Jak rzemiosło metalowe kształtuje sztukę jubilerską

Od drążenia do emaliowania - kompleksowy przewodnik po technikach formowania metalu

Wprowadzenie:

Przedstawiamy podstawy kunsztu tworzenia biżuterii z metalu! Nasz przewodnik zagłębia się w podstawowe techniki obróbki metalu, w tym drążenie, piłowanie i spawanie, które stanowią podstawę wykwintnej biżuterii. Poznaj metody teksturowania, takie jak młotkowanie i odciskanie, aby dodać głębi swoim projektom. Odkryj technikę marszczenia, aby uzyskać charakterystyczne, jedyne w swoim rodzaju tekstury. Ponadto, opanuj grawerowanie i podstawowe emaliowanie, aby podnieść poziom swojego rzemiosła. To kompleksowe źródło informacji jest dostosowane do potrzeb sklepów jubilerskich, studiów, marek, sprzedawców detalicznych, projektantów i platform handlu elektronicznego, oferując wgląd w celu ulepszenia oferty i zaspokojenia niestandardowych zamówień dla celebrytów i wymagających klientów.

Letnia dżungla, czyste srebro 999, grawerowane

Spis treści

Sekcja I Procesy drążenia, piłowania i spawania metali

W produkcji rzemiosła metalowego, o ile koncepcja projektowa jest sprytna, ciekawe prace można tworzyć przy użyciu najbardziej podstawowych technik. Procesy drążenia, piłowania i spawania są podstawą rzemiosła metalowego, a do tworzenia biżuterii możemy używać najbardziej podstawowych łuków pił, brzeszczotów i wierteł.

1. Suszone na powietrzu owoce granatu - studium przypadku produkcji emaliowania drążonego

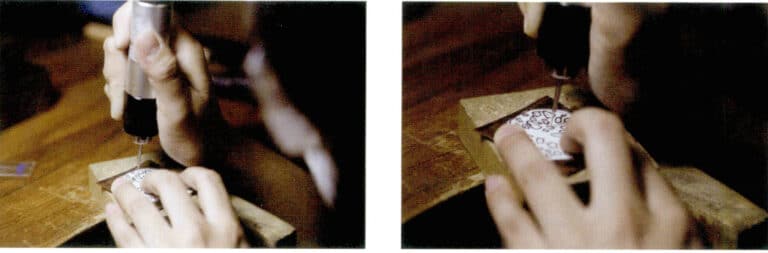

1. Przenoszenie wzoru: Po zaprojektowaniu wzoru musimy przenieść go na metal; w przypadku płaskich elementów metalowych zazwyczaj używamy kalki kreślarskiej do narysowania lub bezpośrednio rysujemy wzór, a następnie przyklejamy go do metalowego elementu za pomocą pasty.

2. Użyj dłuta i młotka, aby zlokalizować miejsce wiercenia.

3. Użyj wiertła do szlifierki wiszącej, aby wykonać otwór.

4. Wydrążenie: Włóż brzeszczot wyrzynarki przez otwór i zamontuj go, a następnie wytnij kształt od wewnątrz.

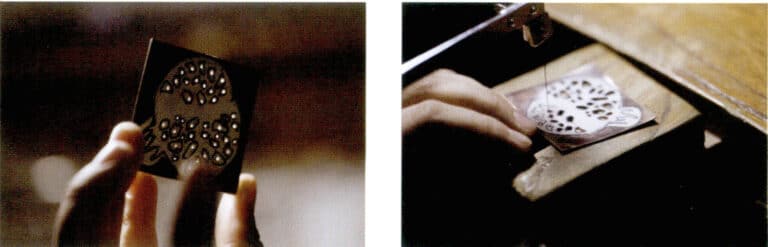

5. Po wyżarzeniu użyj drewnianego patyczka, aby nadać wydrążonej części kształt łuku.

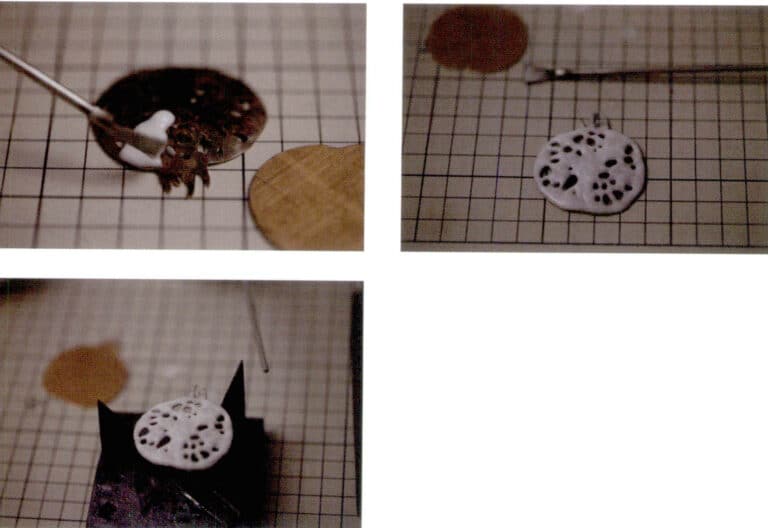

6. Wypełnić szkliwo.

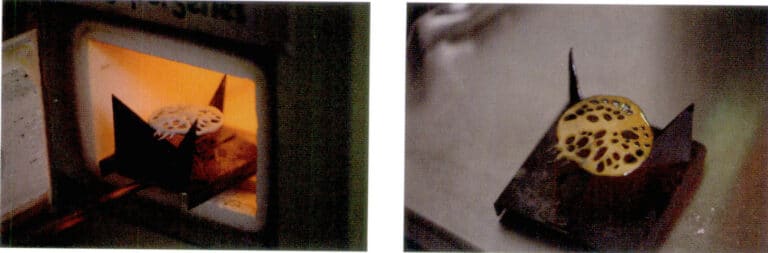

7. Umieść go w piecu do emaliowania i wypalaj przez około 1 minutę w temperaturze około 750 ℃.

8. Różne kolory emalii mogą być dodawane i wypalane wielokrotnie w zależności od koloru granatu.

9. Suszenie granatu na powietrzu jest zakończone.

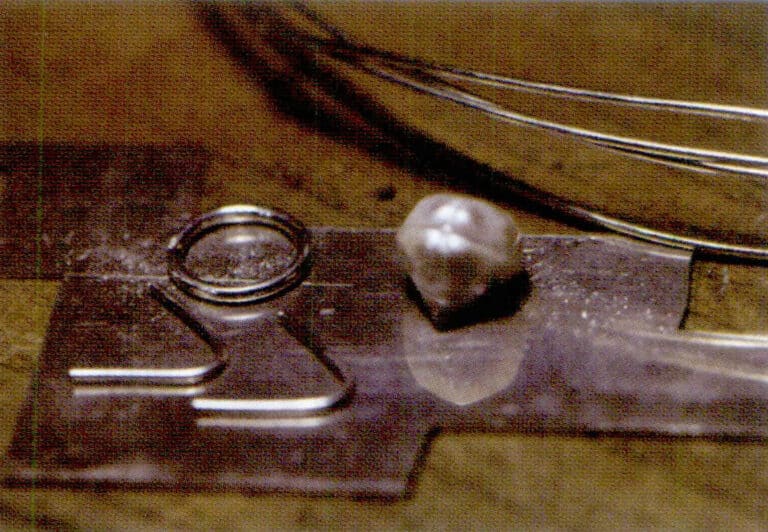

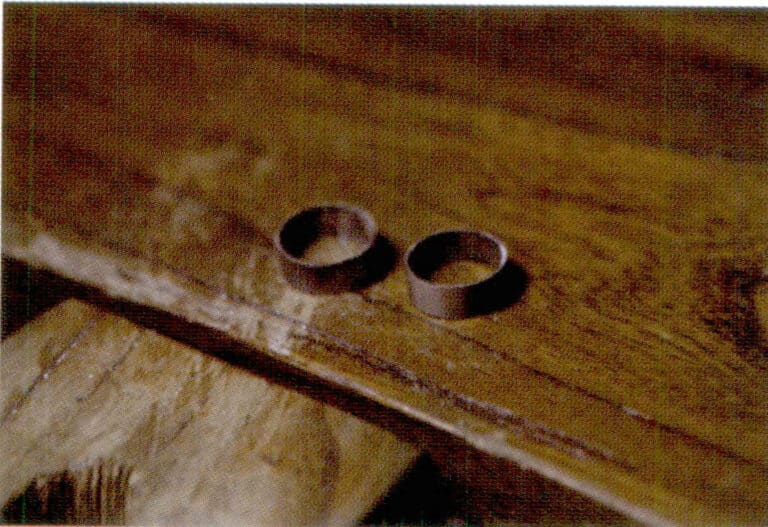

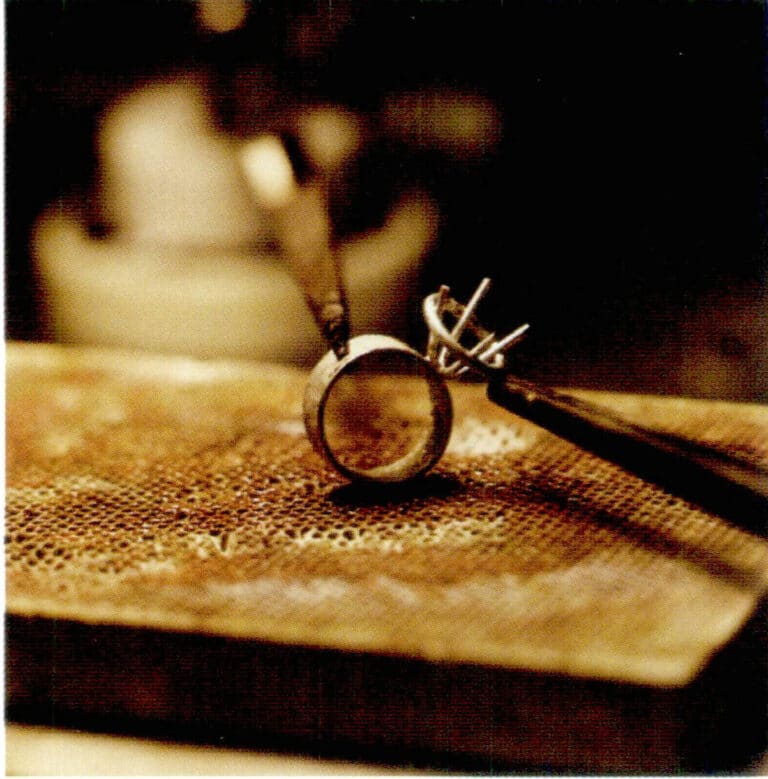

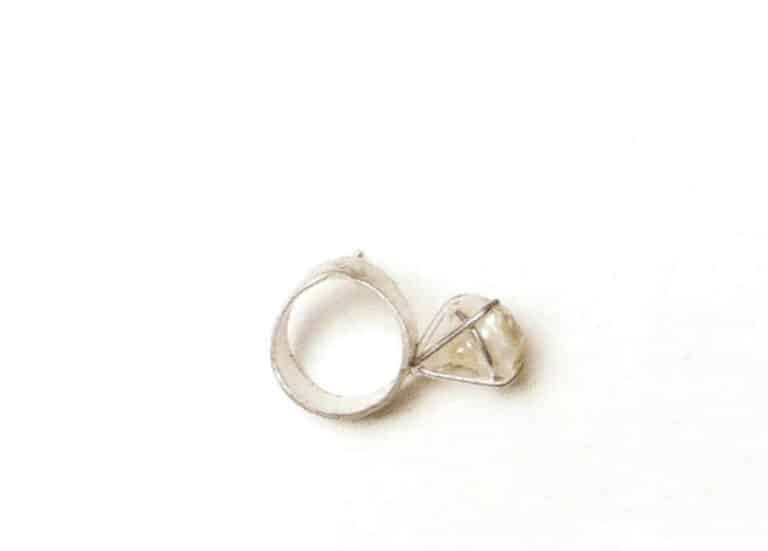

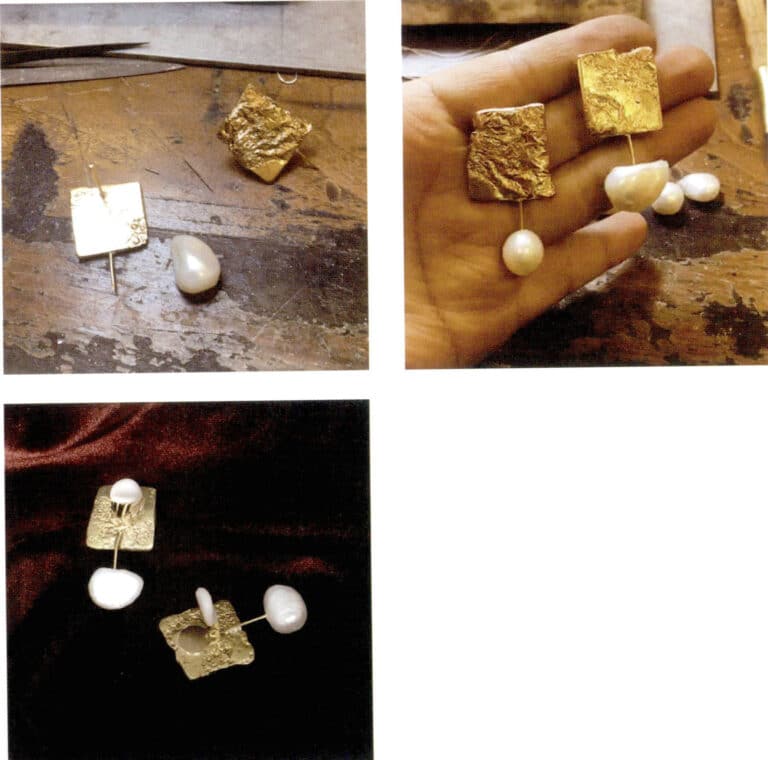

2. Etui do tworzenia pierścionków i kolczyków z perłami w kształcie diamentów

(1) Prace przygotowawcze

1. Potrzebne materiały: Blacha srebrna 925, drut srebrny, perły barokowe.

2. Cięcie deski, rozmiar 5 cm x 1,4 cm.

3. Wyżarzanie kawałka srebra.

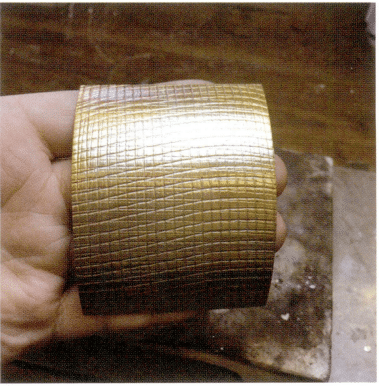

(2) Spawanie pierścienia

1. Za pomocą szczypiec płaskich symetrycznie zgiąć blachę na obu końcach pod kątem 90°.

2. Zegnij oba końce w zamknięte półkole.

3. Pokryj złącza boraksem.

4. Odetnij odpowiednią ilość topnika lutowniczego i umieść go na spawanej części.

5. Spawanie za pomocą pistoletu spawalniczego w celu stopienia lutu.

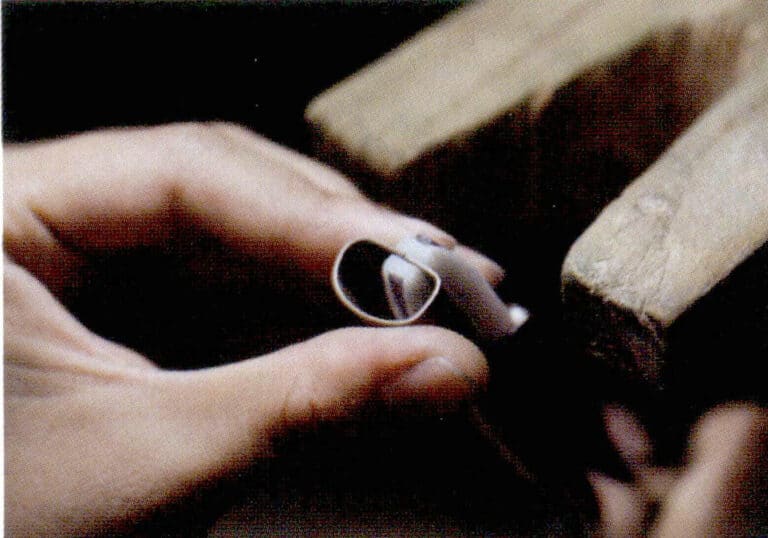

(3) Metalowy pierścień z segmentami całkowitymi

1. Po zakończeniu spawania nadaj mu kształt za pomocą pierścienia i drewnianego młotka.

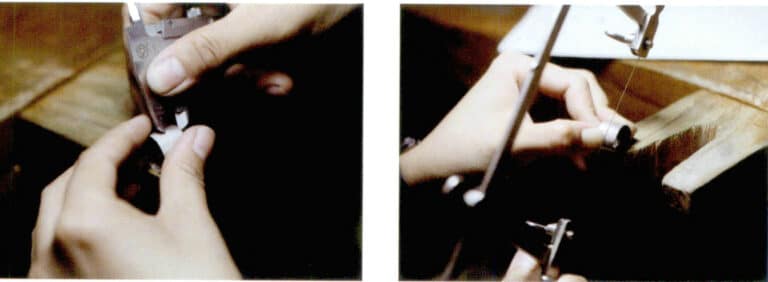

2. Użyj suwmiarki, aby równomiernie podzielić i ustawić metalowy pierścień.

3. Wytnij równo metalowy pierścień, aby przygotować parę symetrycznych kolczyków.

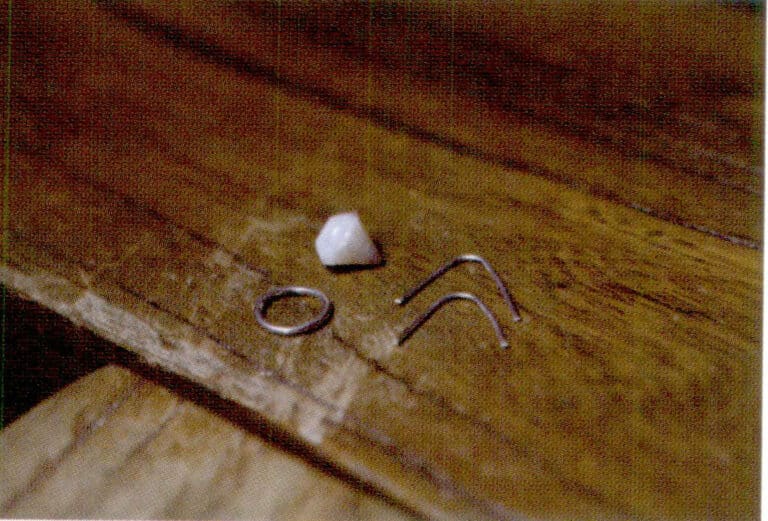

(4) Wykonywanie pereł z pazurem

1. Zmierz odpowiednią długość struktury w kształcie litery U podstawy pazura zgodnie z rozmiarem perły w kształcie rombu; drut metalowy o średnicy 0,8 mm może być użyty do wykonania struktury w kształcie litery U, a drut metalowy o średnicy 1 mm może być użyty do wykonania pierścienia.

2. Za pomocą okrągłego pilnika wyszlifuj szczelinę poniżej dolnej części kształtu U do spawania.

3. Oszlifować rowki w średnim 4-punktowym położeniu po wewnętrznej stronie pierścienia za pomocą okrągłego pilnika do spawania.

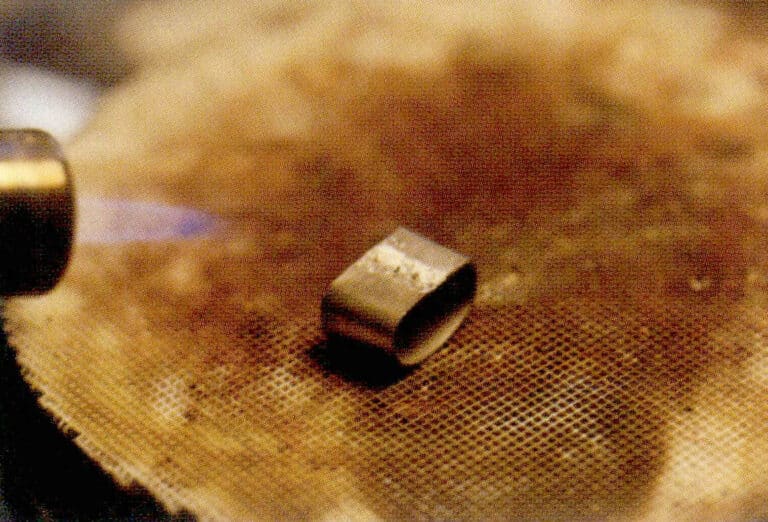

(5) Spawanie

1. Najpierw zespawaj dwa metalowe druty w kształcie litery U.

2. Następnie przyspawaj pierścień do spawanego metalu.

3. Na koniec, gotowe ustawienie pazura zostanie przyspawane do pierścienia, a szpilka do ucha zostanie przyspawana do tylnej strony pierścienia.

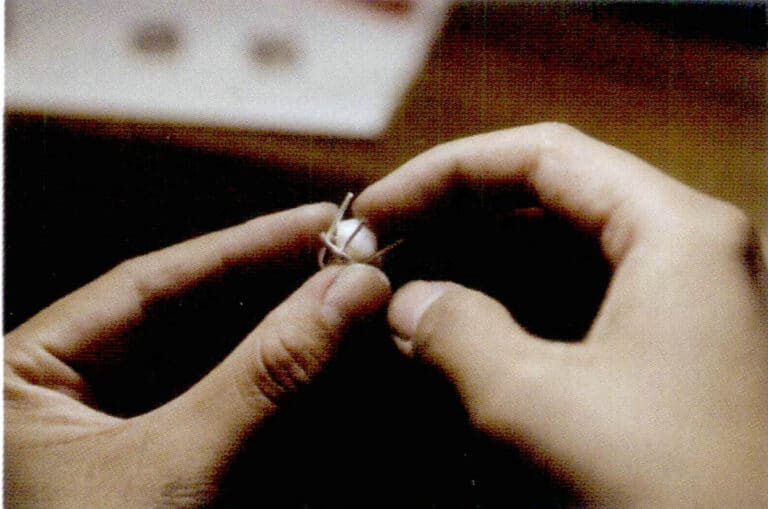

(6) Polerowanie i ustawianie

1. Metalowa oprawa jest wytrawiona, wypolerowana i bezpiecznie zamontowana za pomocą pereł w kształcie diamentu.

2. Zakończone.

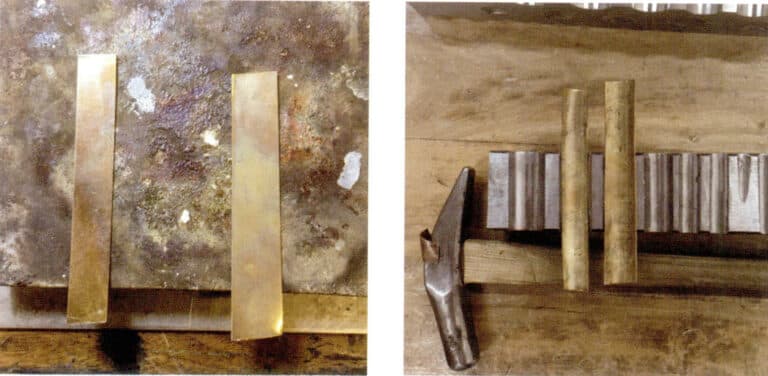

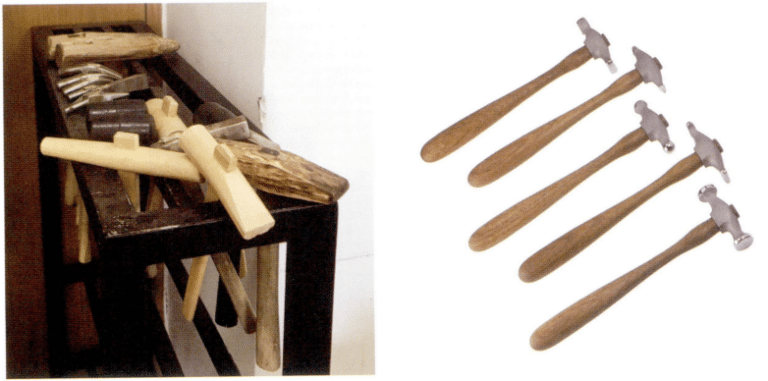

Sekcja II Techniki teksturowania metalu

Oprócz polerowania, istnieje wiele innych technik teksturowania powierzchni metalowych, które doskonale nadają się do eksploracji i nauki oraz mogą być stosowane do tworzenia biżuterii. Podczas przetwarzania tekstury metalowej powierzchni ważne jest, aby pamiętać o wcześniejszym wyżarzeniu metalu, dzięki czemu będzie on bardziej elastyczny i łatwiejszy w obróbce.

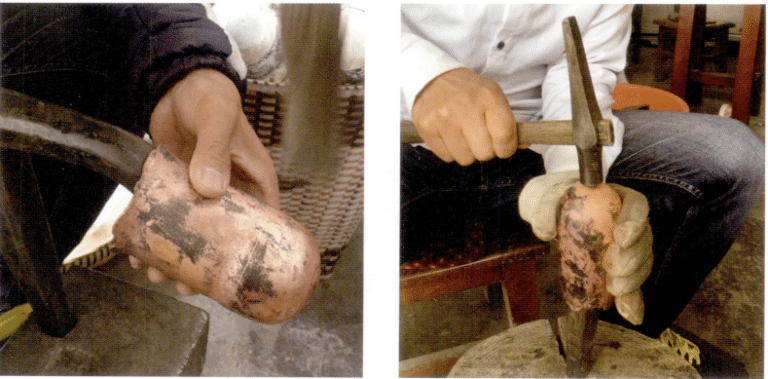

1. Tekstura młotkowania

W obróbce metalu, używanie różnych młotków, dłut i innych narzędzi może tworzyć różnorodne tekstury.

Wypełnianie wnętrza metalowych naczyń ołowiem

Wybierz odpowiednie dłuto

Młotkowanie nierównej tekstury młotkiem i dłutem

Bezpośrednie uderzanie młotkiem w teksturę

Zmiana kształtu metalowej puszki za pomocą młotka

Przycinanie krawędzi metalowej miski

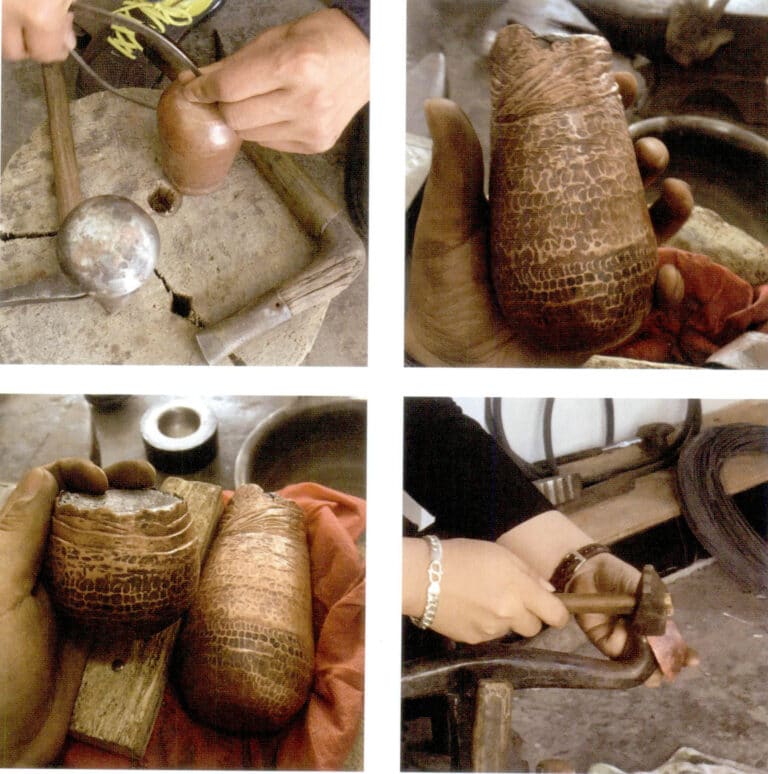

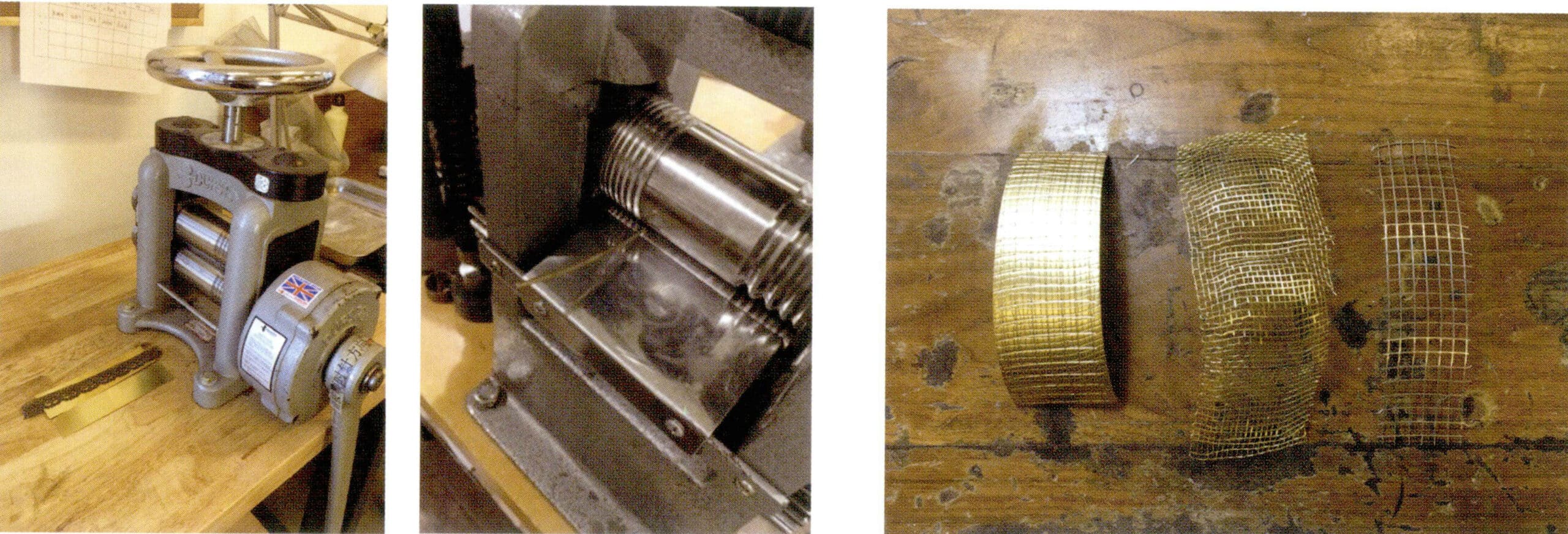

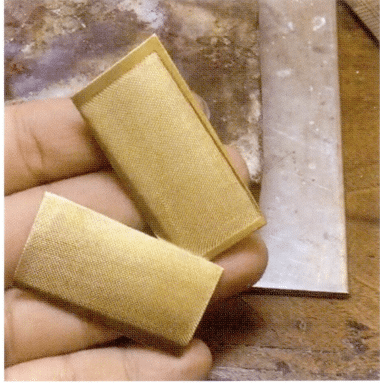

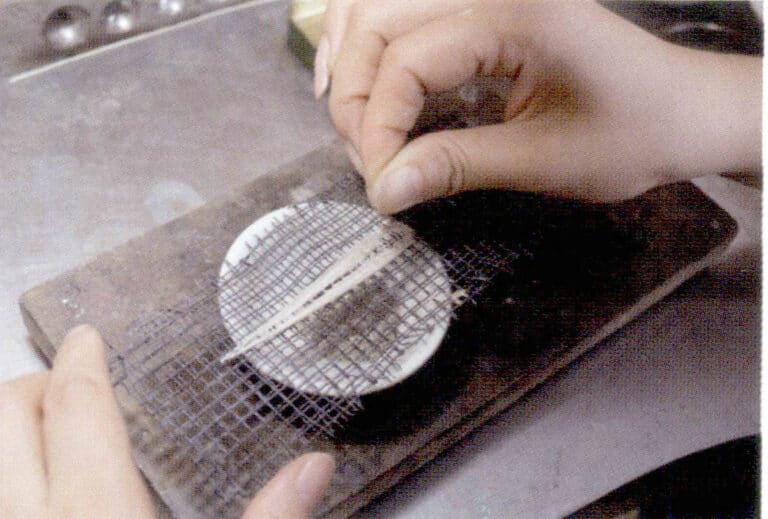

2. Tekstura nadruku

Wybierz stosunkowo odpowiednie elementy pod względem miękkości, twardości i rozmiaru, a następnie użyj ich w połączeniu z walcarką, aby stworzyć interesujące tekstury. Miedziana siatka, teksturowany papier, liście, koronka i inne przedmioty to wysokiej jakości materiały do tworzenia tekstur nadruków.

Jeśli wymagane jest wielokrotne nakładanie się tekstur, konieczne jest wielokrotne prasowanie, a metal musi być ponownie wyżarzany przed każdą operacją. W ten sposób metal ma dobrą elastyczność, nie jest łatwy do złamania i ma lepszy efekt nadruku.

Metal musi być wyżarzony przed każdą operacją nadruku.

Duży efekt nadruku siatki miedzianej

Efekt nadruku z drobnej siatki miedzianej

Efekt wielokrotnego nadruku siatki miedzianej

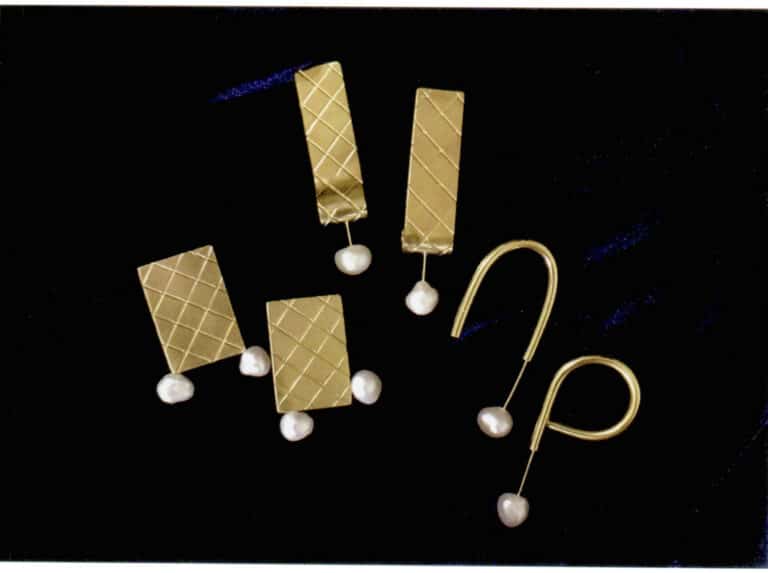

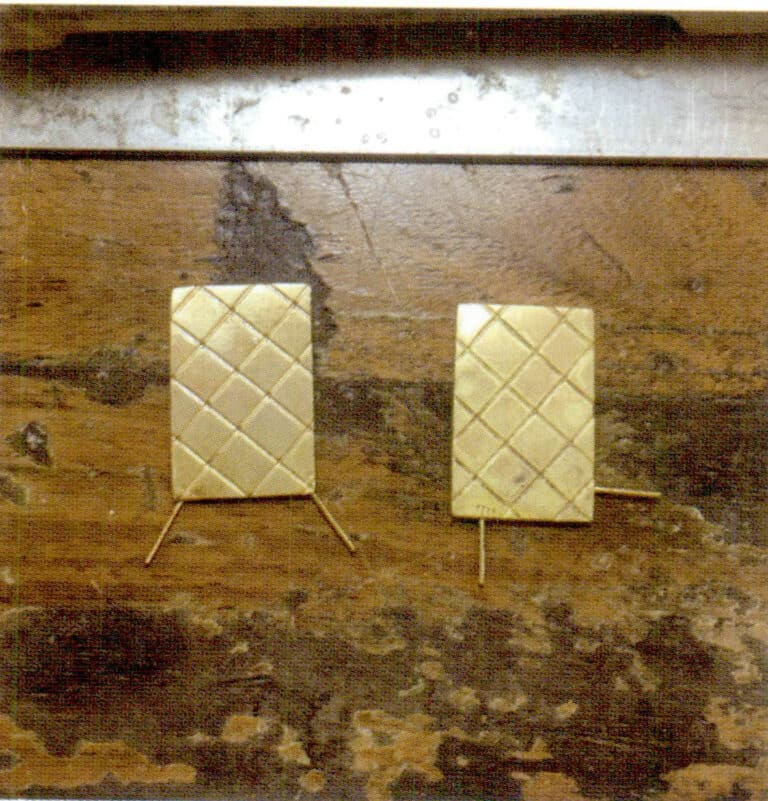

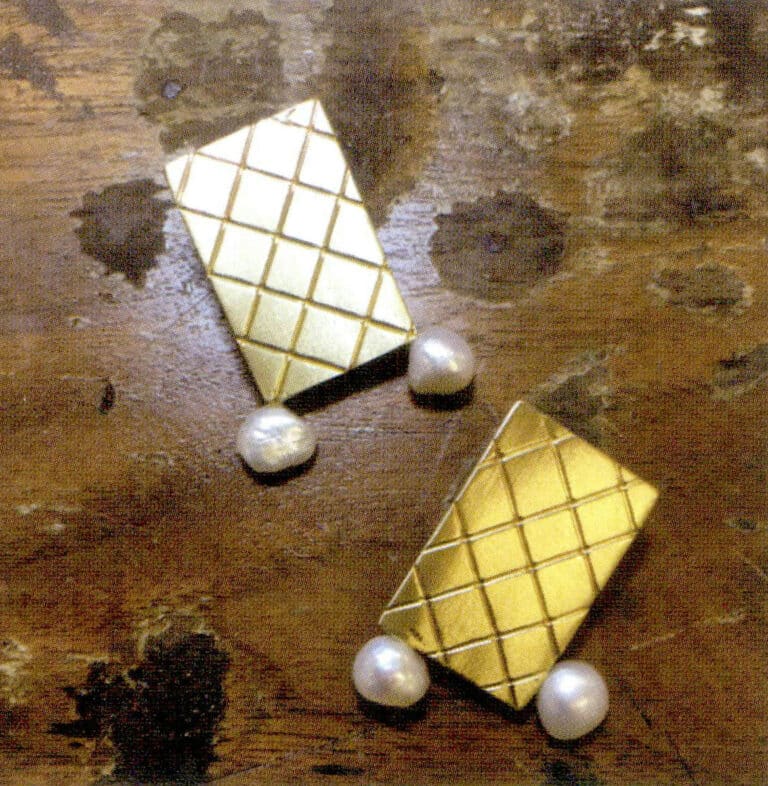

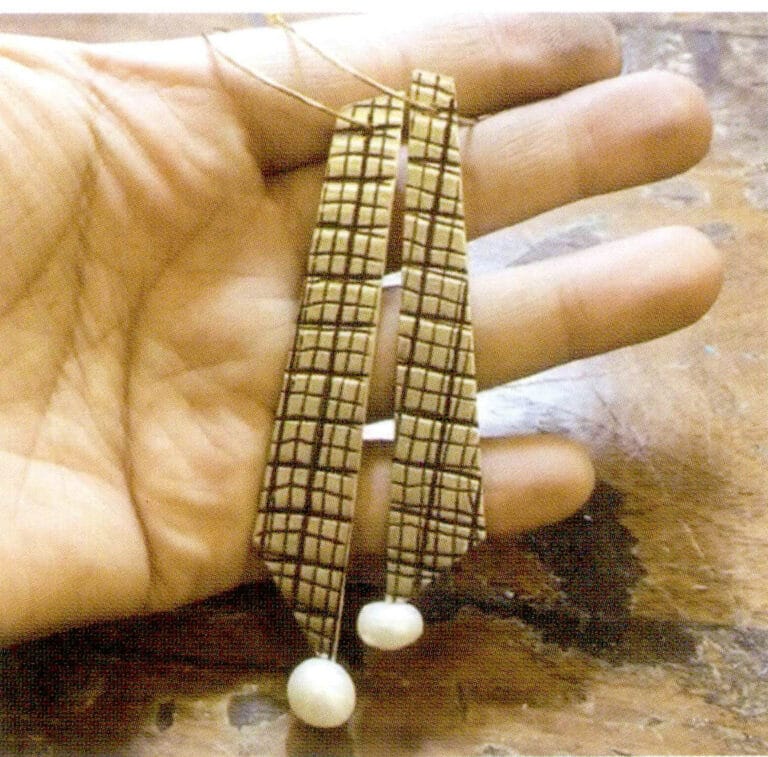

(1) Biżuteria rzemieślnicza z czekoladowym nadrukiem w kształcie diamentu

Xiebai, diamentowa czekolada, seria kolczyków, mosiądz, perły barokowe

1. Umieść wyżarzoną blachę mosiężną i siatkę miedzianą w prasie w celu utworzenia tekstury, wytnij wzorzyste arkusze metalu zgodnie z potrzebami i przyspawaj mosiężne kołki.

2. Mycie kwasem, a następnie polerowanie i szlifowanie.

3. Mocno przymocuj perełki za pomocą kleju 502.

4. Zakończenie produkcji.

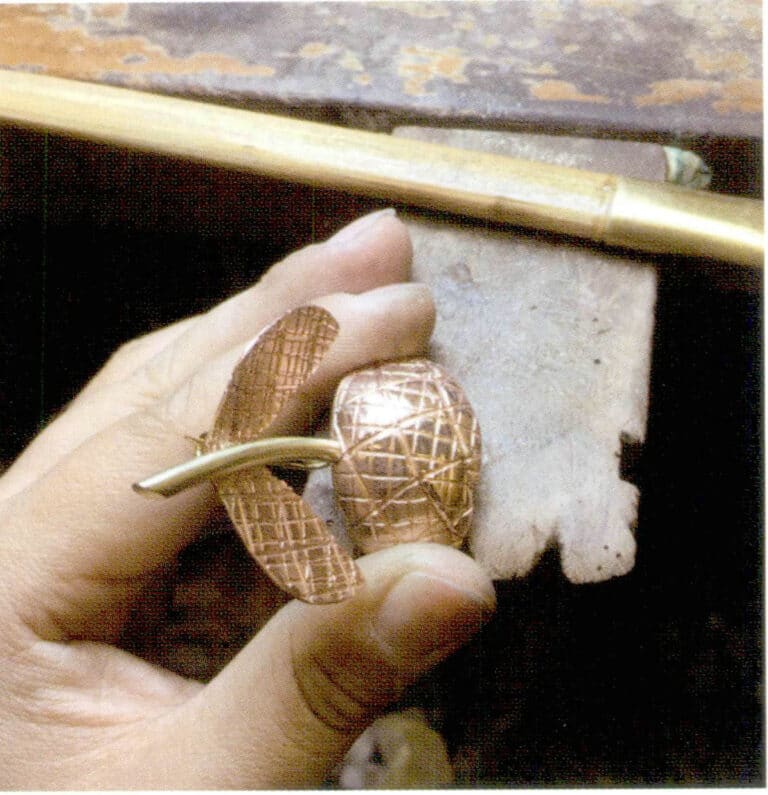

(2) Broszka z nadrukowaną teksturą w kształcie kopuły bratka

Xiebai, bratek, broszka, fioletowa miedź, mosiądz, perła barokowa

1. Użycie młotka do wbicia przygotowanego teksturowanego kawałka metalu w łuk 1/4 przed spawaniem.

2. Polerowanie po myciu kwasem, jeśli chcesz, aby metalowy połysk miał wrażenie warstw, możesz użyć agatowego noża do wypalania wystających metalowych części.

Produkcja metalowych broszek dzieli się na dwa rodzaje: jeden to agrafka typu 9, a drugi to agrafka sprężynowa

(3) Cold Mountain - nadrukowana tekstura, kolczyki w stylu vintage

Cold Mountain 1, kolczyki, mosiądz

Efekt po polerowaniu i szlifowaniu

Bogate tekstury wymagają wielokrotnego prasowania w celu uformowania

Naturalne suszenie

Cold Mountain 2, kolczyki, mosiądz, perły barokowe

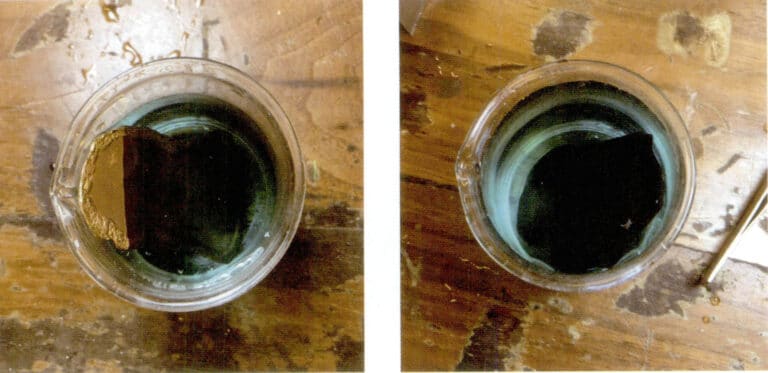

Po wykonaniu metalowych części, namocz je w roztworze do postarzania miedzi, kontrolując czas zgodnie z instrukcjami używanego roztworu do postarzania. Po naturalnym wyschnięciu na powietrzu, użyj szlifierki wiszącej i drobnego papieru ściernego, aby wypolerować powierzchnię, pozostawiając naturalną postarzaną czerń w teksturowanych rowkach. W przeciwieństwie do tego, metalowa powierzchnia po polerowaniu prezentuje jedwabisty połysk.

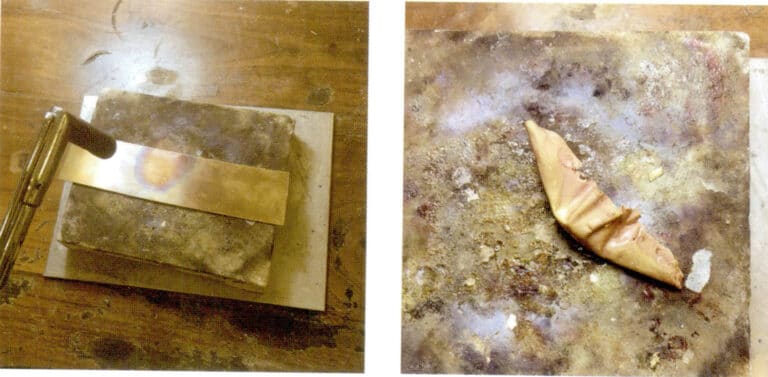

Sekcja III Technika marszczenia metalu

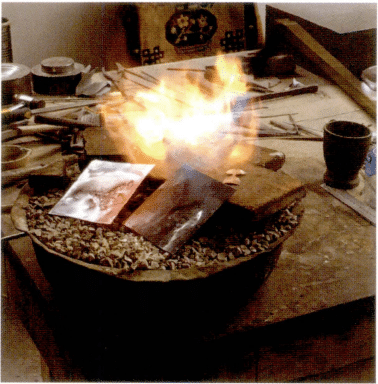

Technika marszczenia wykorzystuje wysoką temperaturę płomieni do stopienia powierzchni metalu, a następnie tworzy biżuterię o pomarszczonej fakturze. Pomarszczony efekt tej techniki jest nie do odtworzenia; nawet przy bogatym doświadczeniu nie można uzyskać identycznych tekstur, dzięki czemu prace tworzone tą techniką są bardziej unikalne i przypadkowe.

Xiebai, seria biżuterii z techniką marszczenia, Flowing Golden Years, mosiądz, perły barokowe

1. Zasady procesu marszczenia

Proces marszczenia jest ściśle związany z temperaturą topnienia metali, kątem natryskiwania płomieniowego i czasem chłodzenia. Chociaż proces marszczenia tworzy tekstury tylko na powierzchni metalu, podczas ogrzewania najpierw topi się warstwa wewnętrzna, a powierzchnia tworzy zmarszczki i tekstury w miarę przepływu wewnętrznego metalu. Na przykład, kawałek srebra 925 jest wykonany z 92,5% srebra i 7,5% miedzi. Podczas procesu nagrzewania zmarszczek miedź jest najpierw stale utleniana, a następnie srebro zaczyna się utleniać, co skutkuje dwoma punktami topnienia metalu, co zapewnia dobre warunki do marszczenia. Im niższa czystość stopu srebra, tym łatwiej jest uzyskać efekt marszczenia. Podobnie, stopy miedzi mogą być również teksturowane w procesie marszczenia.

Xiebai, seria biżuterii Wrinkling Technique, płyn w płynie, mosiądz, perły barokowe

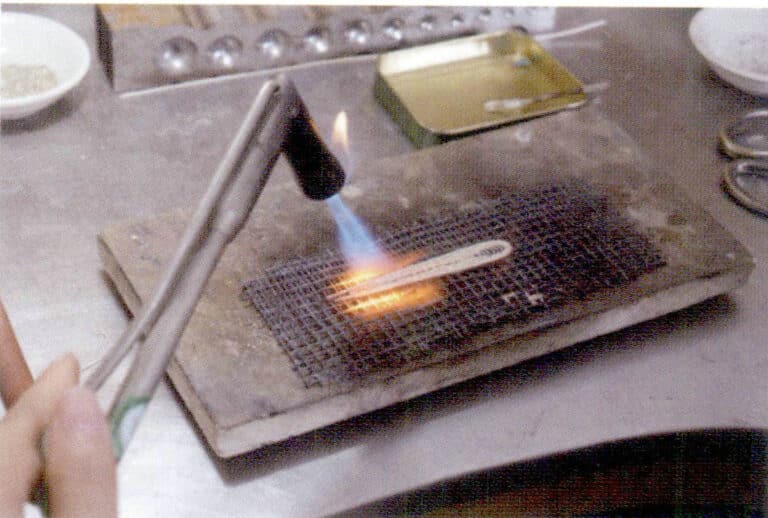

2. Wyświetlanie procesu marszczenia

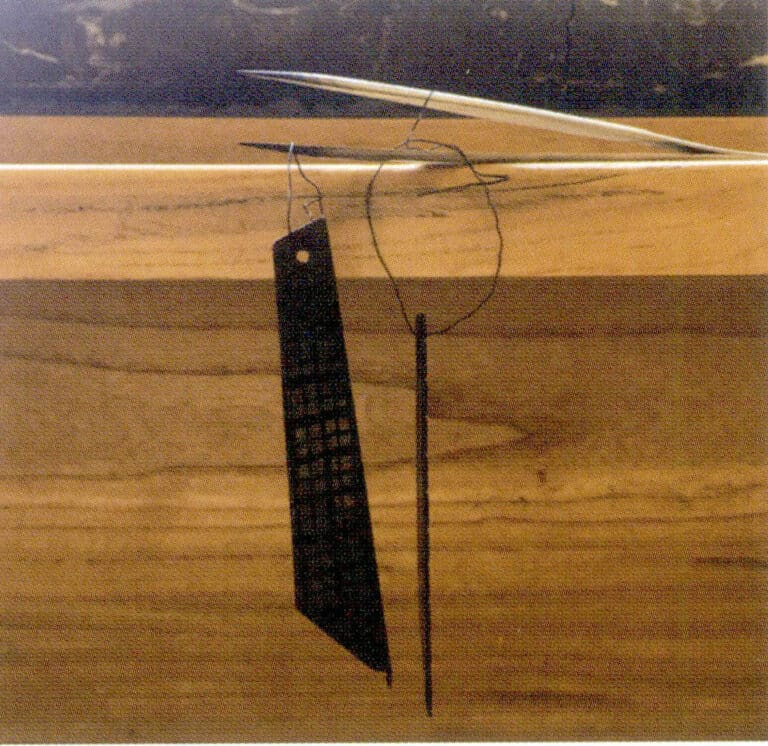

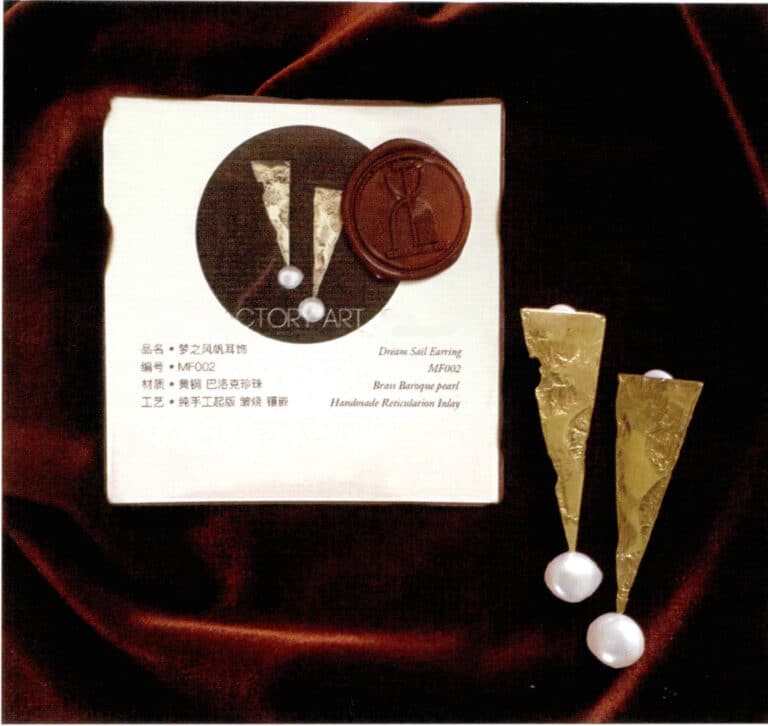

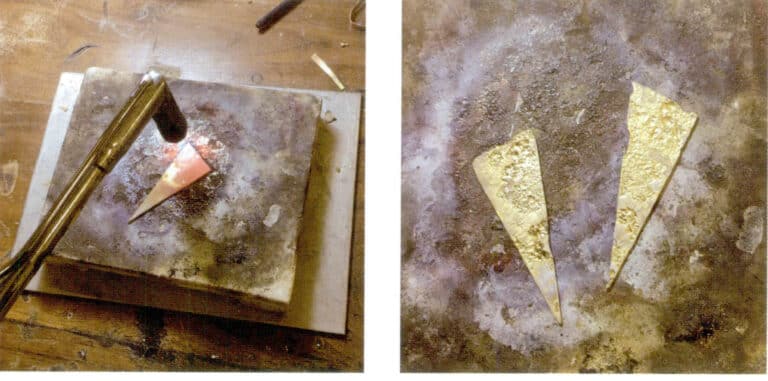

(1) Żagiel wiatru marzeń - kolczyki z procesem marszczenia

Xiebai, kolczyki Dream's Wind Sail, mosiądz, perły barokowe

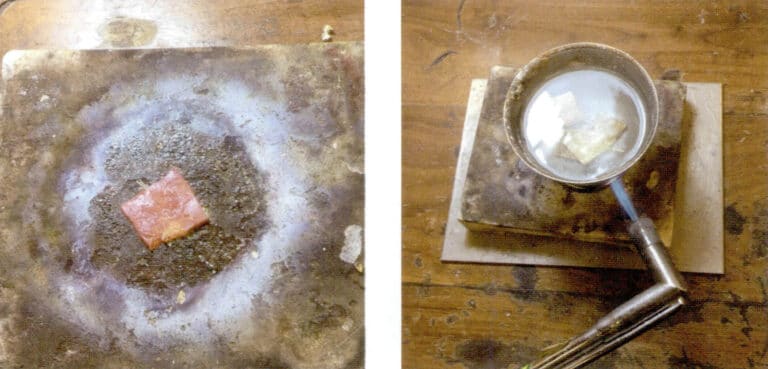

1. Podgrzej wycięte metalowe kawałki mosiądzu za pomocą dużego i miękkiego płomienia, aby ogrzać cały obszar. Gdy mosiądz stopniowo zmieni kolor na czerwony, dostosuj płomień do twardego ognia w celu miejscowego ogrzewania, pozwalając temu obszarowi stopniowo osiągnąć efekt topienia, dostosowując obszar ogrzewania w razie potrzeby.

2. Po zakończeniu marszczenia należy schłodzić mosiężny element, a następnie umieścić go w wodzie z ałunem w celu podgrzania i oczyszczenia.

3. Po spłukaniu czystą wodą i wysuszeniu należy wybrać odpowiednie narzędzia do szlifowania i polerowania, takie jak wisząca szczotka miedziana, bęben magnetyczny lub nóż do wypalania agatu. Tekstura prac wykonanych techniką marszczenia silnie opisuje warstwowanie.

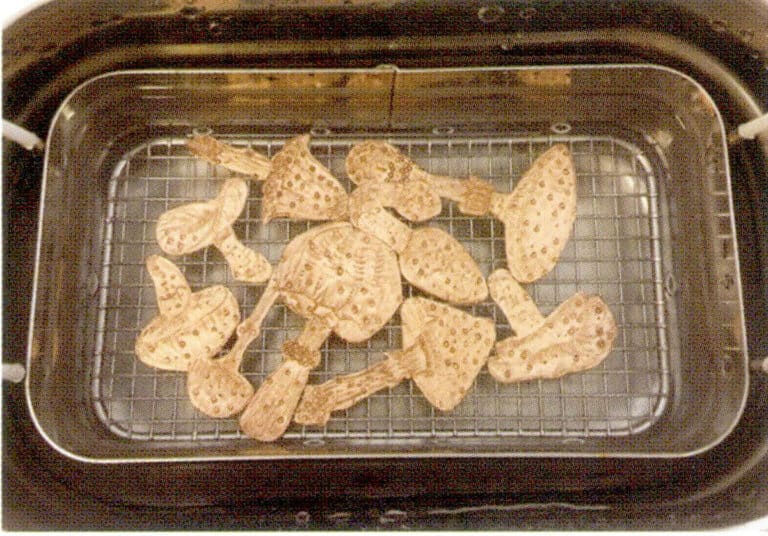

4. Po wypolerowaniu należy wykonać czyszczenie ultradźwiękowe, a na koniec przymocować perły, kończąc produkcję; ta para kolczyków może być wykonana jako sztyfty lub klipsy w zależności od potrzeb.

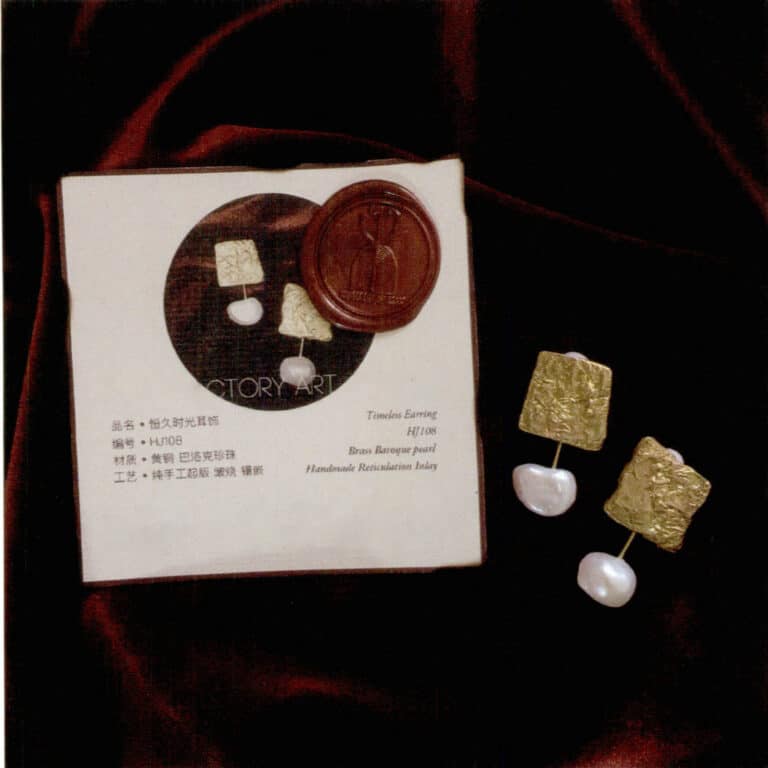

(2) Eternal Time - kolczyki z techniką marszczenia

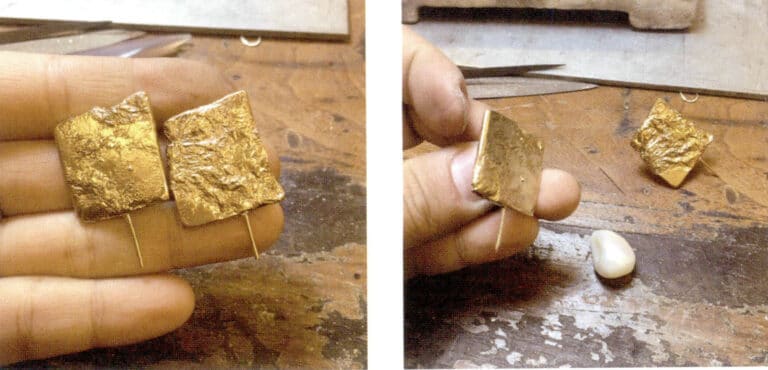

Xiebai, kolczyki Eternal Time, mosiądz, perły barokowe

1. Podgrzej metal ogniem, aby zakończyć marszczenie i poczekaj, aż czerwony kolor metalu zniknie przed przystąpieniem do hartowania i czyszczenia ałunem.

2. Przyspawaj perłę i igły do uszu do metalu, który zakończył marszczenie.

3. Po czyszczeniu, polerowaniu i inkrustowaniu pereł produkcja jest zakończona.

(3) Złote kolczyki w kształcie pomarszczonej kopuły

Xiebai, złote kolczyki, mosiądz, perły barokowe

1. Weź blachę mosiężną o grubości 0,5 mm, wyżarz ją i wygnij w kształt strąka.

2. Użyj techniki marszczenia, aby stopić metalową krawędź w celu uzyskania naturalnie płynnego efektu, a po przemyciu kwasem użyj pilnika, aby wygładzić szorstkie krawędzie.

3. Po wypolerowaniu w bębenku magnetycznym, zamocuj zaczepy w metalowych szczelinach.

4. Pozostaw odpowiednią przestrzeń, aby włożyć trzy perły barokowe i użyj szczypiec, aby je zacisnąć i zabezpieczyć. Użyj noża do wypalania agatu, aby wypalić wystającą część strąka do pożądanej wysokości, kończąc proces.

(4) Złoty pęd bambusa - pomarszczona zawieszka w kształcie kopuły

Xiebai, złoty wisiorek z pędem bambusa, mosiądz

1. Po wyżarzeniu mosiężnego arkusza, użyj młotka, żelazka i żelaznego pręta, aby uformować go w łuk.

2. Za pomocą markera obrysuj ogólny kształt pędu bambusa i wytnij kontur nożyczkami.

3. Użyj pilnika, aby lekko przyciąć zadziory na metalowych krawędziach i zagnij jedną stronę spiczastej części szczypcami, aby utworzyć otwór na naszyjnik.

4. Użyj techniki marszczenia, aby osiągnąć pożądany efekt.

5. Polerowanie po czyszczeniu ałunem.

6. Złota zawieszka w kształcie pędu bambusa jest gotowa.

(5) Starożytna złota moneta - zawieszka z procesem marszczenia

Xiebai, starożytny i nowoczesny wisiorek moneta, mosiądz

Ilustracja procesu tworzenia starożytnego wisiorka na monetę

Wybierz mosiężny pręt o średnicy 2 cm, przytnij go, przyspawaj otwór na naszyjnik z tyłu monety po zmarszczeniu, a na koniec wypoleruj.

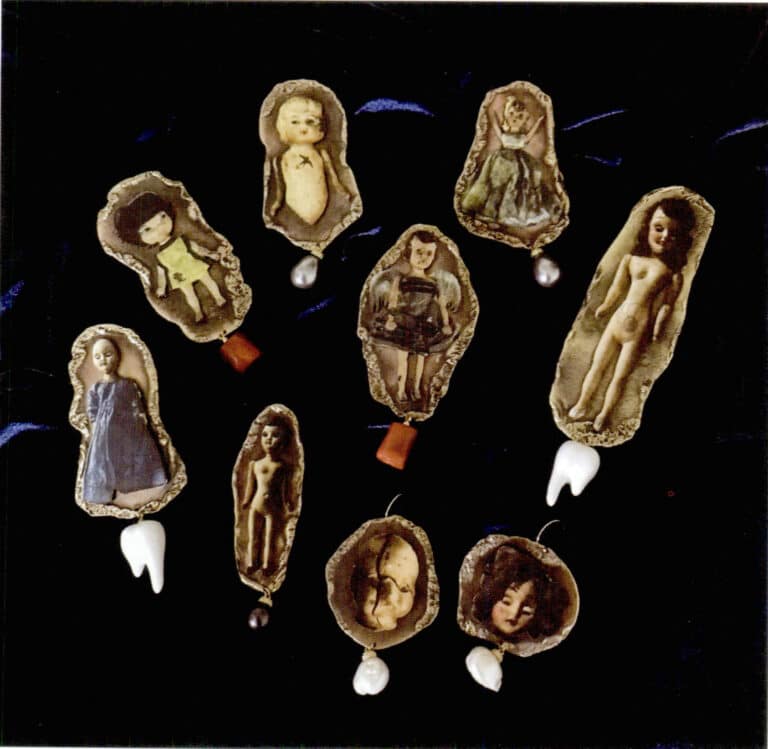

3. Marszczenie + metalowa antyczna gablota na rękodzieło

Istnieją różne techniki barwienia metali, a obecnie najłatwiejszą i stosunkowo bezpieczną metodą jest użycie roztworu do postarzania metalu. Roztwory do postarzania są zwykle dostępne w sklepach z narzędziami, przy czym bardziej powszechne są roztwory do postarzania srebra i miedzi. Oprócz postarzania do czerni, miedź może być postarzana do zielonkawej miedzi itp.

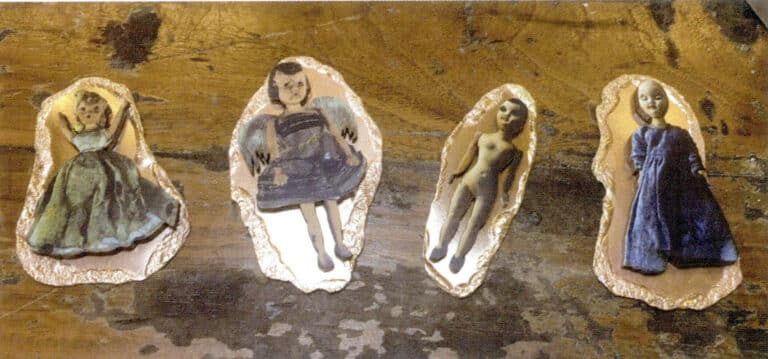

(1) Noc Muzealnej Fantazji: Seria biżuterii rzemieślniczej z marszczeniem i antykowaniem metalu

Biżuteria z serii Museum Fantasy Night, mosiądz, zabytkowe drewniane lalki, barokowe perły, ceramika, morski koral bambusowy itp.

1. Wytnij mosiężne elementy zgodnie z rozmiarem drewnianych elementów i użyj szczypiec, aby uzyskać swobodny kształt sylwetki.

2. Użyj techniki wypalania i marszczenia, aby stopić krawędzie blachy miedzianej, tworząc naturalny efekt płynnej ramy; wyczyść ałunem, a następnie wypoleruj metal w bębnie magnetycznym.

3. Namocz metal w roztworze do postarzania przez około 5 minut (Uwaga: konkretny czas trwania powinien odnosić się do instrukcji roztworu do postarzania każdej marki).

4. Zdejmij metal do naturalnego wyschnięcia na powietrzu, a na koniec użyj szlifierki wiszącej, miedzianej szczotki drucianej i drobnego papieru ściernego, aby wykonać miejscowe polerowanie, nadając metalowi efekt vintage z ciemnym połyskiem. Ręczne polerowanie można wykonać za pomocą najdelikatniejszej gąbki polerskiej, jeśli pożądany jest gładszy dotyk.

5. Wywierć otwory w pobliżu metalowej krawędzi, zainstaluj akcesoria, takie jak perły i morskie korale bambusowe, i zabezpiecz drewniane elementy lalki Vintage metalowym klejem AB, kończąc produkcję.

(2) Wave- Dome, wypalanie zmarszczek i patynowanie kolczyków.

Ilustracja procesu tworzenia kolczyków z falą.

Efekt patyny jest bardziej złożony niż w przypadku zwykłego czarnego antykowania i wymaga dwóch dodatkowych kroków. Najpierw należy użyć czarnego płynu do postarzania jako bazy; następnie, po wyschnięciu, zanurzyć w płynie do postarzania patyny na 20 minut, wyjąć i pozostawić do naturalnego wyschnięcia na powietrzu, umożliwiając stopniowe tworzenie się zielonej patyny; na koniec zanurzyć w roztworze warstwy ochronnej, aby zachować kolor patyny.

(3) Proszek łagodzący zmartwienia - wgniecenia, zmarszczki po wypalaniu i biżuteria w procesie postarzania.

Xiebai, biżuteria z serii Worry-relieving Powder, mosiądz, kawałki drewna z butelki lekarskiej w stylu vintage, morski koral bambusowy, perła muszlowa

Najpierw wytnij kawałek metalu o grubości około 1 mm i odpowiednim rozmiarze, a następnie użyj walcarki i miedzianej siatki, aby uzyskać teksturę; następnie użyj techniki wypalania zmarszczek, aby stopić krawędzie, wyczyść ałunem, a następnie wypoleruj; następnie zanurz w roztworze do postarzania miedzi na 5 minut, wyjmij i wysusz na powietrzu, wykonaj częściowe polerowanie, zachowując niektóre gradientowe warstwy postarzające; na koniec użyj kleju do metalu, aby przymocować kawałki drewna butelki lekarskiej do metalu, wywierć otwory i zainstaluj kolczyki, perły itp.

Ilustracja procesu tworzenia kolczyków Worry-relieving Powder

Kolczyki z procesem postarzania metalu

Każdy może użyć swojej wyobraźni, aby stworzyć interesującą biżuterię przy użyciu stosunkowo łatwych w obsłudze technik tworzenia i barwienia metalu.

Copywrite @ Sobling.Jewelry - Producent biżuterii na zamówienie, fabryka biżuterii OEM i ODM

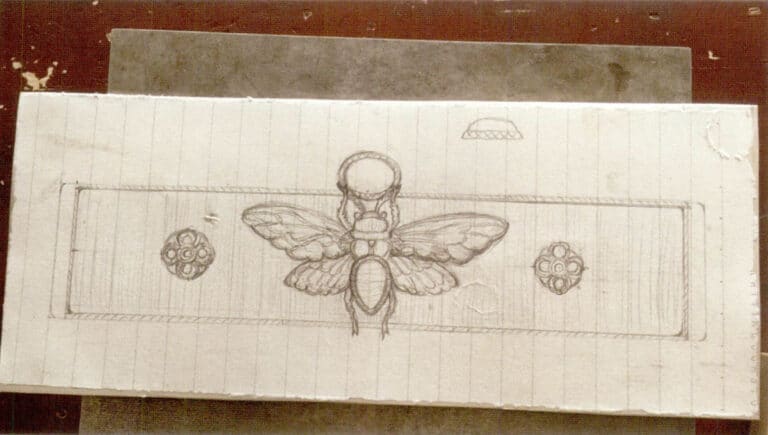

Sekcja IV Produkcja rzemieślnicza w zakresie grawerowania metali

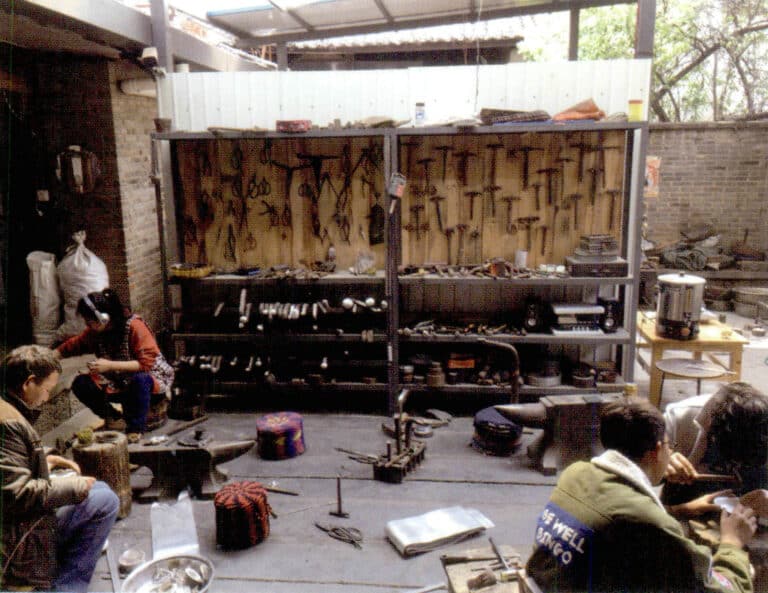

Rzemiosło grawerowania, dłutowania i kucia naczyń metalowych ma długą historię zarówno na Wschodzie, jak i na Zachodzie.

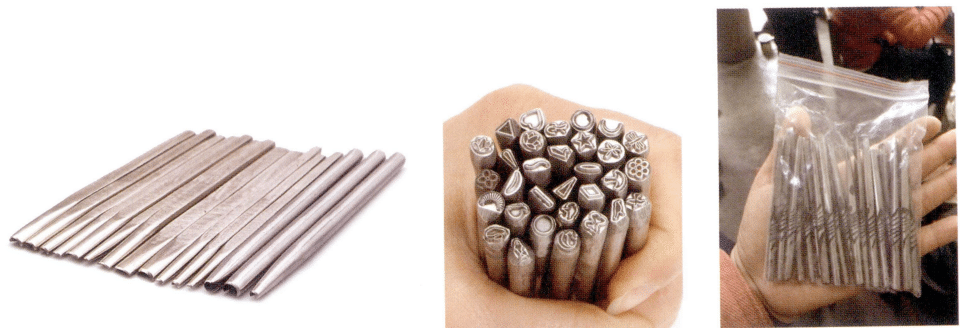

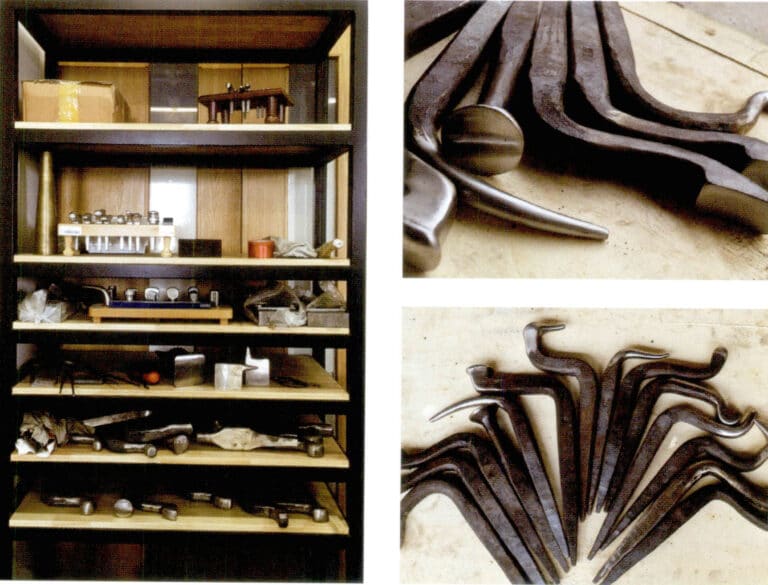

1. Główne materiały i narzędzia do grawerowania

Warsztat grawerski (Yunnan)

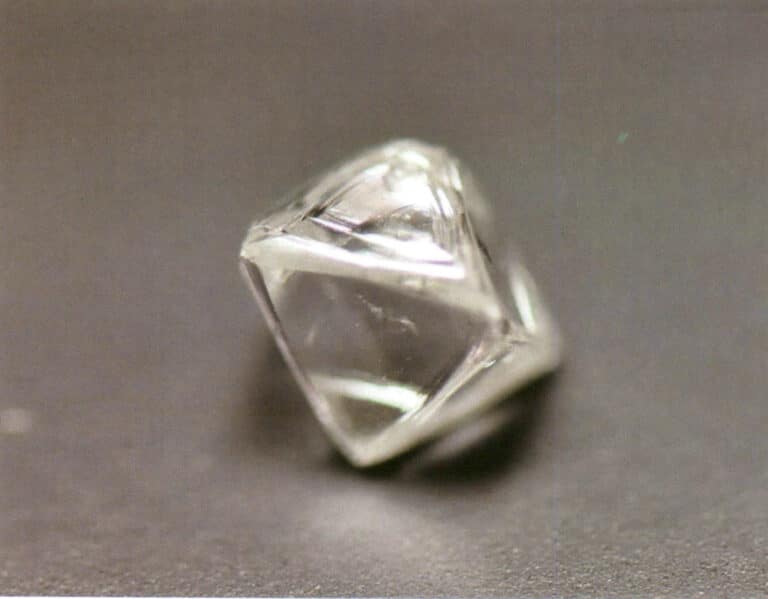

Srebrny materiał o zawartości srebra 990‰ lub wyższej

Ołówek

Uszczelniająca kulka woskowa

Płyta kalafonii

Wszystkie rodzaje młotków

Wszystkie rodzaje dłut

Wszystkie rodzaje haków żelaznych

Inne narzędzia i materiały

Oprócz powyższych narzędzi, drewniane paliki lub worki z piaskiem, szczotki miedziane, ołów, rozcieńczony kwas azotowy itp.

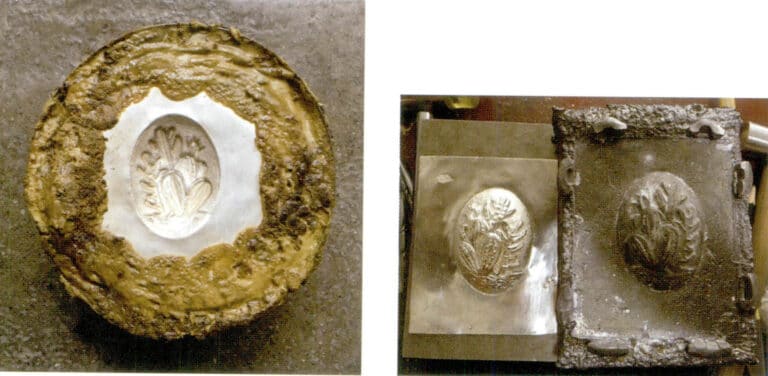

2. Studium przypadku rzemiosła grawerskiego

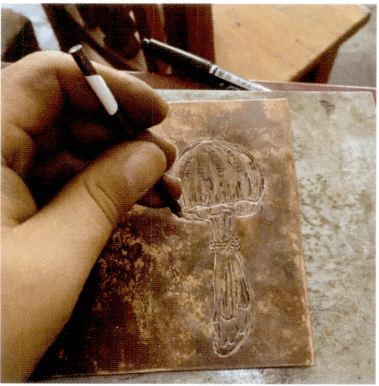

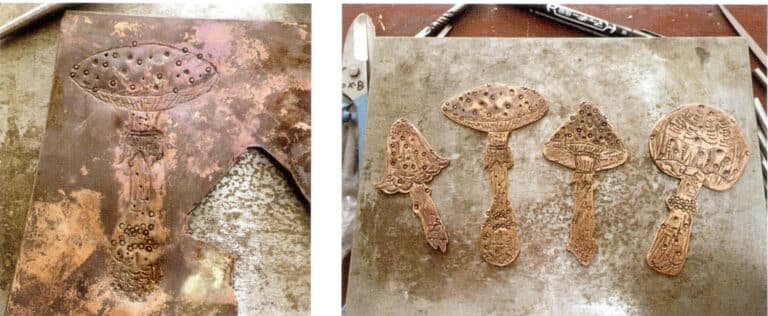

(1) Biżuteria rzemieślnicza grawerowana grzybami fantasy

Xiebai, Fantasy Fungus, fioletowa miedź, grawerowanie

1. Nożyce do cięcia fioletowej blachy miedzianej.

2. Wyżarzanie i wyrównywanie metalu.

3. Do narysowania szkicu grawerunku użyj markera olejowego.

4. Wykonaj rowki wzdłuż wzoru za pomocą dłuta do wyrównywania i młotka do dłut, a następnie narysuj linie za pomocą dłuta, tak jakbyś rysował obrazek.

5. Należy zwrócić uwagę na grawerowanie przez pewien czas. Należy go wyżarzać, aby uniknąć utwardzenia i kruchości metalu.

6. Wymień dłuta o różnych wzorach, aby jeszcze bardziej wzbogacić projekt.

7. Po wypolerowaniu należy umieścić go w bębnie ultradźwiękowym w celu oczyszczenia, co kończy produkcję.

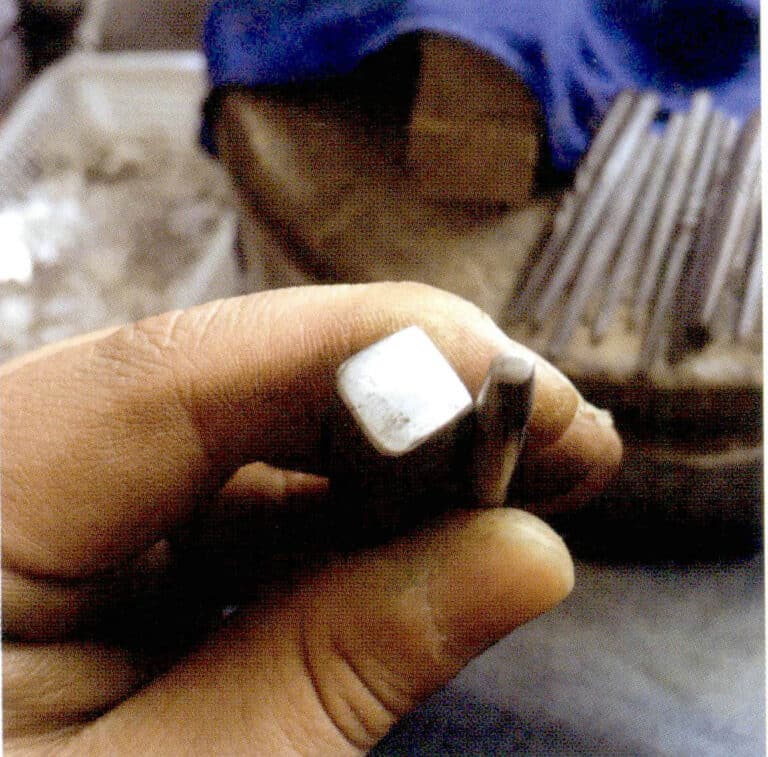

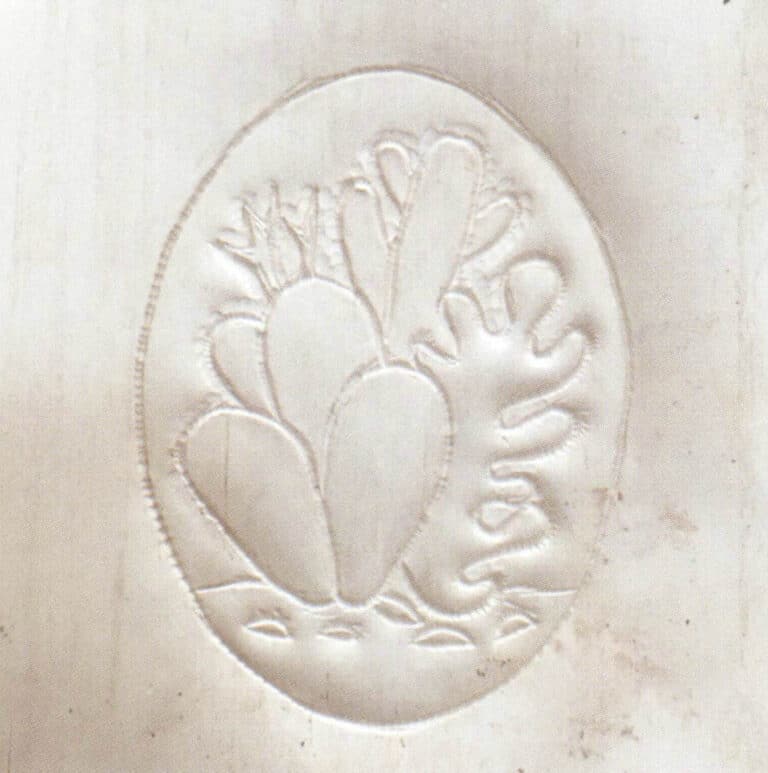

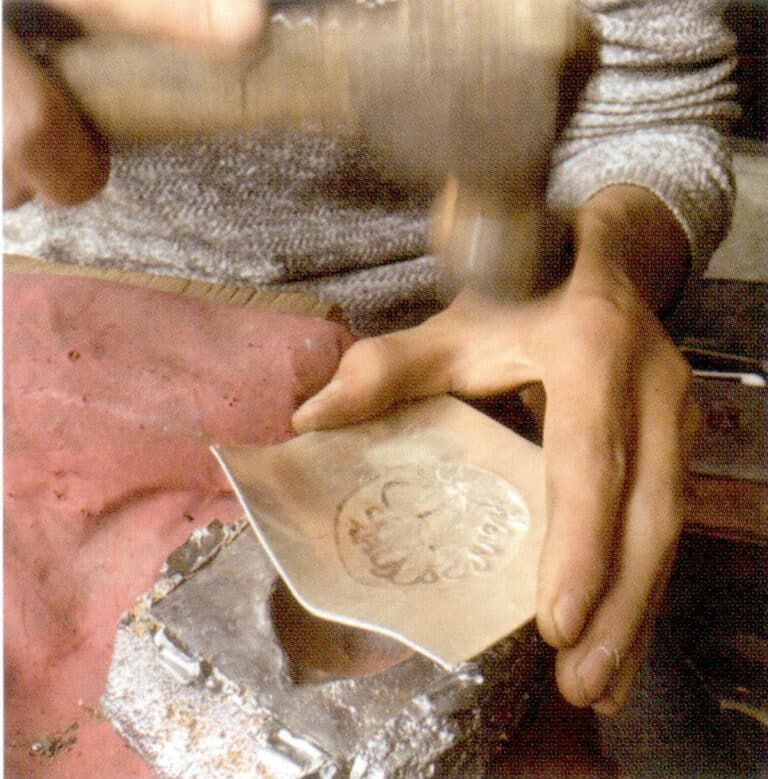

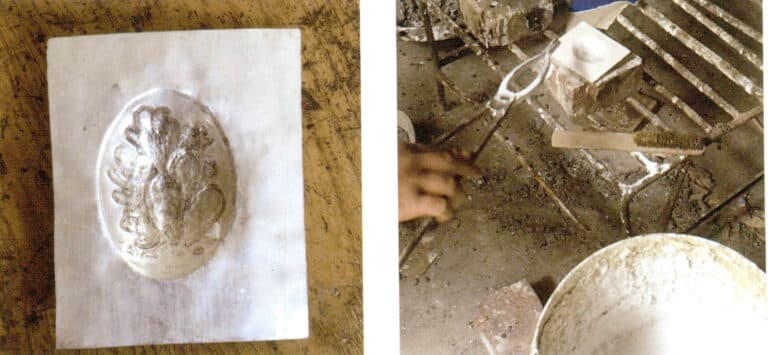

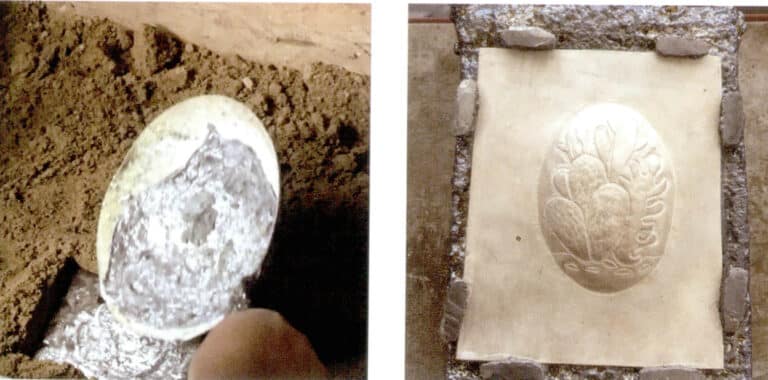

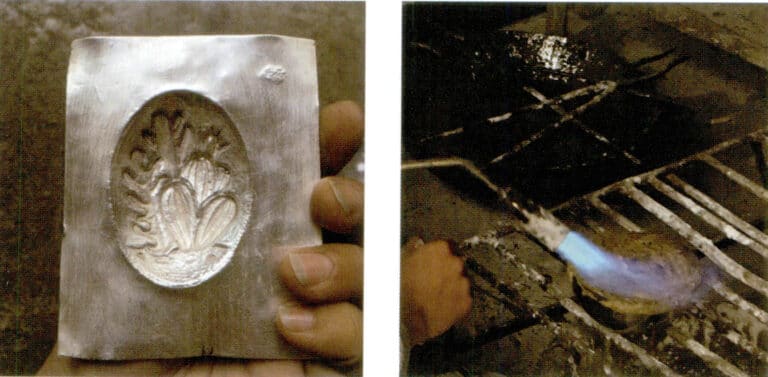

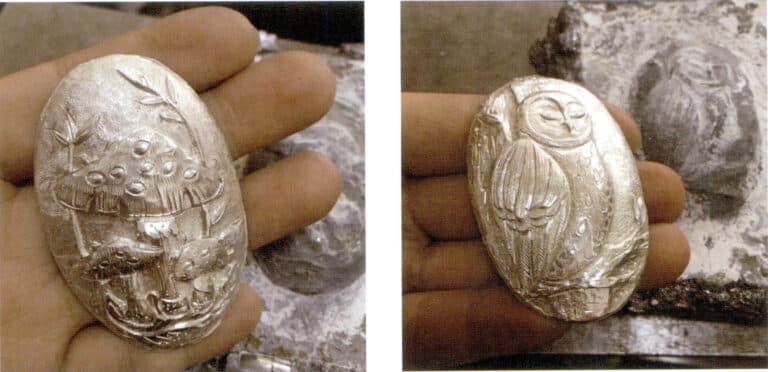

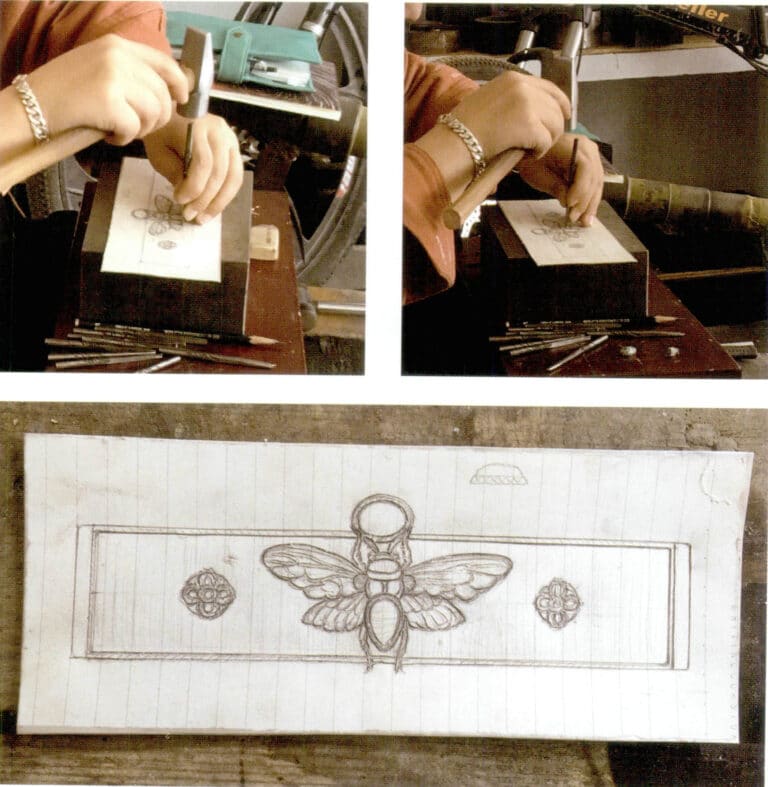

(2) Letnia dżungla - zakrzywione grawerowanie biżuterii rzemieślniczej

Xiebai, Letnia dżungla, czyste srebro 999, grawerowane

1) Przygotować płytkę z czystego srebra 999 i wyżarzyć ją.

2. naszkicuj wzór ołówkiem na srebrnej płytce.

3. naszkicuj kontur wzoru na srebrnej płytce za pomocą dłuta i młotka.

4. pogłębić grawerowanie wyrównujące.

5) Za pomocą drewnianej łopatki lub młotka z okrągłą główką wybij półkole z tyłu srebrnej płytki, umieszczając pod spodem ołowiany klocek, aby uniknąć uszkodzenia srebrnej płytki.

6) Po wykonaniu półokrągłego łuku wybierz mniejszy młotek, aby wykonać miejscowe wklęsłe i wypukłe kształty, dzięki czemu wzór kaktusa będzie rytmicznie prezentował efekt wklęsłości i wypukłości od przodu.

7. chronić srebrną płytkę, owijając ją wodą wapienną.

8) Podgrzanie srebrnej płytki owiniętej w wodę wapienną za pomocą palnika może szybko wysuszyć wodę wapienną, a także wyżarzyć srebrną płytkę.

9 Ogień stopił ołów.

10. wykop odpowiedniej wielkości kwadraty piasku. najpierw umieść srebrną blaszkę w piaskownicy przodem do piasku, a następnie wlej roztopiony ołów do srebrnej blaszki i piaskownicy. Po zastygnięciu i ostygnięciu można usunąć osadzony srebrny arkusz.

11. użyj markera, aby wyraźnie zarysować wzór, użyj ołowianego bloku jako podstawy i rzeźb za pomocą różnych dłut z młotkiem.

12) Po zakończeniu grawerowania zdejmij srebrny element i użyj miedzianej szczotki drucianej, aby usunąć proszek wapienny z powierzchni.

13) Kolczasta część kaktusa musi być wygrawerowana z tyłu srebrnego elementu. Podgrzej i roztop garnek z kalafonią, a następnie umieść w nim srebrny element, aby go zabezpieczyć.

14 Po zakończeniu grawerowania od tyłu, roztop kalafonię i usuń srebrny element.

15 Po czyszczeniu i polerowaniu, grawerowanie zakrzywionej powierzchni jest zakończone.

16. Metoda ta umożliwia tworzenie serii zakrzywionych grawerunków powierzchniowych.

(3) Bransoletka rzemieślnicza z grawerem Taniec Fal

Xiebai, taniec fal, jadeit oceaniczny, czyste srebro 999, grawerowane

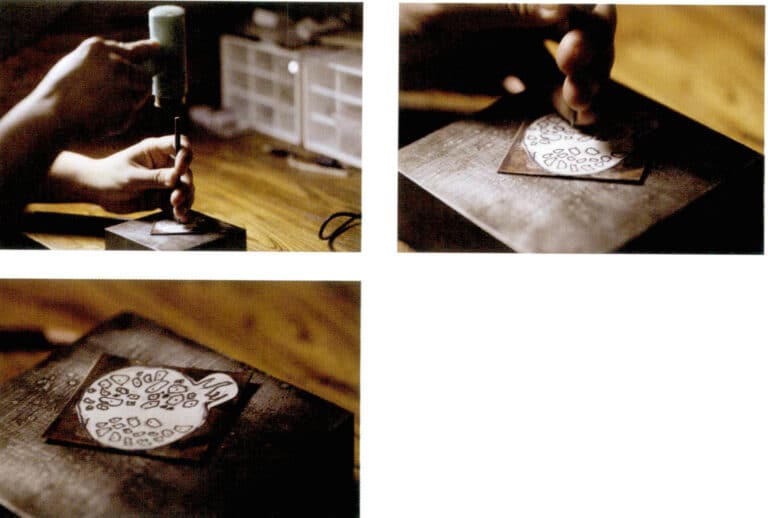

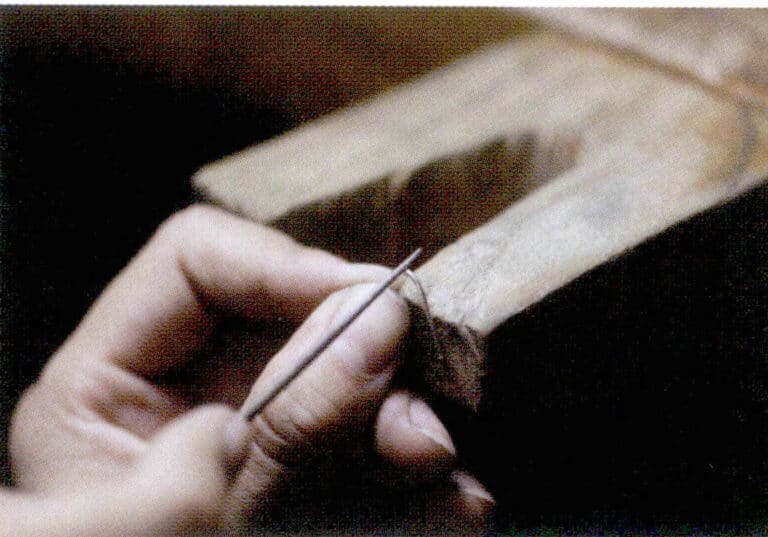

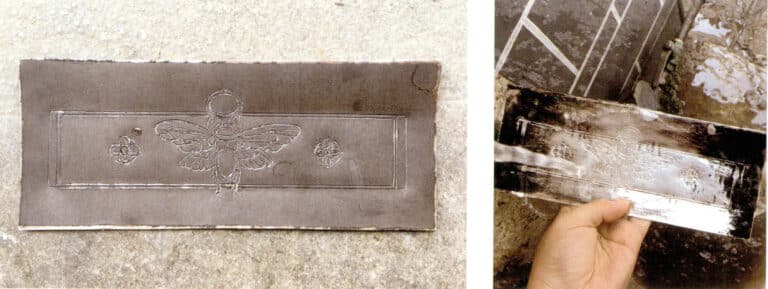

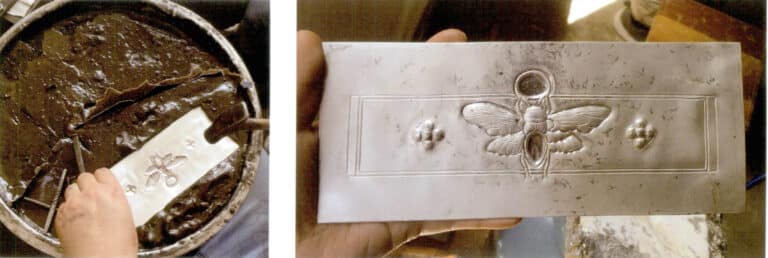

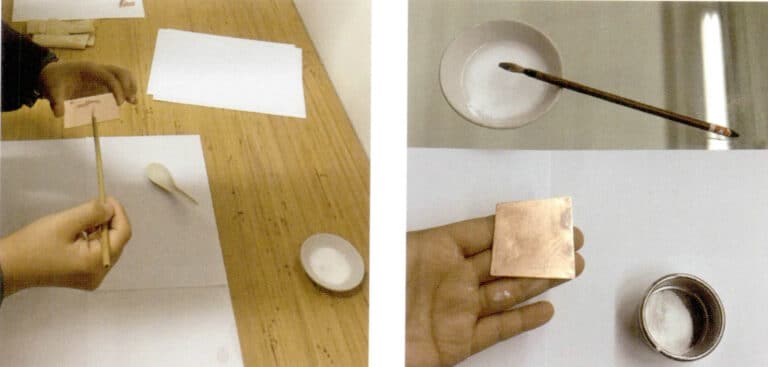

1. Przyklej narysowany szkic do wyżarzonej płytki z czystego srebra 999 za pomocą mlecznego kleju lub pasty.

2. Do dłutowania krawędzi użyj dłuta liniowego i młotka.

3. Wykonaj wyżarzanie, wypal papier i oczyść powierzchnię za pomocą miedzianej szczotki drucianej.

4. Ponowne przyzwyczajenie.

5. Roztop kalafonię i umieść srebrny arkusz w garnku kalafonią do góry, aby go zabezpieczyć.

6. Po wybiciu skrzydeł owadów i części kwiatowych, zdejmij srebrną płytkę, zabezpiecz tył kalafonią, twarzą do góry i wybij rowki na wkładkę z kamieniami szlachetnymi.

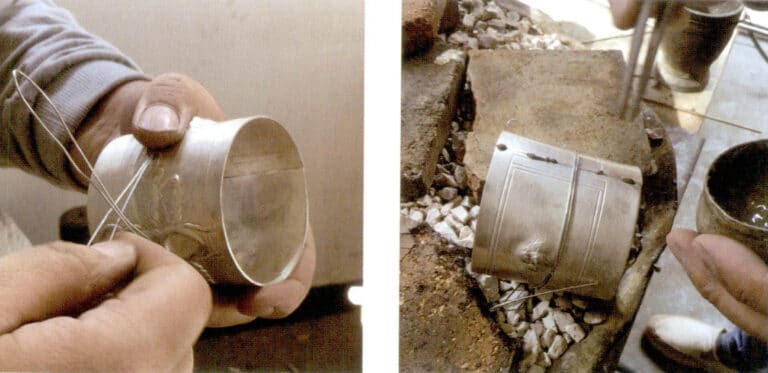

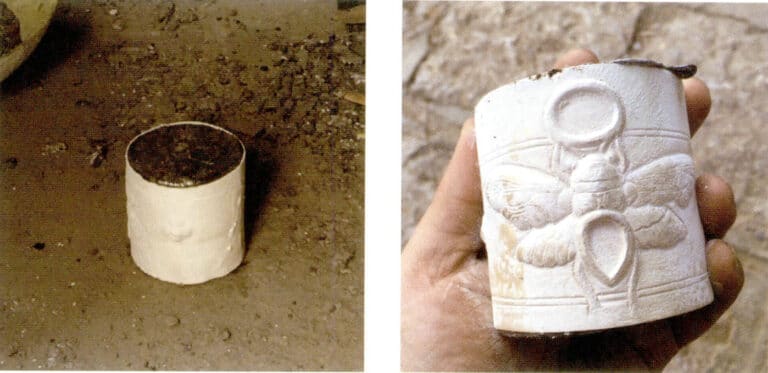

7. Uformuj srebrny arkusz w okrąg, ciasno owiń go drutem stalowym i umieść go w pastowatym lutowiu do spawania, przekształcając go w cylindryczny.

8. Po namoczeniu w wodzie wapiennej wlej ołów do srebrnego cylindra.

9. Użyj ołowianego bloku jako podstawy do szczegółowego grawerowania.

10. Umieść go w kamieniu szlachetnym, nadając mu kształt.

11. Użyj płaskiego dłuta, aby stworzyć subtelną teksturę młotka na głównej części bransoletki, a następnie użyj cienkiego dłuta, aby wygrawerować imię i datę.

12. Po wygrawerowaniu ołów jest topiony, a srebrna bransoleta jest usuwana. W tym momencie na srebrnej bransolecie mogą pozostać ślady ołowiu, które można namoczyć w rozcieńczonym kwasie azotowym i umyć wodą. Odetnij nadmiar srebra, a na koniec wypoleruj i wypoleruj; bransoletka jest gotowa.

Grawerowany naszyjnik noszony przez postać Zhou Xun w filmie "The Poetry Eye Weary of the Horizon", wykonany ze srebra próby 999, naturalnych kamieni szlachetnych i pokryty czystym złotem.

Sekcja V Podstawowa produkcja emalii i filigranu

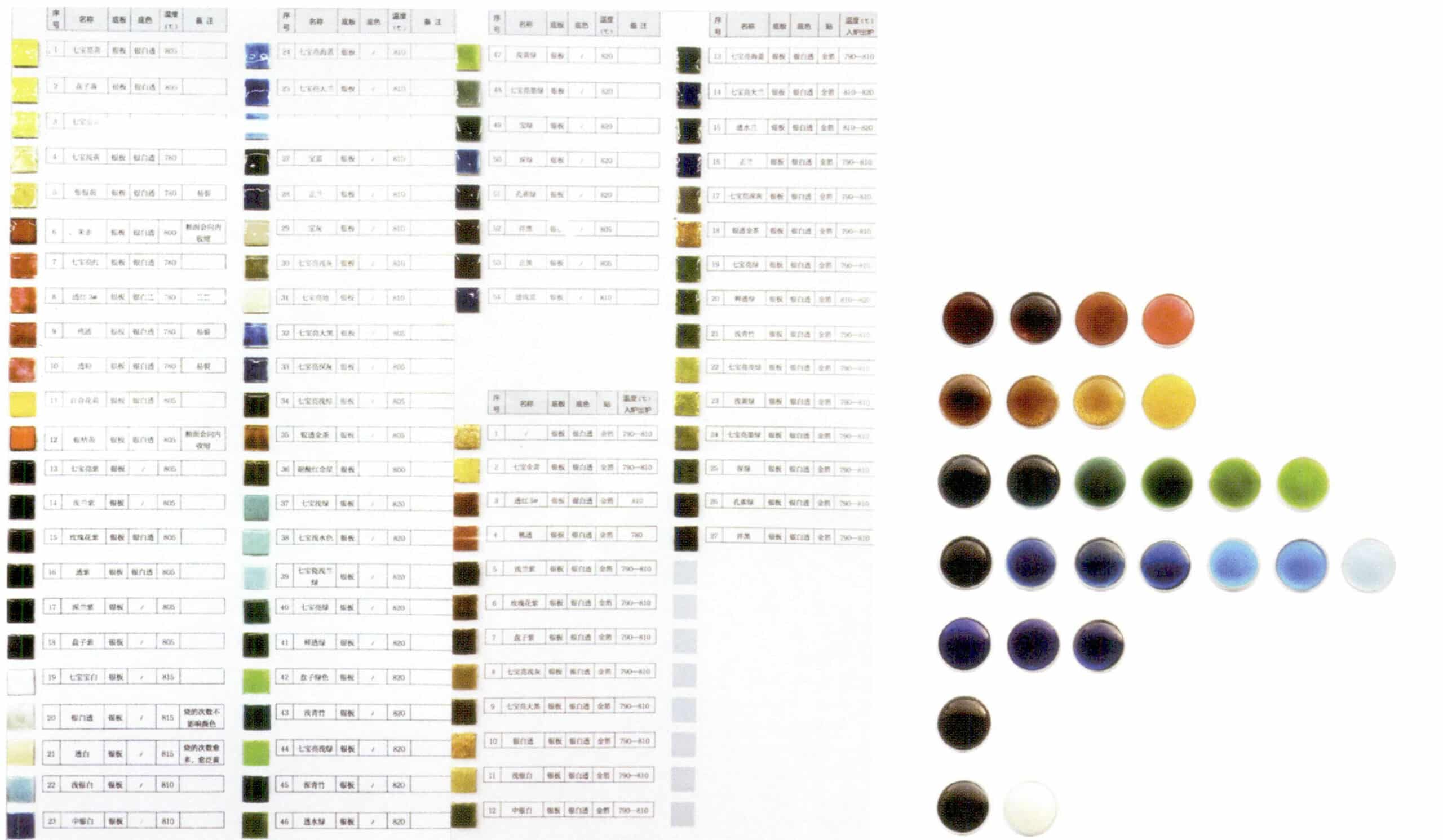

Emalia to sproszkowana glazura wytwarzana przez mieszanie surowców mineralnych, takich jak krzemionka, boraks, kwarc i tlenek ołowiu w odpowiednich proporcjach, dodawanie różnych tlenków metali, a następnie wypalanie i mielenie; gdy szkliwo emaliowane jest łączone z podłożami takimi jak metal, szkło lub ceramika i wypalane, staje się produktami emaliowanymi; popularne techniki obejmują emalię cloisonné i emalię malowaną.

Szkliwo emaliowane

Próbki kolorów szkliwa po wypaleniu

1. Emalia Cloisonné

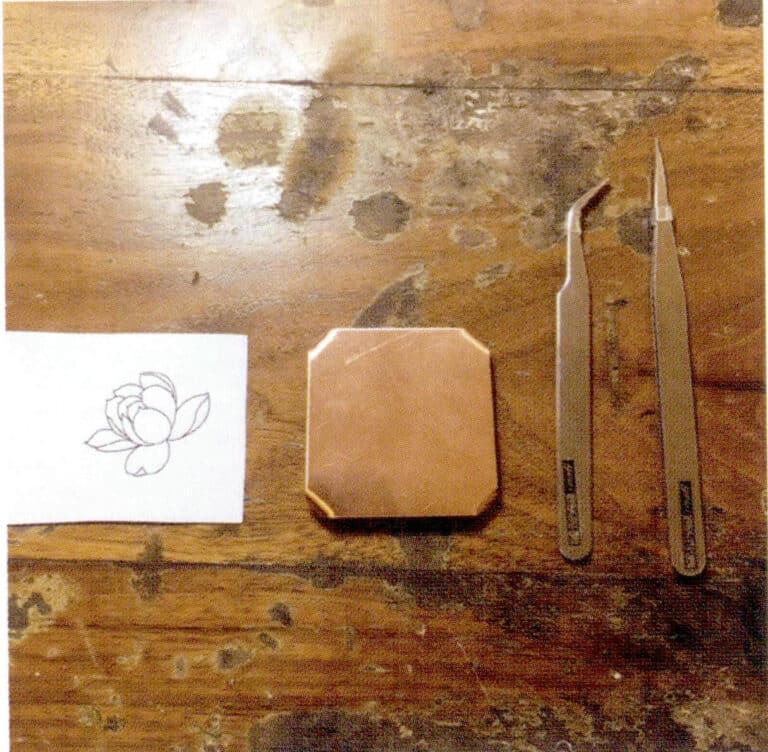

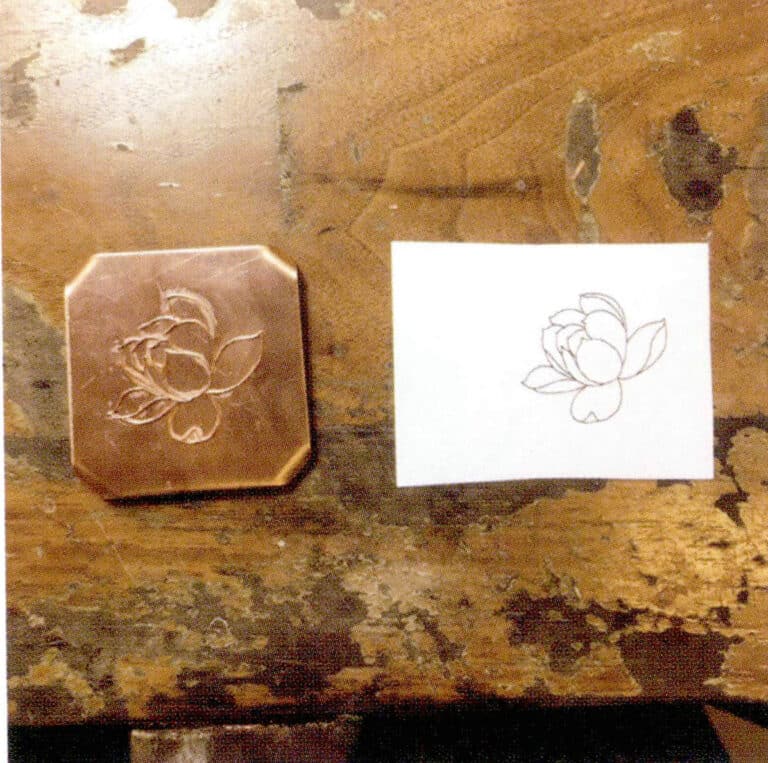

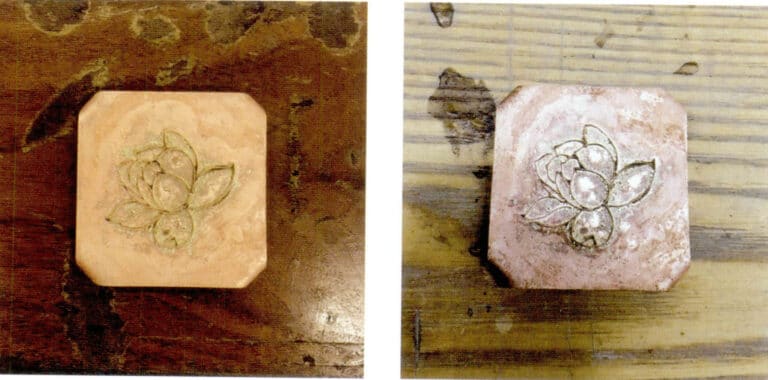

Summer Lotus Pond: Podstawowy wyświetlacz Cloisonné

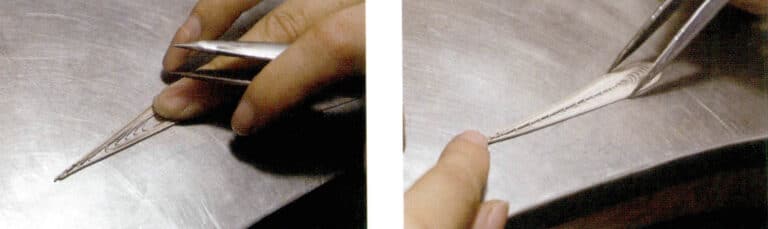

1. Zegnij cztery rogi miedzianej płytki, aby utworzyć blat, a następnie przygotuj szablon i pęsetę.

2. Za pomocą pęsety utwórz wzór lotosu z drutu miedzianego, zanurz go w białym kleju i przyklej do miedzianej płytki.

3. Równomiernie posypać proszkiem spawalniczym.

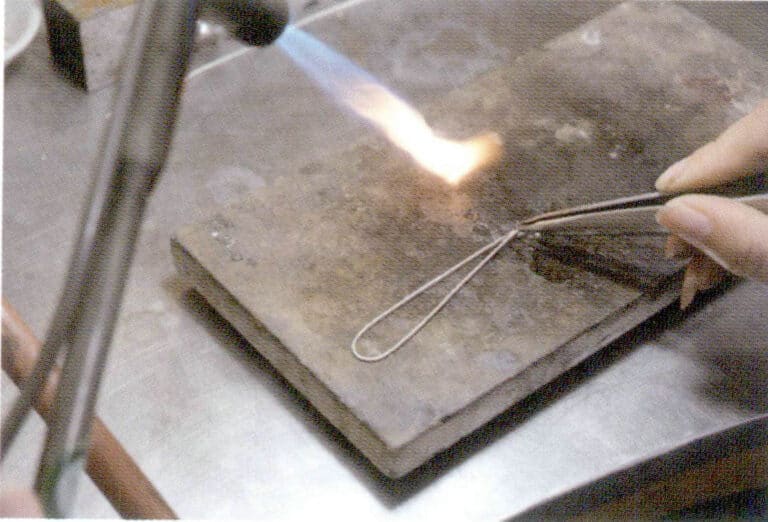

4. Podgrzej część lotosu palnikiem, aby przyspawać drut miedziany do płytki.

5. Przeprowadzić mycie kwasem w celu usunięcia brudu związanego z powierzchnią.

6. Najpierw wypełnij wzór lotosu białą miedzianą glazurą jako bazą.

7. Umieść go w piecu elektrycznym i wypalaj przez 1 minutę w temperaturze około 800 ℃.

8. Usunąć lotos z białą glazurą, dodać zieloną, żółtą i inne przejściowe glazury i wielokrotnie wypalać.

9. Lotos emaliowany z gradientem drutu jest teraz gotowy.

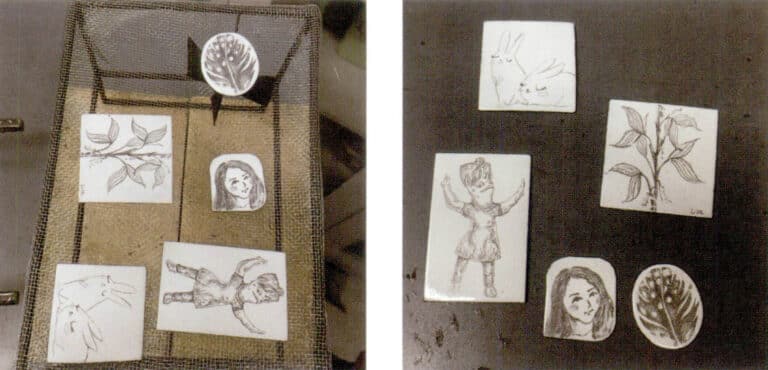

2. Emalia do rysowania ołówkiem

Sztuka walki - rysunek ołówkiem - emalia rzemieślnicza

Xiebai, marzenie o sztukach walki, rysunek ołówkiem, emalia rzemieślnicza

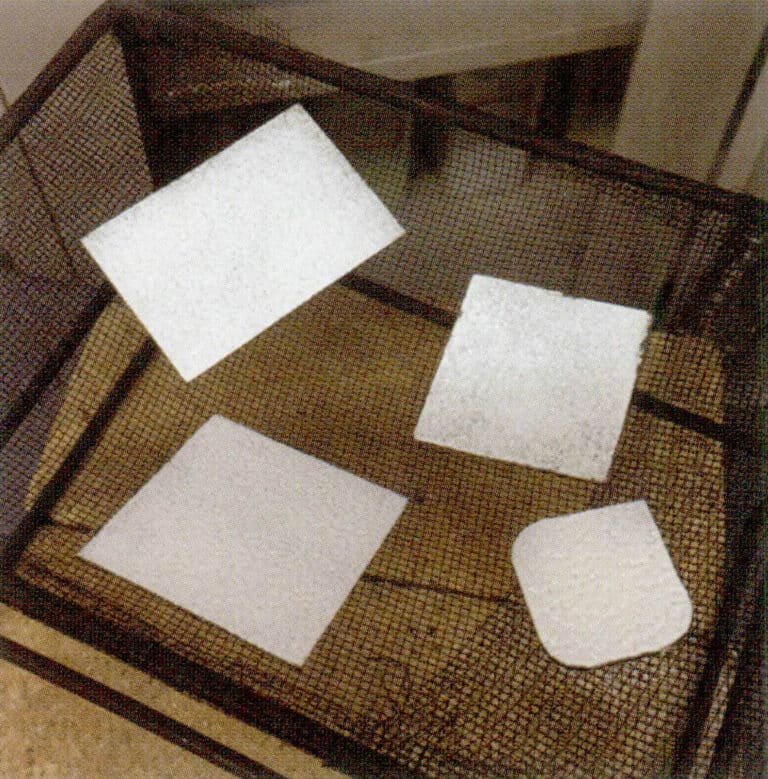

1. Dodaj drobno zmieloną białą glazurę do czystej wody i równomiernie nałóż ją na blachę miedzianą.

2. Umieść wysuszoną białą glazurę w koszyczku i równomiernie posyp nią wilgotną miedzianą blachę.

3. Umieścić w piecu elektrycznym w celu podgrzania.

4. Biała glazura bazowa musi być wypalana wielokrotnie, aby osiągnąć równomierny stan.

5. Po każdym wypalaniu powierzchnia glazury musi być wypolerowana na płasko diamentowym pilnikiem, a następnie biała glazura jest ponownie posypywana do wypalania.

6. Po wypaleniu i wypolerowaniu białej glazury do matowego wykończenia, wzory można narysować ołówkiem 2B lub 4B; ponieważ kolor ołówka nieco wyblaknie podczas procesu wypalania, możemy odpowiednio pogłębić kolor podczas malowania.

7. Umieść go w piecu elektrycznym na około 1 minutę; zbyt długie wypalanie spowoduje nadmierne wyblaknięcie koloru.

8. Czasami podczas procesu produkcji mogą wystąpić nieoczekiwane efekty, takie jak tylna część metalu pokazująca kolorowe odcienie retro.

Ukończony rysunek ołówkiem w emalii

9. Tą samą metodą można stworzyć serię prac emaliowanych rysowanych ołówkiem.

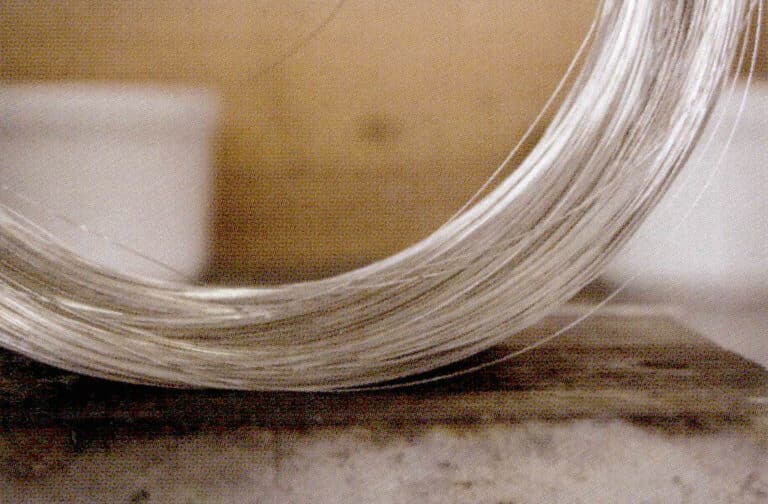

3. Filigranowe rzemiosło

Filigranowe rzemiosło, znane również jako rzemiosło z drobnego złota lub rzemiosło z drutu kumulacyjnego, polega na ciągnięciu metali takich jak złoto, srebro i miedź w cienkie druty i tworzeniu dzieł za pomocą technik takich jak układanie, nakładanie warstw, tkanie i spawanie. Filigranowe rzemiosło powstało w okresie Wiosennej Jesieni i Walczących Królestw i jest tradycyjną chińską techniką obróbki metali.

Seria Metamorphosis #6, naszyjnik, srebrne włókno, szkło

Broszka Harvest, 18-karatowe złoto, diamenty, żarnik, odlew, rzemiosło inkrustacji

Picking Up Fun, Nakrycia głowy, Silver Filament

Morska bryza - filigranowe kolczyki rzemieślnicze (pokaz: Qin Jielu)

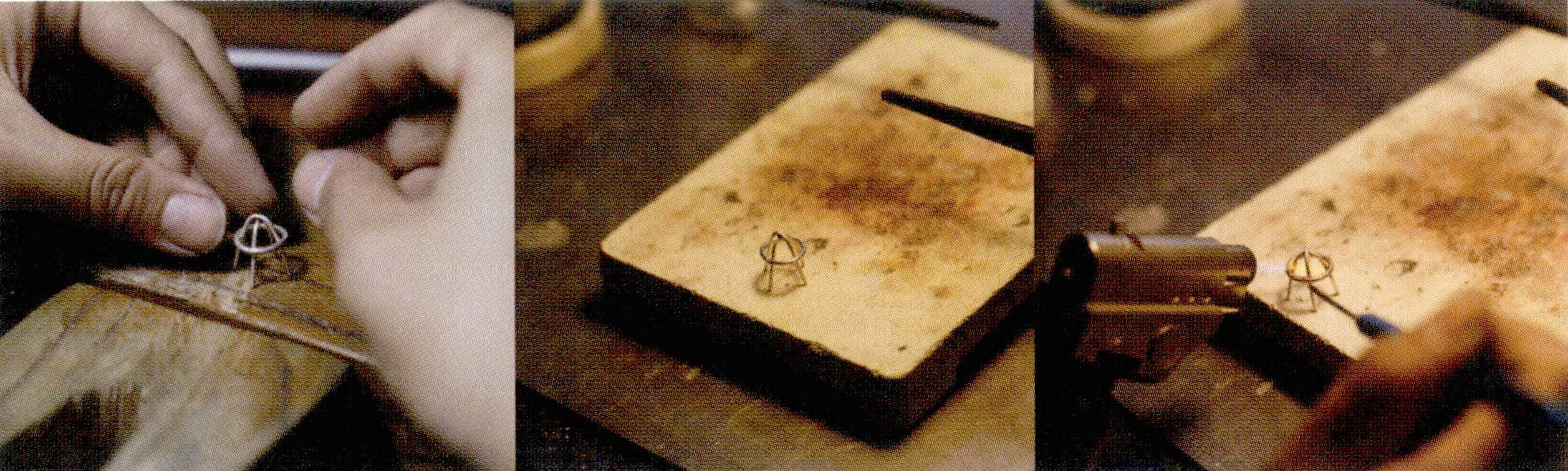

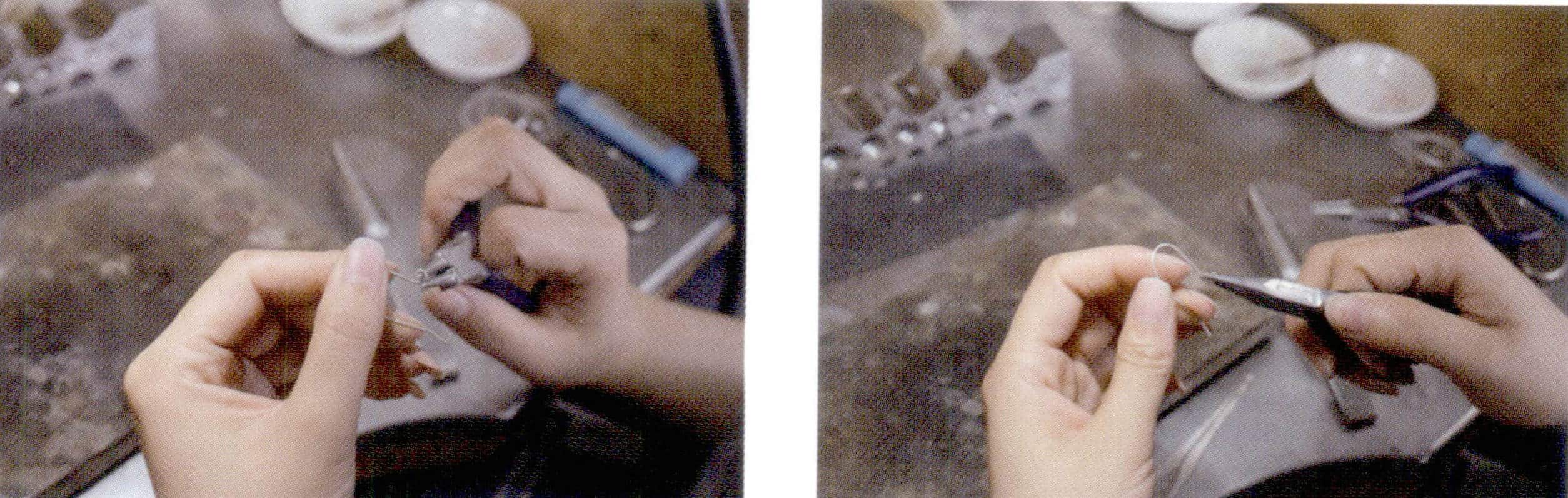

Morska bryza, kolczyki, filigranowe rękodzieło

Drut srebrny 0,3 mm

1. Narzędzia i materiały przygotowawcze: pęseta, nożyczki, lut, pistolet lutowniczy, cegły lutownicze, drut z czystego srebra 999.

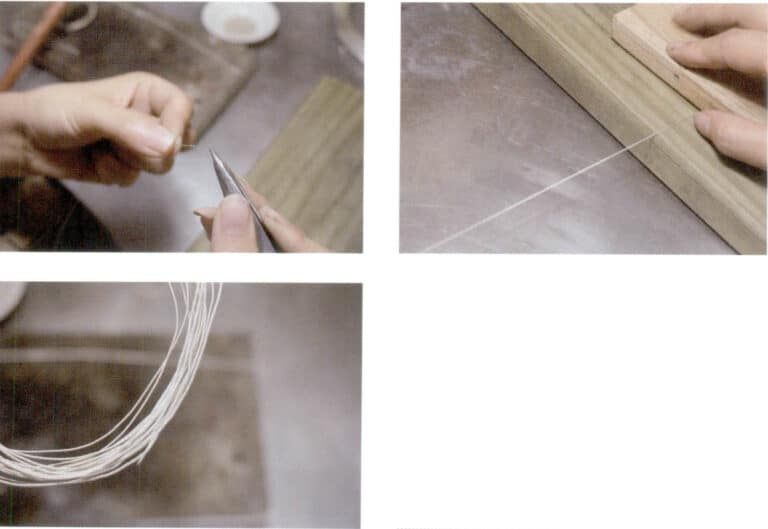

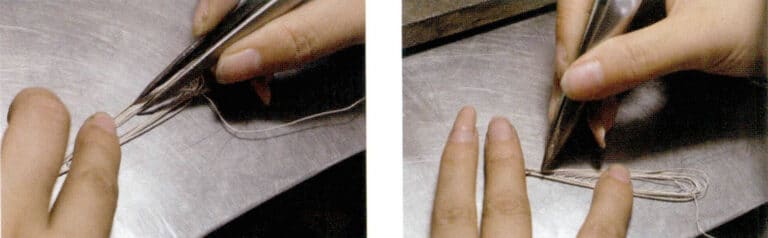

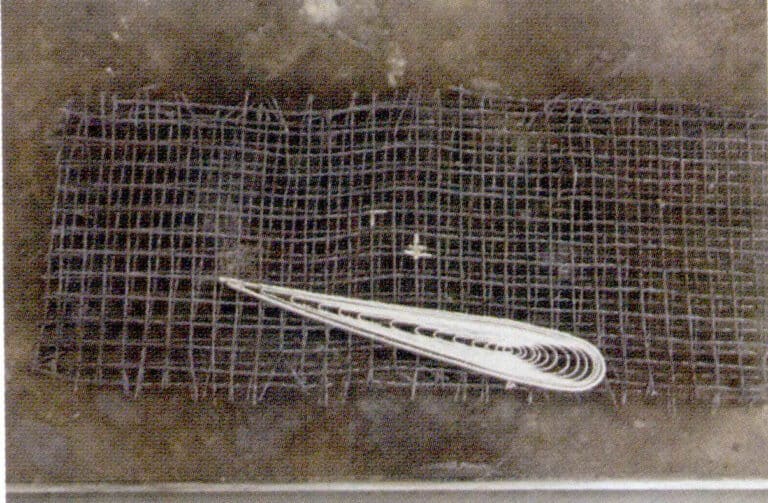

2. Po nałożeniu na siebie 0,3 mm srebrnego drutu, skręć go w kształt spirali; następnie użyj drewnianej deski, aby zacisnąć spiralny drut.

3. Wyżarzanie

4. Zwykła rama druciana po wyżarzaniu.

5. Dokończ kształtowanie ramki w kształcie kropli wody.

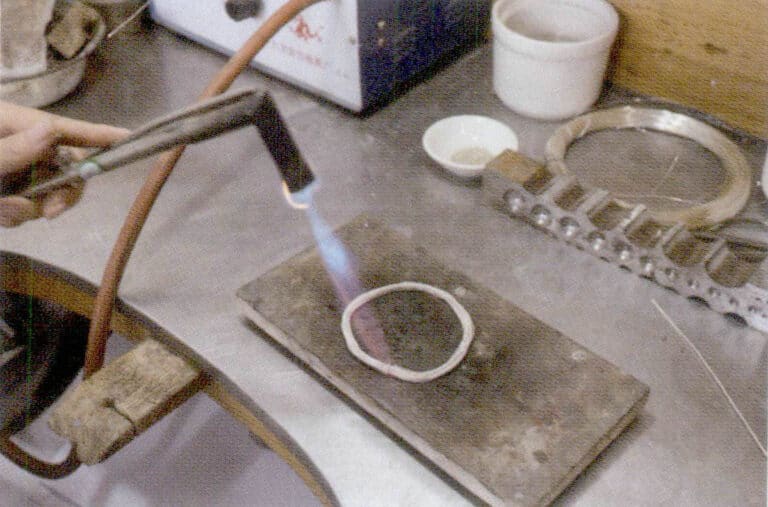

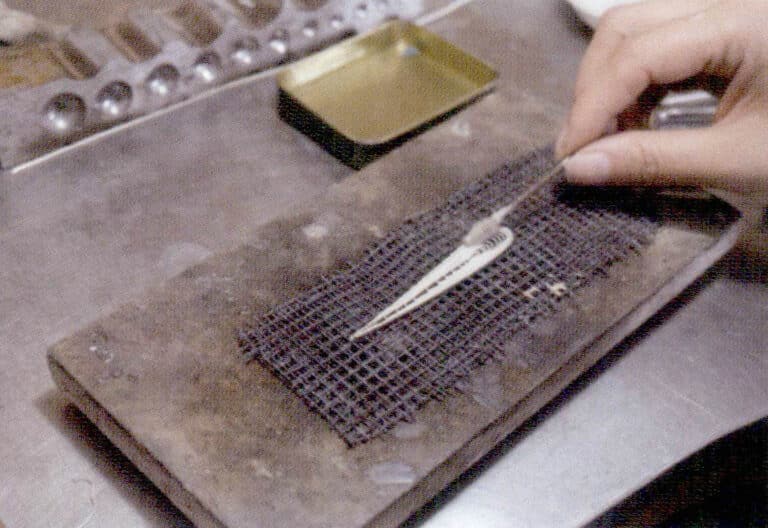

6. Spawać ramę.

7. Wypełnij żarnik, żarnik wypełniający jest nieco cieńszy niż żarnik na granicy.

8. Dostosuj ogólny kształt.

9. Zakończ skręcanie drutu i przygotuj się do spawania.

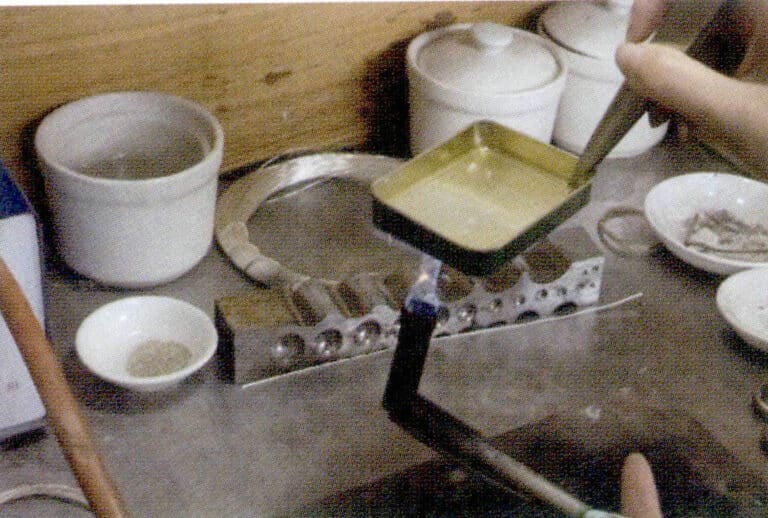

10. Podgrzać wodę z boraksem.

11. Całkowicie pokryj żarnik wodą z boraksem.

12. Równomiernie rozsypać topnik spawalniczy.

13. Ogólne spawanie.

14. Przyspawać pierścień podnoszący.

15. Wykonywanie haczyków na uszy.

16. Haczyki do spawania.

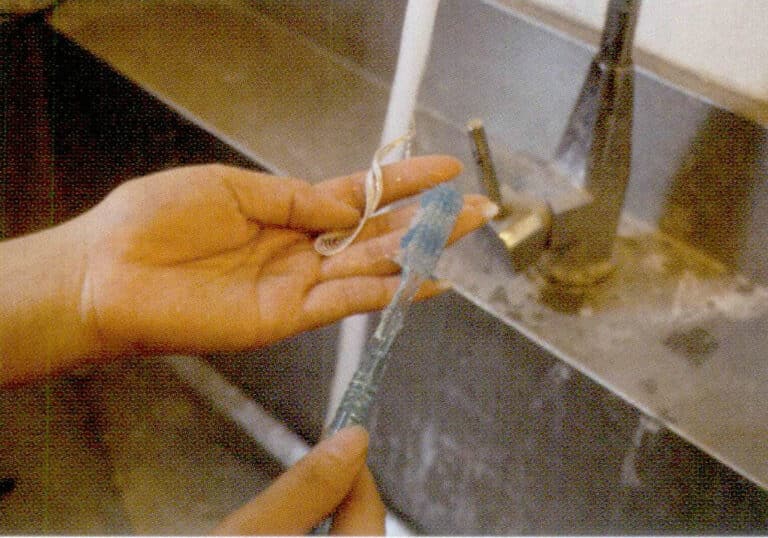

17. Wytrawianie

18. Czyszczenie kolczyków za pomocą miedzianej szczotki drucianej.

19. Gotowe kolczyki z płaskich włókien.

20. Użyj pierścienia, aby obrócić i dostosować kształt, tworząc trójwymiarowy efekt.

21. Wyczyść za pomocą bębna magnetycznego (nadaje się tylko do ściśle ustrukturyzowanych i bezpiecznie zespawanych filamentów).

22. Staranne czyszczenie.

23. Zakończono.

Metamorphosis Series #1, naszyjnik, srebrny żarnik