Made Simple for Small Jewelry Business --- All-in-One Jewelry Services

Verwirklichen Sie Ihre Schmuckideen in 15 Tagen.

From Designs, Manufacturing, Delivery to Launch, get everything at one supplier.

Stop Struggling With Too Many Different Suppliers!!!

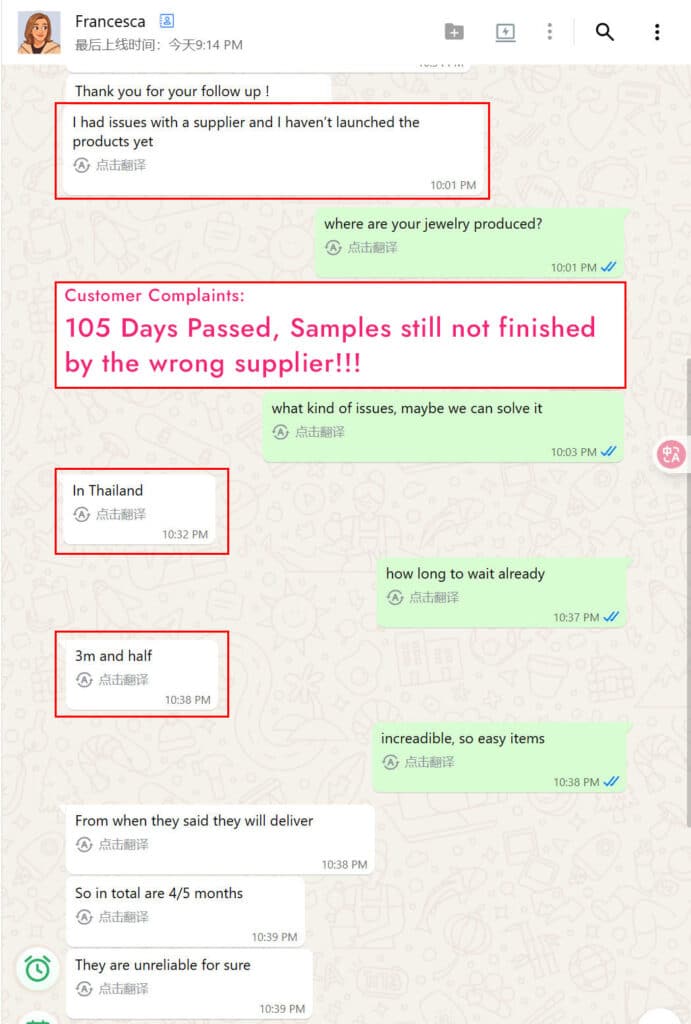

- “Designers take forever to reply, and the samples never look like what I asked for.”

- “CAD freelancers keep delaying the work — or they just disappear out of nowhere.”

- “Different Suppliers understand the details totally different, and we end up doing revision after revision.”

- “Photography and packaging always need extra vendors… more cost, more time, more communication.”

- “I have to repeat the same instructions to different suppliers again and again at every step. It’s exhausting.”

- “The production timeline is never predictable, and communication between multi suppliers breaks down so easily.”

Inhaltsübersicht

Don’t Wasting Time Coordinating Suppliers: Focus on Growing Your Business Sales Again.

What Is a Jewelry Small Business, and Why Does It Exist?

A jewelry small business is often run by solo founders, designers, small studios, or online sellers. They love jewelry but don’t have the large budgets, teams, or factories big brands rely on, so they depend on flexible small-batch production to launch collections and test trends.

The jewelry industry has high entry costs — building a factory, hiring experts, and managing supply chains all require significant investment. Small businesses can’t carry that burden, which is why they seek manufacturers that offer low MOQs, customization, transparent pricing, und reliable delivery.

This model gives small brands a realistic way to create products without heavy upfront costs. They can release new styles quickly, adapt based on customer feedback, and grow their identity step by step.

But the process is not always smooth. With limited experience, small businesses are more vulnerable to unreliable suppliers — unclear specs, hidden costs, poor communication, and unstable quality. That’s why choosing the right manufacturing partner matters from day one.

Everything Looks Simple… Until Your Small Jewelry Business Started to Grow

Running a small jewelry business sounds straightforward — find a style, customize a few details, place an order, and start selling. But once real production begins, the hidden workload shows up fast.

Design revisions, 3D modeling, sampling, packaging choices, product photos, quality checks, shipment planning… each step demands time, skills, and coordination that most small businesses simply don’t have.

Instead of focusing on selling and building your brand, you end up managing designers, factories, photographers, and logistics — all on your own. This is where delays, miscommunication, and extra costs start piling up.

That’s why Sobling created a true All-in-One Jewelry Manufacturing Service — bringing design, modeling, production, testing, packaging, photography, and delivery under one roof, so small brands can grow without the overwhelm.

9 Traps of Small Businesses Facing When Working With Too Many Separate Suppliers.

🔻 Trap 1: Designs Soul Get Lost in Translation

🔻 Trap 2: CAD Files That Look Good but Can’t Be Manufactured

🔻 Trap 3: Samples Don’t Match the Final Production

🔻 Trap 4: No One Takes Responsibility Across the Workflow

🔻 Trap 5: Packaging Doesn’t Fit the Product

🔻 Trap 6: Quality Control Fails Between Multiple Suppliers

🔻 Trap 7: Severe Delays from Uncoordinated Timelines

🔻 Trap 8: No Reliable Visual Content for Launch

🔻 Trap 9:Costs Multiply Across Separate Suppliers

What You Choose Next Can Transform How Your Jewelry Business Runs

Managing separate designers, CAD modelers, factories, packagers, and photographers doesn’t just slow you down — it drains your time, adds unexpected costs, and makes every launch harder than it should be. But your small business doesn’t need to struggle through this alone. Use these 9 traps as a guide to understand where the workflow breaks — and how a true all-in-one partner fixes it.

Choose a team that handles every step under one roof, keeps communication clear, and delivers exactly what your brand needs from idea to delivery. The right partner isn’t just another supplier — they’re the all-in-one system that helps your jewelry business grow with confidence.

How To Evaluate a Supplier’s All-In-One Capability?— 9 Essentials Every Small Jewelry Brand Needs

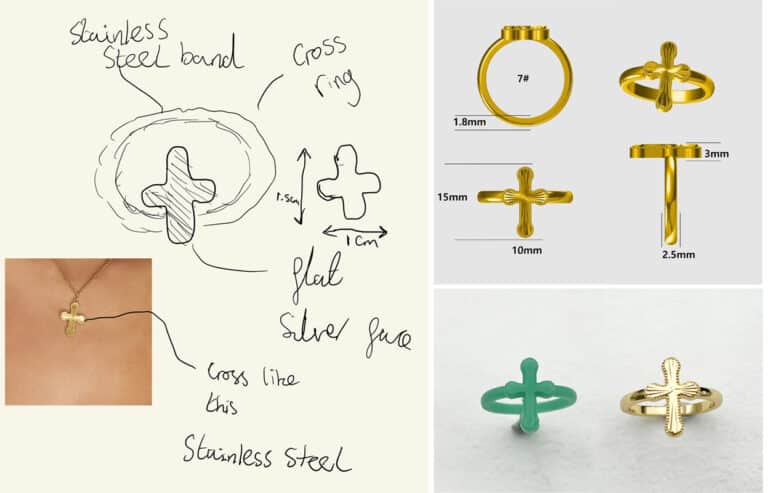

1st. Creative Jewelry Design

At Sobling, your ideas go straight to our in-house design team — the same team that works hand-in-hand with production every day.

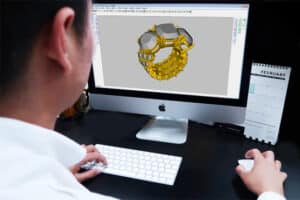

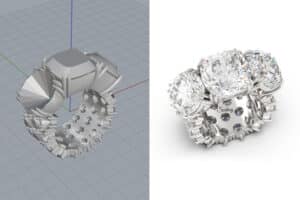

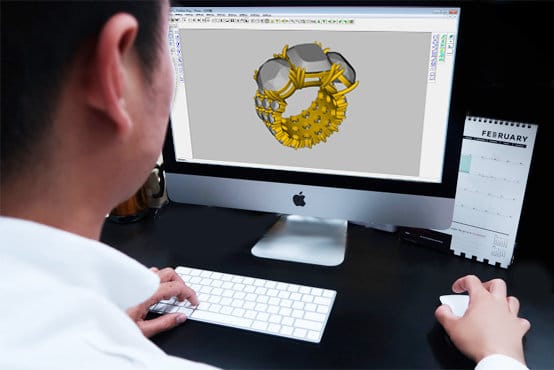

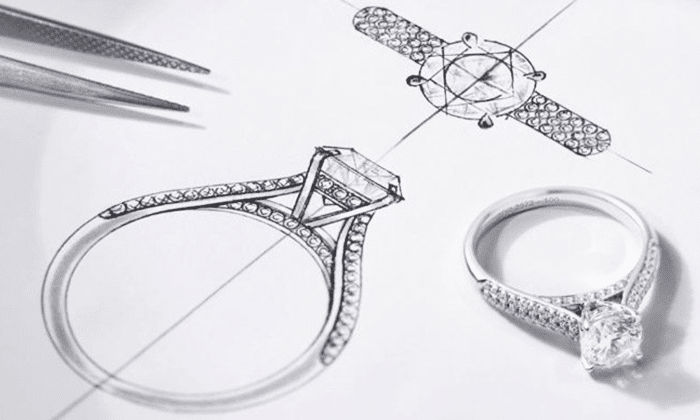

2nd. Production-Ready 3D jewelry Modeling

At Sobling, your CAD models are built by engineers who work side-by-side with our production team every day.

3rd.One-stop Jewelry Manufacturing

At Sobling, the same in-house team handles both your samples and your mass production.

Individuelle Formenherstellung

Exaktes Mischungsverhältnis für gleichbleibende Ergebnisse über alle Chargen hinweg.

Ein gleichmäßiger Wachsfluss gewährleistet eine reibungslose Chargenreplikation.

Durch die präzise Platzierung des Wachses wird das Risiko verringert, dass Steine übersehen werden.

Fortschrittlicher Metallguss

Zuverlässiges Gießverfahren für Formstabilität und Oberflächengüte.

Entfernt Mikrodefekte für einen spiegelähnlichen Glanz.

Rein handgefertigte Ketten und Details

Jedes einzelne Teil wurde vor der endgültigen Verpackung manuell geprüft.

Robuste, gleichmäßige Beschichtung, die beständig gegen Ausbleichen und Abnutzung ist.

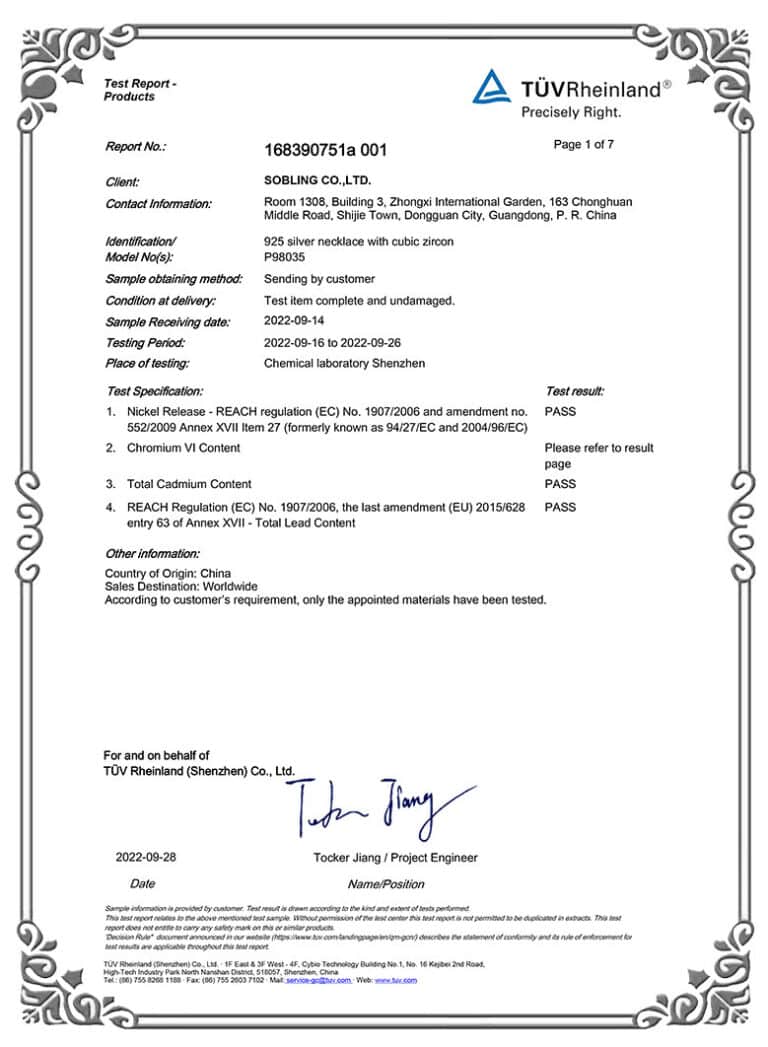

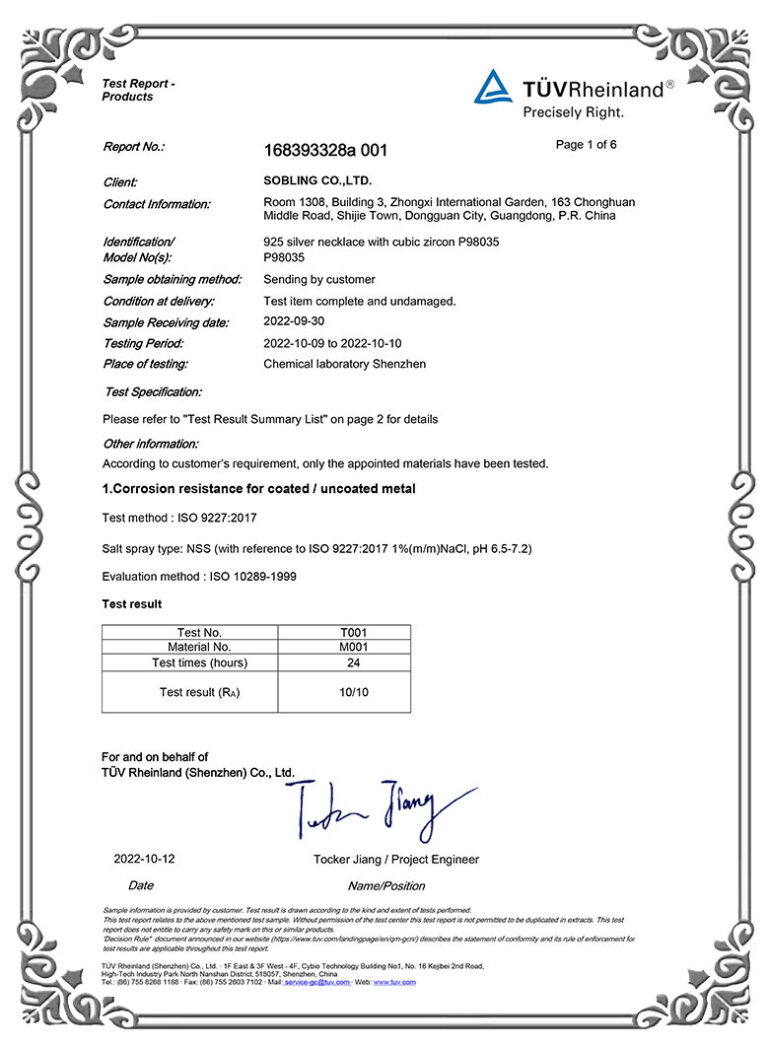

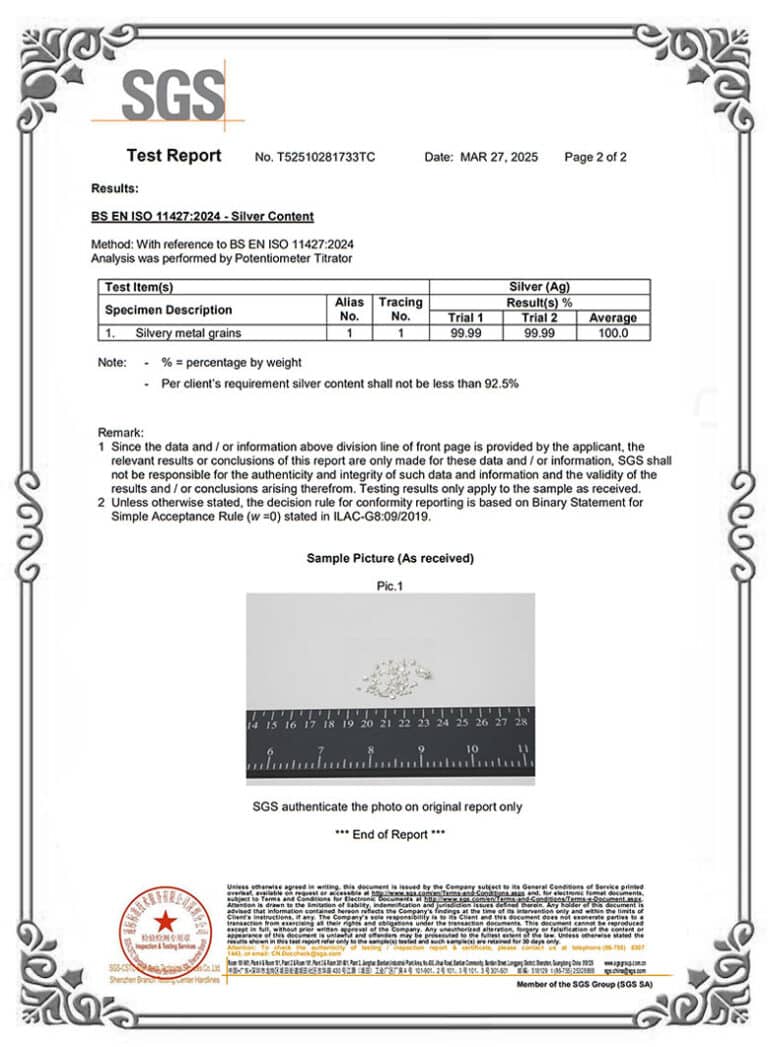

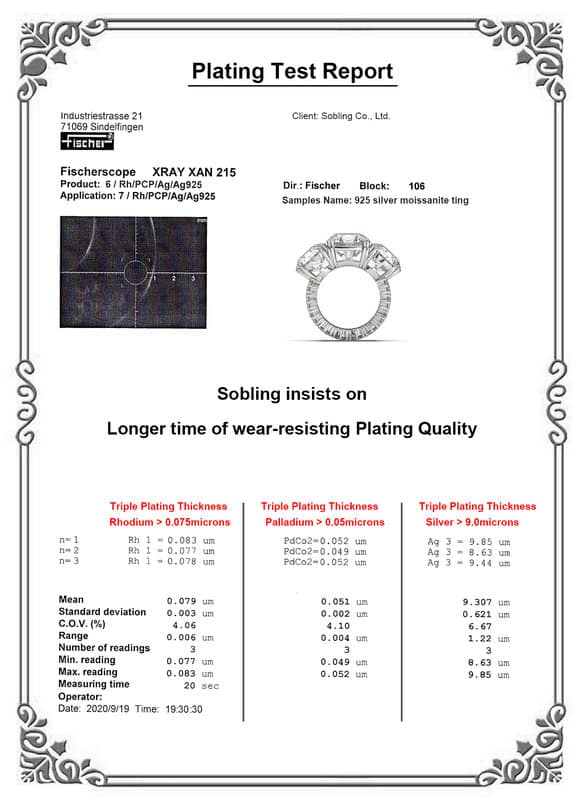

4th. Jewelry Quality Assurance & Product Testing

Keine toxischen Substanzen nachgewiesen → Weltweit anerkannte Materialstandards.

Verbesserter Rostschutz → Sorgt dafür, dass Ihr Schmuck länger glänzt.

Authentischer Reinheitsgrad von 999 → Materialintegrität, auf die Sie sich verlassen können.

Zuverlässige Dreifachbeschichtung → Langanhaltender Glanz mit reduziertem Verblassen.

5th. Custom Jewelry Packaging Solutions

At Sobling, your packaging is created and tested by the same team that makes your jewelry.

6th. Jewelry Product Photography

At Sobling, professional photographers shoot your actual samples in-house, delivering consistent, accurate, e-commerce-ready photos every time.

Model-Fotografie

Erwecken Sie Ihren Schmuck mit Lifestyle-Shootings mit professionellen Models zum Leben. Ideal für soziale Medien, Lookbooks oder Kampagnen, die visuelles Storytelling erfordern.

7th. Jewelry 3D Rendering

At Sobling, your 3D renders are created by the same team that builds your CAD files

8th. Door-to-Door Delivery

At Sobling, your orders are shipped directly to your address with full tracking and export support

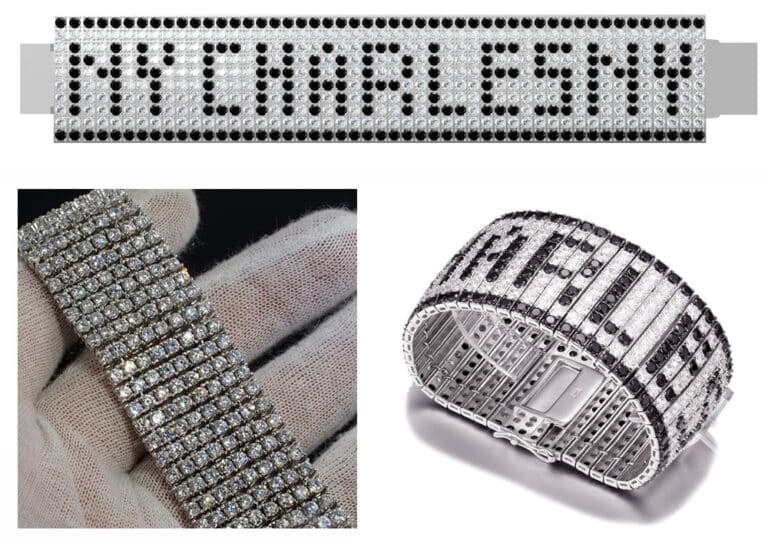

9th. Custom Logo Engravings

At Sobling, all laser engravings are done in-house with precise alignment, ensuring clean, consistent branding across every piece and every order.

Chemisch geätzt

Dieses Verfahren ist ideal für detaillierte Muster und verwendet kontrollierte chemische Reaktionen, um Motive auf die Metalloberfläche zu drucken.

Mechanisch eingraviert

Perfekt für tiefere, fühlbare Logos oder Texte, die mit Präzisionswerkzeugen direkt in Ihre Stücke geritzt werden.

Lasergraviert

Die Lasergravur bietet scharfe Details ohne Oberflächenverzerrung - ideal für feine Linien und moderne Ästhetik.

All-in-One-Produktlösung für Ihre vielfältigen Bedürfnisse

Lösungen für den High-End-Feinschmuckmarkt

Sterling Silberschmuck mit Halbedelsteinen besetzt

Top 15 der beliebtesten leuchtenden Edelsteine

Sterling Silber Schmuck mit Labor gezüchteten Moissanit

Was ist laborgezüchteter Moissanit?

Lösungen für den mittleren bis gehobenen Schmuckmarkt

Sterlingsilber & Moissanit

Sterling Silberschmuck mit synthetischen Edelsteinen eingelegt

Was sind synthetische Edelsteine?

Schnelle Lösungen für den Modeschmuckmarkt

Sterlingsilber & synthetische Edelsteine

Der am weitesten verbreitete Schmuckmarkt

Sterlingsilber & Zirkonia

Sterling Silber-Schmuck mit Cubic Zirkon-Fassungen

Was ist ein kubischer Zirkon (CZ)?

How To Choose a True All-In-One Jewelry Partner — A Practical Comparison Guide

| Key Service | Was zu beachten ist | How Sobling Delivers |

|---|---|---|

| Schmuck Kreatives Design | Designers who understand your brand style und real production limits – not just pretty sketches. | ✅ In-house designers co-work with engineers, creating concepts that match your market and can be produced without rework. |

| 3D-Modellierung von Schmuck | Production-ready CAD files that factories can use directly for molds and setting – no second CAD fee. | ✅ CAD modeling done in-house, verified by our production team so every file is 100% manufacturable the first time. |

| Schmuckherstellung | Stable quality, reliable plating, and details that match the approved sample in every batch. | ✅ Experienced craftsmen, controlled processes, and unified QC from casting to polishing for small and large orders. |

| Paket anpassen | Packaging sized to real products, aligned with your brand image, and safe for shipping. | ✅ Custom boxes, cards, and inserts developed after sample approval, with logo options and export-safe packing. |

| Prüfung von Schmuckprodukten | Clear testing standards for metal, plating, and stone security to protect customer experience and your reputation. | ✅ In-house testing for composition, plating thickness, stone firmness, and visual inspection for every batch. |

| Lieferung von Tür zu Tür | One team that handles export, documents, and carrier booking so deadlines stay under control. | ✅ Coordinated logistics from our factory to your address, with tracking, paperwork, and customs support included. |

| Schmuckfotografie | Accurate, consistent images that match the real jewelry – without style leaks or endless re-shoots. | ✅ In-house studio photography and model shooting, color-checked to real samples, ready for web and social launch. |

| Schmuck 3D-Rendering | Photorealistic renders based on final CAD, ideal for pre-launch marketing or styles without physical samples. | ✅ Rendering done by the same CAD team, ensuring perfect detail, metal texture, and stone layout for your visuals. |

| Individuelle Logo-Gravuren | Clean, repeatable engraving that strengthens your brand identity across every piece. | ✅ Precise laser engraving in-house – logos, initials, or serial codes applied consistently in every production run. |

| All-In-One Products Solutions | Ability to cover different market levels and stone types from one factory – fewer suppliers, easier planning. | ✅ Complete product lines in sterling silver with Semi-Precious Gems, Lab Grown Moissanite, Synthetic Gems, and Cubic Zircon settings, all under one roof. |

Key Insight Before You Decide

If a supplier can only support one or two of these services, you’ll end up coordinating the rest yourself — and that’s where delays, mistakes, and extra costs appear. A true all-in-one partner connects design, CAD, manufacturing, packaging, testing, visuals, delivery, and product solutions into a single, manageable system.

Sobling’s integrated services are built for small jewelry businesses that want fewer moving parts and more control. Use this checklist to compare your current supplier and see how much easier your next collection could be with a complete all-in-one jewelry partner.

Why More Small Jewelry Business Choose Sobling?

70% Faster Workflow

Design, CAD, sampling, production, packaging, photos — all handled by one team for shorter timelines.

40% Lower Total Cost

ne integrated supplier means no duplicated CAD fees, no extra photography cost, and no middlemen markup

100% Process Control

With all services centralized, you get stable quality, consistent communication, and zero unexpected issues.

7×24 Dedicated Support

One team follows your entire project — faster replies, clearer answers, and real support whenever you need it.

- ✅ One Team, One Workflow: No more coordinating designers, CAD freelancers, factories, photographers, and packagers. A single integrated team handles every step — from idea to delivery.

- ✅ Fewer Delays & Fewer Mistakes:: When design, CAD, sampling, production, and packaging stay under one roof, quality stays consistent and communication stays clear. You eliminate the delays caused by scattered suppliers.

- ✅ Lower Overall Costs: No extra CAD fees, no repeated sampling, no reshoots, no lost time fixing others’ mistakes. An all-in-one system reduces hidden costs and removes unnecessary middle steps.

- ✅ Full Control & Peace of Mind: You always know who is responsible, what stage your project is in, and when everything will be delivered. One partner = one standard of quality + one accountable process.

What You’ll Actually Gain from Sobling All-in-one Services?

Bewährter Erfolg: Über 1500 kundenspezifische Schmuckprojekte geliefert

Benutzerdefinierte Verpackung Design Fall

Schmuck 3D Rendering Fall

Fotoshooting-Bilder

Luxus-Schmuckvideokoffer

Was unsere Kunden über Sobling sagen?

Die Produktionszeit ist kurz, die Qualität konstant gut und die Kommunikation beispiellos. --- Vienna Domani

Arbeiten Sie mit Sobling an Ihren Schmuckprojekten

Wem dienen wir?

- Schmuck Marken

- E-Commerce-Verkäufer

- Dropshipping-Verkäufer

- Berühmtheiten Maßgeschneidert

- Schmuckhändler und -geschäfte

- Schmuckdesigner & Ateliers

Wo werden unsere OEM-Dienstleistungen eingesetzt?

- Schmuck für Geschenkaktionen

- Limited Collection Launches

- Hochzeitsschmuck nach Maß

- Print-on-Demand-Dropshipping-Modelle

- Maßgefertigter Schmuck für Prominente und Influencer

Sobling respektiert Qualitätsstandards

WhatsApp uns

Ultimativer Leitfaden für Business Sourcing

Schmuck Fabrik, Schmuck Anpassung,Moissanite Schmuck Fabrik,Messing Kupfer Schmuck,Halbedelstein Schmuck,Synthetische Edelsteine Schmuck,Süßwasser Perlen Schmuck,Sterling Silber CZ Schmuck,Halbedelstein Anpassung,Synthetische Edelsteine Schmuck