Bagaimana Cara Melakukan Pemotongan, Pemasangan, dan Pemotongan Batu Permata?

Membentuk dan Merekatkan pada batang batu permata dari bahan kasar, Memotong dan Memoles batu permata bersegi

Pendahuluan:

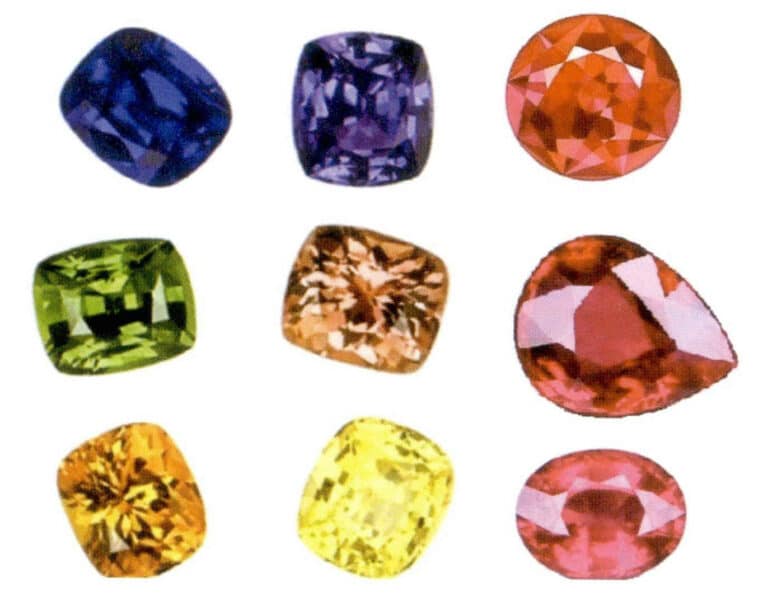

Panduan ini menawarkan pandangan mendalam ke dalam dunia pembentukan batu permata, dengan fokus pada proses penting pembentukan batu kasar, pemasangan batu permata pada batang, dan pemotongan dan pemolesan batu permata. Buku ini wajib dibaca oleh siapa pun di industri perhiasan yang ingin mengasah keterampilan mereka dalam mengubah batu permata mentah menjadi perhiasan yang dipoles. Pelajari cara mencapai presisi dalam pembentukan batu, memastikan kualitas dalam ikatan perekat, dan menguasai seni pemotongan segi untuk hasil akhir yang sempurna.

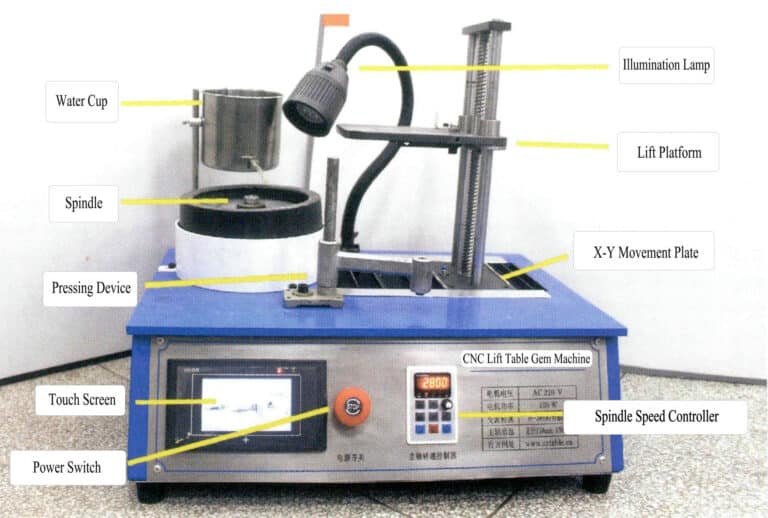

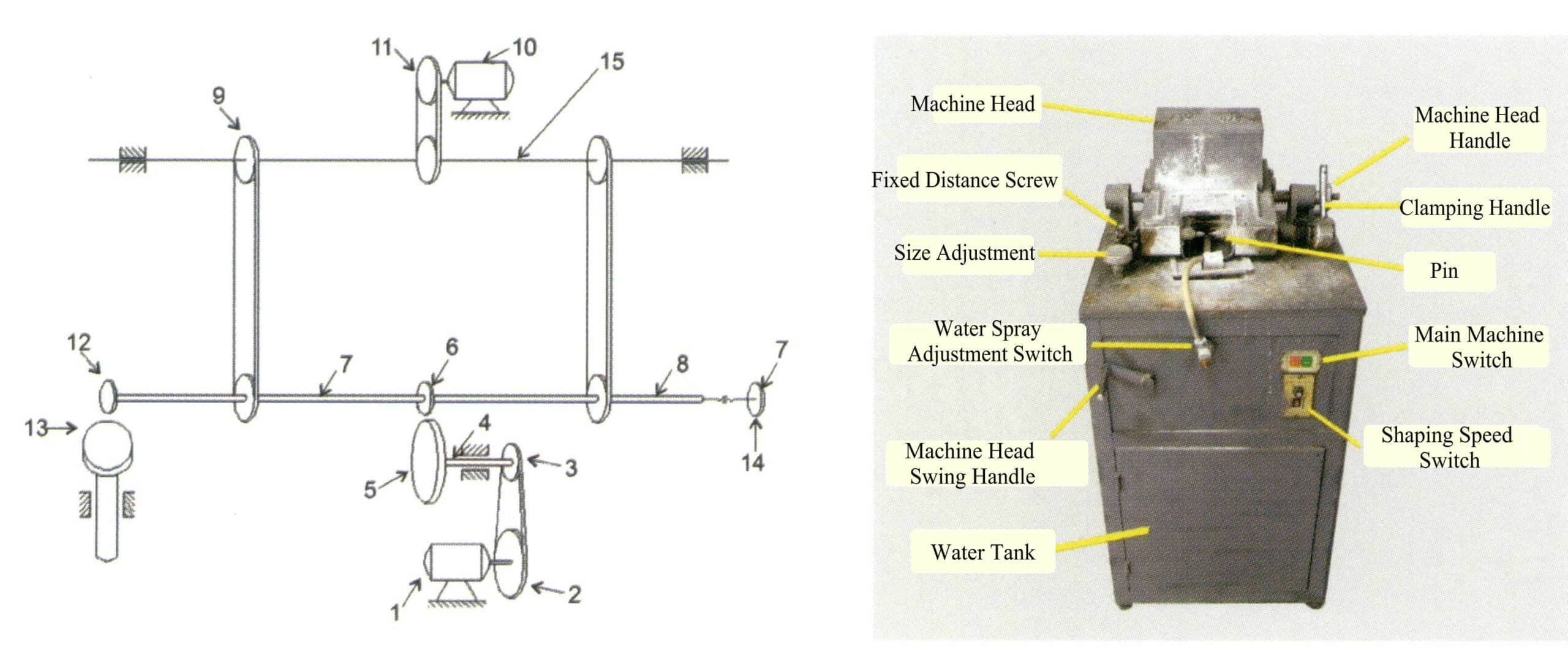

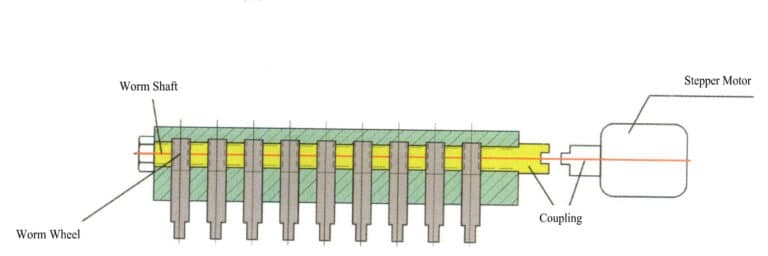

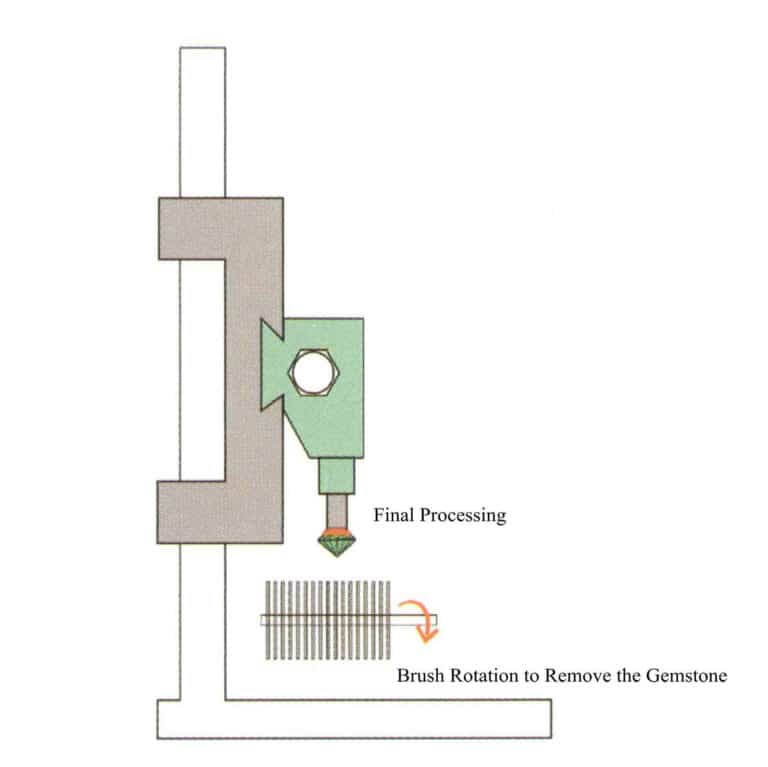

Struktur mesin pemotong batu permata CNC

Daftar Isi

Bagian I Pembentukan Batu Kasar Batu Permata

1. Prinsip dan metode pembentukan batu kasar

Membentuk batu permata adalah membentuk ukuran pinggang setelah memotong bahan mentah.

1.1 Prinsip Pembentukan Batu Kasar

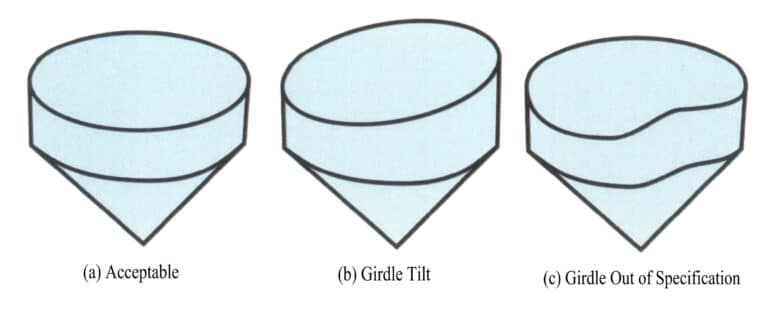

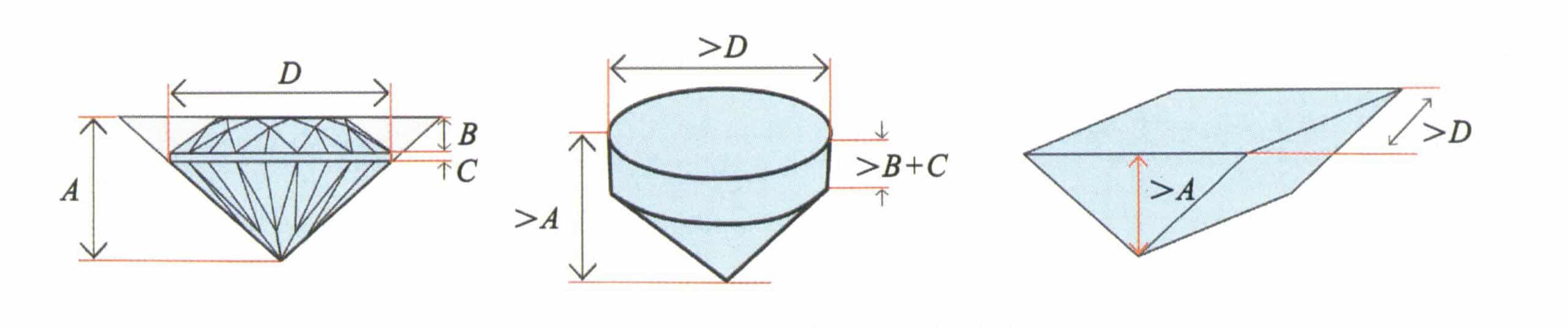

Prinsip Pembentukan Batu Permata-Penggilingan bentuk pinggang yang dirancang dan ukuran batu permata pada batu permata kasar. Dalam produksi, batu permata yang telah dipotong kasar digiling untuk mencapai bentuk dan ukuran pinggang yang memenuhi persyaratan desain, seperti yang ditunjukkan pada Gambar 5-1.

1.2 Metode Pembentukan Kasar Batu Permata

(1) Pembentukan Batu Tunggal

Batu permata alami yang berharga dan batu permata sintetis yang berharga dengan jumlah pesanan kecil menggunakan metode pembentukan partikel tunggal.

(2) Pembentukan untuk produksi massal

Batu permata alami dan sintetis biasa menggunakan mesin semi-otomatis untuk metode pembentukan produksi batch.

2. Persyaratan kualitas untuk pembentukan batu permata

2.1 Bentuk pinggang batu permata akurat (Gambar 5-2)

2.2 Konsistensi Dimensi Produk

Toleransi dimensi untuk blanko batu kasar presisi adalah dalam ± 0,01 mm untuk pemrosesan batu kasar skala besar, seperti yang ditunjukkan pada Gambar 5-3.

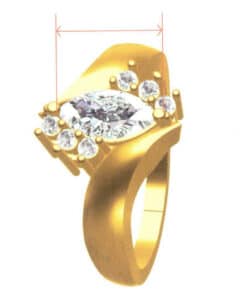

2.3 Menetapkan Permata Menurut Contoh Cincin (Gambar 5-4)

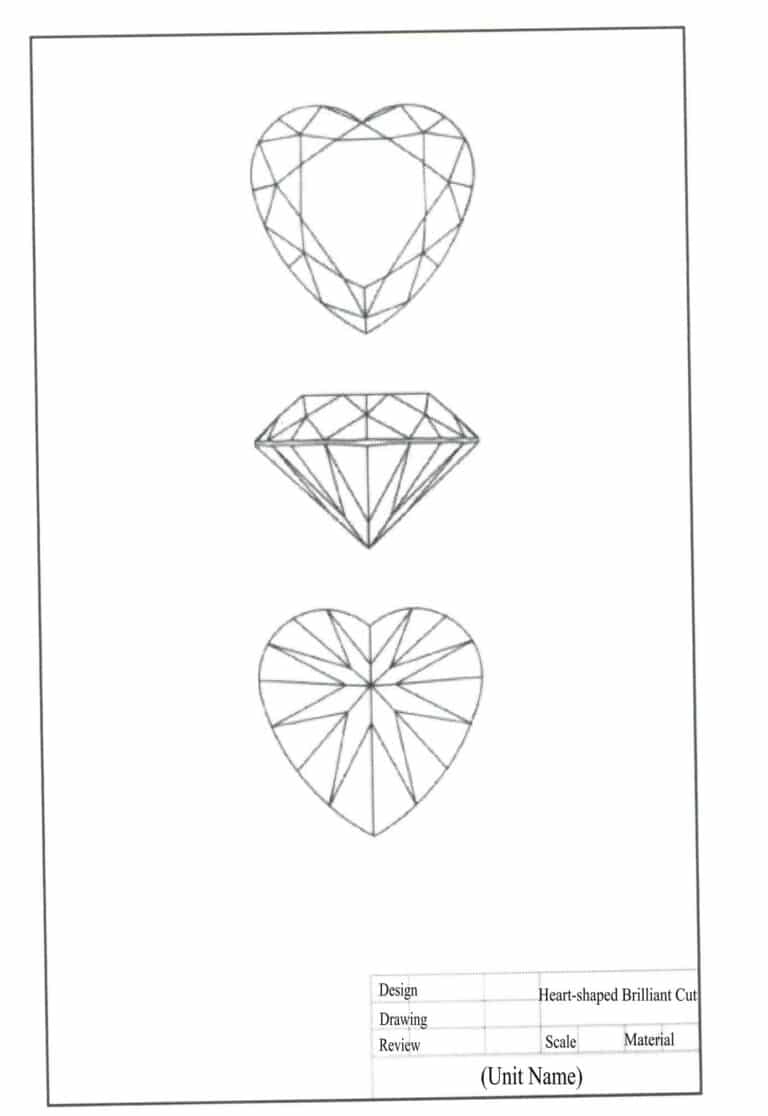

2.4 Produksi menurut gambar pesanan (Gambar 5-5)

3. Proses dan Peralatan Pembentukan Kasar Batu Permata Tunggal

Lingkar pinggang batu permata kasar harus dibentuk dan diukur secara akurat melalui penggilingan, yang membutuhkan proses produksi yang wajar, peralatan yang tepat, dan teknik pemrosesan batu permata yang terampil untuk menghasilkan blanko yang dibentuk secara akurat dan memenuhi standar ukuran.

3.1 Mesin universal umum atau mesin permata biasa untuk pembentukan permata tunggal

Proses pembentukan permata tunggal melibatkan pengikatan potongan segitiga dengan batang besi, membentuknya pada peralatan, dan memeriksa kualitas dan dimensi pembentukan.

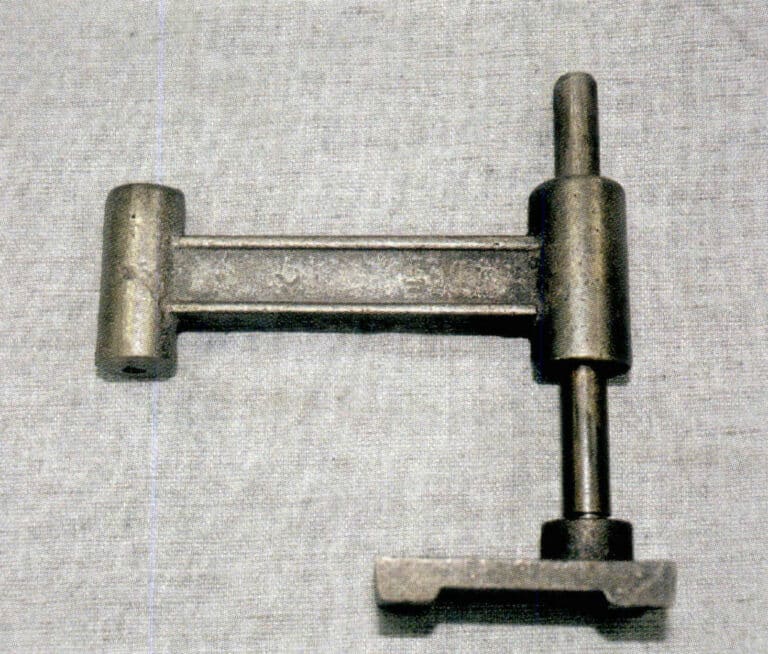

(1) Rekatkan bahan ubin segitiga dengan perekat permata pada batang besi khusus (Gbr. 5-6)

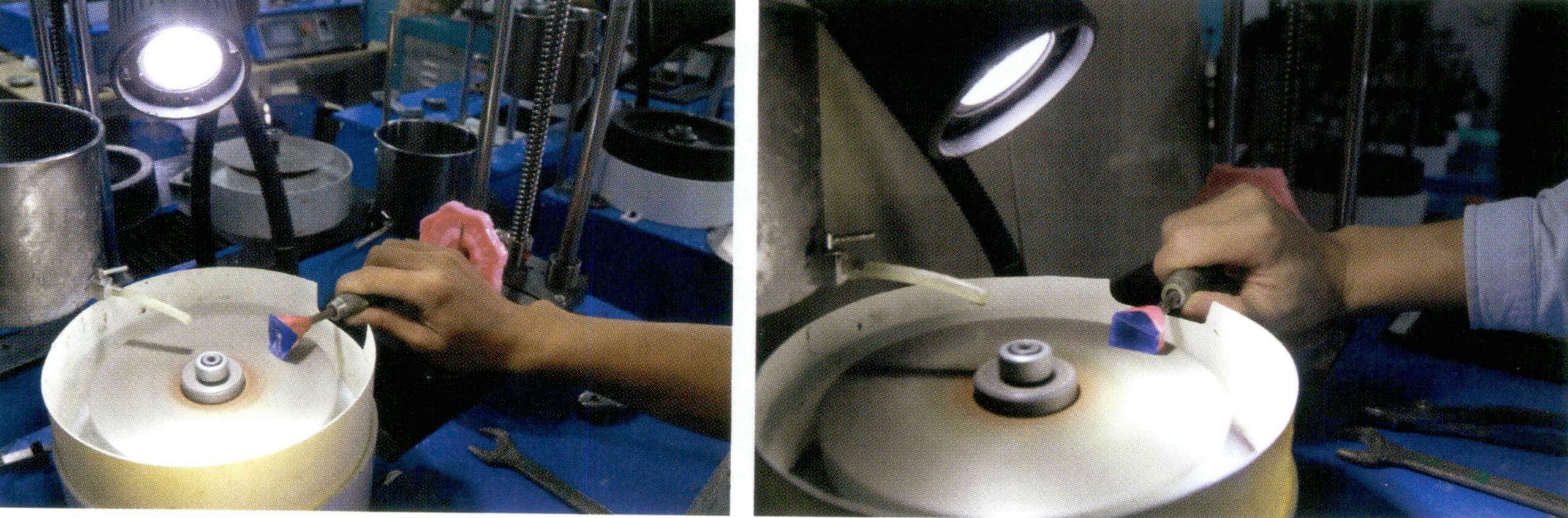

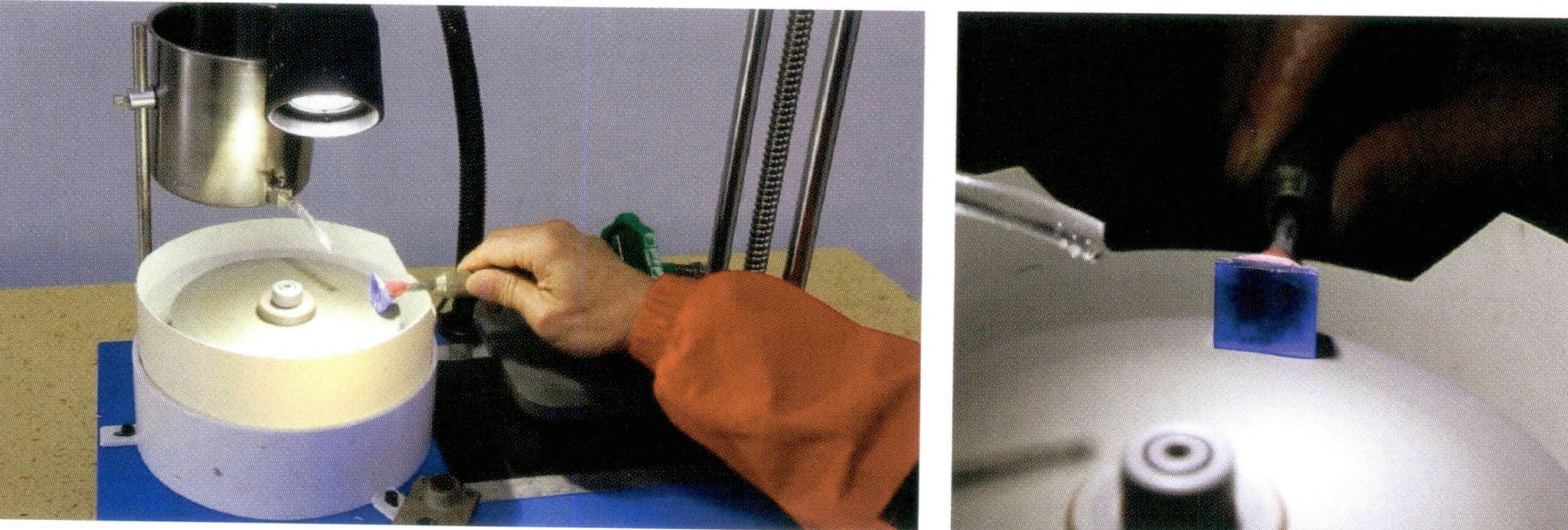

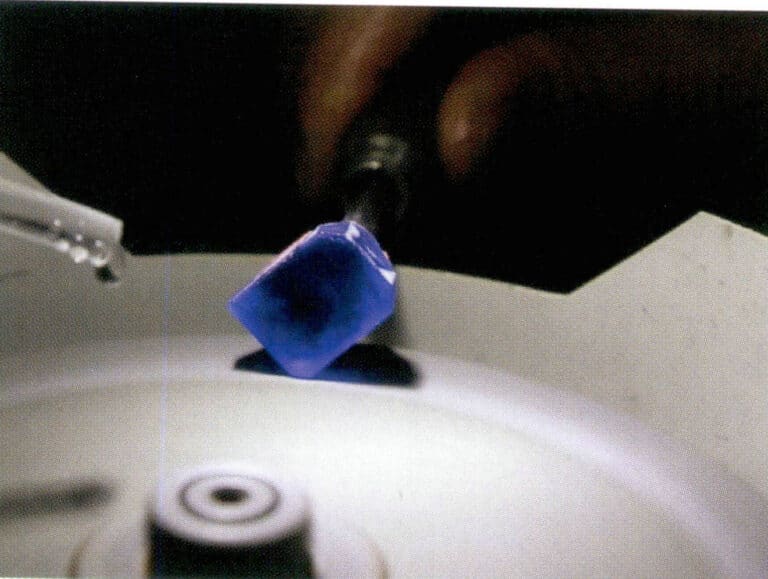

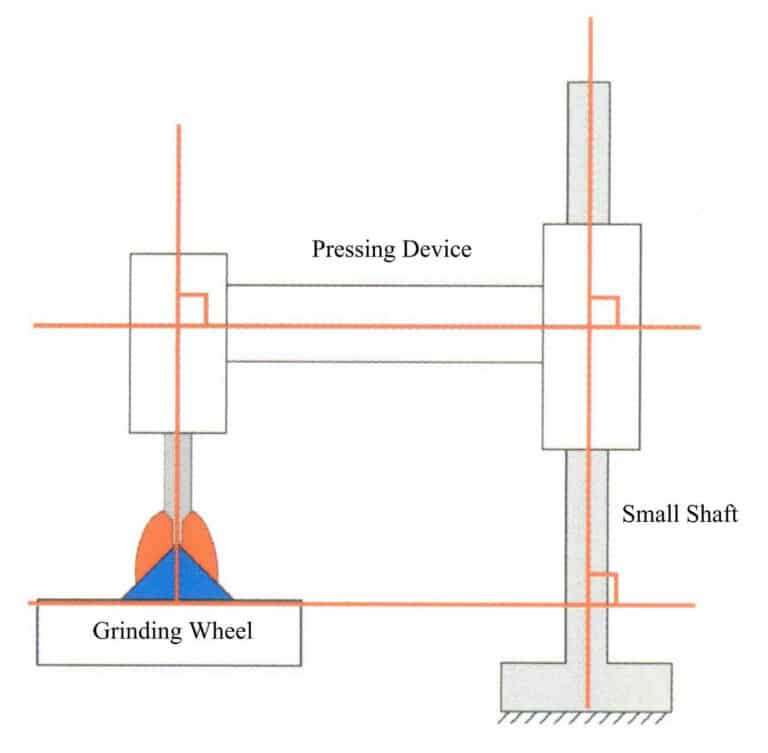

(2) Membentuk pada peralatan

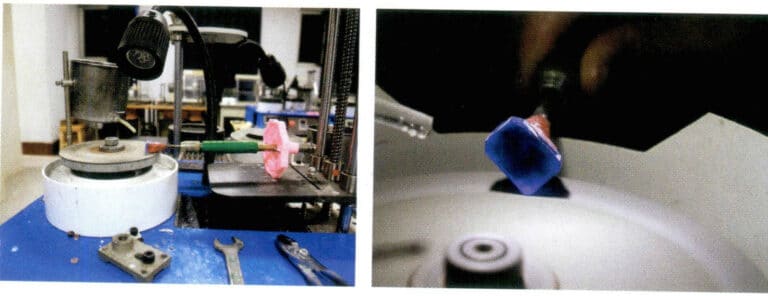

Pembentukan pada mesin universal ditunjukkan pada Gambar 5-7, dan pembentukan pada mesin permata biasa ditunjukkan pada Gambar 5-8.

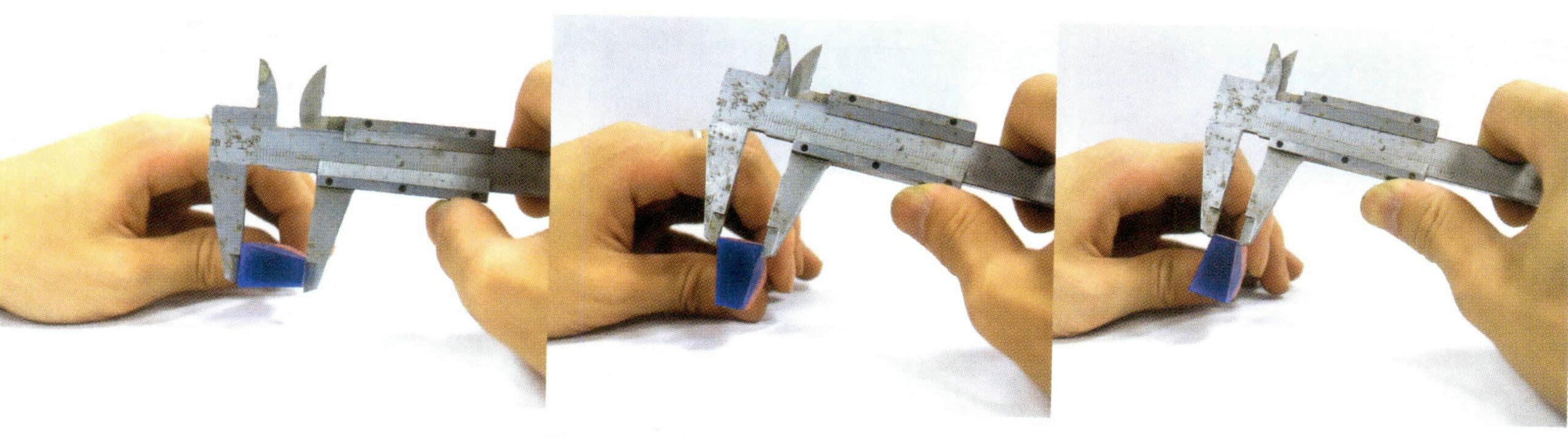

(3) Periksa dimensi pembentukan (Gambar 5-9)

3.2 Peralatan dan Struktur Pembentuk Umum untuk Produksi Batu Permata Tunggal

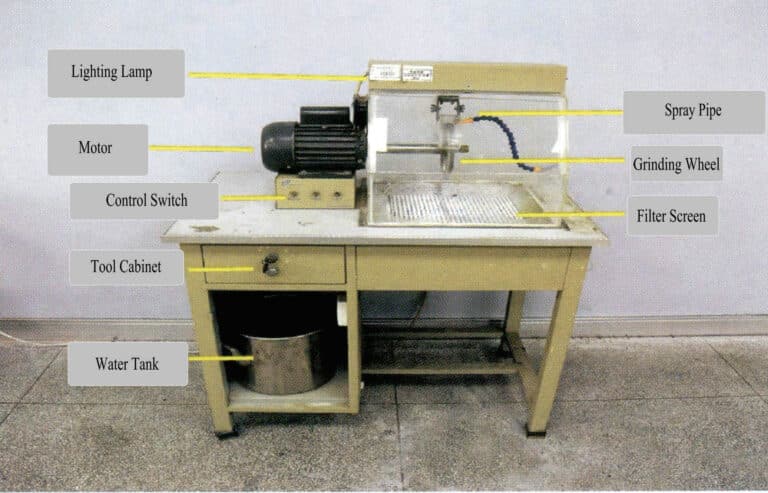

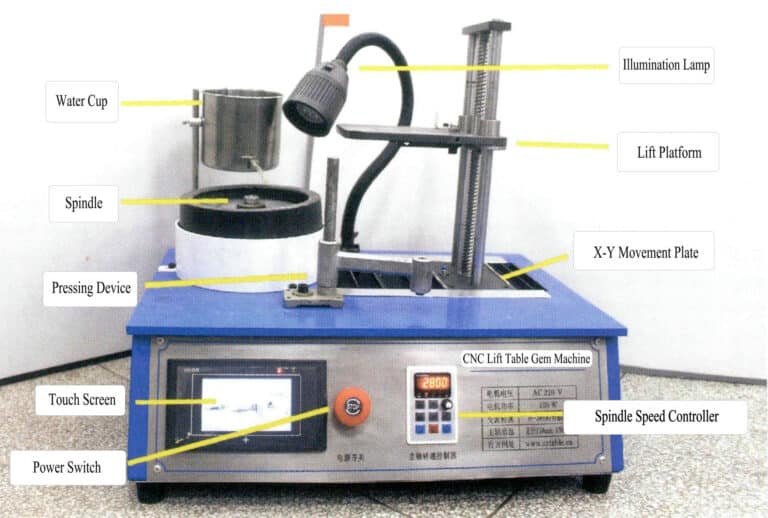

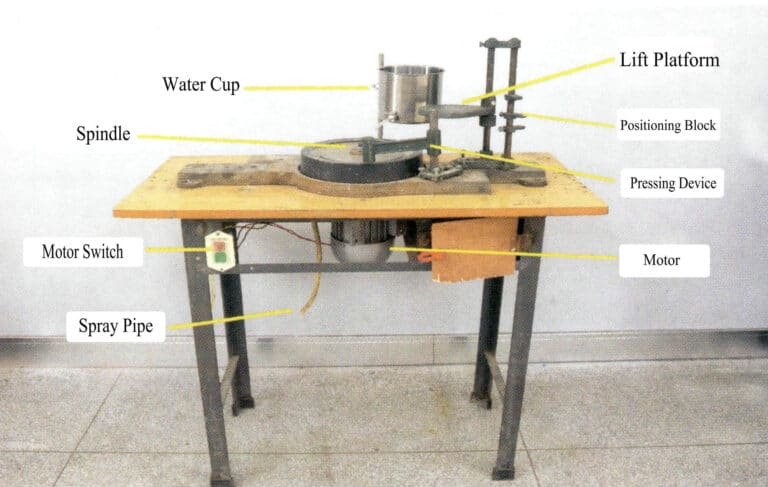

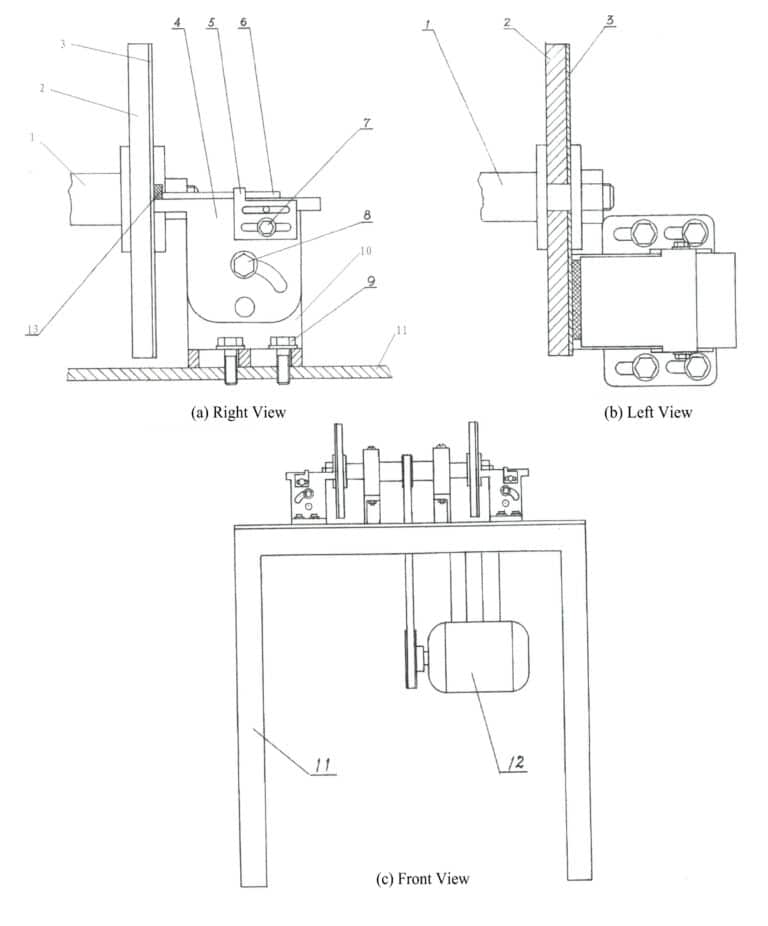

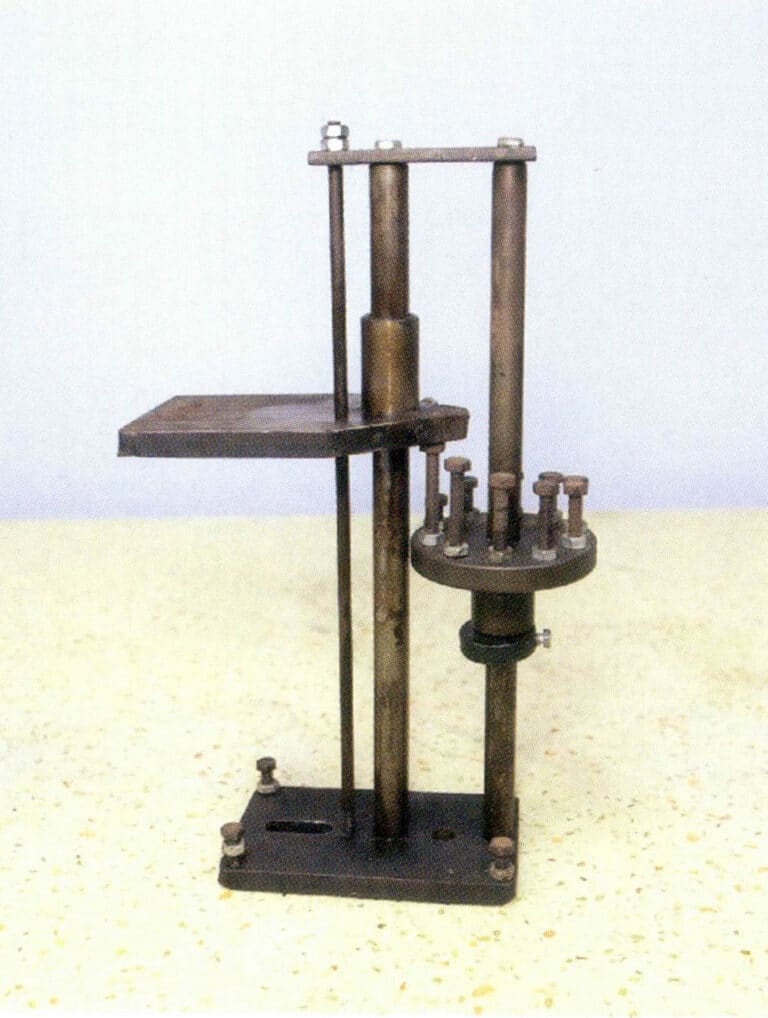

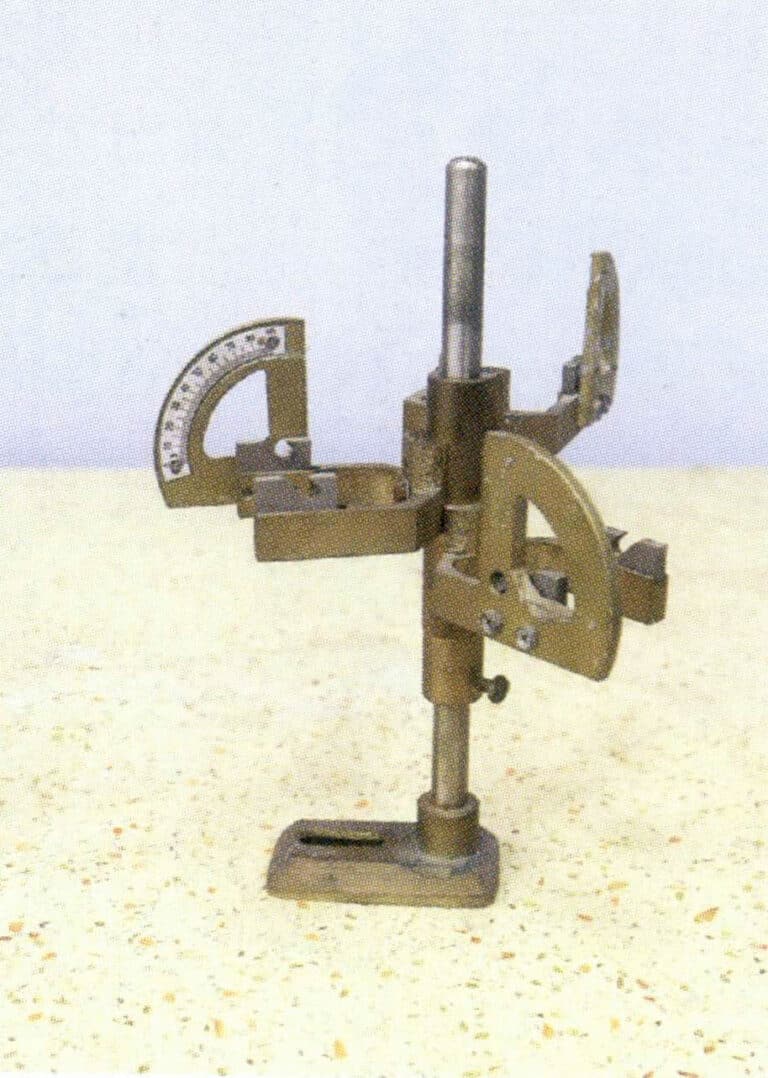

Struktur mesin universal ditunjukkan pada Gambar 5-10, struktur mesin batu permata platform pengangkat CNC ditunjukkan pada Gambar 5-11, dan struktur mesin batu permata biasa ditunjukkan pada Gambar 5-12.

3.3 Fungsi dan Cakupan Aplikasi Mesin Pemoles Permata Universal

Kekuatan mesin pemoles permata universal disediakan oleh motor 250 W ① yang dipasang pada alasnya, dengan kecepatan 1400r/menit. Motor ① memiliki spindel ② yang dipasang pada porosnya, dan roda gerinda ③ dipasang di ujung depan spindel, yang dapat diganti dengan berbagai alat untuk aplikasi spesifik sebagai berikut.

(1) Pembentukan

Ganti dengan roda gerinda yang diperlukan untuk membentuk permata, seperti yang ditunjukkan pada Gambar 5-13.

(2) Pemolesan

Ganti dengan roda pemoles untuk memoles batu permata, seperti yang ditunjukkan pada Gambar 5-14.

(3) Ukiran

Beralih ke alat pahat giok untuk mengukir batu permata, seperti yang ditunjukkan pada Gambar 5-15.

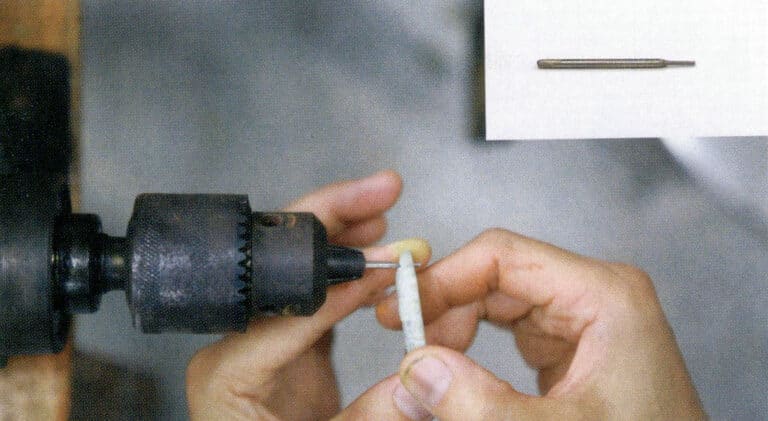

(4) Pengeboran

Beralih ke chuck bor dan alat untuk mengebor batu permata, seperti yang ditunjukkan pada Gambar 5-16.

(5) Mengolah Batu Permata Permukaan Melengkung

Batu permata dengan permukaan melengkung dapat diproses dengan mengubahnya menjadi roda slot, seperti yang ditunjukkan pada Gambar 5-17.

4. Contoh Produksi Kasar Permata yang Umum

4.1 Pengolahan Permata Kasar Permukaan Datar

Batu permata halus (cembung atau melengkung) kasar- Bentuk pinggang batu permata terdiri dari permukaan yang melengkung, seperti bulat, oval, pir, marquise, bentuk hati, dll. Pinggang yang dibentuk oleh permukaan melengkung disebut batu permata permukaan melengkung kasar.

(1) Pengolahan batu permata yang halus menjadi kasar

Tempelkan batu kasar yang sudah dipotong ke batang besi menggunakan lem batu permata. Setelah lem mendingin, bentuklah sesuai dengan metode yang ditunjukkan pada Gambar 5-18 untuk batu permata yang halus (melengkung). Keakuratan bentuk dan ukuran batu kasar sangat bergantung pada tingkat keterampilan seseorang.

Video Pembentukan dan Penyelesaian Batu Permata Cabochon

(2) Pengolahan batu permata kasar berbentuk oval (telur)

Tempelkan potongan kasar ke batang besi menggunakan lem batu permata, dan setelah lem mendingin, ikuti operasi pemrosesan untuk batu permata berbentuk oval (telur) seperti yang ditunjukkan pada Gambar 5-19. Tingkat keterampilan seseorang terutama mengontrol bentuk kasar dan akurasi ukuran.

Video Pembentukan dan Penyelesaian Batu Permata Oval (Berbentuk Telur)

4.2 Proses Pembentukan Kasar Batu Permata Linier

Batu permata bentuk linear yang kasar terdiri dari garis-garis lurus, seperti bentuk zamrud (segi delapan kecil), bujur sangkar, persegi panjang, trapesium, dll. Garis pinggang dari bentuk-bentuk ini disebut batu kasar bentuk batu permata linier.

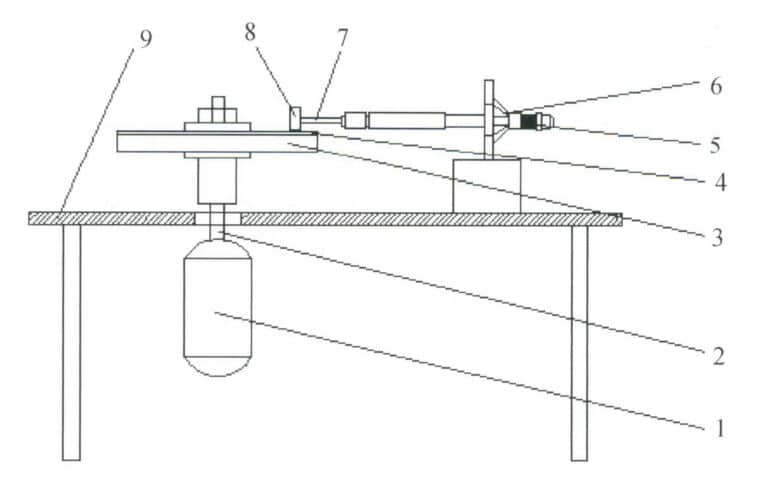

(1) Prinsip Pembentukan Kasar Batu Permata Linier

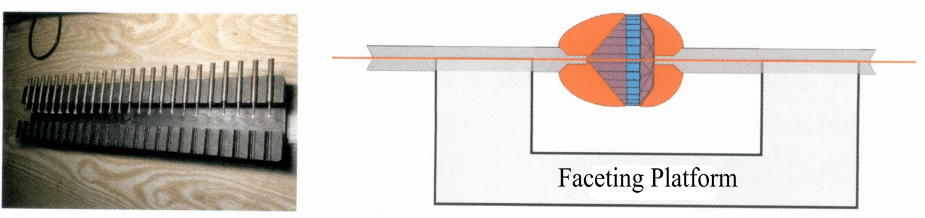

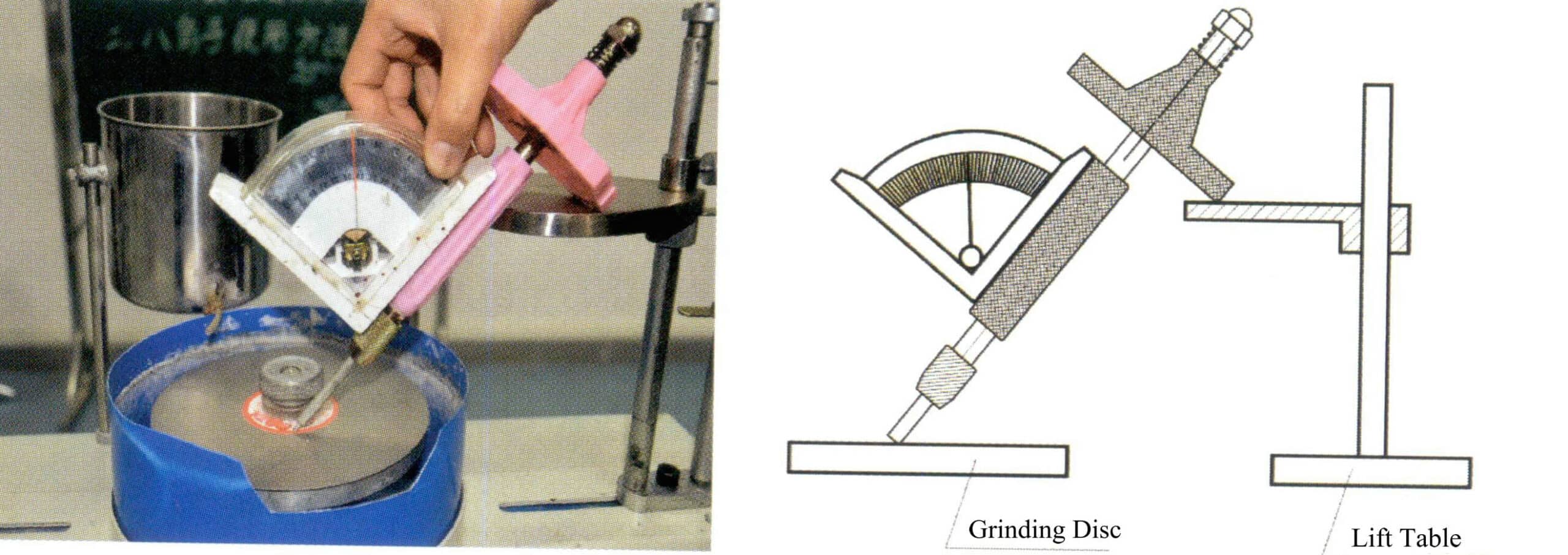

Komposisi peralatan: Dipasang pada alas adalah motor 180 W dengan kecepatan 2800r/menit (1). Motor (1) memiliki spindel dengan kepala (2) yang dipasang di atasnya, kepala (2) memiliki baki (3) dan cakram gerinda (4) yang terpasang, dan ada bantalan tangan delapan persegi paralel (5) pada mesin. Selama operasi, sumbu tangan delapan persegi (6) harus sejajar dengan meja kerja (9) peralatan untuk memastikan paralelisme batu permata yang kasar. Batu permata kasar (8) direkatkan ke batang besi (7) menggunakan perekat batu permata (Gambar 5-20).

1. Motor; 2. Kepala poros; 3. Baki; 4. Cakram pasir; 5. Pengatur jarak; 6. Pegangan delapan persegi; 7. Batang besi; 8. Batu kasar; 9. Meja kerja

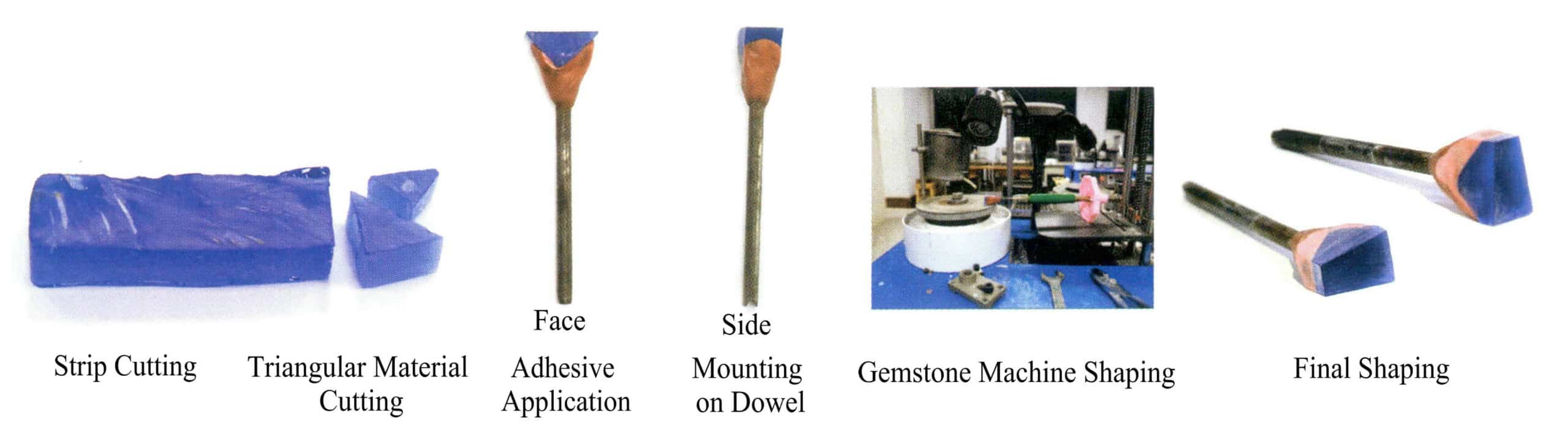

(2) Pemrosesan pembentukan kasar batu permata potong langkah kristal tunggal

Alur pemrosesan: potong strip - potong bahan segitiga - lem - batang atas - pembentukan mesin batu permata - pembentukan lengkap, seperti yang ditunjukkan pada Gambar 5-21.

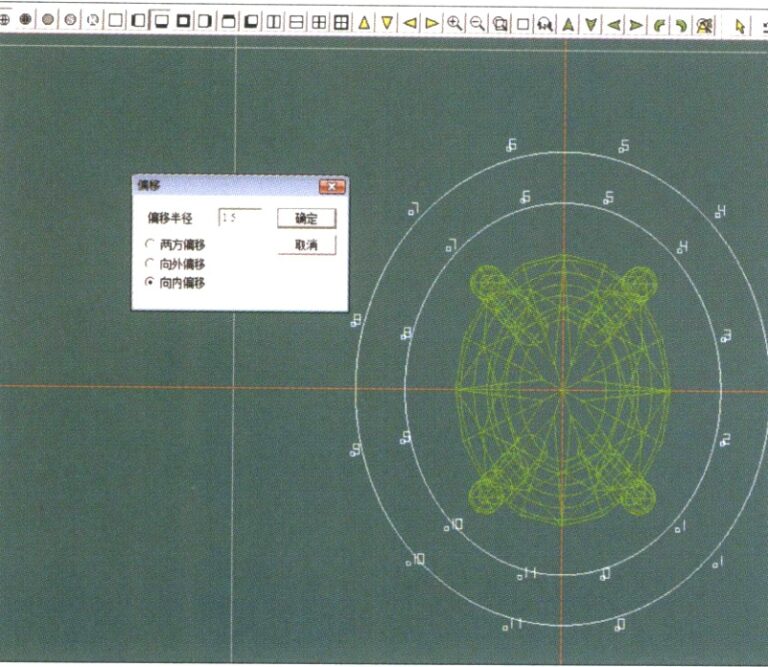

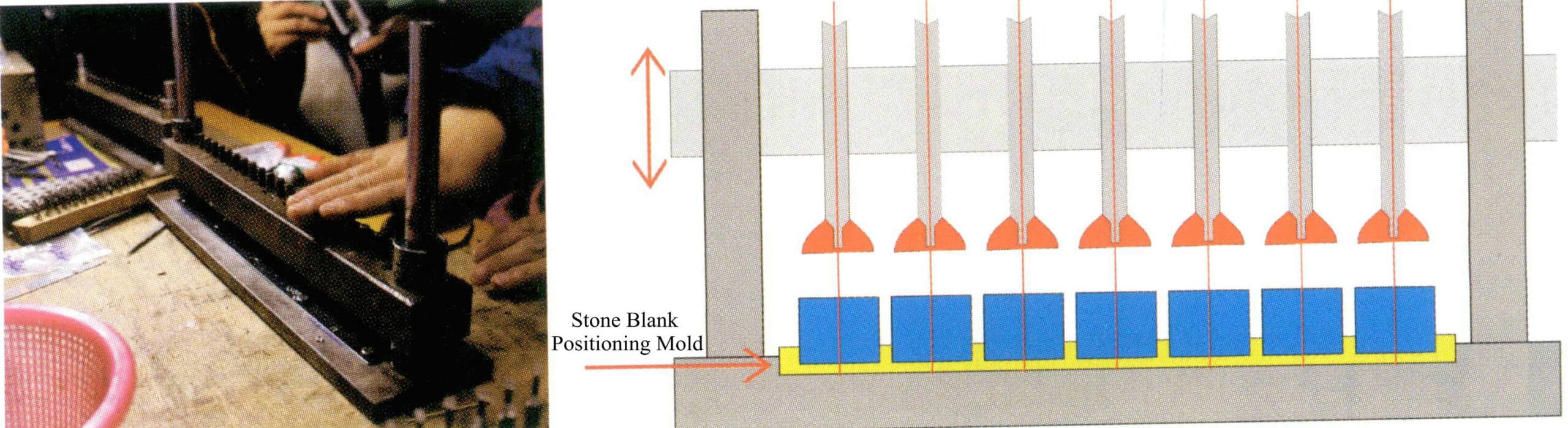

Operasi pembentukan batu permata dengan mesin CNC ditunjukkan pada Gambar 5-22.

(3) Pemrosesan pembentukan batu permata jenis garis paralel sudut kanan persegi kristal tunggal yang kasar

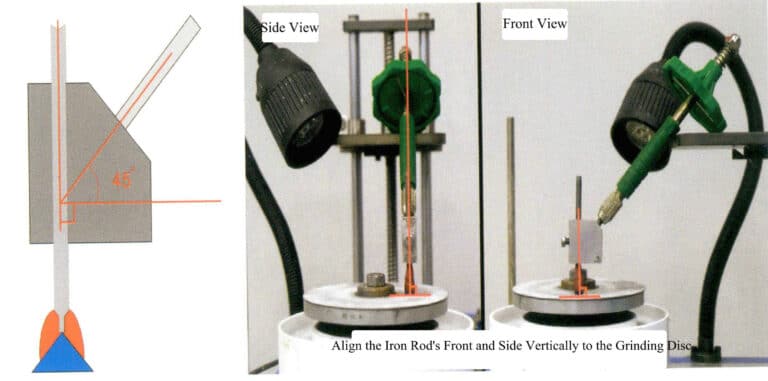

Masukkan batang besi dengan batu permata kasar ke dalam pemegang segi delapan, sesuaikan sudut meja kerja sehingga pemegang segi delapan sejajar dengan piringan gerinda mesin gerinda, nyalakan sakelar motor, nyalakan sakelar air pendingin (ukuran blanko menentukan besar aliran air), pegang pemegang segi delapan dengan tangan kanan, letakkan pegangan segi delapan di atas meja kerja, dan letakkan batu permata di atas piringan gerinda (Gbr. 5-23).

(4) Proses Penggerindaan Zamrud Tunggal (Bevel Persegi Panjang) (Gambar 5-24)

Video Pembentukan dan Penyelesaian Batu Permata Potongan Zamrud (Miring Persegi Panjang)

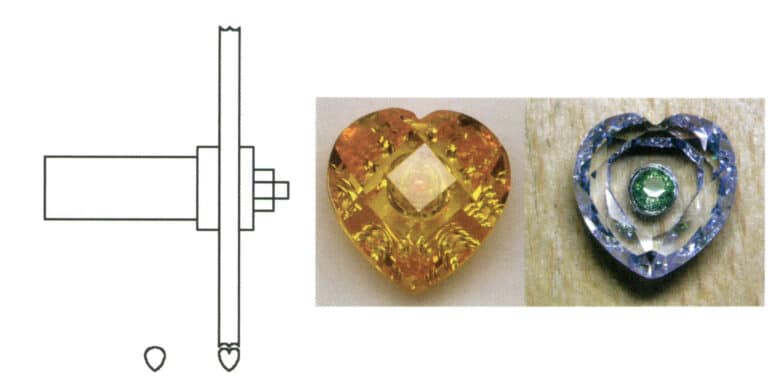

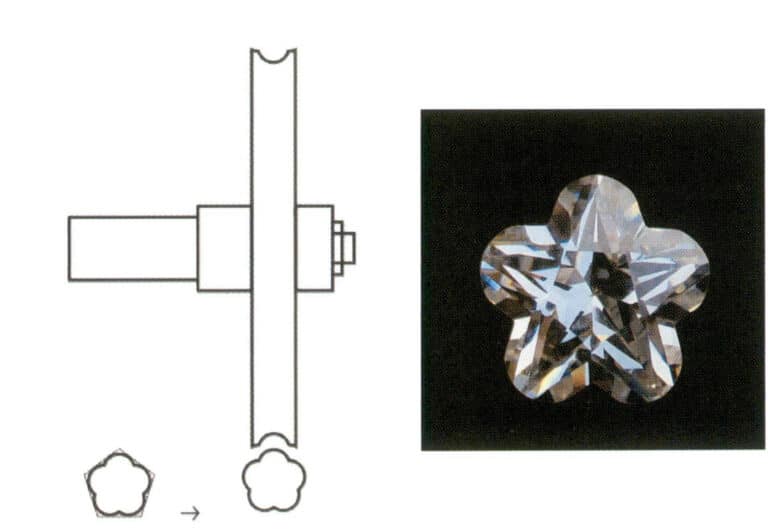

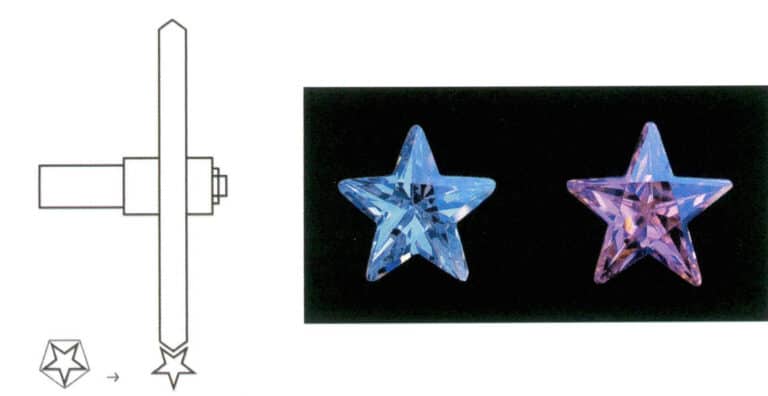

4.3 Proses Pembentukan untuk Batu Permata Kasar Berbentuk Khusus

Selain batu kasar yang disebutkan di atas, jika lubang muncul di bagian tertentu dari batu kasar, itu dianggap sebagai jenis buruk berbentuk khusus. Batu permata berbentuk khusus ini kasar dalam bentuk hati, bentuk bunga plum, bentuk pentagram, dll., memiliki lubang yang diproses berdasarkan bentuk luarnya, dan harus menggunakan mesin pelubang batu untuk membentuknya.

(1) Prinsip Pembentukan Batu Permata Kasar Berbentuk Hati (Gambar 5-25)

(2) Prinsip Pembentukan Permata Kasar Bunga Plum (Gambar 5-26)

(3) Prinsip Pembentukan Permata Pentagram Kasar (Gambar 5-27)

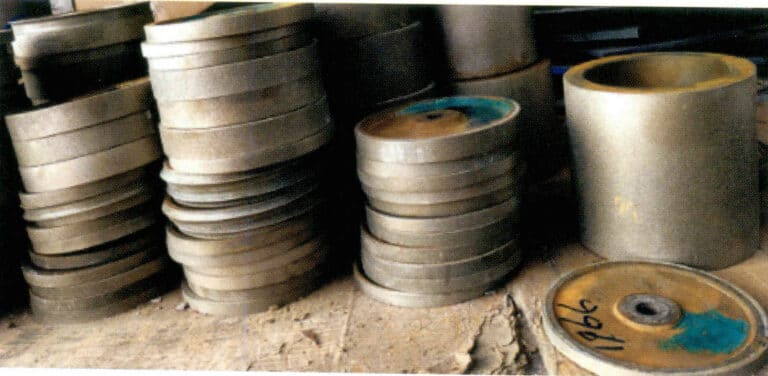

5. Peralatan untuk Produksi Massal Cacat Permata

5.1 Peralatan pembentukan semi-otomatis

(1) Struktur dan prinsip kerja mesin pembentuk semi-otomatis

Membentuk batu permata kasar dalam produksi batch menggunakan peralatan yang ditunjukkan pada Gambar 5-28. Roda gerinda digerakkan oleh sebuah sabuk yang menyalurkan daya ke kepala spindel. Roda gerinda dipasang pada kepala spindel, dan satu set alat pemutar untuk batu kasar juga dipasang pada rangka. Dengan menggerakkan cetakan, berbagai bentuk blanko yang berbeda dapat dihasilkan. Keakuratan bentuk dan ukuran batu kosong ditentukan oleh ketepatan cetakan dan penyetelan roda tangan.

1. Motor; 2. Katrol besar; 3. Katrol kecil; 4. Spindel; 5. Roda gerinda berlian; 6. Permata kosong; 7. Pin atas tetap; 8. Pin atas yang dapat digerakkan; 9. Sproket; 10. Motor reduksi; 11. Sproket motor reduksi; 12. Cetakan permata; 13. Batang penyetel cetakan; 14. Roda tangan; 15. Roda gigi; 16. Roda gigi Poros sproket

Prinsip kerja peralatan: Hubungkan catu daya untuk menghidupkan motor (1), yang menggerakkan katrol segitiga besar (2) yang dipasang pada poros motor (1), yang mengarah ke rotasi katrol segitiga spindel (3) dan roda gerinda berlian yang dipasang di ujung spindel yang lain. Cetakan batu permata (12) dipasang di salah satu ujung pin ejektor tetap (7), sedangkan ujung lainnya menekan batu permata kasar (6). Ujung lain dari batu permata kasar (6) dilengkapi dengan pin ejektor yang dapat digerakkan (8), yang mengencangkan batu permata kosong (6) di bawah aksi roda tangan (14). Motor reduksi (10) menggerakkan tiga sprocket yang dipasang pada poros rantai (15) untuk berputar. Sprocket di kedua ujung poros rantai (15) menggerakkan pin ejektor yang dapat digerakkan dan tetap untuk berputar, menyelesaikan proses pembentukan batu. Tuas penyetelan cetakan menyesuaikan ukuran batu kosong.

Mesin pembentuk semi-otomatis dapat membentuk bentuk bulat, dan dengan memasang berbagai jenis roda pembentuk profil, mesin ini dapat memproses berbagai bentuk permata, lensa kaca, dll., dengan dimensi yang seragam dan presisi tinggi. Itu juga dapat memproses berbagai liontin yang tidak beraturan, seperti berbentuk hati, bulat, oval, berbentuk daun, segi delapan, segitiga, berbentuk labu, berbentuk tetesan air, berbentuk lentera, dll.

Kerugian dari mesin pembentuk semi-otomatis adalah, mesin ini memerlukan penjepitan blanko secara manual dan kemudian menurunkan batang tarik secara manual untuk menyelesaikan siklus proses.

5.2 Peralatan pembentukan yang sepenuhnya otomatis

Peralatan pembentuk sepenuhnya otomatis menggunakan peralatan pembentuk semi-otomatis sebagai mesin utama, menambahkan mekanisme penjepitan dan pelepasan batu kasar secara otomatis dan perangkat pengumpanan otomatis untuk membentuk peralatan pembentuk sepenuhnya otomatis.

5.3 Peralatan pembentuk khusus untuk persegi, persegi panjang, dan trapesium

Peralatan pembentukan cepat cetakan kasar batu permata buatan trapesium memiliki struktur sederhana, presisi tinggi, dapat diproduksi secara massal, memiliki kapasitas produksi tinggi, proses operasional sederhana, biaya produksi rendah, investasi minimal, dan pengembalian tinggi. Pekerja dapat mulai beroperasi setelah hanya satu hari pelatihan. Jika jalur produksi diatur secara ilmiah, dengan 2 orang untuk mengiris, 2 untuk membentuk, dan 1 untuk melepas perekat, total 5 orang dapat mencapai hasil harian rata-rata lebih dari 10.000 lembar per pekerja setelah periode pengenalan. Ini adalah peralatan pemrosesan untuk cetakan kasar batu permata trapesium yang "output tinggi, produksi cepat, kualitas bagus, dan hemat bahan."

Peralatan produksi ditunjukkan pada Gambar 5-29.

1. Spindel; 2. Baki Aluminium; 3. Cakram Gerinda Berlian; 4. Kepala Ayun Meja Kerja; 5. Modul Batas; 6. Templat; 7. Sekrup Penyetel; 8. Sekrup Penyetel Berputar; 9. Sekrup Penyetel Meja Kerja; 10. Meja Kerja; 11. Rangka; 12. Motor

6. Contoh Peralatan Produksi Kasar Batu Permata Perusahaan

Produksi massal batu permata kasar biasanya digunakan dalam produksi batu permata buatan, seperti pada peralatan pemotongan dan pembentukan zirkonia kubik sintetis. Tidak ada perangkat standar yang ada di pasaran; semua peralatan dirancang dan diproduksi berdasarkan proses produksi. Meskipun beberapa bagian dari peralatan ini mungkin berbeda, namun prinsip-prinsip pengoperasiannya sama. Berikut ini akan diilustrasikan dengan contoh-contoh pabrik.

6.1 Produksi Batu Kasar Trapesium

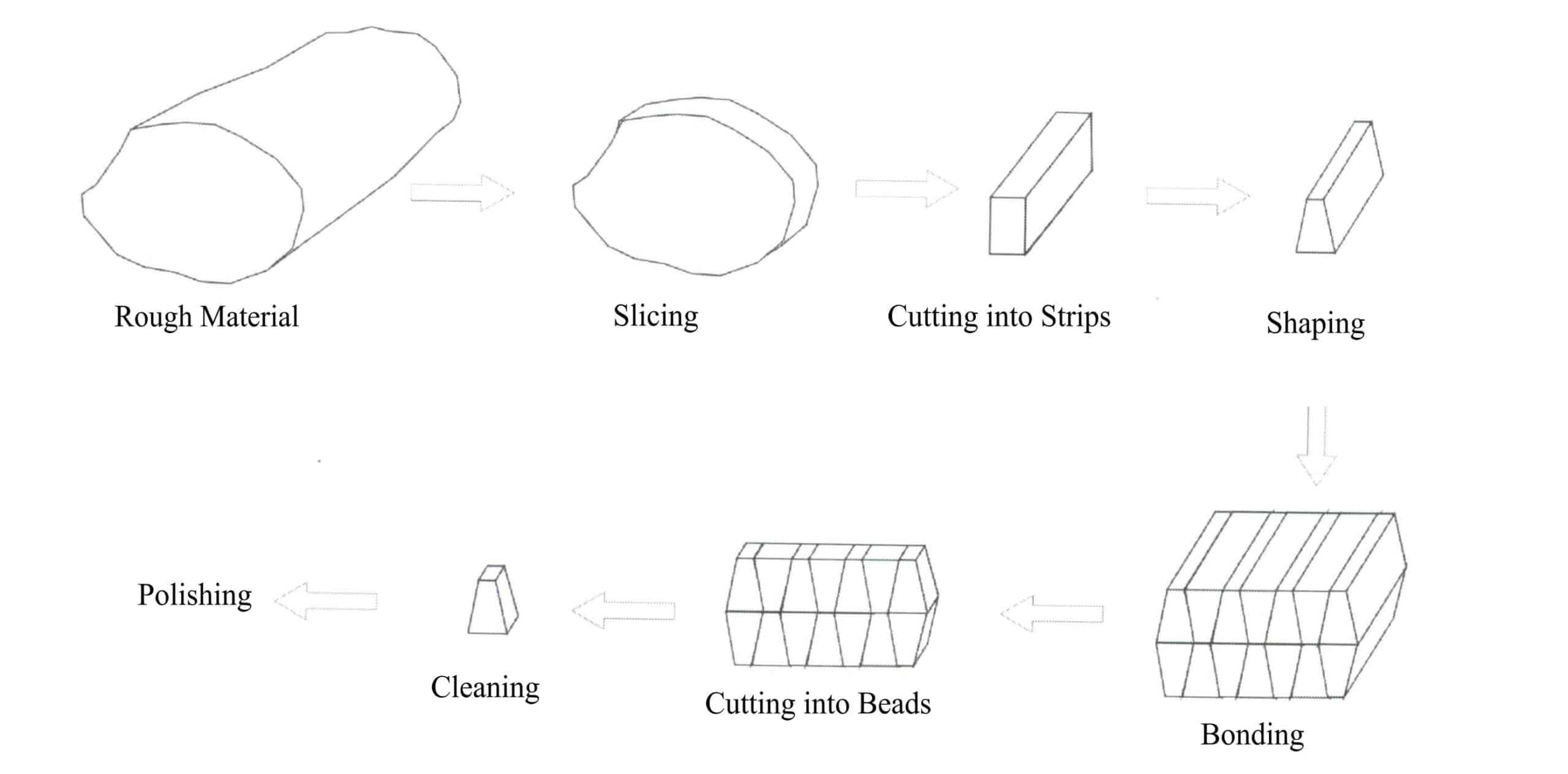

Proses produksi batu permata buatan berbentuk trapesium kasar adalah sebagai berikut (Gambar 5-30).

- Jepit bahan mentah dalam mesin pemotong multi-pisau untuk mengiris.

- Letakkan bahan yang sudah diiris di atas meja kerja mesin pemotong pisau tunggal untuk dipotong-potong.

- Tempatkan potongan potongan pada mesin cetak untuk dibentuk.

- Susun strip yang memenuhi syarat menurut diagram dan rekatkan dengan lem 502.

- Setelah menunggu lem 502 mengering, letakkan bahan blok berikat pada mesin pemotong batu pisau tunggal untuk memotongnya menjadi butiran.

- Bersihkan lem 502.

- Pemolesan getaran buruk batu permata yang kasar.

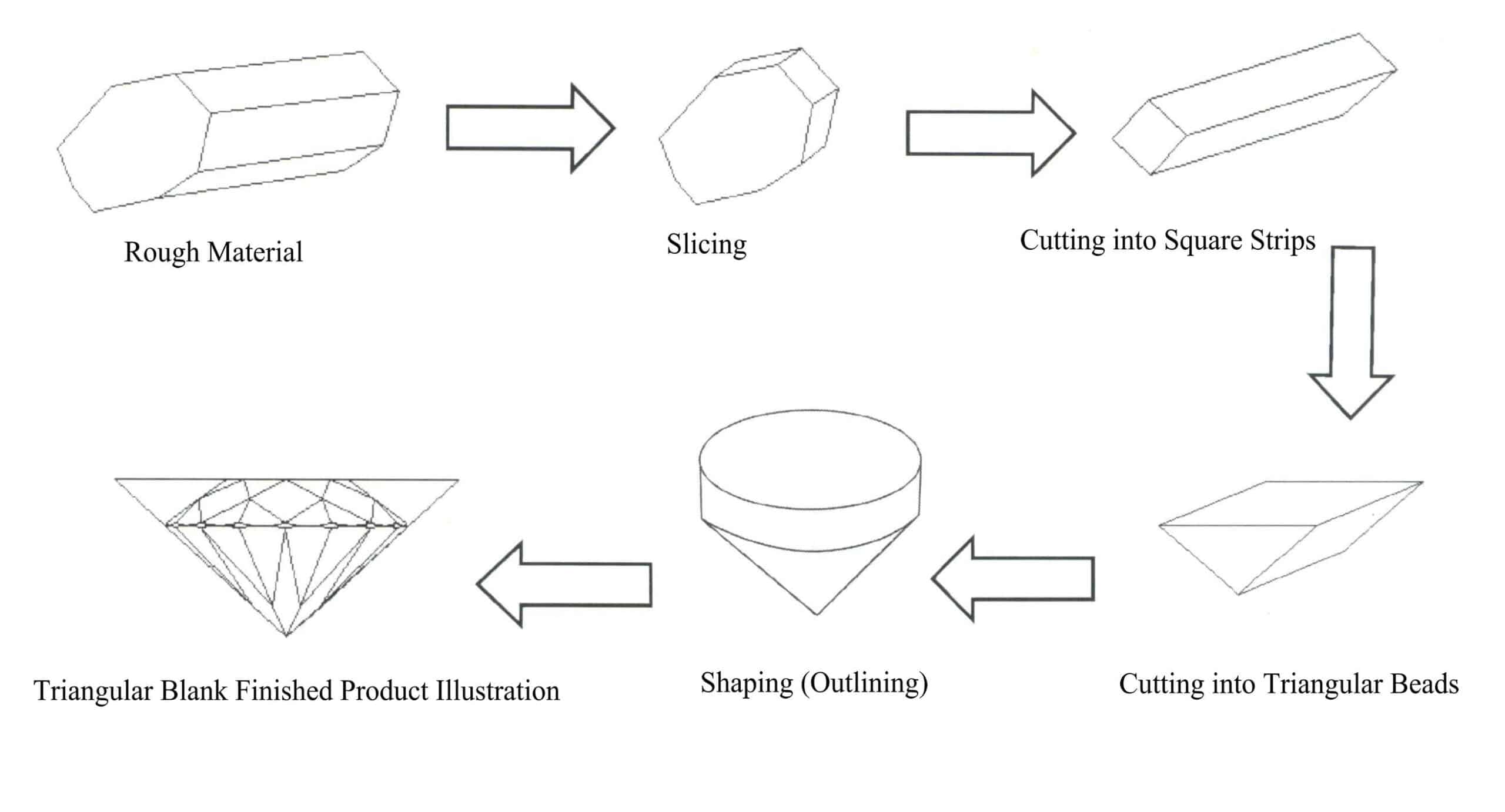

6.2 Produksi ubin segitiga

Proses produksi ubin segitiga ditunjukkan pada Gambar 5-31.

6.3 Produksi silinder kosong

Proses produksi silinder kosong ditunjukkan pada Gambar 5-32.

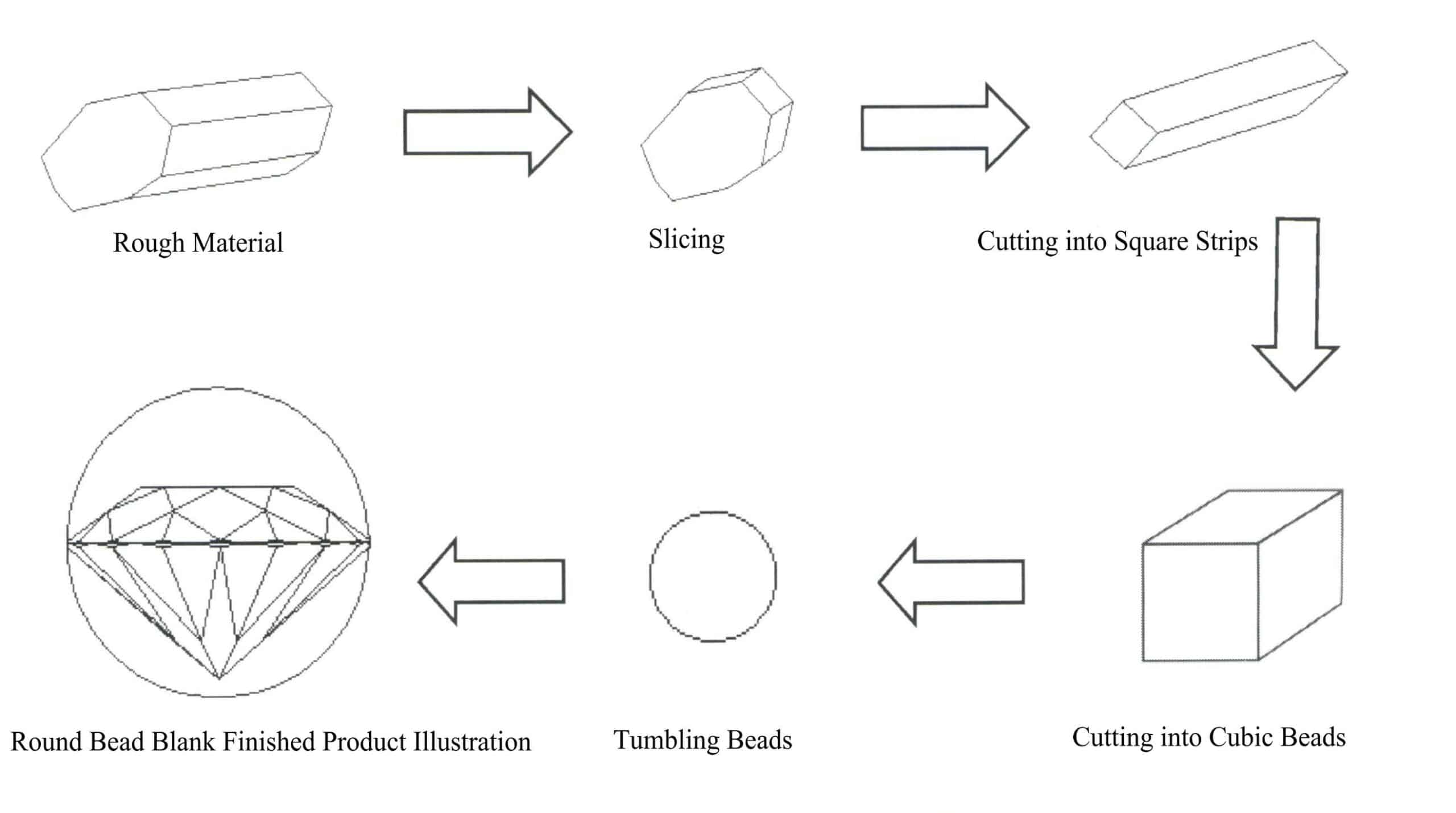

6.4 Produksi manik-manik bulat kosong

Proses produksi manik-manik bulat ditunjukkan pada Gambar 5-33.

7. Akuntansi biaya untuk produksi kasar batu permata

7.1 Perbandingan tiga jenis batu kasar yang umum digunakan di pasar

Ubin segitiga: mengiris - memotong strip - memotong partikel segitiga - bentuk sekeliling - batu kasar

Silinder kosong: iris, potong-potong, giling menjadi potongan-potongan bulat, potong menjadi partikel silinder

Manik-manik bulat kosong: iris - potong-potong - potong partikel kubik - talang dan sarang manik-manik bulat

7.2 Perbandingan input peralatan untuk dua atau tiga jenis batu kasar (Tabel 5-1)

Tabel 5-1 Ikhtisar perbandingan input peralatan untuk tiga jenis umum batu kasar

| Parison | Alat pengiris pemotong tunggal | Mesin potong dadu multitool | Mesin Pemotong Kontur | Mesin faceting | Mesin Penggiling Batang Bulat Tanpa Pusat | Granulator strip pemotongan multi-pisau | Mesin manik-manik bersarang |

|---|---|---|---|---|---|---|---|

| Ubin segitiga | √ | √ | |||||

| Silinder kosong | √ | √ | √ | ||||

| Manik-manik bundar kosong | √ | √ | √ | √ |

7.3 Analisis Efisiensi Produksi untuk Tiga Jenis Batu Kasar

Mengambil Bentuk Bulat 2 mm sebagai Contoh

| Segitiga Kosong | 2 Orang | 2000 Potongan / Hari | 10 jam, rata-rata 1.000 lembar/orang |

| Silinder kosong | 4 orang | 100.000 lembar/hari | 10 jam, rata-rata 2.500 lembar/orang |

| Silinder kosong | 4 orang | 200.000 lembar/hari | 10 jam, rata-rata 50.000 lembar/orang |

7.4 Tingkat ekstraksi dan biaya bahan baku dari tiga batu kasar

(1) Tabel tingkat ekstraksi per kilogram bahan baku (Tabel 5-2).

Tabel 5-2 Tingkat ekstraksi per kilogram batu kasars

| Nama | Spesifikasi (mm) | |||

| 1.5 | 2 | 2.5 | 3 | |

| Ubin segitiga | 30000 | 14000 | 8000 | 4000 |

| Silinder kosong | 16500 | 7700 | 4400 | 2200 |

| Manik-manik bulat kosong | 15000 | 7000 | 4000 | 2000 |

(2) Biaya material untuk setiap cacat batu ditunjukkan pada Tabel 5-3 (berdasarkan harga timbal oksida A + B di Wuzhou, Guangxi, 200 yuan /kg, Desember 2012).

Tabel 5-3 Ikhtisar tingkat ekstraksi setiap batu kasar

| Nama | Spesifikasi (mm) | |||

| 1.5 | 2 | 2.5 | 3 | |

| Ubin segitiga | 0.0067 | 0.0143 | 0.025 | 0.05 |

| Silinder kosong | 0.012 | 0.026 | 0.045 | 0.091 |

| Manik-manik bulat kosong | 0.013 | 0.029 | 0.05 | 0.10 |

7.5 Persyaratan kasar dan ukuran batu permata

- Diameter batu permata D harus menyisakan kelonggaran pemrosesan untuk memoles garis pinggang.

- Meja batu permata harus menyisakan ruang pemrosesan untuk penggilingan dan pemolesan.

- Tinggi total batu kasar harus lebih besar dari tinggi total produk.

- Ketinggian mahkota di atas garis pinggang batu kasar harus lebih besar daripada ketinggian mahkota di atas garis pinggang produk (Gambar 5-34).

Bagian II Perlekatan bahan kasar batu permata ke batang

1. Bahan umum untuk mengikat batu permata yang kasar ke batang

Mesin batu permata biasa digunakan untuk menggiling batu permata tunggal bersama dengan pemegang segi delapan atau peralatan mesin. Karena beragamnya spesifikasi dan bentuk batu permata, batu permata yang cacat diikat ke batang besi dengan lem batu permata sebelum diproses. Mereka kemudian ditempatkan ke dalam pemegang segi delapan atau peralatan mesin untuk memproses dan menggiling batu permata sesuai dengan persyaratan operasional. Setelah digiling, batu permata dilepaskan dari batang besi dan lem, dan sisa lem serta noda minyak dibersihkan.

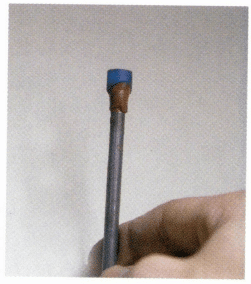

Setelah batu permata kasar melewati pemeriksaan, batu kosong diikat ke batang besi khusus sebelum memasuki proses selanjutnya. Kualitas ikatan permata memengaruhi kualitas ukiran permata, pemolesan, dan efisiensi pemrosesan.

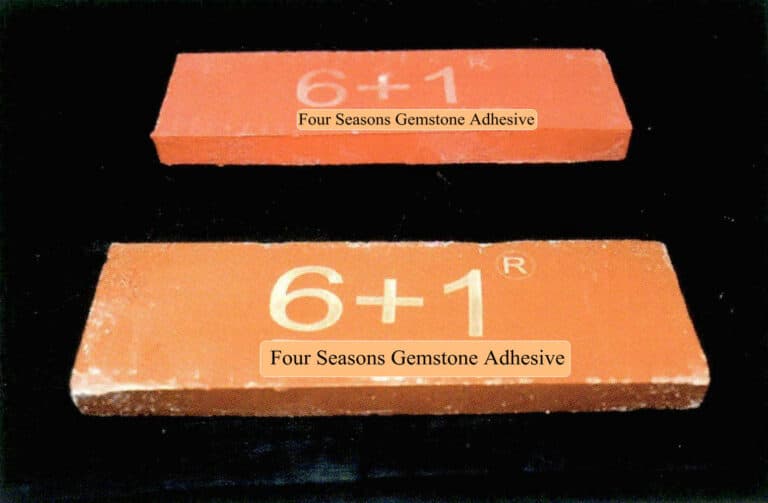

1.1 Perekat permata yang dapat digunakan kembali

Setelah pemrosesan permata selesai, permata dilepaskan dari batang besi. Perekat permata yang tertinggal di batang besi masih dapat merekatkan permata, dan sisa perekat permata juga dapat dilelehkan dan digunakan kembali. Perekat permata jenis ini disebut perekat permata yang dapat digunakan kembali, asalkan tidak terbakar, berasap, atau berkarbonisasi dan kehilangan kinerjanya selama pemanasan (Gambar 6-1).

(1) Bahan yang digunakan untuk pengikatan permata harus memenuhi persyaratan dasar berikut ini.

- Ini harus memiliki kemampuan ikatan, kekuatan, dan kekerasan yang memadai dan tidak boleh pecah atau bergeser selama pengukiran dan pemrosesan normal.

- Titik leleh tidak boleh lebih rendah dari 70℃ dan lebih tinggi dari suhu yang dihasilkan selama pemotongan, penggerindaan, dan pemolesan.

- Penggunaan perekat batu permata secara berulang-ulang akan mempertahankan kinerjanya setelah beberapa kali pemanasan.

- Produk ini harus larut dengan baik dalam pelarut organik dan anorganik, tetapi tidak boleh larut dalam minyak tanah dan oli mesin.

- Seharusnya tidak mahal dan tidak langka.

(2) Bahan perekat batu permata yang dapat digunakan kembali

- Lak (Gambar 6-2). 80°C Melunak, 113°C mencair, 165°C mulai melepaskan gas dengan kuat, menjadi zat seperti spons yang longgar, 210°C berkarbonisasi dan kehilangan kemampuan rekat, suhu optimal untuk lak adalah 85-105°C, larut dalam alkohol.

- Rosin (Gambar 6-3). Suhu pelunakan 50-70°C, 90-130°C meleleh sepenuhnya, memiliki kemampuan rekat yang lebih tinggi dan kekuatan yang memadai, serta mudah larut dalam alkohol, eter, aseton, terpentin, dan pelarut lainnya.

- Lilin penyegel. Terdiri dari damar dan oksida besi bermutu rendah, 100℃ melembutkan sekitar, lebih keras daripada lak dan damar, dengan kekuatan yang lebih tinggi, dan larut dalam alkohol, eter, aseton, terpentin, dan pelarut lainnya.

- Bubuk lem permata. Lem permata dihancurkan menjadi bubuk, dan bubuk lem permata umumnya digunakan dalam perekatan batu otomatis (Gambar 6-4).

Gambar 6-2 Lak

Gambar 6-3 Rosin

Gambar 6-4 Bubuk lem permata

(3) Prinsip-prinsip Pemilihan Bahan Perekat Permata

Apabila memilih bahan perekat, pertimbangan harus mencakup bentuk dan ukuran benda kerja, presisi, suhu pemrosesan, dan panas yang dihasilkan selama pemrosesan. Semakin besar gaya pada benda kerja dan semakin kecil areanya, maka, semakin tinggi kekuatan perekat yang harus dipilih. Lak terutama berfungsi sebagai perekat, sedangkan lilin penyegel dan damar memiliki sifat perekat dan meningkatkan sifat mekanis bahan perekat. Perekat dengan proporsi lilin penyegel yang tinggi lebih lembut dan memiliki ketahanan panas yang buruk, sedangkan perekat dengan proporsi damar yang tinggi lebih keras dan lebih rapuh.

(4) Formulasi Perekat Permata

Persyaratan formulasi: Pertimbangkan panas yang dihasilkan selama penggilingan dan variasi musiman saat memformulasikan.

Rumusannya adalah sebagai berikut:

- 95% Lilin penyegel + 5% Lak.

- 80% Rosin + 20% Shellac.

Warna perekat permata yang tersedia secara komersial tidak terkait dengan kinerja ikatannya dan terkait dengan warna permata yang diproses. Perekat ini harus dipilih dengan warna yang kontras dengan warna permata; misalnya, permata merah harus menggunakan lem permata putih atau hijau (Gambar 6-5).

1.2 Perekat permata sekali pakai

Perekat permata yang tidak dapat didaur ulang untuk digunakan kembali setelah pemrosesan permata selesai disebut perekat permata yang tidak dapat didaur ulang. Sebagai contoh, lem 502 dapat merekatkan permata dengan baik tetapi tidak dapat didaur ulang untuk digunakan kembali.

Saat ini, pasar memproduksi perekat permata sekali pakai khusus untuk ikatan permata, termasuk varietas seperti lem yang cepat kering, peka terhadap cahaya, dan lem AB. Perekat ini transparan dan memiliki daya rekat yang kuat, kecepatan rekat yang cepat, dan efisiensi yang tinggi. Mengambil limbah permata 2 mm sebagai contoh, satu orang yang bekerja 8 jam sehari dapat merekatkan lebih dari 12.000 keping, dan satu kilogram lem dapat merekatkan 400.000 hingga 200.000 keping limbah permata.

(1) Perekat fotosensitif (Gambar 6-6)

Metode pengikatan: Masukkan batang besi ke dalam papan sisipan khusus, gunakan ujung runcing dari tutup botol untuk langsung mengoleskan perekat ke ujung batang besi, dan gunakan pinset untuk meletakkan batu permata kosong di ujung batang besi yang dilapisi perekat dan ratakan. Gunakan lampu UV untuk menyinari selama 1 menit untuk mengeringkan perekat sebelum diproses. Jarak optimal antara lampu UV dan batu permata adalah 100 mm.

(2) Lem 502 (Gambar 6-7)

Metode ikatan: Masukkan batang besi ke dalam papan sisipan khusus, gunakan ujung runcing dari tutup botol untuk langsung mengoleskan perekat ke ujung batang besi, dan pegang pinset di tangan kanan untuk meletakkan batu permata kosong di ujung batang besi yang dilapisi perekat dan ratakan. Harap letakkan di lingkungan bersuhu 25-30 ℃ selama 15-20 menit untuk menyembuhkan perekat sebelum diproses. Oven harus digunakan jika suhu tidak mencapai 25-30 ℃.

(3) Lem AB (Gambar 6-8)

Metode pengikatan: masukkan batang besi ke dalam soket khusus, campur lem A dan lem B sesuai dengan 1: 1, langsung celupkan lem AB dalam jumlah yang sesuai ke kepala batang besi, letakkan permata di kepala batang besi yang dilapisi dengan lem, dan biarkan di lingkungan di atas 25 derajat selama 5 ~ 8 menit untuk menyembuhkan. Ini dapat diproses setelah sekitar 15 menit.

Gambar 6-7 502 Lem

Gambar 6-8 Lem AB

2. Alat Umum untuk Pengikatan Permata

2.1 Lampu Alkohol

(1) Lampu alkohol digunakan dalam proses perekat permata yang dapat digunakan kembali, yang berfungsi sebagai sumber panas untuk pemrosesan permata tunggal. Lampu ini biasanya digunakan untuk memanaskan permata dan memanaskan perekat selama produksi permata tunggal. Setelah pemrosesan permata selesai, perekat yang dipanaskan membantu melepaskan permata dari batang besi. Lampu alkohol dan strukturnya ditunjukkan pada Gambar 6-9.

(2) Prosedur pengoperasian yang aman untuk menggunakan lampu alkohol ditunjukkan pada Gambar 6-10.

- Alkohol mudah terbakar. Saat menambahkan alkohol ke lampu alkohol, jika ada tumpahan di atas meja, alkohol harus dilap hingga kering sebelum dinyalakan.

- Kedap udara lampu alkohol buruk, dan alkohol mudah menguap. Untuk lampu alkohol yang sudah lama tidak digunakan, akumulasi gas di dalam lampu harus dilepaskan sebelum dapat dinyalakan.

- Jumlah alkohol yang ditambahkan tidak boleh melebihi 2/3 dari lampu alkohol.

- Lampu alkohol tidak boleh dimiringkan saat dinyalakan.

- Saat tidak digunakan, lampu alkohol tidak boleh dipadamkan dengan meniupnya dengan mulut; lampu harus dipadamkan dengan penutup lampu.

Video Pengaturan Batu Lampu Alkohol

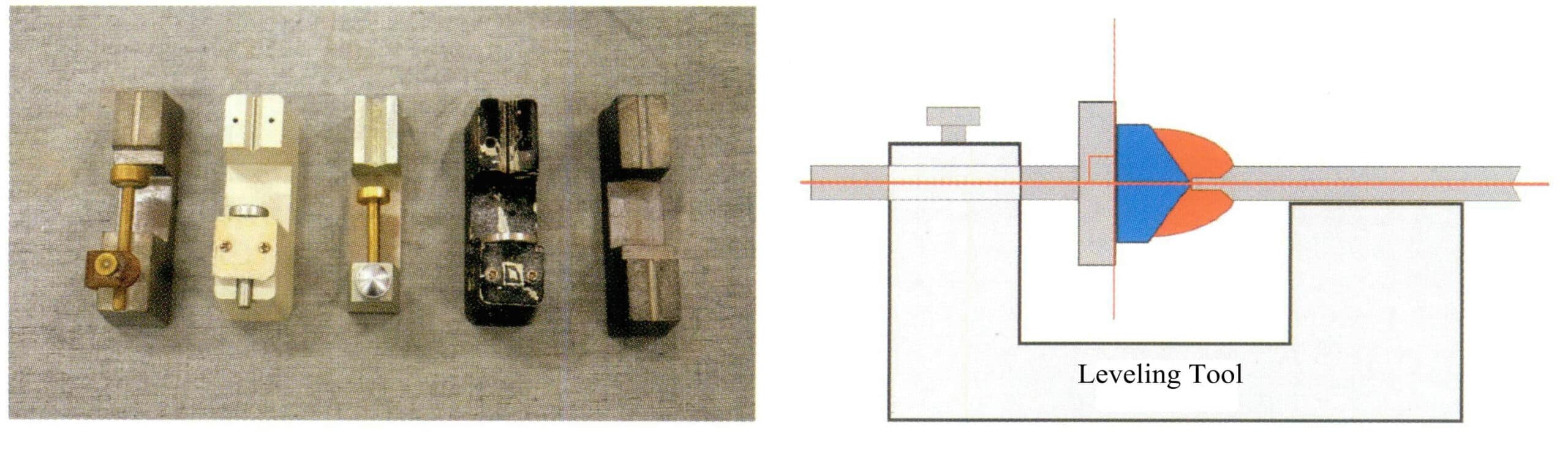

2.2 Basis Horisontal (Perangkat Perata)

Jaga agar permukaan batu permata tetap tegak lurus terhadap sumbu batang besi untuk meningkatkan efisiensi dan kualitas daya rekat batu (Gbr. 6-11).

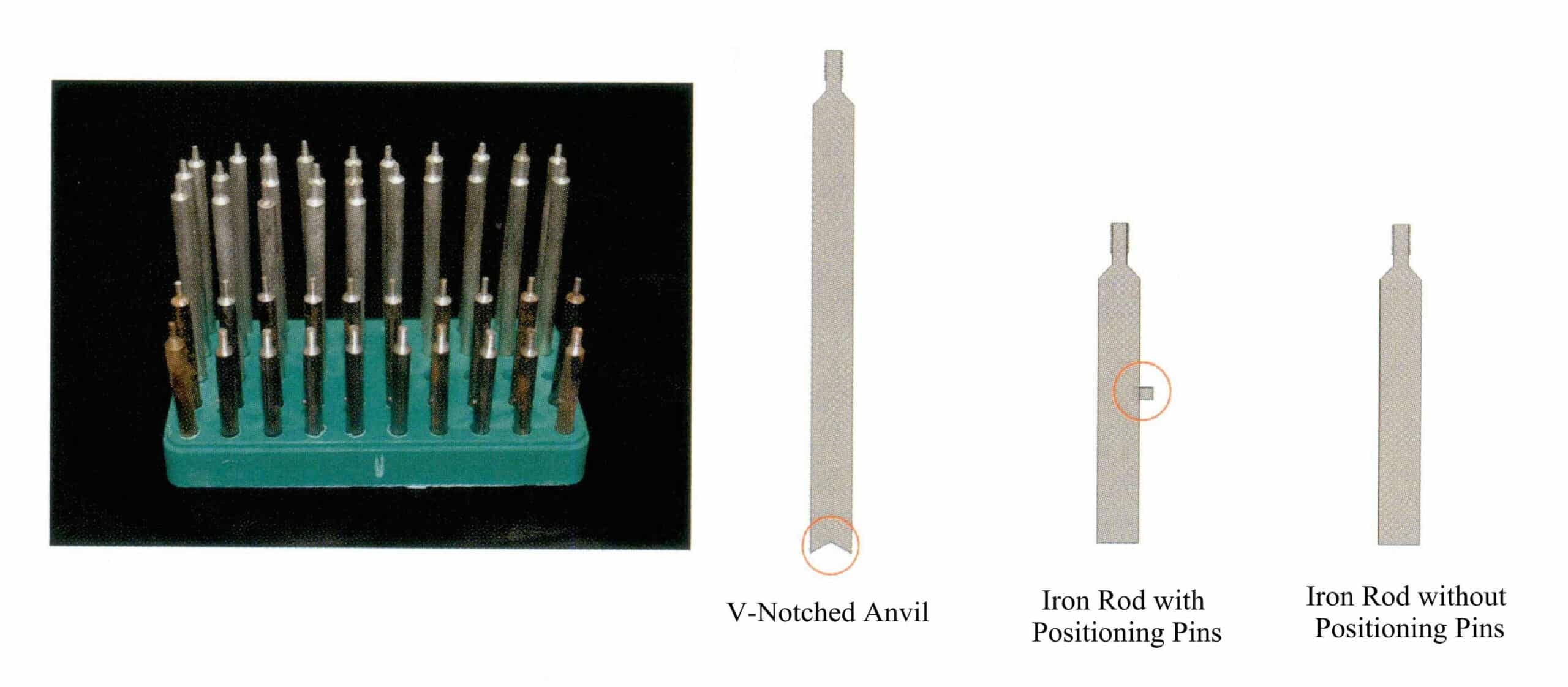

2.3 Batang Tembaga atau Batang Besi

Untuk mengikat dan menyangga batu permata, masukkan gagang segi delapan atau gagang mesin untuk mengoperasikan dan memproses batu permata. Batang tembaga dan besi tersedia dalam berbagai bentuk, termasuk batang besi dengan pin pemosisian, batang besi tanpa pin pemosisian, dan batang besi dengan lekukan berbentuk V di bagian ekor, dengan panjang mulai dari 30 ~ 90 mm. Kepala batang besi bisa datar atau runcing. Batang besi dengan pin pemosisian biasanya digunakan untuk memproses batu permata bulat, sedangkan batang besi tanpa pin pemosisian sering digunakan untuk memproses batu permata yang tidak beraturan (Gambar 6-12).

2.4 Alat Pengujian Permata

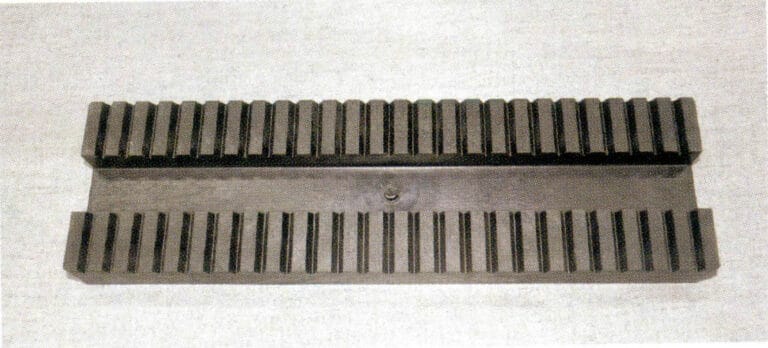

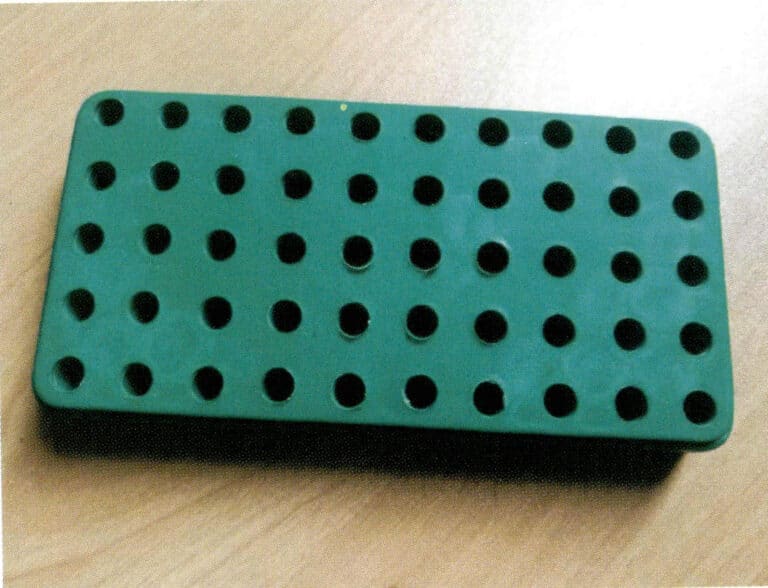

Untuk pemasangan batu terbalik, setelah pemrosesan mahkota batu permata selesai, lepaskan batang besi dari gagangnya dan letakkan di alur panjang di salah satu sisi alat pemasangan. Ambil batang besi lain yang dilapisi dengan perekat dan segera pasangkan dengan mahkota bekas gerinda pada alat pengasahan. Setelah perekat mengeras, gunakan gunting untuk memotong ujung batang besi yang tidak digerinda dari perekat, dan selesaikan proses pembubutan batu terbalik (Gbr. 6-13). Catatan: Alat dan metode pemasangan batu terbalik ini sering digunakan dalam proses batu terbalik batch dengan perekat sekali pakai.

2.5 Pelat Penyisipan Batang Besi

Setelah mengikat batu permata yang cacat, masukkan ke dalam lubang pelat untuk disimpan, sehingga memudahkan produksi jalur perakitan, klasifikasi produk, dan pemeriksaan kualitas (Gambar 6-14).

2.6 Produksi Perekat Permata Skala Besar, Alat Pengujian Permata, dan Prinsip-prinsipnya (Gambar 6-15, 6-16)

Copywrite @ Sobling.Jewelry - Produsen perhiasan khusus, pabrik perhiasan OEM dan ODM

3. Analisis Kualitas Perekat Permata dan Batu Akik

Kualitas daya rekat batu permata dan kualitas anti-batu mempengaruhi kualitas dan efisiensi proses produksi selanjutnya.

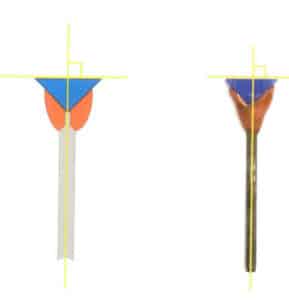

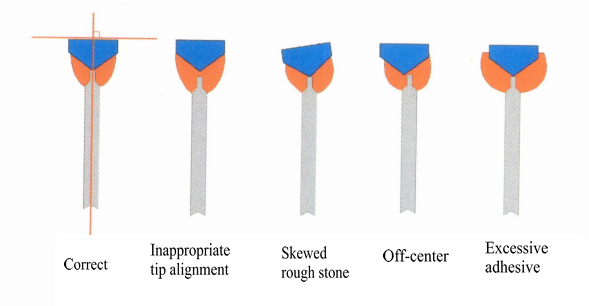

3.1 Analisis diagramatik kualitas daya rekat batu permata (Gambar 6-17, 6-18)

Gambar 6-17 Analisis diagramatik kualitas daya rekat batu permata

Gambar 6-18 Gambar perlekatan aktual

3.2 Analisis kualitas daya rekat batu permata

- Lapisan perekat harus seragam dan halus. Terlalu banyak perekat akan mempengaruhi operasi penggerindaan, sementara terlalu sedikit perekat dapat menyebabkan perekat pecah selama penggerindaan. Jumlah perekat yang digunakan harus berdasarkan ukuran batu.

- Pastikan untuk memanaskan batang perekat sebelum mengaplikasikan perekat; suhu pemanasan awal yang tidak mencukupi dapat dengan mudah menyebabkan kegagalan perekat.

- Perekat api tidak boleh menyebabkan perekat berasap atau terbakar. Jika perekat berasap atau terbakar, maka akan mengkarbonisasi lapisan perekat dan kehilangan kinerjanya. Panaskan hingga terasa sedikit cair.

- Apabila merekatkan batu kosong, garis tengah desain batu permata yang kosong harus sama dengan garis tengah batang perekat; jika tidak, hal ini bisa menghasilkan ujung yang miring atau batu permata yang bentuknya aneh sewaktu diproses.

- Apabila merekatkan batu kosong, permukaan batu permata yang kosong harus tegak lurus terhadap sumbu batang perekat.

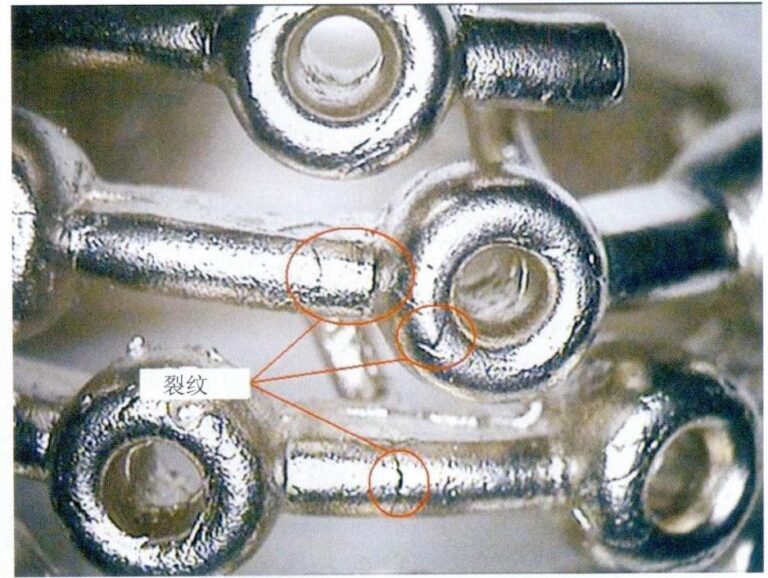

- Batu permata yang baru diikat tidak boleh langsung dimasukkan ke dalam air dingin untuk didinginkan, karena hal ini dapat dengan mudah menyebabkan batu permata retak karena pendinginan mendadak.

- Saat memanaskan batu permata kasar, sangat penting untuk memastikan pemanasan yang merata; jika tidak, retakan termal dapat dengan mudah terjadi.

3.3 Masalah Kualitas Umum dalam Pengikatan Batu Permata

- Penuaan perekat batu permata - pemanasan dalam waktu lama menyebabkannya mengeluarkan asap putih, yang mengindikasikan bahwa koloid telah menua dan kekuatan ikatannya menurun.

- Jika limbah batu permata tidak dibersihkan dengan benar dan memiliki noda minyak atau kotoran, hal ini juga akan mempengaruhi kualitas ikatan.

- Jika permata kasar atau batang perekat tidak dipanaskan terlebih dahulu dengan cukup, batang besi dan koloid akan mudah menjadi longgar atau permata dan koloid akan menunjukkan daya rekat yang salah, yang menyebabkan deformasi dan kehilangan batu selama pemrosesan.

- Apabila koloid belum mengeras, koloid harus ditempatkan pada pelat sisipan khusus untuk mendinginkan dan mengeras; pengoperasian yang tidak tepat dapat dengan mudah menyebabkan blanko permata dan batang besi tidak sejajar, sehingga memengaruhi kualitas produk jadi.

3.4 Contoh Batu Adhesi Pabrik dan Batu Terbalik (Gambar 6-19)

Video Pengaturan Batu Manual dan Faceting

Video Pengaturan Batu dan Faceting Semi-Otomatis

3.5 Contoh Batu Adhesi dan Batu Terbalik Otomatis (Gambar 6-20)

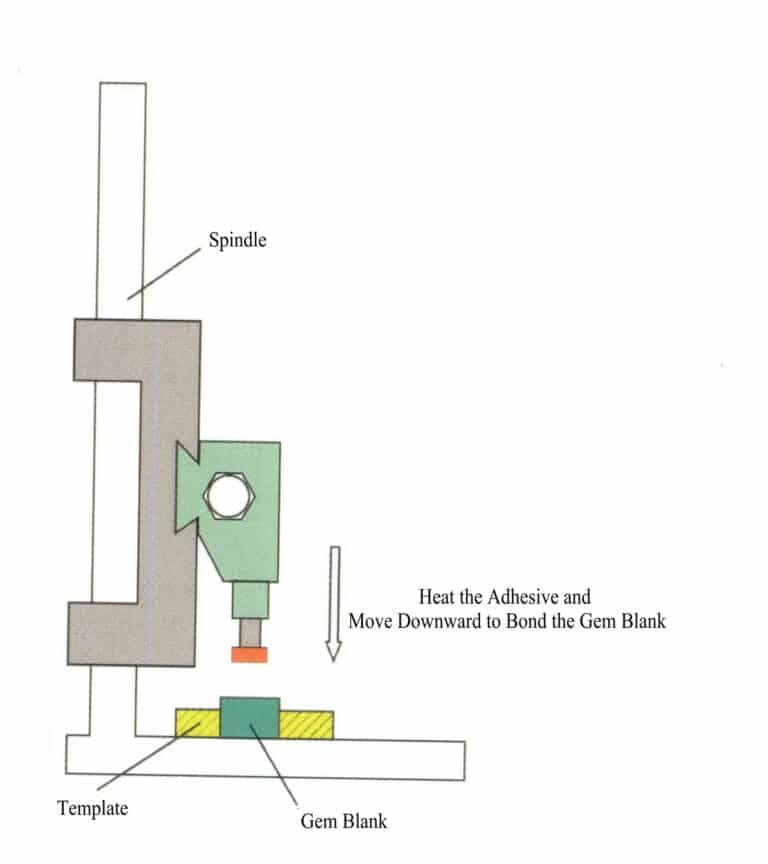

(1) Alur Proses Mesin Perekat Batu Sepenuhnya Otomatis

- Tempatkan limbah batu ke dalam alur cetakan.

- Gas secara otomatis menyala untuk memanaskan kepala batang besi.

- Baki serbuk lem berpindah ke kepala batang besi.

- Kepala batang besi menyerap bubuk lem permata dan meleleh karena panas (Gbr. 6-21).

- Baki serbuk lem menjauh dari kepala batang besi.

- Kepala batang besi serbuk lem permata perekat turun ke atas permata kosong (Gbr. 6-22).

- Tunggu hingga koloid permata meleleh pada blanko permata untuk menyelesaikan ikatan.

(2) Aliran proses mesin anti-batu yang sepenuhnya otomatis.

- Tempatkan strip aluminium dengan mahkota gerinda yang sudah jadi di bawah platform batu perekat [Gambar 6-23(a)].

- Tempatkan strip aluminium kosong di atas.

- Pengapian otomatis gas memanaskan kepala batang besi strip aluminium.

- Baki serbuk lem permata berpindah ke kepala batang besi.

- Kepala batang besi menyerap bubuk lem permata dan meleleh karena panas.

- Cakram bubuk lem bergerak menjauhi kepala batang besi.

- Kepala batang besi yang dilapisi dengan lem permata turun dan bersentuhan dengan meja permata yang telah dipoles dan diukir [Gambar 6-23(b)].

- Baris atas menghembuskan udara untuk mendinginkan lem permata. Setelah lem permata mengeras, baris bawah gas dinyalakan untuk memanaskan kepala batang besi [Gbr 6-23(c)].

- Kepala batang besi bagian atas terangkat, menyelesaikan proses anti-batu.

Bagian III Pemotongan dan Pemolesan Batu Permata Berfaset

1. Mekanisme Pemrosesan Material Super Keras

Pengasahan batu permata adalah penggerindaan permukaan yang seragam, kecil, dan datar berdasarkan kekasaran batu permata. Pemrosesan bahan batu permata dengan kekerasan relatif di atas lima dianggap sebagai pemrosesan bahan keras, dan pengasahan dan pemolesan batu permata pada cakram gerinda pada dasarnya adalah pengasahan.

1.1 Penerapan kekasaran permukaan dalam pemrosesan batu permata

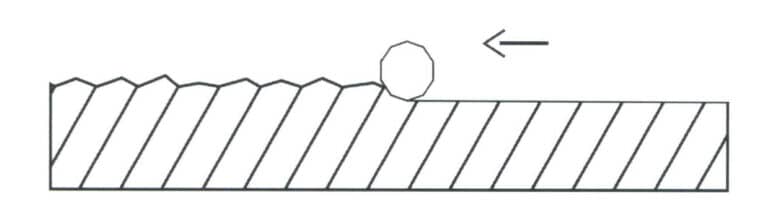

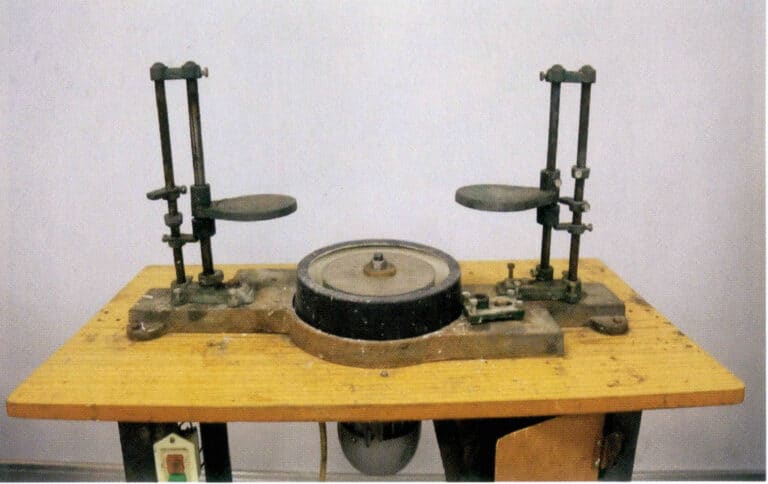

Pemrosesan batu permata melibatkan abrasif yang bekerja pada permukaan batu permata untuk membentuk puncak dan lembah, terutama melalui efek "membajak". Proses penggerindaan menggunakan bahan abrasif kasar dan halus, dan puncak serta lembah yang dibentuk oleh bahan abrasif kasar berbeda dari yang dibentuk oleh bahan abrasif halus. Hal ini menjelaskan, mengapa permukaan batu permata yang diproses dengan abrasive kasar, tampak kasar. Gambar yang diperbesar yang mengilustrasikan goresan yang dibuat oleh sebutir pasir pada permukaan batu permata menunjukkan penerapan kekasaran permukaan dalam pemrosesan batu permata. Gambar 7-1 menunjukkan prinsip penggerindaan abrasif butiran tunggal, dan Gambar 7-2 menunjukkan kekasaran permukaan penggerindaan dengan kekasaran abrasif yang berbeda.

Dari analisis kekasaran permukaan, perbedaan antara pemolesan dan penggilingan terletak pada kenyataan bahwa pemolesan dilakukan di bawah aksi partikel abrasif yang lebih halus, dan proses pemolesan merupakan kelanjutan dari proses penggilingan. Praktik telah menunjukkan bahwa, di bawah parameter tetap seperti bahan batu permata, bahan cakram gerinda, abrasif, dan kecepatan peralatan dalam pemrosesan batu permata, kekasaran permukaan batu permata tergantung pada ukuran dan bentuk partikel abrasif.

1.2 Mekanisme Penggilingan dan Pemolesan Permata

Selama proses penggilingan dan pemolesan permata, ada fenomena aliran molekul pada permukaan bahan penggilingan dan pemolesan, dan fenomena berikut terjadi selama pemolesan.

- Serbuk pemoles bekerja pada permukaan permata dengan cara "membajak", menghilangkan puing-puing yang bekerja dengan ukuran yang sama dengan partikel serbuk pemoles.

- Gerakan tekanan termal dari bubuk pemoles menyebabkan penataan ulang molekul di lapisan permukaan permata, di mana suhu yang tinggi memainkan peran yang sangat penting.

- Bahan pembantu seperti air atau minyak poles memainkan peran kimiawi selama pemolesan.

Pemrosesan permata jangka panjang telah membuktikan bahwa tindakan mekanis adalah faktor utama dalam memoles bahan keras, tindakan reologi lemah, dan tindakan kimiawi tidak ada dalam pemolesan hard disk bubuk berlian. Namun, menambahkan beberapa bahan kimia dalam pemolesan permata tertentu dapat meningkatkan kecepatan pemolesan; misalnya, menambahkan asam fluorida saat memoles zirkonia kubik sintetis meningkatkan kecepatan pemolesan.

2. Karakteristik Penggerindaan dari Abrasif Tetap dan Abrasif Longgar

2.1 Proses Penggerindaan Abrasif Lepas

Dalam proses pemolesan permata, bahan abrasif yang longgar melekat pada piringan pemoles, dan bahan abrasif menekan permukaan permata. Di bawah aksi gaya umpan, partikel abrasif ditekan dengan kuat ke permukaan benda kerja. Karena kekerasan partikel abrasif lebih besar daripada permata, maka partikel abrasif akan terkompresi dan berubah bentuk. Ketika gaya yang diterapkan oleh partikel abrasif melebihi gaya ikatan antara molekul material permata, sebagian material permata akan terpisah dari permata, yang disebut sebagai serpihan. Di bawah tekanan dan kecepatan potong, fragmen kecil yang tak terhitung jumlahnya terbentuk pada permukaan benda kerja melalui pemotongan yang berpotongan. Dengan gerakan dan tekanan yang terus menerus dari abrasive, fragmen-fragmen ini "digali" dari permukaan permata dan "didorong menjauh."

2.2 Aplikasi Bahan Abrasif Tetap dan Bahan Abrasif Longgar dalam Penggerindaan dan Pemolesan Permata

Ada sebuah eksperimen: tumpukan pasir dan sepotong amplas; manakah yang lebih cepat membuat pisau berkarat? Semua orang akan mengatakan amplas karena amplas adalah gesekan tetap, sementara tumpukan pasir adalah gesekan bergulir. Memoles permata pada cakram pemoles juga membuktikan hal ini; praktik menunjukkan bahwa menggunakan tisu untuk menyeka cakram pemoles mengubah gesekan bergulir dari bubuk pemoles yang ditekan ke dalam bahan lembut cakram pemoles menjadi gesekan tetap, yang secara efektif meningkatkan kecepatan pemolesan. Hal ini mengilustrasikan penerapan handuk kertas dalam pemolesan permata.

Sebagai contoh, penggerindaan aspek permata dilakukan pada cakram gerinda abrasif tetap, di mana partikel abrasif dipasang pada cakram dengan pengikat, dan menggiling permata. Partikel abrasif menciptakan efek "membajak" pada permukaan permata, dan karena partikel abrasif terus menerus melakukan tindakan "membajak" ini, retakan, dan serpihan pada permukaan permata akan rontok, membentuk permukaan kasar yang baru. Bubuk pemoles pada cakram pemoles adalah bahan abrasif yang longgar; praktik menunjukkan bahwa menggunakan handuk kertas untuk menekan bubuk pemoles ke dalam tubuh cakram pemoles, memasang bubuk pemoles di dasar cakram pemoles dalam bentuk yang tertanam menciptakan gesekan tetap, menghasilkan peningkatan kecepatan dan efisiensi pemolesan.

3. Analisis Efisiensi Pengolahan Permata

3.1 Hubungan Antara Partikel Abrasif dan Efisiensi

Semakin kasar partikel abrasif, semakin dalam lekukannya dan semakin cepat pemotongannya, sehingga menghasilkan efisiensi penggerindaan yang lebih tinggi namun permukaannya lebih kasar. Partikel abrasif yang lebih halus menghasilkan kecepatan penggerindaan yang lebih lambat dan permukaan akhir yang lebih halus pada batu permata.

3.2 Hubungan antara kekerasan abrasif dan efisiensi

Apabila kekerasan bahan abrasif meningkat, kedalaman lekukan yang dihasilkan, juga meningkat. Apabila menggerinda batu permata, tekanan batu permata pada piringan tidak boleh melebihi kekuatan tekan partikel abrasif; melebihi hal ini akan menyebabkan partikel abrasif pecah.

Seiring dengan meningkatnya kekuatan tekan partikel abrasif, jumlah keausan pada batu permata meningkat, dan lapisan kerusakan pun semakin dalam.

3.3 Hubungan antara kecepatan cakram dan efisiensi

Meningkatkan kecepatan spindel alat mesin dalam kondisi yang sama akan mengurangi kekasaran permukaan benda kerja. Kecepatan saat ini adalah 3000r/menit, dan kecepatan linier adalah 20~35 m/s.

3.4 Hubungan antara material roda gerinda dan efisiensi

Tekanan roda gerinda dan kecepatan alat mesin tidak mempengaruhi kedalaman lapisan reses permata.

Diameter cakram gerinda sekitar 300 mm, dengan kecepatan linier yang tinggi dan runout yang signifikan dari roda gerinda.

3.5 Hubungan antara konsentrasi serbuk poles dan efisiensi

Terlalu banyak bubuk pemoles meningkatkan jumlah partikel bubuk pemoles untuk memoles batu permata, sehingga menghasilkan tekanan rata-rata yang lebih rendah pada bubuk pemoles dan kehalusan permukaan yang buruk.

3.6 Hubungan antara tekanan cakram pemoles dan efisiensi

Tekanan cakram pemoles saat memoles korundum adalah 0,2 ~ 0,3kgf/cm2.

Tekanan cakram pemoles saat memoles batu akik adalah 0,15-0,2kgf/cm2.

Tekanan cakram gerinda yang tinggi meningkatkan laju pengumpanan, membuat batu permata rentan terhadap keretakan (ketika tekanan yang diberikan melebihi kekuatan partikel abrasif, menyebabkan batu permata pecah dan menjadi lebih halus).

Bahan cakram gerinda lunak, menghasilkan gaya kecil yang ditransmisikan ke benda kerja, membentuk lapisan yang rusak dengan kedalaman yang dangkal. Oleh karena itu, penggerindaan dan pemolesan batu permata yang lebih halus sebaiknya menggunakan cakram gerinda yang terbuat dari bahan yang lebih lembut.

- Tekanan piringan gerinda tidak terkait dengan kedalaman pemrosesan, hanya terkait dengan efisiensi.

- Kecepatan putaran piringan gerinda tidak terkait dengan kedalaman pemrosesan, hanya terkait dengan efisiensi.

4. Peralatan dan Perlengkapan untuk Pengolahan Batu Permata Berfaset

4.1 Peralatan untuk Pemrosesan Batu Permata Berfaset

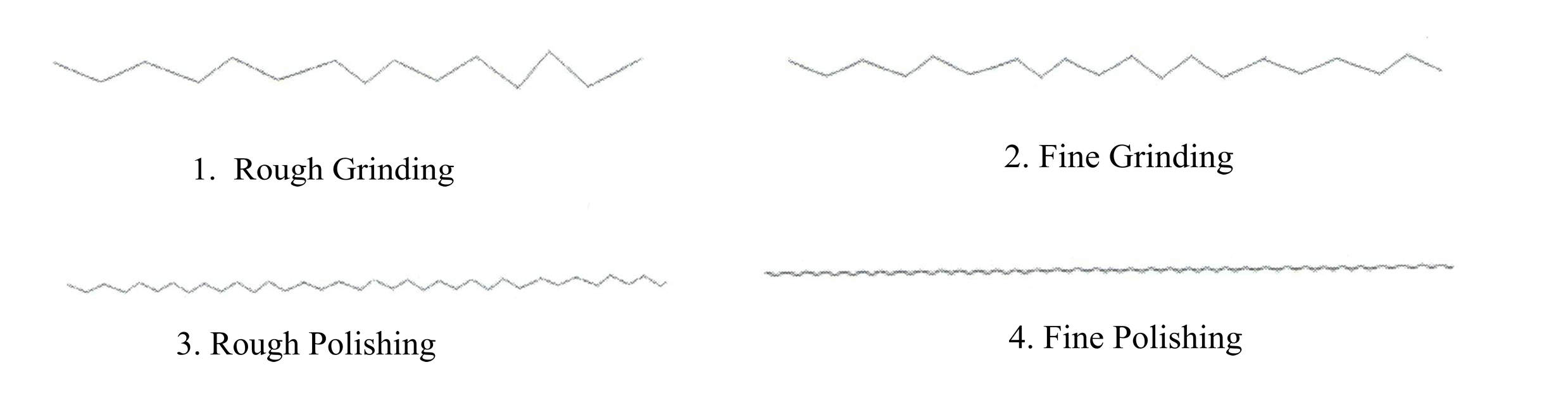

(1) Mesin Faceting Sudut Potong Tangan Sudut Biasa Ganda (Gambar 7-3)

Video Mesin Batu Permata Standar

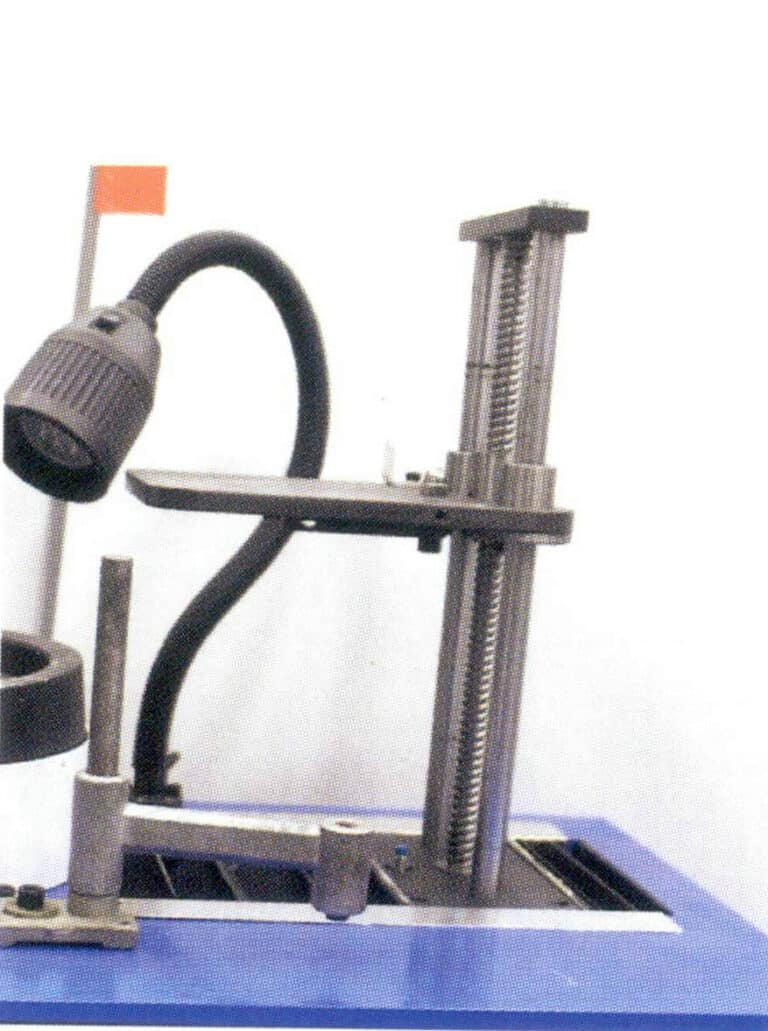

(2) Mesin Faceting Platform Peninggian CNC (Gambar 7-4)

(3) Perhiasan segi robot cakram ganda (Gambar 7-5)

4.2 Alat Pengukiran dan Pemolesan Meja

(1) Alat Tekanan

Alat-alat meja penggerindaan dan pemolesan permata ditunjukkan pada Gambar 7-6, dan demonstrasi pengoperasian meja penggerindaan dan pemolesan permata ditunjukkan pada Gambar 7-7. Prinsip kerja mesin cetak ditunjukkan pada Gambar 7-8.

Video Pemrosesan Tabel Batu Permata

(2) Tekan 45°

Perangkat tekanan 45° ditunjukkan pada Gambar 7-9, dan prinsip kerja perangkat tekanan 45° ditunjukkan pada Gambar 7-10.

4.3 Alat penyesuaian sudut pengukiran permata

- Platform pengangkat dengan perangkat pemosisian (Gbr. 7-11).

- Platform pengangkat posisi bunga teratai (Gambar 7-12).

- Platform pengangkat posisi berputar trisula (Gambar 7-13).

- Platform pengangkatan bertingkat (Gambar 7-14).

- Platform pengangkatan CNC permata (Gambar 7-15).

- Alat dan skema pengukuran sudut penggerindaan permata (Gbr. 7-16).

Gambar 7-11 Platform pengangkatan dengan perangkat pemosisian

Gambar 7-12 Platform pengangkat pemosisian pelat teratai

Gambar 7-13 Platform pengangkat posisi berputar trisula

Gambar 7-14 Platform pengangkat dengan timbangan

Gambar 7-15 Platform pengangkatan CNC Permata

4.4 Alat Penyesuaian Sudut Pemotongan Permata

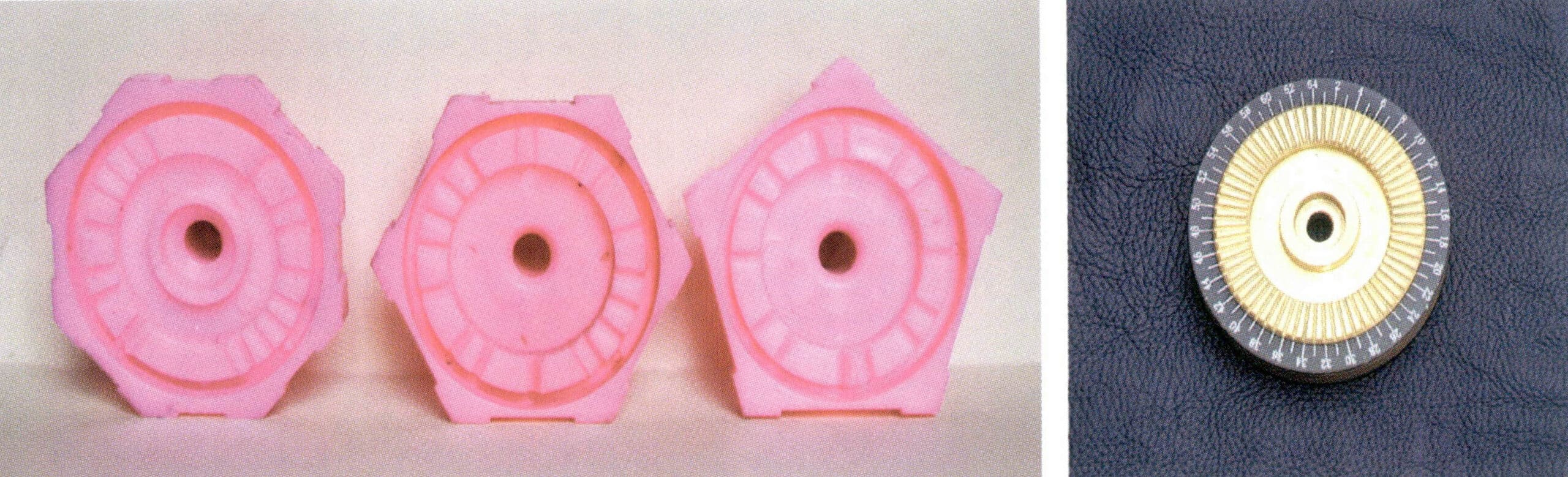

(1) Dudukan dan Struktur Segi Delapan (Gambar 7-17)

Video Perakitan dan Pembongkaran Kunci Segi Delapan dan Lengan Robotik

(2) Dudukan dan Struktur Mekanis (Gambar 7-18)

4.5 Hubungan Penggerindaan Antara Dudukan Mekanis dan Dudukan Segi Delapan

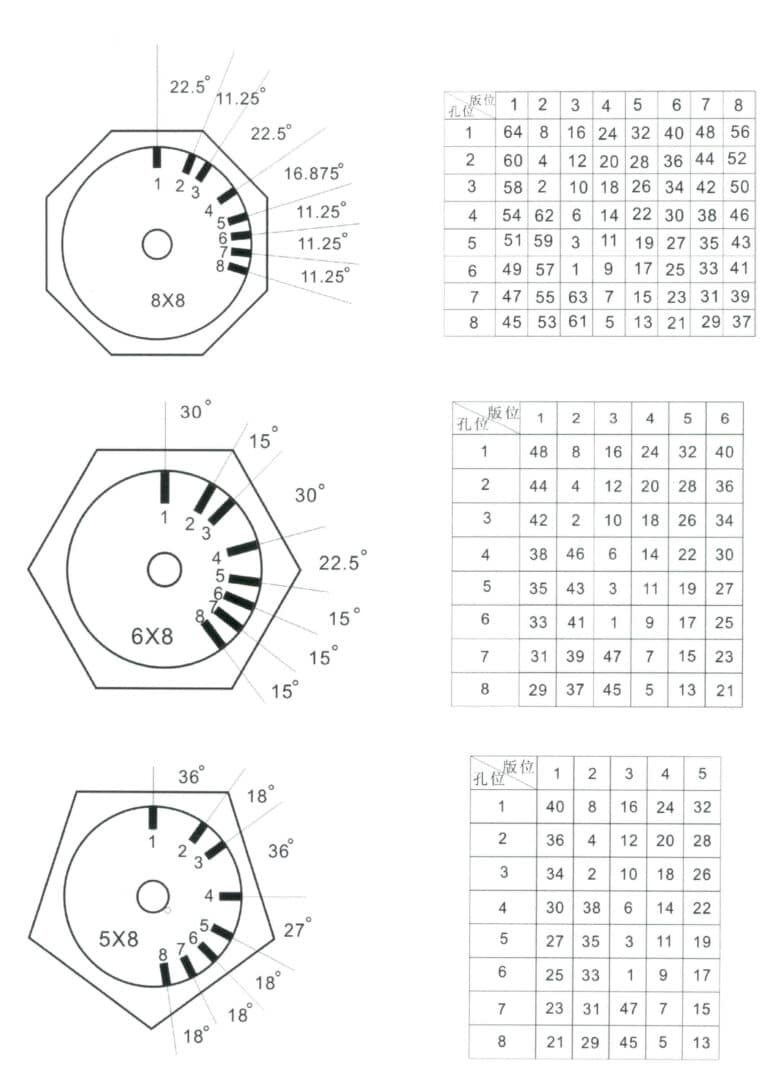

Pemegang segi delapan dapat mengukir semua bentuk batu permata berdasarkan 8 (disebut sebagai delapan dasar), sesuai dengan pemegang mekanis dengan 64 divisi (8×8). Pemegang heksagonal dapat mengukir batu permata berdasarkan 6, sesuai dengan pemegang mekanis dengan 48 divisi (6×8). Dudukan segi lima dapat mengukir batu permata berdasarkan 5, sesuai dengan dudukan mekanis dengan 40 pembagian (5×8), seperti yang ditunjukkan pada Gambar 7-19.

4.6 Hubungan Konversi Penggerindaan Antara Dudukan Mekanis dan Dudukan Oktagonal (Gambar 7-20)

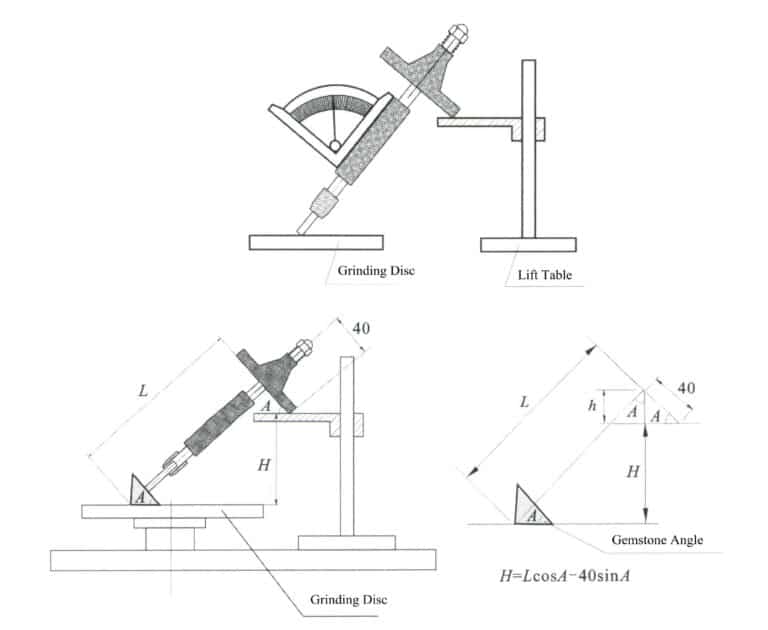

4.7 Pengukuran sudut penggerindaan batu permata dan konversi ketinggian platform pengangkat (Gambar 7-21, Tabel 7-1)

Tabel 7-1 Tabel Konversi Sudut dan Ketinggian

| Sudut L (°) | Panjang L (mm) | |||||

| 155 | 160 | 165 | 170 | 175 | 180 | |

| Tinggi H (cm) | ||||||

| 10 | 145.7 | 150.6 | 155.5 | 160.5 | 165.4 | 170.3 |

| 15 | 139.4 | 144.2 | 149.0 | 153.9 | 158.7 | 163.5 |

| 20 | 132.0 | 136.7 | 141.4 | 146.1 | 150.8 | 155.5 |

| 25 | 123.6 | 128.1 | 132.6 | 137.2 | 141.7 | 146.2 |

| 30 | 114.2 | 118.6 | 122.9 | 127.2 | 131.6 | 135.9 |

| 35 | 104.0 | 108.1 | 112.2 | 116.3 | 120.4 | 124.5 |

| 40 | 93.0 | 96.9 | 100.7 | 104.5 | 108.3 | 112.2 |

| 45 | 81.3 | 84.9 | 88.4 | 91.9 | 95.5 | 99.0 |

| 50 | 69.0 | 72.2 | 75.4 | 78.6 | 81.8 | 85.1 |

| 55 | 56.1 | 59.0 | 61.9 | 64.7 | 67.6 | 70.5 |

| 60 | 42.9 | 45.4 | 47.9 | 50.4 | 52.9 | 55.4 |

5. Contoh Ukiran dan Pemolesan Permata

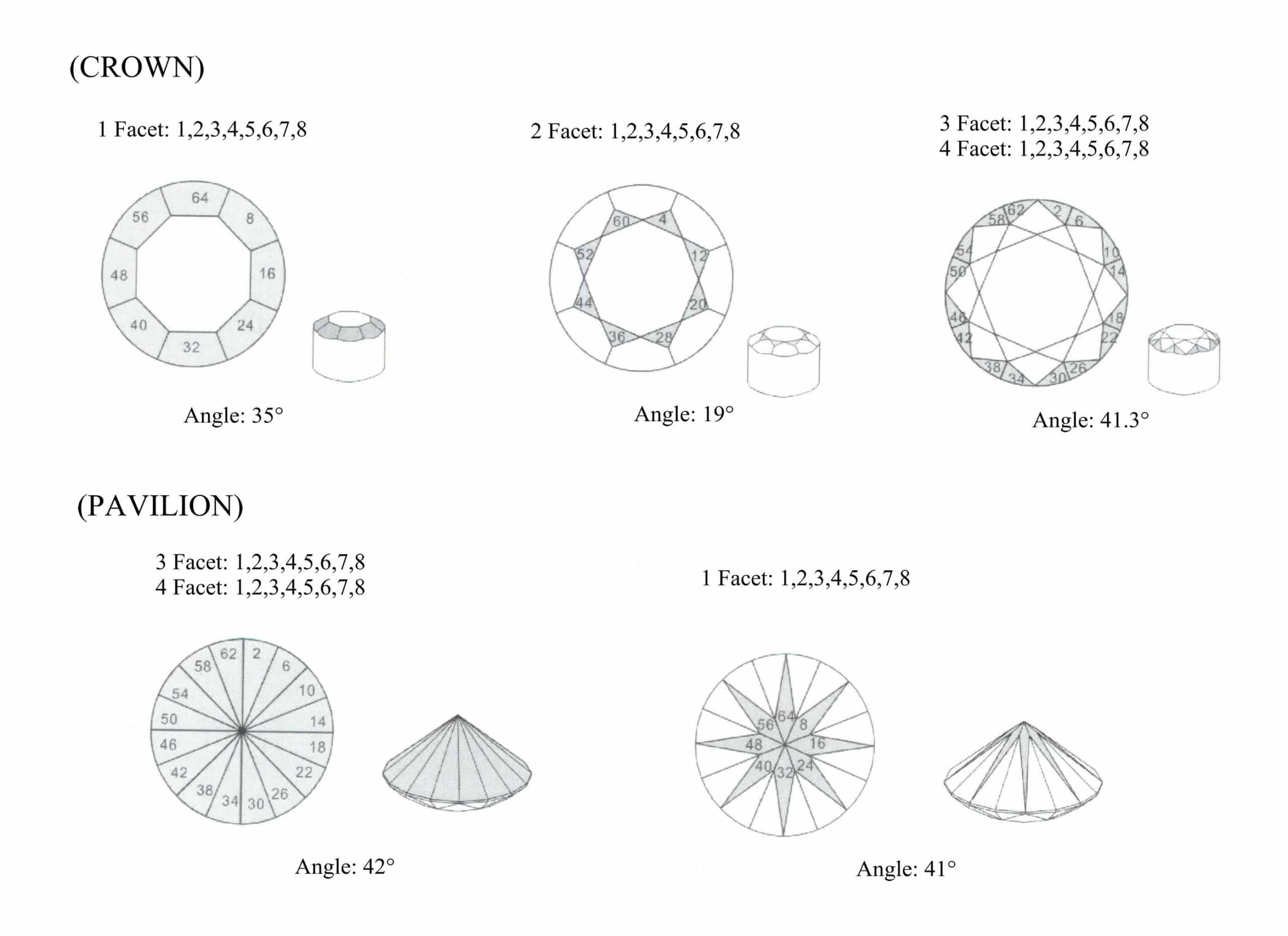

(1) Jenis Bor Bulat Standar (Gambar 7-22)

Video Lapping Paviliun Brilian Putaran Bulat Standar

Video Pemolesan Paviliun Brilian Bulat Standar

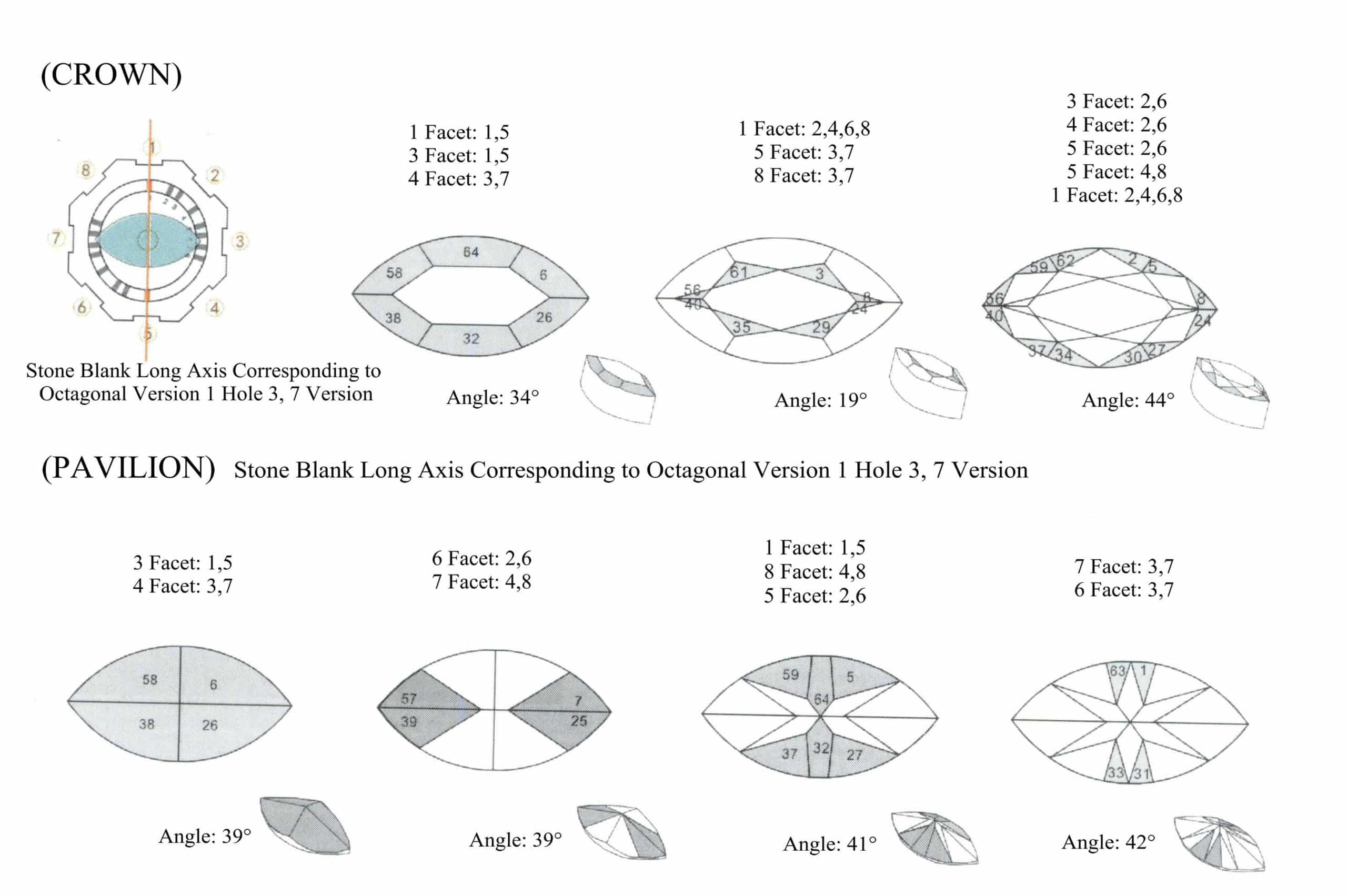

(2) Bentuk marquise (Gambar 7-23)

(3) Bentuk Telur (Oval) (Gambar 7-24)

.png)

.png)

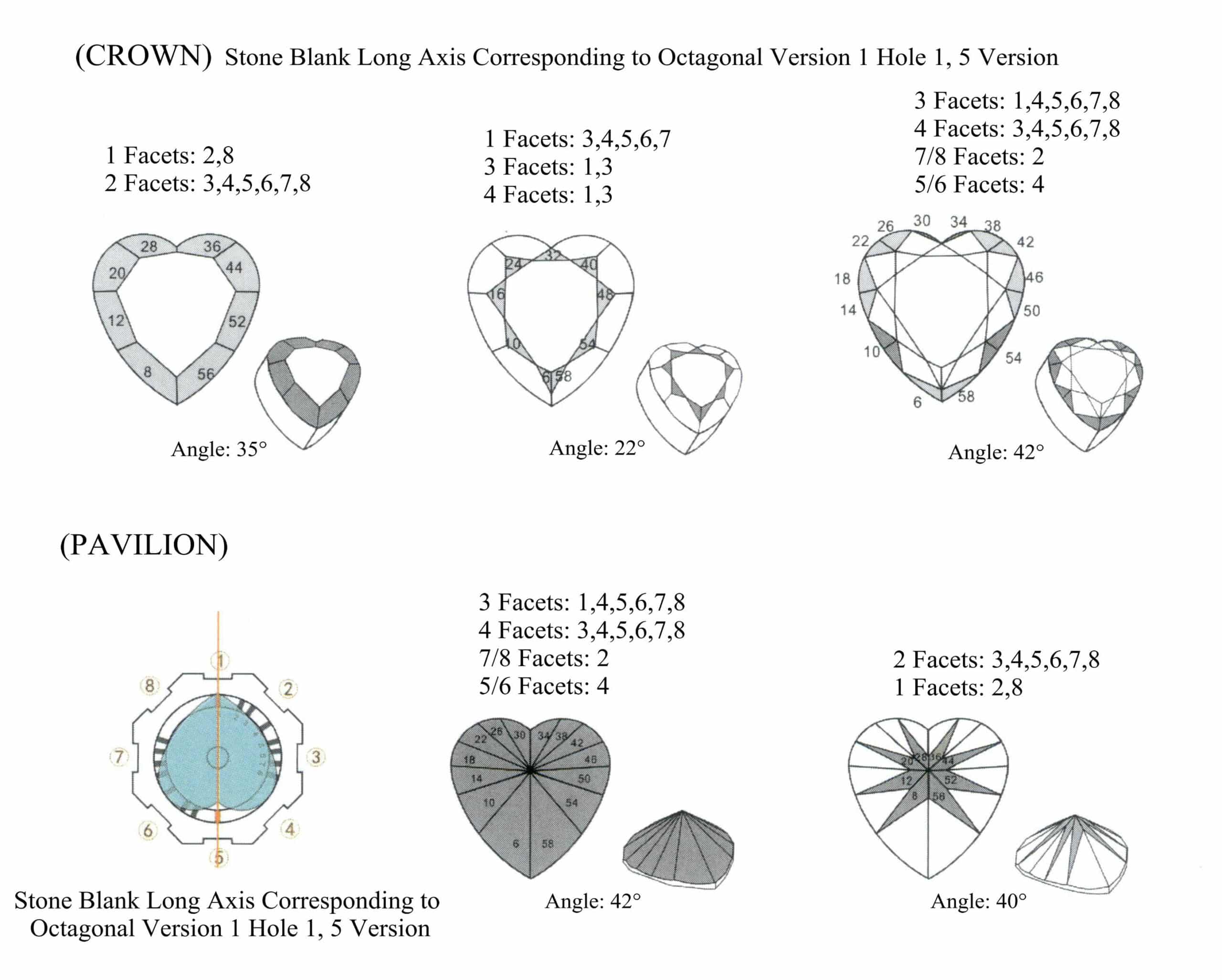

(4) Bentuk Hati (Gambar 7-25)

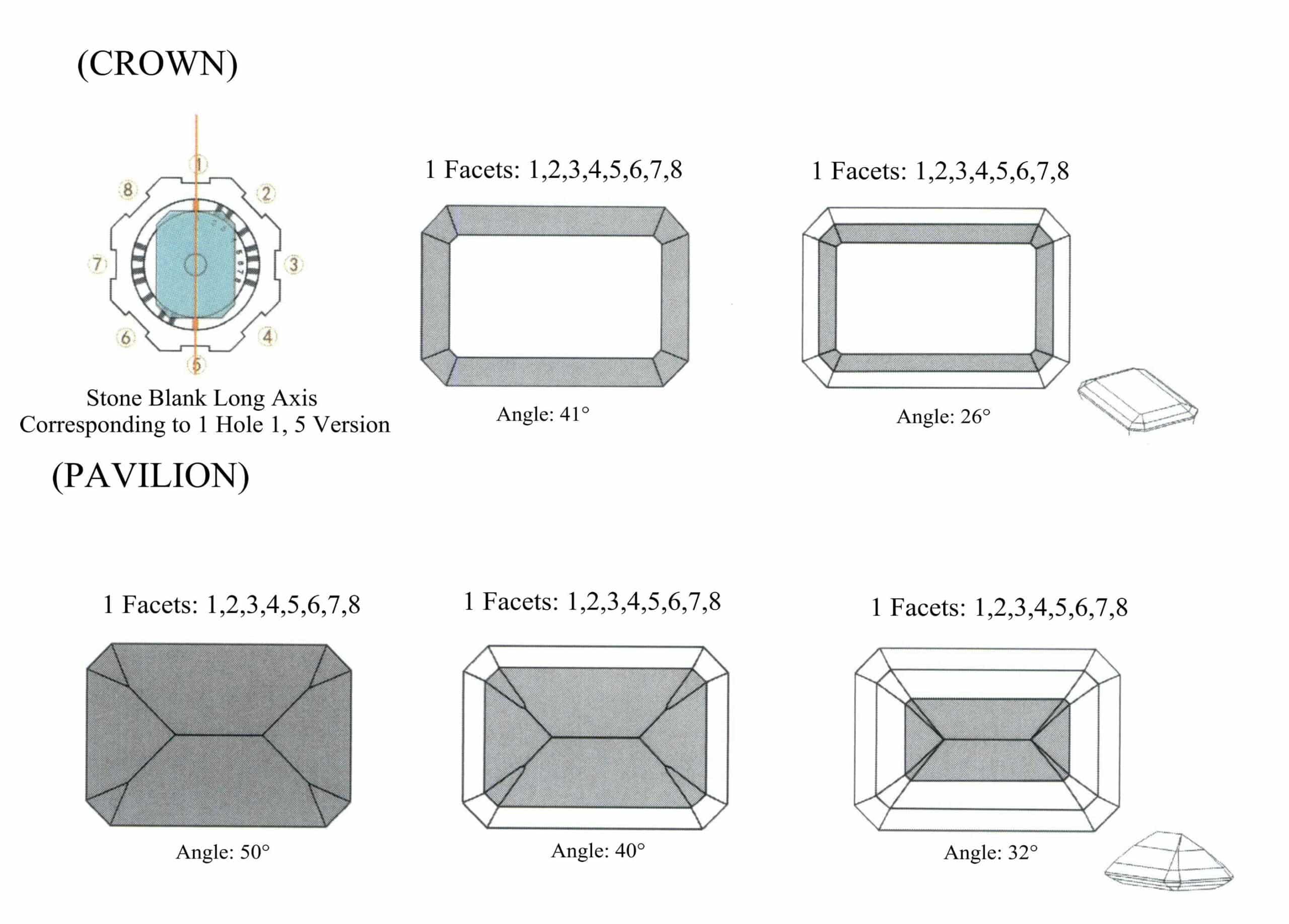

(5) Potongan Zamrud (Gambar 7-26)

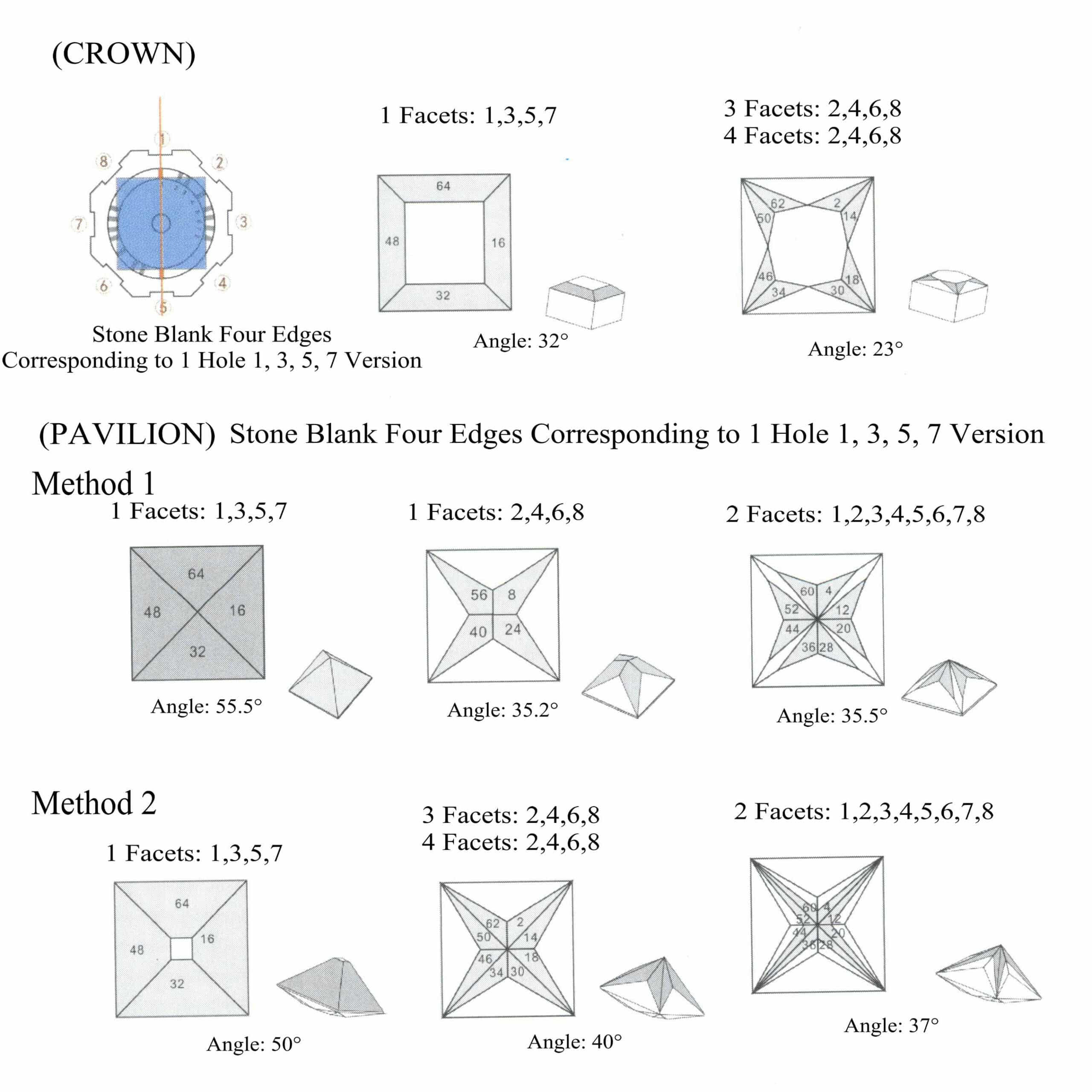

(6) Putri Potong Persegi (Gambar 7-27)

(7) Bentuk Buah Pir (Tetesan Air) (Gambar 7-28)

6. Bahan Tambahan dalam Pengolahan Batu Permata

(1) Peran Air dalam Pengolahan Batu Permata

- Saat memotong dan menggiling batu permata, diperlukan kelembapan yang cukup untuk mendinginkan batu permata agar tidak terlalu panas pada bahan kasar permata, yang dapat menyebabkan keretakan.

- Saat memotong dan menggiling batu permata, diperlukan kelembapan yang cukup untuk mendinginkan batu permata agar tidak terlalu panas pada bahan kasar permata, yang dapat menyebabkan pelunakan koloid.

- Bersihkan serbuk yang tertinggal selama pemotongan dan penggilingan.

(2) Peran Amplas dalam Pemrosesan Batu Permata

- Tekan bubuk pemoles ke dalam dasar cakram.

- Memperbaiki disk.

- Menyeimbangkan serbuk di dalam cakram.

- Kikis sisa serbuk pemoles dan residu dari pemolesan.

(3) Peran minyak pemoles dalam pemrosesan batu permata.

- Bedak poles untuk pencampuran.

- Bertindak sebagai pelumas untuk melindungi bantalan pemoles.

- Memastikan serbuk pemoles didistribusikan secara merata pada pad.

(4) Peran tisu toilet dalam pemolesan batu permata.

- Seka kelebihan minyak dari bantalan pemoles.

- Bersihkan serbuk poles yang mengambang di permukaan cakram poles.

- Tekan bubuk pemoles di dalam badan cakram pemoles untuk menjadi pemolesan gesekan tetap.

7. Pengukiran dan Penggilingan Batu Permata Milenium

Gaya batu permata Milenium, juga dikenal sebagai gaya batu permata cekung, adalah metode pemrosesan yang merupakan pengembangan dari metode pemrosesan batu permata segi. Perbedaan di antara keduanya adalah pemrosesan batu permata faceted menggunakan cakram gerinda datar yang berisi bubuk berlian, dan pemolesan dilakukan dengan batang pemoles keras dari paduan seng yang dikombinasikan dengan bubuk berlian, sehingga menghasilkan serangkaian permukaan kecil berbentuk busur cekung.

Gaya batu permata Milenium memproses serangkaian permukaan kecil berbentuk busur yang dapat mengumpulkan dan memantulkan cahaya, sehingga cahaya dan warna api yang dipantulkan dari bagian dalam batu permata lebih kuat daripada batu permata faceted. Ketika batu permata diputar, batu permata ini akan berkilau dan bersinar dengan cemerlang, membuatnya menarik dan menjadi gaya batu permata yang paling populer saat ini.

7.1 Peralatan Pemrosesan Batu Permata Milenium (Gambar 7-29)

7.2 Teknologi Pengolahan Batu Permata Milenium

(1) Memotong dan Membentuk

Menurut persyaratan produksi, mesin pemotong pertama-tama digunakan untuk memotong bahan segitiga dan kemudian membentuknya pada mesin melingkar semi-otomatis untuk menghasilkan bahan kasar dengan ukuran yang diperlukan.

(2) Batu Perekat

Letakkan batang perekat batu permata yang dilapisi dengan perekat batu permata di bawah kompor Bunsen untuk memanaskannya, sehingga perekat batu permata terpanggang, meleleh, dan melunak. Kemudian, tempelkan bahan kasar batu permata ke batang perekat. Ukuran perekat pada batang dapat ditentukan berdasarkan ukuran gaya batu permata; untuk batu permata yang lebih besar, gunakan perekat yang lebih besar; untuk bahan kasar batu permata yang lebih kecil, gunakan perekat yang lebih kecil.

Setelah batu permata dipasang pada batang perekat, periksa apakah ada ketidaksejajaran, apakah garis tengah batu permata bertepatan dengan garis tengah batang perekat atau jika ada terlalu banyak perekat. Jika ada masalah yang muncul, maka harus segera diperbaiki.

(3) Pengukiran dan Pemolesan Batu Permata

Setelah batu permata dipasang pada batang, bisakah Anda memasukkannya ke dalam lengan robot? Untuk mempercepat efisiensi pengukiran produk jadi, mesin batu permata standar digunakan untuk memproses permukaan datar dengan cakram gerinda 320 # sesuai dengan pola pengukiran mahkota berbentuk bor bundar. Pasang tongkat bubuk berlian 800 # pada chuck bor mesin cekung, nyalakan mesin utama dan motor mikro, dan pahat permukaan busur cekung kecil sesuai dengan pola ukiran melingkar pada mesin cekung. Selama pemrosesan, pastikan untuk menggunakan spons yang dibasahi air untuk pendinginan agar batu permata tidak retak karena panas selama pemrosesan.

Setelah menyelesaikan proses penggerindaan: gantilah dengan batang pemoles paduan seng, gunakan bubuk pemoles berlian dan ulangi proses penggerindaan untuk menyelesaikan pemolesan mahkota.

Setelah penggerindaan dan pemolesan mahkota batu permata selesai, batu permata dapat dilepaskan dari batang perekat, dibalik, dan dipasang kembali ke batang perekat untuk penggerindaan dan pemolesan paviliun.

7.3 Isu-isu teknis utama dalam peralatan pengolahan batu permata milenium

Pemrosesan gaya batu permata Pekerja Milenium dalam prosesnya membutuhkan keterampilan yang terampil, tetapi juga dalam persyaratan kinerja peralatan juga tinggi, masalah teknis utama adalah poin-poin berikut.

- Motor pemrosesan menggunakan sistem dua kecepatan, menggunakan kecepatan yang berbeda untuk ukuran batu permata yang berbeda. Kecepatan rendah digunakan untuk batu permata kecil, sedangkan kecepatan tinggi digunakan untuk batu permata besar, dengan kecepatan motor yang dikontrol untuk performa optimal antara 5000 ~ 6000r/menit. Pada kecepatan ini, batu permata yang dipoles memiliki kecerahan yang baik dan efisiensi yang tinggi.

- Kecepatan motor mikro dikontrol pada 20 putaran per menit untuk memastikan ketepatan dan efisiensi pengukiran dan pemolesan. Motor mikro terutama menggerakkan meja kerja mikro dalam gerakan bolak-balik; jika kecepatannya terlalu cepat, maka akan menyebabkan pantulan yang signifikan pada meja kerja mikro, memengaruhi ketepatan pengukiran dan pemolesan, sementara jika terlalu lambat akan memengaruhi efisiensi kerja.

- Apabila mengukir batu permata, batu permata harus ditempatkan pada perlengkapan, yang menjaga batu permata tetap sejajar dengan sumbu batang bundar, memastikan ukuran segi yang diukir seragam. Karena diameter batang bundar kecil, maka, setiap pergeseran akan mengurangi ketepatan segi cekung, yang menyebabkan ukuran segi yang diukir tidak merata.

- Garis tengah gerakan meja kerja mikro harus sejajar dengan garis tengah spindel; jika tidak, sisi cekung yang dihasilkan akan tampak miring atau berubah bentuk.

Jika metode pemrosesan batu permata gaya milenium berbeda, berbagai gaya milenium akan muncul; beberapa memiliki mahkota dan paviliun yang diproses sebagai permukaan melengkung, sementara yang lain memiliki mahkota yang diproses dengan aspek datar kecil dan paviliun sebagai permukaan melengkung. Gaya-gayanya selalu berubah, seperti berbentuk bintang, memancar, berbentuk krisan, spiral, dll., tampil modis dan mendalam, dikombinasikan dengan kecemerlangan batu permata yang menyilaukan, membuatnya sangat populer di kalangan konsumen.

8. Contoh Produksi Pabrik

(1) Penambahan Batu Permata Tunggal

Video Pemrosesan Batu Permata Tunggal CNC

(2) Penambahan Otomatis Batu Permata Tunggal Mekanis

Video Pemrosesan Batu Permata Tunggal Secara Manual di Pabrik