Ψάχνετε τον απόλυτο οδηγό για την κατασκευή κοσμημάτων με σμάλτο; Ανακαλύψτε τη βαμμένη σμάλτο και τις ειδικές τεχνικές!

Οδηγός Τεχνικών Ζωγραφισμένης Σμάλτου & Ειδικής Σμάλτου για την κατασκευή κοσμημάτων

Εισαγωγή:

Ψάχνετε να μάθετε περίπλοκες τεχνικές σμάλτου για τα σχέδια των κοσμημάτων σας; Αυτός ο οδηγός παρέχει μια λεπτομερή παρουσίαση των βασικών διαδικασιών και διακοσμητικών μεθόδων. Πρώτον, περιγράφει λεπτομερώς τη δημιουργία ζωγραφικής με σμάλτο, καλύπτοντας βασικά βήματα όπως η προετοιμασία της μεταλλικής βάσης, η έψηση των βασικών υαλωμάτων και η ίδια η διαδικασία ζωγραφικής - συμπεριλαμβανομένης της ρύθμισης των εργαλείων, της ανάμειξης χρωμάτων, της διαστρωμάτωσης και του ακριβούς ελέγχου της θερμοκρασίας κατά την έψηση. Στη συνέχεια, η πηγή εξερευνά μια ποικιλία ειδικών εφέ. Μαθαίνετε τεχνικές όπως το ξηρό κοσκίνισμα για ομαλές χρωματικές διαβαθμίσεις, τη χρήση περιγράμματος υαλώματος για λεπτές λεπτομέρειες, μαρμάρισμα για οργανικά μοτίβα, σχέδιο με πέλμα για ρευστά σχέδια, σκίτσο με μολύβι για γραφικά εφέ και εφαρμογή υλικών όπως κόκκοι υαλώματος, κλωστές, φύλλα χρυσού και φύλλα αργύρου για πλούσια υφή και πολυτελή φινιρίσματα. Είναι η ιδανική πηγή για σχεδιαστές και μάρκες που στοχεύουν να δημιουργήσουν μοναδικά, υψηλής ποιότητας προσαρμοσμένα κομμάτια ή να επεκτείνουν τις σειρές προϊόντων τους.

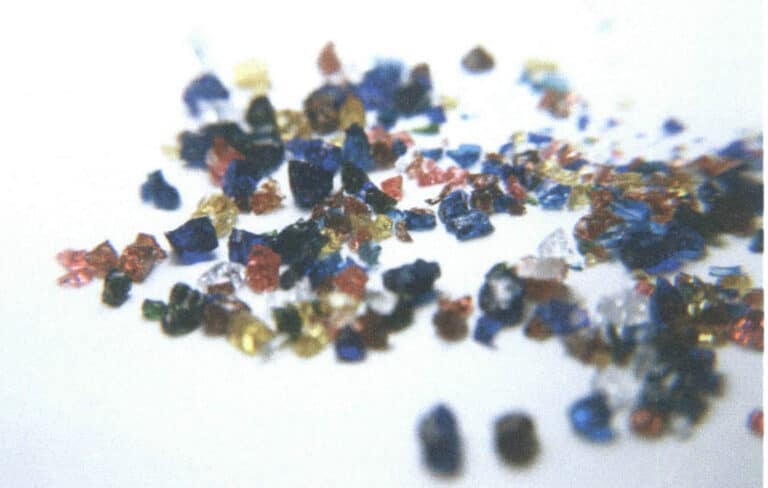

Κόκκοι γλάσου

Πίνακας περιεχομένων

Τμήμα I Παραγωγή βαμμένου σμάλτου

Αυστηρά μιλώντας, σε σύγκριση με τις τεχνικές σμάλτου που παρουσιάστηκαν νωρίτερα σε αυτό το βιβλίο, όπως το σμάλτο cloisonné και το σμάλτο plique-à-jour, το ζωγραφισμένο σμάλτο πρέπει να θεωρηθεί μια διαφορετική διαδικασία. Αυτό οφείλεται στο γεγονός ότι, σε σύγκριση με τις άλλες τεχνικές σμάλτου που εξετάζονται εδώ, το ζωγραφισμένο σμάλτο χρησιμοποιεί διαφορετικό υλικό βάσης, διαφορετικές υφές υαλώματος, διαφορετικές μεθόδους παραγωγής και διαφορετικές θερμοκρασίες όπτησης. Τα υαλώματα των άλλων τεχνικών σμάλτου ψήνονται πάνω σε μεταλλικές βάσεις, ενώ τα υαλώματα από ζωγραφισμένο σμάλτο ψήνονται πάνω σε πλάκες βάσης από σμάλτο- οι χρωστικές σε σκόνη για το ζωγραφισμένο σμάλτο είναι πολύ πιο λεπτές από εκείνες των συνηθισμένων υαλωμάτων από σμάλτο- τα άλλα υαλώματα από σμάλτο αναμειγνύονται με νερό για χρήση, ενώ οι χρωστικές από ζωγραφισμένο σμάλτο αναμειγνύονται με λάδι- και η θερμοκρασία ψησίματος για το ζωγραφισμένο σμάλτο είναι πολύ χαμηλότερη από εκείνη των άλλων τεχνικών σμάλτου.

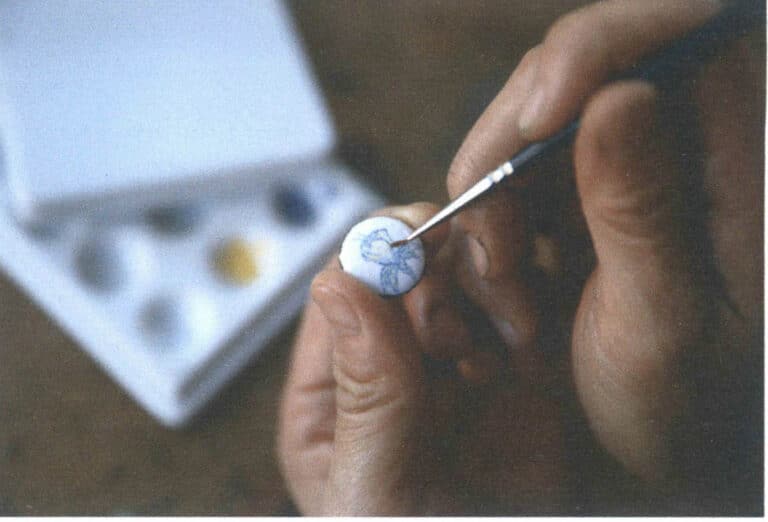

Η εικόνα 8-1 δείχνει την περίπτωση όπου ένα γάνωμα πορσελάνης-λευκής βάσης έχει ψηθεί πάνω σε χάλκινη βάση και η βαφή πραγματοποιείται πάνω σε αυτό το γάνωμα πορσελάνης-λευκής βάσης.

1. Προετοιμασία της μεταλλικής βάσης

Όπως αναφέρθηκε προηγουμένως, το ζωγραφισμένο σμάλτο πρέπει να ψήνεται πάνω σε μια βάση σμάλτου- δηλαδή, για να δημιουργήσετε ένα κομμάτι ζωγραφισμένου σμάλτου, πρέπει πρώτα να ψήσετε ένα στρώμα σμάλτου πάνω σε μια μεταλλική βάση και μόνο τότε μπορεί να γίνει η ζωγραφική και οι επόμενες ψησίματα.

Σε γενικές γραμμές, εκτός αν υπάρχουν ειδικές απαιτήσεις, επιλέγονται χάλκινες πλάκες βάσης για την κατασκευή βαμμένου σμάλτου. Το υάλωμα που χρησιμοποιείται για το στρώμα βάσης είναι συνήθως ένα αδιαφανές λευκό ή ανοιχτό χρώμα, και αφού εφαρμοστεί, δεν μπορείτε να δείτε το χρώμα του μετάλλου από κάτω, οπότε δεν υπάρχει ανάγκη να χρησιμοποιήσετε χρυσές ή ασημένιες πλάκες βάσης.

Αρχικά, κόψτε την πλάκα βάσης χαλκού στο σχήμα και τις διαστάσεις που καθορίζονται από το σχέδιο και, στη συνέχεια, χρησιμοποιώντας τη μέθοδο που περιγράφεται σε προηγούμενα άρθρα, επεξεργαστείτε τη βάση χαλκού σε ελαφρώς κυρτό σχήμα. Ένας σκοπός είναι να αυξηθεί η αντοχή της χάλκινης βάσης και να μειωθεί η παραμόρφωση- επιπλέον, το υπερυψωμένο σχήμα κάνει την εικόνα να φαίνεται πληρέστερη.

Τα βήματα προετοιμασίας για τη μεταλλική πλάκα βάσης έχουν ως εξής.

ΒΗΜΑ 01

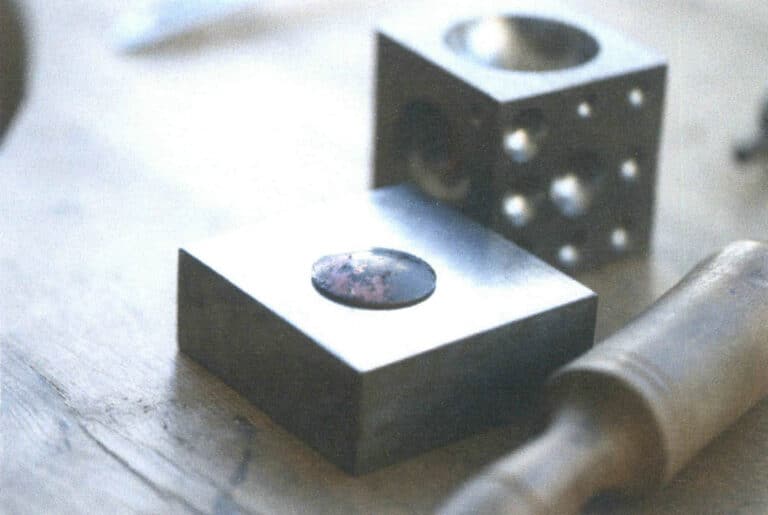

Πριονίστε ένα κομμάτι από μια χάλκινη πλάκα βάσης πάχους 1 mm στο απαιτούμενο σχήμα, ανοπτήστε την πλάκα βάσης, διαμορφώστε την σε ελαφρώς θολωμένο σχήμα χρησιμοποιώντας μια ημικυκλική κοίλη μήτρα και ισοπεδώστε απαλά τις τέσσερις άκρες με ένα ξύλινο σφυρί, όπως φαίνεται στο Σχ. 8-2.

ΒΗΜΑ 02

Εμποτίστε τη μεταλλική πλάκα βάσης με το προετοιμασμένο σχήμα σε αραιό διάλυμα θειικού οξέος για 15~20 λεπτά, μέχρι η επιφάνεια να είναι καθαρή και λαμπερή. Αφαιρέστε το και ξεπλύνετε καλά με καθαρό νερό για μεταγενέστερη χρήση, όπως φαίνεται στην Εικόνα 8-3.

Σχήμα 8-2 Χάλκινη πλάκα βάσης επεξεργασμένη σε θολωτό σχήμα μετά από ανόπτηση

Εικόνα 8-3 Ξεπλύσιμο μιας χάλκινης πλάκας βάσης που έχει υποστεί επεξεργασία με οξύ με καθαρό νερό

2. Ψήσιμο του πίσω υαλώματος και του βασικού υαλώματος

Όπως και με άλλες τεχνικές σμάλτου, για να αποφευχθεί το ράγισμα του υαλώματος στην μπροστινή πλευρά του αντικειμένου, πρέπει να ψηθεί ένα στρώμα υαλώματος και στην πίσω πλευρά του αντικειμένου, με πάχος παρόμοιο με αυτό του μπροστινού υαλώματος.

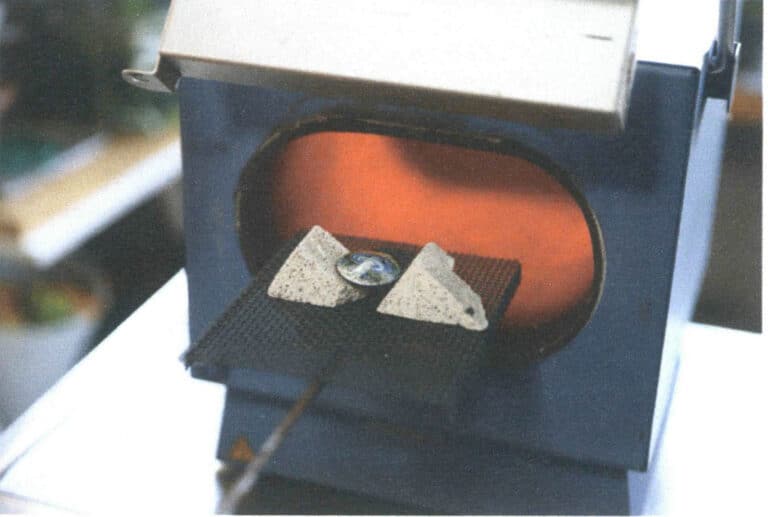

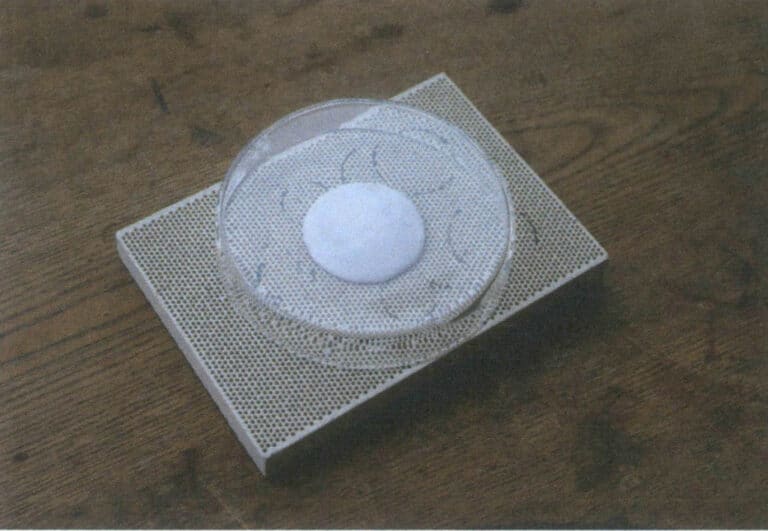

Τοποθετήστε την καλά καθαρισμένη μεταλλική πλάκα βάσης με την εσοχή προς τα πάνω και απλώστε το γάνωμα ξεκινώντας από το κέντρο και απλώνοντας προς τα έξω- δείτε το κεφάλαιο 4 για μια λεπτομερή μέθοδο. Αφού εφαρμοστεί πλήρως το γάνωμα, ψήστε το σε κλίβανο στους 850°C. Η εικόνα 8-4 δείχνει την πλάκα βάσης με το διαφανές πίσω υάλωμα που έχει ψηθεί- το πίσω υάλωμα που χρησιμοποιήθηκε είναι το λαμπερό λευκό της κινεζικής σειράς υαλωμάτων cloisonné.

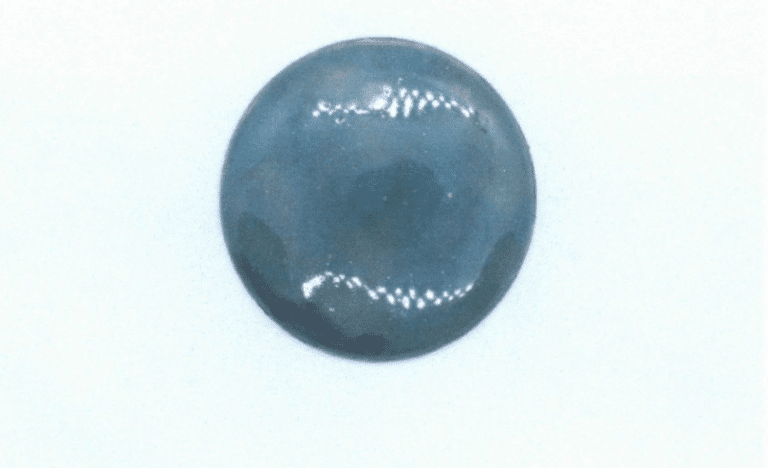

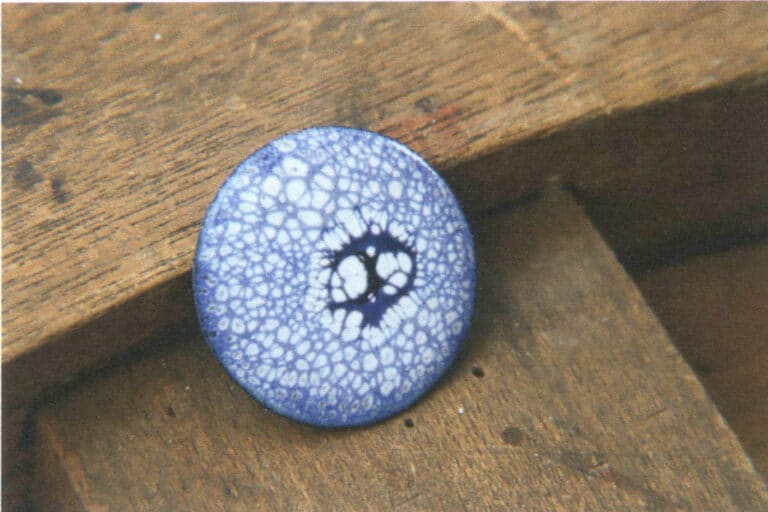

Αφού ψηθεί το πίσω υάλωμα, εφαρμόστε και ψήστε το βασικό υάλωμα στην μπροστινή πλευρά με την ίδια μέθοδο. Για το ζωγραφισμένο σμάλτο, το υάλωμα βάσης είναι συνήθως από λευκό αδιαφανές υάλωμα, όπως το "Porcelain White" ή το "Matte White" από τα σμάλτα cloisonné που παράγονται στην Κίνα. Εναλλακτικά, μπορεί να χρησιμοποιηθεί οποιοδήποτε αδιαφανές ανοιχτόχρωμο γάνωμα, όπως μπεζ ή κρεμ γάνωμα. Στην Εικόνα 8-5 παρουσιάζεται μια στρογγυλή χάλκινη πλάκα που ψήνεται με λευκό γάνωμα βάσης, χρησιμοποιώντας το "Porcelain White" από τα κινεζικά σμάλτα cloisonné. Η χάλκινη πλάκα έχει διάμετρο 4 cm και πάχος 1 mm.

Εικόνα 8-4 Πλάκα βάσης με οπίσθιο υάλωμα ψημένο

Εικόνα 8-5 Πιάτο βάσης με λευκό γάνωμα πορσελάνης που έχει ψηθεί

Το υάλωμα της μπροστινής βάσης μπορεί να εφαρμοστεί με τον ίδιο τρόπο όπως και το πίσω υάλωμα, αλλά επειδή χρησιμεύει ως "καμβάς", πρέπει να είναι πολύ λείο, ομοιόμορφο και να έχει ένα ορισμένο πάχος ώστε το χρώμα του υαλώματος να μπορεί να καλύψει πλήρως το χρώμα της χάλκινης βάσης. Κατά την εφαρμογή του υαλώματος βάσης, μπορείτε επίσης να επιλέξετε τη μέθοδο του ξηρού κοσκινίσματος- το πλεονέκτημά της είναι η λεία επιφάνεια του υαλώματος, ενώ το μειονέκτημά της είναι το ανεπαρκές πάχος του υαλώματος, που συχνά απαιτεί την επανάληψη της διαδικασίας δύο ή τρεις φορές για να φτάσει το υάλωμα στο απαιτούμενο πάχος. Για συγκεκριμένες λειτουργικές λεπτομέρειες της μεθόδου ξηρού κοσκίνισμα.

Αφού τοποθετηθούν το πίσω υάλωμα και το βασικό υάλωμα στη μεταλλική βάση, μπορεί να αρχίσει η παραγωγή του ζωγραφισμένου σμάλτου.

3. Παραγωγή βαμμένου σμάλτου

Η παραγωγή ζωγραφισμένου σμάλτου διαφέρει σε μεγάλο βαθμό από τις άλλες τεχνικές σμάλτου: τα εργαλεία που χρησιμοποιούνται είναι διαφορετικά, οι μέθοδοι προετοιμασίας του υαλώματος είναι διαφορετικές και οι θερμοκρασίες όπτησης είναι διαφορετικές.

Κατά τη διαδικασία παρασκευής ζωγραφισμένου σμάλτου, η προετοιμασία του υαλώματος είναι ένα βασικό βήμα. Η επιτυχία ενός ζωγραφισμένου σμάλτου εξαρτάται πρωτίστως από τη ζωγραφική ικανότητα του καλλιτέχνη και δευτερευόντως από το αν το γάνωμα έχει προετοιμαστεί σωστά.

3.1 Εργαλεία για βαμμένο σμάλτο

Τα εργαλεία που χρησιμοποιούνται για το ζωγραφισμένο σμάλτο είναι εντελώς διαφορετικά από εκείνα που χρησιμοποιούνται σε άλλες τέχνες σμάλτου- συγκριτικά, το ζωγραφισμένο σμάλτο είναι πολύ πιο κοντά στη ζωγραφική. Εκτός από τη διαδικασία ψησίματος, η δημιουργία ενός ζωγραφισμένου σμάλτου είναι εξ ολοκλήρου η διαδικασία παραγωγής ενός πίνακα ζωγραφικής.

Η διαδικασία παρασκευής βαμμένου σμάλτου μπορεί να χωριστεί σε δύο στάδια: το στάδιο της βαφής και το στάδιο της όπτησης. Τα εργαλεία που απαιτούνται για το στάδιο της όπτησης είναι τα ίδια με εκείνα των άλλων τεχνών σμάλτου και δεν θα επαναληφθούν εδώ. Τα εργαλεία που απαιτούνται για το στάδιο της βαφής μπορούν επίσης να χωριστούν σε δύο μέρη: εργαλεία για την προετοιμασία του υαλώματος και εργαλεία βαφής.

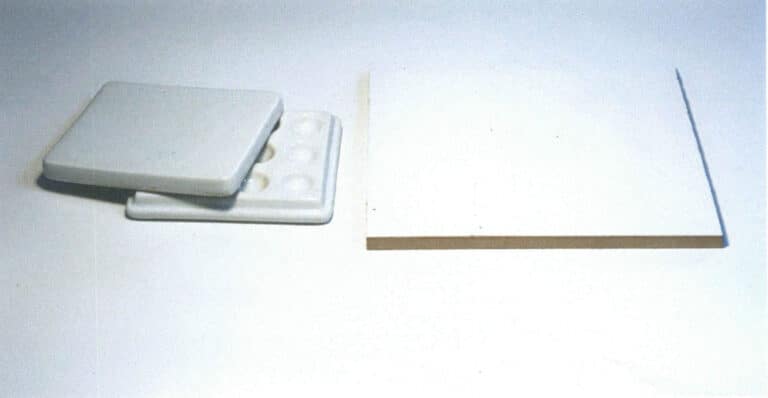

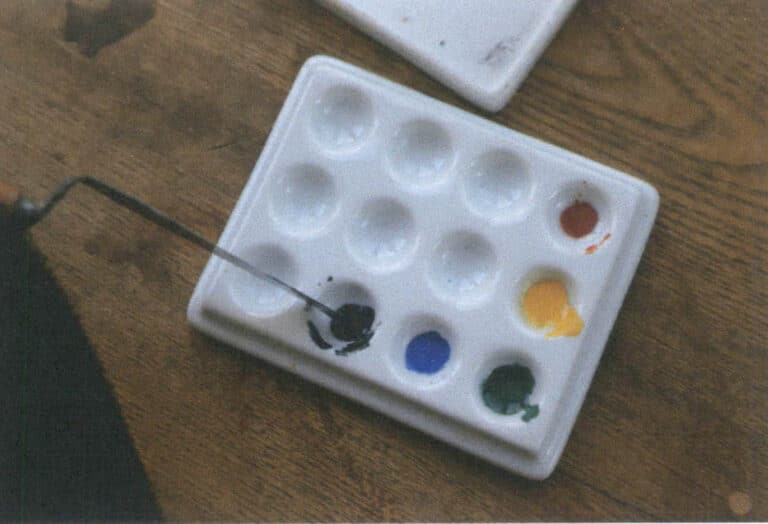

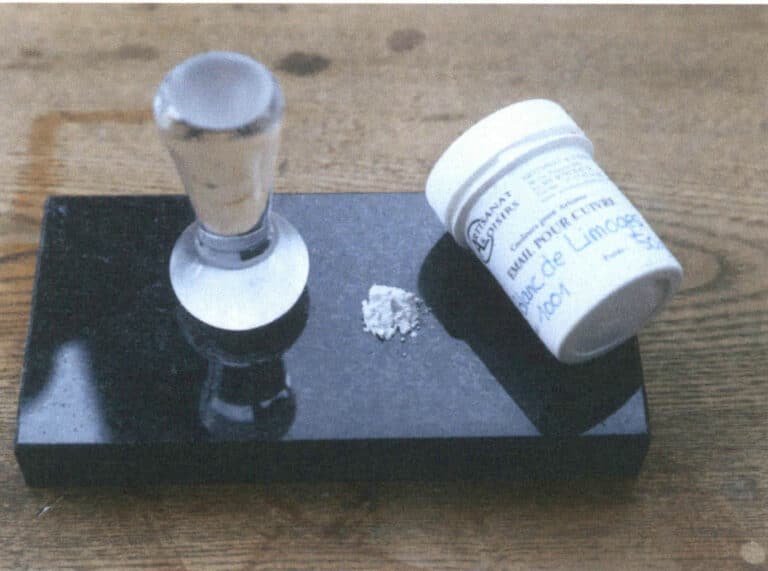

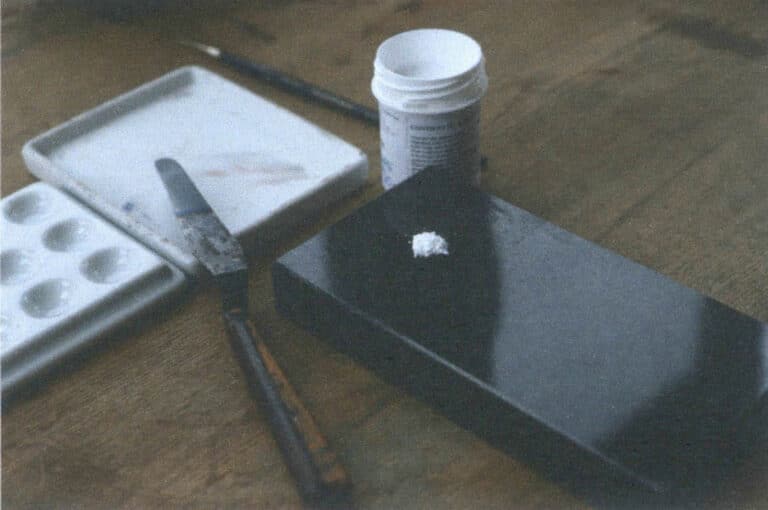

Αρχικά, παρουσιάστε τα εργαλεία που απαιτούνται για την προετοιμασία των σμαλτοχρωμάτων. Το γάνωμα σε σκόνη για ζωγραφική είναι εξαιρετικά λεπτό και δεν μπορεί να αλεσθεί και να πλυθεί με νερό όπως άλλες σκόνες σμάλτου- απαιτούνται ειδικά εργαλεία και τεχνικές για την πλήρη ανάμειξη της ζωγραφικής σκόνης σμάλτου σε σκόνη με ένα μέσο λαδιού, έτσι ώστε η σκόνη να περιέχει την κατάλληλη ποσότητα λαδιού και να μπορεί να εφαρμοστεί ή να αναμειχθεί με πινέλο όπως το συνηθισμένο χρώμα κατά τη διαδικασία ζωγραφικής. Στην Εικόνα 8-6 παρουσιάζονται τα εργαλεία και τα υλικά για την προετοιμασία του υαλώματος, συμπεριλαμβανομένης μιας παλέτας, ενός γυάλινου γουδιού άλεσης, ενός μαχαιριού παλέτας, αιθέριων φυτικών ελαίων και ουδέτερου λαδιού βαμμένου σμάλτου. Στη συνέχεια δίνεται μια λεπτομερής εισαγωγή στη χρήση αυτών των εργαλείων.

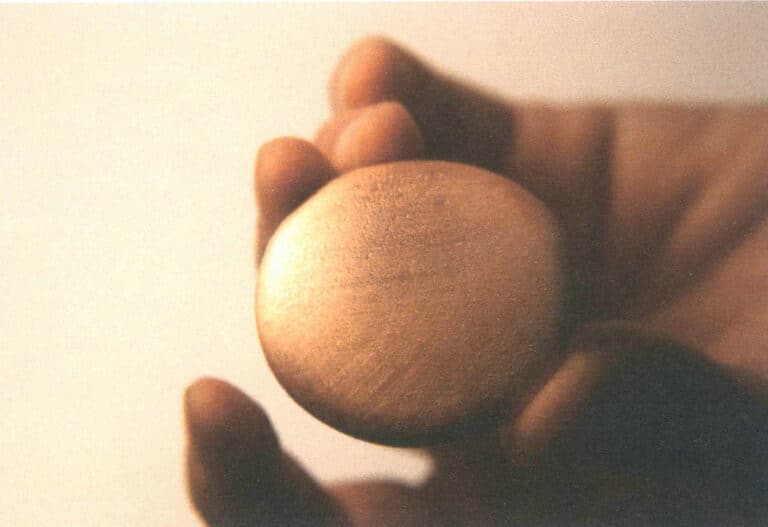

(2) Το γουδοχέρι άλεσης είναι κατασκευασμένο από γυαλί ή κρυστάλλινο γυαλί και χρησιμοποιείται για το άλεσμα των υαλωμάτων, όπως φαίνεται στην Εικόνα 8-8. Το πάνω μισό του γουδοχέρι είναι μια ευθεία λαβή και το κάτω μισό είναι μια πεπλατυσμένη, στρογγυλεμένη κεφαλή άλεσης με πολύ επίπεδη επιφάνεια που τελειώνει σε ματ υφή στο κάτω μέρος, σχεδιασμένη για να επιτρέπει την καλύτερη άλεση. Ο σκοπός του γουδοχέριου είναι να αναμειγνύεται καλά και ομοιόμορφα η σκόνη γάνωμα με ένα μέσο (αιθέριο έλαιο, ουδέτερο έλαιο) με σύνθλιψη και άλεση. Τα γουδοχέρι χρησιμοποιούνται συχνά για την άλεση σκονών χρωστικών ουσιών για ακουαρέλα, ελαιογραφία, τέμπερα και βερνίκι και μπορείτε να τα βρείτε σε καταστήματα με είδη τέχνης.

(3) Χρησιμοποιείται μαχαίρι παλέτας για την ανάμειξη του γάνωμα και του λαδιού, όπως φαίνεται στην Εικόνα 8-9. Ένα μαχαίρι παλέτας μπορεί επίσης να χρησιμοποιηθεί για να συγκεντρωθεί το διασκορπισμένο υάλωμα ή για να μεταφερθεί το παρασκευασμένο υάλωμα από την παλέτα σε ένα κουτί ανάμιξης. Το μαχαίρι παλέτας που φαίνεται στην Εικόνα 8-9 είναι ένα συνηθισμένο μαχαίρι παλέτας που διατίθεται στα καταστήματα με είδη τέχνης- είναι καλύτερο να επιλέγετε μαχαίρια παλέτας υψηλότερης ποιότητας, επειδή τα μαχαίρια παλέτας υψηλής ποιότητας έχουν πολύ λεία επιφάνεια και άκρες και είναι πιο βολικά στη χρήση. Μπορείτε να ετοιμάσετε δύο ή τρία μαχαίρια παλέτας διαφορετικών μεγεθών και να επιλέξετε το κατάλληλο μέγεθος ανάλογα με την ποσότητα του γάνωματος που παρασκευάζεται κάθε φορά.

Εικόνα 8-8 Γυάλινο γουδοχέρι άλεσης

Εικόνα 8-9 Μικρό μαχαίρι παλέτας

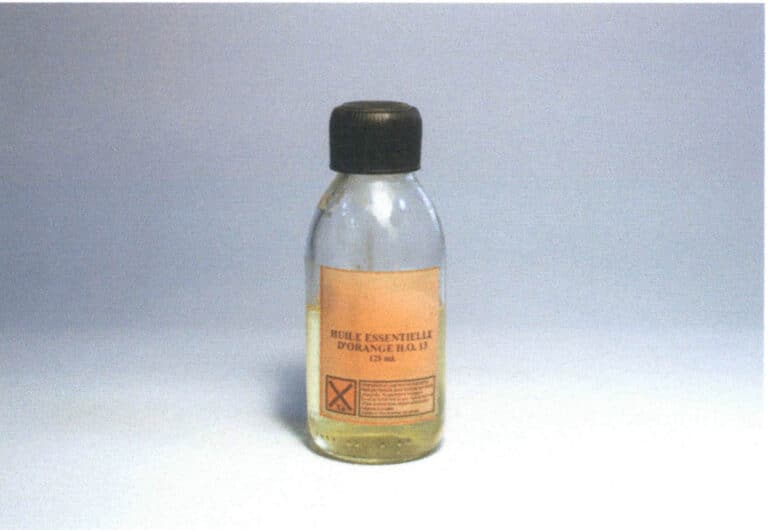

(4) Για την προετοιμασία του βερνικιού από βαμμένο σμάλτο απαιτούνται δύο είδη ελαίων: ένα φυτικό αιθέριο έλαιο και ένα εξουδετερωτικό έλαιο ειδικά για βαμμένο σμάλτο. Προσθέστε πρώτα το φυτικό αιθέριο έλαιο κατά την ανάμιξη. Το φυτικό αιθέριο έλαιο που χρησιμοποιείται για το βαμμένο σμάλτο πρέπει να είναι φυσικό φυτικό αιθέριο έλαιο υψηλής καθαρότητας- μπορεί να είναι οποιουδήποτε τύπου, όπως πορτοκαλέλαιο, έλαιο λεβάντας, έλαιο τριαντάφυλλου κ.λπ. Στο παράδειγμα αυτού του βιβλίου χρησιμοποιείται το αιθέριο έλαιο πορτοκαλιού που φαίνεται στην Εικόνα 8-10.

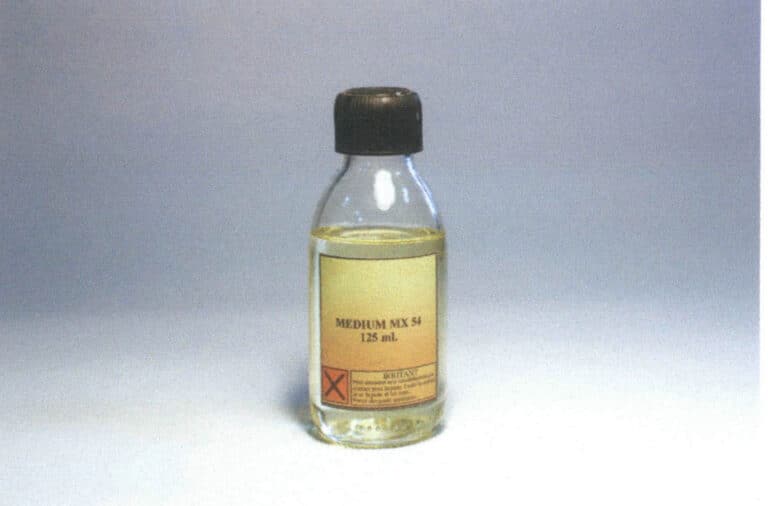

(5) Το εξουδετερωτικό έλαιο που αναφέρεται στο παρόν βιβλίο είναι ένα εξουδετερωτικό έλαιο ειδικά για βαμμένο σμάλτο, το οποίο χρησιμοποιείται για να αυξήσει τη ρευστότητα του βερνικιού βαφής με σμάλτο- είναι γενικά διαθέσιμο σε εξειδικευμένα καταστήματα βερνικιών για σμάλτο. Το εξουδετερωτικό λάδι για ζωγραφική με σμάλτο κυκλοφορεί σε τρεις βαθμίδες: χαμηλή, μεσαία και υψηλή, με ρευστότητα που αυξάνεται από τη χαμηλή στην υψηλή, αντίστοιχα κατάλληλο για τη ζωγραφική χρωμάτων, το περίγραμμα και τη χάραξη λεπτών γραμμών. Στην εικόνα 8-11 φαίνεται ένα μπουκάλι με εξουδετερωτικό λάδι μεσαίου βαθμού, που σημαίνει ότι το γάνωμα που αναμιγνύεται με αυτό έχει μέτρια ρευστότητα.

Εικόνα 8-10 Αιθέριο έλαιο πορτοκαλιού

Εικόνα 8-11 Ουδέτερο λάδι

(1) Το βαμμένο σμάλτο απαιτεί πολύ λεπτά πινέλα. Η εικόνα 8-13 δείχνει ένα πινέλο ακουαρέλας κορεατικής κατασκευής με την ένδειξη πέντε μηδενικά. Επειδή το ζωγραφισμένο σμάλτο περιλαμβάνει συνήθως πολύ μικρές επιφάνειες και πολλές λεπτομέρειες, ένα πολύ λεπτό, υψηλής ποιότητας πινέλο είναι απαραίτητο εργαλείο. Μπορείτε να προετοιμάσετε πολλά πινέλα διαφορετικών μεγεθών και να επιλέξετε το μέγεθος του πινέλου ανάλογα με τη χρήση για την οποία προορίζεται.

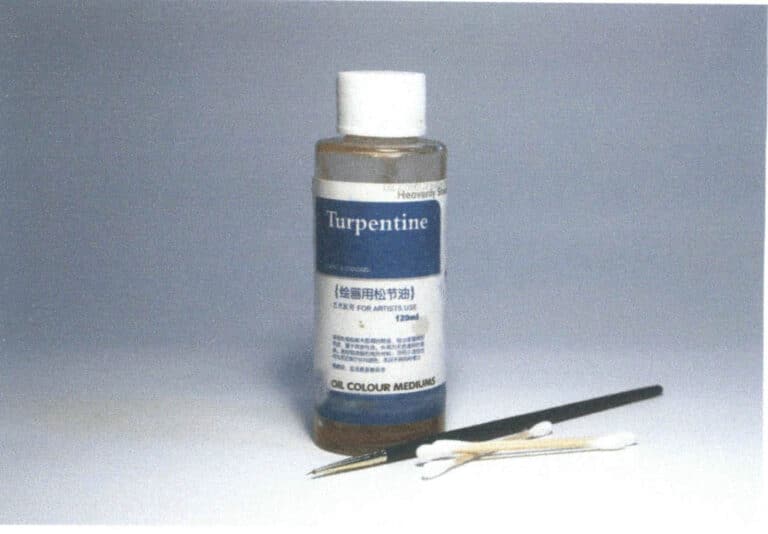

(2) The cotton swabs used here are ordinary medical or cosmetic cotton swabs, used to dip in turpentine and to wipe off mistakes or remove excess glaze, as shown in Fig. 8–14.

Figure 8–13 Ultra-fine watercolour brush

Figure 8–14 Medical cotton swab

3.2 Preparation of Painted Enamel Glaze

ΒΗΜΑ 01

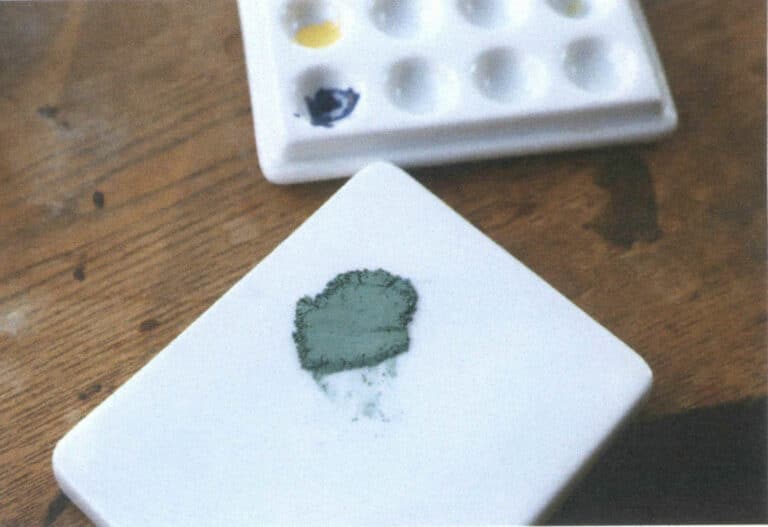

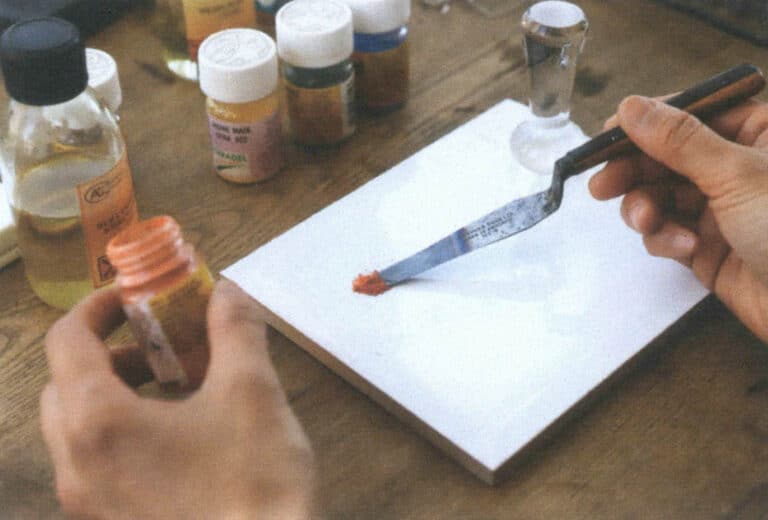

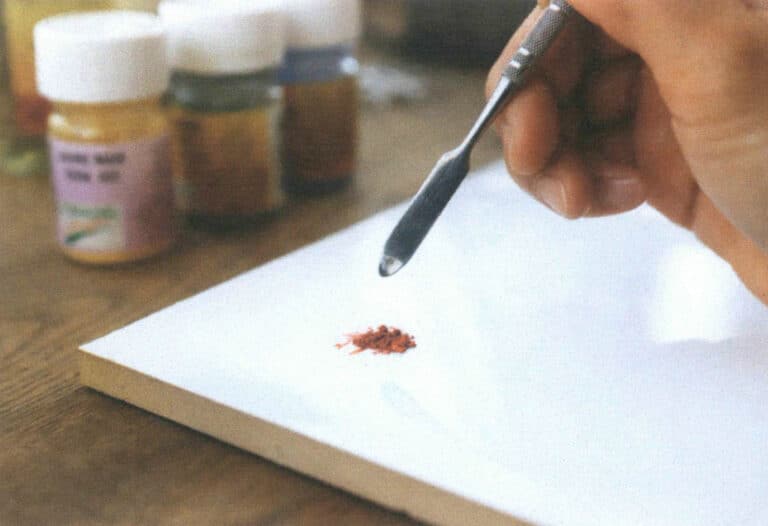

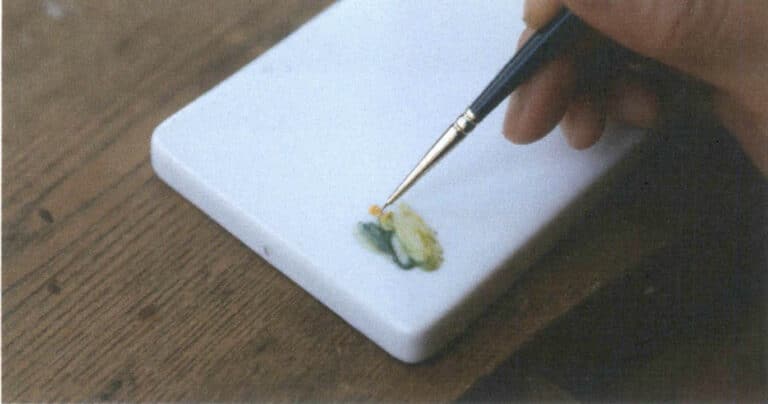

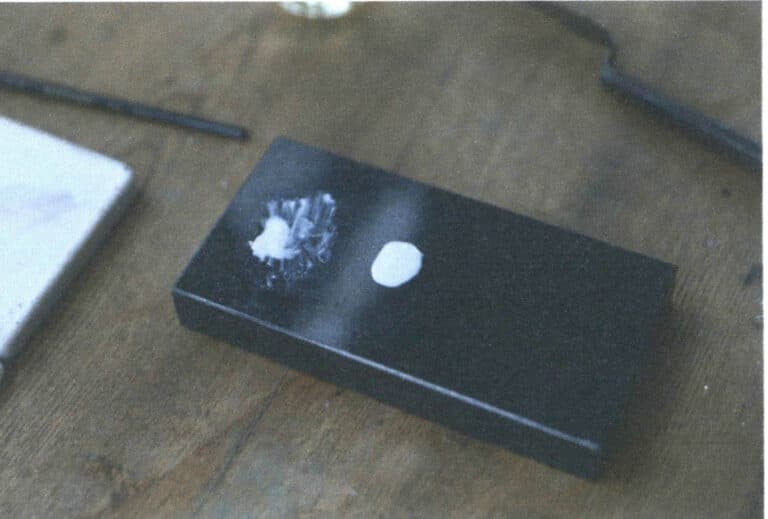

Scoop out a small amount of painted enamel glaze powder and place it on the palette, as shown in Fig. 8–17. Because the painted enamel glaze powder is very fine, be very careful when taking it—do not spill it, and do not take too much at once. You can use the tip of a palette knife or the flat end of a wax-carving tool to remove the powder from the jar. Painted enamel glaze is relatively durable, and once mixed, it cannot be stored for later use, so do not mix more than you need at one time to avoid waste.

ΒΗΜΑ 02

Drop an appropriate amount of vegetable essential oil into the glaze, as shown in Fig. 8–18, and mix the powder and oil evenly with a palette knife. When adding the oil, wait for each drop to penetrate the powder before adding more; otherwise, it is easy to add too much. Although excess vegetable oil can be allowed to evaporate into the air, this takes a long time and makes it difficult to control the drying and moisture level.

Figure 8-17 Scooping out a small amount of painted enamel glaze

Figure 8-18 Adding an appropriate amount of plant essential oil dropwise

STEP 03

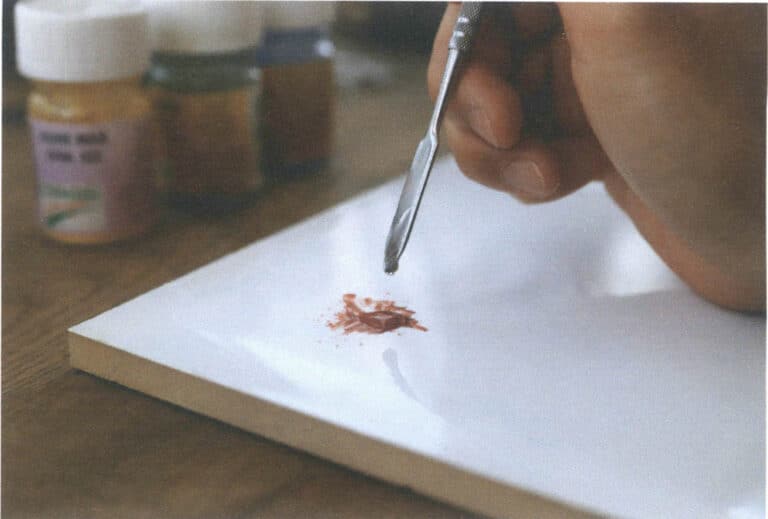

Add one drop of painted enamel neutral oil; as shown in Figure 8-19, after adding the neutral oil, the glaze becomes smoother. For the amount of glaze powder shown in the figure, 3~4 drops of plant essential oil may be added as appropriate, but only a tiny drop of neutral oil should be used; otherwise, excess can cause problems during firing. During the addition of neutral oil, it can be observed that even an extremely small amount added to the glaze will immediately dilute it and increase its fluidity.

STEP 04

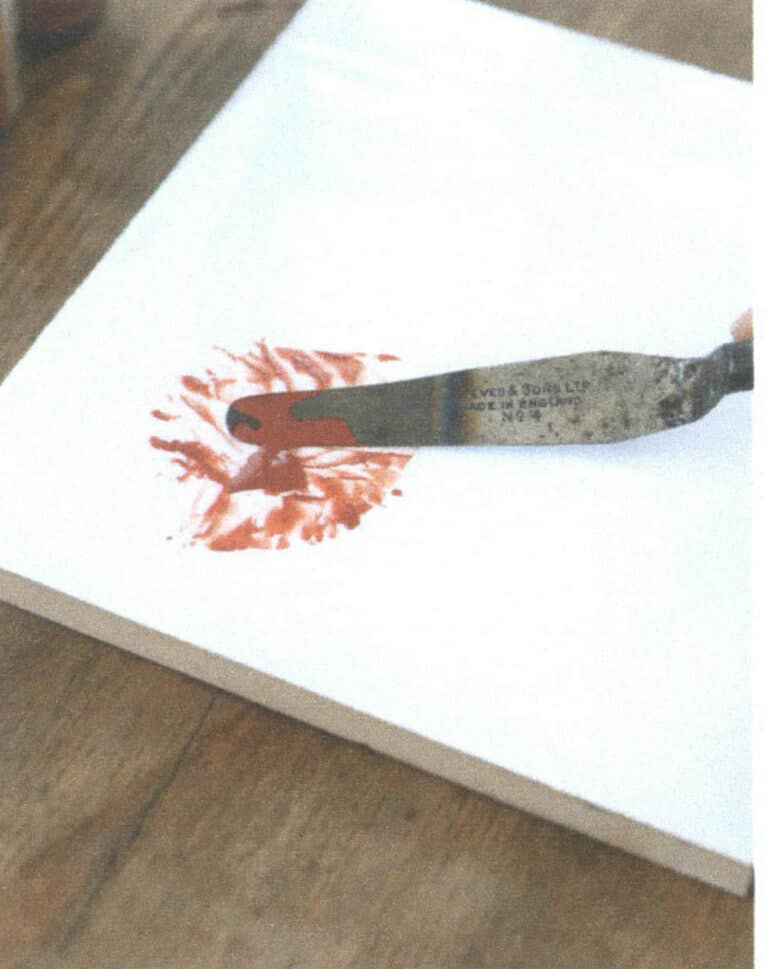

Use a palette knife to thoroughly mix the enamel glaze, essential oil, and neutral oil, as shown in Figure 8-20. Then, place the flat surface of the glass pestle against the flat surface of the ceramic tile and slowly and evenly grind in small circles, as shown in Figure 8-21. The purpose of this step is to crush any lumps in the enamel glaze and ensure it is fully blended with the two oils. During this process, the glaze must be ground sufficiently until it is completely free of any granular texture.

Figure 8-20 Mixing glaze and oil with a palette knife

Figure 8-21 Grinding glaze with a glass pestle

STEP 05

After thorough grinding, use a palette knife to gather the mixed glaze together, as shown in Fig. 8-22.

STEP 06

Transfer each of the prepared colored glazes one by one into small porcelain dishes or a palette box for later use, as shown in Fig. 8-23.

STEP 07

In Figure 8-24, you can see that the palette box contains several prepared painted enamel glazes, so painting can begin.

Figure 8-23 Using a palette knife to transfer the mixed glazes into a palette box

Figure 8-24 Preparation completed

Notes

(1) When preparing the glaze, you can add a bit more essential oil from plants; this makes it easier to work with. If there is too little essential oil, it is hard to mix the powder and oil. If, after mixing, you feel you have added too much essential oil, you can let it sit for a while to allow some of it to evaporate.

(2) Do not add too much neutral oil; otherwise, problems are likely to occur during firing. The oil needs to be removed during firing; essential oils evaporate easily due to their volatility, but neutral oil will remain in the glaze, so do not add too much at the start.

(3) Painted enamel glazes are like painting pigments; different colored glazes can be mixed to produce new colours. Therefore, as long as you have red, yellow, and blue, you can mix the colours you need. This means that when preparing glazes each time, you don’t need to prepare too many different colours, since many colours can be mixed.

3.3 Painted Enamel: Painting and Firing

Painted enamels are usually not completed in a single firing. The more realistic the style and the more complex the colours, the more firings are required; sometimes it may even need to be fired repeatedly, more than ten times. However, care must be taken because if fired too many times, the enamel layer used as the base colour may be damaged. For this reason, if the design is complex and requires multiple firings, it is best to choose a more firing-resistant glaze for the base layer.

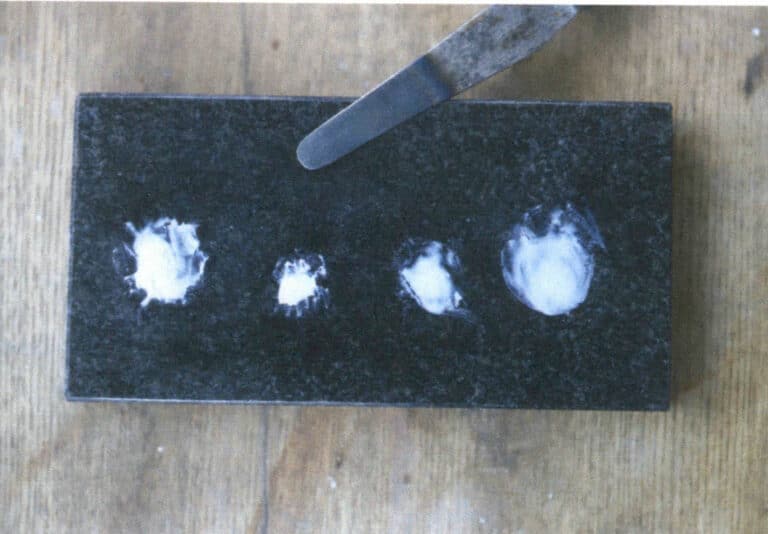

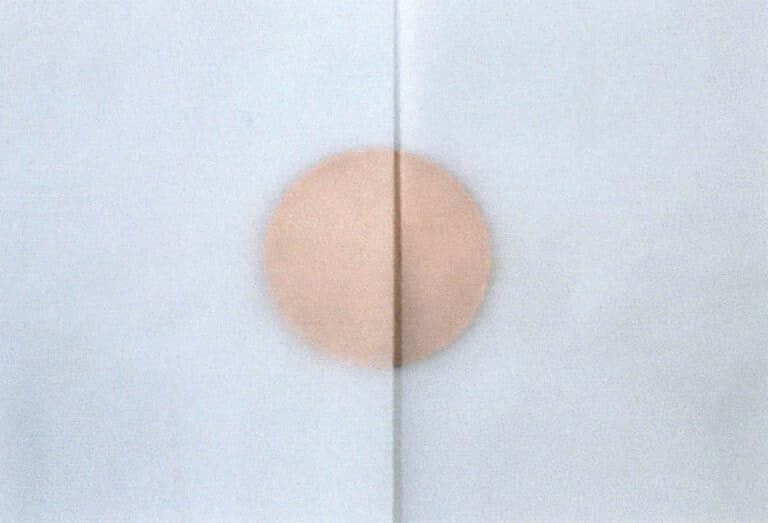

In the examples in this book, we use the porcelain white from domestically produced cloisonné glazes. The porcelain white glaze fires to a very bright white and has strong covering power. One can also choose the niè white from Chinese cloisonné glazes, which, after firing, presents a slightly greyish white with somewhat weak coverage; when used as an undercolor for painted enamel, it must be fired two to three times for the white to be even. Figure 8-25 shows the comparison between porcelain-white base glaze and niè-white base glaze: the left is porcelain-white, the slightly greyish one on the right is niè-white.

Figure 8-26 Glaze not fully matured

Figure 8-27 Checking whether the piece is properly fired by observing reflections

The specific steps for painted enamel production are as follows.

ΒΗΜΑ 01

Clean the fired back glaze and porcelain-white ground glaze metal base plate thoroughly and dry off the moisture, as shown in Fig. 8–28. If the porcelain-white ground glaze has just been fired and the surface has not been touched, you can paint the painted enamel directly onto the ground glaze. If fingers have touched it, it should be cleaned with waste water from glaze-cleaning materials to remove any contaminants that might affect the glaze. Generally, it is not necessary to pickle the metal base plate with fired back glaze and ground glaze when making painted enamel.

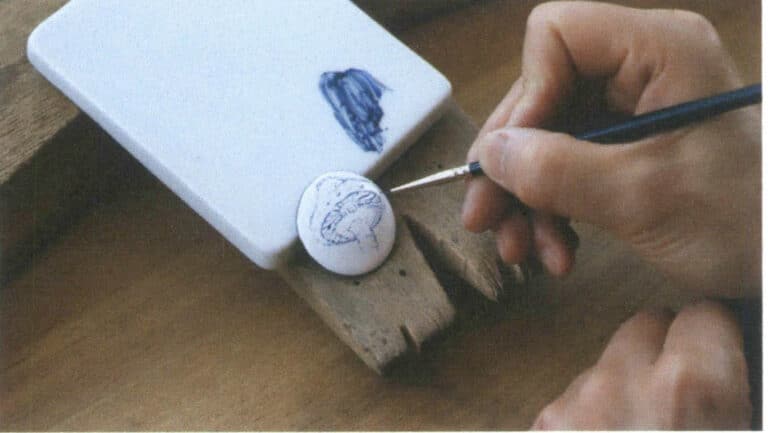

ΒΗΜΑ 02

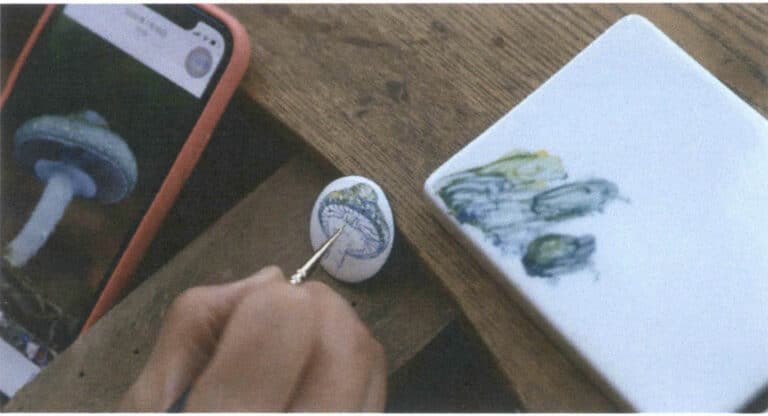

Select a dark colour from the prepared painted enamel glaze and outline the contours. Trace the line drawing onto the white ceramic base glaze according to the design, as shown in Figure 8–29.

After completing the line drawing, set the kiln temperature to 780°C; first, use the kiln heat to dry the glaze and remove the oil from the glaze, then fire it in the kiln. Figure 8–30 shows the first firing process.

Figure 8-29 Outlining the line drawing

Figure 8-30 Drying the piece in the kiln

STEP 03

Use turpentine as a thinner to mix colours. As mentioned earlier, painted enamel glazes can be mixed like painting pigments to create new colours—for example, red plus yellow makes orange, yellow plus blue makes green… A few basic colours can be mixed to produce a fairly rich palette; Figure 8–31 shows the process of mixing colours using different hues.

First, paint and fire the dark outline, then apply the first layer of colour. Figure 8-32 shows the work while the first layer of colour is being applied. After the entire surface has been thinly covered with colour, put it back in the kiln and fire it at the same temperature.

Figure 8-31 Colour mixing with different colours

Figure 8-32 First layer of colouring

STEP 04

After firing, apply the second layer of colour. Each pass continues on top of the previous one, gradually building up the colour layers and image details. Figure 8-33 shows the work after the second layer of colour has been completed.

STEP 05

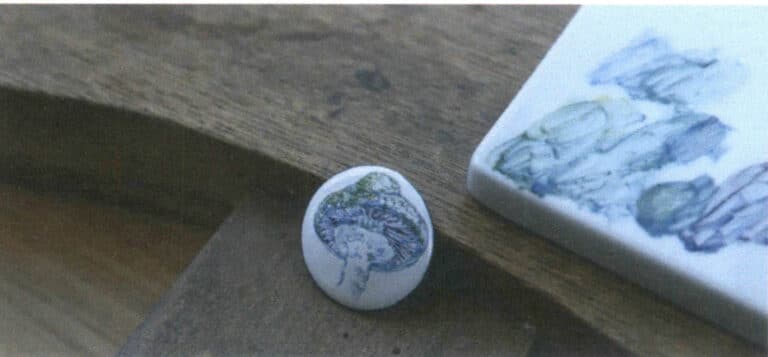

Painted enamel glazes are extremely fine powders; after a thin application and firing, the resulting colour has almost no covering power, so darker colours or more complex images require repeated colour applications and firings. If the colour is applied too thickly or too heavily at once, it is prone to insufficient firing penetration. Figure 8-34 shows the piece after the fifth layer of colour has been applied.

Figure 8-33 Second layer colouring

Figure 8-34 Fifth layer of colouring

Notes

(1) Each layer of glaze must be applied very thinly, because painted enamel glazes have almost no covering power and achieve colour saturation and depth only by repeated layering. When the glaze is applied too thickly, it often cannot be properly fired, causing the glaze colour to scorch or blur, as shown in Fig. 8–36.

(2) As with the firing process for ordinary enamel, the piece must also have the glaze baked dry before entering the kiln, but the purpose here is to dry the oil in the glaze to prevent it from affecting the glaze. Figure 8–37 shows the situation of using furnace temperature to dry the oil in the glaze before firing.

Figure 8–36 Situation of incomplete firing due to excessively thick glaze layers

Figure 8-37 Using kiln temperature to dry oils in the glaze

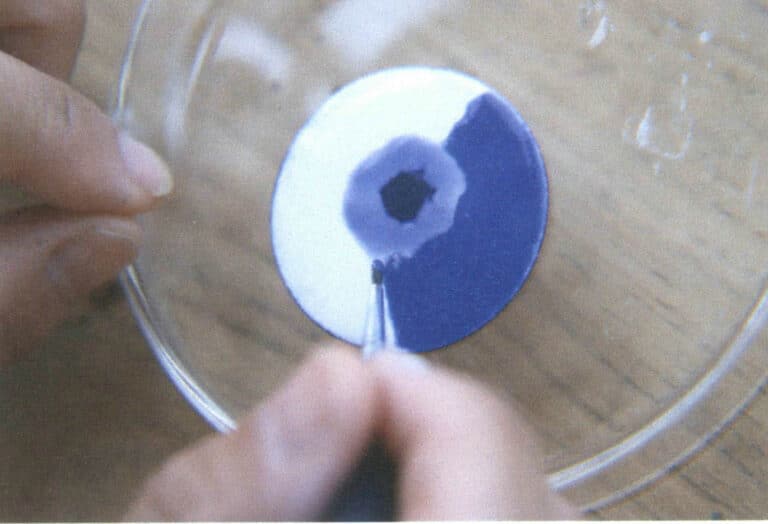

4. Drawing and Firing of Grisaille

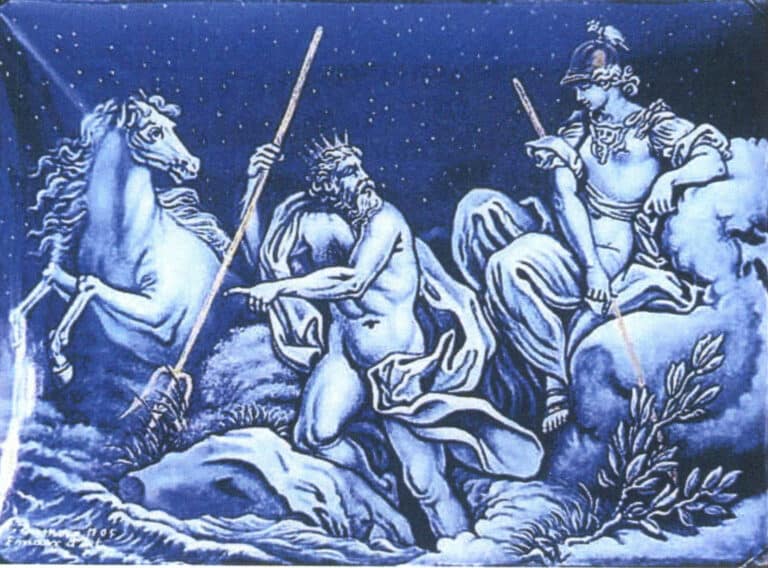

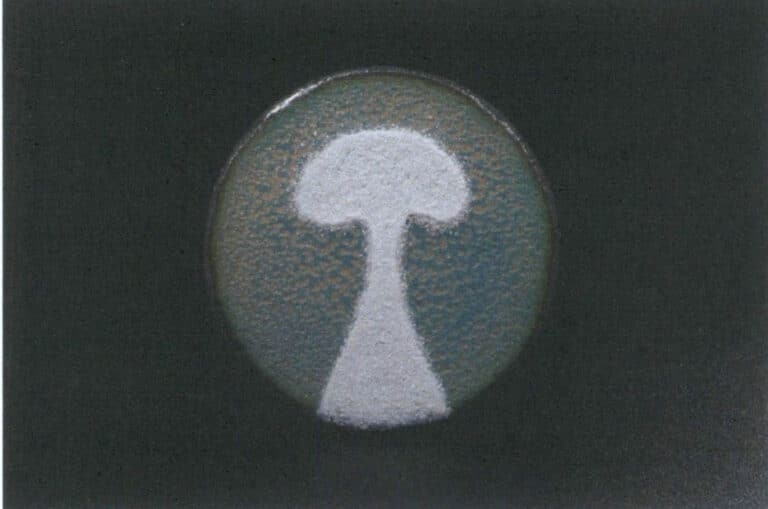

In enamel painting, besides the commonly seen polychrome painted enamel, there is a less common technique called “grisaille.” Grisaille is an earlier form of painted enamel. Figure 8-39 shows a grisaille work created in 2010 by artist Jen Zamora, held in the Museo Archivio, an enamel museum near Milan, Italy. The painting and firing methods for grisaille are largely the same as for polychrome painted enamel; the difference is that grisaille uses a white enamel painted onto a black or deep-blue ground. By altering the consistency of the white enamel, a rich range of grey tones is produced, hence the name “grisaille.”

The glaze shown in Figure 8-40 is the white glaze specifically used for grisaille, Limoges white, produced in the south-central French city of Limoges. Its characteristics are strong opacity, very fine texture, and good firing durability.

Figure 8-39 Modern grisaille work

Figure 8-40 Limoges white, the white glaze for grisaille

ΒΗΜΑ 01

Saw the copper plate to the required shape and fully anneal it. Then form it into a slight arch, pickle it in acid, remove it and rinse it with clean water for later use.

ΒΗΜΑ 02

Apply a colourless transparent copper base glaze to the back of the copper substrate and fire it in the kiln.

STEP 03

On the front of the copper base plate with the fired back glaze, apply French No. 27 glaze and fire it in the kiln. Figure 8-42 shows the copper base pate with No. 27 glaze fired on the front.

ΒΗΜΑ 01

Scoop an appropriate amount of Limoges white glaze onto the palette, as shown in Fig. 8-43.

ΒΗΜΑ 02

Following the colour painted enamel mixing method, add an appropriate amount of essential oil and neutral oil to the glaze powder, and grind and mix evenly according to the painted enamel glaze preparation method.

STEP 03

Set aside a small portion of the prepared Limoges white glaze and keep it aside for later use, as shown in Figure 8-44.

Figure 8-43 Scoop an appropriate amount of Limoges white glaze

Figure 8-44 Divide a portion of the prepared glaze

STEP 04

Add an appropriate amount of essential oil and one drop of neutral oil to the remaining glaze, and mix thoroughly, as shown in Figure 8-45.

STEP 05

Set aside a small portion of the prepared glaze for later use; at this point, you can observe that this portion is slightly lighter in colour than the first portion. As shown in Figure 8–46, each time oil is added to the Limoges white glaze, the white becomes a bit paler.

Figure 8-45 Adding an appropriate amount of essential oil and one drop of neutral oil

Figure 8-46 The white colour of the glaze gradually fades

Repeat the above steps until you obtain several portions of prepared white glaze ranging from dark to light, forming a gradient of tones. Place them in the paint box for later use, and you can begin painting in layers.

The painting and firing methods for the grisaille technique are basically the same as for coloured painted enamel; the difference is that grisaille is painted in white on a dark ground, building up highlights layer by layer until the light areas and specular highlights of the object or figure are completed. This is not only the opposite of the painted enamel technique but also contrary to the general painting process, so beginners often need a period of adjustment before they can handle it confidently.

Below, using a practice exercise as an example, we briefly introduce the steps for painting and firing in the grisaille technique.

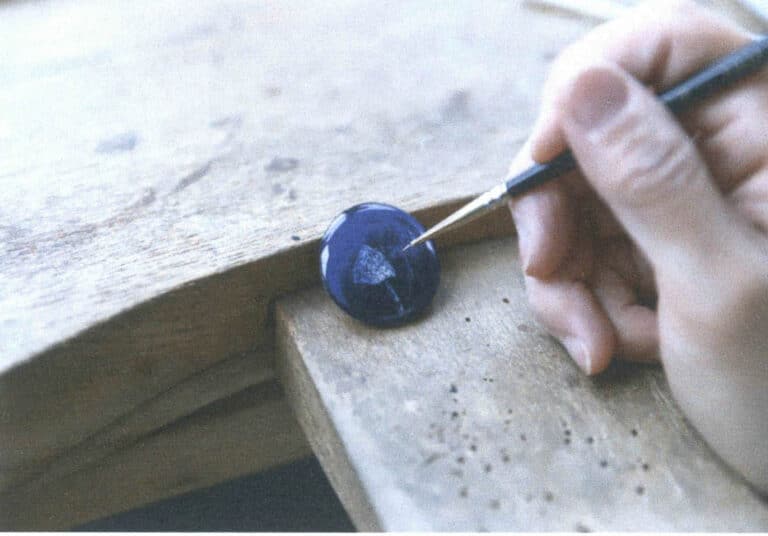

ΒΗΜΑ 01

Select the palest white glaze to sketch the outlines, as shown in Fig. 8-47, set the kiln temperature to 700°C, and fire in the kiln.

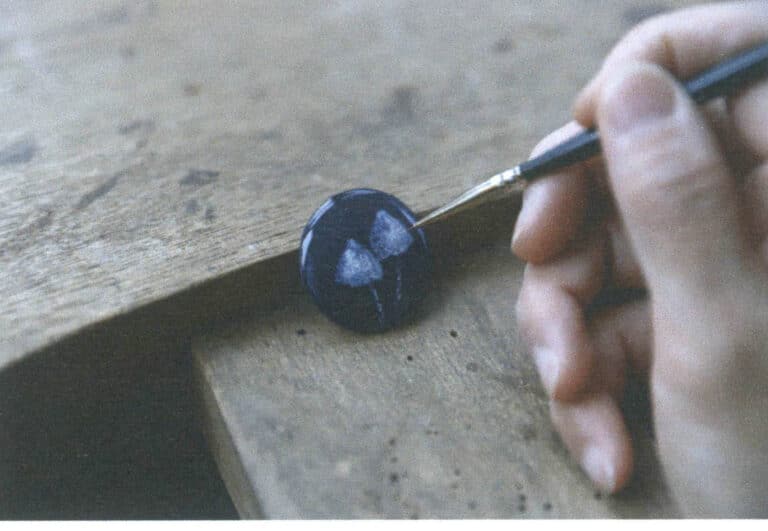

ΒΗΜΑ 02

From the second layer onward, choose a slightly denser white glaze to depict the tonal variations across the entire image, as shown in Fig. 8-48, and fire in the kiln.

Figure 8-47 Outlining the contours

Figure 8-48 Using a slightly denser white glaze to depict tonal layers

STEP 03

Select progressively denser white glazes layer by layer for detailed rendering; the image is gradually brightened, as shown in Figure 8-49. Grisaille, like colored painted enamel, also requires multiple applications and firings.

STEP 04

In the final pass, use the densest white glaze to outline the brightest highlights and the areas that need the most emphasis, as shown in Figure 8-50. Fire it in the kiln once more, and a grisaille painted piece is complete.

Figure 8-49 The image is gradually brightened

Figure 8-50 The completed work

Notes

(1) The firing temperature for grisaille enamel is lower than for colored painted enamel; the kiln can be set to 700°C for firing, and the condition of the glaze should be carefully observed during the firing process.

(2) Because a relatively large amount of neutral oil is added when preparing Limoges white glaze, the piece must be thoroughly dried before it goes into the kiln to allow the oil in the glaze to evaporate. Therefore, the drying time for grisaille works is longer than that required for colored painted enamel works.

Section II Some Special Techniques in Enamel Craft

1. Dry Sieving Method

Under normal circumstances, we mix enamel glaze with water and use the adhesive force of the water to make the glaze temporarily adhere to the metal surface, then fire it. There is actually another glazing method that uses a sieve to sift dry glaze powder onto a metal base before firing; we call this method dry sieving.

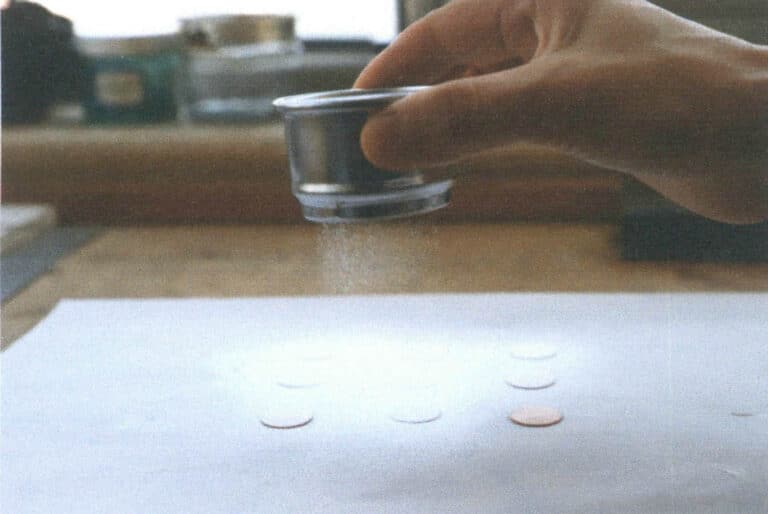

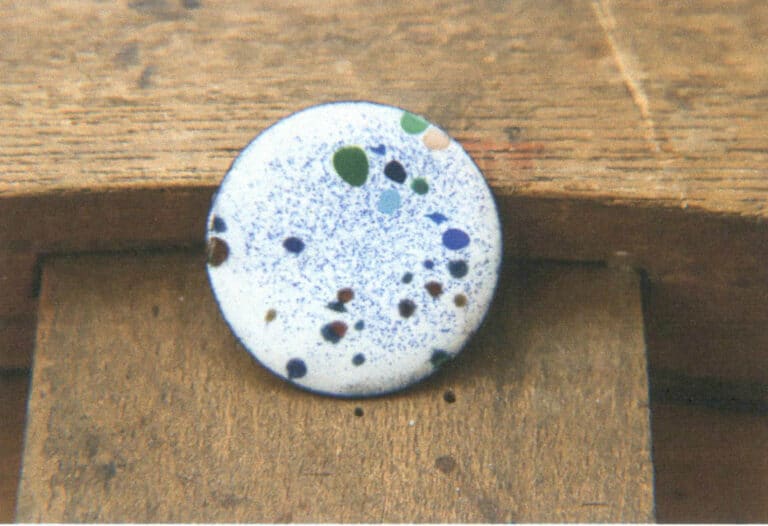

The dry sieving method is suitable for spreading glaze over a relatively large area or when applying the same colour glaze to several pieces at once. Figure 9-1 shows the case of sieving a transparent base glaze onto multiple colour test plates at the same time. Compared with conventional glazing methods, dry sieving is more efficient and produces a smoother glaze surface. However, it should be noted that when using dry sieving to lay glaze, the glaze layer tends to be thin, and sometimes repeated sieving and firing are required. Figure 9-2 shows the appearance after sieving and firing one layer of pink glaze onto a copper base plate; although an opaque glaze was used, because the glaze layer applied by dry sieving is very thin, the colour of the copper base plate can still be seen through the glaze.

Figure 9-1 Sieving a base glaze onto multiple colour test plates using the dry sieving method

Figure 9-2 Copper base plate after sieving and firing one layer of pink glaze

Copywrite @ Sobling.Jewelry - Κατασκευαστής προσαρμοσμένων κοσμημάτων, εργοστάσιο κοσμημάτων OEM και ODM

The specific operating steps for the dry-sieving method are as follows.

ΒΗΜΑ 01

Soak the metal base plate in a dilute sulfuric acid solution for cleaning; after about 15 minutes, remove it and rinse thoroughly with running water, then set it aside.

ΒΗΜΑ 02

Evenly spray water onto the clean, dry metal base plate with a small watering can. The amount of water is critical: if there is not enough moisture, the glaze will not adhere; if there is too much, the glaze will clump together. After spraying, you should observe a layer of fine, uniform water droplets attached to the surface of the metal base plate, as shown in Figure 9-3. Be careful that there are no large droplets of water; otherwise, when sieving and placing the glaze powder in subsequent steps, the glaze powder will concentrate in areas with more moisture, causing uneven thickness of the glaze distribution.

STEP 03

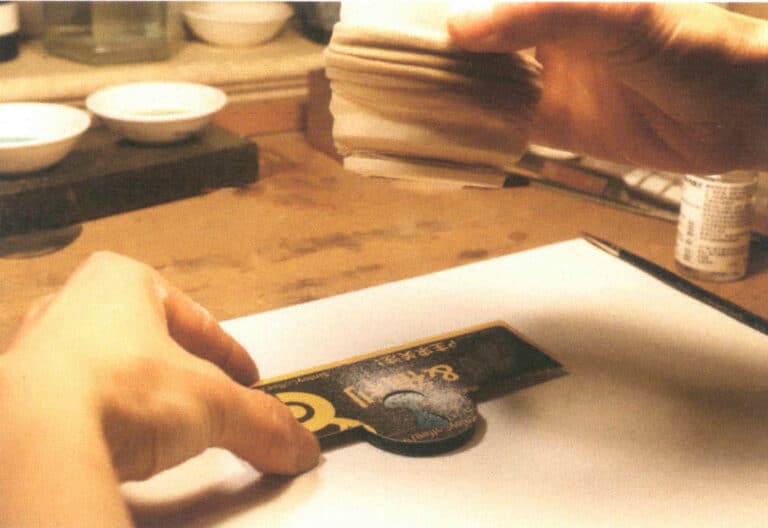

Place the water-sprayed metal base plate on the stand, with a clean sheet of white paper underneath, as shown in Figure 9-4. The stand can be made of steel or plastic; its purpose is to make it easy to place and remove the piece after the glaze has been sifted over it. The white paper is used to collect glaze powder that is sprinkled around the piece, because when sifting glaze, it is impossible to precisely control the boundary — to cover the piece completely, some glaze will inevitably fall around it.

Figure 9-3 Fine, uniform water droplets on the surface of the metal base plate

Figure 9-4 Place the metal base plate on a stand padded with white paper

STEP 04

When sifting glaze, first choose a sieve of suitable mesh size, put a small amount of dry glaze powder into the sieve, hold the sieve about 10 cm above the metal base plate, and gently tap the edge of the sieve with a metal spoon. At this point, you can observe the glaze powder falling evenly onto the metal surface, as shown in Figure 9-5.

STEP 05

Ensure the glaze powder is sprinkled evenly over the entire surface of the piece by slowly moving the position of the sieve. When the entire surface is uniformly coated with a layer of glaze powder, stop sieving and fire it in the kiln, as shown in Fig. 9-6.

Figure 9-5 Sifting glaze with a sieve

Figure 9-6 Glaze sieved to cover the metal surface

Notes

(1) When making works using the dry sieving method, a large amount of glaze powder will become airborne when the glaze is sifted, so the maker must wear a protective mask to avoid inhaling dust into the lungs and damaging their health.

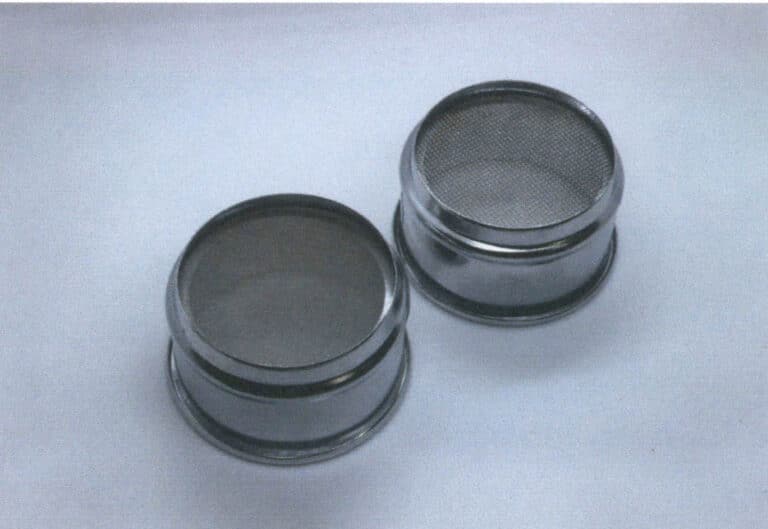

(2) Screens come in different coarseness, and you can choose the mesh count according to your needs. Generally, when you need to lay glaze flat, you can choose an 80-mesh screen; if you need to create more detailed patterns, you can choose a finer screen, for example, 100 mesh. Figure 9-7 shows 30-mesh and 100-mesh stainless steel screens. Of course, if the screen is too fine, the glaze powder will not pass through smoothly, which will affect the evenness of the glaze sifting degree. In short, the coarseness of the screen should be chosen based on the needs of different works, and often relies on the maker’s experience to decide. When unsure, firing one or two test pieces first to observe the effect is the safer approach.

In addition to applying glaze in a flat, even layer, the dry-sieving method can produce many special effects. For example, by varying the density of the glaze powder, you can create colour gradients; by masking off parts, you can produce fine lines; by using masks of special shapes, you can create complex tiled patterns.

Figure 9-8 shows a gradient effect made with the dry-sieving method. On this copper-backed piece, the base glaze is a domestic cloisonné-style porcelain white that has been fired, and French No. 66 opaque blue glaze powder was sifted over it. The sifting technique is the same as for applying an even layer: move the sieve loaded with blue glaze from the right side of the piece toward the left; when you reach the middle, pause slowly and then begin moving back to the right, lingering longer at the right edge. The purpose is to make the glaze powder densest and the colour deepest at the right edge. Note that while moving the sieve left and right, the frequency of tapping the sieve rim should remain steady so the powder is sifted out at a constant speed and in a constant amount; only then can an even gradient be achieved. Experience is very important when using the dry-sieving method. The distance between the sieve and the piece, the force used to tap the sieve, the speed at which the sieve is moved, and the amount of glaze held in the sieve all affect the sifting result, and must be mastered through repeated experiments. Of course, even with rich experience and skilled technique, a certain degree of uncontrollability in this method is unavoidable; the purpose of testing and practice is to minimise that unpredictability.

When firing lines with the dry-sieving method, mask off the areas on both sides of the line according to the design, then sift other colored glaze powder over the exposed area and fire to obtain a single line. Figure 9-9 shows the situation of sifting glaze with both sides masked by stiff cardboard; besides cardboard, thin metal or plastic sheets can also be used. The same method can be used to produce curves. Lines of any thickness can be made with this approach. Note that the glaze between the two masks should not be piled too thickly; otherwise, after removing the masks, the dried glaze powder will have difficulty retaining a stable linear shape.

Figure 9-8 Gradient effect made with the dry-sieving method

Figure 9–9 The sides are blocked with cardboard before sifting and sprinkling enamel

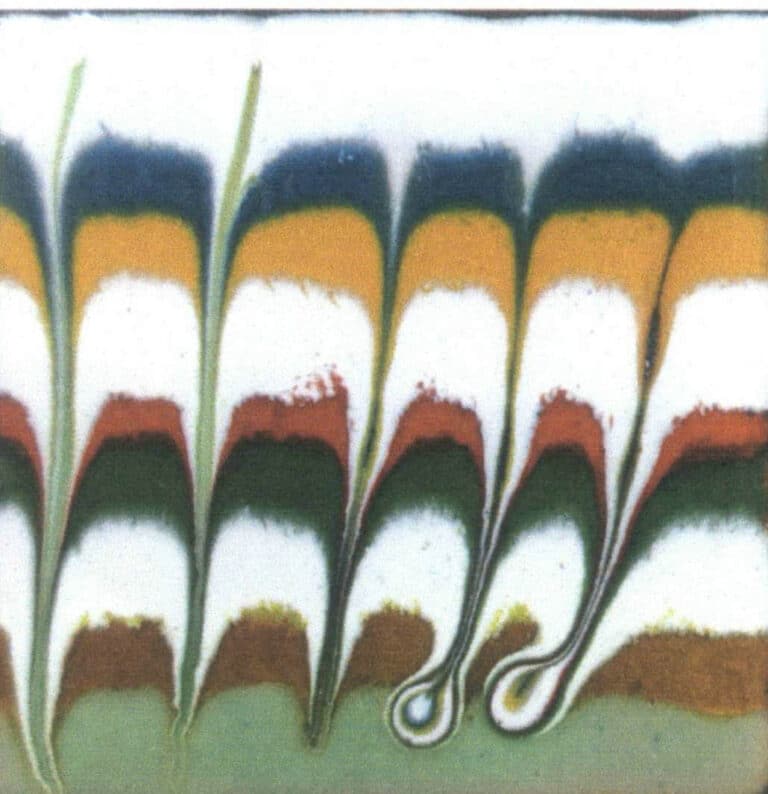

Figure 9–11 shows a tiled pattern with complex edges produced by the dry-sieving method. On a white ground fired with porcelain-white enamel, a three-petal flower-shaped metal stencil was used to mask the surface while French opaque green glaze No. 248 was sifted and fired. Then a metal stencil with a pierced pattern was applied, and French No. 76 yellow glaze and domestic coral red glaze were sifted and fired in two separate passes. Finally, two circular masks were overlapped and placed on the left and right sides, blue glaze was sifted to create a slight gradient effect, and the piece was fired. As long as suitably shaped masks can be found, this method can produce patterns of various shapes; with multiple layers of overlay, a wide range of effects can be achieved. Experimentation during the creative process can continually expand the possibilities.

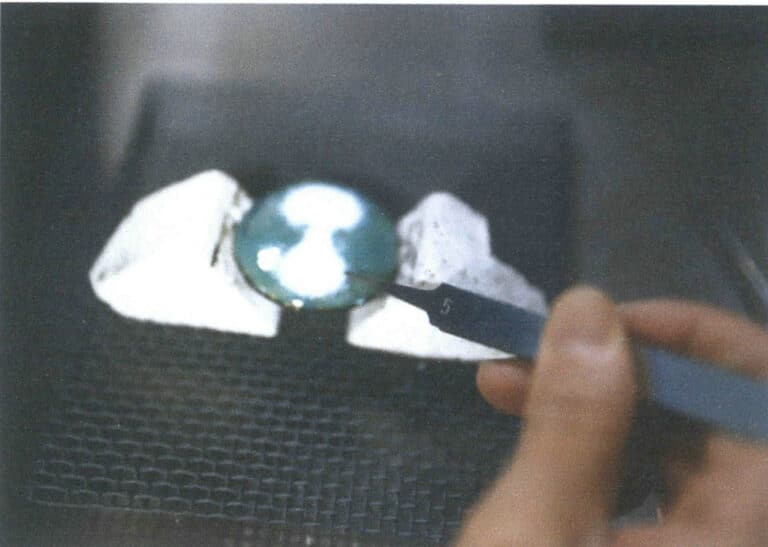

The melting of enamel glaze does not occur instantly; it goes through a process from powder to granules and then to liquid. Taking advantage of this characteristic of the glaze, when applying glaze by the dry-sifting method, opaque glazes can be fired to a semi-melted granular state. At this point, the enamel surface shows a matte, velvety effect, as in the work shown in Figure 9–12. The specific procedure is to fire a layer of transparent ground glaze on a copper base, then thinly sift a layer of domestically produced Chinese Cloisonné soft green glaze, and fire at a kiln temperature of 820 °C, as shown in Figure 9–13.

Carve the shape of the mushroom on the cardboard used to mask the work, sift on the porcelain white glaze—note that this layer should be sifted rather thick, as shown in Figure 9–14.

Figures 9–11 Tiling pattern of complex edges

Figure 9–12 Mushroom No. 17

Figure 9–13 Firing soft green ground

Figure 9–14 Sieving and applying mushroom-like porcelain-white glaze

2. Transparent Base Glaze Outlining Method

A transparent, colourless copper-base glaze is a rather special type of glaze. Besides serving as a transparent base glaze, it also helps prevent metal oxidation. If transparent base glaze is applied locally on a copper base plate, the unglazed areas will oxidise to black during firing, while the glazed areas will still show the original colour of the copper base plate.

This section describes a special technique that takes advantage of the properties of transparent base glazes. Before firing, part of the transparent base glaze is scraped away to expose the copper substrate; after firing, this produces two colours: the original copper tone and an oxidised black. Then a layer of another transparent colour is applied over it, resulting in natural and interesting dark traces beneath the transparent colour glaze. These traces can be lines or patches, depending on the shape of the removed base glaze. The work shown in Figure 9–16 was made using the transparent-base glaze outlining method: the mountain-shaped lines display a beautiful dark red, with varying depths of colour and naturally varying line shapes and widths.

The specific operating steps are as follows.

ΒΗΜΑ 01

Soak the metal base plate in a dilute sulfuric acid solution for cleaning; after about 15 minutes, remove it and rinse thoroughly with running water for later use.

ΒΗΜΑ 02

Apply a layer of transparent base glaze to the back and fire it in a kiln at 850°C.

STEP 03

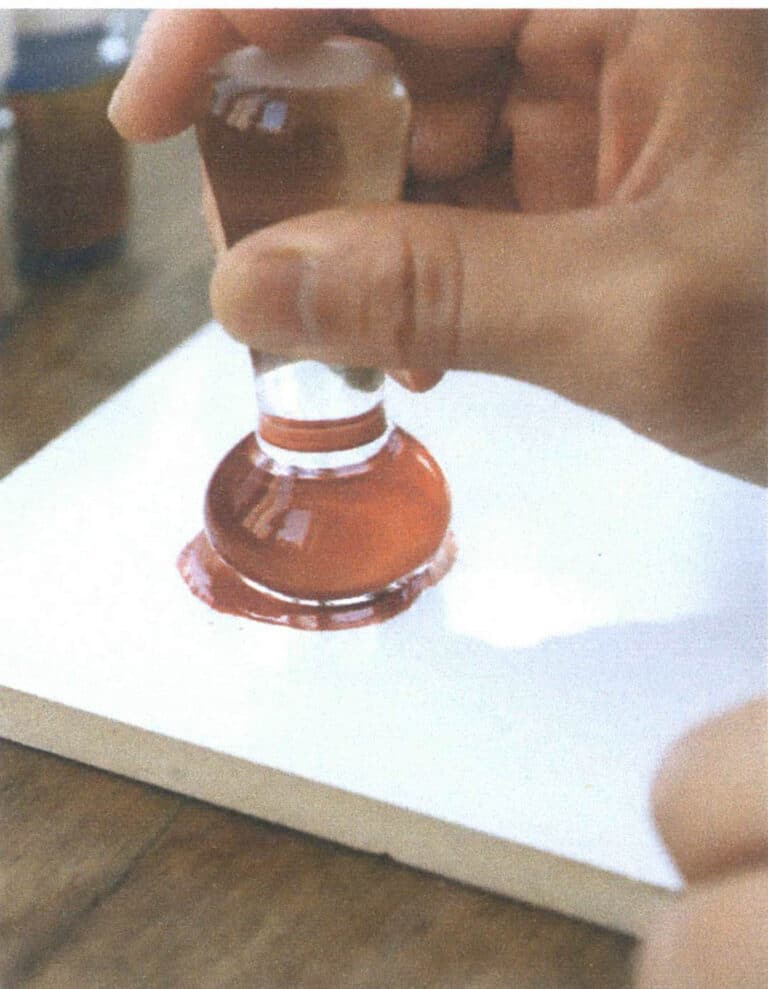

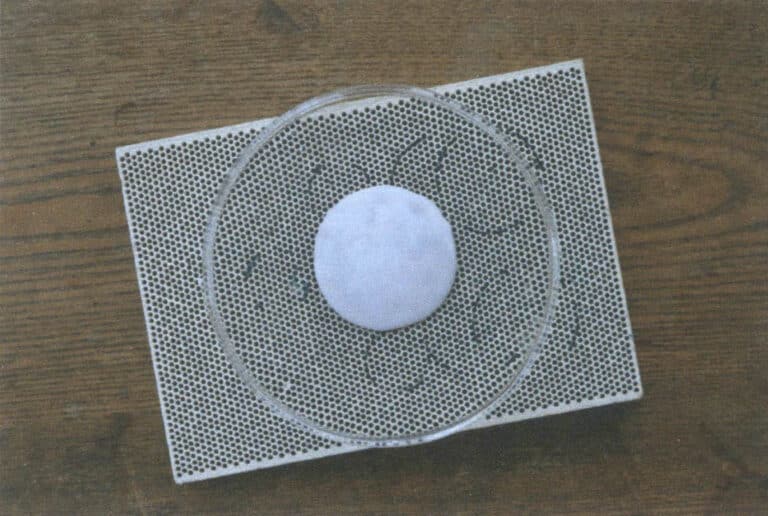

Spread a layer of transparent base glaze on the front, about 0.5 mm thick; take care not to make it too thick. Place the piece inside a glass dome to dry the moisture, as shown in Figure 9–17.The purpose of the glass cover is to prevent dust from falling onto the glaze surface.

STEP 04

When the transparent base glaze on the front is almost dry, use a needle tip to remove the unwanted transparent base glaze according to the design, then fire it in a kiln at 850°C. The base glaze shown in Fig. 9-18 already has the required lines removed with a needle tip.

Figure 9–17 Place the piece inside a glass cover to dry

Figure 9-18 Removed required lines

STEP 05

After firing, the parts of the metal base plate where the glaze was removed turn black due to oxidation, while the glazed parts remain a bright copper colour, as shown in Fig. 9-19. On this basis, continue to apply a layer of transparent glaze, such as transparent blue, transparent green, transparent red, or any other transparent glaze, as shown in Fig. 9-20.

Figure 9–19 Parts that oxidised and blackened after firing when the glaze was removed

Figure 9–20 Applying a layer of transparent glaze

STEP 06

Sprinkle small pieces of gold leaf on the surface and fire in a kiln at 850°C. Figure 9–21 shows the completed piece.

Notes

(1) When scraping lines, the moisture content in the transparent base glaze is very important. If there is too much moisture, the glaze removed by the needle tip will rejoin due to the water and will not form a clear boundary; conversely, if there is too little moisture, the glaze will be in an almost dry powder state and will also be unable to produce a clear boundary.

(2) After removing the glaze and firing, the scraped areas turn black or dark red; this is the copper substrate exposed, where there is no transparent base glaze being oxidised. Be sure never to soak the piece in acid, as is sometimes done, otherwise the oxidised black and dark red textures will disappear.

3. White Base Glaze Marbling Method

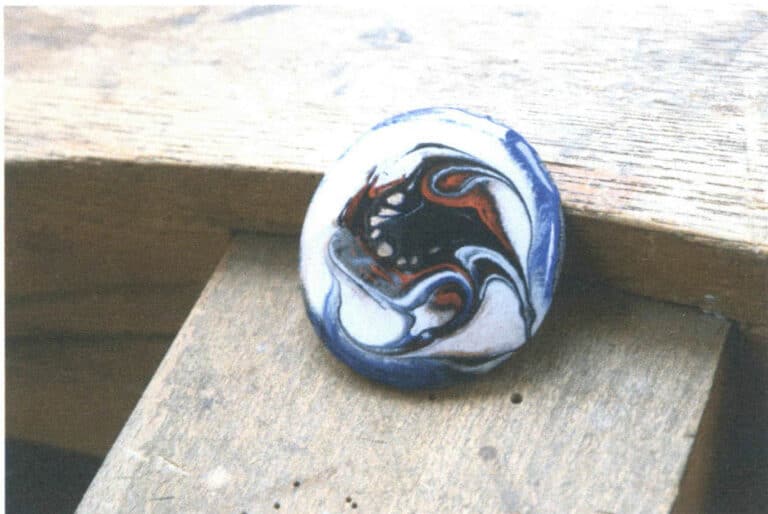

Strictly speaking, the melting temperature of each type of enamel glaze is not the same. The melting temperatures of transparent and opaque glazes differ by about 30~50 degrees Celsius, and the melting temperatures also vary among individual transparent glazes and among individual opaque glazes. The special technique described below takes advantage of this property of enamel glazes — using the differences in melting temperatures between different glazes to layer different colored glazes so that, after high-temperature firing, interesting and irregular marbling effects appear.

The craft example shown below demonstrates the marbling effect achieved by applying other colours over a white base glaze; using another base colour is also feasible, but the glaze thickness and firing temperature will differ and will require repeated experiments to achieve satisfactory results.

The specific steps for the white-base glaze marbling method are as follows.

ΒΗΜΑ 01

Soak the metal substrate in a diluted sulfuric acid solution for cleaning; after about 15 minutes, remove it and rinse thoroughly with running water and set it aside.

ΒΗΜΑ 02

Apply a transparent base glaze to the back and fire it in a kiln at 850 °C.

STEP 03

Apply a slightly thicker white glaze to the front, as shown in Figure 9-22. Here, the porcelain-white from Chinese Cloisonné glazes was chosen; other brands of white glaze or other opaque glazes can be used instead. Fire in a kiln at 810 °C.

STEP 04

Apply a thin layer of another glaze colour over the fired white glaze; it can be one colour or several, applied freely or according to a design, as shown in Figure 9-23.

Figure 9-22 Applying a slightly thicker white glaze

Figure 9-23 A thin layer of other glaze applied over the fired white glaze

STEP 05

Place the piece into the kiln and fire it at a temperature of 900°C. When the temperature reaches 900°C, the lower layer of glaze will bubble up to the surface like boiling water. After removal and cooling, the enamel glaze surface will display a marbled effect with droplet-like, colorful patterns, as shown in Figure 9-24.

Notes

(1) The first layer of white glaze on the front should be thicker, and the second layer of colored glaze should be thinner; this helps produce a clear marbling pattern effect.

(2) Different colored glazes produce different marbling effects. Some can turn into large, very obvious patterns; some produce fine, dense patterns; and some colours show no obvious marbling effect even when fired to 900°C… Which specific colours yield which patterns must be determined through repeated testing.

4. Tread Drawing Technique

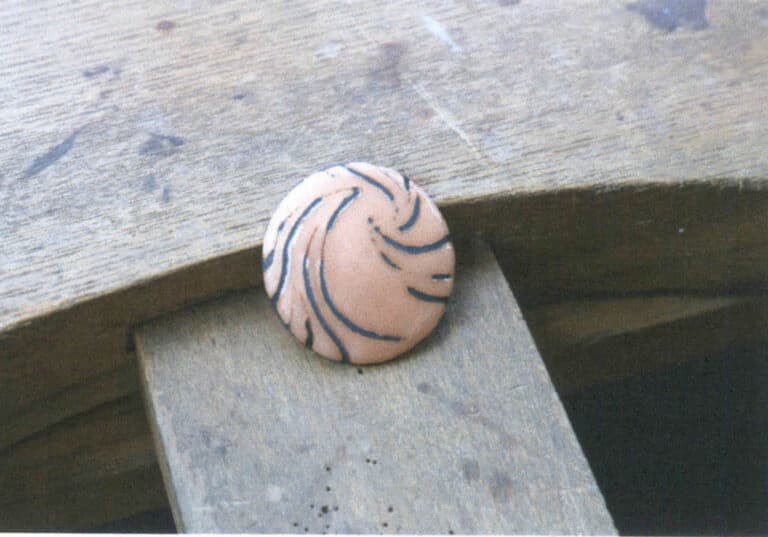

The tread drawing technique takes advantage of enamel glazes melting into a liquid state at high temperatures. The “tread drawing” method uses special tools to draw on the glaze while it is in a molten state, allowing different colored glazes to mix together in that state and form special patterns. The effect shown in Fig. 9-25 was created using the tread drawing technique.

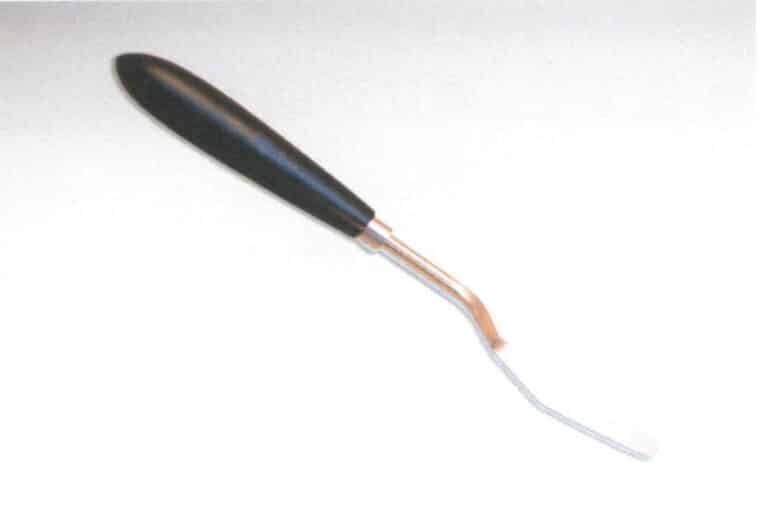

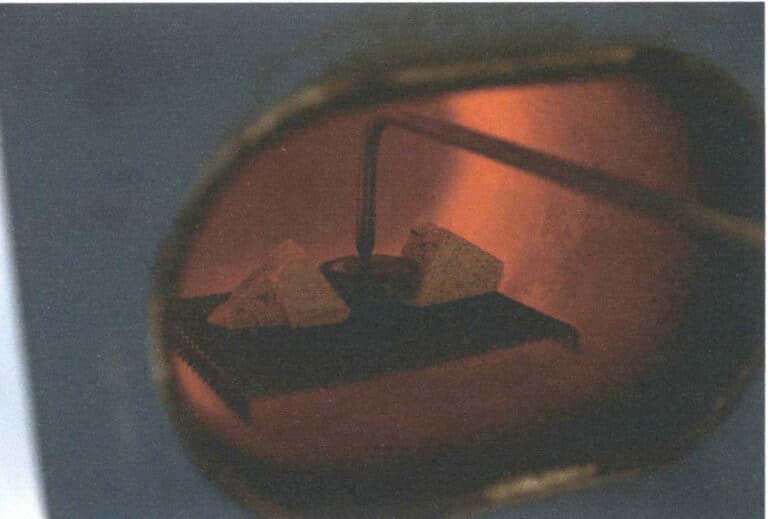

The tread drawing method requires a special tool — a steel rod long enough, with a diameter of 5~10 millimetres and a length of about 50 centimetres; bend it about 5 centimetres from the tip, grind the tip to a point, and fit the other end with a handle for easy gripping, as shown in Figure 9–26.

Figure 9–25 Presentation effect of the tread drawing method

Figure 9-26 A special tool for tread drawing

The specific operating steps of the tread drawing technique are as follows.

ΒΗΜΑ 01

Soak the metal base plate in a dilute sulfuric acid solution for cleaning; after about 15 minutes, remove it and rinse thoroughly with running water and set it aside.

ΒΗΜΑ 02

Fire the back glaze and base glaze on the back and front of the metal base.

STEP 03

On the front of the piece, apply two or more different colored glazes according to the design, with the requirement that the layer be slightly thicker. When using the tread drawing technique, opaque glazes are generally chosen, as the effect will be more pronounced. The piece shown in Figure 9-27 used French No. 194 transparent deep purple glaze, Chinese cloisonné coral red glaze, Chinese cloisonné porcelain white glaze, and French No. 27 deep blue transparent glaze, arranged concentrically in irregular circular patterns from the centre outward.

STEP 04

Please place it in the kiln and fire at a kiln temperature of 900°C. When the glazes have reached a fully melted state, open the kiln door and, using a special tool inserted into the kiln, draw a spiral pattern from the centre outward, as shown in Figure 9-28.

Figure 9-27 Applying the glaze for the pattern

Figure 9-28 Thread drawing in the kiln

STEP 05

Close the kiln door and fire again to 900°C. Figure 9-29 shows the completed piece.

Notes

(1) When the glaze melts, and patterns are drawn with a steel hook, they are generally sketched radially or in a spiral from the inside outward, or back and forth, left-right and up-down. Be careful not to break the boundaries between different colored glazes so that attractive patterns can form.

(2) The drawing motion should be as quick as possible; otherwise, once the kiln temperature drops, the glaze will congeal.

(3) When making works using the tread drawing technique, it is easier to operate with a large enamel kiln. Because a small enamel kiln has a relatively small heat capacity, once the door is opened, the temperature will drop rapidly and then struggle to rise to the target 900 degrees Celsius. When the temperature is insufficient, the tread drawing effect will be affected.

(4) There are two commonly used methods for doing tread drawing: one is the method described above, using a tool long enough to reach into the furnace to draw on the work; the other is to forgo an enamel kiln and melt the glaze with a blowtorch, then draw with some sharp tool while the glaze is molten. The advantage of this method is that it is easier to observe and manipulate, and does not require specialised tools.

5. Pencil Drawing

Pencil drawing refers to using the characteristic of pencil powder, which is able to withstand high temperatures around 760°C and fuse with the glaze. On a light-colored base glaze, a design is drawn with pencil, producing an effect similar to a sketch or pencil study.

The method for making pencil drawings is similar to making painted enamel. First, an opaque glaze is fired onto a copper plate to create the ground colour. After the ground is fired, the enamel surface needs to be roughened with an polishing oil stone— that is, abraded to a matte, non-reflective finish—because pencil cannot leave marks on a smooth glazed surface. Only after roughening can the design be drawn with a pencil on the glaze. After the drawing is finished, it is fired at a set temperature of 760°C; the pencil-applied design is fixed to the glaze surface by the high-temperature firing, and the glaze surface will be restored to a smooth, even state, completing the piece.

Because the glaze surface must be roughened before pencil drawing can be applied, the design can only be drawn and fired once; additions or modifications cannot be made after the first firing, since the glaze will have become smooth and it will be impossible to draw on the surface with pencil again—unless the glaze is roughened again with an polishing oil stone, but doing so would also abrade away the pencil design from the first pass.

Because the pencil drawing technique requires the composition to be completed successfully in a single pass, it is not suitable for depicting scenes with very complex layers or tones. If compared to drawing techniques such as sketching and quick studies, pencil drawing is closer to sketching.

The specific production method for pencil drawing is as follows.

ΒΗΜΑ 01

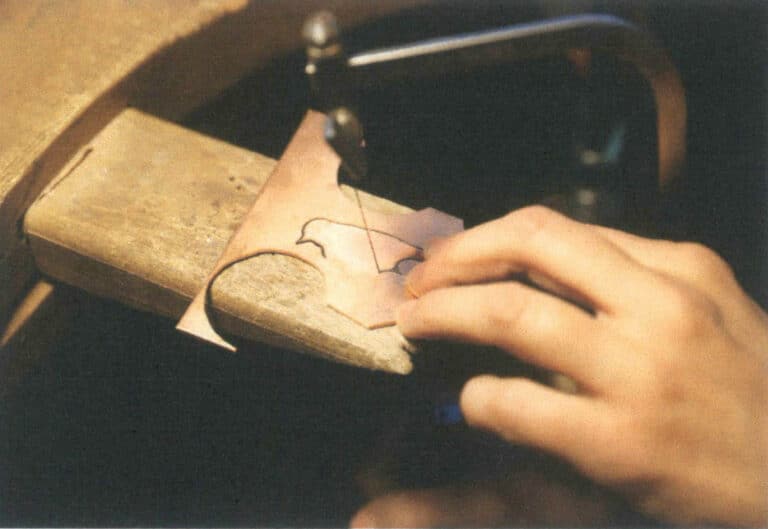

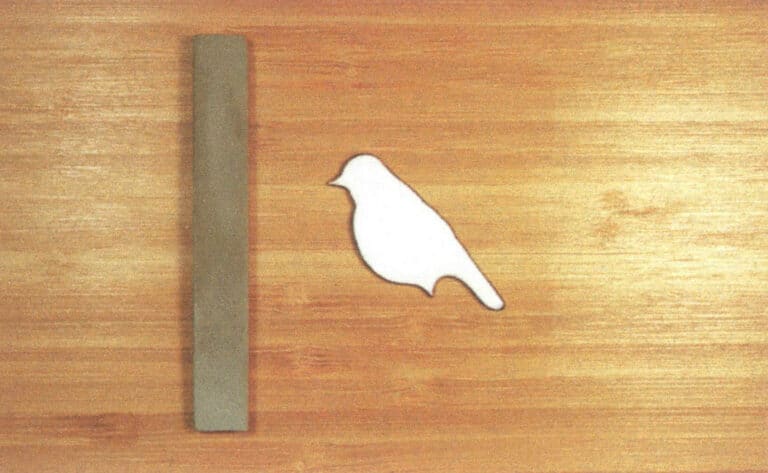

Saw the copper plate to the appropriate shape according to the design on a 1 mm thick copper sheet, as shown in Figure 9-30. File and dress the edges of the sawn copper base neatly, anneal it, then pickle it in acid for later use.

ΒΗΜΑ 02

Apply a bright white glaze to the back of the copper base as a back glaze, set the kiln temperature to 850 °C and fire it; Figure 9–31 shows the piece with the bright white back glaze fired.

STEP 03

Apply a light opaque glaze to the front of the piece as the base colour — for example, white, off-white, beige, or light blue — choosing according to personal preference or design needs. In the production example, the porcelain-white from the Chinese cloisonné glazes was used, set to fire at 810 °C. Because the base glaze functions like a sheet of paper, it must be very smooth and uniform in colour; if one layer of glaze does not evenly cover the copper base, two firings are required, and using the dry-sieving method may even require three firings. The fired porcelain-white base glaze is shown in Figure 9–32.

Figure 9-31 Firing the bright white back glaze

Figure 9-32 The fired porcelain white base glaze

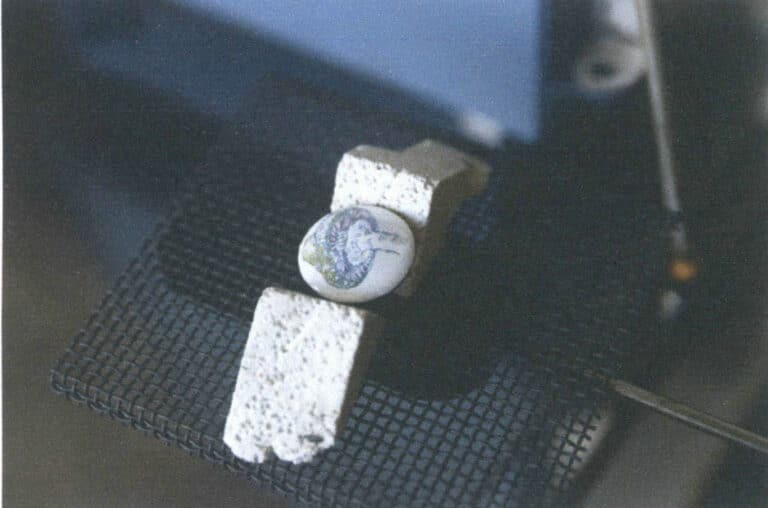

STEP 04

Use an polishing oil stone to sand the glaze surface into a rough frosted-glass texture. Choose a rectangular polishing oil stone, lay it flat against the glaze surface and sand in circular motions, as shown in Figure 9–33. Sand while observing the surface reflections; when all reflected spots on the glaze surface have disappeared, the base plate has been sanded to a rough surface and can be drawn on with a pencil. Figure 9–34 shows the sanded base plate.

Figure 9–33 Grinding the porcelain-white ground glaze with an polishing oil stone

Figure 9–34 Ground panel prepared for drawing

STEP 05

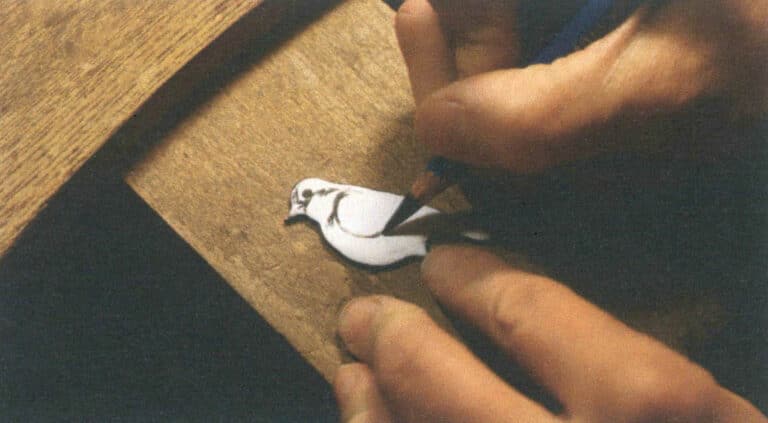

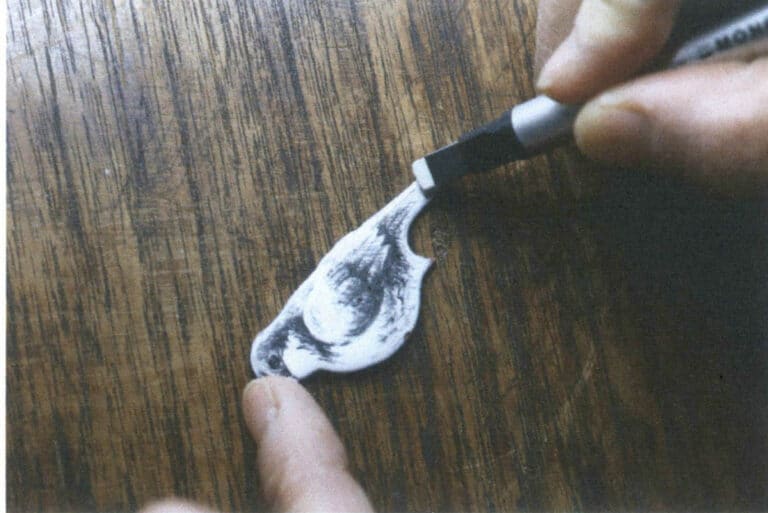

Use an 8B pencil to draw the design on the ground porcelain-white panel that has been roughened, as shown in Fig. 9–35.

STEP 06

After the pattern painting is completed, set the kiln temperature to 760 degrees Celsius for firing. Figure 9-36 shows the finished piece after firing.

Figure 9–35 Drawing the design with an 8B pencil

Figure 9-36 Finished piece after firing

Notes

(1) Because firing can only be done once, all patterns on the surface must be drawn completely before firing; they cannot be modified afterwards. This requires the maker to have an accurate prediction of the final effect during the creation process. Figure 9-37 shows a pencil drawing with very good control of black-and-white tones.

(2) If modifications are needed during the drawing process, localised, lighter pencil marks can be erased with a rubber eraser, as shown in Figure 9-38. Parts that cannot be removed with an eraser can be wiped away with turpentine or gently rubbed off with an polishing oil stone.

Figure 9-37 Pencil drawing

Figure 9-38 Erasing pencil marks that need modification with a rubber eraser

(3) Pencil drawings must be made using a high-quality 8B drawing pencil; the example uses Faber-Castell’s 8B drawing pencil. Pencil marks will become somewhat lighter after firing. Figure 9-39 shows a comparison of a pencil drawing before and after firing; you can see the overall image has lightened somewhat. For this reason, you can deliberately deepen the darkness of the drawing during creation so that after firing, the tones will be appropriately balanced.

(4) The firing temperature for pencil drawings must not be too high; the kiln is generally set to 760 °C for firing. If the temperature is too high, the pencil marks will noticeably fade or even disappear. Figure 9-40 shows a pencil drawing fired at too high a temperature; you can see the design has become very faint, nearly vanished.

Figures 9–39 Comparison before and after firing

Figure 9–40 Pencil drawings with glaze fired at excessively high temperature

6. Use of Glaze Granules and Glaze Threads

Figure 9-41 Glaze granules

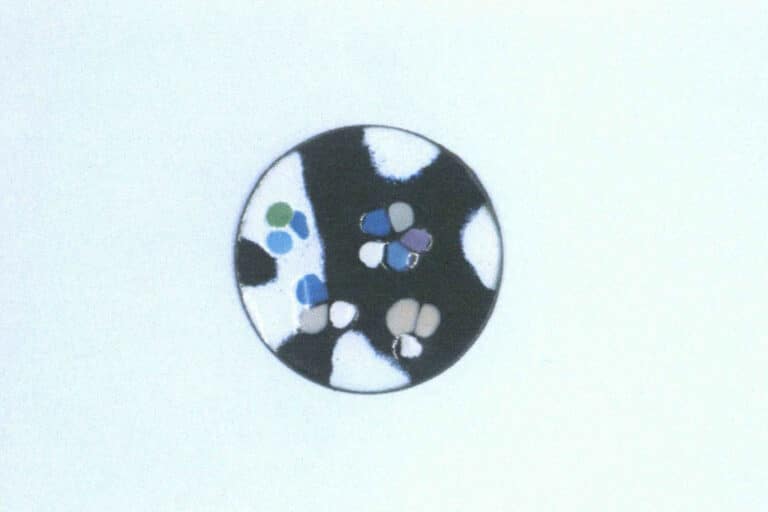

Figure 9-42 Interesting effects formed by glaze granules

Figure 9-43 Glaze threads

Figure 9-44 Effect after firing glaze threads

The specific steps for using glaze granules or glaze threads are as follows (taking glaze granules as an example).

ΒΗΜΑ 01

Soak the metal base plate in a dilute sulfuric acid solution for cleaning; after about 15 minutes, remove it and rinse thoroughly with running water and set it aside.

ΒΗΜΑ 02

Apply a transparent base glaze to the back of the metal base plate, then fire in a kiln at a temperature of 850 °C.

STEP 03

Apply a layer of transparent base glaze to the front of the metal backing and fire it in a kiln at a temperature of 850°C.

STEP 04

Apply the base glaze according to the design requirements; it can be a single colour or multiple colours, and it is best to choose a glaze that is relatively kiln-stable. The example shown in Fig. 9-45 is French opaque blue sifted over domestically produced cloisonné porcelain white glaze, with the kiln temperature set to 820°C for firing.

STEP 05

Scatter glaze granules over the fired base glaze surface and fire again; Fig. 9-46 shows the finished piece.

Figure 9-45 Blue glaze sifted over porcelain white base glaze

Figure 9-46 Finished work

Notes

When using powdered glaze granules, choose smaller granules; granules that are too large are difficult to melt, and prolonged firing may damage the base glaze.

7. Use of Gold Leaf and Silver Leaf

Leaf (gold or silver) has two uses in the enamel craft: one is to lay the leaf as an underlay at the bottom, over which glaze is applied and fired; the other is to apply the leaf to the surface of a finished piece. These two methods serve different purposes and produce completely different visual effects.

Taking gold leaf as an example, one method is to apply the gold leaf at the very bottom and then cover it with other transparent glazes; the final colour effect of using gold leaf in this way is not a gold colour but the effect of firing transparent colours over a gold base. In addition, when the gold leaf is covered beneath the glaze, the glaze’s shrinkage during high-temperature firing causes the gold leaf to form fine wrinkles. Due to the principle of diffuse reflection of light, the wrinkles of gold leaf beneath a transparent glaze create a gorgeous shimmering effect, similar to the effect of metal ground patterns in basse-taille enamel. The sunflower petals on the cloisonné enamel work “Growing Toward the Sun”, shown in Figure 9–48, were made by applying gold leaf on a silver base and covering it with two transparent yellow glazes, French No.15 and No.30, and firing them.

Another method is to, after all colour layers have been fired and the piece has been polished, clean the work in an ultrasonic cleaner and, before the final firing for colour brilliance, apply gold leaf to the designed locations; after the final colour firing, the gold leaf is firmly adhered to the surface of the glaze. Using this method to attach the leaf, because no glaze covers the gold leaf, the surface of the gold leaf is smooth and flat, its colour is that of gold, producing a strong decorative effect, and the gilded areas become the highlights of the entire piece. For example, in the cloisonné enamel work “Cui” shown in Fig. 9-49, the three dots along its axis have gold leaf applied to their surfaces.

Figure 9-48 Cloisonné enamel work "Growing Toward the Sun"

Figure 9-49 Cloisonné enamel work "Cui"

The specific steps for applying gold leaf are as follows (in the example, the leaf is applied to the base of the cloisonné enamel piece, materials: silver base plate, silver wire, gold leaf).

ΒΗΜΑ 01

Immerse the metal base plate in a dilute sulfuric acid solution for cleaning; after about 15 minutes, remove it and rinse thoroughly with running water for later use.

ΒΗΜΑ 02

On the front of the piece, place the shaped silver wires on one side and spread transparent base glaze on the other, then fire in a kiln at 850°C; see Chapter 5 for detailed methods of cloisonné wire placement and arrangement.

STEP 03

Apply transparent base glaze to the back of the metal base plate and fire in a kiln at 850°C.

STEP 04

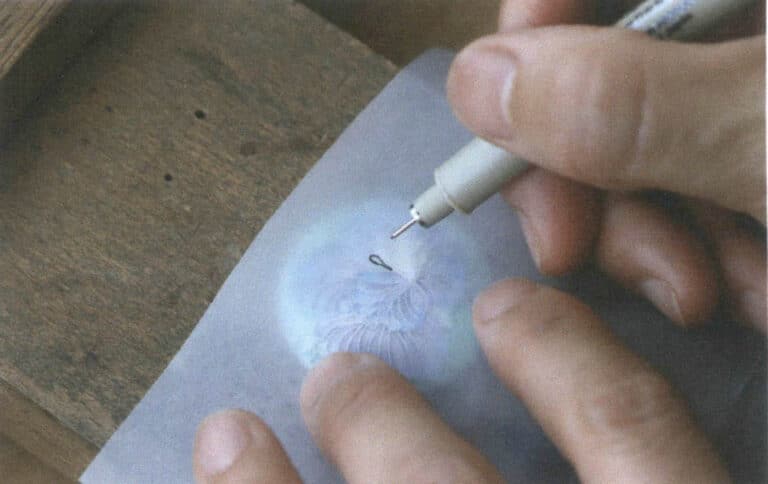

Cover the area where foil is to be applied with semi-transparent tracing paper and accurately trace the shape of the area to be foiled with a pen, as shown in Figure 9-51.

STEP 05

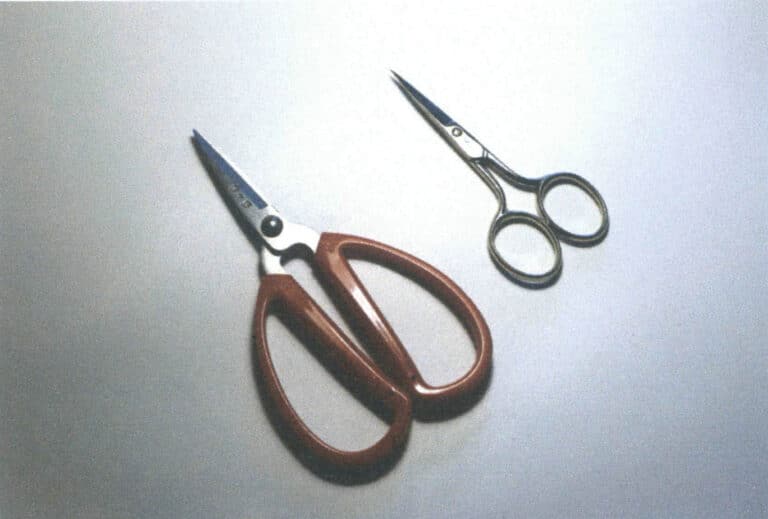

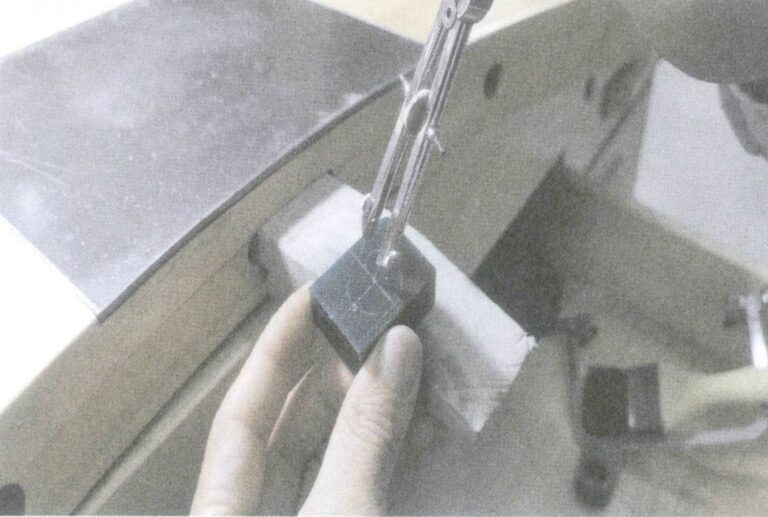

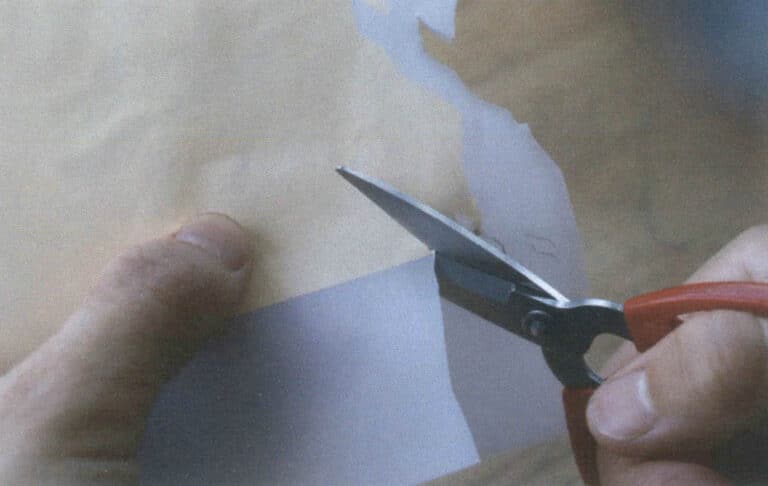

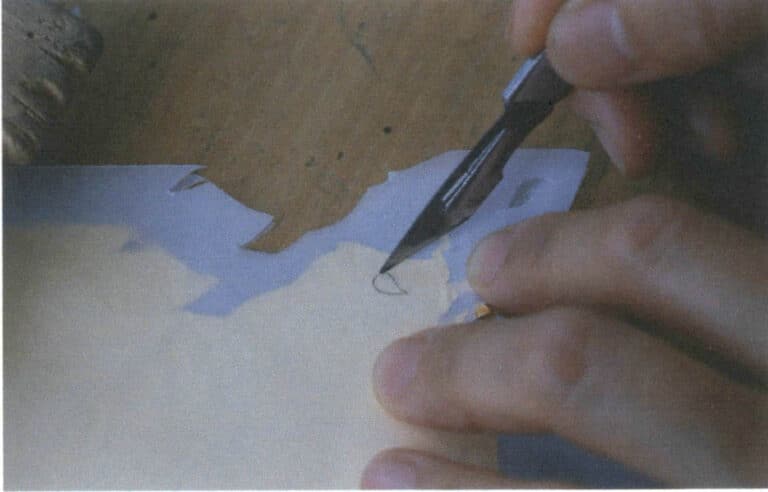

Place the tracing paper with the drawn pattern over the gold leaf and cut along the lines with sharp, small scissors, as shown in Fig. 9-52; you can also use a carving knife on a cutting board, as shown in Fig. 9-53. Scissors are suitable for larger, simpler-shaped patterns, while a carving knife is suitable for more complex, finer designs.

Figure 9-52 Cutting gold leaf

Figure 9-53 Carving gold leaf

STEP 06

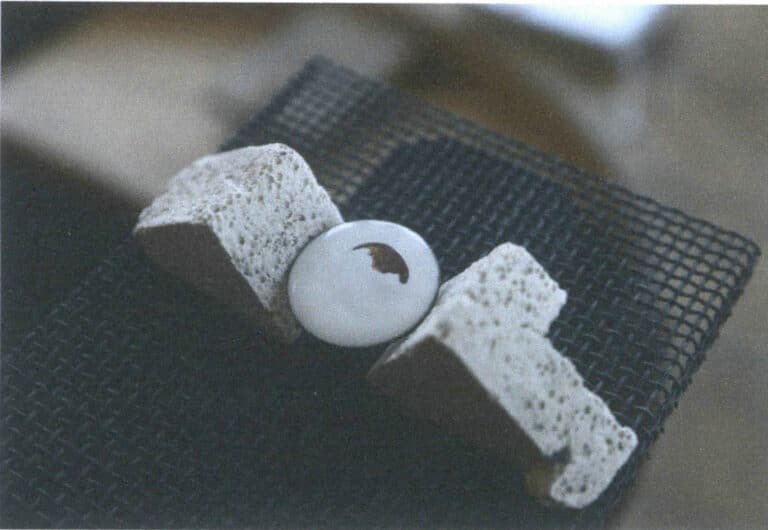

Apply a layer of enamel adhesive to the enamel surface where the foil will be applied. Use the glue-brushing pen to gently pick up the cut-to-shape gold leaf and place it where needed, as shown in Figure 9-54. While the enamel adhesive is still wet, you can make slight position adjustments; use the brush to gently tap down on the surface of the gold leaf to ensure it adheres closely to the enamel surface. The gold leaf in the flower centre shown in Figure 9-55 has already been applied.

Εικόνα 9-54 Συλλογή φύλλων χρυσού με πινέλο για βούρτσισμα με κόλλα

Figure 9-55 Flower centre with gold leaf applied

STEP 07

Fire the enamel piece with the applied gold leaf in the kiln, setting the temperature according to the melting temperature of the glaze layer beneath the gold leaf. After this firing, the gold leaf will be firmly bonded to the underlying enamel layer.

Notes

(1) The gold leaf required for enamelling should be 4 micrometres thick, which is much thicker than the gold leaf commonly used in lacquerware or woodworking. Therefore, when purchasing gold leaf, be sure to confirm with the seller whether it is specifically intended for enamelling.

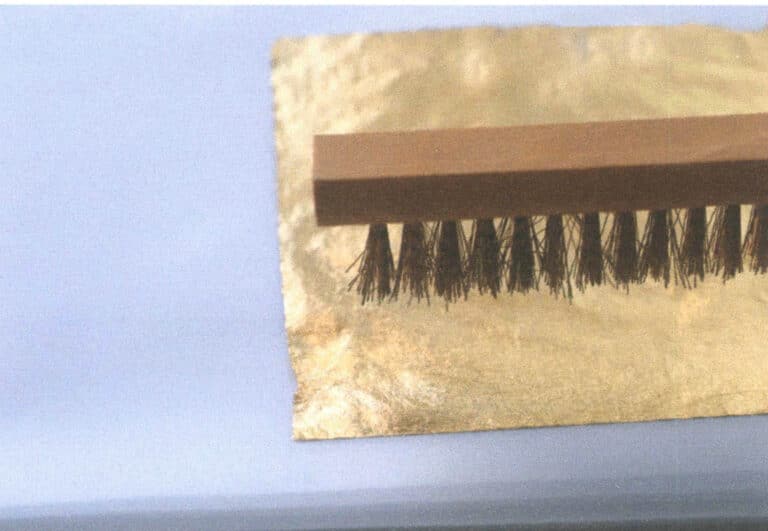

(2) The purchased gold leaf must be pretreated before use. The method is to lay the gold leaf flat on a relatively soft paper and gently tap it from top to bottom with a brush; the brush will produce fine, evenly distributed tiny holes on the surface of the gold leaf, as shown in Figure 9-56. Move the brush position evenly and slowly, continuing to tap until tiny holes cover the entire sheet of gold leaf. Hold the treated gold leaf up to a light source to observe the uniformly distributed fine holes, as shown in Figure 9-57. Store the treated gold leaf properly between two sheets of tracing paper for future use. Pretreating the gold leaf is necessary because when the piece is fired in the kiln, the adhesive used to attach the leaf will release gases at high temperature; these tiny holes serve to vent the gases beneath the gold leaf. If gas accumulates under the gold leaf, it will cause blistering and affect the adhesion between the gold leaf and the enamel surface.

Figure 9-56 Tapping the gold leaf with a brush

Figure 9-57 The treated gold leaf covered with fine holes