Who Masters the Art of Metal Chasing and Relief? Unveiling Tools, Techniques, and Modern Workshops

Basic Techniques and Work Scenes of Chasing and Relief Techniques

소개:

Ever wondered how intricate, dimensional patterns are created on metal jewelry? This guide dives into the traditional craft of chasing and relief. We explain key techniques like form punching, embossing, and line chasing, detailing the essential tools—from chisels and hammers to anvils and polishers. Discover the complete workflow, from design transfer to final polishing, and explore modern workshop environments, from personal studios to professional school labs. Whether you’re a jewelry designer, retailer, or custom maker, this is your practical overview of turning metal sheets into textured, detailed works of art.

Hand form punching

목차

Section I Basic Techniques

1. Form Punching

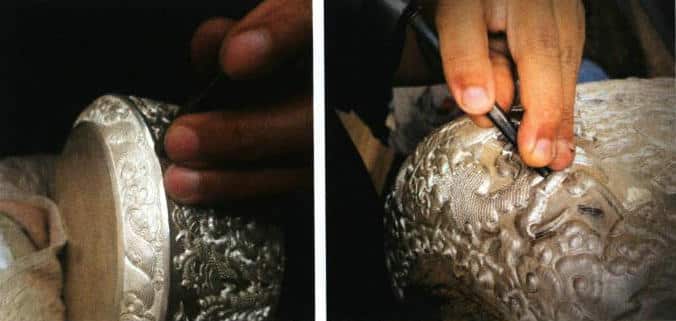

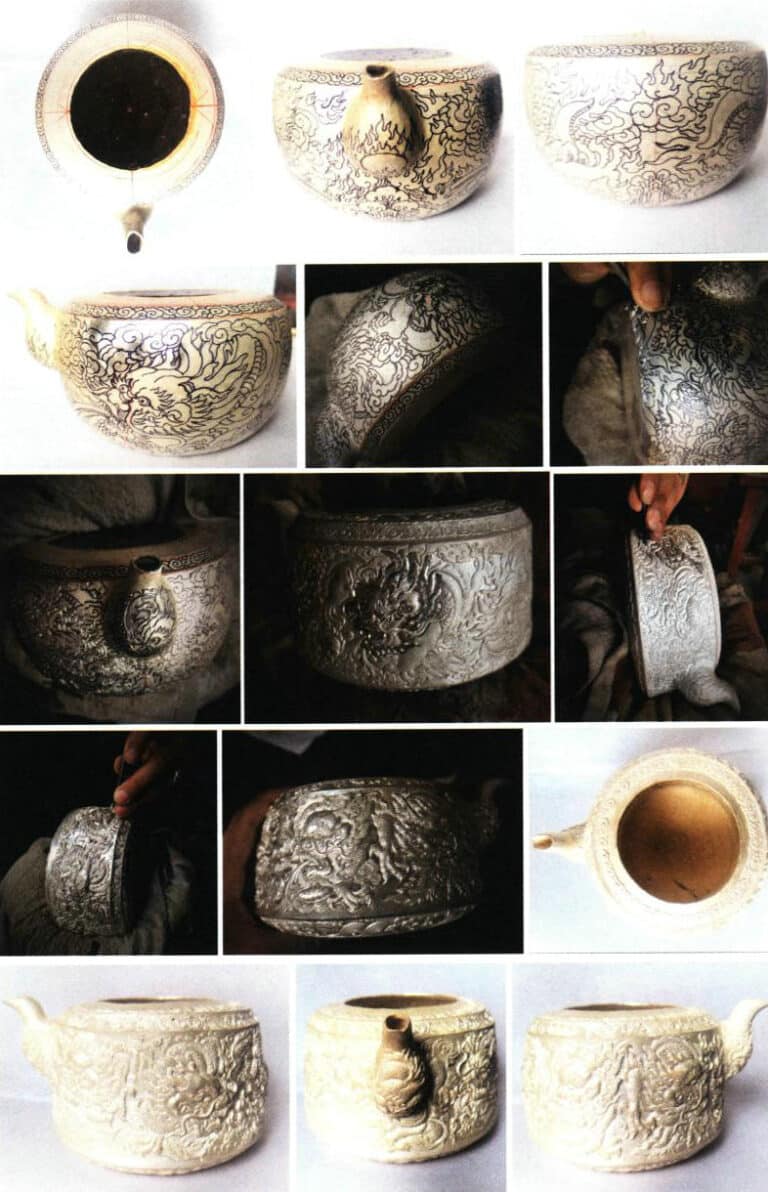

From punching is a commonly used technique for forming relief shapes. To model the spatial sense of the form, the metal sheet is first pushed up from the back to approximately the height required by the design on the front. During the from-punching process, the thickness of the metal sheet should be determined according to the size of the decorative area and the levels of relief: the more pronounced the relief, the thicker the metal sheet, typically about 0.7 mm. For raising, chisels with round, square, or teardrop-shaped mouths are usually chosen. There are generally two methods of form establishing: one is to hand-raise the basic large shape using a form-establishing chisel; the other is to stamp the basic form of the pattern to be chiseled using a pre-made metal mold. The specific operation methods are as follows.

(1) Hand form-punching

① Using the ductility of the metal, strike the metal sheet from the reverse side with form-establishing chisels, chasing hammers, and similar tools to raise it to the approximate height required by the design on the front; typically used for high relief (Fig. 4-1).

② On the front, use line chisels to trace the pattern to be chased, then use embossing chisel along the outer contour to flatten the outer edges of the lines; by utilizing the metal’s ductility and the extrusive force of the pitch, the central area of the pattern to be chased is raised, typically used for low relief.

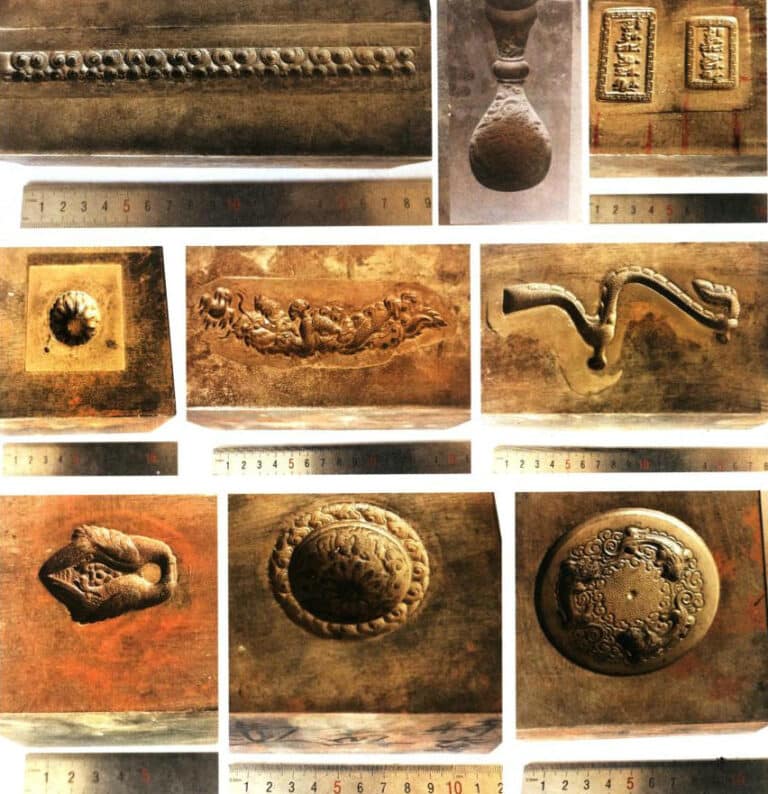

(2) Mold from-punching

① Traditional mold from-punching generally uses zinc for the molds because of its low melting point and high hardness (Fig. 4-2). Using sand-molding techniques, zinc male and female molds in the shape of the piece to be chased are produced, then annealed gold, silver, or copper sheets are placed in them and hammered to press out the basic large shape of the piece to be chased.

Mold from-punching is simple and easy to operate, but zinc molds have a limited service life; usually, after imprinting dozens of gold, silver, or copper sheets, the mold’s relief details become blurred and indistinct.

② Modern from-punching dies (Fig. 4-3): Using computer numerical control (CNC) systems, 3D scanning technology, or turning and milling techniques, high-hardness steel male and female dies are produced, and annealed gold, silver, or copper sheets are placed between the dies for pressing.

Modern from-establishing die has the following characteristics.

① Steel dies are often hard and capture fine details clearly; usually, one set of dies can ensure large-scale production of the product, but the cost of making the dies is high, and the input-output ratio must be considered.

② Operation is simple and can be done by a single person; the technical threshold is low, production speed is fast, and labor costs are greatly reduced.

③ The embossed metal sheets produced have clearer detailed patterns, which can reduce the number of subsequent secondary hand chiseling operations and improve work efficiency.

참고

① Lead has a considerable effect on gold and silver, so rubber pads are often used when embossing with a die; the number and thickness of the rubber pads can be determined by the height that needs to be stamped out. Copper sheets can use lead blocks as backing/pressure pads.

② The protruding height of a metal sheet is proportional to its thickness; the higher the lift, the thicker the metal sheet needs to be. The ductility of gold, silver, and copper also differs: gold is the most ductile, silver is next. However, metal ductility is limited, and allowance must be made for the thickness needed during chasing/engraving operations. Generally, for heavily chased pieces with varied modeling and rich texture, the metal sheet thickness is about 0.7 mm.

2. Embossing

Embossing, also called is the step after form punching; it is performed on the surface of the raised form. Embossing is also a process of shaping — using different chisels to turn abstract protrusions into concrete forms. During operation, based on the spatial structure of the pattern, chisels with different head shapes are used to treat the spatial details of the design, reflecting how the folded and flipped shapes change in space. Embossing has the following characteristics.

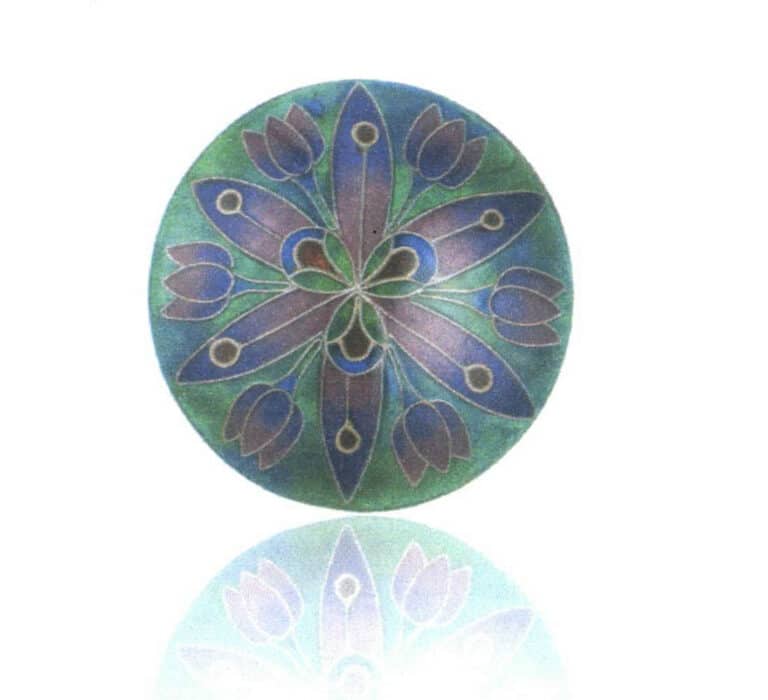

① It usually enriches the modeling and carves details for high-relief patterns (Figures 4-4 to 4-6).

② Form establishing can already produce undulations on the metal surface, but the resulting form is, in trade terms, “fat” and needs embossing to make the modeling appear clearer (Figure 4-7).

③ The embossing process serves to highlight and polish the patterns.

④ Dot-pattern embossing also falls under the category of embossing. When a smooth base surface is dot-pattern embossing, the surface produces diffuse reflection of light, presenting effects with different levels (Fig. 4–8).

⑤ Many patterned chisels can also be used for embossing; for example, in northern chased and embossed handicrafts, many exquisite and formally expressive background patterns are created using patterned chisels.

Figure 4-4 Detail modeling

Figure 4-5 Small embossing chisel leveling

Figure 4-6 Embossing

Figure 4-7 Specific shaping after embossing

3. Line Chasing

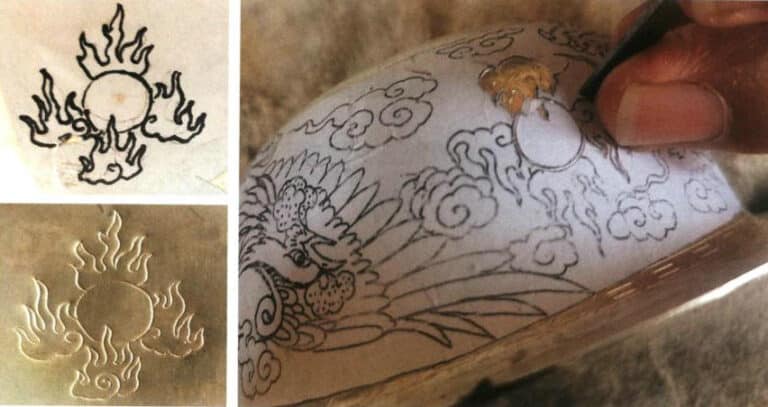

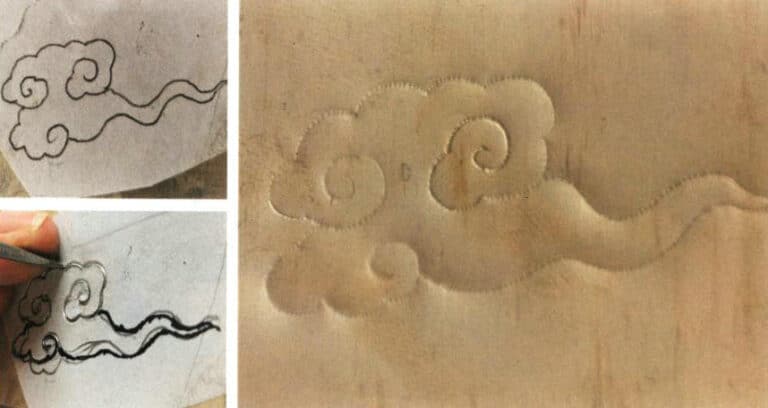

Figure 4-9 Fire pattern

Figure 4-10 Auspicious Cloud Pattern

4. Carving off

Carving off requires the chisel edge to be sharp. In the West, it is also called “gilded carving,” similar in effect to flat chisel work; its essence is a subtractive process on metal.

Carving off is also called “qiang huo” or “tuo”; in ancient times, it was called “zu lü.” It is a technique that can create openwork effects on a metal surface. Because there were no steel saw blades in ancient times, to produce openwork on gold, silver, or copper, one had to use very sharp chisels to cut through the metal. These types of chisels are also called “fast chisels” or “cutting chisels.” When used with light force, they can incise very fine lines on the metal surface; when used with greater force, they can sever the metal. Chasing along the edge of a pattern is also called “tuo kou.”

In chasing and relief craftsmanship, the techniques mentioned above—form punching, embossing, line tracing, and carving off—are the most commonly used, all containing the accumulated experience of craftsmen from countless regions over millennia. With advances in craft materials, new tools and techniques continuously appear. In short, chasing and relief tools come in a wide variety of forms and endless variations; as the leaders of this craft, we must not stand still, but neither be burdened by material things. Exquisite patterns and the mysteriously lively spatial forms depend on a spirit of bold innovation and perseverance.

카피라이팅 @ 소블링.쥬얼리 - Sobling. 맞춤형 주얼리 제조업체, OEM 및 ODM 주얼리 공장

Section II Process flow

Chasing and relief craftsmanship has developed over a thousand years; its methods have been continuously refined, but the basic procedures have not undergone major changes. Different regions, according to transmission paths and local habits, may have slight differences in methods and processes. The basic process is as follows (Fig. 4–12).

① Pattern transfer: draw the design on gold, silver, or copper surfaces, or transfer a printed line drawing onto the metal surface.

② Choose backing and padding: glue, lead, sandbags, steel chasing plates, etc.

③ Forming: if a high relief is required, the undulating space must be knocked out before performing another round of glue removal and filling. Glue removal and filling are repeatable steps in the chasing and engraving process; the number of repetitions depends on the craftsman’s skill level and the complexity of the design.

④ Shaping: Use different chisels to carve rich patterns on the blank; this also includes the process of embossing details.

⑤ Trimming and brazing: Remove the flux from the carved components and inspect them; if there are missed carvings, cracks, or places that need assembly, trim them before brazing and assembling.

⑥ Polishing: Perform surface treatment.

Section III Working Posture

The posture and movements of the worker during chasing and relief have a great impact on the outcome. Incorrect posture can also lead to work fatigue, affect health, and compromise safety during operations. Working postures (Fig. 4–13) vary slightly with the work situation, but the basic points are the same.

(1) Keep the body upright, legs naturally slightly apart, and adopt a comfortable stance.

(2) Position the workpiece being chased at chest level, with a distance from the chest of about 20 cm.

(3) Hold the chisel in one hand and the chasing hammer in the other, with the arm and hand in a natural embracing position, and keep the object being chased within the line of sight.

(4) When chasing, tilt the tail of the chisel outward; strike the chisel with the hammer from top to bottom and from outside to inside, keeping the chased object continuously within the line of sight.

참고

① The chasing and relief process is also one in which the stresses in the metal sheet continuously change, so annealing is very necessary; otherwise, the hardness of the metal sheet will affect the quality and effect of the chasing and relief.

② In handicraft production of chasing and relief, an assembly-line workflow is generally used. For example, forming and die punching are done by the same person; there are specialists who are responsible for carving a particular shape and craftsmen who are responsible for polishing. This can improve efficiency, keep the chased patterns neat and consistent, and increase product output and quality.

③ When performing chasing and relief work, unbecoming sitting postures such as crossing one’s legs should be avoided.

Section IV Work Environment

1. Personal Studios

The chasing and relief craft does not have high environmental requirements; the space of an individual workbench varies by person. Because most chased pieces are relatively small and have little impact on the surrounding area during work, the workbench is mainly arranged with the artisan’s posture and comfort during the chasing process in mind. Typically, a single workstation is about 0.5 m², and most studios have spaces of about 30 m². Craftsmen are generally around five people; depending on the product categories a studio produces, it’s common to pair a chasing master with a filigree inlay master, or a forging master with a chasing master, forming a small workshop, supplemented by 1~2 apprentices to prepare materials and assist. The overall pattern is small but complete. The chasing process relies heavily on the master’s years of technical experience and coordination among trades.

As Chinese people place increasing value on the ethnic and personalized aspects of jewelry, many large manufacturers have begun to increase the development of jewelry with traditional craft elements. Most capable manufacturers establish relatively independent research-and-development and production spaces for traditional crafts according to modern enterprise management and production models, and based on the characteristics of the traditional techniques. In terms of personnel, they both hire experienced masters to make custom pieces and collaborate with designers to solve technical problems, and bring in computer modelers who use modern production technologies to simulate traditional craft forms. The overall result is market-oriented production, product diversification, and efficient operation across departments.

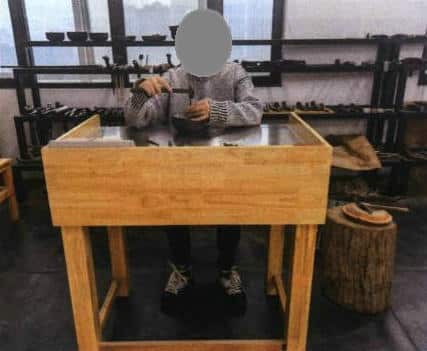

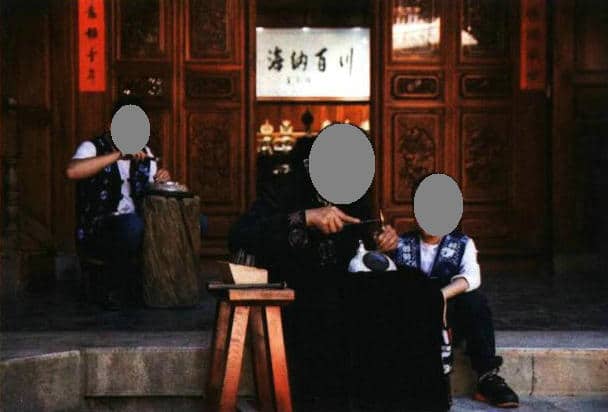

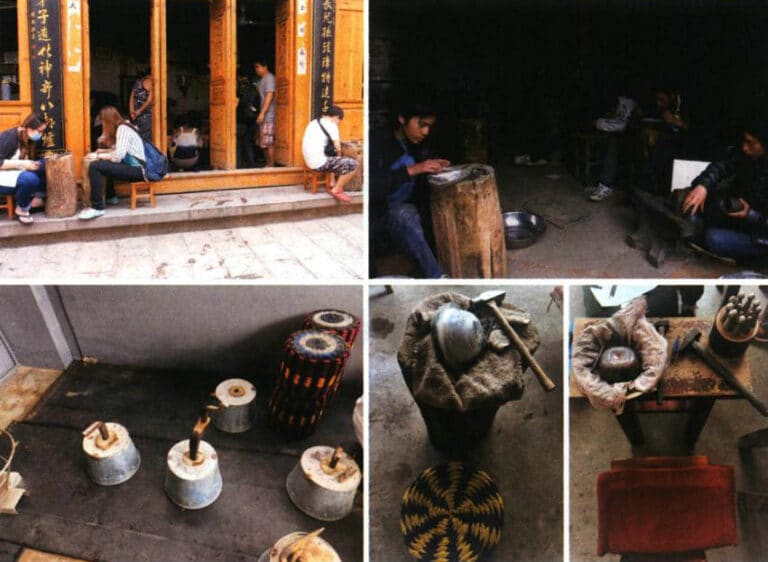

In recent years, the state has stepped up efforts to protect intangible cultural heritage, and silversmithing and forging handicrafts have developed rapidly in regions such as Yunnan, Guizhou, and Tibet. For example, Heqing County in Dali Bai Autonomous Prefecture, Yunnan, has invested heavily in protecting the intangible heritage of silver forging; after more than a decade of continuous investment, it has developed into a silverware hometown renowned at home and abroad. Local artisans generally work in family units, largely following the traditional master-apprentice system with improvements over time. Local authorities have made full use of a series of national revitalization and support policies to construct workshops and street-front shops, vigorously promoting traditional craft production through various forms such as front-shop back-factory. These folk craftsmen mostly use processed tree stumps (adjusted according to the operator’s experience and working habits) and low stools for their work (Fig. 4–15); such equipment helps keep their necks, trunks, and arms relatively comfortable during long working hours. A 30 m² chasing-and-forging workshop typically allocates a quarter of space for chasing and relief operations, with the remaining space placed against the walls for racks holding forging tools.

Each workshop recruits apprentices according to its own craft characteristics and operates on a “old-to-new, work-based learning” model. The overall characteristics of the local gold and silverware processing industry are: ① master-apprentice system plus modern management; ② each household specializes and produces professionally; ③ an interconnected handicraft processing model between workshops.

2. Professional School Laboratories

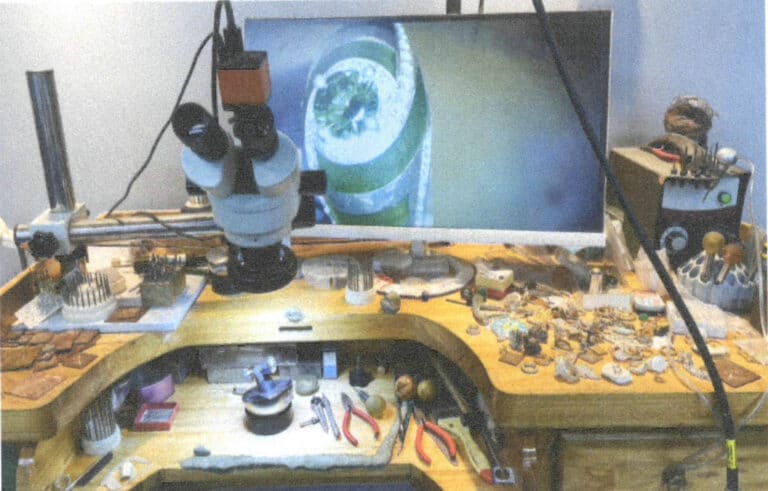

Over more than 40 years since the Reform and Opening Up, the state has put forward new development requirements for higher education, integrating traditional culture and ideological education into the construction of many disciplines. At present, more than 100 institutions nationwide offer programs in jewelry and ornamentation, and the vast majority have successively introduced courses in traditional crafts. In 2012, the School of Gemology at China University of Geosciences (Wuhan) reformed its curriculum to offer traditional craft courses such as chasing and relief, filigree, and enameling, and, in accordance with higher education laboratory construction requirements and the specific needs of these crafts, established a traditional crafts laboratory.

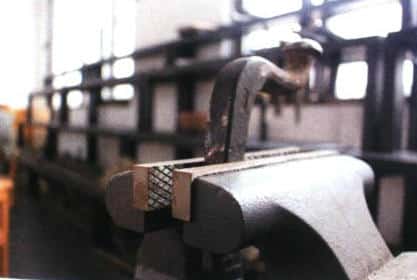

The domestic professional schools’ chasing and relief craft laboratory (Figure 4–16) is built primarily to meet its own teaching requirements and must also ensure proper safety protection. The chasing and relief workbench is similar to a jewelry workbench but lower in height, making it better suited for student practical exercises.

Besides the workbenches, the chasing and relief laboratory and equipment room contain many related tools and pieces of equipment (Figures 4–17 through 4–20); their specific characteristics are as follows.

① The laboratory should have a sufficient number of workbenches to accommodate a standard teaching class simultaneously.

② The workbench positions should suit the characteristics of chasing and relief operations and facilitate both teaching and student learning.

③ The laboratory should meet the operational needs related to chasing and relief, such as allowing for annealing, stamping, forging, shaping, and similar operations.

④ Fully consider all types of safety issues in practical teaching, such as fire prevention and accidental injuries.

Figure 4-17 Anvil

Figure 4-18 Bench vise

Figure 4-19 Partial View of Polisher

Figure 4-20 Tools and equipment in the equipment room