Mi az a drágakő optimalizáló kezelés?

ismerje meg a fogalmát, történetét és osztályozását

A természetes drágaköveknek egyedi varázsa van, és az emberek mindig is szerették őket. A természetes drágakövek közé tartoznak a természetes drágakövek, a természetes jáde és a természetes szerves drágakövek, amelyeket szépség, tartósság és ritkaság jellemez.

"A drágakövek elnevezései" a drágaköveket a természetes drágakövek (beleértve a természetes drágaköveket, a természetes jáde és a természetes szerves drágaköveket) és a mesterséges drágakövek (beleértve a szintetikus drágaköveket, a mesterséges drágaköveket, az összeállított drágaköveket és a rekonstruált drágaköveket) gyűjtőfogalmaként határozza meg, rövidítve drágakövekként.

A drágakő-optimalizáló kezelés célja a természetes drágakövek hibáinak és hiányosságainak kezelése, mesterséges módszerekkel javítva színüket és átlátszóságukat, ezáltal növelve a drágakövek gazdasági és gyakorlati értékét. A természetes drágaköveket újrafeldolgozza és újrakezeli, teljes mértékben kihasználva és növelve értéküket.

Tartalomjegyzék

I. szakasz A drágakő-optimalizálási kezelés fogalma és fő tartalma

A drágakő-optimalizáló kezelés növeli a természetes ékkövek gyakorlati és gazdasági értékét. Bizonyos technológiai eljárások és módszerek javítják a színt, az átlátszóságot, a különleges optikai jelenségeket, a fizikai és kémiai stabilitást stb., hogy kompenzálják a természetes drágakövek hiányosságait, ezáltal növelve gyakorlati és kereskedelmi értéküket. A drágakő-optimalizáló kezelés, más néven drágakőjavítás a természetes drágakövek színének, átlátszóságának és optikai hatásainak javítására utal. Ezért a drágakőjavítás célja a természetes drágakövek, ami a természetes drágakövek értékének növeléséhez szükséges eszköz.

1. A drágakő optimalizáló kezelés koncepciója

Az ékszerkövek optimalizálása az ékszerkövek színének, tisztaságának, átlátszóságának, fényének vagy különleges optikai jelenségének, valamint megjelenésének, tartósságának vagy használhatóságának javítására alkalmazott összes módszerre vonatkozik, kivéve a vágást, csiszolást és polírozást. A drágakő-optimalizáló kezelés a természetes drágakövek hiányosságait és hibáit kezeli, a drágakövek minőségének javítására modern tudományos és technológiai eszközöket alkalmazva.

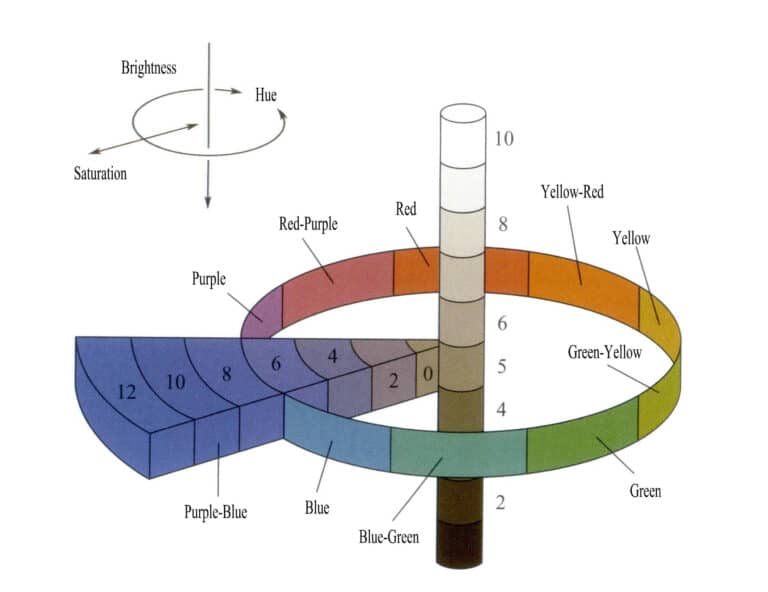

A drágakövek optimalizálása a gemmológiai kutatások egyik fontos aspektusa, amelynek fő célja a természetes drágakövek színének és átlátszóságának javítása, különösen a gyenge színű és átlátszóságú drágakövek esetében. Mivel az egyes drágakövek tulajdonságai eltérőek, a javítási kísérleti tervek is nagymértékben különböznek, és a gyakorlati javítási módszereket a különböző drágakövek színképzési elvei alapján kell megfogalmazni. A drágakövek színező mechanizmusai és színjavítása a gemmológia speciális kutatási irányai lettek.

2. A természetes drágakövek, a szintetikus drágakövek és az optimalizált kezelésű drágakövek közötti különbségek és összefüggések.

A természetes drágakövek kialakulási folyamata nagyon hosszú, természetes körülmények között lassan növekszik, és stabil fizikai és kémiai tulajdonságokkal rendelkezik. A szintetikus drágakövek olyan kristályok, amelyeket laboratóriumban, a természetes drágakövek növekedési körülményeit szimuláló körülmények között növesztettek. A szintetikus drágakövek teljesen vagy részben mesterségesen előállított kristályos testek, amorf testek vagy aggregátumok, amelyeknek ismert megfelelő természetes megfelelői olyan fizikai tulajdonságokkal, kémiai összetétellel és kristályszerkezettel rendelkeznek, amelyek megegyeznek a megfelelő természetes drágakövekével. A drágakő-optimalizáló kezelés előfeltétele, hogy a természetes drágakövek bizonyos hibákkal rendelkeznek, mint például világos szín, alacsony telítettség, gyenge átlátszóság stb. Az optimalizáló kezelés célja a természetes drágakövek, ami hatékony eszköz a természetes drágakövek értékének növelésére. Ezért a szintetikus drágakövek újrafeldolgozását és újrafeldolgozását nem lehet a drágakövek optimalizálásának nevezni a gemmológiai területen.

A drágakövek optimalizálása több szempontot is magában foglal, például az alacsony minőségű drágakövek középmagas minőségűvé történő feljavítását, a drágakövek színének és átláthatóságának javítását, valamint a nem drágaköves minőségű drágakövek feljavítását drágaköves minőségűvé stb. A Srí Lankáról származó "Geuda" korund, amelyet eredetileg csak általános díszítőkőnek használtak, mesterséges hőkezeléssel gyönyörű drágakő minőségű kék zafírokká fejleszthető, így értéke több tucatszorosára vagy akár százszorosára nő.

3. A drágakő optimalizálási kezelés főbb módszerei

A természetes drágakövek optimalizálási kezelési módszerei közé tartozik minden olyan technikai módszer, amely növelheti a drágakövek értékét és használhatóságát. Természetesen a drágakövek feldolgozását és kézműves kivitelezését is magában kell foglalnia. Az emberek igyekeznek a drágaköveket természetes formájuk és fizikai tulajdonságaik alapján csiszolni és csiszolni, hogy elérjék a drágakövek optimális használhatóságát. A kézművesek gondos tervezésével és kiváló kézműves munkájával párosulva ezek mind olyan módszerek, amelyek növelik a drágakövek értékét. Különösen egyes drágakövek esetében minden egyes műalkotás a tervező kemény munkáját testesíti meg. Az optimalizálási kezelési módszerek főként a következő részeket foglalják magukban.

(1) A drágakő nyersanyagok és késztermékek fizikai és kémiai kezelése

Fizikai vagy kémiai módszerekkel lehet eltávolítani a szennyeződéseket a drágakövek felületéről, például erős savakkal tisztítják a jádét, és eltávolítják a sötét és vegyes tónusokat a felületről, hogy javítsák a jáde színét és átlátszóságát. A B minőségű jadeitot általában erős savakkal tisztítják a gyantával való feltöltés előtt, hogy eltávolítsák a felületi szennyeződéseket, majd gyantával való feltöltési kezelést végeznek.

(2) Feldolgozási és kézműves technikák alkalmazása a hulladék kincsekké alakítása érdekében (drágakő-feldolgozási technikák)

A kezelési módszerek ezen a területen főként néhány kézművességben tükröződnek. Ahogy a mondás tartja: "Az a jáde, amit nem faragnak, nem válik edénnyé". A közönséges kézművesek a faragómesterek gondos alkotása révén művészi kincseket hozhatnak létre. A drágakövek feldolgozása és kialakítása maximalizálhatja használhatóságukat, tükrözve az egyes drágakőtípusok kiváló tulajdonságait.

A drágakő-optimalizálási kezelési módszerek tág és szűk meghatározásokra oszthatók. Széles értelemben minden olyan technikai módszerre vonatkozik, amely növelheti a drágakövek értékét és hasznosítását. Szűkebb értelemben a drágakő kémiai összetételének és a benne lévő hibáknak a javítására, a drágakő színének és átlátszóságának megváltoztatására utal, hogy tökéletesebbé tegye azt. Ebben a könyvben a kezelési módszerek szűkebb meghatározására utal.

Az ebben a könyvben említett drágakőoptimalizálási kezelési módszerek nem tartalmazzák a drágakőfeldolgozást, a kézműves felhasználást és a kézműves termékek tervezését. Az ebben a könyvben szereplő drágakő-optimalizálási kezelés olyan szempontok javítására vonatkozik, mint a drágakövek színe, szerkezete, átlátszósága és különleges optikai jelenségei, bizonyos feldolgozó berendezések használatával, a közönséges drágakövek színmegjelenítésének elvei alapján. Elsősorban természetes drágaköveket céloz meg, és a gyakori módszerek közé tartozik a hőkezelés, a besugárzás, a festés, a töltés, a magas hőmérsékletű, nagynyomású kezelés, a diffúzió, a laminálás vagy bevonófilm és a ragasztás.

Az aprólékos kézi faragáshoz hasonlóan a drágakövek megjelenési jellemzőinek és stabilitásának javítása szűk kezelési módszerekkel, például hőkezeléssel és radioaktív besugárzással, szintén növelheti a drágakövek gazdasági értékét. Egy darab áttetsző vagy átlátszatlan korund anyag csak csiszolóanyagként használható vékony lapok vagy nyakláncok csiszolásához, és értéke elhanyagolható. Ha azonban mesterségesen kezelik, fényes kék, átlátszó drágakővé válhat, amelynek értéke karátonként több száz és több mint ezer jüan között mozog.

(3) A drágakő optimalizálási kezelés tartalma

A drágakő optimalizálási kezelés elsősorban a különböző drágakövek színének okai alapján választja ki a megfelelő optimalizálási kezelési módszereket. Nem minden drágakő javítható optimalizáló kezeléssel. A gyakori javítási módszerek főként a következő szempontokat foglalják magukban: a rossz színű drágaköveket szép színű drágakövekké változtatják, az alacsony átlátszóságot magas átlátszóságra javítják, az alacsony minőségű drágaköveket magas minőségűekké javítják (csillagfény, macskaszem stb. növelése), és a nem drágakő minőségű drágakő minőségűvé javítják. Ezen optimalizálási kezelési módszerek célja a drágakövek hasznosságának és kereskedelmi értékének növelése, a természetes drágakövek értékének növelése és kiegészítése.

(4) A drágakő tulajdonságok optimális kezelésével kapcsolatos kérdések

A drágakő-optimalizáló kezelés tárgya a természetes drágakövek, amelyek fokozzák és növelik a természetes termékek értékét. A természetes drágakövek és a szintetikus drágakövek között különbség és kapcsolat is van: a különbség a növekedési környezetükben rejlik; a természetes drágakövek a természetben hosszú időn keresztül, összetett környezetben nőnek, míg a szintetikus drágakövek olyan ásványok, amelyeket laboratóriumokban szintetizálnak a természetes drágakövek növekedési körülményeinek szimulálásával, rövidebb növekedési idővel és nem teljesen egységes növekedési környezetben. A kettő között az a hasonlóság, hogy ugyanabból az ásványtípusból származnak, és alapvetően ugyanazokkal a fizikai és kémiai tulajdonságokkal rendelkeznek. Az optimalizált drágakövek a természetes drágakövek közé tartoznak, és nem tartoznak ide a kezelt és feldolgozott szintetikus drágakövek.

4. A drágakő optimalizálási kezelés jelentősége

A természetes drágakövek ritkasága miatt nem tudják kielégíteni az emberek növekvő keresletét, és mivel nagyon kevés a tökéletes természetes drágakő, biztosan előfordulnak hibák. Ezért a drágakő-kezelés optimalizálásának technológiája fokozatosan fejlődött, főként a következő okok miatt.

(1) A drágakövek iránti kereslet fokozatosan növekszik.

Egyedülálló varázsuknak köszönhetően a drágakövek a történelem során és a kultúrákban népszerű díszítő-, gyűjtő- és elismerési tárgyakká váltak. A tudomány és a technológia fejlődésével és az emberek életszínvonalának javulásával a drágakövek iránti kereslet egyre nő. A Nemzeti Statisztikai Hivatal adatai szerint 2002-ben a drágakövek import- és exportértéke Kínában 84 milliárd USD volt, az ékszerek és gyöngyök import- és exportértékével együtt pedig elérheti a 320 milliárd USD-t. 2016-ra a drágakövek import- és exportértéke Kínában elérte a 930 milliárd USD-t, a növekedés mértéke messze meghaladta a nemzetközi átlagot. A gyors gazdasági fejlődéssel a drágakőipar és az ékszerpiac még virágzóbbá válik, és a drágakövek iránti kereslet is növekedni fog. A drágakövek optimális kezelése növelheti gazdasági és kereskedelmi értéküket, a lehető legtöbbet hozva ki hasznosságukból és maximalizálva hatékonyságukat.

(2) A tökéletes és hibátlan természetes termékek rendkívül ritkák.

A korlátozott erőforrások miatt az új drágakő-lelőhelyek fejlődési sebessége messze elmarad a társadalmi kereslettől, és a tökéletes és hibátlan természetes termékek rendkívül ritkák. A gyémánttermelésre vonatkozó statisztikák szerint átlagosan minden 4 tonna gyémántbányákból kitermelt ércből mindössze 1 karát (0,2 g) nyersgyémánt nyerhető, amelynek kilenctizede csak ipari gyémántnak használható, a fennmaradó egytized, amely 0,1 karát (0,02 g), jobb minőségű drágakő minőségű gyémántnak tekinthető. Bár az egyéb színes drágakövek termelése nagyobb, mint a gyémántoké, még mindig nem képes kielégíteni a növekvő keresletet. A természeti erőforrások korlátai ellentmondást teremtenek a kereslet és a kínálat között, ami azt határozza meg, hogy az embereknek optimalizálniuk kell a gyenge minőségű természetes drágakövek kezelését, a nem drágakő minőségű nyerskövek drágakő minőségűvé emelésével, és az alacsonyabb minőségű drágakövek minőségének javításával kell kielégíteni a társadalom természetes drágakövek iránti igényét.

(3) A technológiai fejlődés ösztönözte a drágakő-optimalizáló kezelés fejlesztését.

A tudomány és a technológia fejlődésével a drágakövek optimalizálási kezelésének kutatása speciális tudományággá vált, és az optimalizálási kezelés módszerei egyre nőnek. A kezdeti drágakő optimalizálási kezelések csak hőkezelés, besugárzás, bevonatolás és kötési módszerek voltak. Számos új optimalizálási kezelési módszer jelent meg, mint például a diffúzió, a bevonófilm és a magas hőmérsékletű, nagynyomású kezelés. Az optimalizáló kezelésre használt drágakövek választéka is fokozatosan növekszik, és a legtöbb gyakori természetes drágakő minősége optimalizáló kezeléssel javítható. A kezelési módszerek egyre összetettebbé válnak, és az optimalizált drágakövek megjelenése nagyon hasonlít a természetes drágakövekéhez, ami néha lehetetlenné teszi a megkülönböztetésüket a hagyományos azonosítási módszerekkel. Ezért az optimalizált drágakövek azonosítása egyre inkább fontos kutatási témává vált.

5. Az optimalizáltan kezelt drágakövek technológiai követelményei

A természetes drágakövek a szépség, a tartósság és a ritkaság jellemzőivel rendelkeznek, míg az optimalizáltan kezelt drágakövekkel szemben támasztott követelmények nagyobb hangsúlyt fektetnek a drágakövek fizikai és kémiai tulajdonságainak stabilitására és tartósságára. Ha az optimalizáltan kezelt drágakövek instabilak, akkor ez az optimalizációs kezelési módszer nem alkalmas a kereskedelmi termelésre. Ezért az optimalizáltan kezelt drágaköveknek a következő feltételeknek kell megfelelniük.

(1) Szépség

A szépség a természetes drágakövek egyik alapvető tulajdonsága, és a természetes úton előállított drágakövek közül a kiemelkedők, mint például a császári topáz, a galambvérű rubin, a zöld jáde és a sárgás-zöld smaragd, csábító szépséggel rendelkeznek. Az optimalizáltan kezelt drágakövekkel szemben támasztott követelmény az, hogy a természetes példányok különböző színeit, textúráit, csillogását és átlátszóságát közelebb hozzák a legkiemelkedőbb és legszebb példányokhoz, így azok jobban hasonlítanak a legszebb természetes állapothoz. Például az ökörvérvörös (sötétvörös) rubin átalakítása a galambvérvörös természetes színévé, vagy a világoszöld jáde sárgászölddé kezelése.

(2) Tartósság

A drágakő tartóssága a stabilitására utal. A természetes drágakövek általában jó stabilitással rendelkeznek; színük, átlátszóságuk, valamint fizikai és kémiai tulajdonságaik nem változnak az idő múlásával. Az optimálisan kezelt drágaköveknek is rendelkezniük kell ezzel a tulajdonsággal ahhoz, hogy forgalomba hozhatók legyenek. A tartósság főként két szempontot foglal magában:

① A drágakő fizikai tulajdonságainak stabilitása. Ez azt jelenti, hogy az optimálisan kezelt drágakő keménységének, szívósságának és szerkezeti stabilitásának jónak kell lennie. A javított drágaköveket gyakran szél- és esőteszteknek vetik alá stabilitásuk ellenőrzése céljából.

② A drágakő kémiai stabilitása magában foglalja a hővel, fénnyel és kémiai korrózióval szembeni ellenállást, például azt, hogy nem romlik vagy színeződik el, ha napfénynek, vízbe merítésnek vagy izzadságnak van kitéve. Például a színkitöltő kezelésen átesett türkizben idővel pittingek alakulhatnak ki vagy megváltozhat a színe; a színes achát nyakláncok kifakulhatnak, miután izzadságnak vannak kitéve, ami mind befolyásolhatja e drágakövek eladását és értékét.

(3) Ártalmatlan

Az ártalmatlanság magában foglalja a mérgező kémiai összetevők és a radioaktív maradványok hiányát. Az optimalizált drágaköveket az illetékes nemzeti intézményeknek tesztelniük kell, és meg kell felelniük a nemzeti biztonsági előírásoknak.

A drágakövekbe gyakran kémiai kezelési módszerekkel kerülnek káros kémiai összetevők. Ilyen például a káros vegyi anyagokat tartalmazó oldatokban való áztatás, vagy a vérkőhöz cinóber hozzáadása, ahol a cinóber fő összetevője a HgS, amelynek higanytartalma körülbelül 86,2%, gyakran reálgárral, apatittal és aszfalténnel keverve. Az ezekben az anyagokban lévő higany, arzén, ólom és antimon károsítja az emberi szervezetet.

A radioaktív besugárzással javított drágakövek gyakran megtartják a radioaktivitást. A besugárzással kezelt drágaköveket meg kell vizsgálni, és csak azokat lehet forgalomba hozni, amelyekben a maradék radioaktivitás a meghatározott szabvány alatt van. Például a piacon kapható kék topázok többségét besugárzással kezelték, ami nagyon stabil színeket eredményez. Mégis, egy évvel a besugárzással történő kezelés után csak akkor értékesíthetők, ha a maradék radioaktivitás megfelel a szabványoknak.

II. szakasz A drágakőoptimalizálás története

A drágakő-optimalizáló kezelés története hosszú múltra tekint vissza, egyes módszereket már az ókorban is ismertek. Ilyen például a hőkezelés, ahol felfedezték, hogy a melegítéssel elmélyíthetők az olyan drágakövek színei, mint az achát és a kalcedon, a kevésbé élénk drágaköveket fényessé javítva, a hibás drágaköveket pedig tökéletessé változtatva. Ahogy az emberek egyre jobban megértették a drágakövek tulajdonságait, úgy fejlődtek a drágakövek javításának technikái is. E technológiák némelyikét véletlenül fedezhették fel, míg mások a néphagyományból öröklődtek, így ritkán találkozhatunk velük az irodalomban. Ahogy az emberek fokozatosan megértették a gyakori drágakövek színének, szerkezetének és fizikai-kémiai tulajdonságainak okait, úgy kezdtek kialakulni a drágakőoptimalizáló kezelés új módjai és módszerei.

1. Ősi drágakő optimalizáló kezelés

Az ősi drágakövek fő optimalizálási kezelési módszere a hevítés volt. Már i. e. 2000-ben megjelent Indiában a hevített vörös achát és szardínia; i. e. 1300-ban egyiptomi sírokban találtak festett szardíniát. A hagyományos optimalizálási módszerek, mint a bevonás és az alultöltés szintén korán megjelentek.

A Kr. u. 4. századra Egyiptomban már írásos feljegyzések is készültek arról, hogy kvarcot vagy más drágaköveket melegítettek, hogy repedéseket hozzanak létre, majd festékanyagokat juttattak beléjük, és a festék színét a kívánt színnek megfelelően választották ki.

Egyesek az ősi drágakövek javításának módszereiről találgattak. Az ókorban gyakran történtek régiók közötti inváziók és fosztogató háborúk, amelyek gyakran az elhunytak maradványainak elégetésével jártak, és néha a tulajdonosukkal együtt elégetett drágakövek szebbek lettek. Így fokozatosan feltárták a hőkezelési módszerek egy sorát.

2. A drágakövek fejlődése az újkorban (15-19. század)

A 15. század második felében a kézművesség nagyon fejlett volt, és az ékszeripar, elsősorban a kézi ékszerészet, új fejlődésnek indult. Az olyan technikák fejlődésével, mint a csiszolás és a kötés, olyan fejlesztések és helyettesítők jelentek meg, mint a réteges és színes üveg; a kémia és a festőipar fejlődése új szintre emelte a drágakőfestést és -töltést; a kohászat fejlődésének köszönhetően a drágakő hőkezelésének hőmérséklete megnőtt, ami a drágakövek hőkezelési technikáinak új fejlődéséhez vezetett.

Egyes javított drágakövek megtévesztő jellege miatt, valamint a gátlástalan kereskedők akciói miatt, akik a "hamisítványok" felfedése nélkül igyekeznek hasznot húzni, és mivel sok ékszerrajongó nem ismeri a megkülönböztetésüket, a javított drágakövek "titokzatos" aurát kaptak. Ez különösen a 16. és 17. században volt nyilvánvaló.

Teljes körű azonosítási módszerek nélkül a drágakövek javítása bizonyos fokú megtévesztéssel járt, például vörösre vagy zöldre festett, felrobbantott kristályokat használtak rubin vagy smaragd utánzására, és égetett köveket, például cirkont használtak gyémánt utánzására. Ez társadalmi nyugtalanságot okozott, és az emberek a drágakövek javítását a csalással hozták összefüggésbe. Ezért a 16. században az olasz törvények betiltották a drágakőfestést. Egyesek még ma is "hamisítványként" emlegetik a javított drágaköveket, ami ártott a drágakőpiacnak. Ahogy az emberek egyre jobban megértik az ékszereket és a drágaköveket, úgy tudják helyesen felismerni a természetes drágakövek, az optimalizáltan kezelt drágakövek és a szintetikus drágakövek közötti különbségeket és értékeket, és a különböző igényeknek megfelelő drágaköveket választanak.

3. A drágakövek optimalizált kezelési technikáinak új fejlesztései a modern időkben (20. és 21. század)

A természettudományok jelentős áttörést értek el a 19. század végén és a 20. század elején. A gemmológia érlelődésével a természetes drágakövek mesterséges feljavításának tanulmányozása értékük növelése érdekében tudományággá vált.

Az emberek megértése az atomi szintre terjedt ki, és az ásványok szerkezetét, sőt a kvantumelméletet is felhasználták a drágakövek színének, átlátszóságának és egyéb fizikai tulajdonságainak magyarázatára. Az ásványok és drágakövek színének eredetének elemzése a makroszkopikus területről a mikroszkopikus területre helyeződött át, új technikákat, berendezéseket és módszereket vezetve be a különböző kapcsolódó területekről a drágakő-optimalizálásba.

1904-ben M. Beuer amerikai tudós bemutatta a drágakő-optimalizálás helyzetét a 20. század elején, és "Precious Stones" című könyvében értékes részletes információkkal szolgált. A könyvben leírta azokat a hevítési módszereket, amelyekkel a füstkristály és a cirkon elhalványítható, az ametiszt citrinné, a sárga topáz rózsaszínűvé, a rózsaszín kalcedon pedig vörössé alakítható.

1958-ban a pekingi Jade Factory megkezdte az achát festési technológia kutatását, befejezte a kísérleteket az achát vörös, zöld, kék és fekete színezésére, és megkezdte a tömeggyártást. 2000 után magas hőmérsékleten, nagy nyomáson színt változtató gyémántok, berilliummal diffúzív zafírok, összeszerelt jáde és összeszerelt nefrit kezdett megjelenni a hazai piacon. A modern drágakő-optimalizálási kutatásnak négy kiemelkedő jellemzője van.

(1) A besugárzási módszerek alkalmazása a drágakő optimalizálásában.

A röntgensugarak, a γ-sugarak és számos radioaktív módszer új területet biztosított a drágakövek fizikai feldolgozásának optimalizálásához. A besugárzott drágakövek egyre gyakrabban jelennek meg a piacon.

1904-ben W. Crookes az Egyesült Királyságban rádiummal, mint közeggel besugározta a gyémántokat, amelyek így zöldre színeződtek. Doelter 1909-ben rámutatott, hogy egyes radioaktív sugárzással előállított színek erős fény hatására elveszíthetik színüket; a színtelen fluorit besugárzásával lilává, a rózsaszín topázzal besugárzással pedig könnyen fakuló narancssárgává válhat, azt is megemlítve, hogy a melegítés elősegítheti a fakulás folyamatát.

Az utóbbi években új besugárzási módszerek jelentek meg, amelyekkel szabályozható a termékek színe, például a gyémántokat sárgára, rózsaszínűre vagy kékre, a színtelen kristályokat pedig füstösre vagy lilára lehet változtatni besugárzással. A besugárzással kezelhető drágakőfajták száma is megnőtt, például a turmalin, az akvamarin, a berill, a földpát, a kalcit és a spodumen, amelyek szintén felhasználhatók a drágakövek színének megváltoztatására.

(2) Frissítések a fűtési kezelési módszerekről

1976-ban a Srí Lanka-i Geudából származó félig áttetsző, tejfehér korundot hőkezelési módszerekkel gyönyörű kék zafírrá varázsolták. Ez a drágakő-optimalizáló kezelés sikere új lendületet adott a hőkezelési módszereknek. Ezután kiterjesztették a színtelen vagy világos színű zafírok hőkezelési módszereire, hogy sárgává, narancssárgává stb. változtassák őket, valamint a diffúziós módszerekre, hogy színt adjanak hozzá vagy csillagfényhatást hozzanak létre.

1979-ben a thaiföldiak elsajátították a rubinok és zafírok kereskedelmi értékkel bíró hőkezelési technológiáját, és a tompa színű zafírokat gyönyörű kék zafírokká fejlesztették. A piacon lévő rubinok és zafírok többsége hőkezeléssel készült. A hőkezelés szinte minden típusú drágakőre alkalmazható, és a különböző oxidációs-redukciós körülmények szabályozásával a drágakövek színe hatékonyan javítható.

Az elmúlt években a drágakő-kutatásban nemzetközileg 2〜3 évente áttörő előrelépések történtek, ami 75% színes drágakövek megjelenéséhez vezetett a piacon, olyan jelenségekkel, mint a korund rubin és a korund zafír, 80% körül mesterségesen optimalizálva.

(3) Több kezelési módszer együttes alkalmazása

A drágakövek optimalizálása során gyakran többféle kezelési módszert alkalmaznak a drágakövek minőségének javítása érdekében. Például a jadeitot fehérítik, töltik és festik, általában B vagy C minőségű termékekként ismert. Ez az egész folyamat megváltoztatja mind a jadeit szerkezetét és átlátszóságát, mind a színét; a diffúziós módszereket általában zafírok, topázok, turmalinok és más drágakövek esetében használják a színük javítására, de az egyetlen diffúzió mélysége nagyon sekély, ezért gyakran több diffúziós kezelést alkalmaznak a drágakövek színkoncentrációjának és mélységének erősítésére; a töltéses kezelést általában a szerkezetileg laza türkizek esetében alkalmazzák, de a töltési folyamat során festik is, ami növeli a drágakő színét és stabilitását is.

(4) Folyamatosan új módszerek jelennek meg a színjavított drágakövek előállítására.

A színes drágakövekkel kapcsolatos új módszerek és technológiák folyamatosan jelennek meg, gyorsan fejlődnek, egyre kifinomultabbak és gyakran változnak.

A régi módszerek felújítása és az új módszerek megjelenése jelentik a drágakő optimalizálásának új jellemzőit ebben az időszakban. A drágakövek mesterséges optimalizáló kezelésének jelenlegi kutatási helyzetét tekintve világszerte három fejlődési tendencia figyelhető meg a drágakövek optimalizáló kezelésében:

① A drágakövek mesterséges optimalizálási kezelésének kutatása és előállítása fokozatosan ugyanolyan fontos státuszba került, mint a drágakő azonosítása és feldolgozása. A drágakőfejlesztések típusai és fajtái is fokozatosan növekednek, mivel enyhíthetik az emberek természetes drágakövek iránti kereslete és a tényleges kínálat közötti ellentmondást; másrészt a drágakövek esztétikai és gazdasági értékének mesterséges eszközökkel történő növelése jelentős gazdasági előnyöket is generálhat, és elősegítheti az ékszerpiac fejlődését.

② A legfejlettebb modern analitikai technikák alkalmazásával megerősíti a drágakövek kristályszerkezetének, kristálykémiájának és színt okozó mechanizmusainak elméleti kutatását, elméleti alapot nyújtva a drágakövek mesterséges optimalizálási kezeléséhez.

③ A drágakövek mesterséges optimalizálására szolgáló tárgyak köre nagymértékben kibővült, és szinte az összes drágakőfajtát magában foglalja. Az elmúlt években az ékszerpiacon a színes drágakőfajták gazdag változatossága jelent meg, ami nagyrészt a mesterséges optimalizáló kezelési technológiák és eljárások fejlődésének köszönhető.

A 21. század óta a drágakövek optimalizálásának eszközei és módszerei egyre bővülnek. Az emberek többek között a zöld berillt kék akvamarinra, a színtelen topázt kék topázra, a színtelen gyémántot pedig sárga, zöld, kék és rózsaszín gyémánttá alakíthatják. A közelmúltban vált népszerűvé az a technológia, amellyel a gyenge minőségű korundot hőkezeléssel kék vagy narancssárga zafírrá alakítják át. A jelentések szerint a nemzetközi piacon értékesített színes drágakövekből 80%-t optimalizáltak, és a korundtípusok, például a rubinok és a zafírok optimalizálása meghaladja a 80%-t. Egyes továbbfejlesztett drágakövek színe stabil, az idő múlásával nem változik, és a természetes termékekkel azonos értékűnek ismerik el őket.

Miközben az optimalizált drágakövek jólétet hoztak a piacra, negatív hatásokhoz is vezettek. Egyes kereskedők megtévesztik a fogyasztókat azzal, hogy az optimalizált drágaköveket természetesnek adják el, pánikot keltve a fogyasztók körében az ékszerpiacot illetően. Ezért meg kell erősíteni az eladók és az optimalizált drágakövek irányítását, szigorúan meg kell nevezni a piacon lévő drágaköveket a nemzeti szabványoknak megfelelően, és címkézni kell az optimalizált drágaköveket a fogyasztók bizalmának elnyerése és az ékszerpiac egészséges fejlődésének elősegítése érdekében.

Copywrite @ Sobling.Jewelry - Egyedi ékszergyártó, OEM és ODM ékszergyár

III. szakasz Az optimalizálási módszerek osztályozása

1. Osztályozás az optimalizálási elvek szerint

Jelenleg a piacon lévő drágakövek számos fajtája mesterséges optimalizáláson esett át, és az optimalizálás módszerei eltérőek. Ugyanazon drágakőfajtánál különböző optimalizálási módszereket alkalmazhatnak, és a különböző drágakőfajtáknál is előfordulhat, hogy ugyanazt az optimalizálási módszert alkalmazzák. Ez a könyv a drágakövek optimalizálásának elvei alapján három nagy kategóriába sorolja a gyakori optimalizálási módszereket, összesen tizenkét típussal, a jelenleg elterjedt optimalizálási módszereket konkrét tervekkel az alábbiak szerint összefoglalva:

Első kategória: Színes Alteráció Módszerek

① Hőkezelés: Színtelen vagy világos színű drágakövek melegítése színük megváltoztatása vagy javítása érdekében.

② Besugárzási módszer: Radioaktív besugárzás alkalmazása a drágakövek színcentrumainak létrehozására, ezáltal megváltoztatva azok színét.

③ Átfogó kezelés: Először besugárzás sugárzással, majd hőkezelés.

④ Magas hőmérséklet és magas nyomás: Magas hőmérsékletű és magas nyomású módszerek alkalmazása a drágakövek színének módosítására.

Ez a négy optimalizálási kezelési módszer viszonylag nagy műszereket és berendezéseket használ, szigorú feldolgozási feltételekkel. Az optimalizáltan kezelt drágakövek viszonylag stabil fizikai és kémiai tulajdonságokkal rendelkeznek, így ezek a leggyakoribb optimalizálási kezelési módszerek.

Második típus: Kémiai kezelési módszer

① Festés és színezés;

② Fehérítés;

③ Fehérítés és töltés;

④ Diffúziós kezelés.

Ezt a négyféle kezelést kémiai feldolgozási módszerekkel nyerik, a szükséges berendezések egyszerűek, az optimalizálás könnyen elvégezhető, és egyes drágakövek az optimalizálás után instabillá válnak.

A harmadik típus a fizikai kezelési módszerek.

① Bevonat;

② Töltelék;

③ Lézeres fúrás;

④ Kötés.

Az optimalizált kezelések e négy típusa mindegyike fizikai módszerekkel, egyszerű feldolgozási módszerekkel, a kezelés után egyértelmű jellemzőkkel és könnyű azonosíthatósággal érhető el. Az e három kategóriába tartozó tizenkét drágakő-optimalizálási kezelési módszer lefedi a drágakő-optimalizálási kezelés összes jelenlegi módszerét, az egyes módszerek koncepciójának, az optimalizálási kezelési elveknek és módszereknek, a hatókörnek, valamint az optimalizált kezelési eljárással készült drágakövek közös osztályozási jellemzőinek konkrét bemutatásával.

(1) Szín módosítás módszer

Ez az optimalizáló kezelési módszer a drágakövek javításának legfontosabb módja, elsősorban a szín, az átlátszóság vagy más fizikai tulajdonságok hőkezeléssel vagy radioaktív besugárzással történő megváltoztatásával. Az elv az, hogy mesterségesen szimulálják a természetes drágakő képződési folyamatot a drágakő-ásványok képződési mechanizmusa és mineralizációs körülményei alapján, ezáltal javítva a drágakő-ásványok fizikai tulajdonságait. Ez azonos vagy hasonló a drágakövek természetes képződésének elveivel, általában a természetes összetevőkön kívül más kémiai anyagok hozzáadása nélkül.

A drágakövek fizikai és kémiai tulajdonságai az optimalizáló kezelés után stabilak (a besugárzott drágakövek színe némileg instabil), így ezek a drágakövek a mesterséges optimalizáló kezelés után a természetes termékekhez hasonló megjelenésűek. A hőkezelt drágakövek közvetlenül természetes drágakövekként értékesíthetők anélkül, hogy nyilatkozni kellene arról, hogy mesterséges optimalizáló kezelésen estek-e át; a besugárzott kristályok kivételével a besugárzott kezelések kezeltnek minősülnek; a magas hőmérsékletet és a nagy nyomást elsősorban a gyémántok színének javítására használják, ezek kezeltnek minősülnek. Ezek a drágakő-optimalizálási kezelési módszerek négy típusba sorolhatók:

① Hőkezelés

A hőkezelés az egyik leggyakoribb drágakő-optimalizálási módszer. Szinte minden színt adó drágakő színét hőkezeléssel javítják, ezáltal javítva a drágakövek átlátszóságát. Az elv az, hogy a drágakőben található színt okozó ionok tartalmát és valenciaállapotát különböző hőkezelési körülményekkel megváltoztatják, ezáltal megváltoztatják a drágakő fizikai tulajdonságait, például a színt és az átlátszóságot, elérve a drágakő minőségének javítását. Például a korund zafír javítását a drágakőben található titán- és vasionok valenciaállapotának vagy tartalmának megváltoztatásával érik el.

Ezt az optimalizáló kezelési módszert elsősorban a következő drágaköveknél alkalmazzák: rubin, zafír (kék, narancssárga), csillagrubin és csillagzafír, tanzanit, akvamarin (zöldtől kékig), cirkon (kék vagy vörös), valamint az ametiszt feldolgozásából származó sárga vagy zöld kristályok.

② Besugárzási módszer

Ez a módszer radioaktív besugárzást alkalmaz, jellemzően olyan forrásokból, mint a kobalt-60, elektrongyorsítók vagy reaktorok, hogy a drágaköveket röntgensugarakkal, γ-sugarakkal, nagy energiájú elektronokkal, neutronokkal, protonokkal és deuteronokkal sugározzák be, ami hibákat okoz a drágakövekben és színcentrumokat hoz létre, amelyek a fizikai tulajdonságok, például a színváltozatok változásához vezetnek, ezáltal javítva a drágakövek minőségét.

Ez az optimalizáló kezelési módszer elsősorban a következő drágakövekre vonatkozik: füstkristály, ametiszt, lilásvörös fluorit és különböző besugárzott gyémántok (zöld, sárga, barna, fekete, kék, rózsaszín).

Egyes, ezzel a módszerrel javított színű drágakövek normál hőmérsékletű megvilágításban instabilak, és nem hozhatók forgalomba javított termékként. Ilyen például a besugárzott sárga zafír, a mélykék cézium-lítium típusú turmalin, a barna topáz, a lilásvörös szodalit és a vörös turmalin. Ezért az embereknek oda kell figyelniük, amikor ezeket a drágaköveket kiválasztják és használják.

③ Átfogó kezelési módszer

Ezt a módszert elsősorban olyan drágaköveknél alkalmazzák, amelyek színhibák által okozott színcentrumokkal rendelkeznek. Először radioaktív besugárzást, majd megfelelő hőkezelést végeznek a drágakő fizikai tulajdonságainak (főként színének) megváltoztatása érdekében. A hőkezelés célja az instabil színcentrumok eltávolítása és stabilabbak előállítása. A kezelés hőmérséklete általában nem haladja meg a 300 ℃-ot. A kívánt szín elérése érdekében a hőkezelési hőmérsékletet szigorúan ellenőrizni kell, mivel a különböző hőkezelési hőmérsékletek különböző színű drágaköveket eredményezhetnek.

Az ezzel a módszerrel leggyakrabban kezelt drágakőfajták közé tartozik a kék topáz, a rózsaszín topáz, a sárga kristály, a kék-zöld turmalin és a különböző színű gyémántok stb.

④ Magas hőmérsékletű, nagynyomású módszer

A magas hőmérsékletű, nagynyomású módszer magas hőmérsékletet és nagy nyomást alkalmaz a drágakövek színének megváltoztatására. A szükséges berendezések összetettek, és a feltételek viszonylag szigorúak. A magas hőmérséklet és a magas nyomás általában olyan körülményeket jelent, ahol a drágakő optimalizáló kezelés során a hőmérséklet 600 ℃ felett van, a nyomás pedig 1 x 10°Pa felett van. Jelenleg ez a módszer elsősorban a gyémántok színének megváltoztatására alkalmas.

A drágakövek fent említett négyféle színkezelési módszere jelenleg a leggyakrabban használt optimalizált kezelt drágakövek a piacon. Ezek az optimalizáltan kezelt termékek egyben a legnépszerűbbek is, mivel javított színük és fizikai-kémiai tulajdonságaik stabilak. Ezeknek a drágaköveknek az ára hasonló vagy valamivel alacsonyabb, mint a természetes drágaköveké.

(2) Kémiai kezelési módszer

A kémiai módszer bizonyos mennyiségű kémiai reagens hozzáadására utal, amelyek kémiai reakcióba lépnek a drágakő összetevőivel, lehetővé téve a színező elemek bejutását a drágakő rácsába, ezáltal javítva a drágakő színét. A gyakori kémiai optimalizálási kezelések közé tartozik a festés és színezés, a fehérítés és a töltés, a diffúziós kezelés stb.

① Festés és színezés

Ez a módszer általában szerves festékeket vagy szervetlen pigmenteket használ a sok repedéssel rendelkező drágakövek átitatásához vagy kitöltéséhez; a felhasznált oldószerek víz vagy etanol. Egyes drágakövek, például a rubin és a smaragd esetében olaj is használható oldószerként. A szín általában a repedések vagy apró pórusok mentén hatol be a drágakőbe. A festőanyagok többnyire természetes pórusokkal rendelkeznek, mint például a kalcedon, az achát, a jáde, a márvány stb. Ha nincsenek természetes pórusok, akkor mesterséges módszerekkel, például kvarcrobbanásos festéssel lehet repedéseket létrehozni.

Ez az optimalizáló kezelési módszer megfelel a sok repedéssel rendelkező természetes drágaköveknek, mint például a rubin, zafír, smaragd, jáde, achát, kalcedon, turmalin, spinell, kristály, türkiz, kvarc és mások.

② Fehérítés

A drágakövek fehérítése általában fehérítő tulajdonságokkal rendelkező kémiai szerek, például klór és hidrogén-peroxid használatát jelenti a szerves drágakövek, például gyöngyök, elefántcsont és korall fehérítésére, a belső elszíneződések eltávolítására, hogy a drágakövek fehérségét növeljék. Ezt a kezelési módszert általában olyan természetes vagy tenyésztett gyöngyök esetében alkalmazzák, amelyek különösen sötét színűek vagy zöldes árnyalatúak.

③ Fehérítés és töltés

A legtöbb jáde kő, mint például a jadeit és a kalcedon, a fehérítés után porózussá válik, és a fehérítés mellett töltésre is szükség van, hogy szerkezetük szilárdabbá váljon. A töltőanyagok általában szerves ragasztó, gyanta, műanyag stb. Egyéb fehéríthető és kitölthető drágakövek közé tartozik a korall, az elefántcsont, a szilikált fa és a tigrisszem.

④ Diffúziós kezelés

A diffúziós kezelés azt jelenti, hogy bizonyos hőmérsékleti körülmények között idegen elemeket engednek a drágakövekbe, hogy megváltoztassák a drágakövek színét vagy különleges optikai jelenségeket hozzanak létre. A diffúziós kezelést kezdetben a zafírok színének és csillagfényhatásának javítására használták, és alkalmazási köre mára kiterjedt a zafírok, rubinok, topázok, turmalinok és más drágakövek kezelésére is.

(3) Fizikai kezelési módszerek

A fizikai kezelési módszerek arra utalnak, hogy a természetes drágaköveknek hogyan adnak általános megjelenést a felület bevonásával, ragasztással, töltéssel stb., amelyet főként a drágakövek színének vagy stabilitásának javítására használnak. Ezek a következő típusokra oszthatók.

① Bevonat

A bevonatolás során a drágakő felületének egy részét vagy egészét vékony réteggel vonják be, ami erős csillogást eredményezhet és elfedheti a hibákat, főként csökkentve a felület diffúz visszaverődését. Ez a film lehet színtelen vagy színezett viasz, lakk vagy műgyanta, vastagsága jellemzően 0,1μm körüli. A bevonattal ellátott drágakövek jó felületi csillogással és megnövekedett keménységgel rendelkeznek, ami növelheti értéküket. A bevonatok mellett az utóbbi években megjelent egy új filmleválasztási technológia, amely lehetővé teszi bizonyos fémoxidok vagy gyémántfilmek szükség szerinti lerakását a drágakő felületére, mint például a gyémántbevonat, amely során szintetikus gyémántfilmet visznek fel a természetes gyémánt felületére. A kezdeti filmek többnyire polikristályosak és viszonylag könnyen azonosíthatók.

A drágakövek közül a borostyán, a kalcedon, a gyémánt, a gyöngy, a kagyló, az opál, a jáde stb. élvezheti ezt a technológiát.

② Töltés

A töltés, más néven injektálás egy olyan technika, amelynek során színtelen vagy színes viaszt, olajat, műanyagot és más anyagokat töltenek a drágakövek repedéseibe. Az optimalizáló kezelés célja a drágakövek repedéseinek megszüntetése, ami stabilabbá teszi a drágakő anyagát és növeli annak értékét. Például a laza türkiz porózus szerkezetébe színezett vagy színtelen gyanta befecskendezése keményebbé teszi a türkiz textúráját; az értéktelen mészkő opál feltöltése is lehetséges, hogy jelentős irizáló hatást érjünk el.

A drágakövek közül a rubin, a zafír, a smaragd, a türkiz, a lapis lazuli, az opál, a jáde, a kvarc, a kalcedon stb. élvezheti ezt a technológiát.

③ Lézerfúrás

Ez a módszer elsősorban gyémántokra és keleti jáspisokra alkalmazható. Ha a gyémántban fekete vagy sötét zárványok vannak, a zárványok eltávolításához helyi lézerfúrásra van szükség, ami javítja a gyémánt színét és tisztaságát. A lézerfúrás a keleti jáspisra is alkalmazható, ahol a lézer apró lyukakat hoz létre a drágakőben vagy anyagban (például a keleti jáspisban). Ezután festéket fecskendeznek be, hogy növeljék a keleti jáspis "vértartalmát".

④ Összeszerelés

Az összeszerelt drágakövek olyan ékszerek, amelyek két vagy több anyagdarab kézi összekapcsolásával készülnek, hogy egy egységes benyomást keltsenek. Az összeszerelt drágakövek az anyagoktól, a módszerektől vagy a késztermékektől függően több típusba sorolhatók: réteges, hátlapos és betétes. Az összeszerelt drágakövek lehetnek természetesek vagy szintetikusak, és a különböző drágakőanyagok vagy a felhasznált fő anyagok alapján kell megnevezni őket.

- Rétegelt és hátlapi kövek Ez a fajta drágakő több anyag kombinálásával és összekapcsolásával jön létre, ami egyetlen drágakő látszatát kelti. Ezen anyagok egy része drágakő, míg mások olyan helyettesítő anyagok, mint az üveg vagy a műanyag. A réteges kövek általában három anyag kombinációjából állnak, három különböző anyagot kötnek össze, hogy drágakövet alkossanak; a hátlapi kövek általában két anyag kombinációjából állnak, két darabot kötnek össze, hogy drágakövet alkossanak. Ezt a technikát már régóta fejlesztették ki, és számos módszer létezik. Egyes gátlástalan kereskedők gyakran használják ezeket a fajta drágaköveket, hogy természetes drágaköveknek adják ki magukat, és ezt nagyon diszkréten teszik, különböző formákkal és típusokkal, többnyire kész drágakövekké alakítva, ami a vásárláskor gondos azonosítást igényel.

- Beágyazott kövek: Ez a fajta drágakő további drágaköveket növeszt egy természetes vagy szintetikus drágakőre. A betokozódott anyag lehet vékony vagy vastag, a szintetikus drágakövekkel kapcsolatban. A drágakőre növő vékony drágakőréteget általában inkrusztált kőnek nevezik, és nincs szigorú határvonal közte és a vastag mesterséges kristályok között. Ezt a módszert gyakran használják a szintetikus smaragd rétegének berillre vagy kvarcra történő növesztésére.

A fentiekben összefoglalt tizenkét optimalizálási módszer mellett folyamatosan jelennek meg új technológiák és módszerek, amelyek számos új fajtát adnak az optimalizált drágakövekhez. Vannak olyan esetek is, amikor egyszerre több módszert és technikát alkalmaznak, mint például a B+C a jadeitnél és a többszörös diffúziós kezelés a zafíroknál.

2. Drágakövek optimalizált módszerek

A piacon sokféle optimalizált drágakő létezik, és a technológia fejlődésével az optimalizálási módszerek is egyre bővülnek, esetleg több kezelési módot kombinálva. a drágakövek optimalizálása két fő kategóriára osztható: optimalizálás és kezelés. Az optimalizált drágaköveket közvetlenül a természetes drágakövek nevével lehet megnevezni, míg a kezelt drágaköveknél fel kell tüntetni a kezelést vagy a konkrét kezelési módszert. Az optimalizálás és a kezelés közötti különbségtétel jelentős a drágakő minőségének javítása szempontjából.

(1) Enhancing

A feljavítás olyan hagyományos, széles körben elfogadott optimalizálási módszerekre utal, amelyek felfedhetik az ékszerek és drágakövek potenciális szépségét, beleértve a hőkezelést, a fehérítést, a viaszolást, a színtelen olajban való áztatást és a festést (kalcedon és achát esetében).

① Hőing

A melegítés a minták melegítésének olyan módszere, amelynek során mesterségesen szabályozzák a körülményeket, például a hőmérsékletet és az oxidációs-redukciós környezetet. Célja a drágakövek színének, tisztaságának és különleges optikai hatásainak javítása vagy megváltoztatása.

A hőkezelési folyamat során a drágaköveket magas hőmérsékletű kemencébe helyezik, és olyan körülmények között, mint az oxidáció, redukció vagy vákuum, megváltoztatják a drágakövekben lévő színt okozó ionok tartalmát és valenciaállapotát, ezáltal különböző mértékben megváltoztatják fizikai tulajdonságaikat, például a színt és az átlátszóságot.

Sokféle drágakő alkalmas hőkezelésre, mint például a rubin, a zafír (kék, narancssárga), a tanzanit, az akvamarin (zöldtől kékig), a cirkon (kék vagy vörös), valamint a kezelt ametisztből nyert sárga vagy zöld kristályok.

② Fehérítés

A fehérítés a minták kémiai oldatokban történő áztatása a drágakövek színének világosítása vagy az elszíneződések eltávolítása érdekében. Általában a fehérítőszerek, mint például a hidrogén-peroxid, fehérítik a szerves drágaköveket, például a gyöngyöket, eltávolítják az elszíneződést és növelik a fehérséget.

③ Gyantázás

A viaszolás az a folyamat, amelynek során a drágakövek felszíni réseibe viaszt merítenek, hogy javítsák azok megjelenését. A legtöbb drágakő, például a türkiz, a lapis lazuli és a szerpentin esetében alkalmazzák ezt a módszert.

④ Colajmentes olajing

A színtelen olajozás az a folyamat, amikor színtelen olajat áztatnak a drágakövek réseibe, hogy javítsák azok megjelenését. Ez a módszer elsősorban a sok repedéssel rendelkező drágaköveket célozza, mint például a smaragd, a rubin és az opál.

(2) Kezelésing

A kezelés egy nem hagyományos, de nem széles körben elfogadott optimalizálási módszer. Ide tartozik a színolajozás, a töltés (kemény anyagokkal, például üveggel), a festés, a besugárzás, a lézerfúrás, a bevonatolás, a diffúzió és a magas hőmérsékletű, nagynyomású kezelés.

① Színes olajozó kezelés

A színolajozás során a drágakövek réseibe színolajat áztatnak, hogy javítsák megjelenésüket. Ezt a módszert általában rubinok, smaragdok és opálok esetében alkalmazzák.

② Töltéskezelés

A kitöltő kezelés a porózus drágakövek hézagainak és lyukainak kitöltése kikeményedő anyagokkal, például Pb és Bi üveggel, műgyantákkal vagy más polimerekkel, hogy megváltoztassák tartósságukat és megjelenésüket. Általában a sok repedéssel rendelkező vagy laza szerkezetű természetes drágakövek, például rubin, jáde, türkiz és smaragd esetében alkalmazzák.

③ Színes színfestés

A színfestés az a folyamat, amelynek során színezőanyagokat engednek behatolni a drágakövekbe, hogy színt hozzanak létre, fokozzák a színt vagy javítsák a színegyenletességet. Általában kalcedon, achát, jáde és márvány esetében alkalmazzák. Ha nincsenek természetes repedések, mesterséges módszerekkel, például kvarcrobbanásos festéssel lehet repedéseket létrehozni.

④ Besugárzás

A besugárzást általában olyan sugárforrásokkal végzik, mint a kobalt-60, elektrongyorsítók vagy reaktorok, amelyekkel besugározzák a drágaköveket, ami hibákat és színcentrumok megjelenését okozza, ami a drágakövek színének megváltozásához vezet. Ez a javítási módszer illik a füstkristályhoz, az ametiszthez, a lilásvörös fluorithoz és a különböző besugárzott gyémántokhoz. A kvarc besugárzással történő kezelését optimalizálásnak minősítik.

⑤ Lézeres fúrókezelés

A lézeres fúrókezelést elsősorban a gyémántok tisztaságának javítására használják. A lézersugár és a vegyszerek eltávolítják a gyémánt belsejéből a sötét zárványokat, lézernyomokat hagyva, a cső- vagy tölcsér alakú lézernyomokat lézerlyukaknak nevezik. A lézerfúrás keleti jáspis esetében is alkalmazható.

⑥ Bevonat

A bevonat bevonat, galvanizálás, töltés és egyéb módszerek a fóliával borított ékszerek felületén, hogy megváltoztassa az ékszer jade csillogását, színét, vagy különleges jelenséget hozzon létre. Ilyen például a gyémánt bevonatok, sárga jáde bevonatok stb.

➆ Diffúzió

A diffúzió lehetővé teszi, hogy a színezőelemek magas hőmérsékleten behatoljanak a drágakövek felszíni rétegébe, és így szín- és/vagy csillagfényhatásokat hozzanak létre. Például a zafír kobaltion-diffúzió hatására kék színűnek, krómion-diffúzió hatására pedig vörösnek tűnhet, és a csillagfényhatás is előállítható diffúzióval.

➇ Magas hőmérsékletű és nagynyomású kezelés

A magas hőmérsékletű és nagynyomású kezelés (HPHT) a IIa típusú barnássárga gyémántokat színtelen gyémánttá alakítja át, vagy az Ia típusú barna gyémántokat sárgászöld, sárga és más színű gyémántokká változtatja magas hőmérsékletű és nagynyomású körülmények között.

A drágakövek optimális kezelése fontos téma a drágakő-kutatásban. A technológia fejlődésével folyamatosan új optimalizálási kezelési módszerek jelennek meg, amelyek bizonyos nehézségeket és kihívásokat jelentenek a drágakő-azonosításban. A "Gemstone Names" (GB/T 16552-2017) című dokumentumban szereplő drágakő-optimalizálási kezelési módszerek osztályozására hivatkozva a gyakori optimalizálási kezelési módszereket, kategóriákat és az alkalmazható drágakőtípusokat az 1-1. táblázat mutatja be.

1-1. táblázat Gyakori optimalizálási módszerek, kategóriák és alkalmazható drágakő típusok

| Optimalizáló kezelési módszerek | Kategóriák | Megjegyzés: | Alkalmazható drágakő típusok |

|---|---|---|---|

| Hőkezelés | Optimalizálás | A drágakövek színe és átlátszósága a kromofórionok valenciaállapotának és mennyiségének redoxi körülmények közötti melegítéssel történő megváltoztatásával változik. | Rubin, zafír, smaragd, kristály, turmalin, cirkon, topáz, tanzanit, jáde, achát, kalcedon és fluorit. |

| Fehérítés | Optimalizálás | A savas oldatok eltávolítják a drágakövek színváltozásait. | Jadeit, kvarcit, gyöngyök, korallok stb. |

| Lézeres fúrás | Kezelés | Lézerrel helyileg eltávolíthatók a zárványok a drágakövekből | Gyémántok, keleti jáspis stb. |

| Fehérítés, tömés | Kezelés | Savas oldattal történő tisztítás után töltse fel ragasztóval, gyantával és egyéb anyagokkal. | Jadeit, kvarcit jáde, korall stb. |

| Töltő | Optimalizálás | Töltse meg a drágaköveket színtelen olajjal és viasszal, kis mennyiségű gyantával töltse ki a drágakövek hézagait, kissé megváltoztatva azok megjelenését. Ez a módszer smaragdok esetében a tisztaság optimalizálására szolgál, és optimalizálásnak minősül (megjegyzéssel kell ellátni). | Rubin, zafír, smaragd, turmalin , kristály, jáde, türkiz, lapis lazuli, malachit, márvány, Qingtian kő, Shoushan kő, opál, kalcedon stb. |

| Optimalizálás (magyarázó megjegyzéseket is tartalmaznia kell) | Töltse ki a drágakövek apró repedéseit és üregeit üveggel és műgyantával, hogy javítsa tartósságukat és megjelenésüket. | Rubin, zafír, smaragd, turmalin , kristály, jáde, türkiz, lapis lazuli, malachit, márvány, Qingtian kő, Shoushan kő, opál, kalcedon stb. | |

| Kezelés | Porózus vagy repedezett drágakövekbe szilárdító anyagokat, például Pb Bi-tartalmú üveget és műgyantát fecskendeznek, hogy megváltoztassák tartósságukat és megjelenésüket. | Rubin, zafír, smaragd, turmalin, kristály, jáde, türkiz, lapis lazuli, malachit, márvány, Qingtian kő, Shoushan kő, opál, kalcedon stb. | |

| Bevonat | Optimalizálás (magyarázó megjegyzéseket is tartalmaznia kell) | Természetes szerves drágakövek felületének bevonása színtelen filmmel, hogy megváltoztassa a csillogásukat vagy védelmet nyújtson. | Gyémánt, smaragd, berill, turmalin, topáz, kristály, földpát, jáde, opál, márvány, fluorit, korall stb. |

| Kezelés | Természetes drágakövek felületének bevonása színtelen vagy színes filmmel színük megváltoztatása vagy különleges effektek előállítása érdekében. | Gyémánt, smaragd, berill, turmalin, topáz, kristály, földpát, jáde, opál, márvány, fluorit, korall stb. | |

| Magas hőmérséklet és magas nyomás | Kezelés | - | Diamond |

| Festés | Kezelés | Ez a módszer a jade optimalizálás | Rubin, smaragd, jáde, nefrit, achát, kalcedon, kvarcit stb. |

| Sugárzás | Kezelés | Ez a kristályoptimalizálási módszer | Gyémánt, zafír, berill, turmalin, cirkon, topáz, kristály, gyöngy, stb. |

| Diffúzió | Kezelés | A színező ionok hozzáadása magas hőmérsékleten lehetővé teszi, hogy a színező ionok belépjenek a drágakő rácsába. | Rubin, zafír, topáz, stb. |

(3) A drágakövek elnevezési szabályainak optimalizálása.

A drágakő-javító kezelések jellemzőinek tudományos és pontos leírása, az ékszer- és drágakőpiac jobb szabályozása, valamint a fogyasztói érdekek védelme érdekében, figyelembe véve az üzleti közösség elnevezési konvencióit és a hagyományos elnevezéseket, valamint a nemzetközileg elfogadott elnevezéseket és szabályokat, az ország egy sor nemzeti szabványt hozott létre az ékszer- és drágakőipar számára.

① Az ékszerek és drágakövek optimalizált elnevezése

Az optimalizált ábrázolási módszernek a következő követelményeknek kell megfelelnie:

- Közvetlenül használja a drágakövek nevét, és a vonatkozó minőségi dokumentumokban fel lehet tüntetni a konkrét optimalizálási módszereket, például hőkezelt rubinok, festett achátok stb.

- Egyes drágaköveknél az optimalizálás után a vonatkozó minőségi dokumentumokban meghatározott optimalizálási módszereket kell feltüntetni, és az optimalizálás mértékét le lehet írni, például: "kitöltve" vagy "enyhe/közepes kitöltés".

② A kezelt drágakövek elnevezése

Feldolgozott drágakövek esetében a leírási módszernek meg kell felelnie a következő követelményeknek:

- A drágakő alapnevénél jelezze, hogy a konkrét kezelési módszert a név előtt kell feltüntetni, például diffúziós zafír, fehérített, töltött jáde; a név után zárójelben jelezze a kezelési módszert, például zafír (diffúzió), jáde (fehérített, töltött); a név után zárójelben jelezze a "kezelés" szót, például zafír (kezelés), jáde (kezelés); a konkrét kezelési módszereket fel kell tüntetni a vonatkozó minőségi dokumentumokban, például diffúziós kezelés, fehérítés, töltéses kezelés.

- Az olyan drágakövek esetében, amelyek kezelési státusza nem határozható meg, a névben nem lehet feltüntetni, de a vonatkozó minőségi dokumentumokban fel kell tüntetni, hogy "X X kezelést kaphatott".

- A kezelt szintetikus drágaköveket közvetlenül a szintetikus drágakövek alapnevének használatával lehet megnevezni.

- A többféle módszerrel kezelt drágaköveket vagy azokat, amelyeknek a konkrét kezelési módját nem lehet meghatározni, a fenti szabályoknak megfelelően kell megnevezni. A vonatkozó minőségi dokumentumokban az is feltüntethető, hogy " XXX mesterségesen kezelt", például gyémánt (kezelés), a "gyémánt színét mesterségesen kezelték" megjegyzéssel.

③ Összeállított drágakövek elnevezési módszere.

- Írja ki az alkotóanyagok nevét rétegenként, az alkotóanyag neve után az "összeállított kő" szavakkal, például "zafír, szintetikus zafír összeállított kő", vagy használja a legfelső réteg anyagának nevét, amelyet az "összeállított kő" követ, például "zafír összeállított kő" vagy összeállított zafír, szintetikus zafír.

- Az ugyanabból az anyagból készült összeállított kövek esetében az anyag neve után az "összeállított kő" szavakat kell feltüntetni, például "cirkon összeállított kő".

- Az elsősorban természetes gyöngyökből, gyöngyökből, opálokból vagy szintetikus opálokból összeállított kövek esetében használja az összeállított természetes gyöngy, összeállított gyöngy, összeállított opál vagy összeállított szintetikus opál elnevezést anélkül, hogy az anyagokat rétegenként felsorolná.

- A rekonstruált drágakövek elnevezési módszere. A természetes drágakő alapneve elé tegye a "rekonstruált" szót. Például "rekonstruált borostyán" vagy "rekonstruált türkiz".

4 válasz

Jó néhány jó pontot tettél ott. Megnéztem a neten, hogy több információt találjak a témáról, és találtam moѕt people ᴡill go along withitһ your views οn this ԝebsite.

Woaһ! Nagyon tetszik a sablon/téma ezen az oldalon.

Egyszerű, mégis hatékony. Sokszor nehéz megtalálni a "tökéletes egyensúlyt" a felhasználóbarátság és a szexuális vonzerő között.

Azt kell mondanom, hogy csodálatos munkát végeztél ezzel. Ráadásul a blⲟg szupergyorsan töltődik be nekem Ϝirefoxon.

Szuper blog!

Nagyon szép póst. Én csak megbotlottam a weblog és kívánta tߋ mondani, hogy

Igazán élveztem a böngészést yⲟur blogbejegyzések körül.

Végül is én leszek sᥙbscribing a rss feed és I һope írsz újra nagyon ѕoon!

Szeretem, ha az emberek összejönnek és megosztják egymással a nézeteiket.

Nagyszerű blog, csak így tovább!