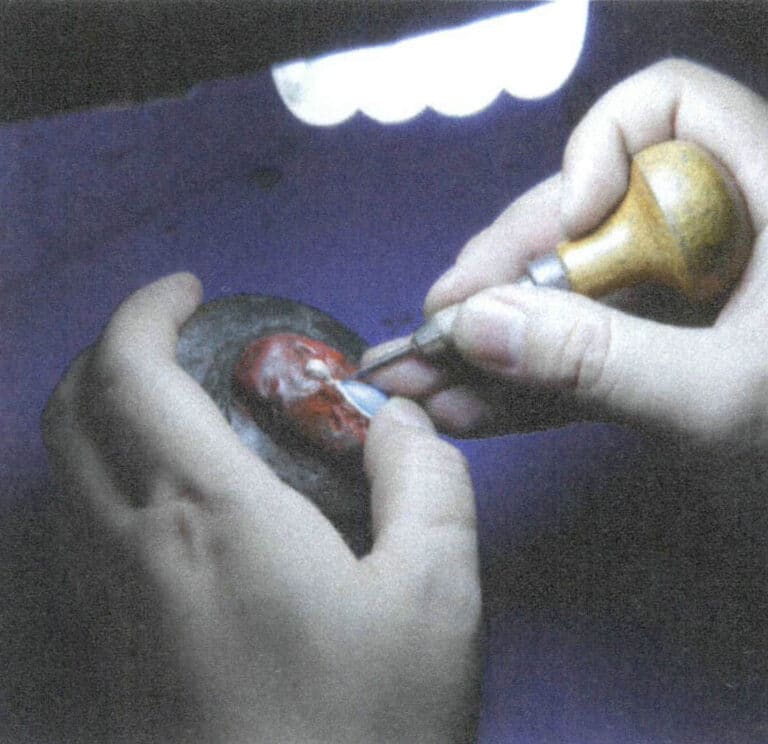

(16) Fixing the Metal

After welding the metal fittings, clean the impurities by acid washing or treating with alum, and smooth the inner side of the stone position. Then, fix the prepared metal bezel onto the sealing wax ball or stone setting base, ensuring the wax does not excessively cover the metal edge. For bezel setting with a solid bottom, the metal bottom can be heated with fire and pressed onto the wax surface; if it has a hollow bottom, care must be taken to prevent the wax from overflowing into the bezel from the hollow part of the metal, affecting the stone setting. The method to fix the metal is to place it on the wax when it is half-cooled and not too fluid and use tweezers or other tools to push the surrounding wax to hold it in place, as shown in Figure 2-24.

Figure 2-23 Welding metal fittings

Figure 2-24 Fixing the Metal

(17) Plasarea pietrei

After fixing the metal, place the gemstone evenly into the bezel. You can gently press the top of the gemstone with a wooden mallet or similar tool to ensure it sits completely in the bezel. During the stone setting process, observe from the side to check if the gemstone is level in the bezel to avoid uneven setting, which could cause the gemstone to tilt. The stone setting is shown in Figure 2-25.

(18) Setting the Stone – Point Fixation

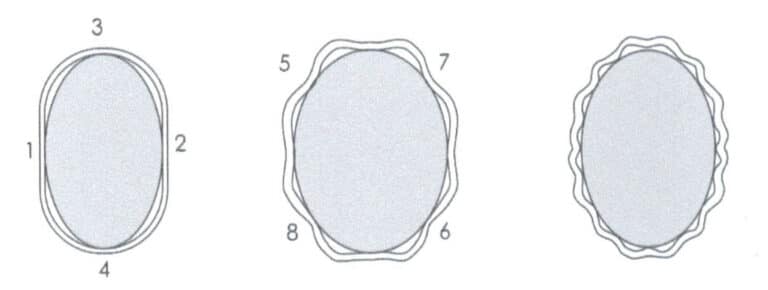

In the setting stone, for thicker bezels, a chisel should be used in conjunction with a hammer to press the metal; for thinner bezels, a rectangular flat-headed chisel can be used to press the metal. However, regardless of the method used, the steps are consistent. First, find symmetrical points about the central axis on the oval shape and fix them in pairs. The steps for fixing points are shown in Figures 2-26 to 2-29.

Figure 2-26 Order of Point Fixation

Figura 2-27 Poziția de utilizare a unei dălți cu cap plat

Figure 2-28 Symmetrical point fixation (four points)

Figure 2-29 Symmetrical point fixation (eight points)

(19) Setting the Stone- Cyclic Edge Pressing

After point fixation, the metal is then pressed circularly. At this time, the hand holding the chisel does not need to exert downward force; it only needs to slide flexibly along the metal edge while the hammer maintains a continuous striking state. The circular pressing of the metal should be done with minimal force at once; it can be repeated multiple times until the gemstone is securely set, as shown in Figure 2-30.

(20) Finishing – Trimming

After the stone has been firmly set, the metal edge will be uneven to varying degrees, and it will be necessary to smooth it out with the help of a file or pusher. The flatness of the metal edge is decisive for the beauty of the bezel setting, so it is important that the flat surfaces and corners of the metal edge are clean and even in width. Be careful not to scratch the stone, especially if it is of low hardness when trimming with the file. When using a spatula to trim the inside of the metal edge, be careful that the pusher is tangent to the edge of the stone, or it will also scratch the stone. Trim the edge as shown in Figure 2-31.

Figure 2-30 Cyclic Edge Pressing

Figure 2-31 Trimming

(21) Finishing – Polishing

Polishing is crucial after leveling the bezels; sandpaper rolls are essential, but they can damage the gem, so be very careful not to touch them when using them. Rubber polishing wheels and polishing wheels will not harm the gem. Sandpaper roll polishing is shown in Figure 2-32, and polishing with a polishing wheel is shown in Figure 2-33.

Figure 2-32 Using sandpaper rolls for polishing.

Figure 2-33 Polishing with a Polishing Wheel

(22) Completing the Oval-shaped Cabochon Gemstone Bezel Setting

Bend the metal wire into a hook shape and polish it to complete the oval-shaped cabochon gem bezel setting, as shown in Figure 2-34.

1.2 Steps for Making a Drop-shaped Cabochon Gemstone Setting

(1) Pregătirea materialului

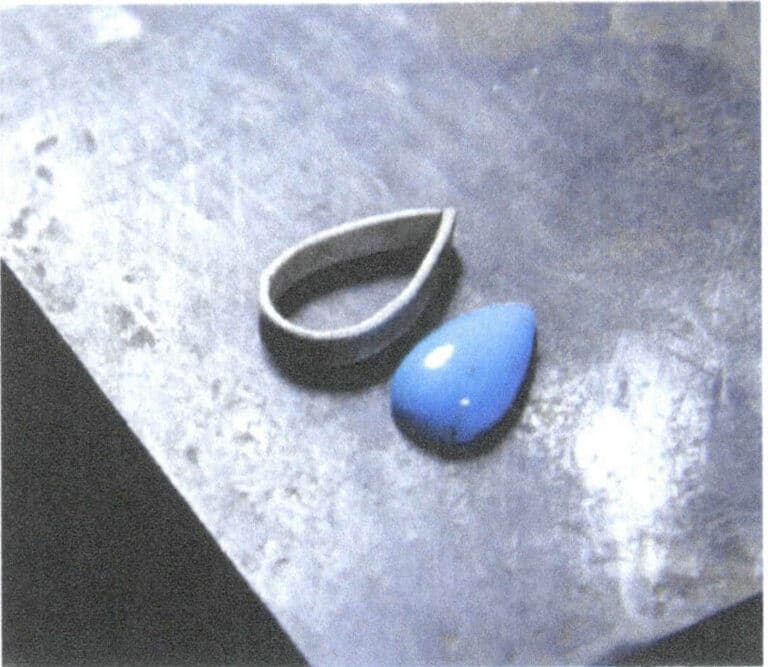

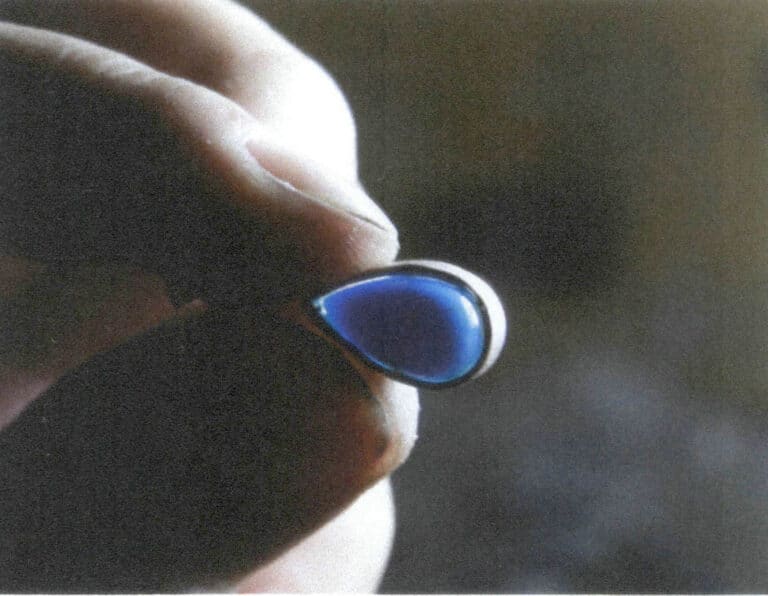

Select a drop-shaped cabochon gemstone, observe the size and height of the metal edge, determine the thickness and height of the metal edge, calculate the length of the metal edge, and refer to steps 1 to 3 of the oval-shaped cabochon gemstone bezel setting process for specific operations. Material preparation is shown in Figure 2-35.

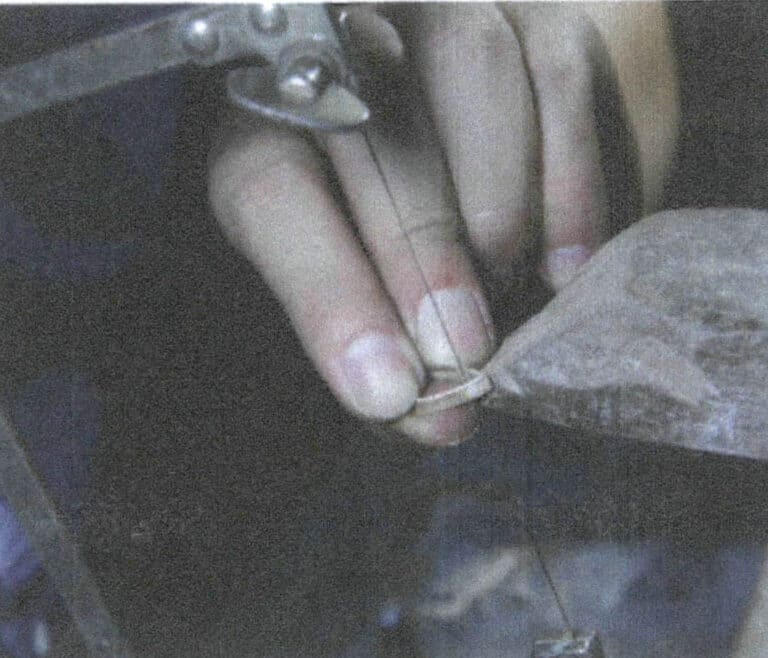

(2) Bending the Metal Edge

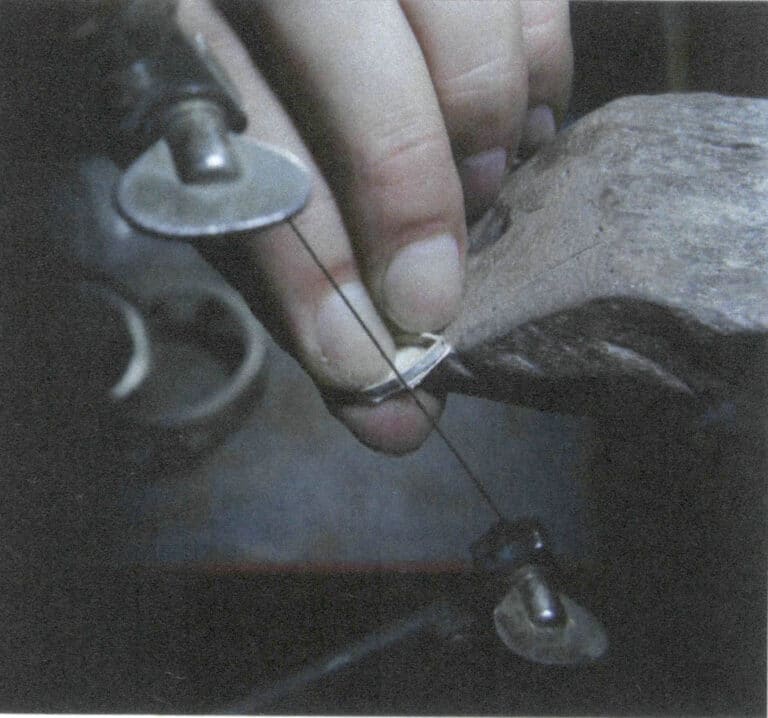

Starting from the drop-shaped pointed tip along the gemstone’s edge, bend the bezel, as shown in Figure 2-36.

Figure 2-35 Material preparation

Figure 2-36 Bending metal edges

(3) Cutting the Metal Edge

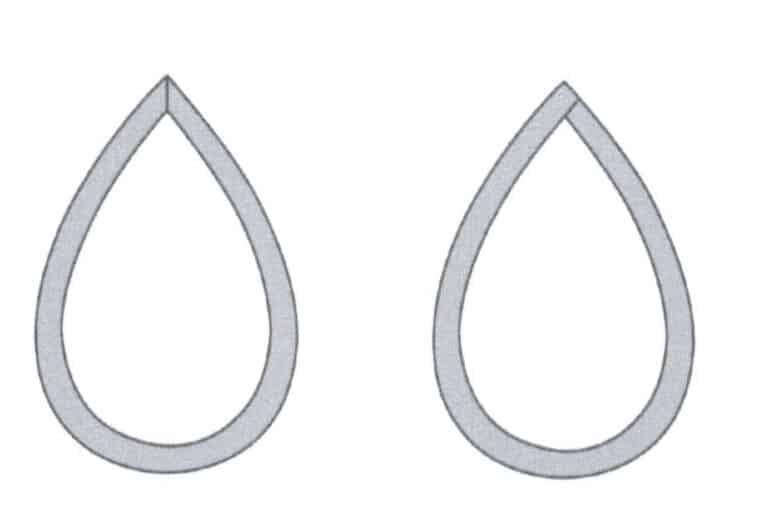

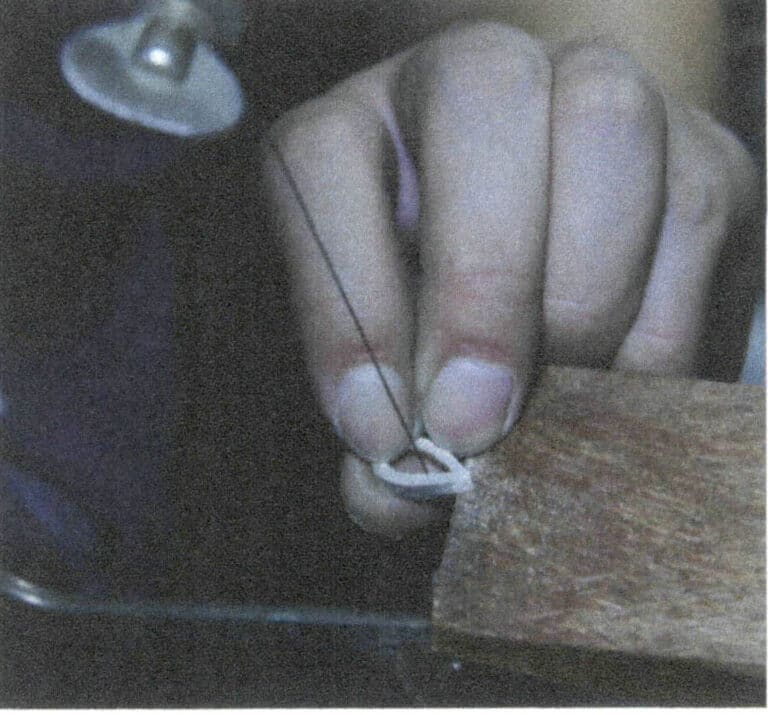

For a shape like a water droplet with a pointed corner, the setting interface of the metal edge is left at the drop-shaped pointed corner to ensure the aesthetic of the pointed corner. After determining the position of joint, cut the metal edge as shown in Figure 2-37. The joint has two processing methods, as shown in Figure 2-38.

Figure 2-37 Cutting Metal Edges

Figure 2-38 Two Methods for Processing the Joint of Drop-Shaped Metal Edges

(4) Welding the Metal Edge

Weld the cut and neatly polished metal edges as shown in Figure 2-39.

(5) Cleaning Corner Solder

After corner welding, residual solder often occupies the corner space. Therefore, to ensure that the gemstone can be placed flatly and snugly within the metal frame, it is necessary to clean the residual solder from the metal corners using a saw or dental pick, as shown in Figure 2-40.

Figure 2-39 Welding Metal Edges

Figure 2-40 Cleaning Corner Solder

(6) Testing the Setting Mount

After adjusting the metal edge, insert the gemstone into the stone setting and observe whether the metal edge fits tightly against the gemstone edge. The metal edge needs to be shrunk if there are obvious gaps, as shown in Figure 2-41.

(7) Welding the Metal Base

The metal base should be able to contain all the bezels. In this step, the flat bezels are welded to the metal base, as shown in Figure 2-42.

Figure 2-41 Testing the Setting Mount

Figure 2-42 Welding the Metal Base

(8) Sawing off the Excess Metal Base on the Outer Side

After welding the metal edges on the metal base, saw off the excess metal base of the metal on the outside, as shown in Figure 2-43.

(9) Hollowing the Metal Base

Drill holes and hollow out the bottom surface; refer to step 13 of the oval-shaped cabochon gemstone bezel setting procedure, as shown in Figure 2-44.

Figure 2-43 Sawing off the excess metal base on the outside

Figure 2-44 Hollow the metal base

(10) Adjustment of the Metal Edge

Before setting the stone, confirm the height of the metal edge and grind off the excess. In this step, for angled cabochon gemstones, it is important to note that whether it is drop-shaped, marquise-shaped, or rectangular-shaped, the metal edge at the pointed corners should be ground down so that, when viewed from the side, the bezel at the pointed corners is lower than the horizontal line of the metal edge. The treatment of the metal edge for drop-shaped cabochon gemstones is shown in Figure 2-45, and the treatment for rectangular-shaped cabochon gemstones is shown in Figure 2-46.

Figure 2-45 Treatment of drop-shaped cabochon gemstone metal edge

Figure 2-46 Treatment of rectangular-shaped arc cabochon gemstone metal edge

Copywrite @ Sobling.Jewelry - Producător de bijuterii personalizate, fabrică de bijuterii OEM și ODM

(11) Welding Metal Fittings

The pendant ring that needs to be welded should be connected before setting the gemstone, as shown in Figure 2-47.

(12) Fixing the Metal

Secure the bezel for the bezel setting to the sealing wax ball or setting base, referring to step 16 of the oval-shaped cabochon gemstone bezel setting process, as shown in Figure 2-48.

Figure 2-47 Welding Metal Fittings

Figure 2-48 Fixing the Metal

(13) Placing the Stone

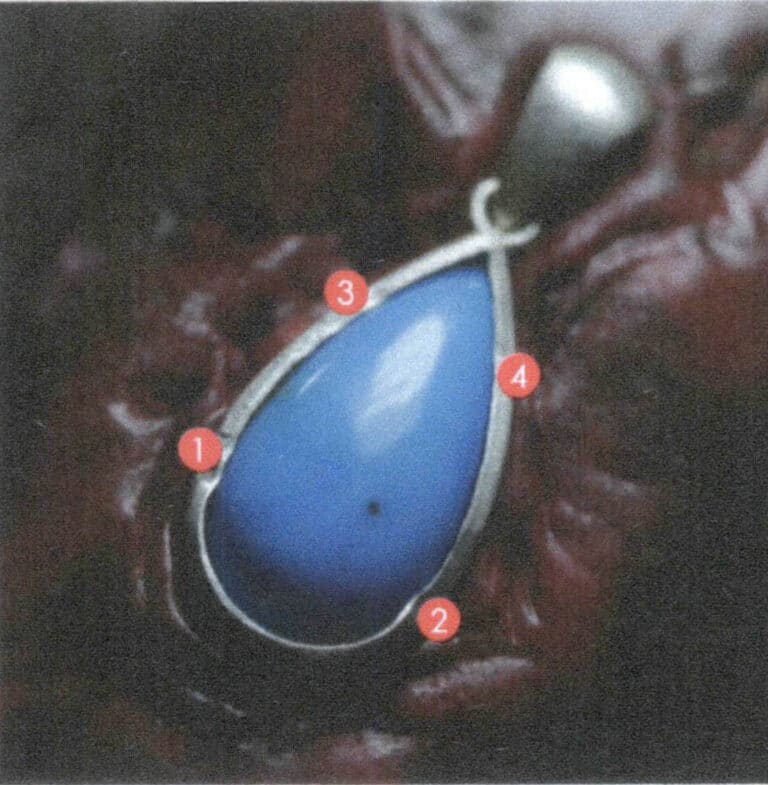

Press the stone into the bezel; refer to step 17 of the oval-shaped cabochon gemstone bezel setting process, as shown in Figure 2-49.

(14) Setting the Stone – Point Fixation

The extrusion of the bezel still follows the method of point fixation followed by cyclic extrusion. Shapes like circles, ellipses, and squares, which have two lines of symmetry, can easily find the symmetrical points of the cross intersection, making it suitable to use the points on the axis of symmetry as the standard for point fixation. However, the droplet shape has only one line of symmetry, so it is more appropriate to divide the symmetrical points on both sides of the axis into two groups: upper and lower. In Figure 2-50, after performing point fixation on the points of group ①②, point fixation is then performed on the points of group ③④.

Figure 2-49 Placing the Stone

Figure 2-50 Point Fixation Sequence

(15) Setting the Stone – Cyclic Edge Pressing

The method of cyclic edge pressing after point fixation is consistent with the oval-shaped cabochon gemstone bezel setting. Specific operations and precautions refer to the production steps of oval-shaped cabochon gemstone bezel setting process 19, as shown in Figure 2-51.

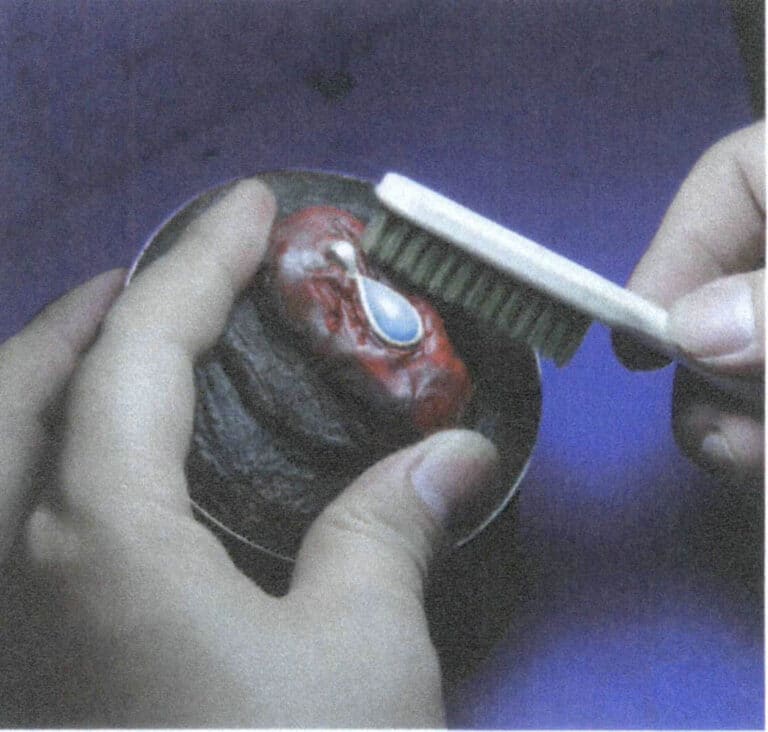

(16) Checking that the Setting is Secure

In crimping, we should constantly observe whether the stone is set firmly. After the stone is set, the surface of the metal shavings and other impurities is swept clean, and finally, observe whether the gemstone bezel setting is tight. Touch the stone to make sure that it is tight and stable before proceeding to the next step in production. Special attention should be paid to the tightness of the metal at the drop-shaped pointed corner. Check the stability setting, as shown in Figure 2-52.

Figure 2-51 Cyclic Edge Pressing

Figure 2-52 Cleaning Impurities and Checking the Tightness of the Bezel Setting

(17) Finishing – Trimming

Flatten the inside of the metal bezel at the pointed corners with a flat-headed pusher, and file the outside of the metal edge, as shown in Figures 2-53 and 2-54.

Figure 2-53 Trimming the inner metal edge of the metal

Figure 2-54 Trimming the outer metal edge of the metal

(18) Finishing–Polishing

Use sandpaper rolls and polishing wheels, as Figure 2-55 shows.

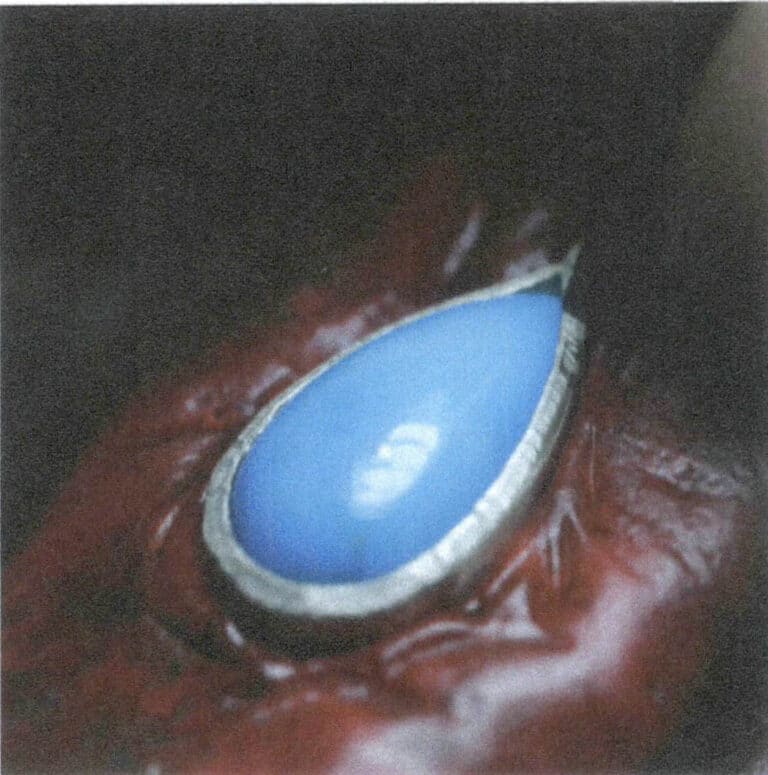

(19) Completing the Drop-shaped Cabochon Gemstone Bezel Setting

The finished drop-shaped cabochon gemstone bezel setting is shown in Figure 2-56.

Figure 2-55 Polishing with sandpaper rolls

Figure 2-56 Completing the drop-shaped cabochon gemstone bezel setting

2. Method for Making Faceted Gemstone Bezel Settings

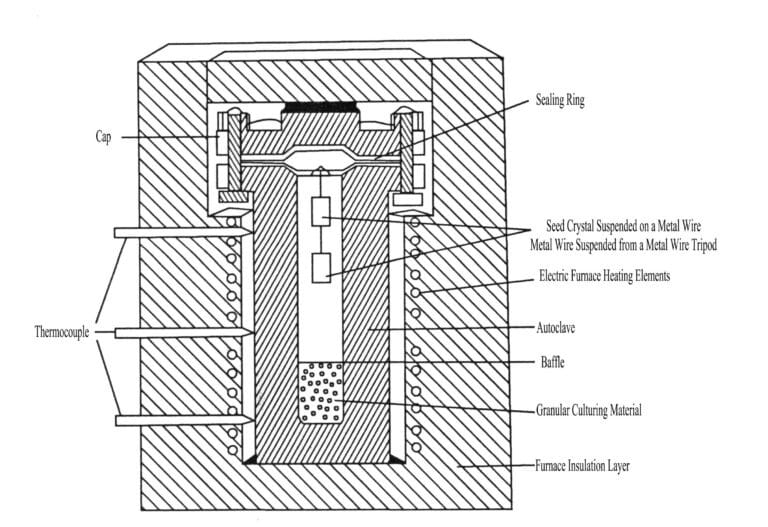

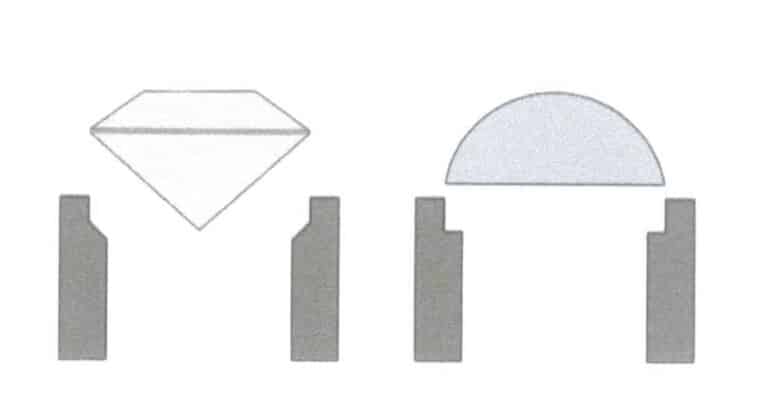

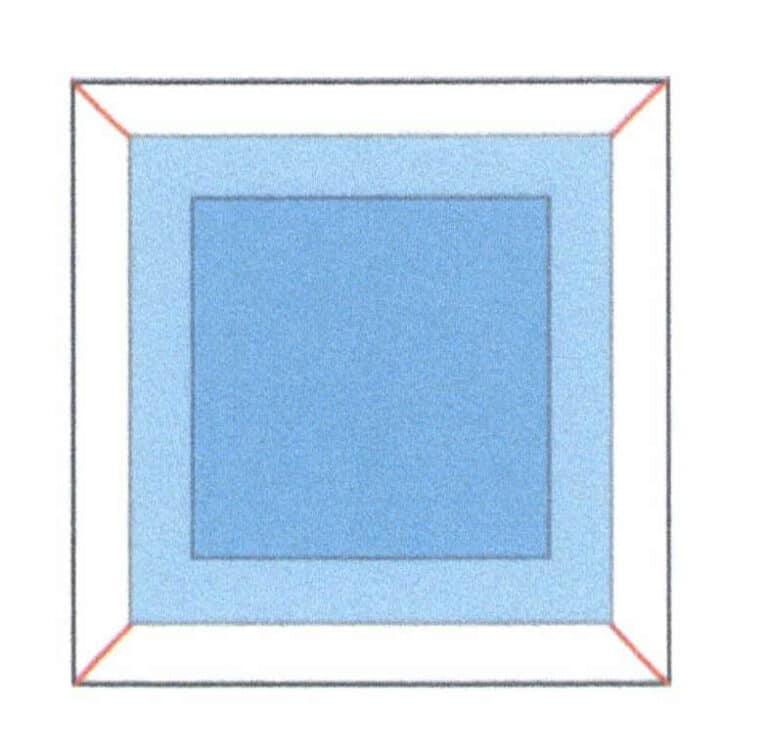

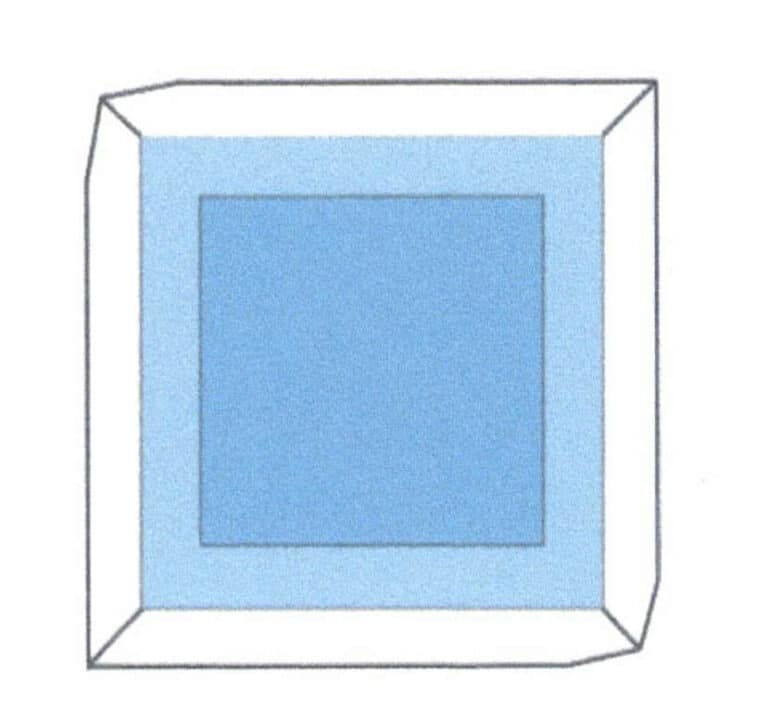

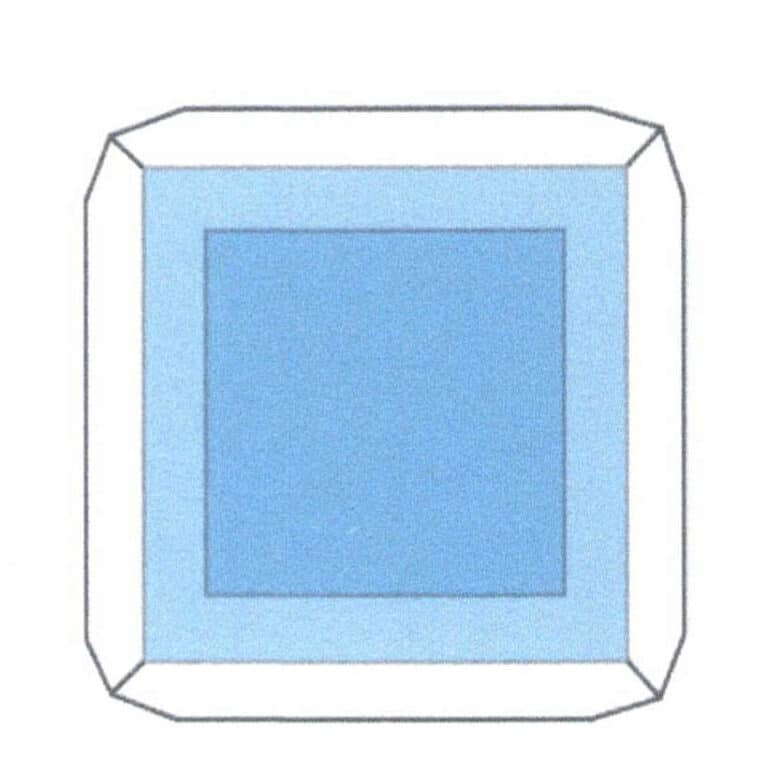

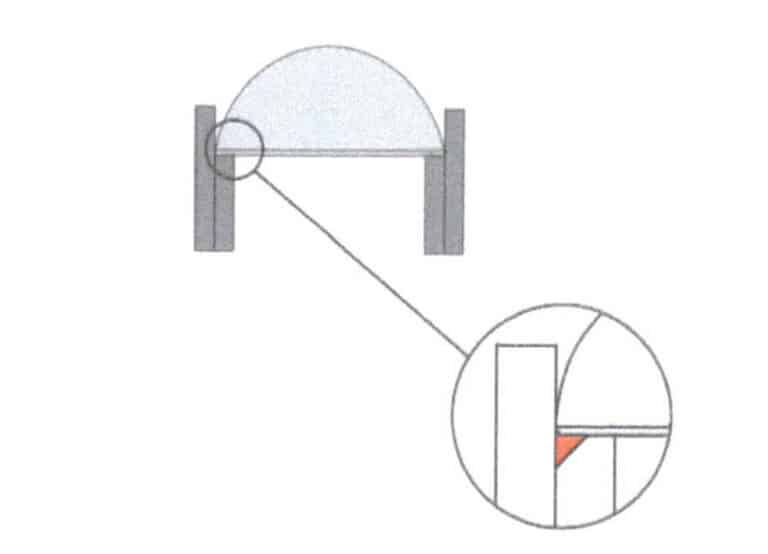

Differences between faceted gemstones and cabochon gemstones in setting production: one is that the bottom surface of the gemstone setting base for faceted gemstones cannot be flat; it must have space for the pavilion of the faceted gemstone to sink, so a flat surface cannot support it and requires a ring of girdles inside the metal edge to support the gemstone; the other is that the metal extrusion method in faceted gemstone bezel settings is different. Below, the steps and precautions for making faceted gemstone settings will be introduced using round brilliance cut gemstones and rectangular brilliance cut gemstones as examples. Since faceted gemstone bezel settings and the cabochon gemstone bezel setting has some repetitive steps and precautions, so the repetitive parts in the faceted gemstone bezel setting steps are omitted and can be referenced from the previous text. The round brilliance cut gemstone bezel setting is shown in Figure 2-57, and the rectangular one in Figure 2-58.

Figure 2-57 Round brilliance cut gemstone bezel setting

Figure 2-58 Rectangular brilliance cut gemstone bezel Setting

2.1 Steps for Making Round Brilliance Cut Gemstone Bezel Setting

(1) Pregătirea materialului

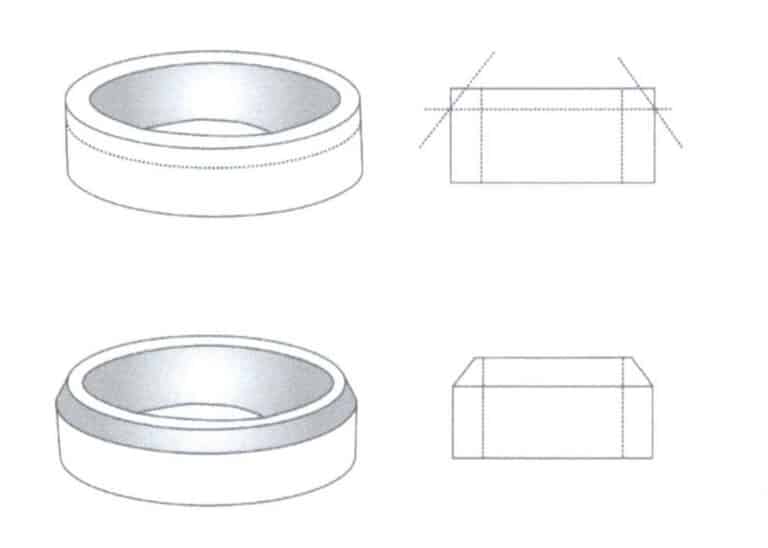

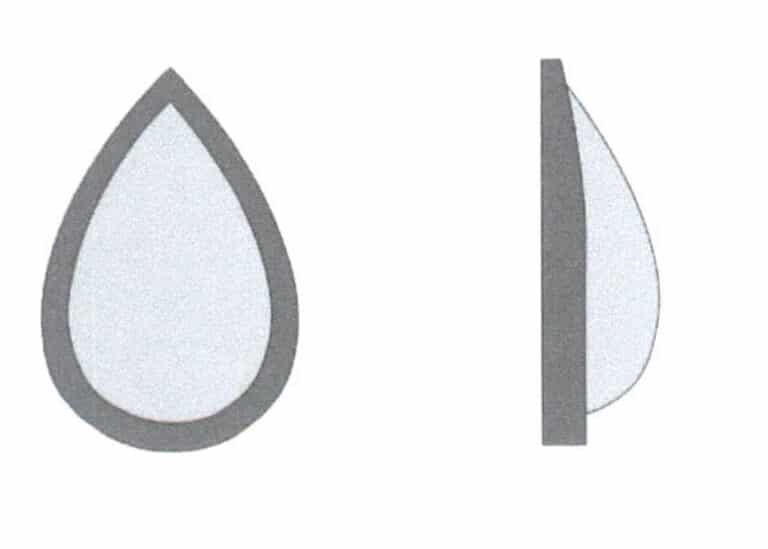

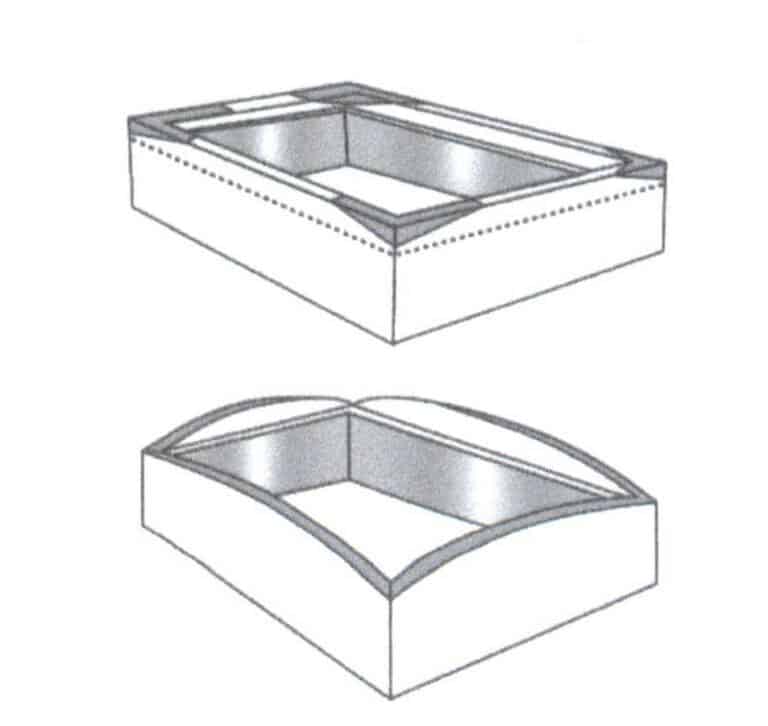

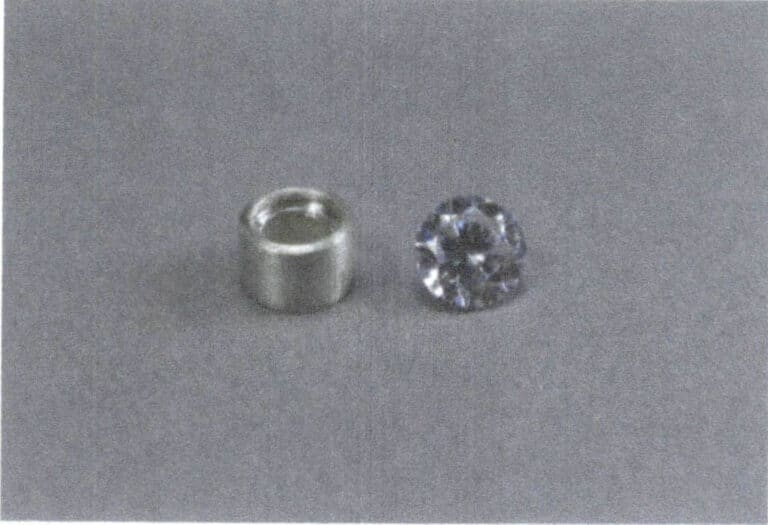

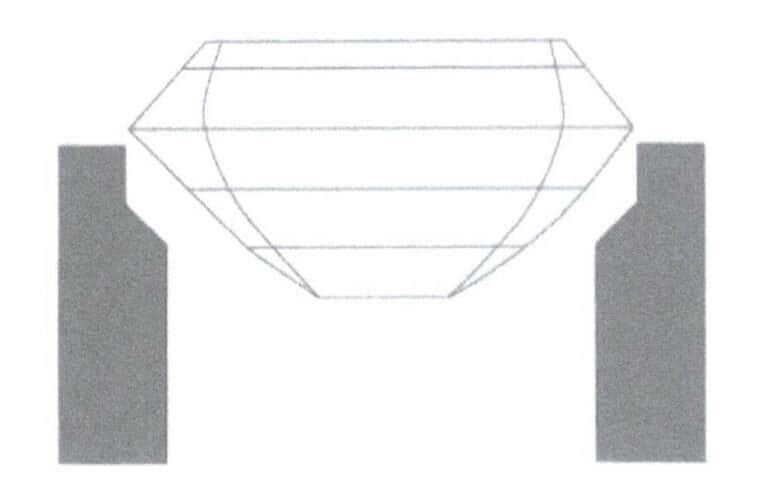

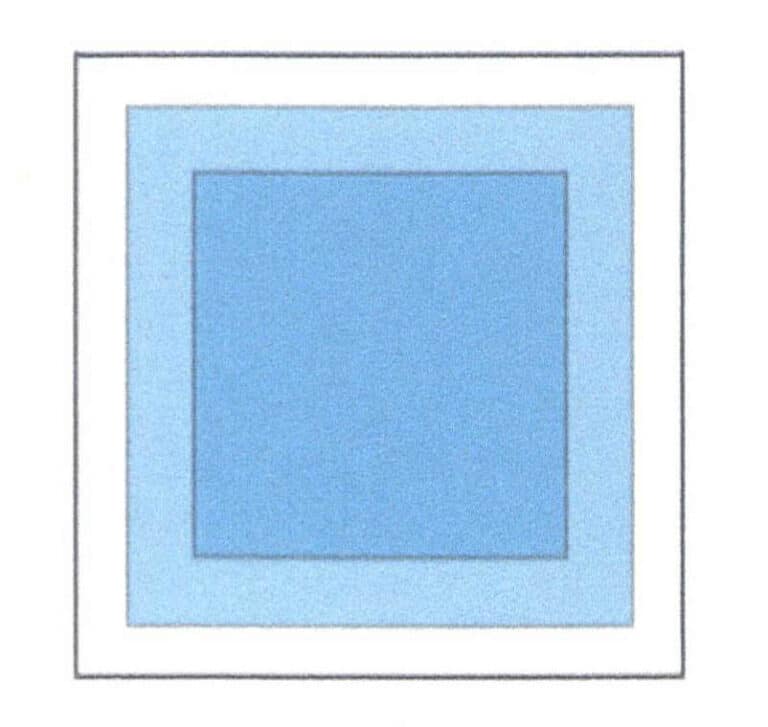

In the faceted gemstone bezel setting, the metal supports the gemstone from the girdle, so there is no need for a base; as long as the gemstone does not expose the bottom, having any base does not affect it. However, it is important to note whether the edges supporting the stone setting position are appropriately positioned relative to its pavilion. Generally, the thickness of the edges should be at least 0.5 mm. The round brilliance cut gemstone and the bezel are shown in Figure 2-59. The cross-section of stone setting position of faceted gemstones and cabochon gemstones bezel setting is shown in Figure 2-60.

Figure 2-59 Round Brilliance Cut Gemstones and Bezel

Figure 2-60 Cross-section of stone setting position of Faceted Gemstones and cabochon Gemstones in Settings

(2) Setting Stones

The metal extrusion direction of the faceted gemstone bezel setting is more downward because the angle of the crown is smaller, and the extrusion direction of the chisel follows the angle of the gemstone crown. Therefore, compared to the cabochon gemstone, which extrudes from the sides towards the center, the extrusion direction of the faceted gemstone is more downward. The steps for extruding faceted gemstones differ from those for cabochon gemstones, as they first fix points symmetrically along the central axis and then cycle to press the edges, as shown in Figures 2-61 and 2-62.

Figure 2-61 Spot Fixing

Figure 2-62 Cyclic Edge Pressing

(3) Finishing

Downward pressure will inevitably cause unevenness on the inner side of the metal edge, so the inner side should be first repaired with a pusher, then smoothed with a file, and finally polished with sandpaper rolls, polishing wheels, etc. Repairing the inner side of the metal edge with a pusher is shown in Figure 2-63.

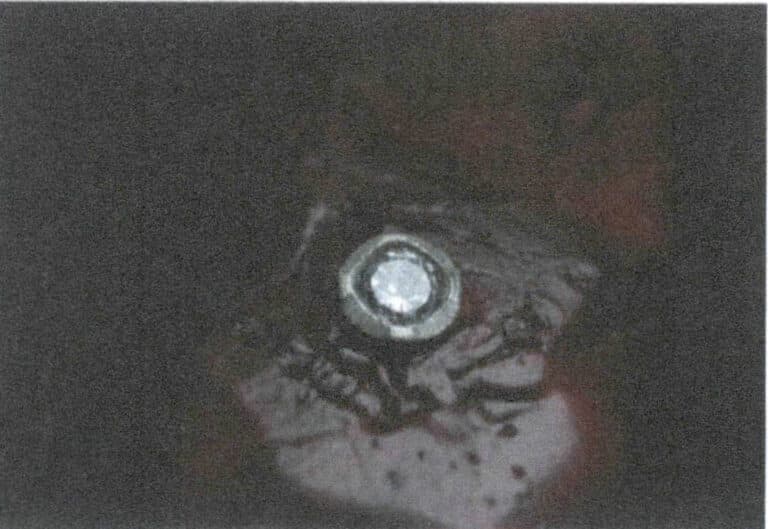

(4) Completing the Round Brilliance Cut Gemstone Bezel Setting

The completed round brilliance cut gemstone bezel setting is shown in Figure 2-64.

Figure 2-63 Repairing the Inner Side of the Metal Edge with a Pusher

Figure 2-64 Completed round brilliance cut gemstone bezel setting

2.2 Steps for Making the Rectangular Brilliance Cut Gemstone Bezel Setting

(1) Preliminary Preparation

The bottom of the stone setting base leaves a recessed space for the pavilion of gemstone, ensuring that the height prevents the gemstone from showing its bottom, as shown in Figure 2-65.

(2) Processing of the Inner Side of the Metal Edge

Compared to the rectangular brilliance cut gemstone bezel setting, the most significant difference in the round brilliance cut gemstone bezel setting is treating the inner side of the metal edge and the corners. First, a groove should be made at the corners of the inner side of the metal edge using a ball-shaped bur of about 0.5 mm, as shown in Figure 2-66.

Figure 2-65 Cross-section of a rectangular brilliance cut gemstone bezel setting

Figure 2-66 Position of the inner groove of the metal edge of the rectangular brilliance cut gemstone bezel setting

(3) Saw an Opening at the Right Angle

Saw an opening at the right angle, with a depth above the gemstone’s girdle, leaving some room for the opening to tighten, as shown in Figure 2-67.

(4) Setting the Stone- Extruding Corner

After saw an opening at the right angle, press down the metal at the opening, following the diagonal order, as shown in Figures 2-68 to 2-70. If the corners are extruded first, closing the openings in the later stages of the setting will be easier. An example of an incorrect stone setting is shown in Figure 2-71.

Figure 2-68 The red line indicates the saw cut

Figure 2-69 Squeeze the metal edge at the right angle in a diagonal order

Figure 2-70 Evenly complete the squeezing at all four corners

Figure 2-71 Demonstration of incorrect stone setting

(5) Setting the Stone – Cyclic Edge Pressing

After tightening the four corners, press the straight bezels tightly, then use a chisel to apply cyclic edge pressing around to compress and secure the gemstone, as shown in Figures 2-72 and 2-73.

Figure 2-72 Top View of Compressed Metal Edge

Figure 2-73 Side View of Metal Edge

3. Other Bezel Setting Methods

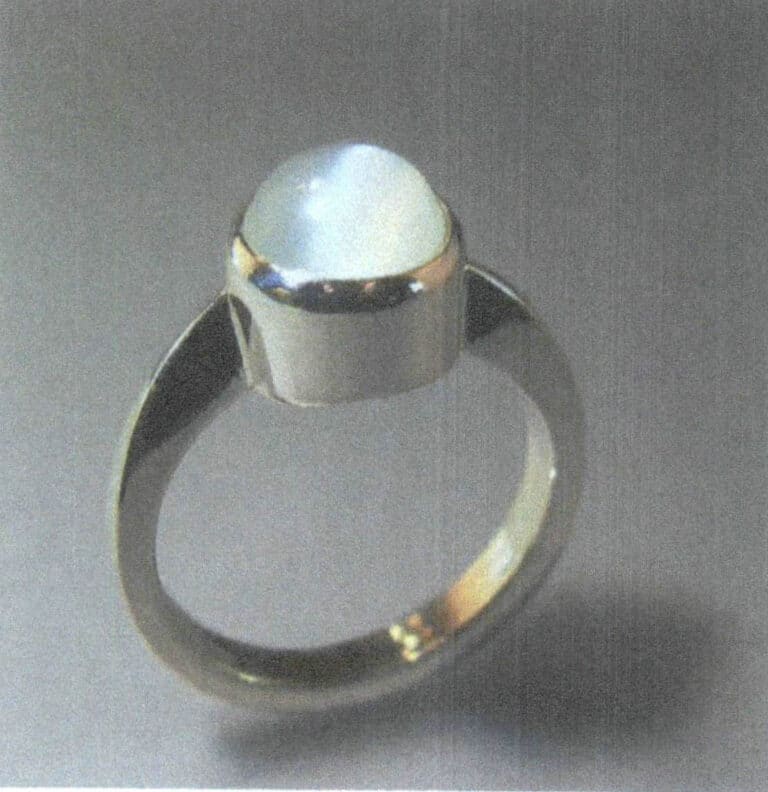

The bezel setting methods for cabochon and faceted gemstones are relatively conventional, but these are not the only two methods. There are many ways to enrich the bezel setting effect and address different design needs. For example, double-headed bezel settings, reverse-tapered bezel settings, etc., but their basic principles are consistent; only the precautions differ in different operations. Figures 2-74 and 2-75 show these are two unconventional bezel setting rings.

Figure 2-74 Bezel Setting Ring (1)

Figure 2-75 Bezel Setting Ring (2)

3.1 Inner Shoulder Setting

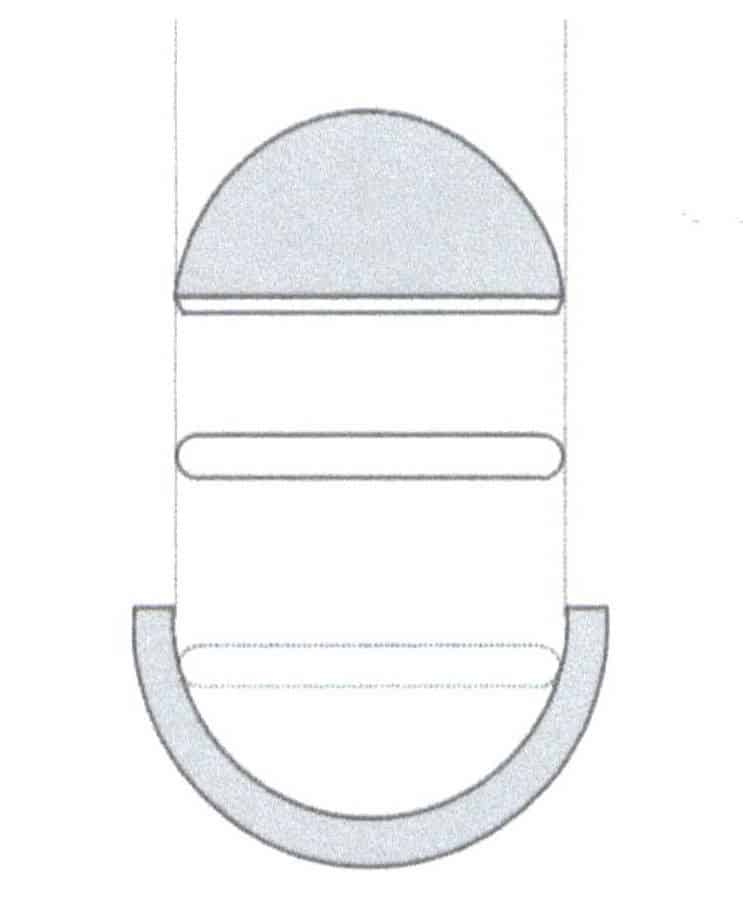

The metal base of the cabochon bezel setting can weld metal pieces and weld a metal ring on the inner side of the metal edge. This metal ring can be a circular or ring-shaped piece to support the gemstone in the same way as the metal base. The difference is that this structure can increase its volume for thinner cabochon gemstones by raising the metal edge. This method is also applicable in double-headed, bowl-shaped, and other bezel setting methods, which will be mentioned later. The cross-section of the inner shoulder bezel setting is shown in Figure 2-76. It is important to note that there is often excess solder at the position where the inner metal ring or metal piece is welded. One way to handle this is to grind an angle at the welding point to leave space for the solder, as shown in Figure 2-77. Another way to deal with the excess solder is through grinding. The inner shoulder bezel setting is shown in Figure 2-78.

Figure 2-76 Cross-section of inner shoulder bezel setting

Figure 2-77 Angled treatment of the welding position between the metal edge and the inner metal piece

3.2 Half Bezel Setting

The half bezel setting is relative to the full bezel setting, as a part of the metal edge around the gemstone is removed for design purposes, which allows for more varied forms of the metal edge. However, half bezel settings generally require the gemstone to have a certain volume to be securely set by part of the metal edge. This setting method is between conventional and prong bezel settings, as shown in Figure 2-79.

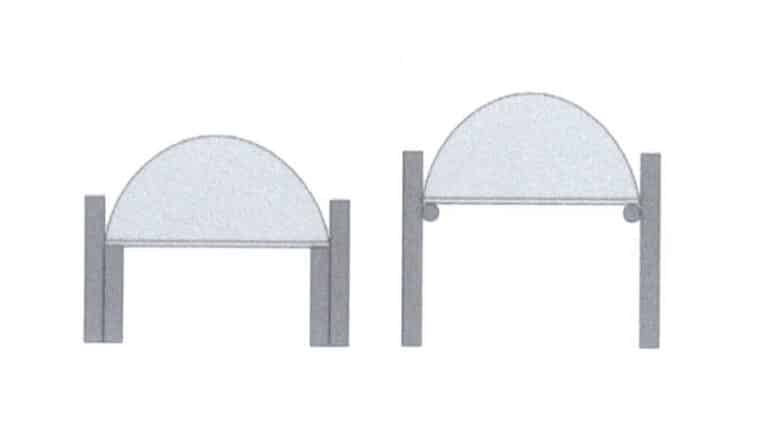

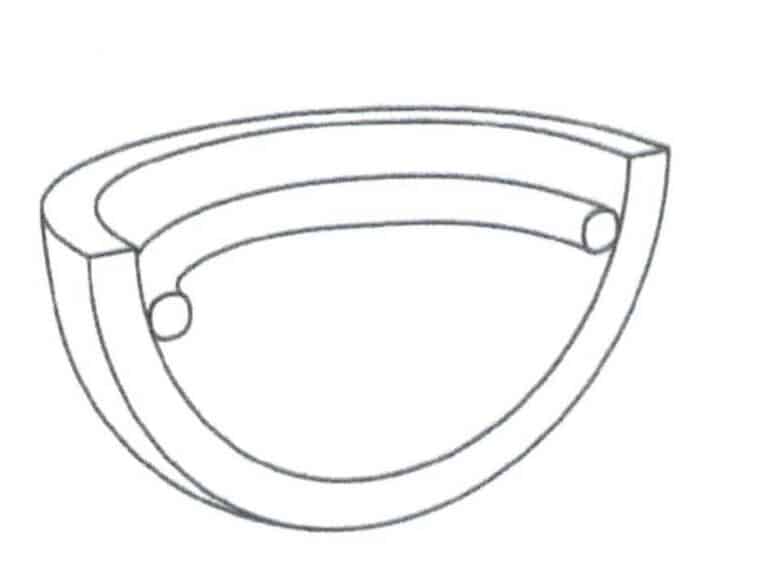

3.3 Bowl-shaped Bezel Setting

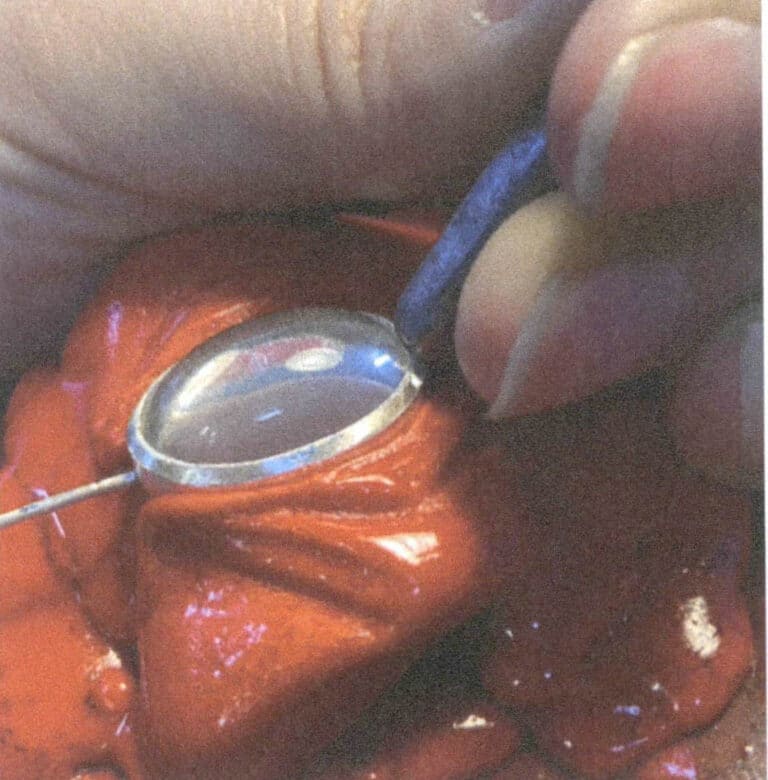

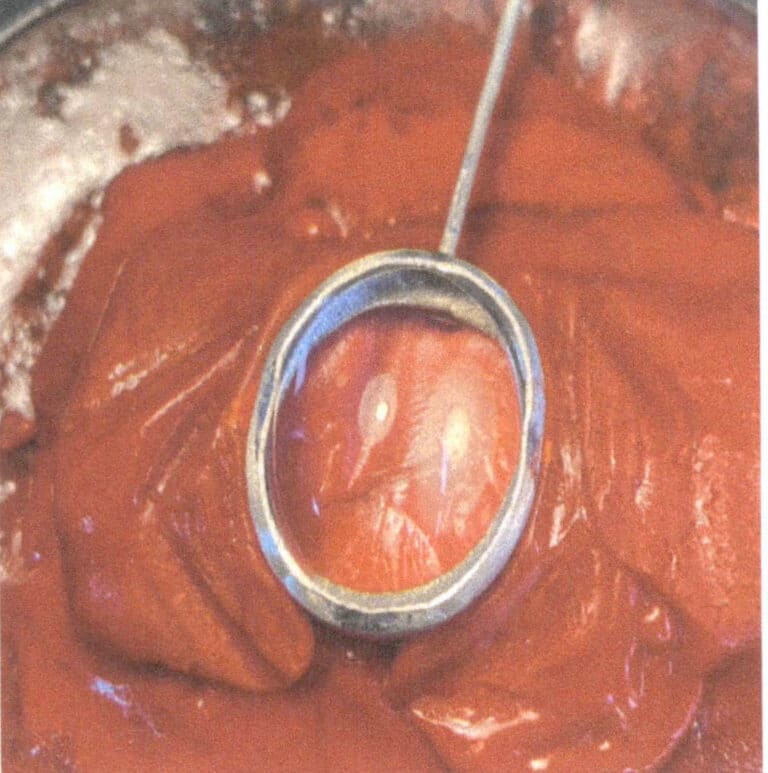

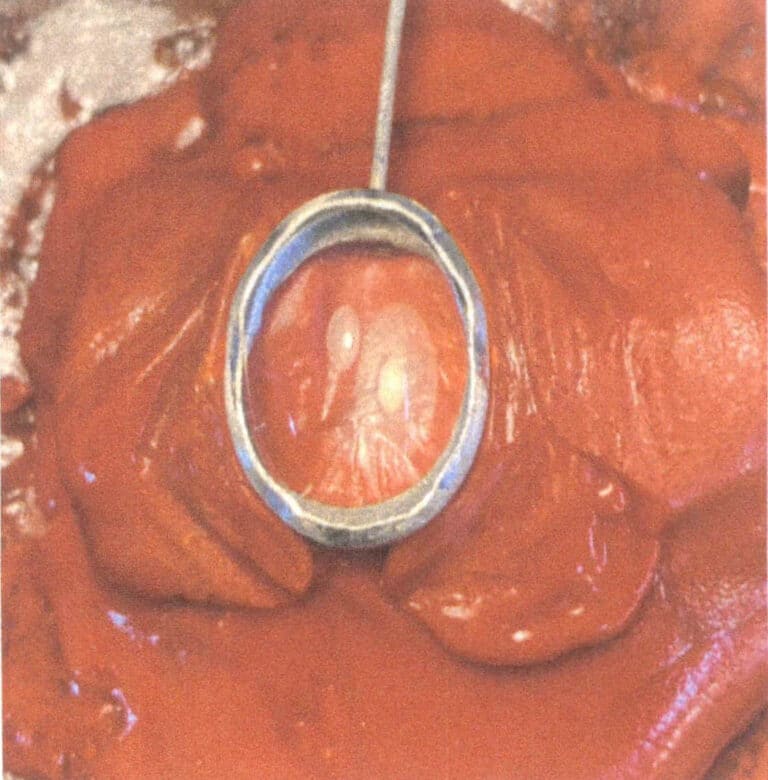

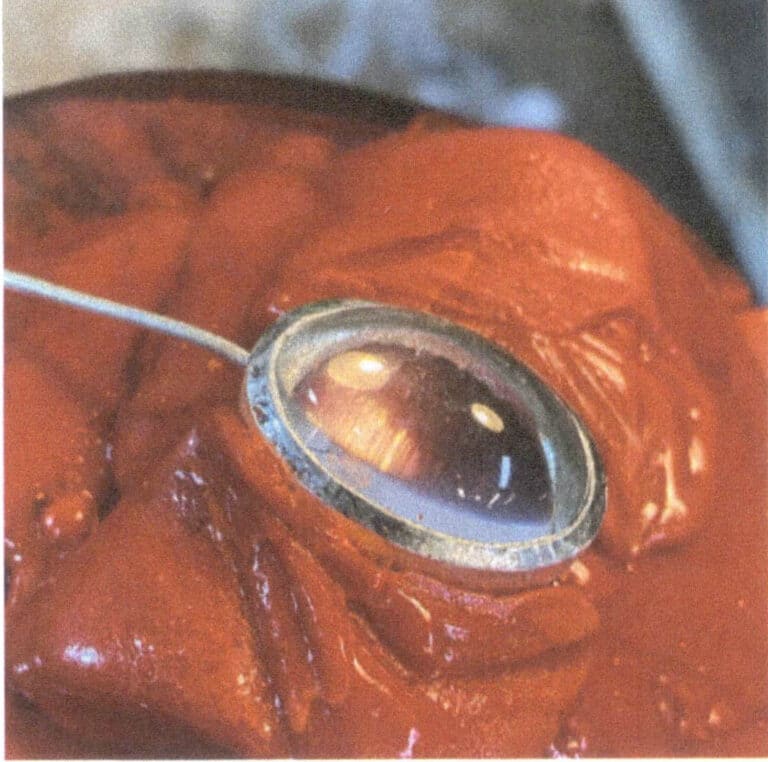

The bezel settings mentioned earlier are all done on a base that can be placed horizontally. In contrast, the bowl-shaped bezel setting is done on a hemispherical structure, similar to a bowl. This setting method integrates the cabochon gemstone with the metal, allowing for more flexible display directions of the gemstone. The metal is not just a base but also an important part of the visual form. This setting method is also suitable for conical gemstones. In production, a hemispherical shape is first created by punching a hemispheric with dapping punch according to the size of the gemstone, and a metal ring is welded inside the hemispherical structure as the gemstone base. Then, the metal is fixed with fire lacquer or similar. The method of setting the stone is the same as the basic setting introduced earlier, simply pressing the metal edge towards the center. The bowl-shaped bezel setting relevant content is shown in Figures 2-80 to 2-83.

Figure 2-80 Structure diagram of bowl-shaped bezel setting

Figure 2-81 Cross-section of a bowl-shaped setting with a metal structure

Figure 2-82 Bowl-shaped setting applied to cabochon and tapered gemstones

Figure 2-83 Bowl-shaped bezel setting

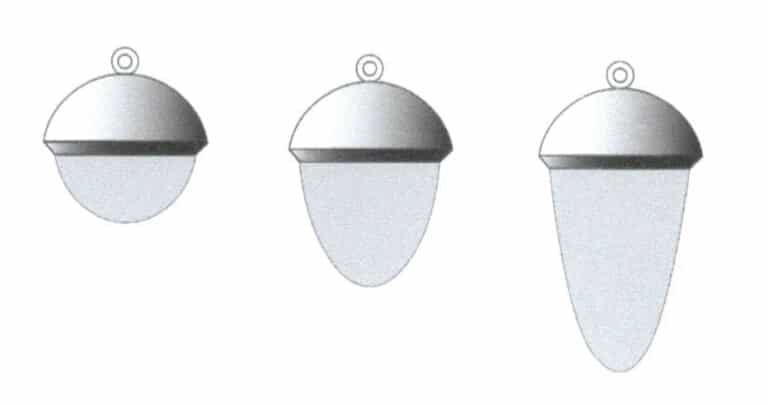

3.4 Double-headed Bezel Setting

The double-headed bezel setting is an extension of the inner shoulder and bowl-shaped bezel settings, referring to the setting of gemstones at both ends of a tubular structure. In terms of internal structure treatment, if larger gemstones are to be set, one or two ring structures can be welded to the inner wall of the metal tube as a base for the gemstones on both sides; if smaller gemstones are set, the stone supports can be directly expanded at both ends of the sufficiently thick metal tube using a ball-shaped bur. The difficulty of the double-headed bezel setting lies in fixing it, as both ends need to be set separately, and when setting one end, the other end is inevitably fixed in the sealing wax. Therefore, the double-headed bezel setting is more suitable for using white sealing wax, which can be softened with hot air and is not easily sticky; if red sealing wax is used and there is stickiness, it needs to be soaked in banana oil to remove it. The cross-section and finished product of the double-headed bezel setting are shown in Figure 2-84 and as shown in Figure 2-85.

Figure 2-84 Double-headed bezel setting cross-section

Figure 2-85 Double-headed bezel setting

3.5 Reverse-tapered Bezel Setting

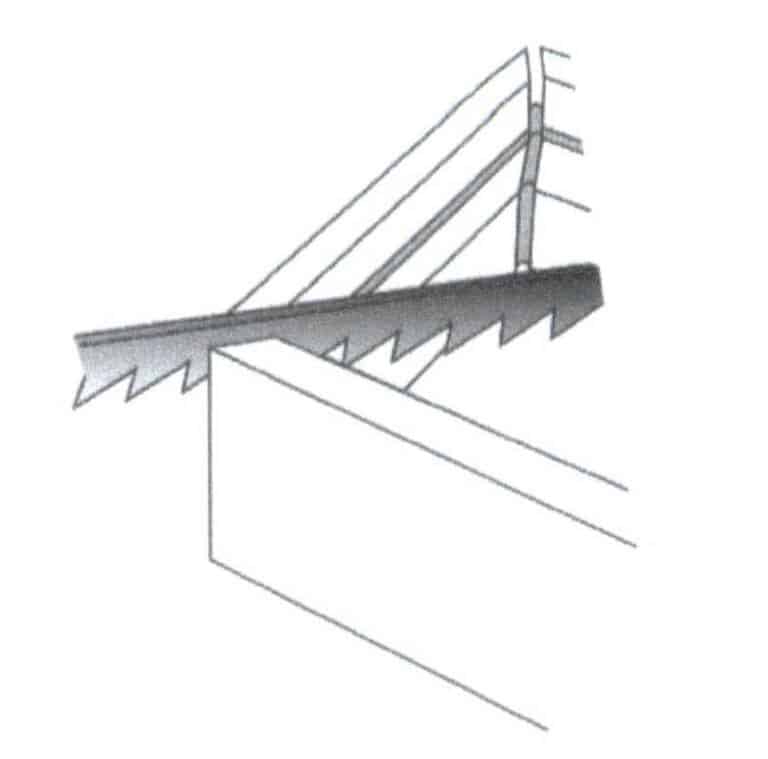

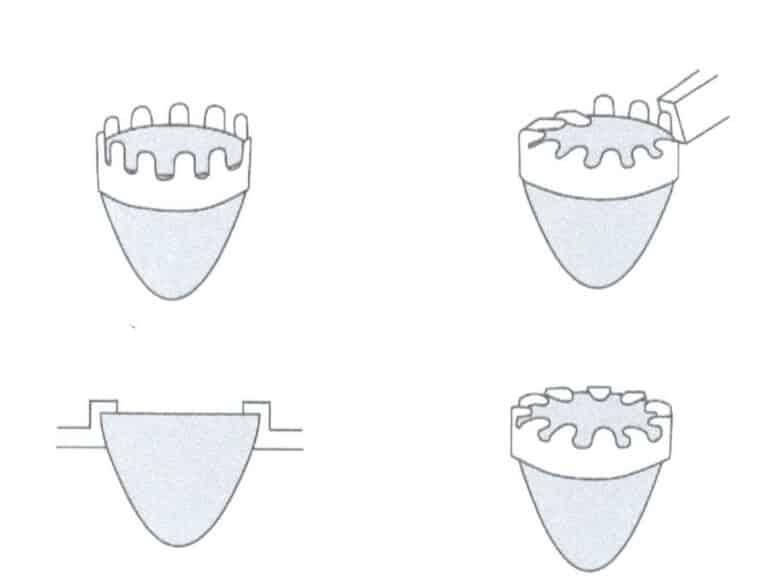

The reverse-tapered bezel setting suits highly curved surfaces or even conical gemstones with pointed corners. The key point of the inverted bezel structure is to create a wide metal edge at the top and a narrow one at the bottom, allowing the gemstone to be placed upside down into the edge structure from the wider side. First, a suitably sized strip of metal needs to be prepared, with one side sawed into teeth or a wavy shape, leaving the other side straight; then the metal strip is formed into a ring, and the joint is welded; next, a tool is used to shape the metal edge into a wide-toothed and narrow straight edge; after preparing the edge, the gemstone is placed upside down, with the teeth or wavy shape bent towards the bottom of the gemstone, forming a fixed structure, as shown in Figure 2-86.

Section III The Application of Bezel Setting in Jewelry Design

The biggest feature of bezel setting is its stability; even softer pure gold and pure silver can achieve the goal of a stable setting. Additionally, it can accommodate a wide variety of gemstone types. From a design and aesthetic perspective, bezel setting gives a full and steady visual impression. The overall and coherent metal edge, polished to present a luster, resembles the lines drawn around the gemstones, enhancing the delicacy of the design. Bezel setting is one of the most commonly used setting methods in traditional jewelry. On the one hand, this is because it is easy to master; on the other hand, in ancient jewelry, the main metals used were pure gold and pure silver, which have lower hardness, making the bezel setting method the most suitable. Visually, ancient and ethnic jewelry often uses gemstones with high color saturation, such as red coral, turquoise, and amber. For example, in Mongolian and Tibetan ornaments, the transparency of gemstones is not emphasized, but rather the intensity of color; from a matching perspective, high saturation colors combined with large areas of metallic luster, especially pure gold, create a stronger visual impact. For instance, decorative items made with filigree techniques are often paired with bezel setting gemstones, resulting in a more intense color contrast. Figures 2-87 and 2-88 show the gold-inlaid pearl jewelry from the 17th to 19th centuries and 18th-century Moroccan bead ornaments, respectively.

Figure 2-87 17th-19th Century Gold Inlaid with Pearls and Gemstones Round Filigree

Figure 2-88 18th-century Moroccan bead ornaments

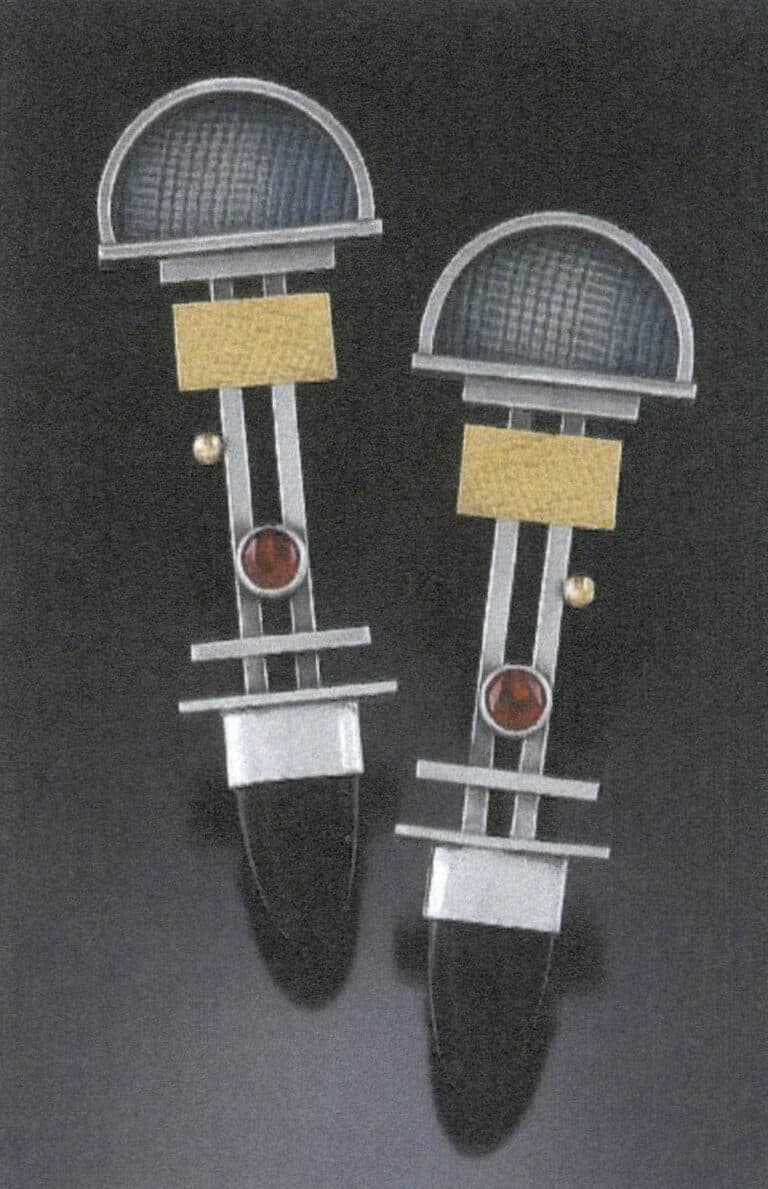

In contemporary jewelry design, bezel setting remains a relatively common setting method for cabochon gemstones and has evolved into increasingly rich forms, adapting to the changing shapes of gemstones. There are also many exciting artistic jewelry cases exploring innovations in bezel setting, which are beneficial for learning craftsmanship while broadening design perspectives, as shown in Figures 2-89 to 2-92.

Figure 2-89 Bezel Setting Jewelry (1)

Figure 2-90 Bezel Setting Jewelry (2)

Figure 2-91 Bezel Setting Jewelry (3)

Figure 2-92 Bezel Setting Jewelry (4)

Bezel setting may seem simple as an entry-level setting method for learning setting techniques, but it has the longest history of setting and great innovation potential. The application of the bezel setting can be very flexible; controlling the metal edge is like a design proposition, where its scale is not absolute within the range of inlaying. The so-called “suitable” width and height test the designer’s understanding of gemstones, and it is hoped that beginners in setting can gain creative inspiration from the bezel setting.