Grow Your Brand with Trusted OEM Jewelry Manufacturer

Turn your jewelry ideas into reality in 15 days.

Low MOQ · Fast Turnaround · Fine Jewelry Quality

Stop Wasting Time, Money, and Trust on the Wrong jewelry OEM !

- “They promised 925 silver, but when tested, impurities showed up and my customers lost trust.”

- “The samples looked perfect, but when the bulk arrived, colors and plating were totally inconsistent.”

- “We’re a small brand, but they pushed me into huge orders that left my stock sitting unsold.”

- “I gave them a clear design, but the final pieces had wrong structure and poorly set stones.”

- “I received defective products, but instead of taking responsibility, the supplier blamed shipping and even my customers.”

- “I had to handle all product photos and copy myself because they provided nothing useful.”

목차

Don’t Fall into traps Again: Take Back Control When Choosing a Jewelry OEM

What Is Jewelry OEM?

When people talk about jewelry OEM, they usually mean working with a factory that produces designs under your own brand. For many buyers, it sounds like the fastest way to expand collections without building a workshop or hiring a big team. You just send designs, place an order, and the factory handles the rest.

That’s why so many small brands, online stores, and new jewelry entrepreneurs turn to OEM. It feels practical: lower costs, faster turnaround, and the chance to compete with bigger players. For anyone trying to test a new market, launch private label jewelry, or scale without heavy investment, OEM looks like the obvious choice.

But the reality isn’t always as smooth as it looks at first.

Everything Looked Great… Until the Problems Hit Me Hard

Sourcing a new Jewelry OEM often appears straightforward. Catalogs look polished, samples seem acceptable, and communication in fluent English creates an impression of professionalism. At first glance, it can feel like a low-risk decision for buyers seeking efficiency and growth.

However, many B2B buyers discover problems after committing. Delayed deliveries, inconsistent quality, and unexpected costs are frequent issues. Packaging and logistics often fall short of requirements, while after-sales responsibility remains unclear. These problems not only damage cash flow but also impact customer trust, compliance, and long-term brand reputation.

Such challenges are not isolated cases but common traps within the jewelry OEM supply chain. A professional appearance does not always equal strong capability, and overlooked details can escalate into costly mistakes. To reduce risk, buyers need to recognize the most frequent pitfalls before placing deposits or scaling orders.

The following section outlines 10 traps jewelry buyers often regret too late — a practical guide to avoiding unnecessary losses.

10 traps of OEM That Jewelry Buyers Wish They Had Avoided

🔻 Trap 1: The Lure of Unrealistic Low Prices

🔻 Trap 2: Inconsistent Quality Standards

🔻 Trap 3: IP Leakage and Design Theft

🔻 Trap 4: Sample vs. Mass Production Double Standard

🔻 Trap 5: Nonexistent After-Sales Support

🔻 Trap 6: Sloppy Packaging and Shipping

🔻 Trap 7: Opaque Production Timeline

🔻 Trap 8: Fake or Misused Certifications

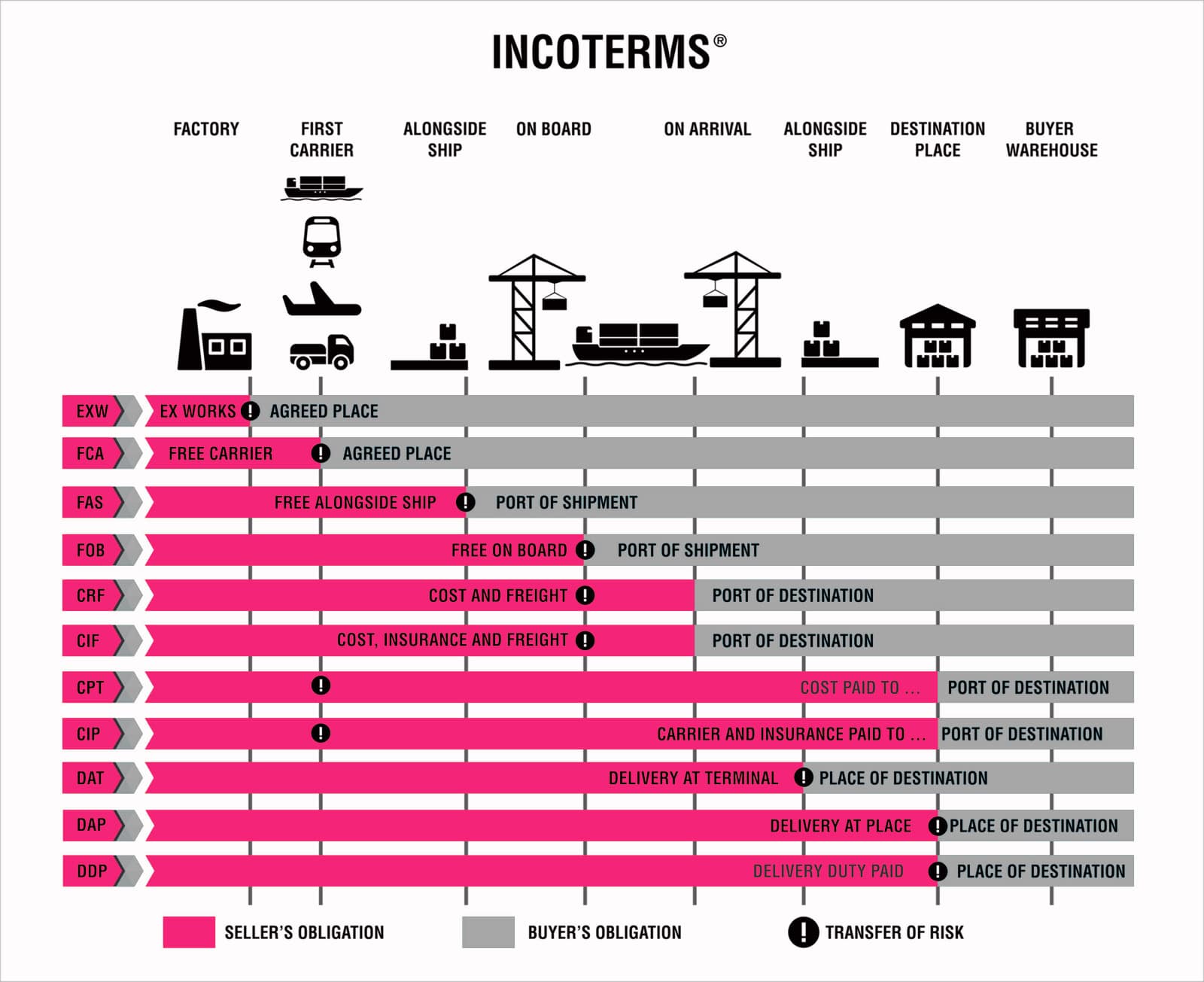

🔻 Trap 9: Allergy and Heavy-Metal Non-Compliance

🔻 Trap 10: Incoterms Misunderstandings

What You Do Next Could Save You Thousands

Sourcing mistakes don’t just hurt margins — they damage trust, delay launches, and exhaust teams. But you don’t have to learn everything the hard way. Use these 10 traps as a checklist. Share them with your sourcing team. Ask the questions early — and choose partners who match answers with evidence. The right supplier isn’t perfect — they’re transparent, realistic, and ready to grow with you.How to tell if a Jewelry OEM is trusted?--- 8 Essential Standards

A truly trusted jewelry manufacturer isn't just about good prices or pretty samples — it's about having the core capabilities to support your brand long term. From in-house design to QC, a solid partner should meet at least these 8 essential standards. Anything less puts your timeline, quality, and customer trust at ris

1. In House Team

Yes, Sobling has 100+ in-house engineers and QC staffs with deep production knowledge

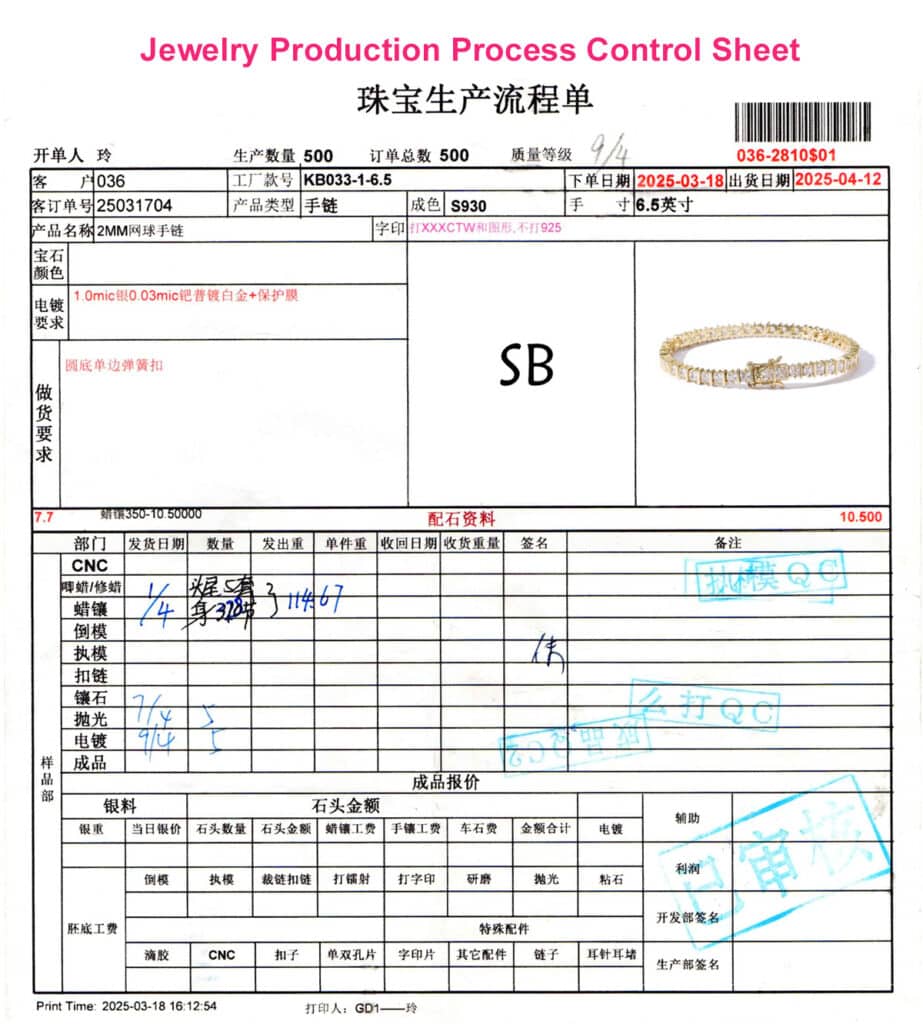

2. Transparent Process

Yes, Sobling gives clear updates at every step — no hidden costs, no surprises

3. Quality Consistent

Yes, Sobling Ensures Consistency in Every Piece Through a Proven Production Control System.

4. Clear Trade Terms

Yes, Sobling walks you through EXW, FOB, DDP, and more — no confusion

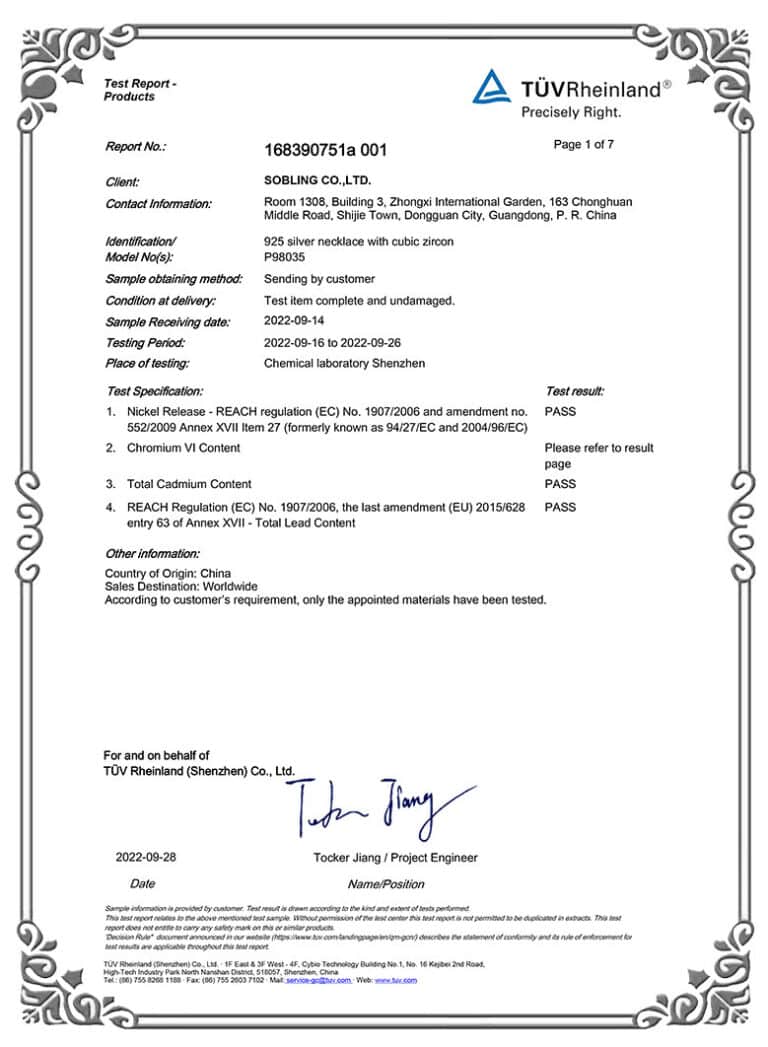

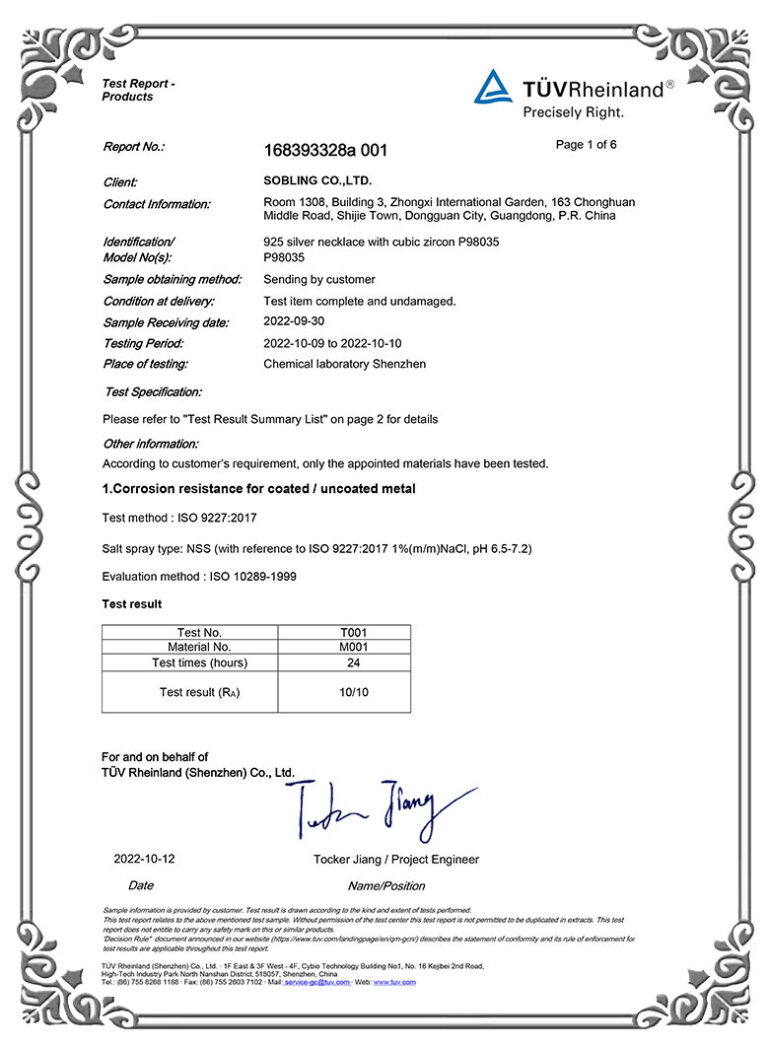

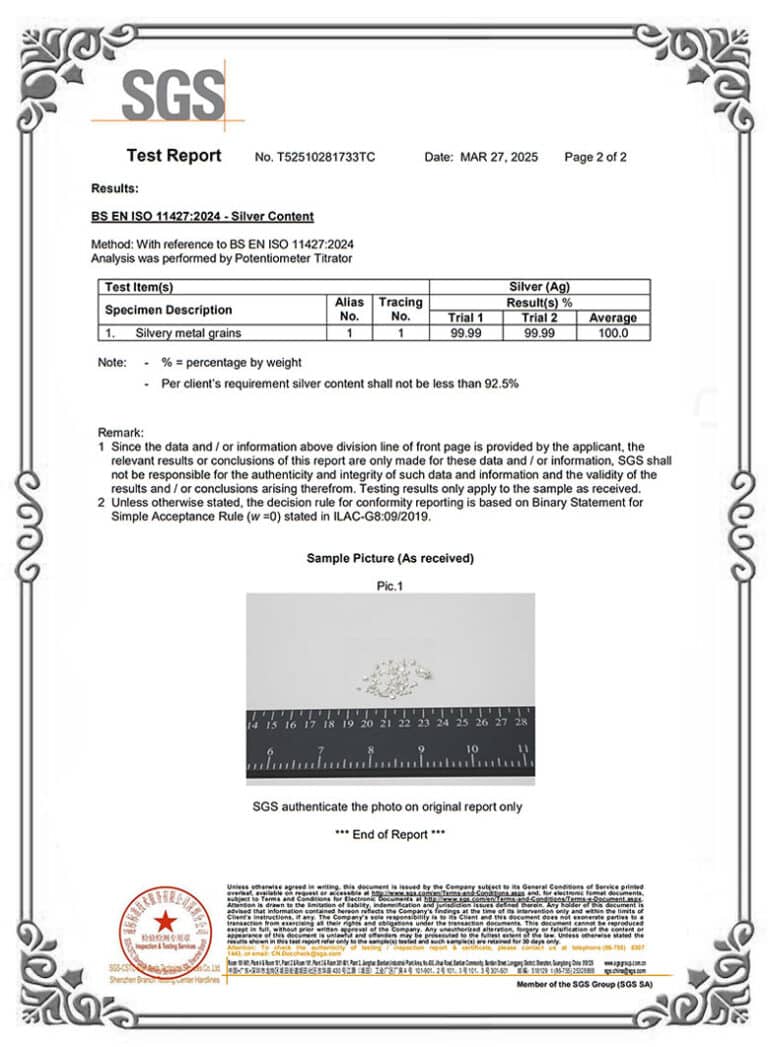

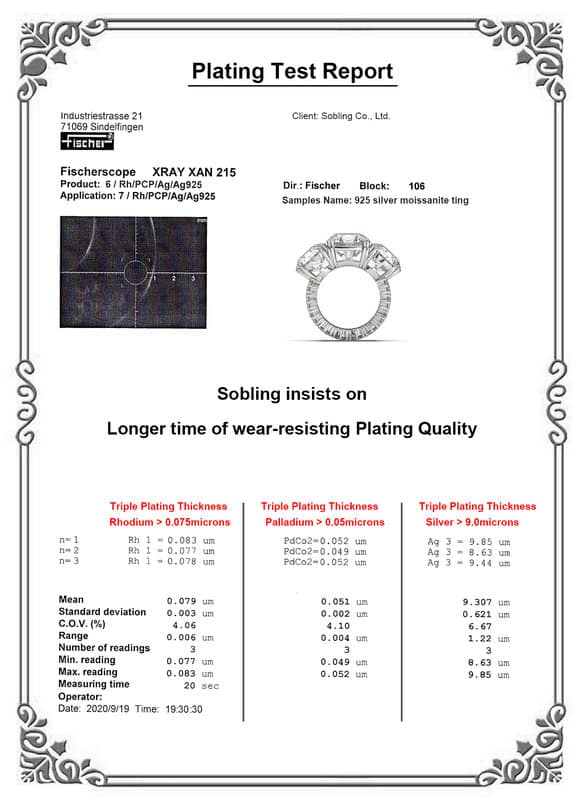

5. Real Certifications

Yes, Your Jewelry is Certified to Global Standards — No Guesswork, No Harmful Surprises

유해 화학 물질 없음 → 글로벌 시장에 안전함

강력한 녹 방지 기능 → 보석이 더 오래 빛납니다.

정품 999 실버 → 실제 순도 보장

내구성이 뛰어난 3중 도금 → 오래 지속되는 아름다움, 변색 감소

6. Allergy-Free Materials

Yes, Sobling Provides Certified Allergy-Free Materials — Silver, Gold, 304 and 316 Steel — All Complying with EU REACH Standards.

7. Flexible Capacity

Sobling: Yes, You can start with 10 pieces low-volume runs and scale up only when you're confident.

8. Verified IP Safety

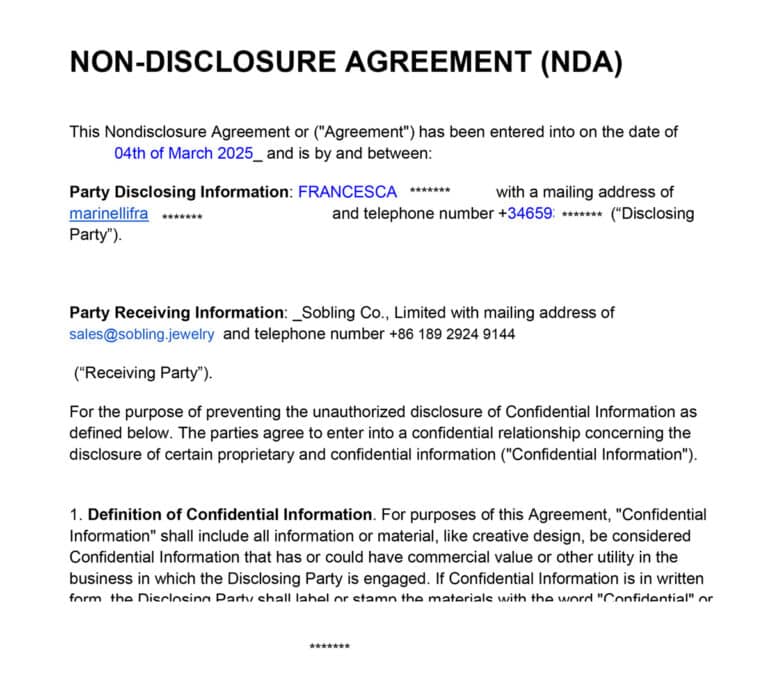

Sobling: Yes, Non-Discloure Agreement(NDA) signed before sampling, so your IP stays yours — always

7 More Key Factors to consider when choosing a trusted supplier

- 9. Focus on Jewelry OEM Over decades

- 10. Precision Equipment for Brand-Ready Quality

- 11. All-in-One Jewelry OEM Services

- 12. All-in-One OEM Jewelry Products

- 13. Real production capacities

- 14. 100% Risk Free Guarantee

- 15. 4 Steps Quality Contorl System

7 Value-Added Advantages to Choose a Trusted Jewelry OEM Supplier

- 16. Sustainable Jewelry Options

- 17. Fast Shipping and Delivery

- 18. One-stop complete jewelry Production

- 19. One-stop Jewelry material options

- 20. One-Stop Package materials

- 21. Private Label jewelry Engravings

- 22. Jewerly photoshoot for marketing ready

How to Spot a trusted Jewelry OEM? — Checklist Based on Industry Insights

Choosing the right jewelry OEM partner can make or break your brand’s success. It’s not just about low prices — it’s about finding a manufacturer who delivers consistent quality, communicates clearly, and helps you meet deadlines without hidden delays or surprises.

Below is a practical checklist to help you evaluate any OEM supplier — including what to look for, why it matters, and how Sobling meets each benchmark. Use this to compare vendors and spot early warning signs before it costs you time and money.| Key Factor | What to look for | How Sobling Measures Up |

|---|---|---|

| Production Transparency | Improved visibility into production progress, helping reduce delays and miscommunication. | ✅ Offers transparent factory access and visual updates |

| Material Assurance | Reliable quality control with verified and certified metals and gemstones. | ✅ RJC, SGS, EU-tested materials used |

| MOQ Flexibility | Lower entry barriers and easier scaling from small to bulk orders. | ✅ 10pcs to 10,000pcs, scalable |

| In-House Manufacturing | Consistent quality and better delivery control without third-party involvement. | ✅ Fully in-house from casting to finishing |

| Full-Service Workflow | Reduced coordination effort with integrated design, sampling, production, and packaging. | ✅ 9-step all-in-one production workflow |

| Fast Prototyping | Shorter product development cycles and faster go-to-market capability. | ✅ 15-day sample making, CAD + wax options |

| Quality Control | Lower defect rates and improved consistency through multi-step quality checks. | ✅ 4 steps QC system (casting, plating, finishing, Final products) |

| Global Experience | Proven capability to meet standards and expectations across different markets. | ✅ Projects across 30+ countries |

| On-Time Delivery | Reliable scheduling and reduced risk of launch delays. | ✅ 98%+ on-time delivery performance |

| English-Speaking Support | Fewer communication issues and faster response time during production. | ✅ Fluent, responsive English-speaking team |

| IP & NDA Protection | Reduced legal and commercial risks for custom or exclusive designs. | ✅ Signed NDA, strict IP protection policy |

| Certification Ready | Smoother customs clearance and compliance with international regulations. | ✅ Compliance with export standards (e.g. REACH, CA65) |

Choosing an OEM partner isn’t just about finding a supplier — it’s about finding someone who helps you move faster, avoid costly mistakes, and grow with confidence. This checklist helped me see the difference: transparent production, strong quality control, fast samples, and real communication matter more than I thought.

With Sobling, everything from IP protection to delivery feels structured and reliable. there are no longer worry about delays, vague updates, or quality gaps. If you want a partner that understands your goals and actually delivers, this checklist is the best place to start asking the right questions.

Why Jewelry Brands Like Yours Choose Sobling?

70% 시간 절약

Shorten your supply Chain

40% cost saved

Factory Direct Price, No Middleman

100% Risk-Free

30일 반품 보장

7x24 VIP services

Rapid response to cut your waiting time

What You’ll Actually Gain from Working with Sobling?

- ✅ Better Quality: TUV certified & REACH compliant. 90% Fewer defects, 200% happier customers.

- ✅ Better Guarantee: 30-day return, 360-day warranty. Peace of mind for your business.

- ✅ Fewer Headaches: All-in-one solution from design to delivery.

- ✅ Lower Costs: Free design & 3D modeling. 40% Save on time and development expenses.

how to do OEM jewelry with sobling?

시장 조사 및 연구

시장을 탐색하고, 경쟁업체를 발견하고, 최신 주얼리 패션에 대한 최신 정보를 확인하세요.

브랜드 요소 만들기

주얼리 제품에 각인하기에 적합한 매력적인 브랜드 이름과 로고를 포함하여 고유한 브랜드 아이덴티티를 개발하세요.

회의, 토론 및 디자인

소블링과 만나서 디자인을 확정하고, 필요한 경우 보석 아이템과 포장까지 포함하여 논의합니다.

평가판 샘플 제작 및 승인

디자인이 완성되면 생산 시설에서 프로토타입과 시험 샘플을 제작하기 위한 제조 공정을 시작합니다.

대량 주문 및 배송

샘플이 만족스럽다면 언제든지 정식 주문을 하세요! 리드 타임을 최소화하고 가장 빠른 배송을 위해 생산 및 배송 프로세스를 신속하게 진행하겠습니다.

What Our Clients Say About Sobling?

사람들의 의견

제작 시간도 빠르고 품질도 일관되게 좋습니다, 그리고 커뮤니케이션은 지금까지 본 적 없는 수준입니다. --- 비엔나 도마니

Get One piece Free 3D Design ( $99 Value ) — Available This Month Only

What is your competitive edge with Sobling OEM jewelry?

1. Maximize Every Dollar

2. Quality That Turns Heads

3.Launch Without Fear

4. Build a Brand That Lasts

5. Stay Ahead of the Curve

6. Your Brand, Your Way

Who Do We Serve?

- 주얼리 브랜드

- 전자상거래 판매자

- 드롭배송 판매자

- 유명인 맞춤 제작

- Jewelry Retailers & Stores

- Jewelry Designers & Studios

Where Our OEM Services Are Used?

- Jewelry for Gift Campaigns

- Limited Collection Launches

- Wedding Jewelry Custom Orders

- Print-on-Demand Dropshipping Models

- Custom Jewelry for Celebrities & Influencers

Internal useful links

품질 기준을 존중하는 소블링